1. Introduction

The recent earthquake in Gaziantep and Sehitkamil, Turkey in 2023 reminded us of the destructive power of earthquakes. Underground tremors of magnitude 7.8 killed more than 50 thousand people and destroyed more than 160 thousand buildings. According to the United Nations, 1.5 million people are homeless.

According to available data on damage caused by earthquakes in the past, almost all of the damage to people was caused by building collapse. The main cause of human casualties is the collapse of multi-storey residential buildings. Such a disaster has made us look back, reassess the earthquake resistance and safety of existing buildings, which are characterized by high vulnerability, in terms of their resilience.

Nowadays, high-tech typical support isolators such as rubber bearings, pendulum friction bearings, elastomeric bearings, lead-rubber bearings and dampers are often used in civil engineering practice. However, the alternative methods and means of seismic protection and seismic isolation, which reduce the intensity of seismic loads, developed to date, do not find their application due to the complexity of structural solutions and technology of their device.

Modern earthquake-resistant buildings equipped with various active seismic protection systems provide a high level of seismic resistance, allowing buildings and structures to withstand earthquakes of design intensity in many cases. At the same time, it is not uncommon for critical long objects with seismic protection systems to be destroyed, especially those exposed to Rayleigh surface waves, the main component of the seismic wave. This forces the development of alternative seismic protection methods that reduce the effects of exposure in the built-up areas. Such methods include the seismic barrier method. The basic idea of seismic barriers is to protect the area occupied by a building or group of buildings from seismic waves. The need for protection against surface seismic waves is confirmed by numerous examples of foundation structures failing due to significant bending vibrations associated with the passage of Rayleigh waves. Depending on the nature of seismic waves most likely to occur in a particular region, different types of seismic barriers can be proposed to increase the earthquake resistance of buildings and structures or a group of buildings and structures from collapse and even damage.

Therefore, the development of new technologies of seismic protection and seismic isolation, characterized by new principles of action, better modified properties of geomaterial, to reduce inertial seismic loads on buildings and structures, are a task of paramount importance.

Discussions regarding a simple and reliable seismic isolation system concept, known as geotechnical seismic isolation (GSI) system, have attracted attention in recent years as a cost-effective design alternative to the traditional base isolation system [

1,

2]. The term GSI was originally introduced by Tsang [

3] in the last decade to refer to a unique layer under the building foundation designed to dissipate seismic energy. Seismic isolation in the GSI system is achieved by using engineered soils with high damping properties and low shear modulus surrounding the building foundation at a limited depth [

4,

5,

6,

7,

8]. The main advantage of this method is that partial energy dissipation occurs within the soil itself before the seismic wave reaches the foundation and superstructure [

9,

10]. Recently, research on GSI methods has been gradually extended to seismic protection of bridge structure and pile-supported bridge piers [

11,

12]. The GSI system placed vertically between the retaining wall and the backfill soil as a seismic buffer system acts as a protective layer with high flexibility and energy absorption capacity, and prevents soil liquefaction [

13,

14].

The basic idea of GSI is to improve the foundation soil in such a way that the seismic energy is partially dissipated within the GSI before being transmitted to the structure [

15,

16,

17,

18,

19]. Among other materials proposed to improve subgrade soils, gravel-rubber mixtures (GRMs) have attracted considerable research attention due to their good static and dynamic properties: low specific gravity, wide range of elastic properties, low shear modulus and high damping (similar) [

20,

21,

22,

23]. In addition, their use has immediate advantages over waste tyres, the disposal of which has become a major environmental issue worldwide in recent years.

This paper presents the effectiveness of vertical seismic barriers consisting of rubber-soil mixture (RSM) on the seismic response of reinforced concrete moment-resisting frames, which are considered typical for frame buildings. designed according to Kazakhstan seismic standards similar to Euro Code 8 [

24]. The frame structures and underlying soil profiles are modeled as a single system with direct consideration of soil-structure interaction phenomena. As for the mixture of rubber and soil, the rubber content is 30% by weight and its mechanical properties were determined by experiments carried out at the Laboratory of Soil Dynamics and Geotechnical Seismic Engineering of Aristotle University of Thessaloniki [

25,

26]. Dynamic analyses of soil-structure systems are performed considering the variation of RSM layer thickness, inlet traffic characteristics and building height. The effects of RSM layers were investigated in terms of foundation-level acceleration, base shear force, maximum interstory drift, foundation deformation, and soil stress distribution beneath the foundation of the structure. Analyses of theoretical and experimental studies show that the GSI system has the potential to significantly reduce seismic hazard.

The aim of the study is to develop a geotechnical seismic isolation system in the form of vertical barriers, with different geometrical characteristics (thickness, height, location from the building), using RSM (rubber-soil mixture). The novelty of the work consists in determination of effective constructive and technical solutions of vertical seismic barriers from RSM, which are characterized by reliability in providing seismic isolation of construction objects.

The proposed system of geotechnical seismic isolation also allows to control the behavior of structures of existing buildings under seismic effects and minimize the risk of their destruction. Devices of this system are aimed at solving practical problems oriented on existing construction technologies with the use of modified soil-composite materials.

The developed methodology of design and creation of geotechnical seismic isolation system, the results of computational and experimental modeling of seismic isolation system efficiency assessment, will become a research, analytical and design basis for the development of new ways to ensure seismic resistance of construction objects.

The results of feasibility study of organizational and technological reliability of the system device in construction and operational periods, will allow the application of this system in increasing the preservation and protection of architectural monuments.

Based on the numerical modeling carried out, screen-barrier shapes, their geometric parameters, dimensions, material of the damping screen-barrier, and its location relative to the building will be developed.

2. Materials and Methods

In this paper, a nonlinear dynamic transient analysis is performed on a two-dimensional finite element model of the soil-foundation-building system in the PLAXIS software package to determine the optimum fill size of vertical barriers using RSM. The PLAXlS programme is a specialized two-dimensional computer program based on the finite element method, which is used to calculate the deformation and stability of various geotechnical objects. The input of geometry of soil layers, structure, loads and boundary conditions is based on CAD drawing procedures that provide detailed and accurate modeling of the real situation.

The reinforced concrete frame of the buildings is modeled in accordance with Code of Rules of the Republic of Kazakhstan Euro Norms 1992 (CR RK EN) [

27]. Static loads on the design scheme were taken according to СR RK 1991 (СR RK - Code of Rules of the Republic of Kazakhstan) [

28].

The soil is modeled in two dimensions with two degrees of freedom using a four-node plane deformation formulation of a bilinear isoperimetric quadrilateral element [

29]. Regarding the dimensions of the soil profiles, the depth is assumed to be 30 m and the width differs for the three frame models to allow for free-field conditions and “quasi-transparency” at the profile boundaries. In this case, the width of the ground profile is defined as 120 for a high-rise building, respectively. The grid geometry is based on the concept of allowing transverse wave propagation at or below a certain frequency, which will place the optimum number within the length of the selected transverse wave.

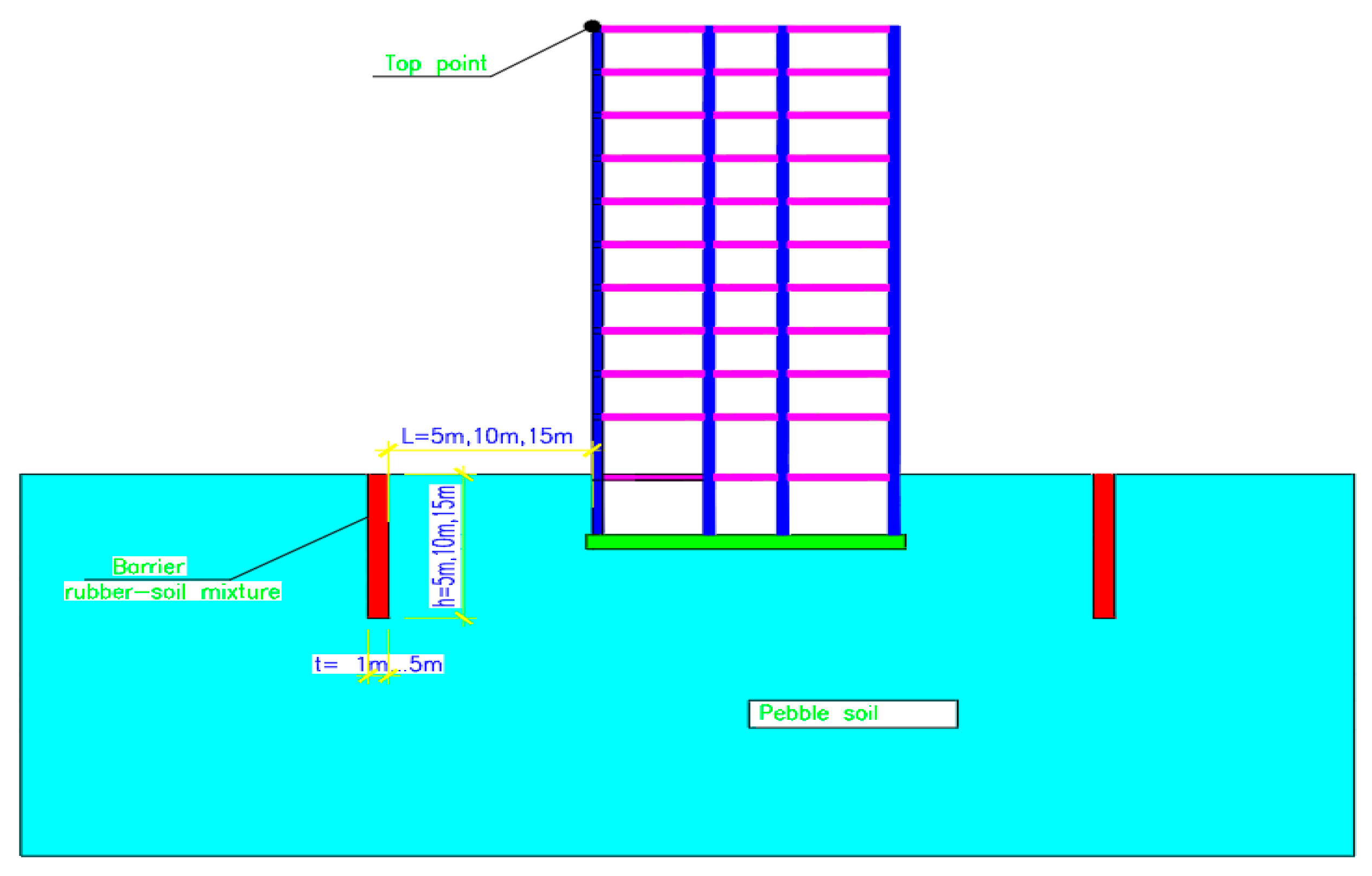

Figure 1 shows the GSI calculation diagram for a 9 storey building, space frame system.

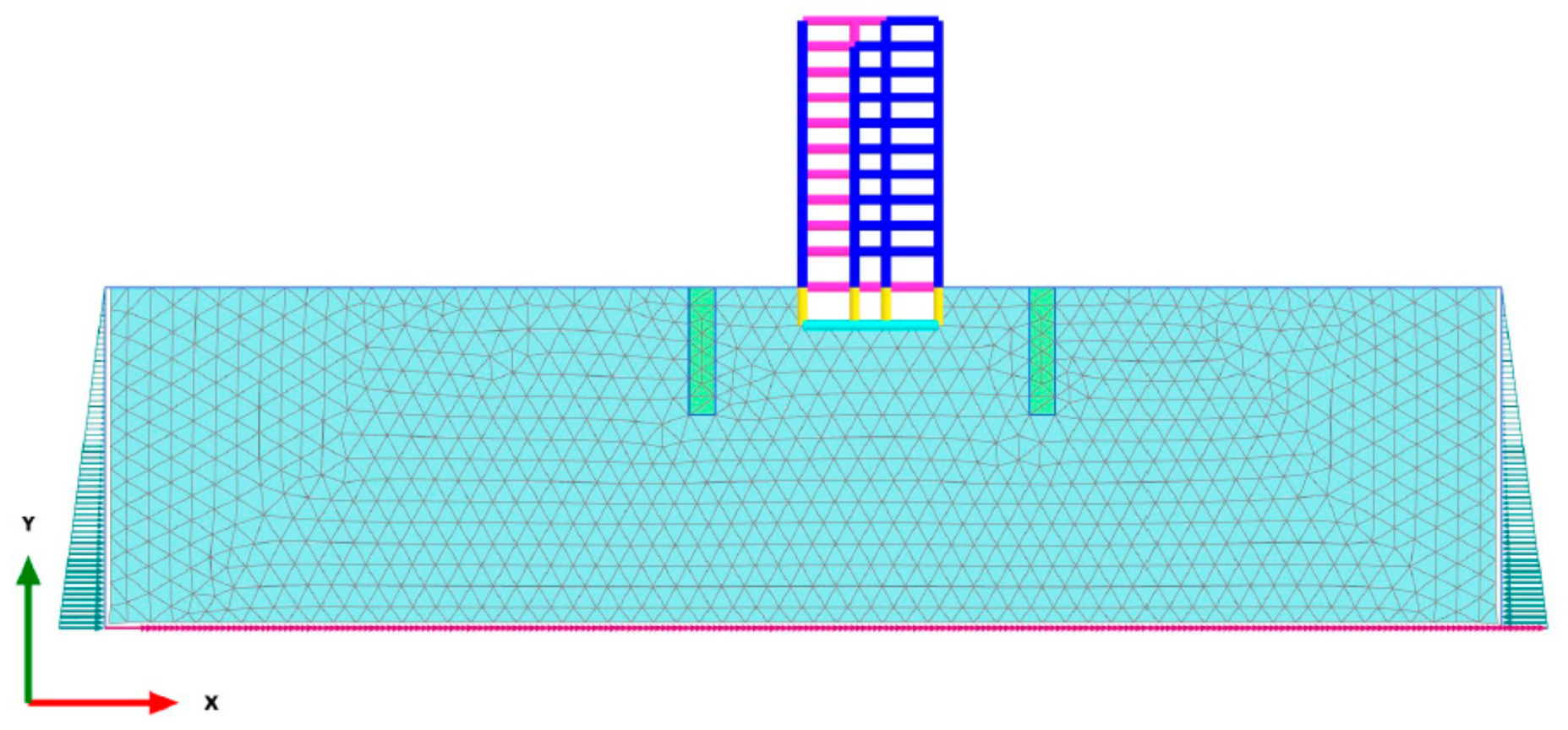

The calculation scheme of the GSI system is modeled by finite element method for a depth of 30m and a width of 120m (

Figure 2).

Extensive research has been carried out to investigate the fundamental engineering properties of RSM such as shear strength, elastic modulus and Poisson's ratio (for example Edil and Bosscher, 1994). The density values of sand and RSM with 75% bulk rubber (abbreviated as RSM 75) selected for finite element modeling are 17.4 and 9.5 kN/m3 respectively. Considering the fact that Poisson's ratio has little effect on the results, different values for different materials were considered irrelevant and a Poisson's ratio value of 0.3 was chosen.

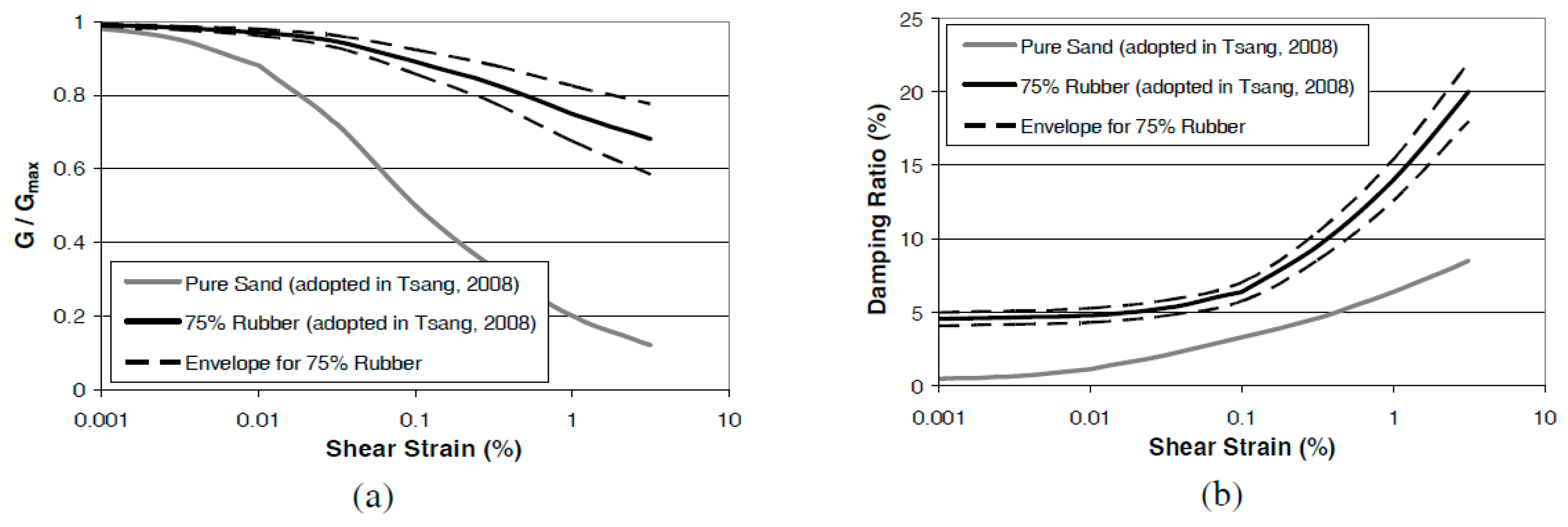

The dynamic properties of RSM have been investigated by Feng and Sutter (2000). The maximum values of shear modulus (G

max) (at very small shear strains (10

-5 - 10

-3 %)) adopted for sand and RSM 75 are 222 and 7.5 MPa, respectively. The strain-dependent G/G

max ratio (shear modulus degradation) and damping ratio are shown in

Figure 3. As can be seen from the graph of dependence of shear modulus on the amplitude of shear strains (

Figure 3a) sand with rubber addition shows a decrease in shear modulus at small strains. And also the damping curve (

Figure 3b) shows the improvement of damping index with increasing percentage of rubber content. Large uncertainty in estimating the dynamic properties of soil materials is unavoidable, so a tolerance of about plus or minus 10% is allowed when modeling the degradation of shear modulus and attenuation in Tsang (2008).

The dynamic properties of soils are well known for their significant dependence on shear deformation of soils. The Plaxis computer programme used in this study uses a commonly used equivalent linear method in which the nonlinear characteristics of soils can be captured using two strain-compatible material parameters, namely secant shear modulus G and damping coefficient ξ.

We take RSM (Tsang 2008) as the reference material, which is shown in

Table 1.

The soil profile and foundation are modeled by solid finite elements, and the oscillator is modeled as a linear-elastic beam element with a concentrated mass at the top. A damping factor of 5% is considered and damping proportional to mass and stiffness is used. The input motion is applied at the base of the model in the form of time acceleration diagrams representing the moving rock.

In SSI systems, it is common for the sway component of structural motion to dominate the response when the rigid superstructure is standing on “normal ground” (Bolisetti and Whittaker, 2015).

For the purpose of earthquake strength modeling, we use the parameters of the accelerograms of the destructive Kobe (Japan, 1994) and Northridge (California, 1995) earthquakes presented in

Table 2.

3. Results and Discussions

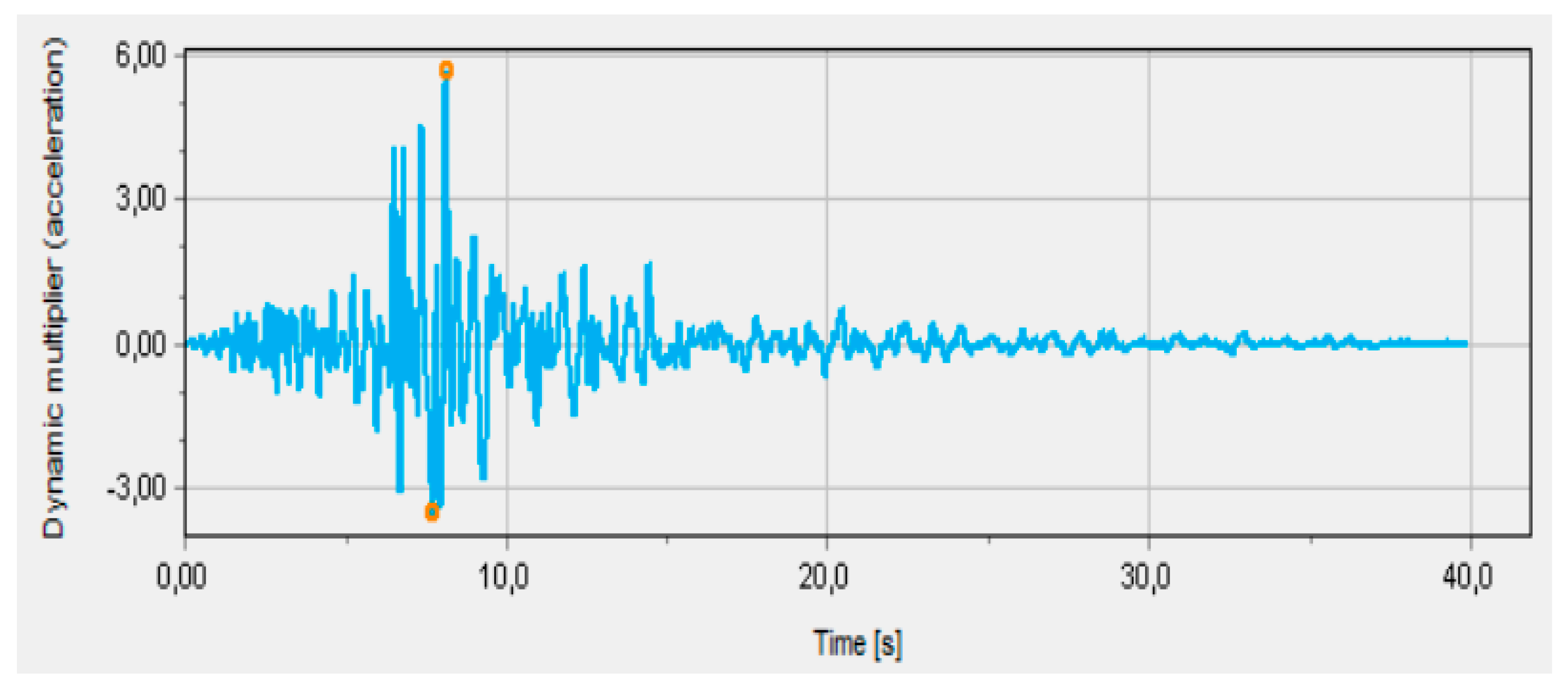

For calculation we use accelerogram of Northridge earthquake in amplitude-frequency parameters typical for destructive earthquakes (

Figure 4). The accelerogram of Northridge earthquakes, is characterized by several high amplitude and high frequency parameters.

Each of these time diagrams is normalized relative to the maximum absolute acceleration of the control model, which used pebble soil as the base material.

In order to determine effective structural and technical solutions for vertical seismic barriers made of RSM, computational and experimental modeling of the effect of the thickness, depth of the barrier, its distance from the building, on the dynamic behavior of buildings was carried out. The final result of the computational-experimental modeling is the indices of horizontal accelerations and the response spectrum to the upper points of the building.

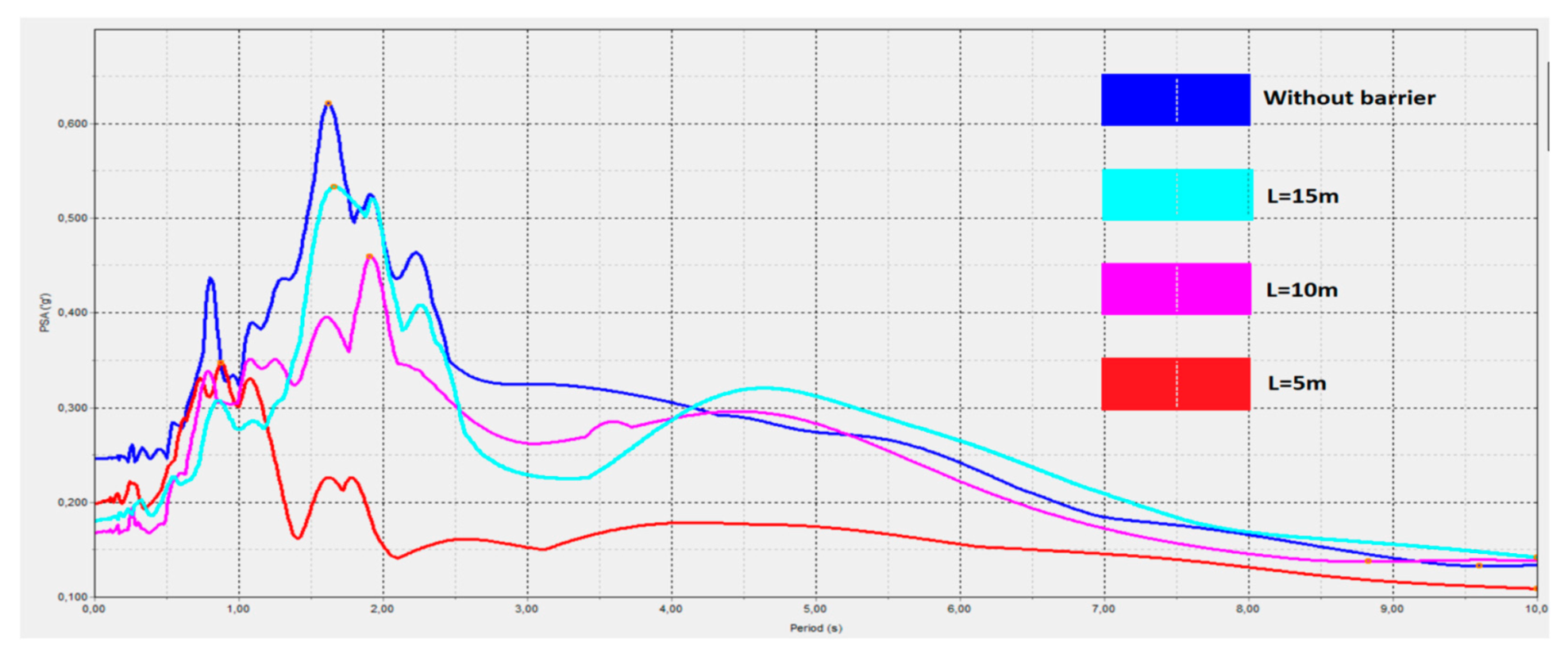

3.1. Effect of Barrier Thickness

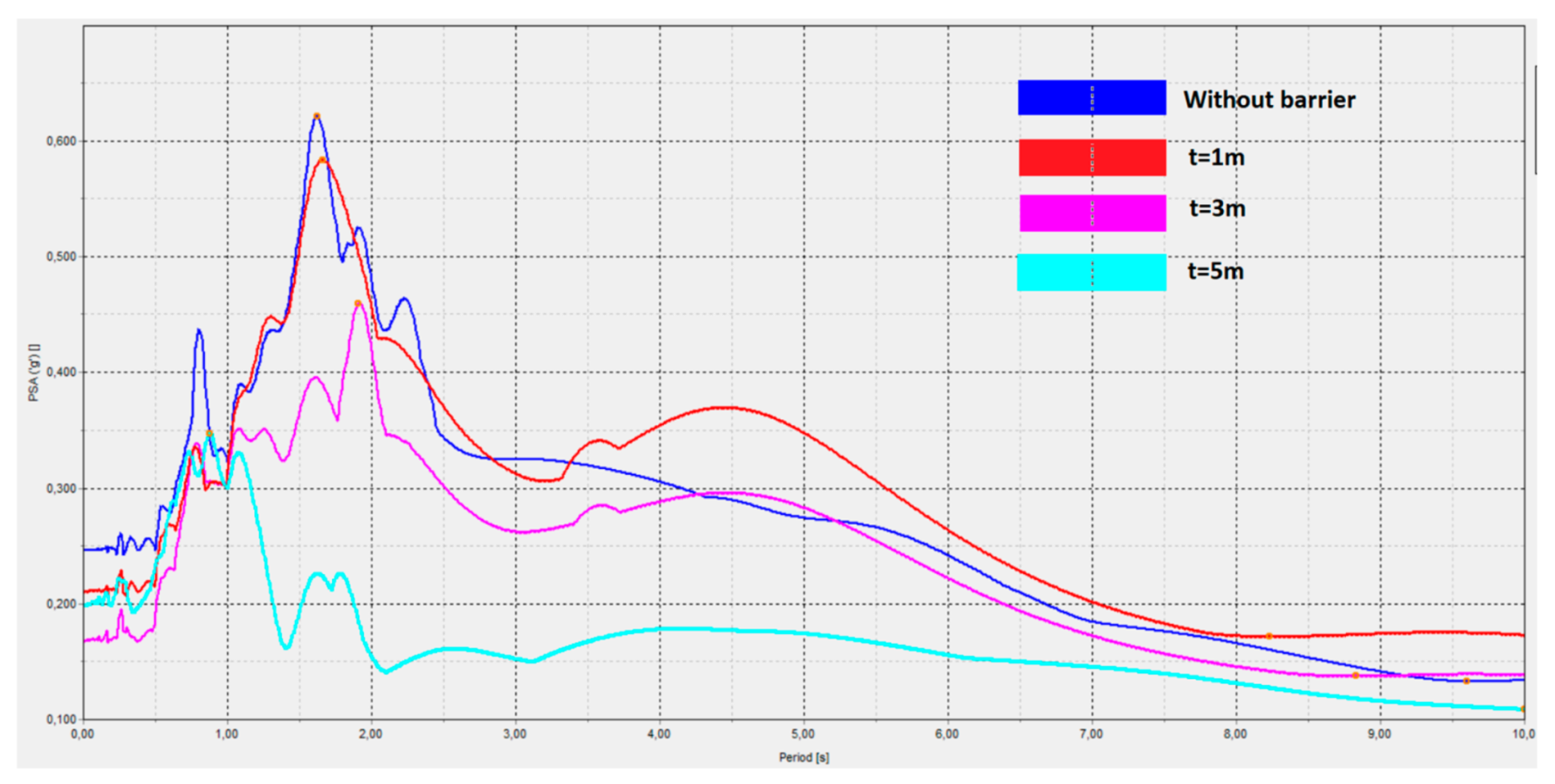

Comparison of the results of the response spectrum (

Figure 5) of the building without a barrier and with the use of a RSM barrier shows the effect of the barrier on the horizontal accelerations at the roof level of the building. It was found that the values of RSM layer thicknesses from 1 to 3 m on the percentage reduction of peak horizontal roof accelerations from 37 to 65 %, respectively. The efficiency is probably due to the much larger amount of energy absorbed by the thicker barrier thickness.

Experiments also found that as the thickness of the RSM layer increases from 3 to 5 m, the value of peak horizontal accelerations at the top point of the building decreases up to 73 %. This is probably due to the wavelength of the oscillation. According to experts, if the wavelength is larger than the barrier width, some of the wave energy passes through the barrier and the barrier efficiency decreases [

33]. This effect is also due to wave energy dissipation.

The results of horizontal accelerations of the top point of the building without barrier and with barriers of different thicknesses showed good parametric data for determining the derivation of barrier design parameters (

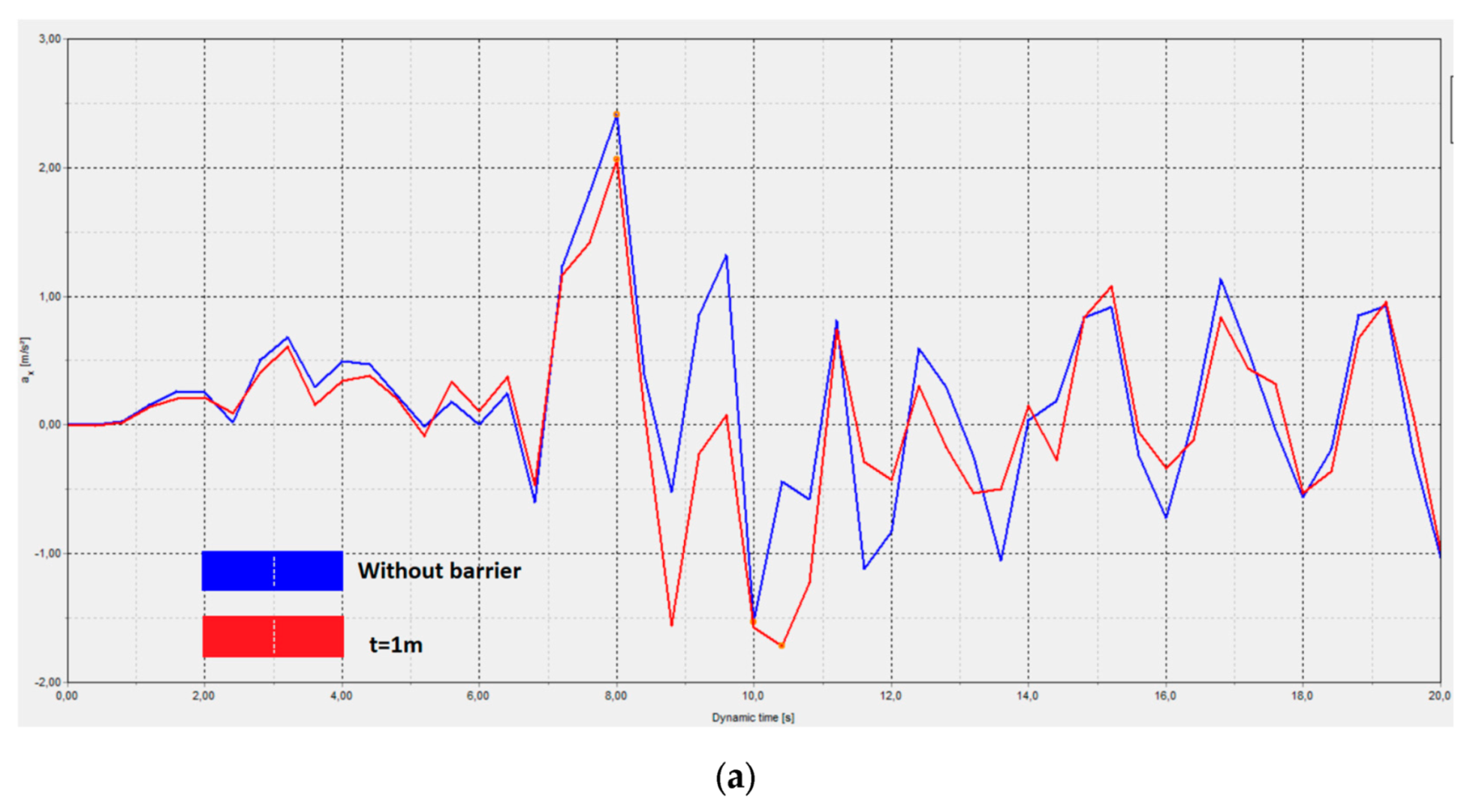

Figure 6).

At a barrier thickness of 1 m (

Figure 6a), the values of horizontal accelerations of the top point of the building without a barrier and with a barrier made of RSM are practically insignificant. While the acceleration for a building without a barrier is 0.241g, the acceleration for a building with an RSM barrier is 0.233g. The reduction in acceleration is 4 %.

While a barrier thickness of 3 m (

Figure 6b) reduces the acceleration of the top point of the building to 0.212g, a barrier thickness of 5 m (

Figure 6c) reduces the acceleration of the top point of the building to 0.050 g, which is a 60% reduction.

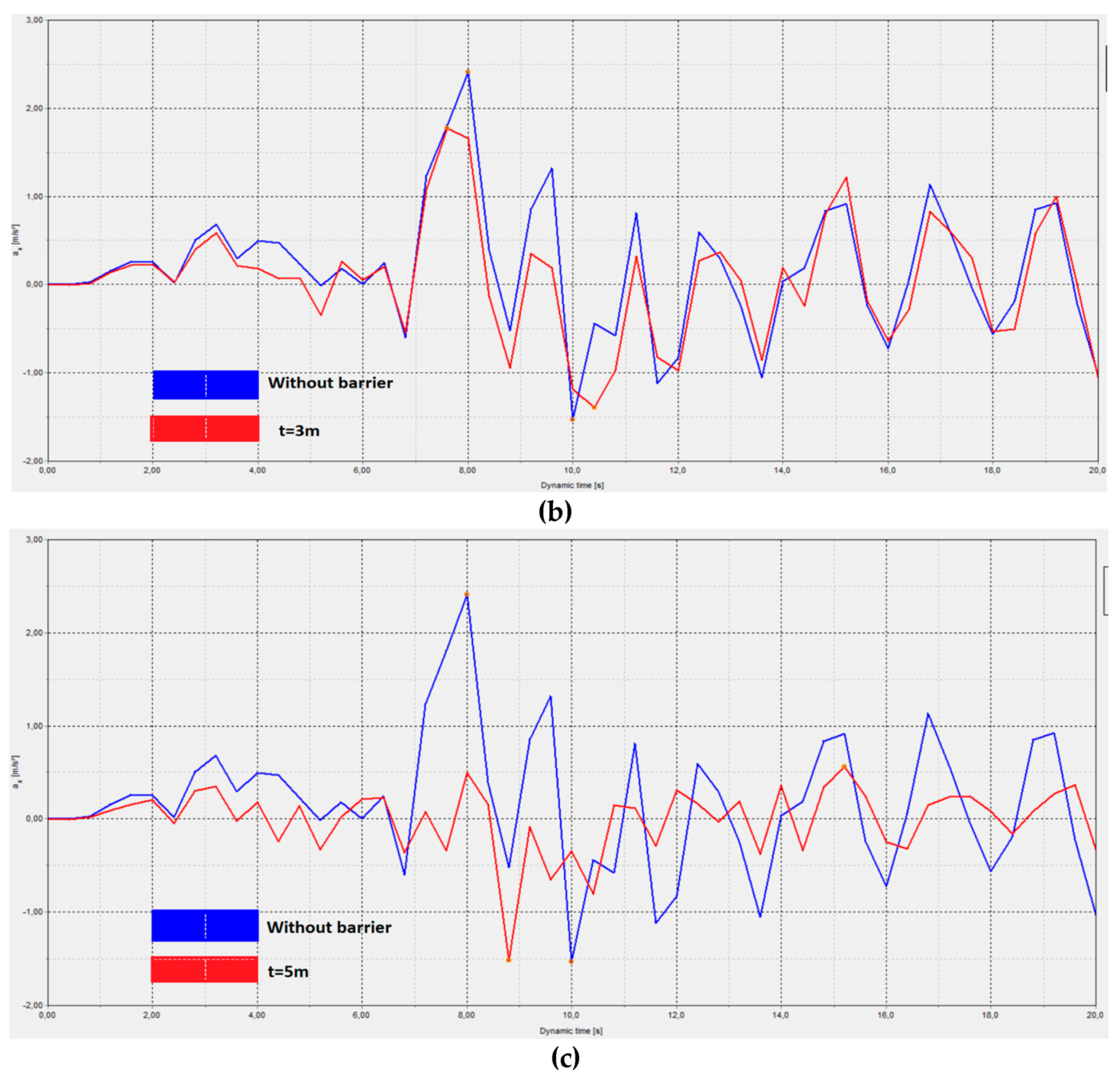

As can be seen from the graph of horizontal acceleration dynamics as a function of barrier thickness (

Figure 7), the thickness parameters significantly affect the effectiveness of the geotechnical seismic isolation system. It is important to note that the results obtained were the most sensitive to the change in the thickness of the RSM, which is in agreement with the results obtained earlier in [

30,

31,

32].

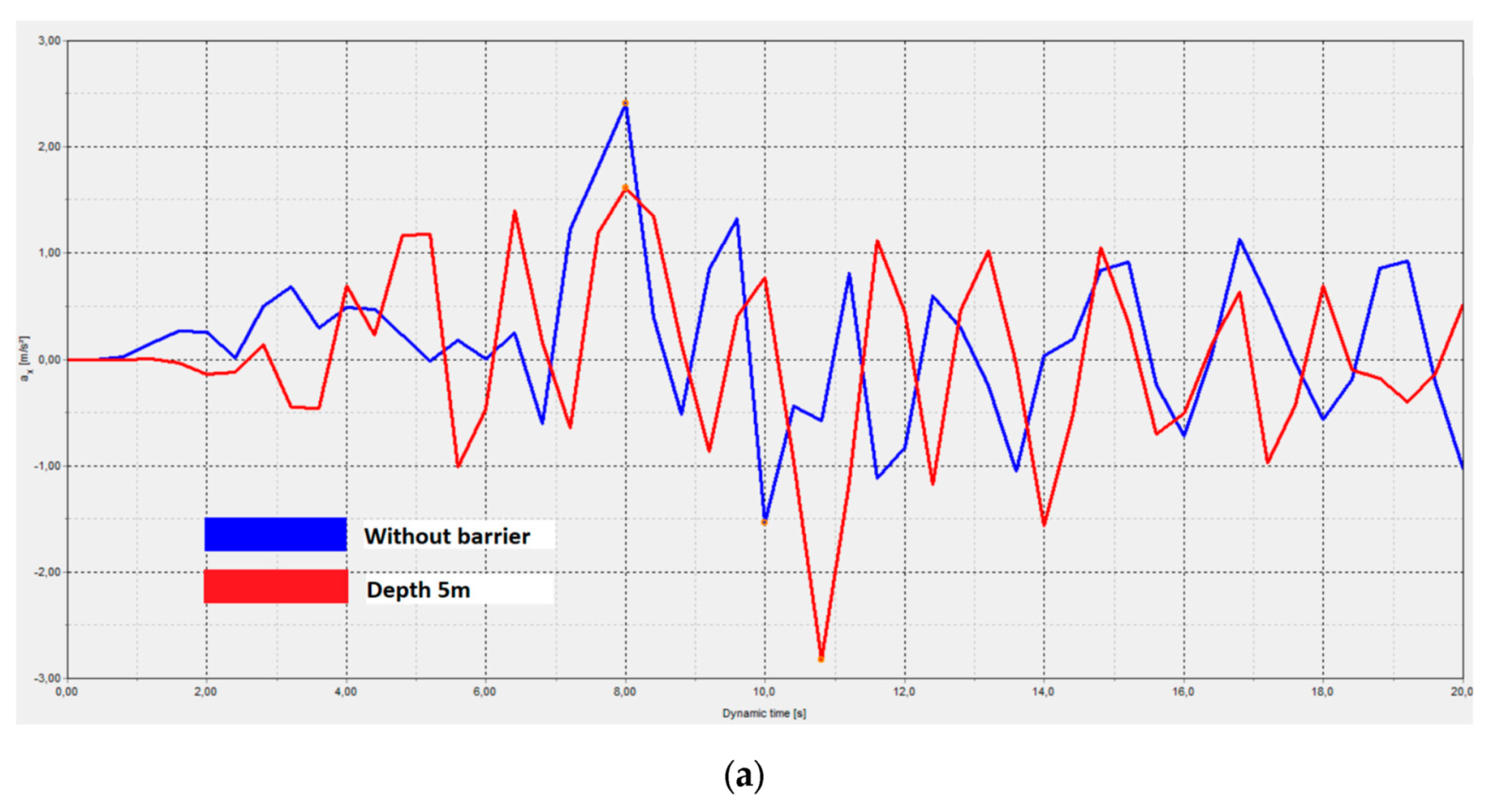

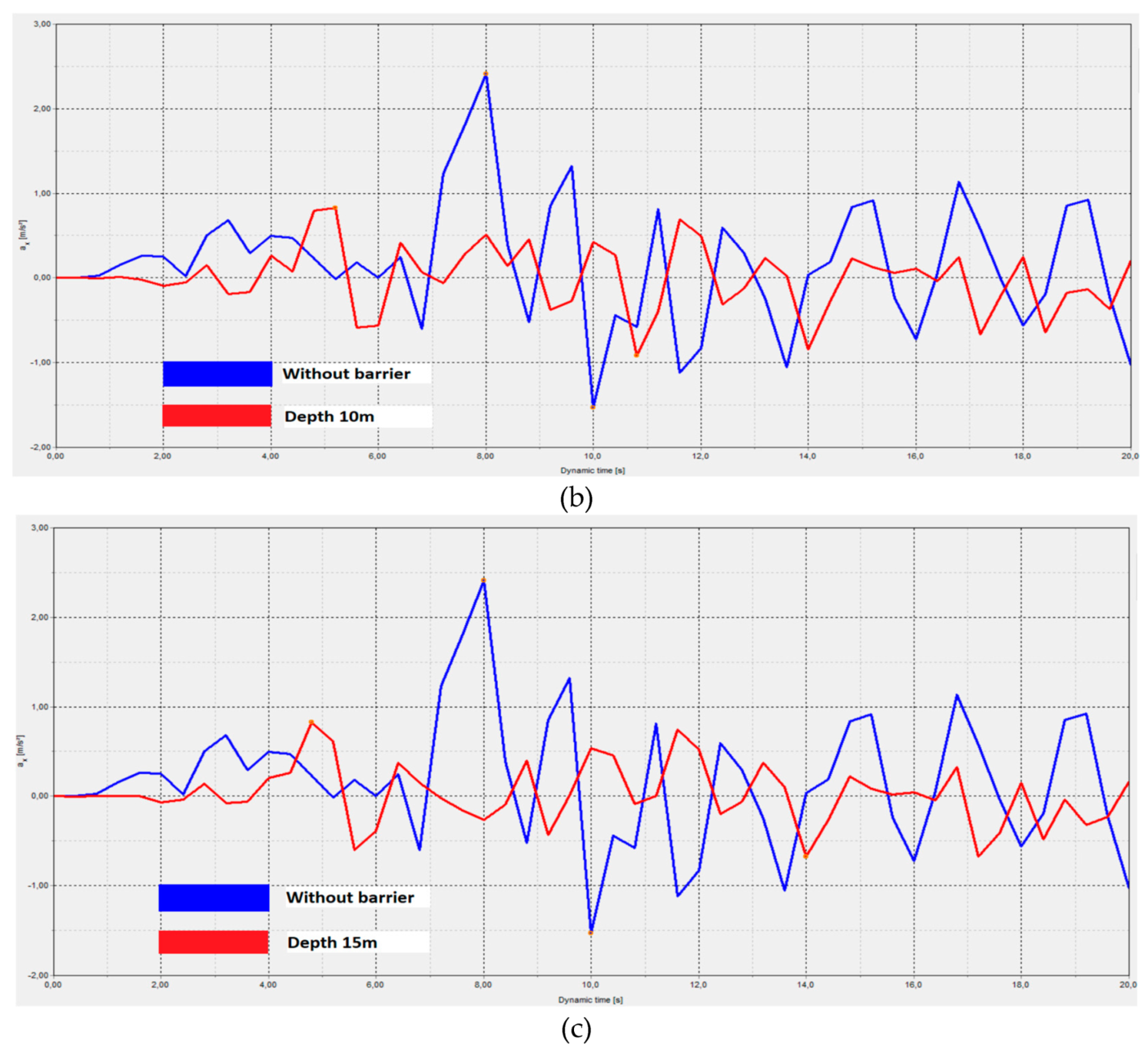

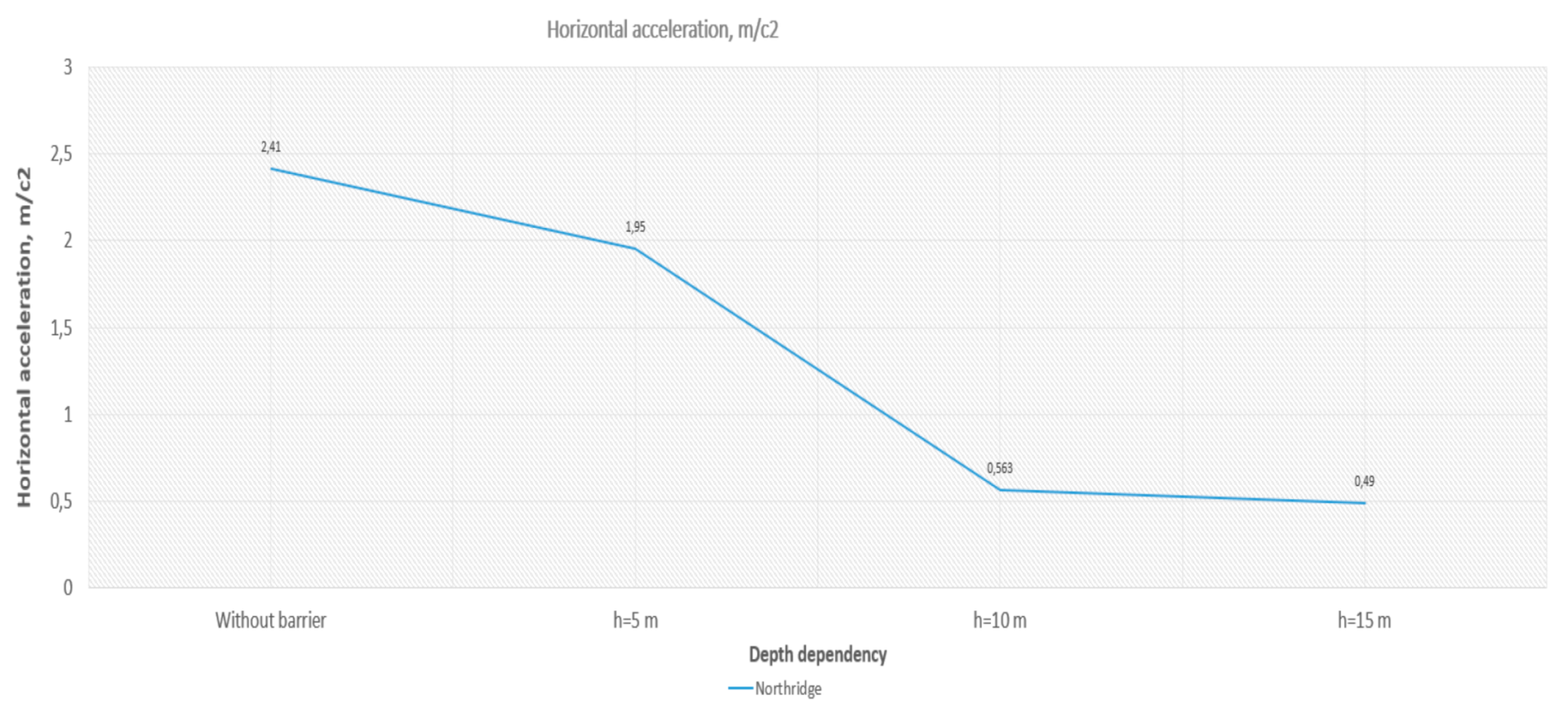

3.2. Effect of Barrier Depth

The design and engineering of RSM barriers were considered to determine the effectiveness of the depth or height of vertical seismic barriers on the degree of reduction of earthquake input motion. The extent to which the input motion amplification is reduced during an earthquake also depends on the depth of the RSM barrier. A numerical analysis was carried out to obtain the effective barrier height and the RSM barrier depth was varied between 5m, 10m, 15m. As can be seen from the horizontal acceleration response spectrum (

Figure 8), the acceleration values for the GSI system decrease with increasing barrier depth up to 15 m, which indicates a sufficiently high effect of reflection and absorption of energy of wave processes.

According to experts, the effectiveness of seismic isolation is also observed when the depth of the barrier increases. The results of the RSM barrier experiment showed that for the barrier depth of 5m (

Figure 9a) the acceleration reduction is 0.195 g, while for the barrier of 10m (

Figure 9b) the acceleration reduction is 0.057 g. When the barrier depth is increased from 10 m to 15 m, no significant difference in soil structure interaction

(SSI)+GSI period is observed (

Figures 9b and 9c). The results show that the value of reduction of horizontal accelerations of the top point of the building with a 15m deep barrier is 60%, which indicates the effectiveness of the GSI system from RSM.

As can be seen from the graph of the dynamics of horizontal accelerations dependence on the depth of the barrier (

Figure 10), the lowest decrease is observed when using a barrier depth of 5 m, intermediate results are obtained at a depth of 10 m, and the best results are obtained when using a depth of 15 m. Typical reduction values in these cases are 5-30%, 10-40%, 15-45%, respectively. This follows from the fact that the 15 m depth is the most ductile of the three depths and has the greatest propensity for large inelastic deformations. As a result, it reaches its shear strength faster, dissipates more energy during an earthquake, and provides greater seismic isolation capacity for the entire system. The decrease in the base period becomes more significant as the barrier depth increases from 10 m to 15 m.

3.3. Effect of Distance from the Building

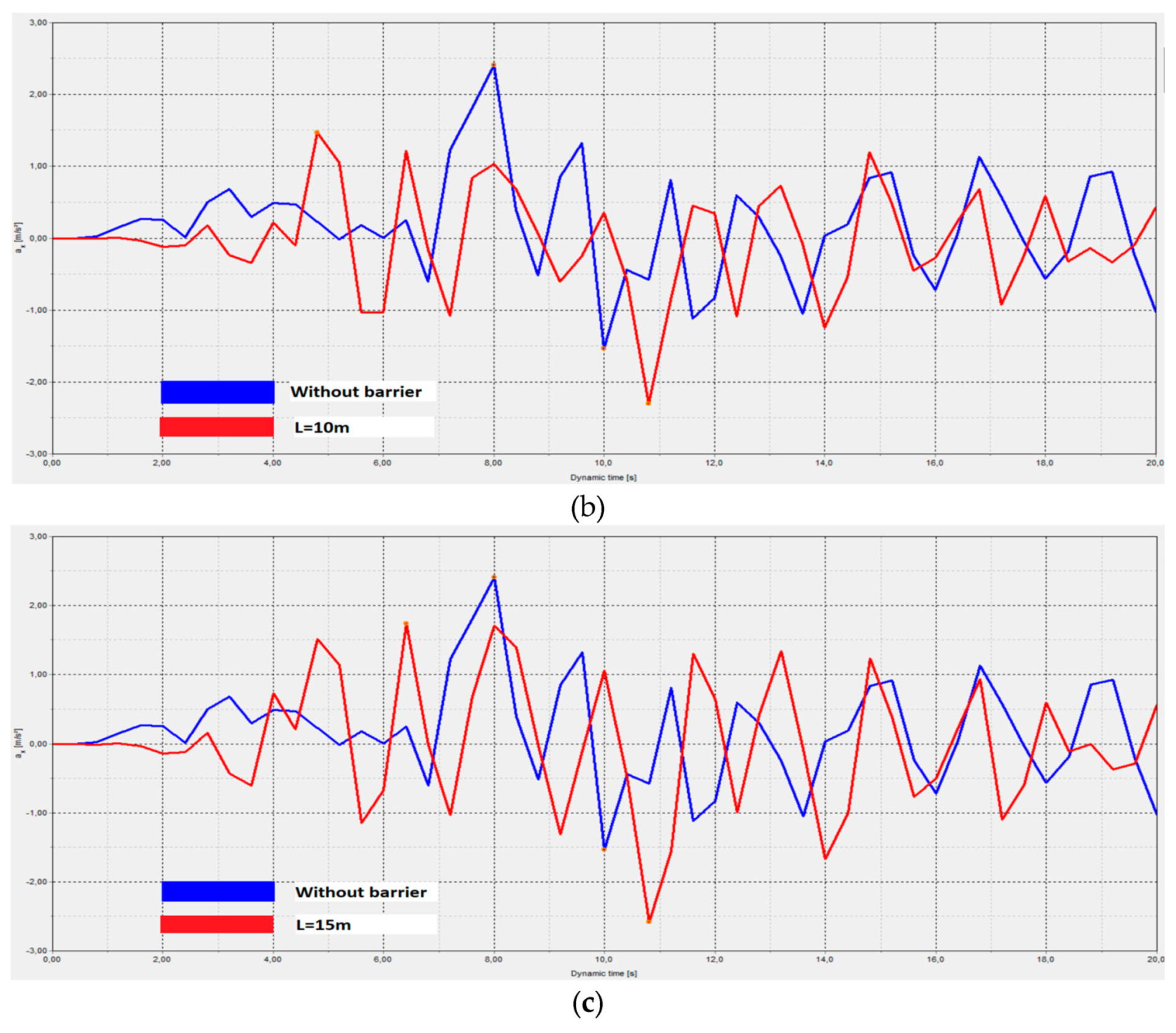

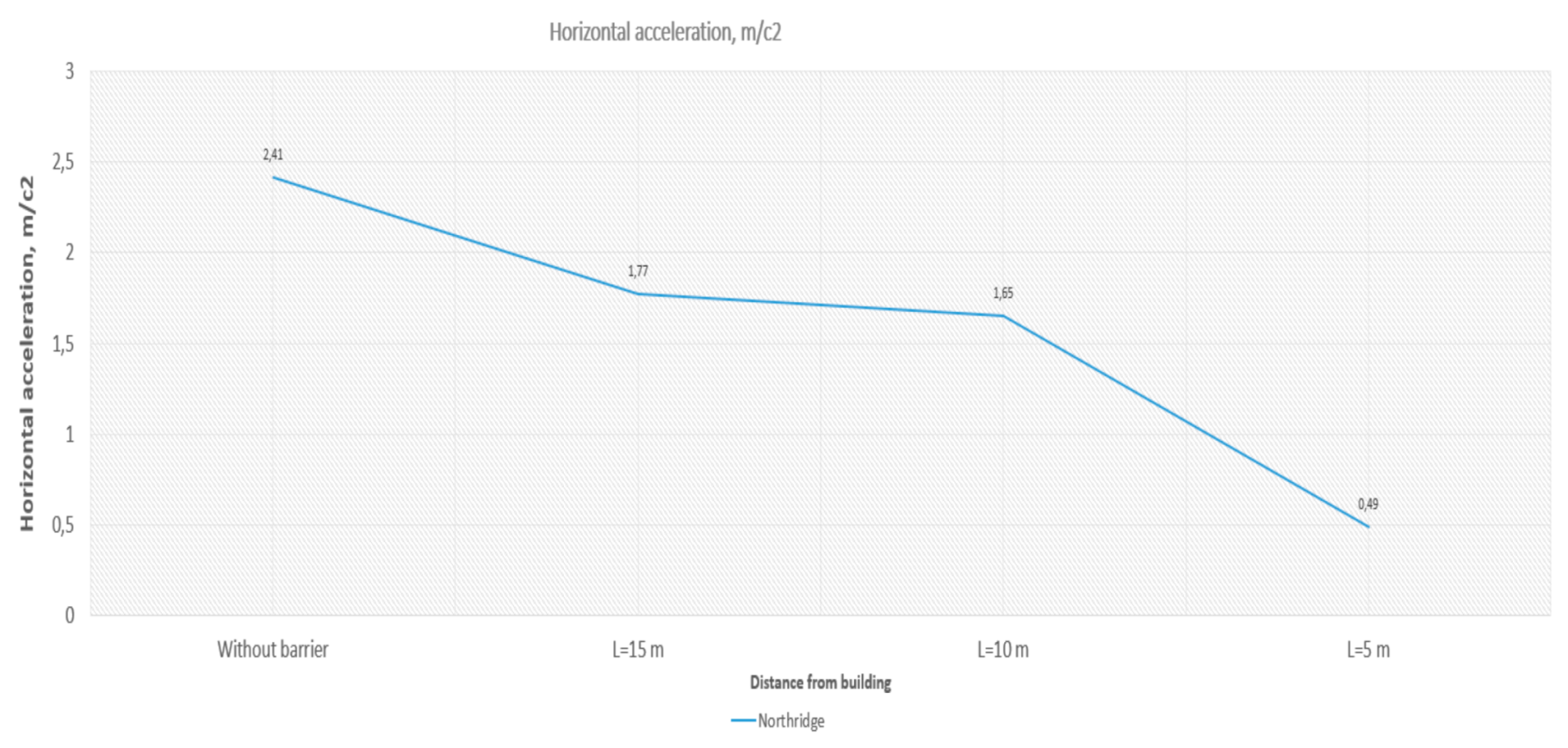

The degree of reduction in earthquake input motion was considered in terms of the location of seismic barriers from the RSM away from the building. The acceleration reduction at the level of the top point of the building obtained in the RSM barrier located at different distances of 5m, 10m, 15m from the building is shown in

Figure 11.

The results of the analysis of the horizontal acceleration response spectrum of the top point of the building without and with the RSM barrier show an increase in acceleration at larger barrier locations from the building. As shown in

Figure 12a, when the barrier is placed at a distance of 5 m, we have an acceleration reduction value of 0.05 g, which corresponds to a reduction efficiency of 60%. So, the smaller the distance from the building, the more acceleration reduction is achieved at the level of the top point of the building.

When the barrier is located further away from the building, a reduction in the reduction effect of up to 40% is observed (Figures 12 b,c).

Figure 13 shows that a significant reduction in acceleration reaches approximately 60% at a distance of 5 m from the building, 40% at a distance of 10 m, and 30% at a distance of 15 m from the building.

The location of the barrier away from the building has a significant effect on reducing horizontal accelerations at the top point of the building. The distance of 5 m from the building, established by the experiments, showed the effectiveness of the GSI system as seismic isolation. When the distance increases up to 15 m, the seismic isolation efficiency decreases due to the possible penetration of seismic waves from below the barrier [

34].

The method of geotechnical seismic isolation in the form of vertical barriers made of RSM is based on the existing soil piling technology. The depth of the barrier is achieved by drilling a borehole to the design grade and packing the RSM to the required density. The width of the barrier is created by installing several rows of rubber-soil piles to a specified thickness. The use of industrial waste greatly reduces the cost of geotechnical seismic isolation technology.

4. Conclusions

The results of the study highlight the favorable effect of using RSM as a vertical barrier material on the response of structures under dynamic loads. As a result of numerical studies, it was found that the thickness, height, distance between the barrier and the building are the main factors determining the damping performance and the degree of reduction of earthquake input motion.

Structural and technical solutions of vertical seismic barriers on RSM are characterized by reliability in providing seismic isolation of objects of existing buildings from the impact of seismic forces and the manufacturability of their construction during construction and operational periods. Vertical seismic barriers made of geomaterials with 75% rubber content reduces horizontal accelerations by 60% at the selected optimum thickness, height and RSM spacing around the building.

The results of the study contribute to the substantiation of methodology and scientific and technical efficiency of geotechnical seismic isolation as a simple and reliable system, an economically favorable design alternative to the traditional seismic isolation system.

The developed system of geotechnical seismic isolation, the results of computational and experimental modeling will become a research, analytical and design basis for the development of new ways of ensuring seismic resistance of construction objects.

Author Contributions

Conceptualization, Y.T.B. and U.T.B.; methodology, Z.O.Z. and D.K.S.; software, A.S.S..; validation, A.S.S., D.K.S. and Z.O.Z.; formal analysis, M.M.B. and Y.Y.U.; investigation, Y.T.B., T.I.I. and U.T.B.; resources, Z.O.Z. and M.M.B.; data curation, T.I.I.; writing—original draft preparation, Y.B.T. and A.S.S.; writing—review and editing, Z.O.Z.; visualization, Y.Y.U.; supervision, Z.O.Z.; project administration, M.M.B.; funding acquisition, Z.O.Z. and M.M.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research is funded by the Committee of Science of the Ministry of Science and Higher Education of the Republic of Kazakhstan (Grant No. BR21882292 – “Integrated development of sustainable construction industries: innovative technologies, optimization of production, effective use of resources and creation of technological park”).

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors are grateful to the leaderships of the Satbayev University and the Science Committee of the Ministry of Science and Higher Education of the Republic of Kazakhstan for creating the conditions for carrying out this work.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Yegian, M.K.; Lahlaf, A.M. Dynamic Interface Shear Strength Properties of Geomembranes and Geotextiles. J. Geotech. Eng. 1992, 118, 760–779. [Google Scholar] [CrossRef]

- Yegian, M.K.; Kadakal, U. Foundation Isolation for Seismic Protection Using a Smooth Synthetic Liner. J. Geotech. Geoenvironmental Eng. 2004, 130, 1121–1130. [Google Scholar] [CrossRef]

- Tsang, H. Seismic isolation by rubber–soil mixtures for developing countries. Earthq. Eng. Struct. Dyn. 2007, 37, 283–303. [Google Scholar] [CrossRef]

- Tsang HH, Lam N, Yaghmaei-Sabegh S, Sheikh MN, Xiong W, Shang SP. Protecting low-to-medium-rise buildings by scrap tyre-soil mixtures. In: Australian earthquake engineering society conference, Newcastle, Australia; 2009. p. 1–8. https://aees.org.au/wp-content/uploads/2013/11/Tsang-et-al.pdf.

- Tsang, H.; Lo, S.H.; Xu, X.; Sheikh, M.N. Seismic isolation for low-to-medium-rise buildings using granulated rubber–soil mixtures: numerical study. Earthq. Eng. Struct. Dyn. 2012, 41, 2009–2024. [Google Scholar] [CrossRef]

- Brunet, S.; de la Llera, J.C.; Kausel, E. Non-linear modeling of seismic isolation systems made of recycled tire-rubber. Soil Dyn. Earthq. Eng. 2016, 85, 134–145. [Google Scholar] [CrossRef]

- Tsiavos, A.; Alexander, N.A.; Diambra, A.; Ibraim, E.; Vardanega, P.J.; Gonzalez-Buelga, A.; Sextos, A. A sand-rubber deformable granular layer as a low-cost seismic isolation strategy in developing countries: Experimental investigation. Soil Dyn. Earthq. Eng. 2019, 125, 105731. [Google Scholar] [CrossRef]

- Tsang, H.-H.; Pitilakis, K. Mechanism of geotechnical seismic isolation system: Analytical modeling. Soil Dyn. Earthq. Eng. 2019, 122, 171–184. [Google Scholar] [CrossRef]

- Hazarika, H. Structural stability and flexibility during earthquakes using tyres (SAFETY) - a novel application for seismic disaster mitigation. In: Proceedings of the international workshop on scrap tire derived geomaterials - opportunities and challenges, IW-TDGM 2007, yokosuka, Japan; 2008. p. 115–25. https://kyushu-u.elsevierpure.com/en/publications/structural-stability-and-flexibility-during-earthquakes-using-tyr.

- Xiong, W.; Li, Y. Seismic isolation using granulated tire–soil mixtures for less-developed regions: experimental validation. Earthq. Eng. Struct. Dyn. 2013, 42, 2187–2193. [Google Scholar] [CrossRef]

- Forcellini, D. Assessment on geotechnical seismic isolation (GSI) on bridge configurations. Innov Infrastruct Sol 2017;2(1):1–6. [CrossRef]

- Karatzia X, Mylonakis G. Geotechnical isolation of pile-supported bridge piers using EPS geofoam. In: 16th world conference on earthquake engineering, santiago, Chile; 2017. Paper No. 2278. https://www.researchgate.net/publication/320258689_GEOTECHNICAL_ISOLATION_OF_PILE-SUPPORTED_BRIDGE_PIERS_USING_EPS_GEOFOAM.

- Hazarika, H.; Kohama, E.; Sugano, T. Underwater Shake Table Tests on Waterfront Structures Protected with Tire Chips Cushion. J. Geotech. Geoenvironmental Eng. 2008, 134, 1706–1719. [Google Scholar] [CrossRef]

- Yasuhara K, Komine H, Murakami S, Miyota S, Hazarika H. Mitigation of liquefaction using tire chips as a gravel drain. In: Proc. 6th international congress on environmental geotechnology, New Delhi, India; 2010. p. 1176–81. [CrossRef]

- Tsang, H.-H.; Lam, J.Y.K.; Yaghmaei-Sabegh, S.; Lo, S.H. Protecting underground tunnel by rubber–soil mixtures. Proceedings of the 7th International Conference on Lifeline Earthquake Engineering, ASCE-TCLEE, Oakland, California, USA. [CrossRef]

- Tsang, H.; Lo, S.H.; Xu, X.; Sheikh, M.N. Seismic isolation for low-to-medium-rise buildings using granulated rubber–soil mixtures: numerical study. Earthq. Eng. Struct. Dyn. 2012, 41, 2009–2024. [Google Scholar] [CrossRef]

- Pitilakis, K.; Karapetrou, S.; Tsagdi, K. Numerical investigation of the seismic response of RC buildings on soil replaced with rubber–sand mixtures. Soil Dyn. Earthq. Eng. 2015, 79, 237–252. [Google Scholar] [CrossRef]

- Pistolas, G.A.; Pitilakis, K.; Anastasiadis, A. A numerical investigation on the seismic isolation potential of rubber/soil mixtures. Earthq. Eng. Eng. Vib. 2020, 19, 683–704. [Google Scholar] [CrossRef]

- Forcellini, D. Assessment of Geotechnical Seismic Isolation (GSI) as a Mitigation Technique for Seismic Hazard Events. Geosciences 2020, 10, 222. [Google Scholar] [CrossRef]

- Senetakis, K.; Anastasiadis, A.; Pitilakis, K. Dynamic properties of dry sand/rubber (SRM) and gravel/rubber (GRM) mixtures in a wide range of shearing strain amplitudes. Soil Dyn. Earthq. Eng. 2012, 33, 38–53. [Google Scholar] [CrossRef]

- Anastasiadis, A.; Senetakis, K.; Pitilakis, K. Small-Strain Shear Modulus and Damping Ratio of Sand-Rubber and Gravel-Rubber Mixtures. Geotech. Geol. Eng. 2011, 30, 363–382. [Google Scholar] [CrossRef]

- Pistolas, G.A.; Anastasiadis, A.; Pitilakis, K. Dynamic Behaviour of Granular Soil Materials Mixed with Granulated Rubber: Effect of Rubber Content and Granularity on the Small-Strain Shear Modulus and Damping Ratio. Geotech. Geol. Eng. 2018, 36, 1267–1281. [Google Scholar] [CrossRef]

- Tsiavos, A.; Alexander, N.A.; Diambra, A.; Ibraim, E.; Vardanega, P.J.; Gonzalez-Buelga, A.; Sextos, A. A sand-rubber deformable granular layer as a low-cost seismic isolation strategy in developing countries: Experimental investigation. Soil Dyn. Earthq. Eng. 2019, 125, 105731. [Google Scholar] [CrossRef]

- Code of Rules of the Republic of Kazakhstan Euro norms (CR RK EN) 1998-1:2004/2012. Design of earthquake-resistant structures. Part 1. General rules, seismic effects and rules for buildings.

- https://new-shop.ksm.kz/upload/e-fond/upload/NTD/NTD_GO_2023/SPRK_EN/48.zip.

- Pistolas GA, Anastasiadis A, Pitilakis K. Cyclic undrained mechanical properties of sand/granulated rubber mixture. In: Proceedings of 7th Greek geotechnical conference, Hellenic Society Of Soil Mechanics And Geotechnical Engineering, Athens, Greece ; 2014a. http://www.hssmge.gr/TEFXOS_No_71_NOVEMBER_2014-%CE%91.pdf.

- Pistolas GA, Anastasiadis A, Pitilakis K. Mechanical shear strength properties of sand/granulated rubber mixtures. In: Proceedings of 7th Greek geotechnical conference, Hellenic Society of Soil Mechanics and Geotechnical Engineering, 2014b, Athens, Greece. http://www.hssmge.gr/TEFXOS_No_72_NOVEMBER_2014-B.pdf.

- Code of Rules of the Republic of Kazakhstan Euro norms (CR RK EN) 1992-1-1:2004/2011. Design of reinforced concrete structures. Part 1-1. General rules and regulations for buildings.

- https://new-shop.ksm.kz/upload/e-fond/upload/NTD/NTD_GO_2023/SPRK_EN/12.zip.

- Code of Rules of the Republic of Kazakhstan Euro norms (CR RK EN) 1991-1-2:2008/2011. Design of reinforced concrete structures. Part 1-1. Own weight, permanent and temporary loads on buildings.

- https://new-shop.ksm.kz/upload/e-fond/upload/NTD/NTD_GO_2023/SPRK_EN/2.zip.

- Code of Rules of the Republic of Kazakhstan 5.01-102-2013. Foundations of buildings and structures. https://new-shop.ksm.kz/upload/e-fond/upload/NTD/NTD_GO_2023/211021/SP_RK_5.01-102-2013.

- Xiong, W.; Tsang, H.H.; Lo, S.; Shang, S.P.; Wang, H.D.; Zhou, F.Y. Geotechnical Seismic Isolation System - Experimental Study. Adv. Mater. Res. 2010, 163-167, 4449–4453. [Google Scholar] [CrossRef]

- Senetakis K, Anastasiadis A, Trevlopoulos K, Pitilakis K. Dynamic response of SDOF systems on soil replaced with sand/rubber mixture. Proceedings of the ECOMAS Thematic Conference on Computation Methods in Structural Dynamics and Earthquake Engineering, Rhodes, Greece, June 22–24, 2009. https://ikee.lib.auth.gr/record/228299.

- Pitilakis K, Trevlopoulos K, Anastasiadis A, Senetakis K. Seismic response of structures on improved soil. Proceedings of the 8th International Conference on Structural Dynamics, Leuven, Belgium, July 4–6, 2011.

- https://bwk.kuleuven.be/apps/bwm/eurodyn2011/papers/KEY99010.pdf.

- Rashidov, T. R, Kuznetsov S.V, Mardonov B.M, Mirzaev I. Applied Problems of Seismodynamics of Structures. 2021 Publisher: – Tashkent, Nauryz. 2021, 172 p. ISBN: 978-9943-659-43-8.

- https://eqworld.ipmnet.ru/ru/library/books/RashidovKuznetsovMardonovMirzaev2021ru.pdf.

- Bessimbayev, Y.; Zhambakina, Z.; Niyetbay, S. Ensuring the seismic of a building using a geotechnical seismic insulaing screen. Eastern-European J. Enterp. Technol. 2022, 3, 59–67. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).