1. Introduction

In recent years, the rapid advancements in technology and the continuous progress of society have led to increasingly stringent demands on materials [

1,

2,

3]. Modern engineering applications require materials not only to possess exceptional mechanical properties, such as high strength and hardness, but also to exhibit substantial toughness and ductility [

4,

5]. This dual demand poses a significant challenge, as conventional single-phase materials often fail to meet these multifaceted requirements. For instance, materials that are extremely hard often lack sufficient toughness, making them susceptible to brittle fracture. Conversely, materials with high ductility may not offer the necessary strength for demanding applications. To address this complex challenge, ceramic-reinforced steel matrix composites have emerged as a promising field of research [

6,

7,

8,

9,

10]. These composites uniquely combine the desirable properties of ceramics and metals, leveraging the inherent hardness and wear resistance of ceramic reinforcements with the ductility and toughness of a metallic steel matrix.

The integration of ceramic particles into a steel matrix can significantly enhance the composite's overall performance [

11,

12]. The ceramic phase contributes to increased hardness and wear resistance, while the metallic phase provides toughness and ductility, ensuring the composite can absorb energy and resist fracture under various loading conditions. Moreover, these composites often exhibit improved thermal stability, making them suitable for high-temperature applications. Such properties are critical in industries ranging from aerospace and automotive to defense and manufacturing, where materials are subjected to extreme stresses and environmental conditions.

The development of ceramic-reinforced steel matrix composites with superior mechanical properties primarily focuses on two key research directions: enhancing the content of ceramic reinforcements and improving the performance of the steel matrix. Increasing the volume fraction of ceramic particles typically leads to significant improvements in hardness, wear resistance, and thermal stability, owing to the intrinsic properties of ceramics. For instance, researchers have extensively studied the effects of incorporating a higher percentage of ceramic particulates such as silicon carbide (SiC), titanium carbide (TiC), or aluminum oxide (Al₂O₃). These materials are known for their high hardness and thermal stability, making them ideal candidates for reinforcement [

13,

14]. However, increasing the ceramic content often results in a trade-off, where the composite's ductility decreases, potentially leading to brittle behavior. Thus, achieving the optimal balance between hardness and ductility remains a critical challenge in the design of these composites.

On the other hand, advancements in the steel matrix itself can further optimize the mechanical properties of the composite. Modifying the steel matrix's composition through alloying elements like chromium, molybdenum, or nickel can enhance its toughness and corrosion resistance, complementing the high hardness of the ceramic phase [

15]. However, the conventional ceramic-reinforced steel matrix composites are limited by the maximum achievable ceramic content due to challenges such as increased brittleness and difficulty in processing. To overcome these limitations, an alternative approach involves the direct incorporation of large-sized ceramic components into the steel matrix [

16]. This method can exceed the constraints imposed by conventional ceramic reinforcement limits, allowing for a greater volume of ceramic material to be integrated without compromising the composite's structural integrity. The use of large ceramic reinforcements can provide substantial improvements in wear resistance and thermal stability, making this approach particularly attractive for high-performance applications.

To ensure effective bonding and compatibility between the large-sized ceramic components and the steel matrix, the choice of matrix material is crucial. High-toughness steels are essential in this regard, and one promising candidate is Twinning-Induced Plasticity (TWIP) steel. TWIP steel is renowned for its exceptional combination of high strength and ductility, making it an ideal matrix material for composites [

17,

18,

19,

20]. This steel exhibits a unique deformation mechanism where mechanical twinning occurs during plastic deformation, significantly enhancing its work-hardening capability. This twinning mechanism allows TWIP steel to absorb large amounts of energy, thereby improving its toughness and resistance to fracture—a critical property for structural applications subjected to dynamic loading conditions [

21,

22,

23].

The incorporation of large-sized ceramic reinforcements into TWIP steel represents an innovative approach in the advancement of composite materials, offering significant potential for applications in industries that require superior mechanical properties and thermal stability. This study primarily investigates the fabrication and characterization of these ceramic-reinforced TWIP steel matrix composites. The research evaluates the influence of ceramic reinforcements on the mechanical properties of the TWIP steel matrix, with a particular emphasis on the mechanical changes that occur during heat treatment. Through this thorough analysis, the study not only enhances the understanding of the fundamental mechanisms driving the behavior of these advanced composites but also provides crucial insights for their practical implementation in industries demanding high-performance materials.

2. Experimental Materials and Methods

2.1. Preparation of Experimental Materials

In this study, we utilized cylindrical ceramic rods with dimensions of φ5 mm × 95 mm as the reinforcing phase in the composite material. The choice of a rod-shaped ceramic reinforcement was deliberate, aimed at maximizing the load-bearing capability and enhancing the mechanical properties of the resultant composite. The matrix material used in this research was Twinning-Induced Plasticity (TWIP) steel, a high-manganese austenitic steel recognized for its exceptional combination of strength, ductility, and energy absorption capabilities. The TWIP effect, which involves the formation of mechanical twins during plastic deformation, significantly contributes to the material's work-hardening rate, making it an excellent choice for composite applications where both toughness and ductility are crucial. The chemical composition of the TWIP steel matrix is provided in

Table 1, which lists the primary alloying elements.

2.2. Preparation of Ceramic Rod-Reinforced TWIP Steel Matrix Composites

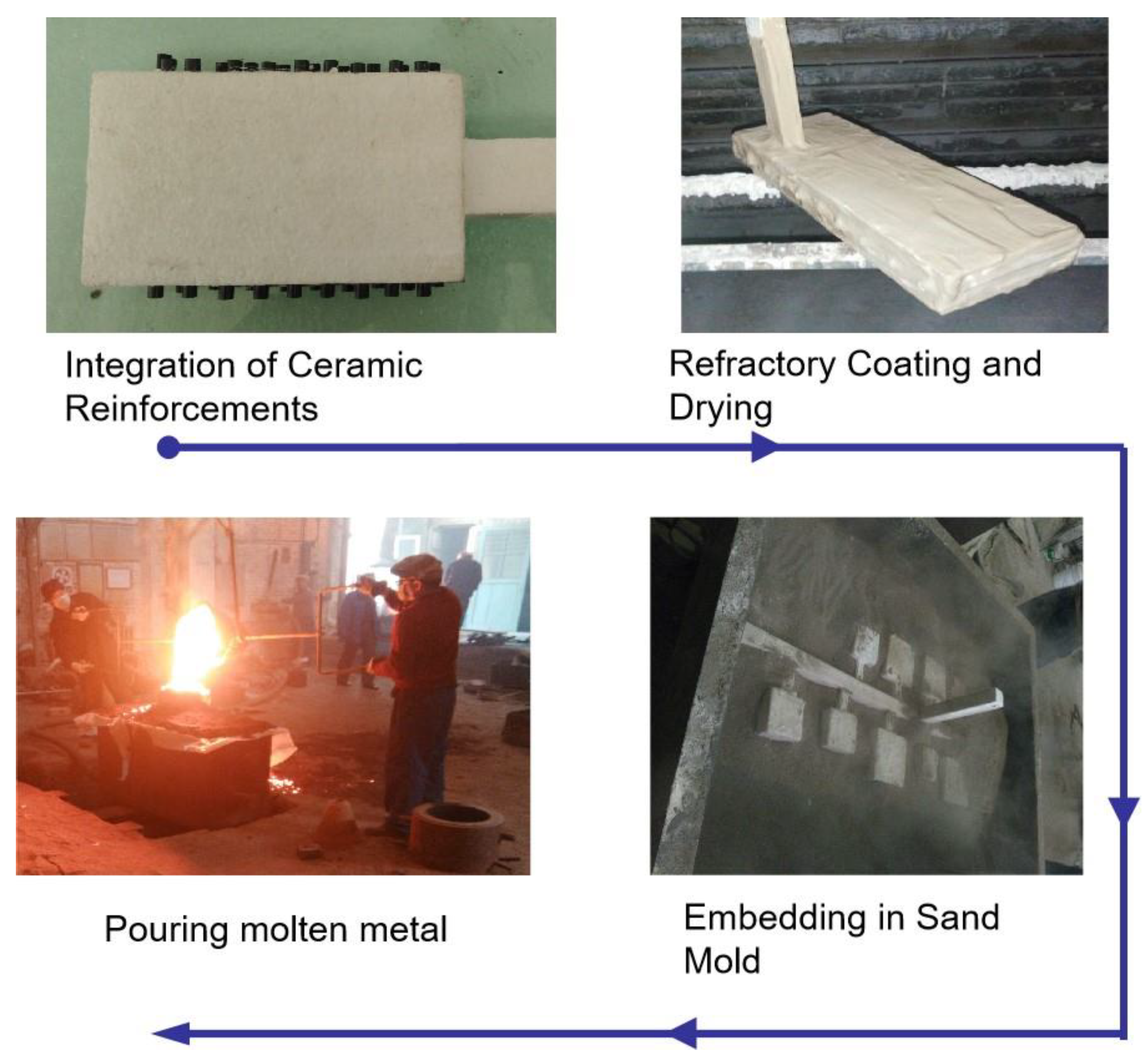

In this study, we utilized the lost foam casting method to fabricate large-sized ceramic rod-reinforced TWIP steel matrix composites. This innovative technique allows for the integration of ceramic reinforcements into the steel matrix, achieving a composite material with enhanced mechanical properties suitable for high-performance applications. The schematic diagram of the preparation process for ceramic rod-reinforced TWIP steel matrix composite is shown in

Figure 1.

The process begins with the preparation of a high-density polystyrene foam model, which serves as the template for the TWIP steel matrix. This foam is precisely cut and shaped into the desired geometric configuration, incorporating cavities designed to house the ceramic rods. Following the creation of the foam model, ceramic rods, each with a diameter of 5 mm and a length of 95 mm, are positioned within the foam cavities. To ensure that the ceramic rods are securely held in place, a suitable adhesive is applied, which helps to maintain their alignment and stability throughout the casting process. The next phase involves coating the foam model with a refractory material. Multiple layers of refractory slurry are meticulously applied to the foam model, and each layer is dried at 45°C to build up a durable and heat-resistant shell. Once the refractory coating is fully cured, the foam model, now reinforced with ceramic rods and encased in a refractory shell, is embedded in a sand casting box. Molten TWIP steel is then carefully poured into the mold cavity. Once the TWIP steel has solidified, the mold is carefully dismantled, and the refractory coating is removed. This reveals the final ceramic rod-reinforced TWIP steel matrix composite.

2.3. Optimization of Heat Treatment for Ceramic Rod-Reinforced TWIP Steel Matrix Composites

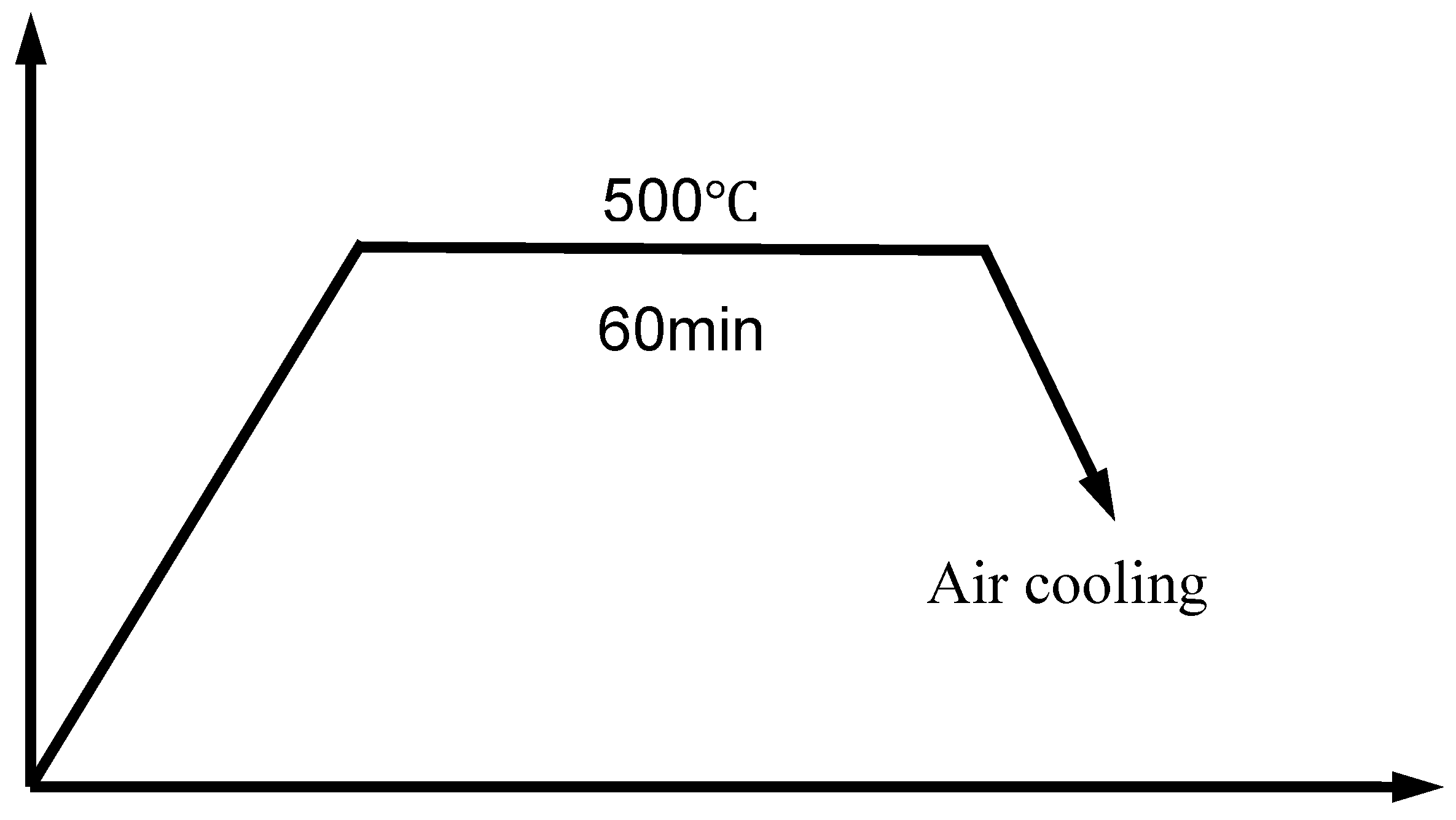

The enhancement of the mechanical properties of ceramic rod-reinforced TWIP steel matrix composites through heat treatment is a critical aspect of this study. Heat treatment techniques are employed to fine-tune the properties of the composite, aiming to improve both its strength and ductility. To verify the feasibility of enhancing the mechanical properties of ceramic rod-reinforced TWIP steel matrix composites through heat treatment, we designed a straightforward and easily implementable heat treatment process, as illustrated in

Figure 2. After preparing the composite samples using the lost foam casting method, the specimens were subjected to heat treatment at 500°C, held for 60 minutes, and then allowed to cool naturally in ambient air. This heat treatment approach is characterized by its simplicity, cost-effectiveness, and ease of implementation, making it well-suited for large-scale production and widespread application.

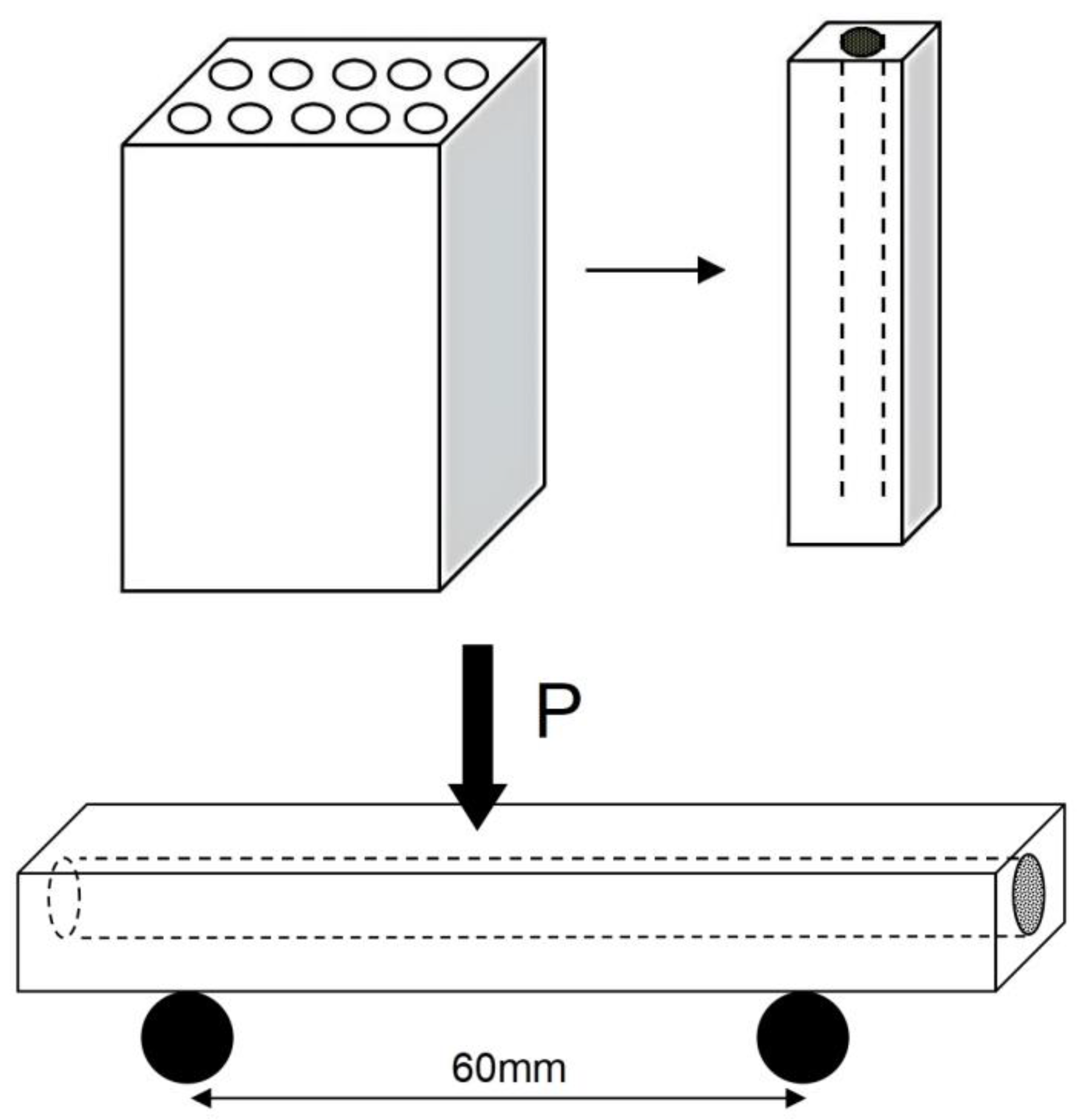

The effectiveness of these heat treatment strategies was assessed by preparing specimens of ceramic rod-reinforced TWIP steel matrix composites and conducting bending tests, as illustrated in

Figure 3. These specimens were carefully cut to standard dimensions to ensure consistent results. Using an electronic universal testing machine, we evaluated their bending performance at a strain rate of 2 mm/min. The bending tests provided critical data on the flexural strength, ductility, and overall toughness of the treated composites. The results of these bending tests were compared against those of untreated TWIP steel matrix materials, allowing us to discern the effects of each heat treatment method.

3. Results and Discussion

3.1. Microstructure and Properties Analysis of the Matrix Material

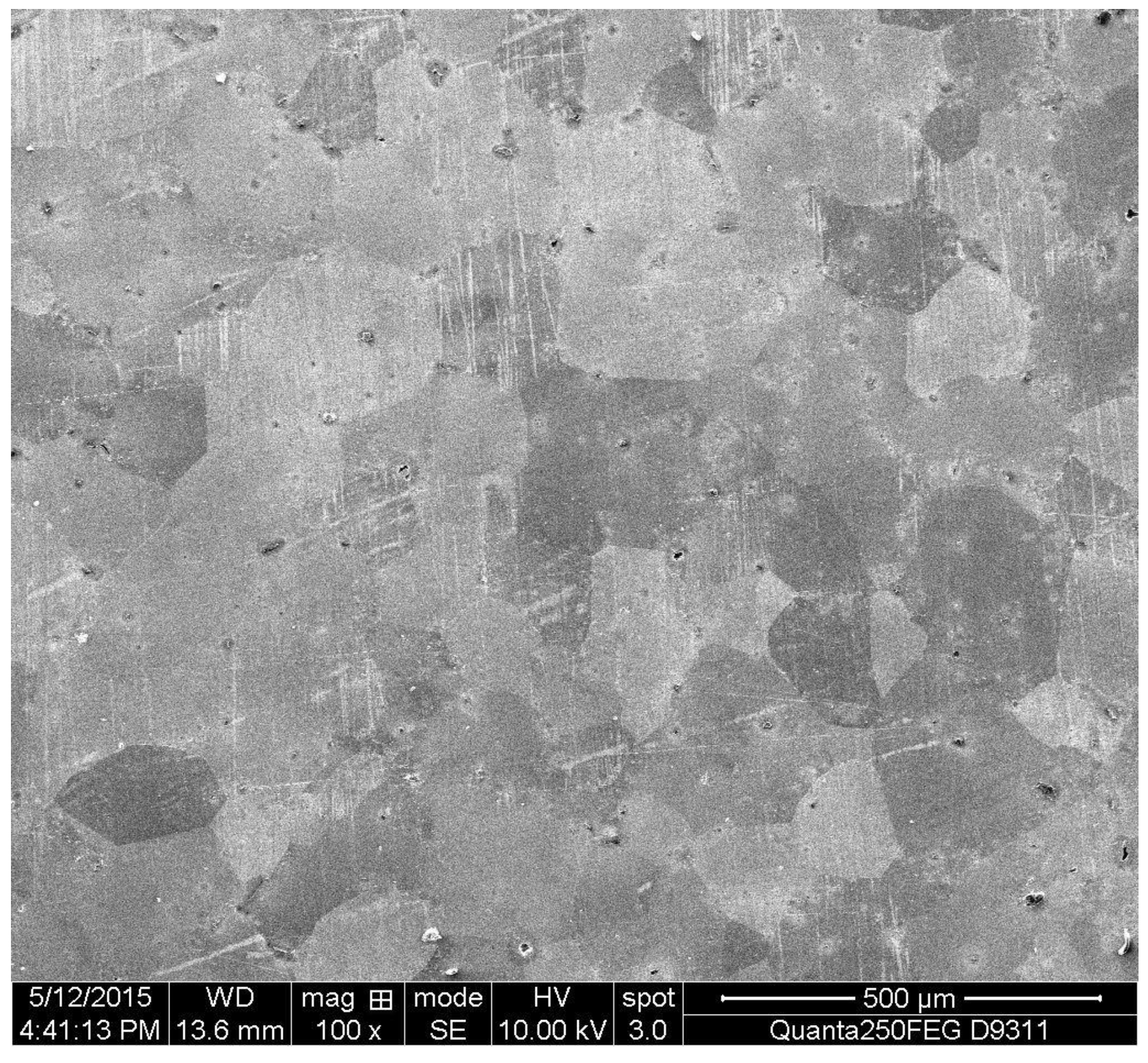

As the matrix material for ceramic-reinforced TWIP steel composites, the mechanical properties of TWIP steel directly influence the overall performance of the composite. Therefore, it is essential to analyze the microstructural state and mechanical properties of the TWIP steel matrix, as well as the impact of heat treatment on its mechanical performance. The microstructural features of the matrix material in its as-cast condition were analyzed using optical microscopy, as shown in

Figure 4.

The microstructure reveals an austenitic phase with granular carbides precipitated along the grain boundaries and, to a lesser extent, within the grains. This morphology is consistent with typical TWIP steel microstructures, where the distribution of carbides tends to be relatively uniform and sparse. During solidification, the formation of carbide precipitates occurs primarily at the austenite grain boundaries, with some precipitates forming inside the grains. This distribution of carbides is significant as it influences the mechanical properties of the material, potentially reducing tensile strength and elongation due to the presence of precipitates, porosity, and residual stresses formed during casting.

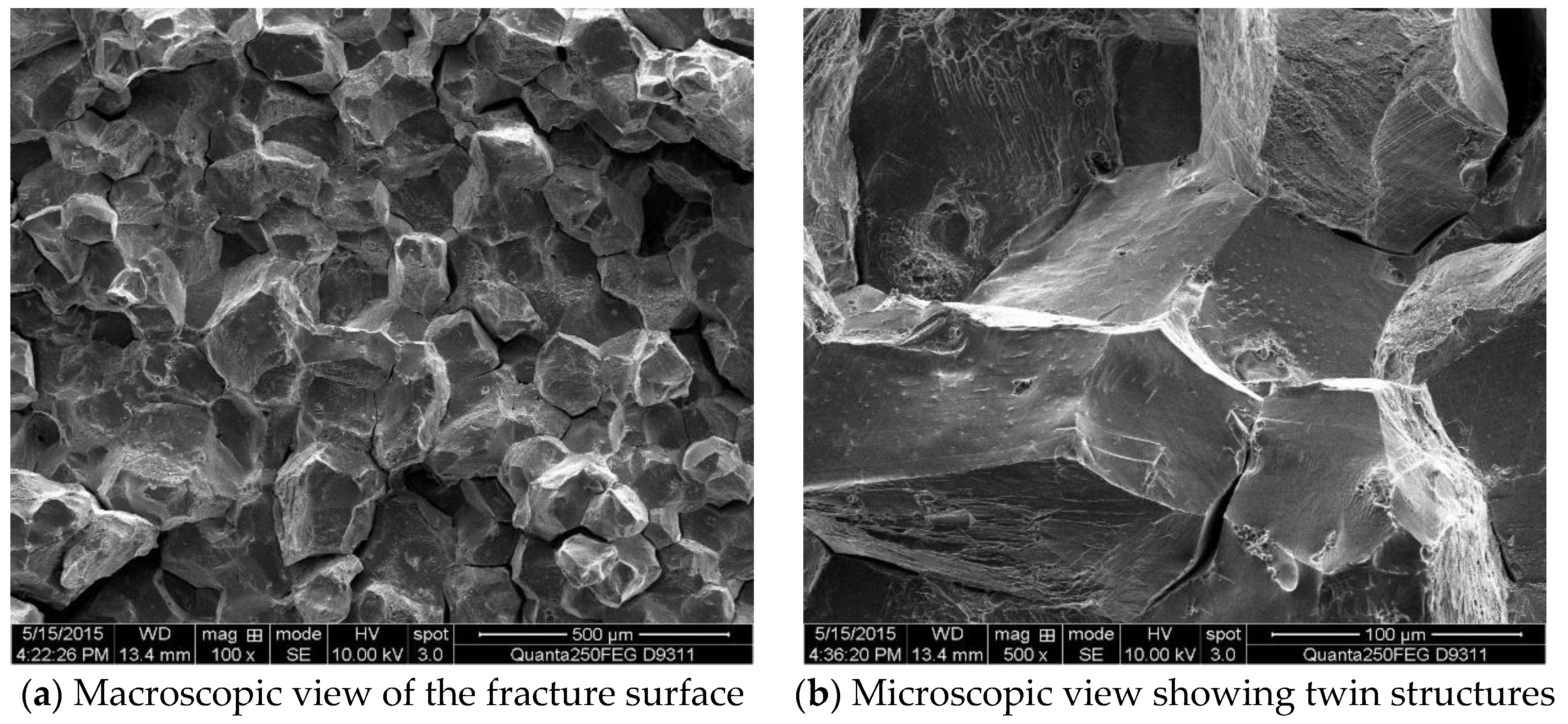

Tensile tests were conducted on the matrix material using an electronic testing machine, yielding a tensile strength of 350 MPa and a yield strength of 264 MPa in the initial casting state. The fracture morphology after tensile testing is shown in

Figure 5.

Although these values indicate a relatively low tensile strength, they are notably higher than the mechanical properties typically observed in as-cast aluminum alloys. The matrix material also demonstrated an elongation of 6.5%, indicating some capability for plastic deformation. This plasticity is attributed to the austenitic structure of the matrix, known for its excellent capacity for plastic deformation. The fracture surface of the tensile test specimen, shown in

Figure 5, exhibits a classic intergranular fracture mode. The presence of twin boundaries in the austenite matrix, which are highlighted by arrows in

Figure 5(b), suggests that twinning contributes to plastic deformation during tensile loading.

To enhance the mechanical properties of the matrix material, and by extension, the overall performance of the ceramic rod-reinforced TWIP steel composite, we investigated the effects of heat treatment. Specifically, the matrix material was subjected to a heat treatment process involving holding at 500°C for 60 minutes followed by air cooling. Post-treatment, standard tensile specimens with a diameter of 5 mm were prepared, and their tensile properties were measured. The results are summarized in

Table 2.

The data in

Table 2 clearly show that the heat-treated matrix material exhibits significant improvements in mechanical properties compared to the as-cast state. The yield strength increased by more than 40 MPa (an improvement of over 10%), while the tensile strength rose by more than 100 MPa (an increase of over 30%). Notably, the elongation and reduction of area doubled, indicating a substantial enhancement in ductility and plasticity. These improvements are attributed to the release of residual stresses and the stabilization of the austenitic structure, which may facilitate the formation of twin boundaries during deformation, thereby enhancing ductility and toughness [

24,

25].

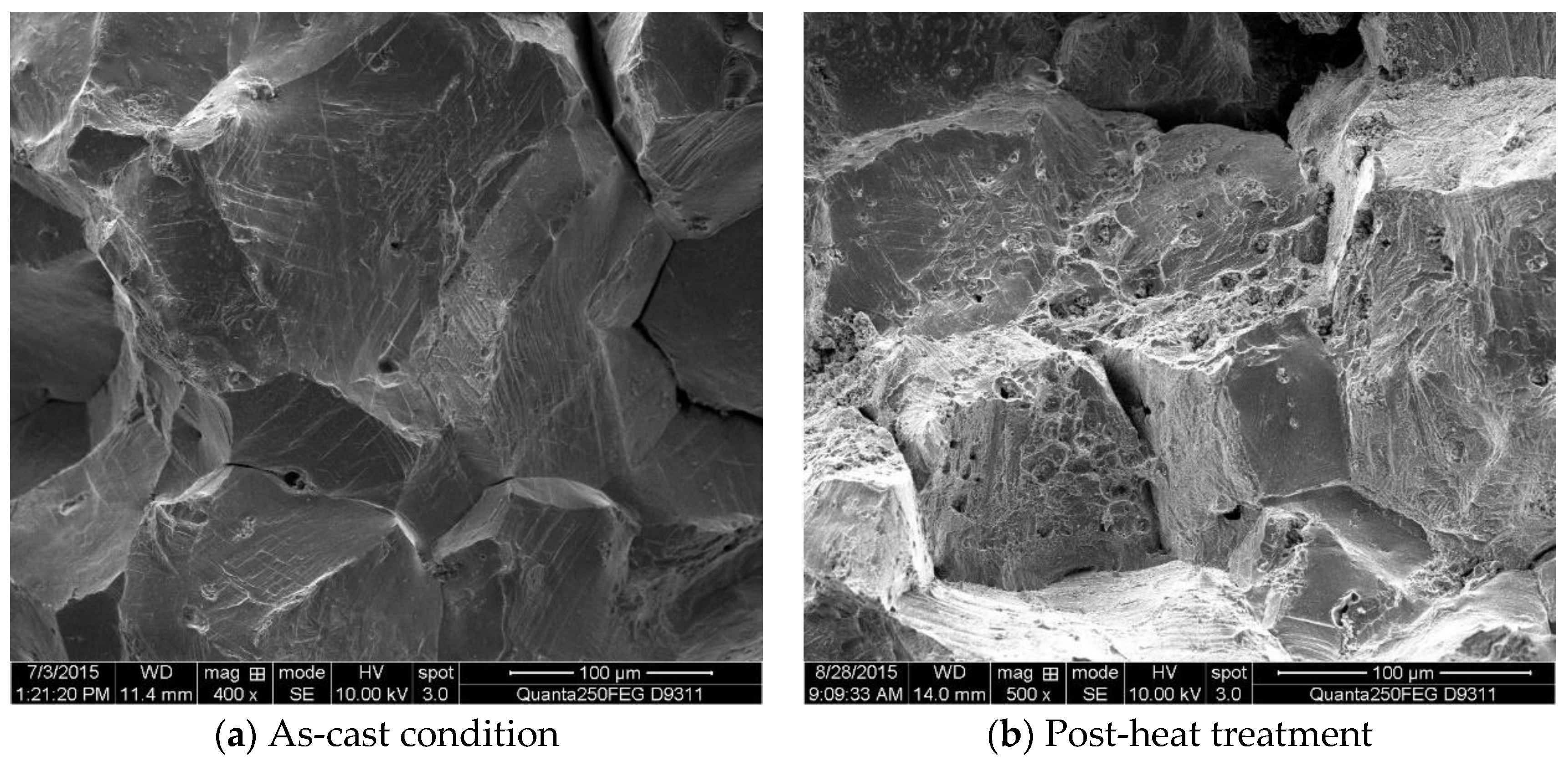

The fracture surface morphology of the TWIP steel matrix in both the as-cast and heat-treated states is shown in

Figure 6.

As shown in

Figure 6, the heat-treated TWIP steel matrix exhibits twinning and the formation of some dimples during tensile testing. These features are crucial for enhancing the material's toughness and ductility [

26,

27]. The microstructural changes observed are consistent with the mechanical property enhancements, underscoring the beneficial effects of the heat treatment process on the matrix material. This treatment, by reducing residual stresses and promoting favorable microstructural features, significantly enhances the overall mechanical performance of the TWIP steel matrix, making it more suitable for high-performance applications in ceramic rod-reinforced composites.

3.2. Mechanical Properties Analysis of TWIP Steel Matrix Composites

In this study, the φ5 ceramic rods were successfully integrated with TWIP steel using the lost foam casting method to fabricate ceramic rod-reinforced TWIP steel matrix composites. Industrial CT non-destructive testing was performed on the composites, and the results are shown in

Figure 7.

As depicted in

Figure 7, the industrial CT non-destructive testing results for the ceramic rod-reinforced TWIP steel matrix composite reveal that there are no significant defects such as pores, cracks, or insufficient filling between the ceramic rods and the matrix. The ceramic rods and the matrix exhibit a strong bond, providing a solid foundation and prerequisite for subsequent mechanical performance analysis and heat treatment process optimization. The inclusion of ceramic rods, known for their exceptional hardness and strength, is anticipated to significantly enhance the mechanical properties of the resulting TWIP steel matrix composites. Specifically, the introduction of these ceramic reinforcements is expected to markedly increase the material's strength. For this study, bending specimens were machined from the φ5 ceramic rod-reinforced TWIP steel matrix composite, as depicted in

Figure 7. The flexural strength of the composite material was then evaluated. Bending performance tests were conducted with a strain rate of 2 mm/min. These tests were performed on both the ceramic rod-reinforced composite and the unreinforced TWIP steel matrix material, allowing for a direct comparison of their flexural properties. The post-test appearance of the specimens under the as-cast condition is shown in

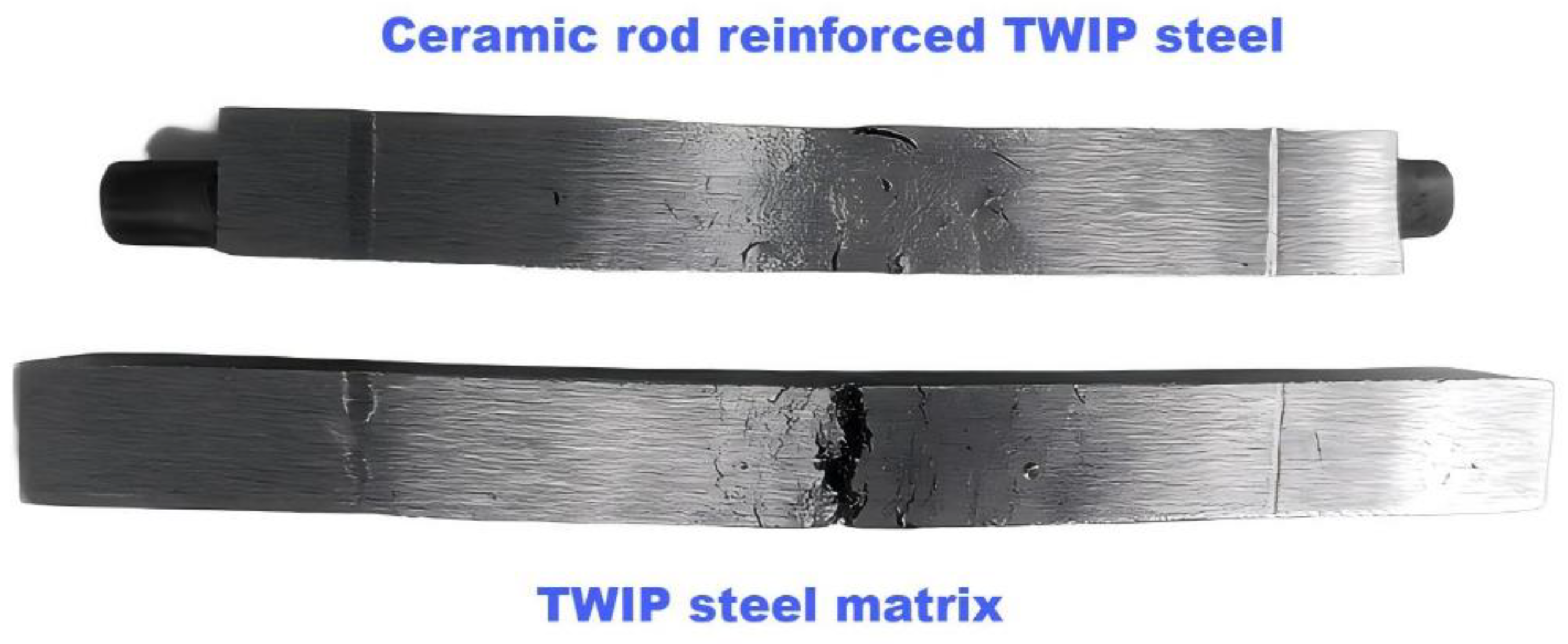

Figure 8.

As illustrated in

Figure 8, the TWIP steel matrix material exhibited significant cracking at the bottom of the specimen, leading to near-complete fracture. In contrast, the ceramic rod-reinforced TWIP steel composite demonstrated superior flexural resistance. The composite maintained structural integrity during bending, with only minor cracks appearing on the specimen's side. Even at greater bending angles, the composite did not suffer complete fracture, showcasing a markedly improved bending performance compared to the standalone TWIP steel matrix. This enhancement in bending performance is further supported by the stress-displacement curves obtained during the flexural tests, which provide a clear comparative visualization of the bending capabilities of the ceramic-reinforced composite and the pure TWIP steel matrix, as shown in

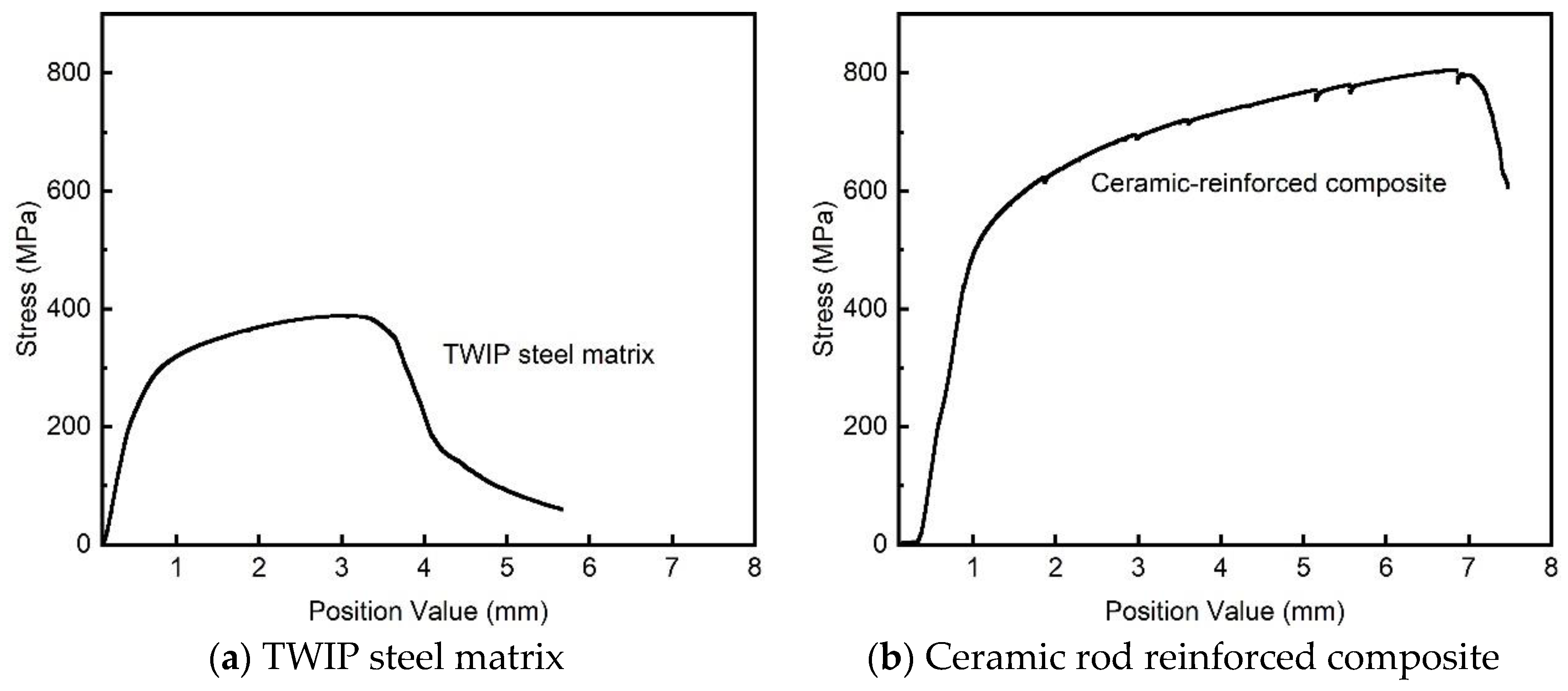

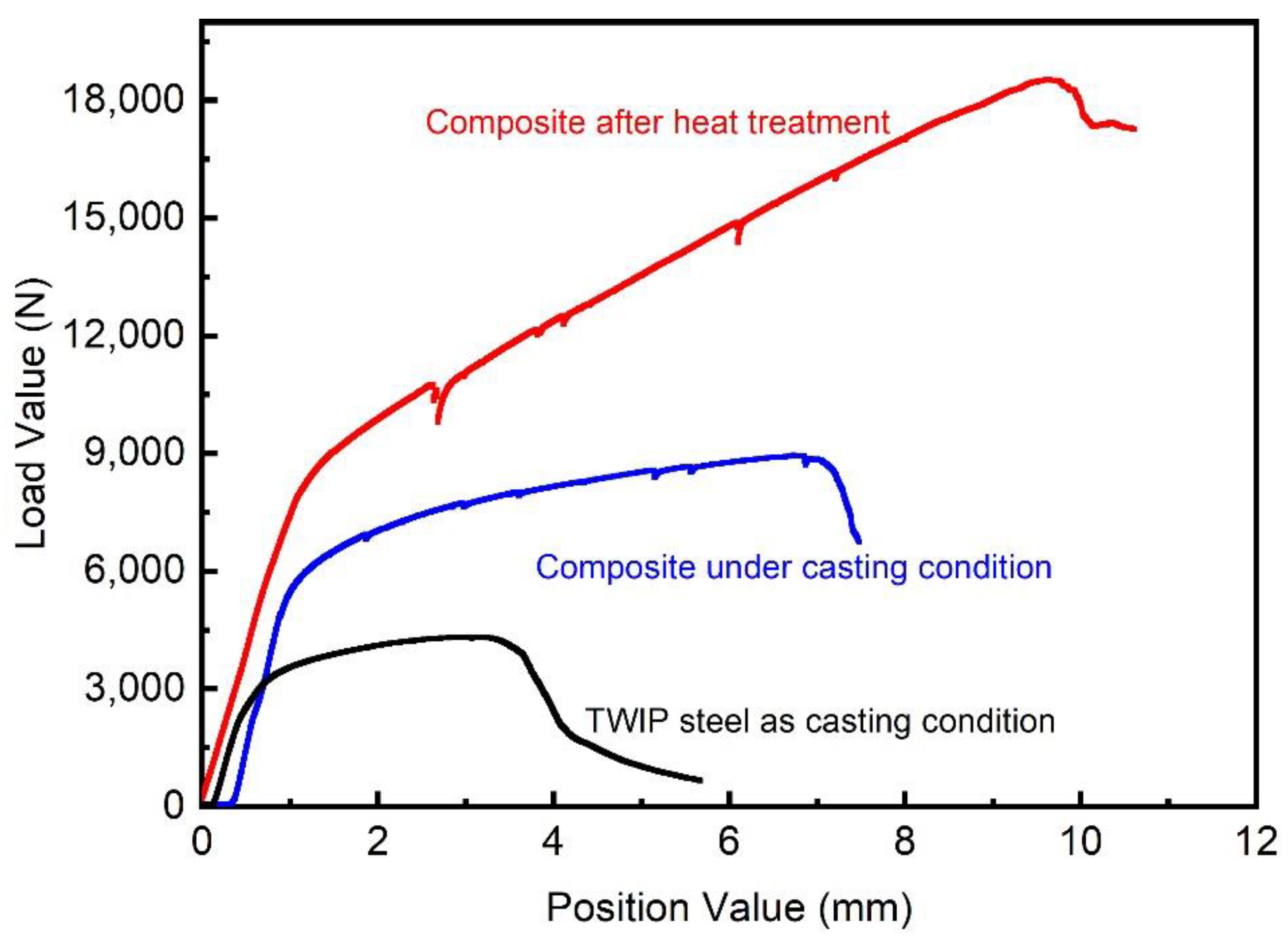

Figure 9.

From

Figure 9, it is evident that the flexural strength of the TWIP steel matrix composite is more than double that of the unreinforced TWIP steel. The TWIP steel began to fail and crack when the punch displacement reached 3.2 mm, as highlighted by the marked circle. Conversely, the ceramic-reinforced composite withstood a punch displacement exceeding 7 mm, more than twice the displacement before fracture compared to the unreinforced matrix. This result indicates a significant optimization in mechanical properties post-reinforcement.

The superior bending mechanical properties of the TWIP steel matrix composite, compared to the pure TWIP steel, can be attributed to the reinforcing effect of the ceramic rods. The composite can be conceptualized as a type of "fiber-reinforced composite," where the "fibers" are the ceramic rods embedded in the TWIP steel matrix. According to the "rule of mixtures" for composite materials, the overall strength of the composite is influenced by the strengths of both the reinforcement (ceramic rods) and the matrix (TWIP steel) [

28,

29]. Given that ceramics typically exhibit higher strength than the metallic matrix, the resultant composite material naturally exhibits enhanced mechanical properties compared to the matrix alone, as confirmed by the experimental data.

While ceramics are inherently brittle, the ceramic-reinforced TWIP steel matrix composite displayed superior plastic deformation capabilities compared to the pure TWIP steel matrix. This observation is somewhat unexpected, given the typical reduction in ductility when brittle materials are introduced into a composite system. However, this phenomenon can be explained by the concept of triaxial compressive stress. Under such stress conditions, brittle materials can exhibit plastic deformation behavior [

30]. According to principles of plastic deformation and superplasticity, materials subjected to triaxial hydrostatic pressure can show enhanced plastic deformation capabilities, even if they are intrinsically brittle. In the case of the ceramic-reinforced TWIP steel composite, the TWIP steel matrix, during cooling and solidification, exerts a compressive force on the ceramic rods, effectively encasing them in a triaxial compressive stress state. This confinement allows the ceramic to exhibit some degree of plasticity, thereby enabling the composite to demonstrate better plastic deformation ability under bending stresses than the unreinforced TWIP steel.

The observed mechanical performance enhancements highlight the efficacy of ceramic reinforcement in improving not only the strength but also the ductility and toughness of TWIP steel matrix composites. This makes such composites highly suitable for applications demanding high strength and resilience, providing a promising avenue for further development and optimization in material science.

3.3. Optimization of Mechanical Properties of Ceramic Rod Reinforced TWIP Steel Matrix Composites

To further assess the feasibility of improving the overall mechanical properties of ceramic rod reinforced TWIP steel matrix composites via heat treatment, a series of tests were conducted following an optimized thermal process. The composites were subjected to heat treatment at 500°C for 60 minutes, followed by air cooling. The bending mechanical properties were then evaluated using a universal testing machine with a deformation rate of 2 mm/min. The flexural performance of the heat-treated composite is illustrated in

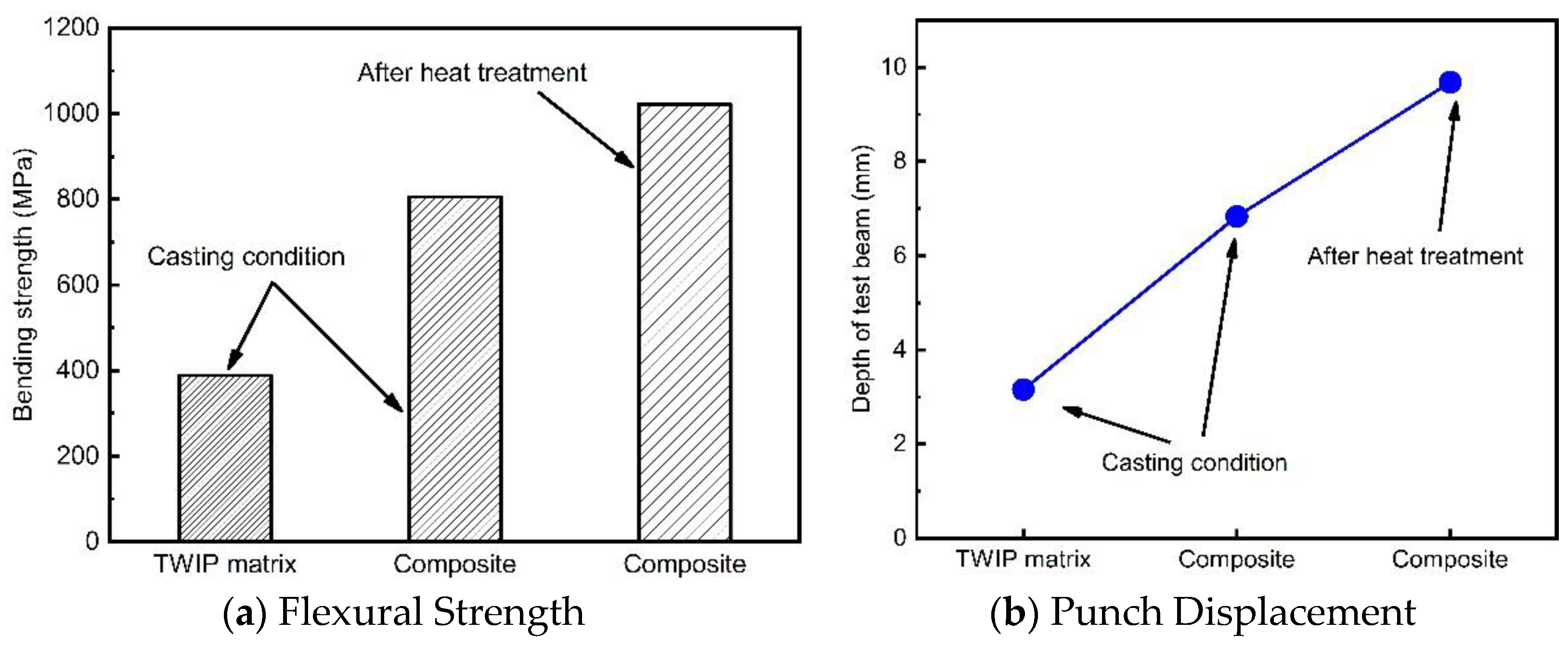

Figure 10.

As shown in

Figure 10(a), the flexural strength of the ceramic rod reinforced TWIP steel matrix composite in its as-cast state reached 805 MPa, significantly higher than the 388 MPa of unreinforced TWIP steel. For comparison, the flexural strength of 7050 aluminum alloy composites prepared by squeeze casting, after heat treatment, typically hovers around 580 MPa. This demonstrates the superior mechanical properties of the TWIP steel-based composite. Following heat treatment, the mechanical properties of the ceramic rod reinforced TWIP steel matrix composite were further enhanced. The flexural strength increased from 805 MPa to 1023 MPa, a rise of over 200 MPa. This improvement not only reflects an increase in strength but also a notable enhancement in ductility. As depicted in

Figure 10(b), the displacement of the punch corresponding to the maximum bending force increased from 6.8 mm to 9.6 mm post-heat treatment, indicating that the composite can undergo greater deformation and thus has improved plastic deformation capability. In contrast, the displacement for the TWIP steel matrix alone was only 3.1 mm, highlighting the advantages of the composite material. This suggests that the heat treatment effectively improved the flexural mechanical properties of the TWIP steel matrix composite.

The bending curves under different conditions, as shown in

Figure 11, reveal additional insights.

From

Figure 11 it can been seen that the bending curve of the TWIP matrix material alone is smooth, whereas the curves for the ceramic rod reinforced TWIP steel matrix composites, particularly after various heat treatments, exhibit a serrated pattern. This serrated behavior can be attributed to the interaction between the hard ceramic rod and the more ductile TWIP steel matrix. During bending, as the applied force increases, the composite initially shows an increase in flexural strength. However, as the force continues to increase, microcracks may form preferentially in the ceramic due to its lower plasticity compared to the TWIP steel. These microcracks can release some of the applied stress, resulting in a temporary decrease in the bending stress observed in the curve. The presence of the TWIP steel matrix, with its excellent plastic deformation capabilities, can accommodate these stresses by allowing the crack-affected zones in the ceramic to realign or shift. This reorientation restores the reinforcing effect of the ceramic rod, leading to an increase in the bending load capacity, thus resulting in the observed sawtooth pattern in the stress-strain curve. This cycle of stress relief and load recovery continues until the ceramic reinforcement can no longer provide additional strength, marking the failure point of the composite.

The results of these mechanical tests highlight that heat treatment significantly improves the flexural strength and plastic deformation capacity of the TWIP steel matrix composites. The increase in flexural strength by over 200 MPa, reaching 1023 MPa, and the substantial increase in the displacement at maximum load from 6.8 mm to 9.6 mm, represent an over 40% improvement in ductility. These enhancements validate the feasibility and effectiveness of using simple heat treatment as a method to optimize the mechanical properties of ceramic rod reinforced TWIP steel matrix composites.

The successful application of heat treatment in this context not only underscores the potential of these composites in high-strength applications but also paves the way for further exploration of tailored thermal processes to achieve specific property enhancements. The ability to fine-tune the mechanical properties through controlled thermal treatments could make these composites highly versatile and suitable for a broad range of engineering applications where a combination of high strength and ductility is required.

4. Conclusion

This study thoroughly investigated the mechanical and microstructural properties of ceramic rod reinforced TWIP steel matrix composites, focusing on the synthesis methods, material characterization, and the effects of heat treatment on the composite's performance. The key findings of this research can be summarized as follows:

1. The use of the lost foam casting process successfully integrated ceramic rods into the TWIP steel matrix, resulting in a composite material that exhibits an exceptionally strong composite effect.

2. The incorporation of ceramic rods significantly enhanced the mechanical properties of the TWIP steel matrix. Notably, the composite exhibited a more than twofold increase in flexural strength compared to the unreinforced TWIP steel. The improved mechanical performance is attributed to the synergistic effect of the hard ceramic phase and the ductile TWIP matrix, which allows for efficient load transfer and crack deflection mechanisms during mechanical deformation.

3. The application of a simple heat treatment at 500°C for 60 minutes followed by air cooling resulted in further optimization of the composite's properties. Post-heat treatment, the flexural strength of the composite increased by approximately 27%, reaching 1023 MPa. Additionally, the ductility of the material, as indicated by the displacement corresponding to the maximum bending force, was significantly enhanced.

Author Contributions

Conceptualization, Guojin Sun; Data curation, Guojin Sun and Qi Wang; Formal analysis, Guojin Sun, Zhenggui Li and Qi Wang; Investigation, Guojin Sun, Zhenggui Li and Qi Wang; Methodology, Guojin Sun, Zhenggui Li and Qi Wang; Supervision, Guojin Sun and Zhenggui Li; Writing – original draft, Guojin Sun; Writing – review & editing, Guojin Sun and Zhenggui Li.. All authors have read and agreed to the published version of the manuscript.

Funding

The authors acknowledge financial support from the Kunlun Talent Project of Qinghai Province (2023-QLGKLYCZX-032).

Data Availability Statement

The data presented in this study are available on request from the corresponding author due to privacy.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Fan, R. , Mei, X. & Cui, J. Process in laser drilling of deep microholes without taper on metal materials. Sci. China Technol. Sci. 67, 37–59 (2024). [CrossRef]

- Shohan, A.A.A. , Ganesan, H., Alsulamy, S. et al. Developments on energy-efficient buildings using phase change materials: a sustainable building solution. Clean Techn Environ Policy 26, 263–289 (2024). [CrossRef]

- Shi, Q. , Chen, D., Pan, Q. et al. Study on the Influence of Warm Die Compaction Behavior on the Mechanical Properties of Iron-Based Powder Materials. J. of Materi Eng and Perform 33, 5655–5666 (2024). [CrossRef]

- Cao, Q. , Ye, J., Liu, Y. et al. Effects of Nitrogen Atmosphere on Microstructure and Mechanical Properties of Ti(C0.5N0.5)-based Cermets. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 34, 259–266 (2019). [CrossRef]

- Wang, L. , Zhou, H., Chen, Y. et al. A Review of High-Temperature Toughness Improvement Strategies for Medium Entropy Alloys. J. of Materi Eng and Perform 33, 2051–2063 (2024). [CrossRef]

- Hu, Z. , Yin, H., Li, M. et al. Research and developments of ceramic-reinforced steel matrix composites—a comprehensive review. Int J Adv Manuf Technol 131, 125–149 (2024). [CrossRef]

- Kim, S.H. , Kim, D.H., Rhee, W.H. et al. Hardness and Transverse Rupture Strength of TiC-Reinforced SKD11 Steel Matrix Composite. Met. Mater. Int. 26, 302–309 (2020). [CrossRef]

- Yuan, G. , Zhu, X., Han, P. et al. Microstructure and Mechanical Properties of High-Chromium Cast Iron/Low-Carbon Steel Composite Prepared by Hot Rolling Process. Trans Indian Inst Met 74, 2761–2769 (2021). [CrossRef]

- Sahoo, S. , Jha, B.B. & Mantry, S. Optimization of Process Parameters of Hot Consolidated Steel Matrix Composites by Taguchi Method. JOM 76, 818–828 (2024). [CrossRef]

- Xiao, H. , Chen, C. & Zhang, M. Microstructure and Mechanical Properties of H13 Steel/High-Speed Steel Composites Prepared by Laser Metal Deposition. J. of Materi Eng and Perform 29, 66–77 (2020). [CrossRef]

- Aslam, M. , Chandan, G.K. & Kanchan, B.K. Development of SiC Ceramic Reinforced Composite Interlayer Cladding with AISI304 Stainless Steel Wire on Low Carbon Steel Substrate Using TIG Cladding Process. Silicon 15, 7733–7743 (2023). [CrossRef]

- Jeyaprakash, N. , Yang, CH., Karuppasamy, S.S. et al. Stellite 6 Cladding on AISI Type 316L Stainless Steel: Microstructure, Nanohardness and Corrosion Resistance. Trans Indian Inst Met 76, 491–503 (2023). [CrossRef]

- Srivastava, A.K. , Das, K., Toor, S.K. et al. Corrosion Behavior of TiC and (Ti,W)C-Reinforced Fe-17Mn and Fe-17Mn-3Al Austenitic Steel Matrix In Situ Composites. Metallogr. Microstruct. Anal. 4, 371–380 (2015). [CrossRef]

- Banerjee, A. , Tungala, V., Sala, K. et al. A Comparative Study on the Dry Sliding Wear Behavior of Mild Steel and 6061Al-15wt.%SiCp Composite. J. of Materi Eng and Perform 24, 2303–2311 (2015). [CrossRef]

- Wu, Z. , Wang, M., He, J. et al. A Novel Cast Multiphase Stainless Steel With High Strength and High Toughness. Metall Mater Trans A 54, 2617–2630 (2023). [CrossRef]

- Andraskar, N. , Tiwari, G., Goel, M.D. et al. Numerical Investigation of the Effect of Layering Thickness on the Ballistic Response of Ceramic/Metal Composite Structure. Mech. Solids 58, 1351–1369 (2023). [CrossRef]

- Sohrabi, M.J. , Mirzadeh, H., Sadeghpour, S. et al. Tailoring the strength-ductility balance of a commercial austenitic stainless steel with combined TWIP and TRIP effects. Archiv.Civ.Mech.Eng 23, 170 (2023). [CrossRef]

- Shen, S. , Wu, C., Xie, P. et al. Positive Strain Rate Sensitivity and Deformation Behavior of a Fe–29Mn–3Al–3Si TWIP Steel. Acta Metall. Sin. (Engl. Lett.) 35, 1825–1836 (2022). [CrossRef]

- Wang, D. , Wang, K., Man, J. et al. Mechanical Behavior and Microstructure Characteristics of Directionally Solidified TWIP Steel. Metall Mater Trans A 47, 3423–3434 (2016). [CrossRef]

- Kusakin, P. , Tsuzaki, K., Molodov, D.A. et al. Advanced Thermomechanical Processing for a High-Mn Austenitic Steel. Metall Mater Trans A 47, 5704–5708 (2016). [CrossRef]

- Mijangos, D. , Mejia, I. & Cabrera, J.M. Influence of Microalloying Additions (Nb, Ti, Ti/B, V and Mo) on the Microstructure of TWIP Steels. Metallogr. Microstruct. Anal. 11, 524–536 (2022). [CrossRef]

- Zheng, Zb. , Yang, Hk., Shatrava, A.P. et al. Revealing effect of aluminum alloying on work hardening and impact behaviors of low-density Fe-18Mn-1.3C-2Cr-(4, 11)Al casting steel. China Foundry 19, 359–368 (2022). [CrossRef]

- Park, J. , Lee, K., Sung, H. et al. J-integral Fracture Toughness of High-Mn Steels at Room and Cryogenic Temperatures. Metall Mater Trans A 50, 2678–2689 (2019). [CrossRef]

- Chen, X. , Zhang, J., Xiong, J. et al. Microstructure Evolution and Tensile Properties of Cold-Rolled and Annealed Fe-30Mn-0.14C-7Cr-0.26Ni Steel. Metall Mater Trans A 52, 3839–3848 (2021). [CrossRef]

- Feng, Y. , Song, R., Pei, Z. et al. Effect of Aging Isothermal Time on the Microstructure and Room-Temperature Impact Toughness of Fe–24.8Mn–7.3Al–1.2C Austenitic Steel with κ-Carbides Precipitation. Met. Mater. Int. 24, 1012–1023 (2018). [CrossRef]

- Jabłońska, M.B. , Jasiak, K., Kowalczyk, K. et al. The influence of the heat generation during deformation on the mechanical properties and microstructure of the selected TWIP steels. Int J Mater Form 16, 30 (2023). [CrossRef]

- Gupta, V.K. , Tewary, N.K., Yadav, M. et al. Effect of Intercritical Rolling on the Microstructure, Texture and Mechanical Properties of Dual Phase TWIP Steel. Metallogr. Microstruct. Anal. 11, 602–616 (2022). [CrossRef]

- Pan, J. , Bian, L. A re-formulation of the Mori-Tanaka method for predicting material properties of fiber-reinforced polymers/composites. Colloid Polym Sci 297, 529–543 (2019). [CrossRef]

- Vignoli, L.L. , Savi, M.A., Pacheco, P.M.C.L. et al. A Novel Micromechanical Model Based on the Rule of Mixtures to Estimate Effective Elastic Properties of Circular Fiber Composites. Appl Compos Mater 29, 1715–1731 (2022). [CrossRef]

- Liu, S. , Li, P., Hu, K. et al. Constitutive modeling of brittle–ductile transition in porous rocks: formulation, identification and simulation. Acta Mech 234, 2103–2121 (2023). [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).