Submitted:

01 August 2024

Posted:

02 August 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Method

2.1. Preparation of PVDF/Graphene Solution

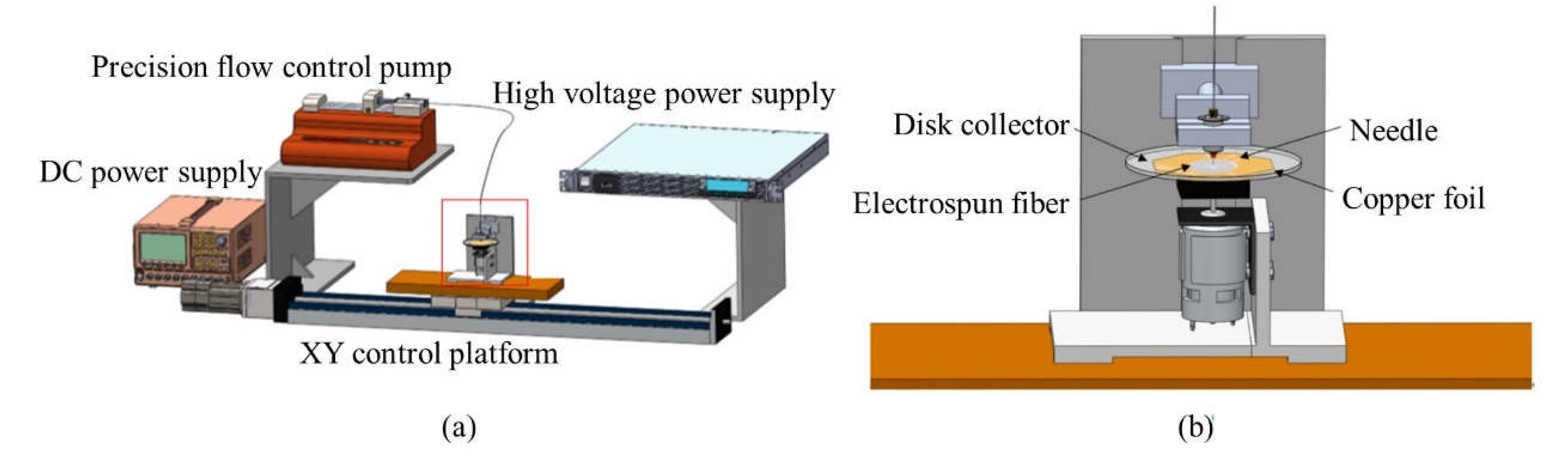

2.2. Near-Field Electrostatic Spinning Process

2.3. Sensor Package and Sheet Resistance Measurement

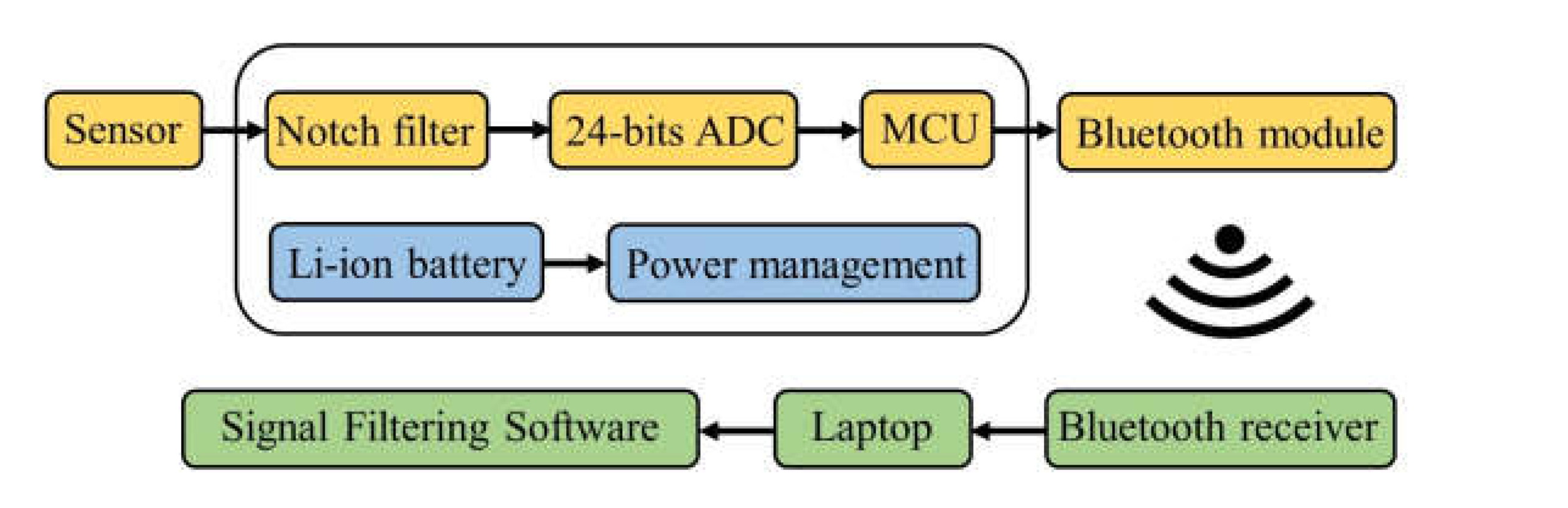

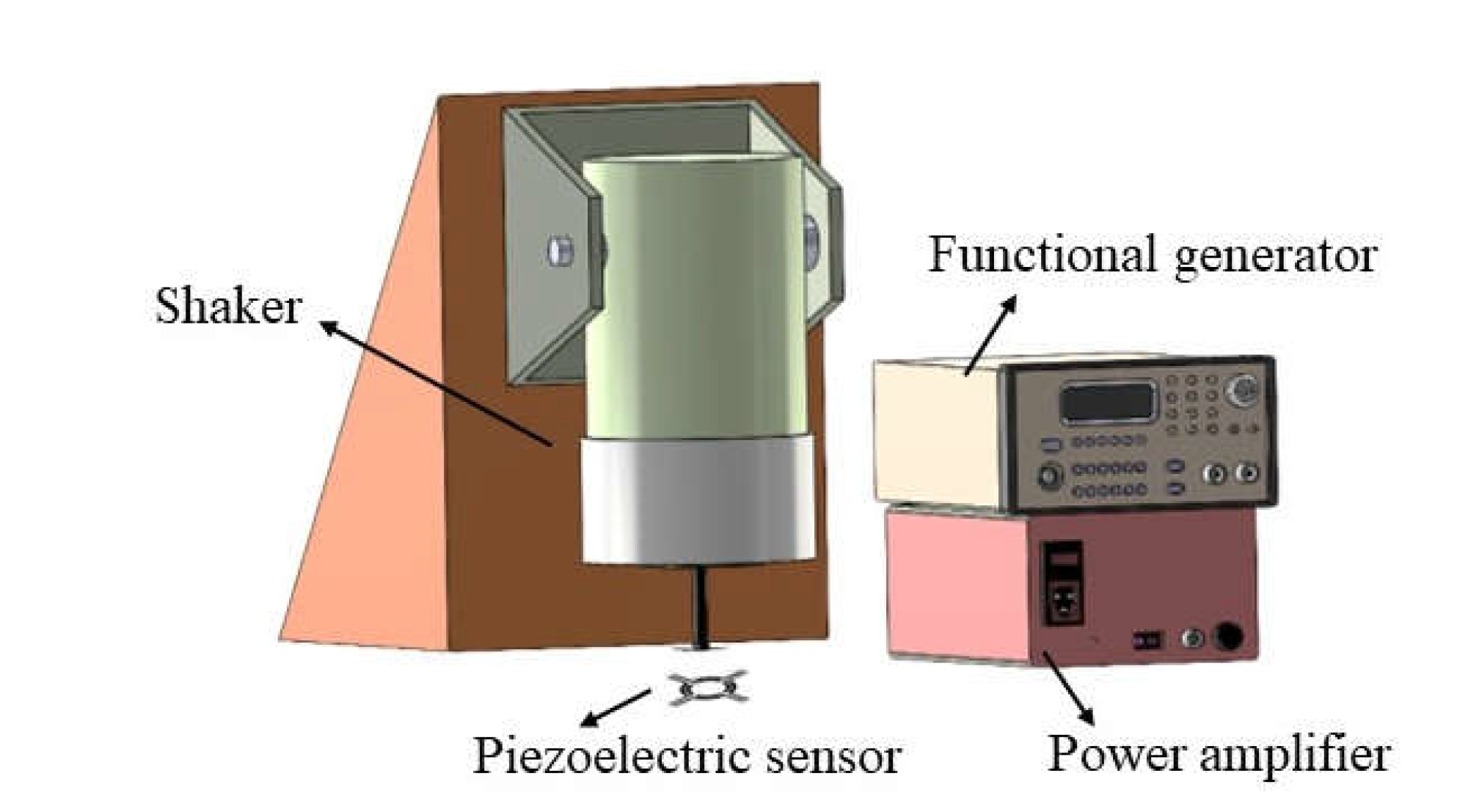

2.4. Electrical Measurements

2.5. Uniform Experimental Design and Kriging Response Surface Method

2.6. Scanning Electron Microscope, SEM

2.7. Electric Conductivity

2.8. Fourier-Transform Infrared Spectroscopy, FTIR

2.9. X-ray Diffraction Analysis, XRD

2.10. Contact Angle Measurement

2.11. Tensile Testing

3. Results and Discussion

3.1. Sheet Resistance Values of Electrode Design

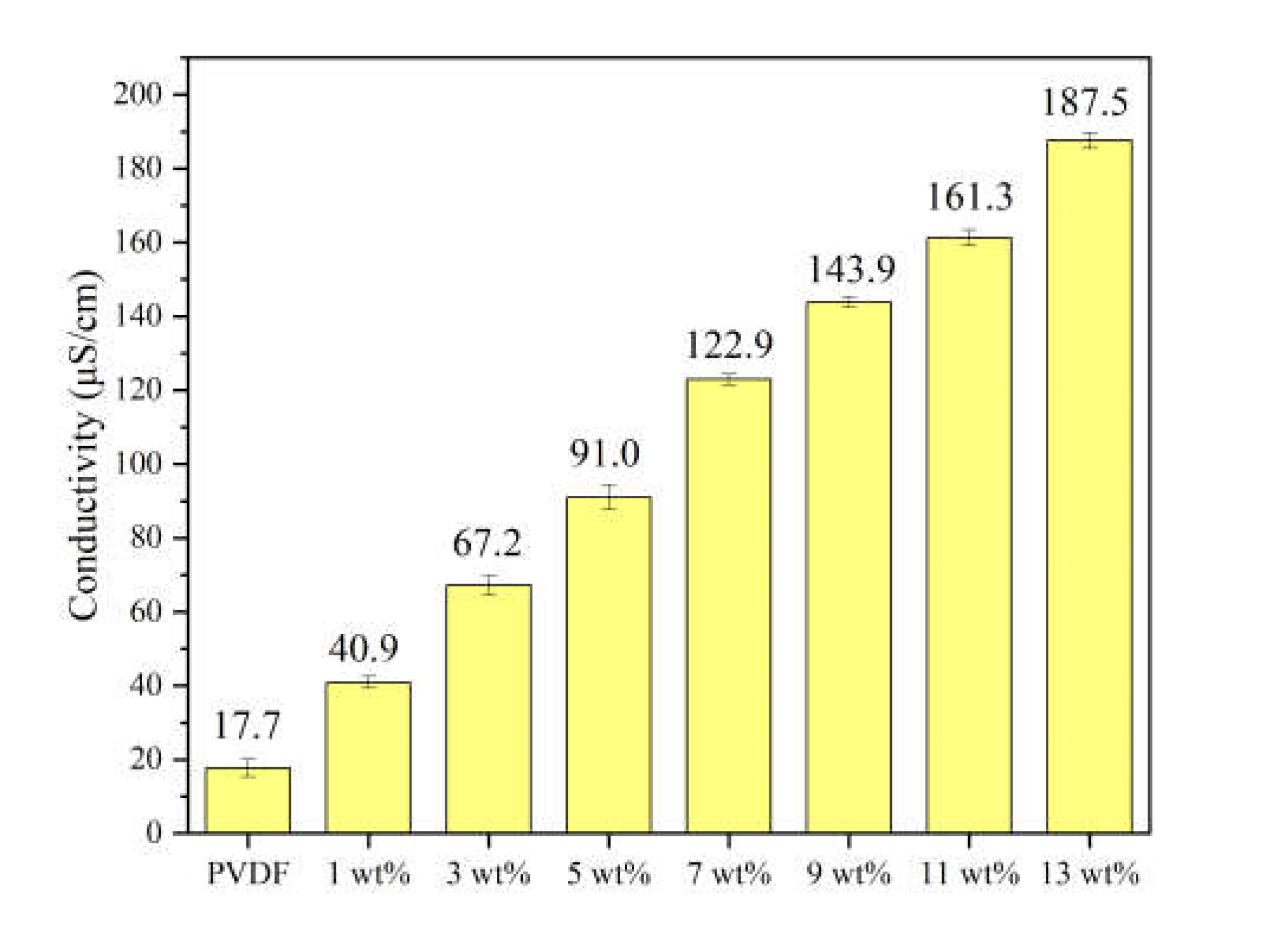

3.2. Conductivity Measurement of the Solution

3.3. FTIR Analysis of the Crystal Structure of Piezoelectric Fibers

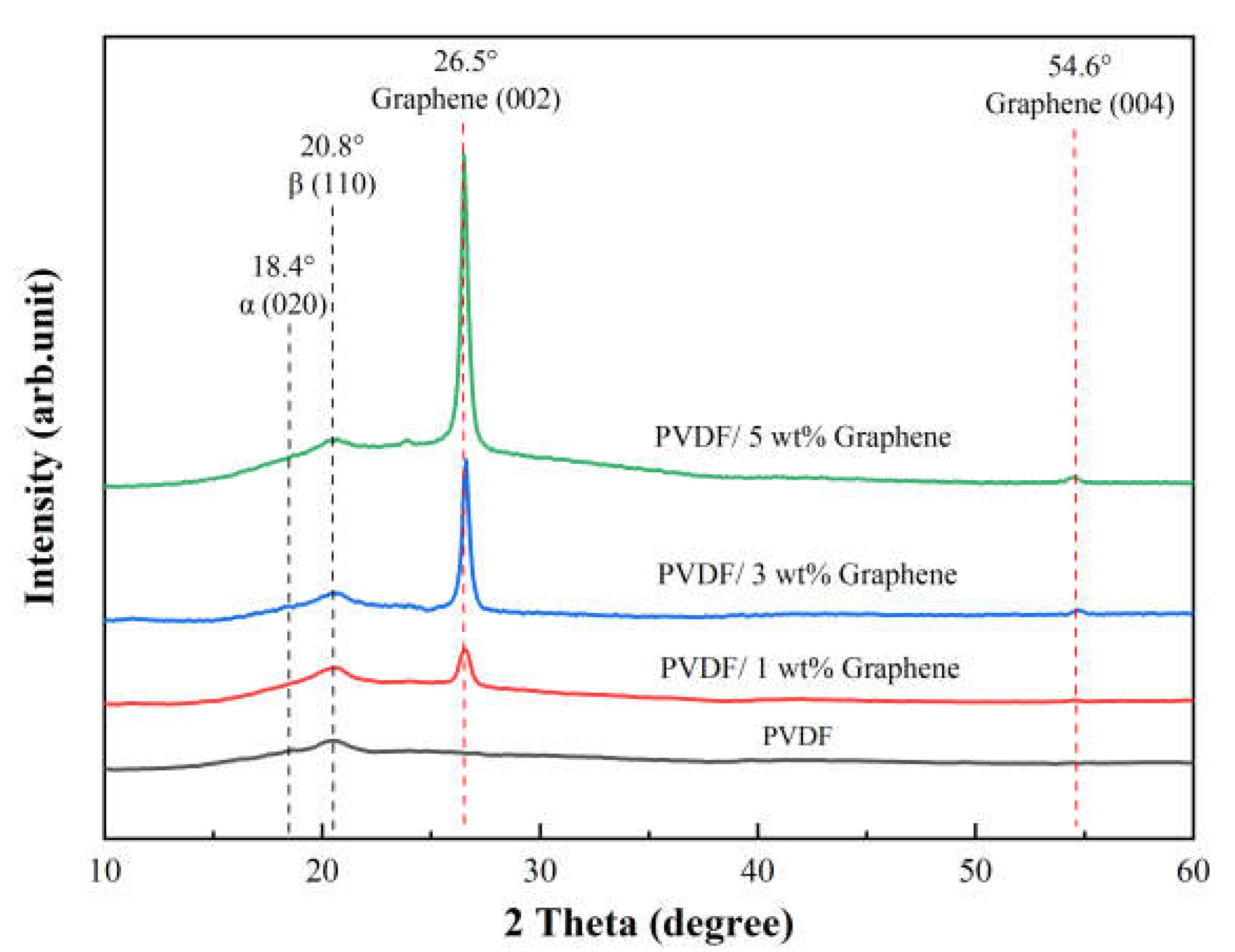

3.4. XRD Analysis of the Crystal Structure of Piezoelectric Fibers

3.5. Measurement of Hydrophobicity of Piezoelectric Fibers

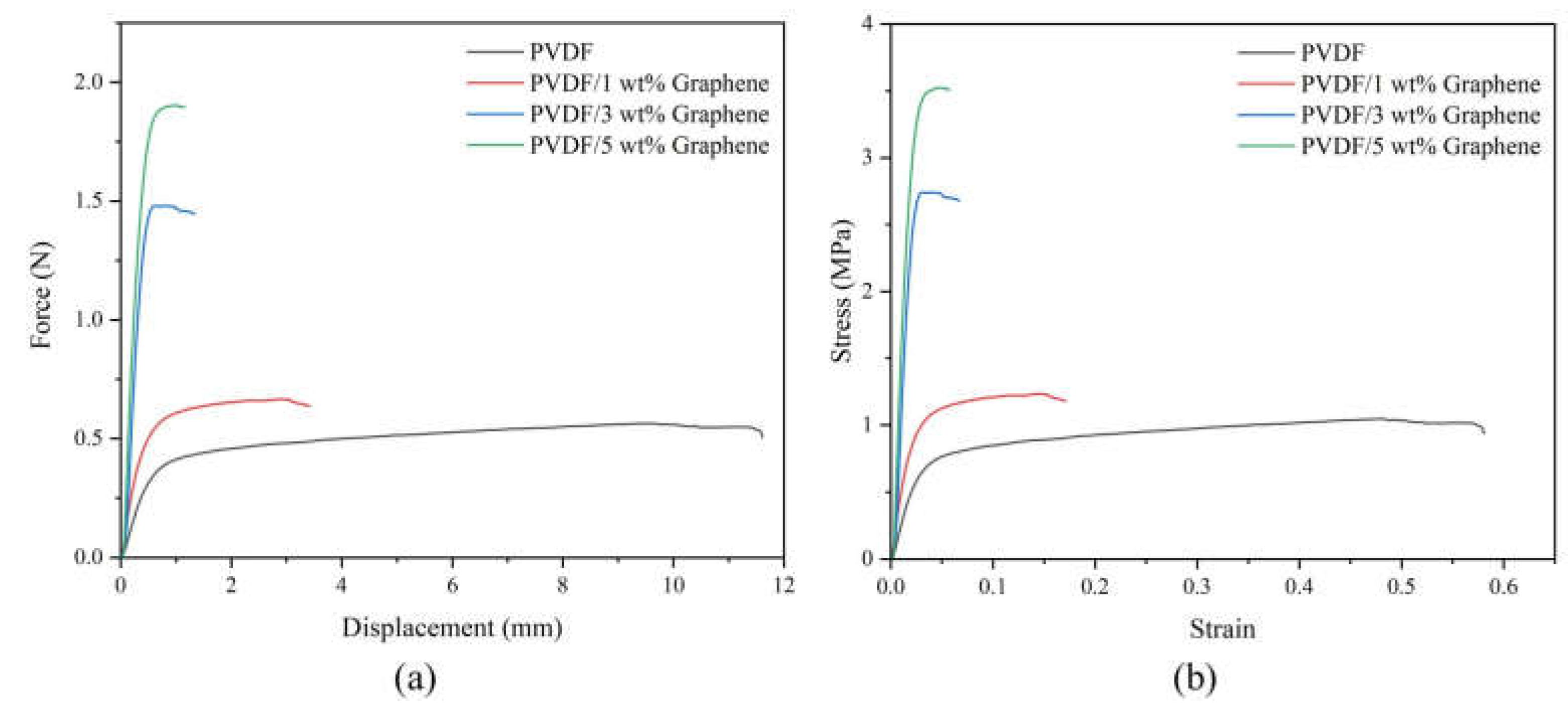

3.6. Mechanical Properties of Piezoelectric Fibers

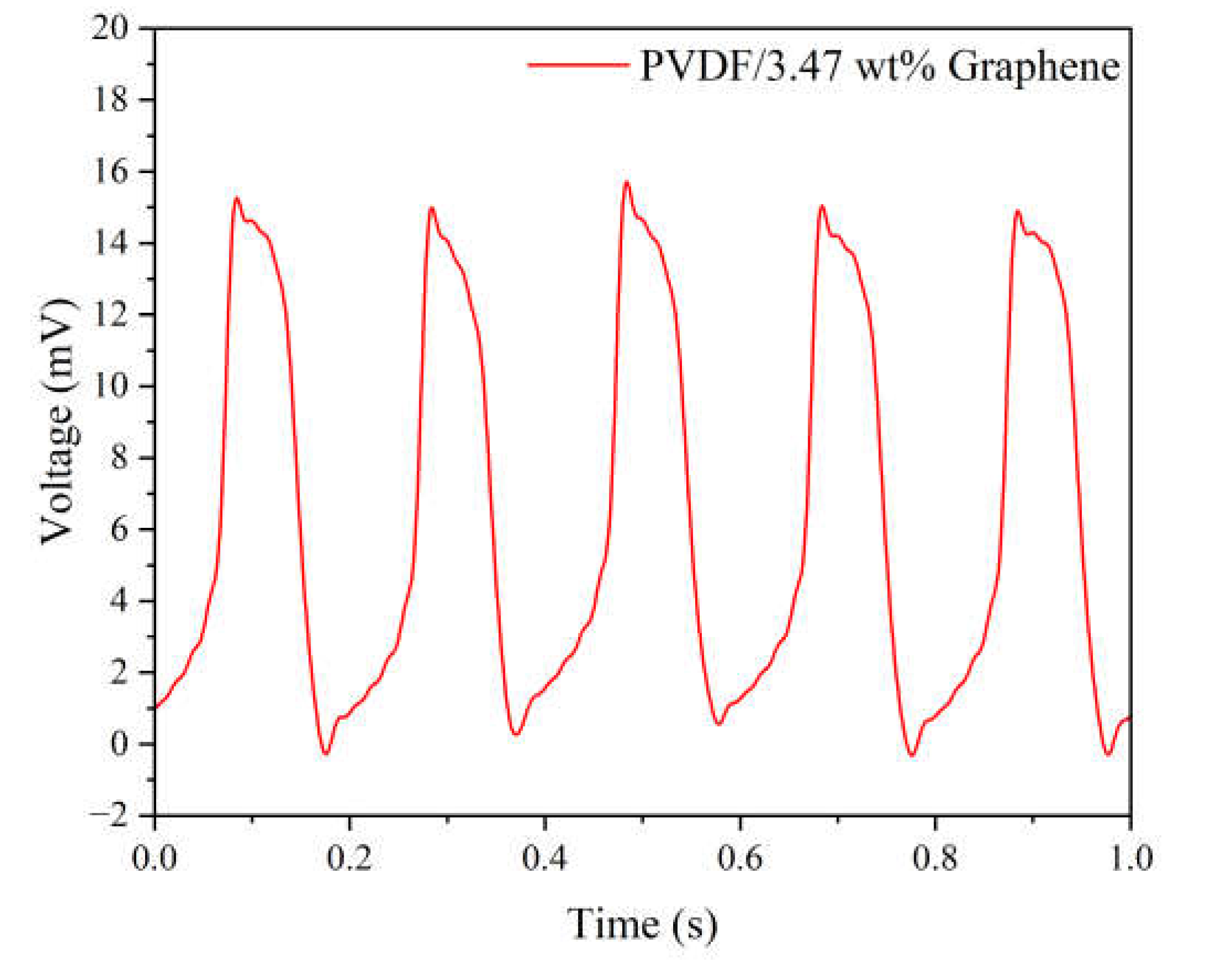

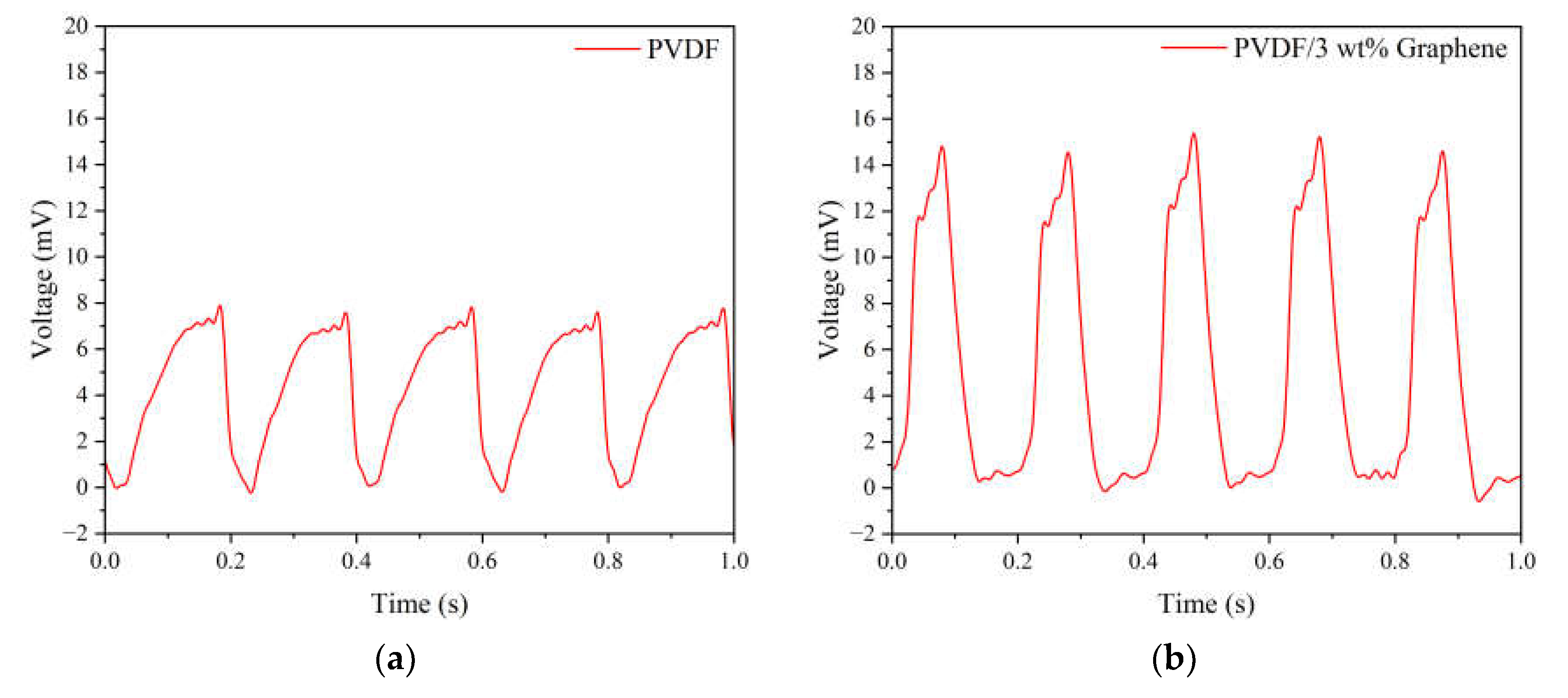

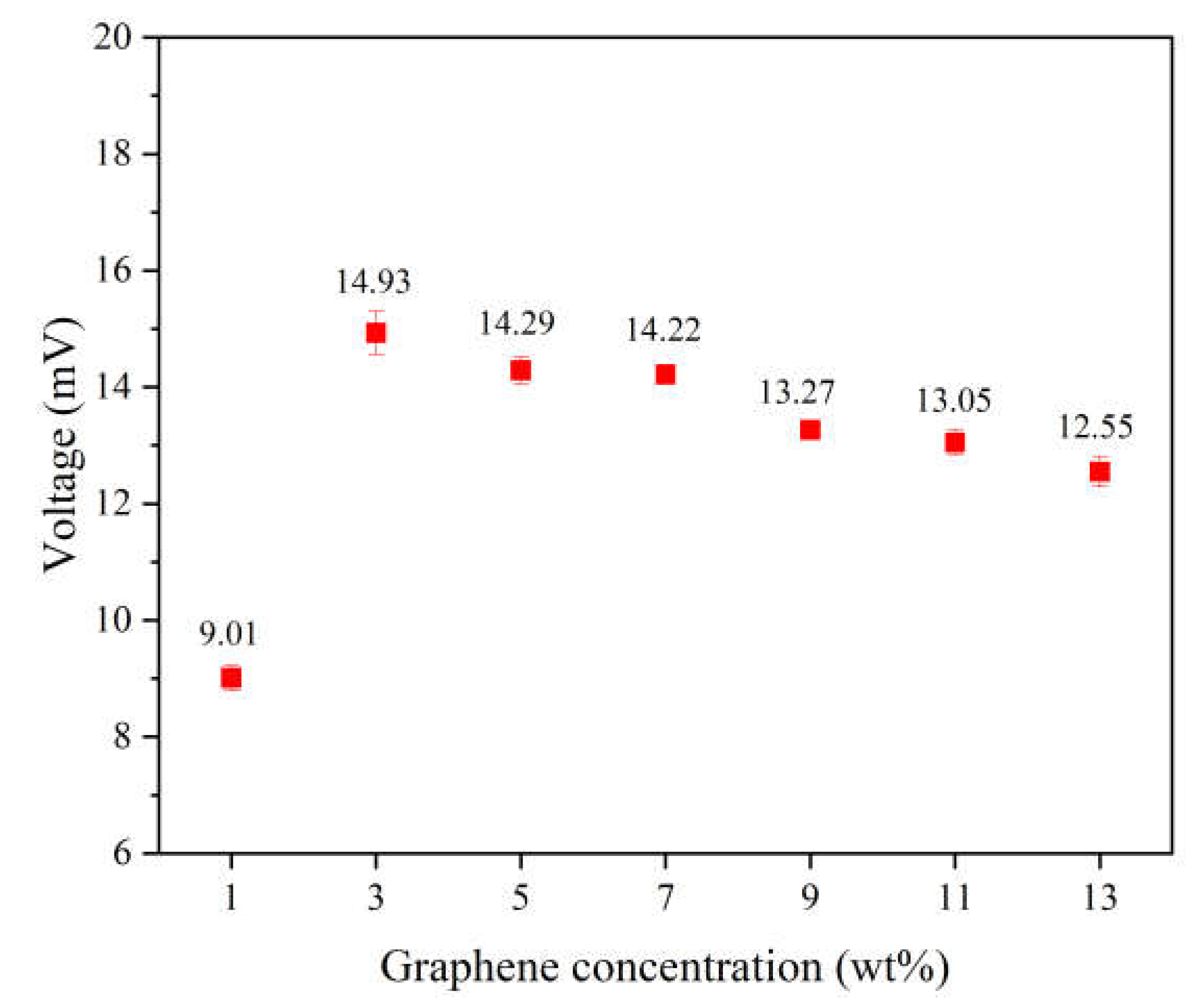

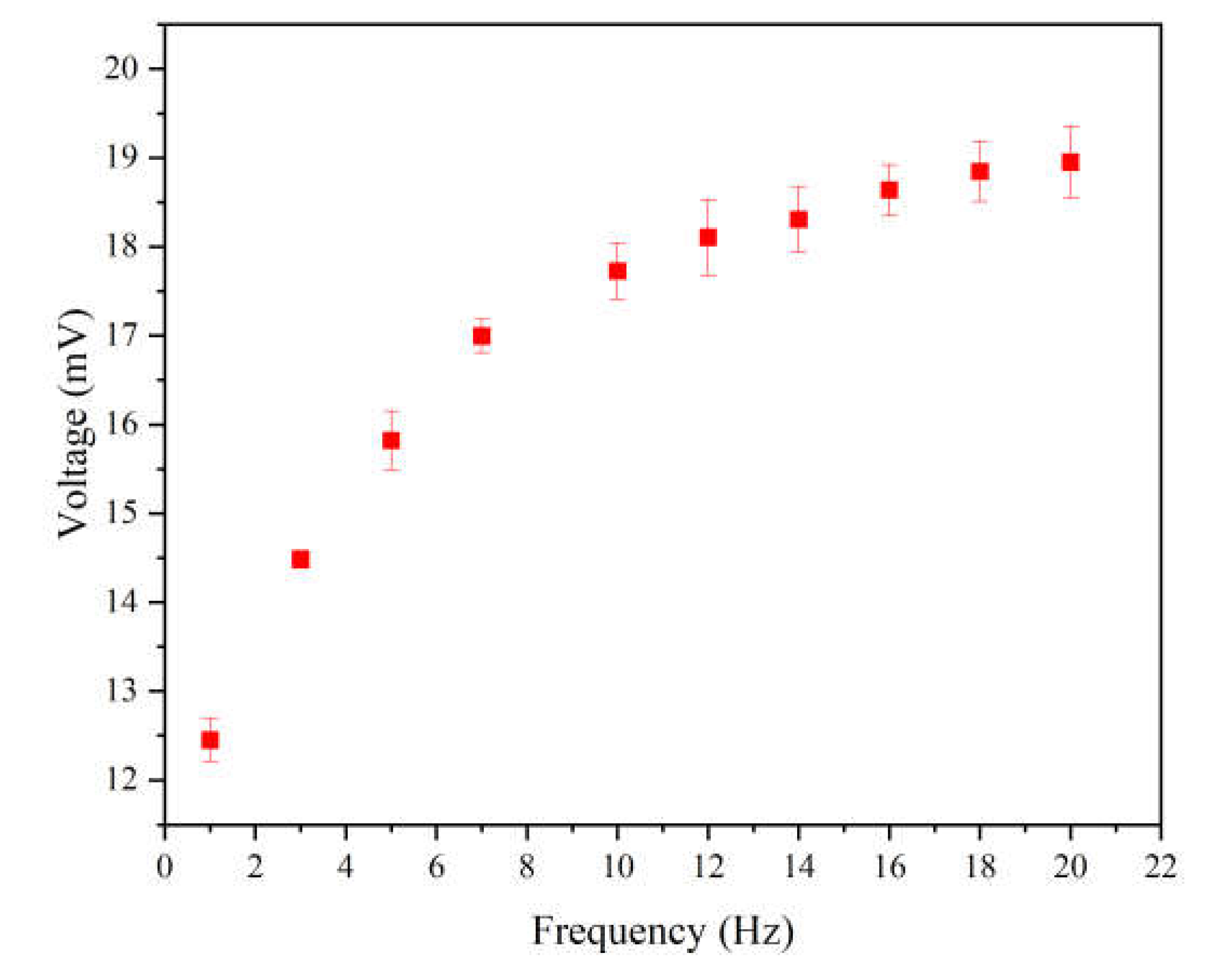

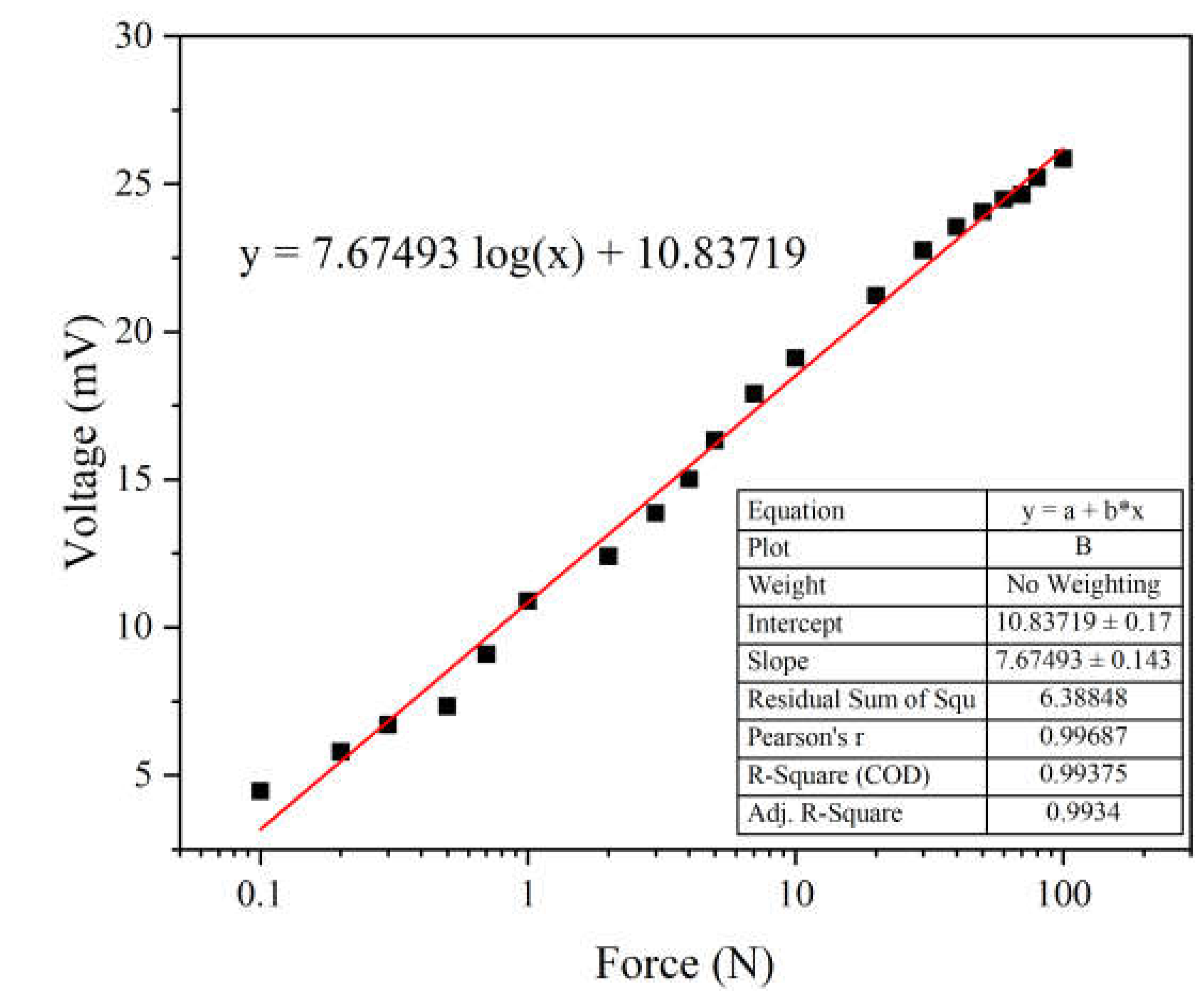

3.7. Piezoelectric Fiber Tapping Output Voltage

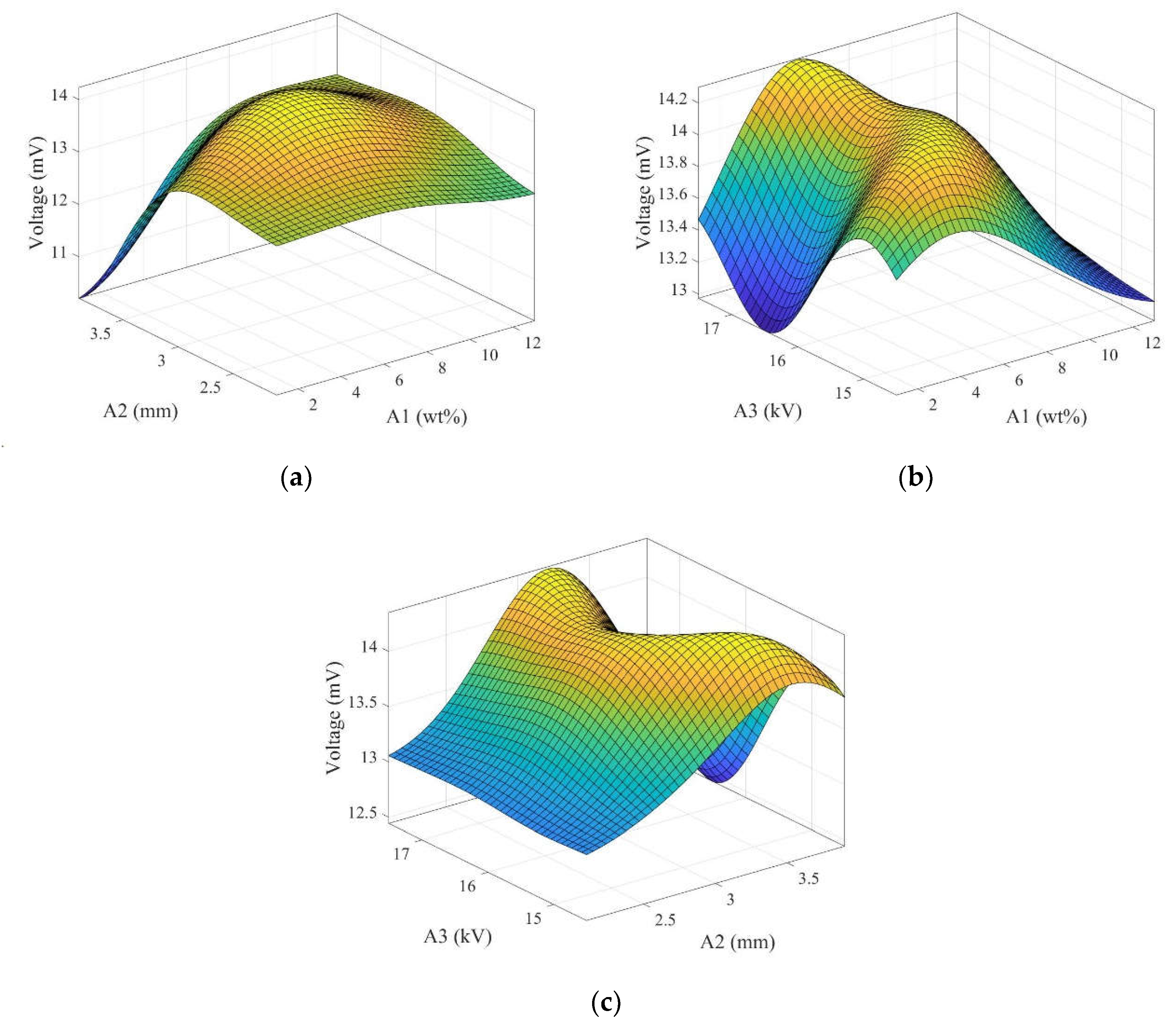

3.8. Kriging Method Result

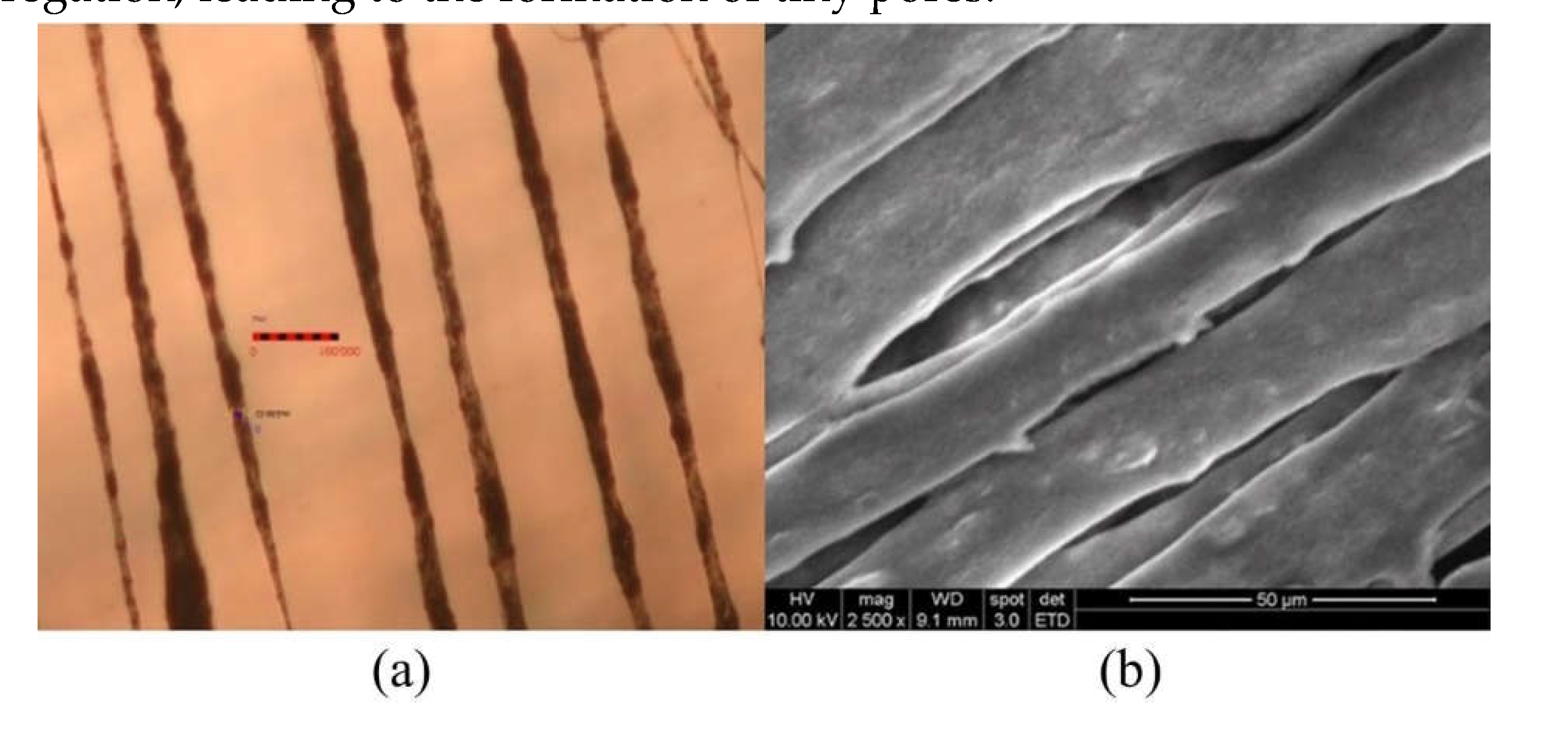

3.9. Surface Morphology of Fibers

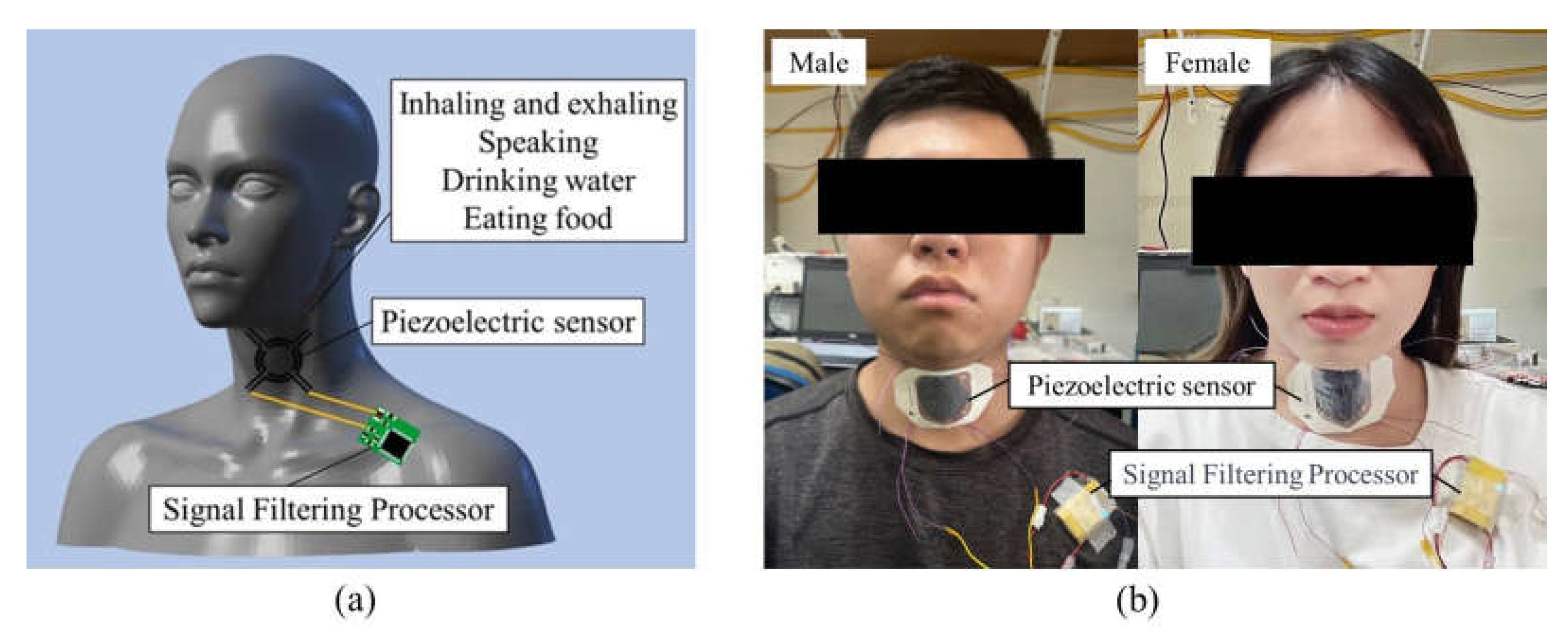

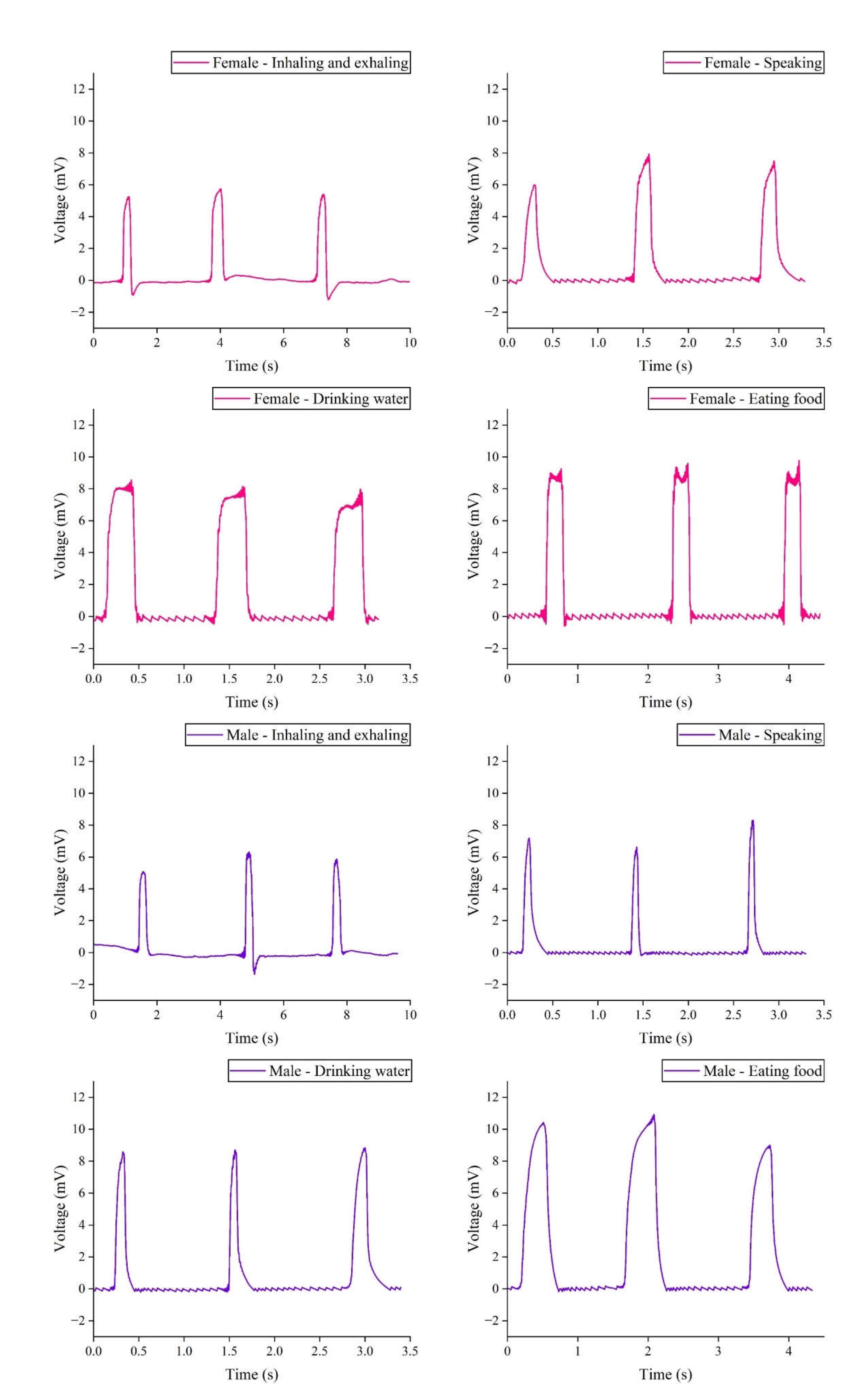

3.10. Application of Physiological Signals in Throat Region

| Gender | Inhaling/exhaling | Speaking | Drinking water | Eating food | ||||

|---|---|---|---|---|---|---|---|---|

| Voltage (mV) | Force (N) | Voltage (mV) | Force (N) | Voltage (mV) | Force (N) | Voltage (mV) | Force (N) | |

| Female | 5.47 | 0.200 | 7.14 | 0.330 | 8.21 | 0.455 | 9.55 | 0.680 |

| Male | 5.76 | 0.218 | 7.39 | 0.356 | 8.72 | 0.530 | 10.12 | 0.806 |

4. Conclusions

Acknowledgments

Appendix A

References

- Wang, Y.; Yu, Y.; Wei, X.; Narita, F. Self-powered wearable piezoelectric monitoring of human motion and physiological signals for the post-pandemic era: A Review. Advanced Materials Technologies 2022, 7. [Google Scholar] [CrossRef]

- Safaei, M.; Sodano, H. A.; Anton, S. R. A review of energy harvesting using piezoelectric materials: State-of-the-art a decade later (2008–2018). Innovative Materials and Structures 2019, 28, 113001. [Google Scholar] [CrossRef]

- Zhao, T.; Zhu, H.; Zhang, H. Rapid prototyping flexible capacitive pressure sensors based on porous electrodes. Biosensors 2023, 13, 546. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.-W.; Oh, G.-Y.; Lee, K.-I.; Yang, Y.-J.; Ko, J.-B.; Kim, Y.-W.; Hong, Y.-S. A susceptible and flexible capacitive pressure sensor based on alignment Airgap dielectric. Sensors 2022, 22, 7390. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Jiang, X.; Yang, H.; Qin, H.; Wang, W. Structural engineering in piezoresistive Micropressure Sensors: A focused review. Micromachines 2023, 14, 1507. [Google Scholar] [CrossRef] [PubMed]

- Xue, B.; Xie, H.; Zhao, J.; Zheng, J.; Xu, C. Flexible piezoresistive pressure sensor based on electrospun rough polyurethane nanofibers film for Human Motion Monitoring. Nanomaterials 2022, 12, 723. [Google Scholar] [CrossRef] [PubMed]

- Aabid, A.; Parveez, B.; Raheman, M. A.; Ibrahim, Y. E.; Anjum, A.; Hrairi, M.; Parveen, N.; Mohammed Zayan, J. A review of piezoelectric material-based structural control and health monitoring techniques for engineering structures: Challenges and opportunities. Actuators 2021, 10, 101. [Google Scholar] [CrossRef]

- Guo, C.-Y.; Wang, K.-J.; Hsieh, T.-L. Piezoelectric sensor for the monitoring of arterial pulse wave: Detection of arrhythmia occurring in PAC/PVC patients. Sensors 2021, 21, 6915. [Google Scholar] [CrossRef] [PubMed]

- Xu, C.; Song, Y.; Han, M.; Zhang, H. Portable and wearable self-powered systems based on emerging energy harvesting technology. Microsystems & Nanoengineering 2021, 7. [Google Scholar] [CrossRef] [PubMed]

- Covaci, C.; Gontean, A. Piezoelectric Energy Harvesting Solutions: A Review. Sensors 2020, 20, 3512. [Google Scholar] [CrossRef]

- Chandra Sekhar, B.; Dhanalakshmi, B.; Srinivasa Rao, B.; Ramesh, S.; Venkata Prasad, K.; Subba Rao, P. S. V.; Parvatheeswara Rao, B. Piezoelectricity and its applications. Multifunctional Ferroelectric Materials 2021. [Google Scholar]

- Ju, M.; Dou, Z.; Li, J.-W.; Qiu, X.; Shen, B.; Zhang, D.; Yao, F.-Z.; Gong, W.; Wang, K. Piezoelectric materials and sensors for structural health monitoring: Fundamental aspects, current status, and future perspectives. Sensors 2023, 23, 543. [Google Scholar] [CrossRef] [PubMed]

- Wan, C.; Bowen, C. R. Multiscale-structuring of Polyvinylidene fluoride for energy harvesting: The impact of molecular-, micro- and macro-structure. Journal of Materials Chemistry A 2017, 5, 3091–3128. [Google Scholar] [CrossRef]

- Lovinger, A. J. Conformational defects and associated molecular motions in crystalline poly(vinylidene fluoride). Journal of Applied Physics 1981, 52, 5934–5938. [Google Scholar] [CrossRef]

- Gomes, J.; Serrado Nunes, J.; Sencadas, V.; Lanceros-Mendez, S. Influence of the β-phase content and degree of crystallinity on the piezo- and ferroelectric properties of poly(vinylidene fluoride). Innovative Materials and Structures 2010, 19, 065010. [Google Scholar] [CrossRef]

- Ruan, L.; Yao, X.; Chang, Y.; Zhou, L.; Qin, G.; Zhang, X. Properties and applications of the β phase poly(vinylidene fluoride). Polymers 2018, 10, 228. [Google Scholar] [CrossRef] [PubMed]

- Ahn, Y.; Lim, J. Y.; Hong, S. M.; Lee, J.; Ha, J.; Choi, H. J.; Seo, Y. Enhanced piezoelectric properties of Electrospun Poly(vinylidene fluoride)/multiwalled carbon nanotube composites due to high β-phase formation in poly(vinylidene fluoride). The Journal of Physical Chemistry C 2013, 117, 11791–11799. [Google Scholar] [CrossRef]

- Pazhamalai, P.; Mariappan, V.K.; Sahoo, S.; Kim, W.Y.; Mok, Y.S.; Kim, S.-J. Free-Standing PVDF/Reduced Graphene Oxide Film for All-Solid-State Flexible Supercapacitors towards Self-Powered Systems. Micromachines 2020, 11, 198. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Zhou, T.; Liu, M.; Zhao, Q.; Liu, Y. An Intelligent Non-Invasive Blood Pressure Monitoring System Based on a Novel Polyvinylidene Fluoride Piezoelectric Thin Film. Micromachines 2024, 15, 659. [Google Scholar] [CrossRef]

- Sur, U. K. Graphene: A rising star on the horizon of materials science. International Journal of Electrochemistry 2012, 2012, 1–12. [Google Scholar] [CrossRef]

- Hamzah, A. A.; Selvarajan, R. S.; Majlis, B. Y. Graphene for biomedical applications: A Review. Sains Malaysiana 2017, 46, 1125–1139. [Google Scholar] [CrossRef]

- Mbayachi, V. B.; Ndayiragije, E.; Sammani, T.; Taj, S.; Mbuta, E. R.; khan, A. ullah Graphene synthesis, characterization and its applications: A Review. Results in Chemistry 2021, 3, 100163. [Google Scholar] [CrossRef]

- Liu, J.; Bao, S.; Wang, X. Applications of Graphene-Based Materials in Sensors: A Review. Micromachines 2022, 13, 184. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Li, J.; Zhang, S.; Yang, H.; Guo, K. Study on Flexible sEMG Acquisition System and Its Application in Muscle Strength Evaluation and Hand Rehabilitation. Micromachines 2022, 13, 2047. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Zhang, Z.; Chen, Z.; Mei, D.; Wang, Y. Development of Pressure Sensor Based Wearable Pulse Detection Device for Radial Pulse Monitoring. Micromachines 2022, 13, 1699. [Google Scholar] [CrossRef] [PubMed]

- Hernández-Rivera, D.; Rodríguez-Roldán, G.; Mora-Martínez, R.; Suaste-Gómez, E. A capacitive humidity sensor based on an electrospun PVDF/graphene membrane. Sensors 2017, 17, 1009. [Google Scholar] [CrossRef] [PubMed]

- Dehghan, S. F.; Golbabaei, F.; Maddah, B.; Latifi, M.; Pezeshk, H.; Hasanzadeh, M.; Akbar-Khanzadeh, F. Optimization of electrospinning parameters for polyacrylonitrile-mgo nanofibers applied in air filtration. Journal of the Air & Waste Management Association 2016, 66, 912–921. [Google Scholar] [CrossRef] [PubMed]

- Kailasa, S.; Reddy, M. S.; Maurya, M. R.; Rani, B. G.; Rao, K. V.; Sadasivuni, K. K. Electrospun nanofibers: Materials, synthesis parameters, and their role in sensing applications. Macromolecular Materials and Engineering 2021, 306. [Google Scholar] [CrossRef]

- He, Z.; Rault, F.; Lewandowski, M.; Mohsenzadeh, E.; Salaün, F. Electrospun PVDF nanofibers for piezoelectric applications: A review of the influence of electrospinning parameters on the β phase and crystallinity enhancement. Polymers 2021, 13, 174. [Google Scholar] [CrossRef]

- Haider, A.; Haider, S.; Kang, I.-K. A comprehensive review summarizing the effect of electrospinning parameters and potential applications of nanofibers in biomedical and biotechnology. Arabian Journal of Chemistry 2018, 11, 1165–1188. [Google Scholar] [CrossRef]

- Lee, M.-C.; Lin, G.-Y.; Hoe, Z.-Y.; Pan, C.-T. Development of Piezoelectric Silk Sensors Doped with Graphene for Biosensing by Near-Field Electrospinning. Sensors 2022, 22, 9131. [Google Scholar] [CrossRef] [PubMed]

- Sun, D.; Chang, C.; Li, S.; Lin, L. Near-field electrospinning. Nano Letters 2006, 6, 839–842. [Google Scholar] [CrossRef] [PubMed]

- Isaac, B.; Taylor, R. M.; Reifsnider, K. Mechanical and dielectric properties of aligned electrospun fibers. Fibers 2021, 9, 4. [Google Scholar] [CrossRef]

- Tariq, A.; Behravesh, A. H.; Utkarsh; Rizvi, G. Statistical modeling and optimization of electrospinning for improved morphology and enhanced β-phase in polyvinylidene fluoride nanofibers. Polymers 2023, 15, 4344. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.-H.; Wan, Y.; Sun, B.; Liu, L.-Z.; Xu, W. Mechanical and electrical properties of electrospun PVDF/MWCNT ultrafine fibers using rotating collector. Nanoscale Research Letters 2014, 9. [Google Scholar] [CrossRef] [PubMed]

- Wu, C.-M.; Chou, M.-H.; Zeng, W.-Y. Piezoelectric Response of Aligned Electrospun Polyvinylidene Fluoride/Carbon Nanotube Nanofibrous Membranes. Nanomaterials 2018, 8, 420. [Google Scholar] [CrossRef] [PubMed]

- Selleri, G.; Mongioì, F.; Maccaferri, E.; D’Anniballe, R.; Mazzocchetti, L.; Carloni, R.; Fabiani, D.; Zucchelli, A.; Brugo, T.M. Self-Sensing Soft Skin Based on Piezoelectric Nanofibers. Polymers 2023, 15, 280. [Google Scholar] [CrossRef] [PubMed]

- Chou, H. M. and Yang, H. C. Development of multi-directional piezoelectric sensor doped with graphene by near-field electrospinning technology for calligraphy writing. International Journal of Modern Physics B 2024, 38 (12n13), 2440009.

- Zhou, Y.; Liu, W.; Tan, B.; Zhu, C.; Ni, Y.; Fang, L.; Lu, C.; Xu, Z. Crystallinity and β Phase Fraction of PVDF in Biaxially Stretched PVDF/PMMA Films. Polymers 2021, 13, 998. [Google Scholar] [CrossRef] [PubMed]

- Shaikh, M.O.; Huang, Y.-B.; Wang, C.-C.; Chuang, C.-H. Wearable Woven Triboelectric Nanogenerator Utilizing Electrospun PVDF Nanofibers for Mechanical Energy Harvesting. Micromachines 2019, 10, 438. [Google Scholar] [CrossRef]

- Samoei, V.K.; Maharjan, S.; Sano, K.; Jayatissa, A.H. Effect of Annealing on Graphene/PVDF Nanocomposites. Omega 2023, 8, 13876–13883. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions, and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

| Reference | Method | Material | Objective |

|---|---|---|---|

| [26] | Electrospinning Plate collector |

PVDF/Graphene | Fabricating capacitive humidity sensors. |

| [34] | Electrospinning Drum collector |

PVDF/DMF | Using the Taguchi design method to enhance the β-phase of PVDF. |

| [35] | Electrospinning Drum collector |

PVDF/MWCNT | We are improving the mechanical and electrical properties of piezoelectric fibers. |

| [36] | Electrospinning Drum collector |

PVDF/CNT | Improving the β-phase and electrical properties of piezoelectric fibers. |

| [37] | Electrospinning Drum collector |

PVDF-TrFE | Fabricating self-sensing soft skin. |

| This work | Electrospinning Disk collector |

PVDF/Graphene | Using the uniform design method to fabricate optimal sensors for throat applications. |

| Factor | Graphene weight percentage (wt%) | Distance between the needle and the disk collector (mm) | Applied voltage (kV) |

|---|---|---|---|

| Minimum | 1 | 2.1 | 14.5 |

| Maximum | 13 | 3.9 | 17.5 |

| Graphene weight percentage (wt%) | Distance between the needle and the disk collector (mm) | Applied voltage (kV) | |

|---|---|---|---|

| 1st test | 5 | 3.3 | 17.5 / 5.30 |

| 2nd test | 11 | 2.4 | 17.0 / 7.08 |

| 3rd test | 1 | 3.9 | 16.5 / 4.23 |

| 4th test | 7 | 3.0 | 16.0 / 5.33 |

| 5th test | 13 | 2.1 | 15.5 / 7.38 |

| 6th test | 3 | 3.6 | 15.0 / 4.17 |

| 7th test | 9 | 2.7 | 14.5 / 5.37 |

| Measurement Point Number | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Sheet resistance (mΩ/sq) | 53.2 | 54.8 | 54.8 | 53.7 | 54.5 | 54.8 | 54.8 | 57.2 | 55.3 | 55.1 |

| Factor | Graphene weight percentage (wt%) | Distance between the needle and the disk collecting device (mm) | Applied voltage (kV) |

|---|---|---|---|

| Optimized parameters | 3.47 | 3.53 | 14.87 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).