Submitted:

06 August 2024

Posted:

08 August 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

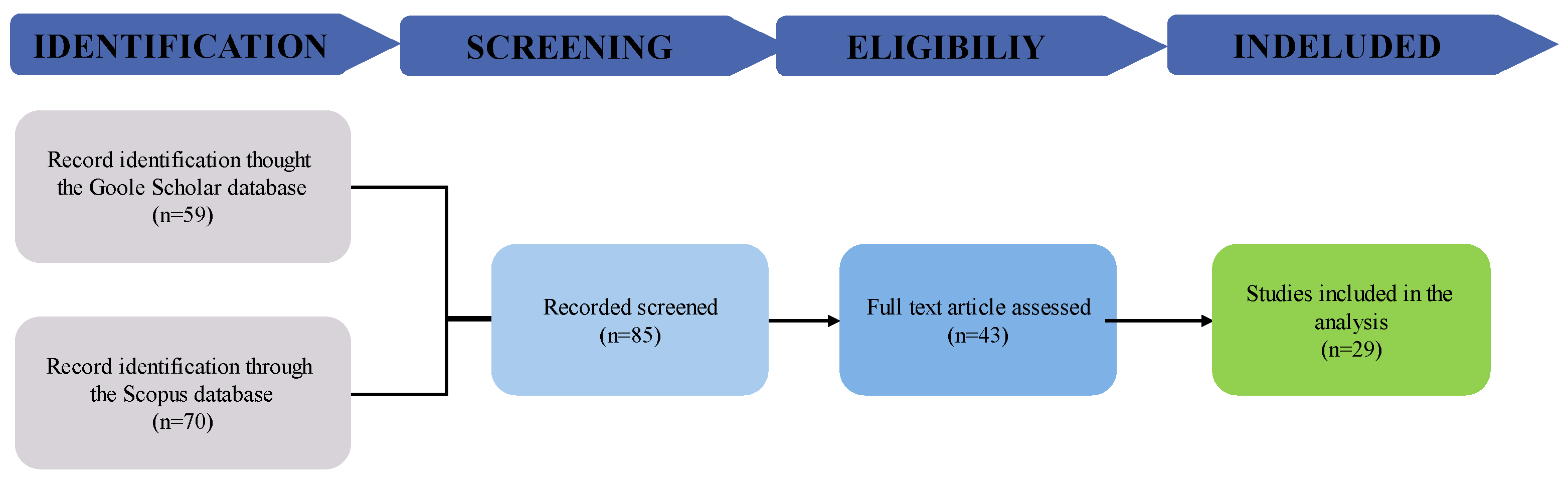

2. Literature Review Methodologies

3. LCA Methodology

- i.

- Food industry: LCA is used to assess the environmental impact of food products, from production to distribution and consumption. For example, in the brewing industry, LCA can identify the production steps that contribute most to greenhouse gas emissions and suggest ways to reduce these impacts.

- i.

- ii. Energy Sector: LCA is used to compare different energy sources, such as fossil fuels and renewable energies, providing a comprehensive assessment of their environmental performance.

- i.

- iii. Construction: In the construction industry, LCA helps assess the environmental impact of building materials and construction processes, promoting the use of sustainable materials and environmentally friendly construction techniques.

3. Results and Discussion

3.1. Goal and Scope

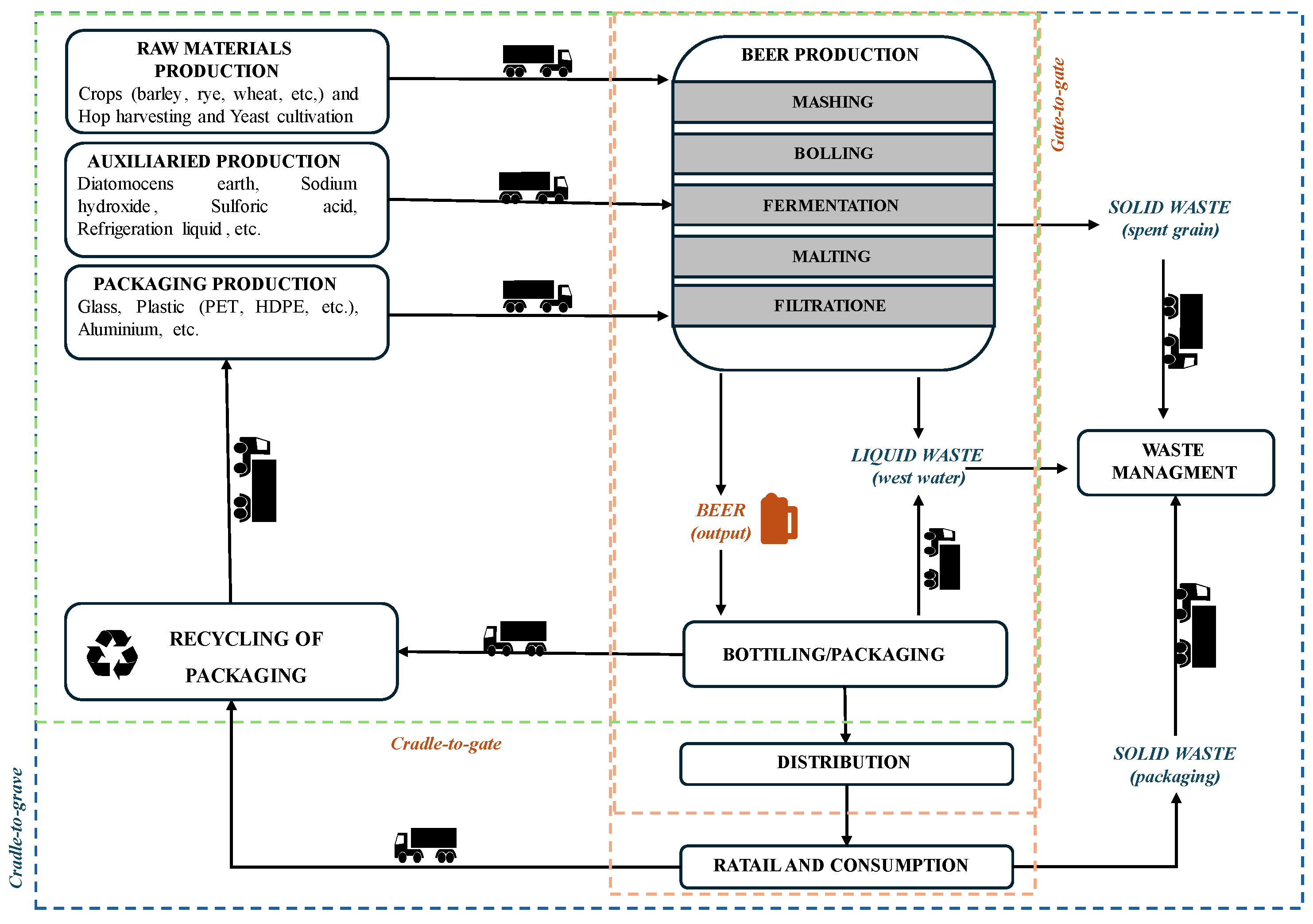

3.1.1. System Boundaries

- -

- Raw materials and auxiliaries: barley and hop cultivation, barley malt production, production of sodium hydroxide, sulphuric acid, carbon dioxide, and other auxiliary materials.

- -

- Beer Production: electricity and materials for beer production, including preparation and milling of malt, fermentation, carbonation, storage, filtration, and bottling.

- -

- Packaging: materials and energy to produce glass bottles (with metal caps and multi-packaging cardboard boxes in which bottled beer is typically sold), aluminum, and steel cans.

- -

- Retail and consumption: refrigerated beer storage at the retailer (only as part of the sensitivity analysis) and post-consumer waste generated after consumption.

3.1.2. Functional Unit

3.2. Life Cycle Inventory

3.2. Life Cycle Impact Assessment

3.3. Interpretation

- -

- identification of hot spots (materials/processes that contribute most to overall impacts are identified),

- -

- assessments of the completeness and robustness of the model (such as sensitivity and uncertainty analysis),

- -

- definition of the study’s conclusions, including considering the limitations present.

3.3.1. Sensitivity and Uncertainty Analysis

4. Conclusion, Limitations, and Future Research

References

- Mattila, T.; Helin, T.; Antikainen, R. Land Use Indicators in Life Cycle Assessment A Case Study on Beer Production. Int. J. Life Cycle Assess. 2012, 17, 277–286. [CrossRef]

- Morgan, D.R.; Styles, D.; Lane, E.T. Thirsty Work: Assessing the Environmental Footprint of Craft Beer. Sustain. Prod. Consum. 2021, 27, 242–253. [CrossRef]

- Gómez-Corona, C.; Escalona-Buendía, H.B.; García, M.; Chollet, S.; Valentin, D. Craft vs. Industrial: Habits, Attitudes and Motivations towards Beer Consumption in Mexico. Appetite 2016, 96, 358–367. [CrossRef]

- Brewers Association Available online: https://www.brewersassociation.org/.

- Donadini, G.; Porretta, S. Uncovering Patterns of Consumers’ Interest for Beer: A Case Study with Craft Beers. Food Res. Int. 2017, 91, 183–198. [CrossRef]

- Diniz, D. de P.; Carvalho, M. Environmental Repercussions of Craft Beer Production in Northeast Brazil. Sustain. 2024, 16, 1–12. [CrossRef]

- Carvalho, G.; Leite, A.C.; Leal, R.; Pereira, R. The Role of Emergent Processing Technologies in Beer Production. Beverages 2023, 9, 1–23. [CrossRef]

- Montanari, L.; Floridi, S.; Marconi, O.; Tironzelli, M.; Fantozzi, P. Effect of Mashing Procedures on Brewing. Eur. Food Res. Technol. 2005. [CrossRef]

- Kalac, P.; Krizek, M. A Review of Biogenic Amines and Polyamines in Beer. J. Inst. Brew. 2003. [CrossRef]

- Talve, S. Life Cycle Assessment of a Basic Lager Beer. Int. J. Life Cycle Assess. 2001, 6, 293–298. [CrossRef]

- Fasi, L.E.; Di, O.; Pesatura, N.E.; Analisi, N.; Ciclo, D.E.L.; Vita, D.I.; Possibili, A.; Arte, S.D.; Cavenago, G.; Rigamonti, L.; et al. Valutazioni Di Sostenibilità. 2021, 8, 188–201.

- Uhlman, B.W.; Saling, P.R. The BASF Eco-Efficiency Toolbox: Holistic Evaluation of Sustainable Solutions; Elsevier, 2017; Vol. 1; ISBN 9780128046777.

- da Fonseca, L.M.C.M. ISO 14001:2015: An Improved Tool for Sustainability. J. Ind. Eng. Manag. 2015. [CrossRef]

- Giuliana, V.; Lucia, M.; Marco, R.; Simone, V. Environmental Life Cycle Assessment of Rice Production in Northern Italy: A Case Study from Vercelli. Int. J. Life Cycle Assess. 2022. [CrossRef]

- Uni En Iso 14001:2015.

- Ahmad, A.; Zoli, M.; Latella, C.; Bacenetti, J. Rice Cultivation and Processing: Highlights from a Life Cycle Thinking Perspective. Sci. Total Environ. 2023, 871, 162079. [CrossRef]

- Sonnemann, G.W.; Solgaard, A.; Saur, K.; Udo de Haes, H.A.; Christiansen, K.; Jensen, A.A. Life Cycle Management: UNEP-Workshop Sharing Experiences on LCM. Int. J. Life Cycle Assess. 2001. [CrossRef]

- Peças, P.; Götze, U.; Bravo, R.; Richter, F.; Ribeiro, I. Methodology for Selection and Application of Eco-Efficiency Indicators Fostering Decision-Making and Communication at Product Level-the Case of Molds for Injection Molding; Elsevier Inc., 2018; ISBN 9780081024140.

- Curran, M.A. Life Cycle Assessment: A Review of the Methodology and Its Application to Sustainability. Curr. Opin. Chem. Eng. 2013, 2, 273–277. [CrossRef]

- Fauzi, R.T.; Lavoie, P.; Sorelli, L.; Heidari, M.D.; Amor, B. Exploring the Current Challenges and Opportunities of Life Cycle Sustainability Assessment. Sustain. 2019, 11. [CrossRef]

- Bozzola, M.; Lamonaca, E.; Santeramo, F.G. Impacts of Climate Change on Global Agri-Food Trade. Ecol. Indic. 2023, 154, 110680. [CrossRef]

- Chen, Z.; Huang, L. Application Review of LCA (Life Cycle Assessment) in Circular Economy: From the Perspective of PSS (Product Service System). Procedia CIRP 2019, 83, 210–217. [CrossRef]

- Martin, M.; Herlaar, S.; Jönsson, A.; Lazarevic, D. From Circular to Linear? Assessing the Life Cycle Environmental and Economic Sustainability of Steel and Plastic Beer Kegs. Circ. Econ. Sustain. 2022, 2, 937–960. [CrossRef]

- I., H. ISO 9000 and ISO 14000 Standards: An International Diffusion Model. Int. J. Oper. Prod. Manag. 2006, 26, 141. [CrossRef]

- 1404; 25. International Organization for Standardization ISO 14040-Environmental Management - Life Cycle Assessment - Principles and Framework; 2006;

- Sala, S.; Beylot, A.; Corrado, S.; Crenna, E.; Sanyé-Mengual, E.; Secchi, M. Indicators and Assessment of the Environmental Impact of EU Consumption; 2019; ISBN 9789279996726.

- Saling, P.; A., K.; B., D.-K.; R., W.; W., Z.; I., S.; W., S.; S., S. Eco-Efficiency Analysis by BASF: The Method. Int. J. Life Cycle Assess. 2002, 7, 203–218. [CrossRef]

- Koroneos, C.; Roumbas, G.; Gabari, Z.; Papagiannidou, E.; Moussiopoulos, N. Life Cycle Assessment of Beer Production in Greece. J. Clean. Prod. 2005, 13, 433–439. [CrossRef]

- Notarnicola, B.; Tassielli, G.; Renzulli, P.A.; Castellani, V.; Sala, S. Environmental Impacts of Food Consumption in Europe. J. Clean. Prod. 2017, 140, 753–765. [CrossRef]

- Brancoli, P.; Bolton, K.; Eriksson, M. Environmental Impacts of Waste Management and Valorisation Pathways for Surplus Bread in Sweden. Waste Manag. 2020, 117, 136–145. [CrossRef]

- Pasqualino, J.; Meneses, M.; Castells, F. The Carbon Footprint and Energy Consumption of Beverage Packaging Selection and Disposal. J. Food Eng. 2011, 103, 357–365. [CrossRef]

- Cimini, A.; Moresi, M. Mitigation Measures to Minimize the Cradle-to-Grave Beer Carbon Footprint as Related to the Brewery Size and Primary Packaging Materials. J. Food Eng. 2018, 236, 1–8. [CrossRef]

- Morgan, D.R.; Styles, D.; Thomas Lane, E. Packaging Choice and Coordinated Distribution Logistics to Reduce the Environmental Footprint of Small-Scale Beer Value Chains. J. Environ. Manage. 2022, 307, 114591. [CrossRef]

- Cimini, A.; Moresi, M. Are the Present Standard Methods Effectively Useful to Mitigate the Environmental Impact of the 99% EU Food and Drink Enterprises? Trends Food Sci. Technol. 2018, 77, 42–53. [CrossRef]

- Cimini, A.; Moresi, M. Carbon Footprint of a Pale Lager Packed in Different Formats: Assessment and Sensitivity Analysis Based on Transparent Data. J. Clean. Prod. 2016, 112, 4196–4213. [CrossRef]

- Hallström, E.; Håkansson, N.; Åkesson, A.; Wolk, A.; Sonesson, U. Climate Impact of Alcohol Consumption in Sweden. J. Clean. Prod. 2018, 201, 287–294. [CrossRef]

- Saget, S.; Porto Costa, M.; Black, K.; Iannetta, P.P.M.; Reckling, M.; Styles, D.; Williams, M. Environmental Impacts of Scottish Faba Bean-Based Beer in an Integrated Beer and Animal Feed Value Chain. Sustain. Prod. Consum. 2022, 34, 330–341. [CrossRef]

- Smedman, A.; Lindmark-Månsson, H.; Drewnowski, A.; Edman, A.K.M. Nutrient Density of Beverages in Relation to Climate Impact. Food Nutr. Res. 2010, 54, 1–8. [CrossRef]

- Mata, T.M.; Costa, C.A.V. Life Cycle Assessment of Different Reuse Percentages for Glass Beer Bottles. Int. J. Life Cycle Assess. 2001, 6, 307–319. [CrossRef]

- Ho, D.M.; Thach, B.T.; Bui, H.M. Establishing Criteria for Advancing Circular Economy Practices in the Beer Industry: A Case Study in South Vietnam. Environ. Qual. Manag. 2024, 1–13. [CrossRef]

- Cimini, A.; Moresi, M. Product Carbon Footprint: Still a Proper Method to Start Improving the Sustainability of Food and Beverage Enterprises. Ital. J. Food Sci. 2019, 31, 808–826. [CrossRef]

- Hanssen, O.J.; Rukke, E.O.; Saugen, B.; Kolstad, J.; Hafrom, P.; Von Krogh, L.; Raadal, H.L.; Rønning, A.; Wigum, K.S. The Environmental Effectiveness of the Beverage Sector in Norway in a Factor 10 Perspective. Int. J. Life Cycle Assess. 2007, 12, 257–265. [CrossRef]

- Salazar Tijerino, M.B.; San Martín-González, M.F.; Velasquez Domingo, J.A.; Huang, J.Y. Life Cycle Assessment of Craft Beer Brewing at Different Scales on a Unit Operation Basis. Sustain. 2023, 15, 1–11. [CrossRef]

- ISO 14040: Environmental Management–Life Cycle Assessment—Principles and Framework. Int. Organ. Stand. 2006.

- Avadí, A.; Fréon, P. Life Cycle Assessment of Fisheries: A Review for Fisheries Scientists and Managers. Fish. Res. 2013, 143, 21–38. [CrossRef]

- Cimini, A.; Moresi, M. Are the Present Standard Methods Effectively Useful to Mitigate the Environmental Impact of the 99% EU Food and Drink Enterprises? Trends Food Sci. Technol. 2018, 77, 42–53. [CrossRef]

- Cibelli, M.; Cimini, A.; Moresi, M. Carbon Footprint of Different Coffee Brewing Methods. Chem. Eng. Trans. 2021, 87, 373–378. [CrossRef]

- Morgan, D.R.; Styles, D.; Thomas Lane, E. Packaging Choice and Coordinated Distribution Logistics to Reduce the Environmental Footprint of Small-Scale Beer Value Chains. J. Environ. Manage. 2022, 307, 114591. [CrossRef]

- de Paula Diniz, D.; Carvalho, M.; Abrahão, R. Greenhouse Gas Accounting for the Energy Transition in a Brewery. Environ. Prog. Sustain. Energy 2021, 40. [CrossRef]

- De Marco, I.; Miranda, S.; Riemma, S.; Iannone, R. Life Cycle Assessment of Ale and Lager Beers Production. Chem. Eng. Trans. 2016, 49, 337–342. [CrossRef]

- Saget, S.; Porto Costa, M.; Santos, C.S.; Vasconcelos, M.; Styles, D.; Williams, M. Comparative Life Cycle Assessment of Plant and Beef-Based Patties, Including Carbon Opportunity Costs. Sustain. Prod. Consum. 2021, 28, 936–952. [CrossRef]

- Cordella, M.; Tugnoli, A.; Spadoni, G.; Santarelli, F.; Zangrando, T. LCA of an Italian Lager Beer. Int. J. Life Cycle Assess. 2008, 13, 133–139. [CrossRef]

- Rosenbaum, R.K.; Hauschild, M.Z.; Boulay, A.M.; Fantke, P.; Laurent, A.; Núñez, M.; Vieira, M. Life Cycle Impact Assessment. In Life Cycle Assessment: Theory and Practice; 2017 ISBN 9783319564753. [CrossRef]

- Boesen, S.; Bey, N.; Niero, M. Environmental Sustainability of Liquid Food Packaging: Is There a Gap between Danish Consumers’ Perception and Learnings from Life Cycle Assessment? J. Clean. Prod. 2019, 210, 1193–1206. [CrossRef]

- Usva, K.; Saarinen, M.; Katajajuuri, J.M.; Kurppa, S. Supply Chain Integrated LCA Approach to Assess Environmental Impacts of Food Production in Finland. Agric. Food Sci. 2009, 18, 460–476. [CrossRef]

- Amienyo, D.; Azapagic, A. Life Cycle Environmental Impacts and Costs of Beer Production and Consumption in the UK. Int. J. Life Cycle Assess. 2016, 21, 492–509. [CrossRef]

- Schau, E.M.; Fet, A.M. LCA for Food Products (Subject Editor: Niels Jungbluth) LCA Studies of Food Products as Background for Environmental Product Declarations*. Int J LCA 2008. [CrossRef]

- Hertwich, E., van der Voet, E., Suh, S., Tukker, A., Huijbregts M., Kazmierczyk, P., Lenzen, M., McNeely, J., Moriguchi, Y. UNEP - Assessing the Environmental Impacts of Consumption and Production: Priority Products and Materials, A Report of the Working Group on the Environmental Impacts of Products and Materials to the International Panel for Sustainable Resource Management.; 2010; ISBN 9789280730845.

- Koroneos, C.; Roumbas, G.; Gabari, Z.; Papagiannidou, E.; Moussiopoulos, N. Life Cycle Assessment of Beer Production in Greece. J. Clean. Prod. 2005, 13, 433–439. [CrossRef]

- Notarnicola, B.; Sala, S.; Anton, A.; McLaren, S.J.; Saouter, E.; Sonesson, U. The Role of Life Cycle Assessment in Supporting Sustainable Agri-Food Systems: A Review of the Challenges. J. Clean. Prod. 2017, 140, 399–409. [CrossRef]

- P: Life Cicle Assesment, 2006; 61. SAID Life Cicle Assesment: Principle and Practice; 2006;

- Hauschild, M.Z.; Goedkoop, M.; Guinée, J.; Heijungs, R.; Huijbregts, M.; Jolliet, O.; Margni, M.; De Schryver, A.; Humbert, S.; Laurent, A.; et al. Identifying Best Existing Practice for Characterization Modeling in Life Cycle Impact Assessment. Int. J. Life Cycle Assess. 2013, 18, 683–697. [CrossRef]

- Heller, M. The Oregon Sustainability Board. 2017.

- Mattila, T.; Leskinen, P.; Soimakallio, S.; Sironen, S. Uncertainty in Environmentally Conscious Decision Making: Beer or Wine? Int. J. Life Cycle Assess. 2012, 17, 696–705. [CrossRef]

- Březinová, M. Beer Industry in the Czech Republic: Reasons for Founding a Craft Brewery. Sustain. 2021, 13. [CrossRef]

- Stillitano, T.; Falcone, G.; De Luca, A.I.; Piga, A.; Conte, P.; Strano, A.; Gulisano, G. A Life Cycle Perspective to Assess the Environmental and Economic Impacts of Innovative Technologies in Extra Virgin Olive Oil Extraction. Foods 2019, 8. [CrossRef]

- Cibelli, M.; Cimini, A.; Cerchiara, G.; Moresi, M. Carbon Footprint of Different Methods of Coffee Preparation. Sustain. Prod. Consum. 2021, 27, 1614–1625. [CrossRef]

- Arzoumanidis, I.; Salomone, R.; Petti, L.; Mondello, G.; Raggi, A. Is There a Simplified LCA Tool Suitable for the Agri-Food Industry? An Assessment of Selected Tools. J. Clean. Prod. 2017, 149, 406–425. [CrossRef]

- Zheng, H.; Xing, M.; Cao, T.; Zhang, J. Uncertainty Study and Parameter Optimization of Carbon Footprint Analysis for Fermentation Cylinder. Sustain. 2019, 11, 1–13. [CrossRef]

| Study | Publication Years | Geographical Area | Goal And Scope | Functional Unit | System Boundaries | Lcia Method | Impact Categories | ||

|---|---|---|---|---|---|---|---|---|---|

| Name | Unit | Result | |||||||

| [31] | 2010 | N/A | Evaluate the environmental impact of manufacturing and disposing of the most common packaging options for three beverage products: juice, beer and water. | packaging required to contain 1 l of beverage | Gate to Grave | - | GWP | g CO 2 eq | 826 |

| Evaluate the contribution of packaging to the environmental profile of a product’s life cycle. This includes an analysis of the impact of beverage production, transport (local), packaging production and packaging disposal. | CED | Mj | 19.06 | ||||||

| [32] | 2018 | NA | Evaluate the potentialities of a series of mitigation opportunities in order to minimize the cradle-to-grave carbon footprint of 1 hL of beer produced in three large- (LS), medium-(MS) and small-(SS) sized breweries and packed in 66-cL glass or PET bottles |

1 hL of beer produced in three large- (LS), medium-(MS) and small-(SS) sized breweries and packed in 66-cL glass or polyethylene terephthalate (PET) bottles | Gate to grave | Carbon Footprint (IPCC 2007) | GWP | Kg CO 2 eq | 127 to 192 |

| [33] | 2022 | N/A | Evaluate the influence of different packaging and distribution options on the environmental footprint of beer produced by seven small-scale breweries, often referred to as “micro-breweries” | 1 L of packaged beer at the point of ratail to consumer | cradle to grave | European Product Enviromental Footprint (PEF) | GWP | g CO 2 eq | 727 to 1336 |

| AP | Mol H+ eq | 0.00952 to 0.0103 | |||||||

| FRDP | Mj | 13.55 to 19.66 | |||||||

| [34] | 2018 | Wester Europe | Assess the carbon footprint of a lager beer, made of malted barley and hop pellets, and produced from industrial and craft breweries |

1 Hl of lager beer packaged in 66-cL glass bottles | Gate to grave | Carbon Footprint (IPCC 2007) | GWP | Kg CO 2 eq | 90 |

| [28] | 2005 | Greece | Identify key issues associated with the life cycle of beer production |

The functional unit is one bottle of beer (combined weight of beer and glass 1.066 kg) |

Cradle to grave | Carbon Footprint (IPCC 2007) | GWP | Kg CO 2 eq | 392.46 |

| N/S | OD | kg CFC11-eq | 0.00234 | ||||||

| AP | kg SO2-eq | 0.00015 | |||||||

| [35] | 2016 | Italy | Develop an LCA model to assess the carbon footprint of a pale lager beer, made of malted barley, maize grits and hop pellets, and produced from the Italian brewery Birra Peroni Srl (Rome, Italy), and consumed in Italy, as well as to identify its life-cycle hot spots |

1 hL of lager beer packaged in different packaging formats and selling units |

Cradle to gate | Ecoindicator 99 | GWP | Kg CO 2 eq | 68.91 |

| [29] | 2017 | N/A | Development of the basket of products method responds to the needs to analyse and monitor European consumption patterns and their global influence, in order to shift to more resourceefficient consumption practices that have a lower impact on the environment |

average food consumption per person in the EU in terms of food categories (including the food losses at each stage) |

Cradel to gate | ILCD 2011 | CC | Kg CO 2 eq | 80 |

| OD | kg CFC- 11eq. |

0.000015 | |||||||

| AP | mol Hþ eq |

0.88 | |||||||

| POF | kg NMVOCeq |

0.32 | |||||||

| [36] | 2018 | Sweden | estimated the GHG emissions related to alcoholic beverages that are representative for Swedish consumption |

kg of carbon dioxide equivalents (CO2e) per liter of specific alcoholic beverage | Cradle to gate | IPCC 2007 | GWP | kg NMVOCeq |

0.73 |

| N/S | AP | kg SO2-eq | N/S | ||||||

| POF | Kg NMOC | N/S | |||||||

| [2] | 2021[37] | N/A | valuate the environmental impact of craft beer production, in particular at small scale in microbreweries | production of 1 litre of beer, packaged according to individual brew- ery specifications and delivered to the retailer | Cradle to grave (end-of-life) | European product Enviromental Foorprint (PEF) | GWP | g Co2 eq | 760 to 1900 |

| FRDP | Mj | 12 to 30 | |||||||

| AP | g Sb eq. | 0.0024 to 0.0067 | |||||||

| AC | molc H + eq | 0.0067 to 0.013 | |||||||

| OD | g CFC 11 eq. | 0.00013 to 0.00037 | |||||||

| [37] | 2022 | N/A | Evaluate the environmental impact of the barley been beer respect the traditional beer | one 330 mL filled beer bottle at the brewery in Edinburgh |

Cradle to gate | European product enviromental footprint (PEF) | CC | g Co2 eq | N/S |

| ME | kg P eq | ||||||||

| AC | mol H⁺ eq. | ||||||||

| FE | mol H⁺ eq | ||||||||

| LU | pt | ||||||||

| [38] | 2010 | Sweden | Evaluate the GWP of beverages in relation to nutritional value | N/S | N/S | GWP | g CO2 eq per 100g | 101 | |

| [10] | 2001 | N/A | assess the potential environmental effects of the different stages of the beer life cycle and to also obtain new and updated information for establishing the new facility. |

505 multi-packs of bottled beer (10 hi of beer) in the shop |

Cradle to gate | Ecoindicator 95 | GWP | g CO2 eq | N/S |

| [39] | 2001 | Portugal | assess the environmental impacts through the life cycle of returnable and non-returnable glass beer bottles comparing different reuse percentages |

is ’the delivery of 330 litres of beer to the consumer’ which corresponds to 1000 bottles |

Cradle to gate | N/S | GWP | Kg CO2 eq | N/S |

| OD | g CFC 11 eq. | ||||||||

| POF | Kg NVMOC | ||||||||

| AP | Kg SO2 eq | ||||||||

| [40] | 2023 | South Vietnam | Establishing criteria for advancing circular economy practices in the beer industry | 1 cubic meter (m³) of beer produced | Gate to grave | N/S | CC | Ton Co2 eq | 57,45 |

| AP | Kg SO2 eq | N/S | |||||||

| FE | Kg P eq | ||||||||

| ME | Kg n eq | ||||||||

| LU | m2 | ||||||||

| WS | m3 eq | ||||||||

| [41] | 2019 | Italy | Establish the Carbon footprint of beer production | 1 hL of malt beer | Cradle to grave | GHG | kg CO2e hL-1] | 127.2 | |

| [42] | 2007 | Norwey | analyze the environmental and resource efficiency and effectiveness of the beverage sector in Norway | mount of beverage products consumed per capita in Norway in the year 2000 | Cradle to grave | N/S | GWP | Kg Co2 eq per L | 22 |

| CED | MJ per L | 8.0 | |||||||

| [23] | 2022 | packaging of 1 l of kegged beer in a 30-l keg | Cradle to grave | Recipe Midpoint (H) | GWP | Kg Co2 eq per L | 0.15 to 0.35 | ||

| WD | m3 | N/S | |||||||

| FD | kg oil-eq) | ||||||||

| MD | kg Fe-eq | ||||||||

| [43] | 2023 | USA | analyze the environmental profile of the brewing process of craft beer and compare the environmental performance of ale and lager brewing in a microbrewing facilit |

1 bbl of beer brewed. | Gate to gate | Recipe Midpoint (E) | GWP | Kg Co2 eq per L | 104 to 126 |

| AP | kg SO2 eq | 0.647 to 0.739 | |||||||

| FWEP | kg P eq | 0.113 to 0.125 | |||||||

| MEP | kg N eq | 0.092 to 0.061 | |||||||

| WU | m3 | 50.2 to 53.3 | |||||||

| INVENTORY ITEM | STUDY | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [31] | [32] | [2] | [34] | [28] | [35] | [29] | [36] | [54] | [33] | [37] | [38] | [55] | [10] | [39] | [40] | [41] | [52] | [42] | [56] | [1] | [43] | |

| DATA ACQUISITION | N/A | |||||||||||||||||||||

| Primary | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | ||||||

| Secondary | x | x | x | x | x | x | x | x | x | x | x | x | x | x | ||||||||

| CROP CULTIVATION | N/A | x | N/A | N/A | N/A | |||||||||||||||||

| Barley | x | x | x | x | x | x | ||||||||||||||||

| Wheat | x | |||||||||||||||||||||

| Faba | x | |||||||||||||||||||||

| Yeast | x | x | ||||||||||||||||||||

| Hop | x | x | x | x | ||||||||||||||||||

| Fertilizer | x | x | x | x | ||||||||||||||||||

| Lime | x | x | ||||||||||||||||||||

| Manure | ||||||||||||||||||||||

| Pesticide | x | x | x | x | ||||||||||||||||||

| BREWY PROCESS | N/A | N/S | N/S | N/A | N/A | N/S | N/S | |||||||||||||||

| Malt | x | x | x | x | x | x | x | x | ||||||||||||||

| Corn Grain | x | |||||||||||||||||||||

| Hops Pellet | x | x | x | x | x | |||||||||||||||||

| Peracetic Acid | x | x | ||||||||||||||||||||

| Filtration Eart | x | |||||||||||||||||||||

| Caustic Soda | x | x | x | |||||||||||||||||||

| PVPP | x | x | ||||||||||||||||||||

| Refrigerant Liquids | x | x | x | x | ||||||||||||||||||

| PRIMARY AND SECONDARY PACKAGING | N/A | x | x | N/A | N/A | N/A | ||||||||||||||||

| Aluminum | x | x | x | x | ||||||||||||||||||

| PET | x | x | x | x | x | |||||||||||||||||

| Glass | x | x | x | x | x | x | x | x | x | |||||||||||||

| HDPE | x | x | ||||||||||||||||||||

| Pallet (wood) | x | |||||||||||||||||||||

| Cardboard | x | x | x | |||||||||||||||||||

| ENERGY SOURCES | x | N/S | N/S | N/S | N/S | N/S | N/S | |||||||||||||||

| Thermal | x | x | x | x | ||||||||||||||||||

| Electricity | x | x | x | x | x | x | x | x | x | |||||||||||||

| Diseal | x | x | x | x | x | x | x | |||||||||||||||

| Natural Gases | x | x | x | x | ||||||||||||||||||

| WATER | x | x | x | x | x | x | x | x | x | x | ||||||||||||

| BY PRODUCTS | ||||||||||||||||||||||

| Surplus Yeast | x | x | x | |||||||||||||||||||

| Spent Grain | x | x | x | x | ||||||||||||||||||

| Westwater | x | x | x | x | ||||||||||||||||||

| STUDIES | IMPACT CATEGORIES | CARBON FOOTPRINT | WATER FOOTPRINT | CED | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FRDP | FEP | WS | ARD | CC | OD | HuT | IR | PM | POF | AP | TE | FE | ME | FEcT | LU | RD | WRD | SW | ||||

| [31] | x | x | ||||||||||||||||||||

| [32] | x | |||||||||||||||||||||

| [2] | x | x | x | x | x | x | x | x | x | x | ||||||||||||

| [34] | x | x | ||||||||||||||||||||

| [28] | x | x | x | x | x | x | ||||||||||||||||

| [35] | x | |||||||||||||||||||||

| [29] | x | x | x | x | x | x | x | x | x | x | x | x | x | x | ||||||||

| [36] | x | |||||||||||||||||||||

| [54] | x | x | x | x | x | x | x | x | x | x | x | x | x | x | ||||||||

| [33] | x | x | x | x | x | x | x | x | x | x | x | x | x | x | ||||||||

| [37] | x | x | x | x | x | x | ||||||||||||||||

| [38] | x | |||||||||||||||||||||

| [55] | x | x | x | |||||||||||||||||||

| [10] | x | x | x | |||||||||||||||||||

| [39] | x | x | x | x | x | x | ||||||||||||||||

| [40] | x | x | x | |||||||||||||||||||

| [41] | x | |||||||||||||||||||||

| [52] | ||||||||||||||||||||||

| [42] | x | x | ||||||||||||||||||||

| [56] | x | x | x | x | x | x | x | x | x | x | ||||||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).