Submitted:

05 July 2024

Posted:

08 July 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Methodology

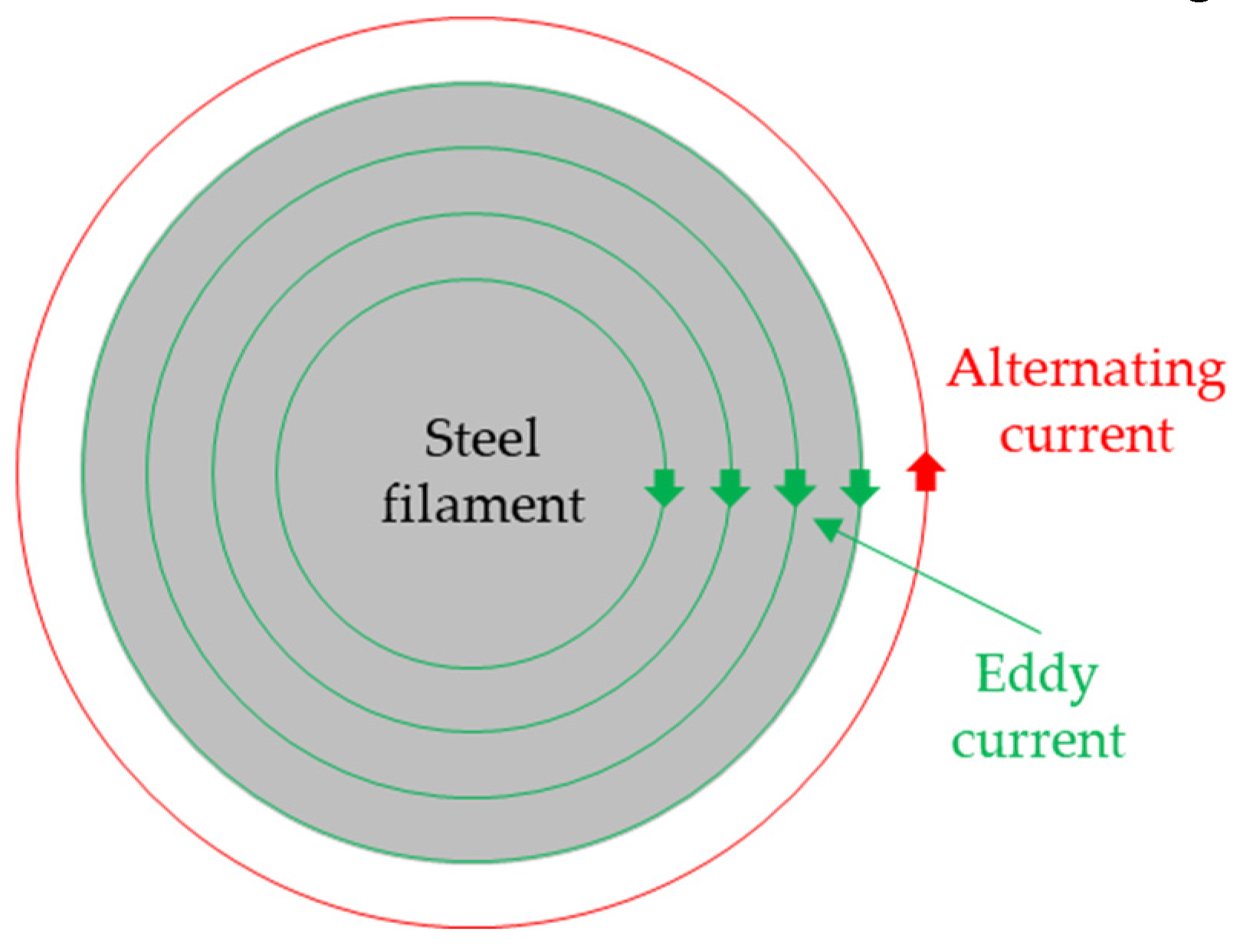

2.1. Working Principle

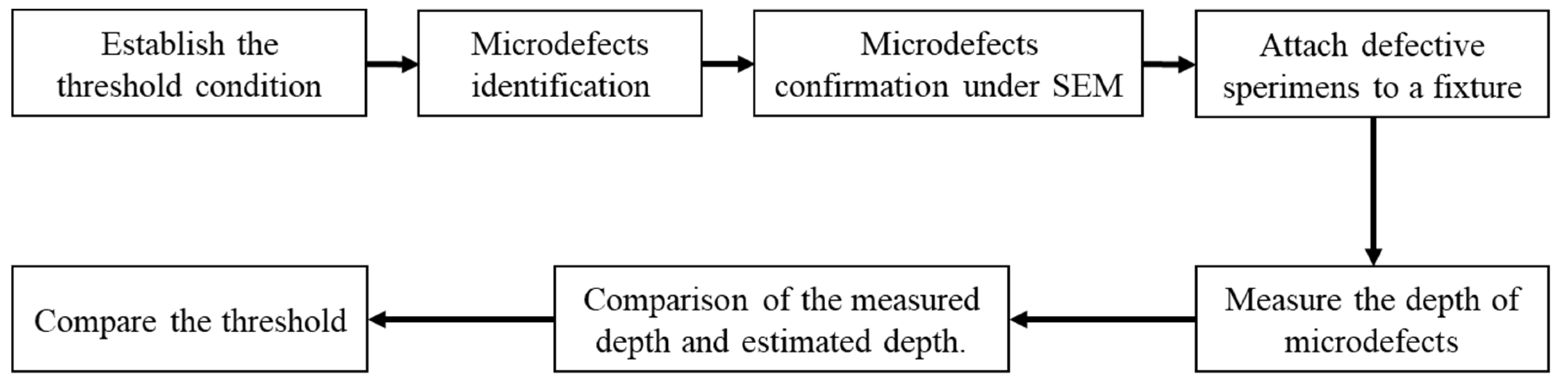

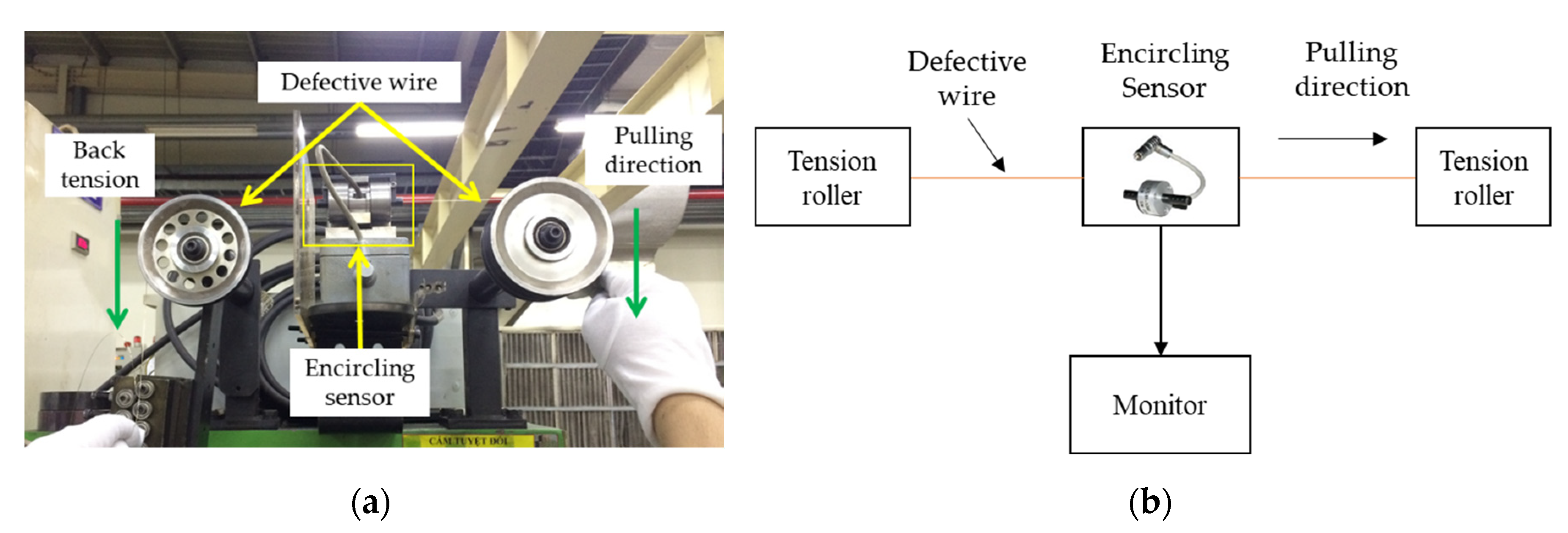

2.2. Experimental Procedure

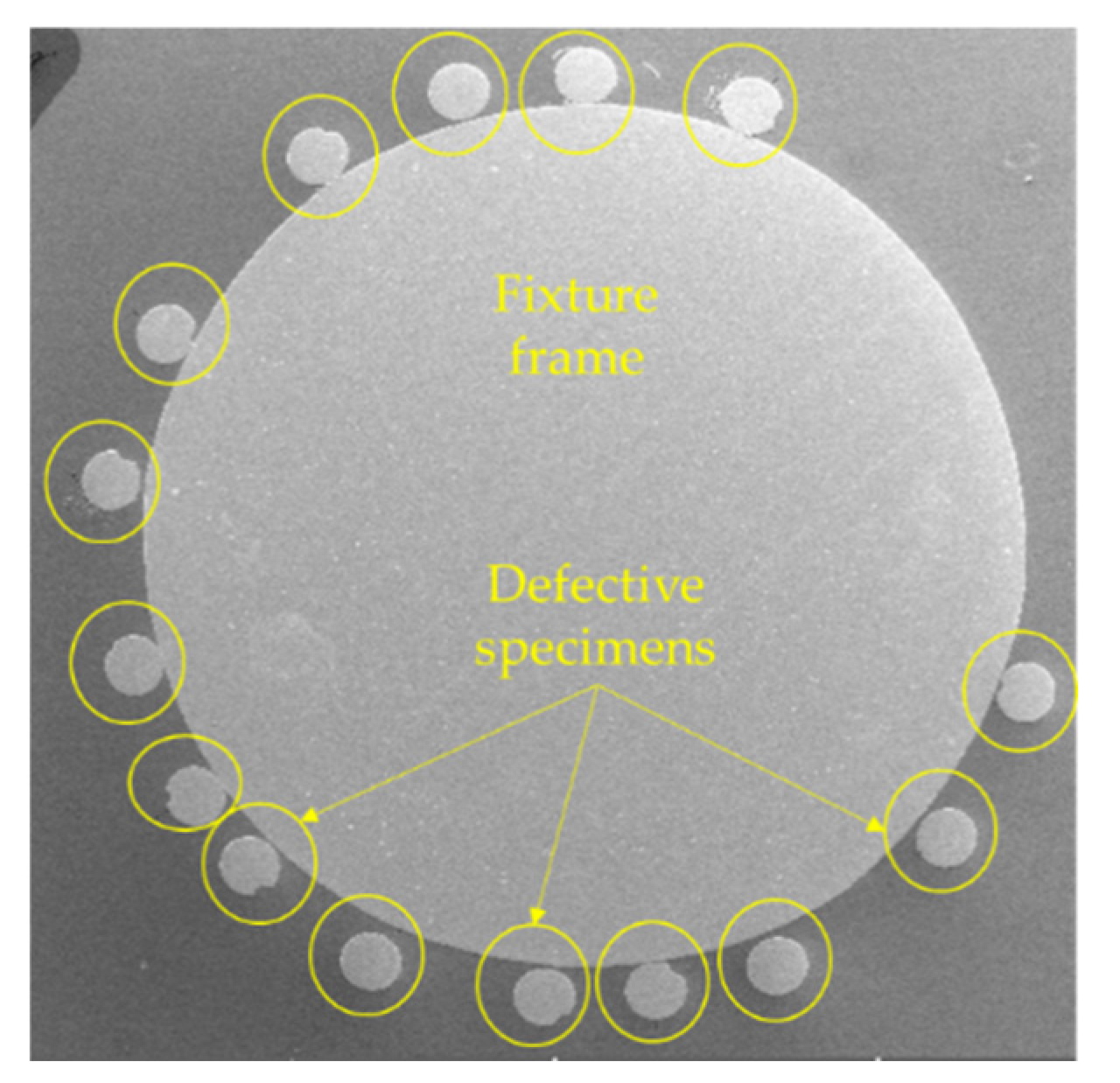

2.2.1. Establishing Identification Methods and Defects Analysis

3. Experimental Results

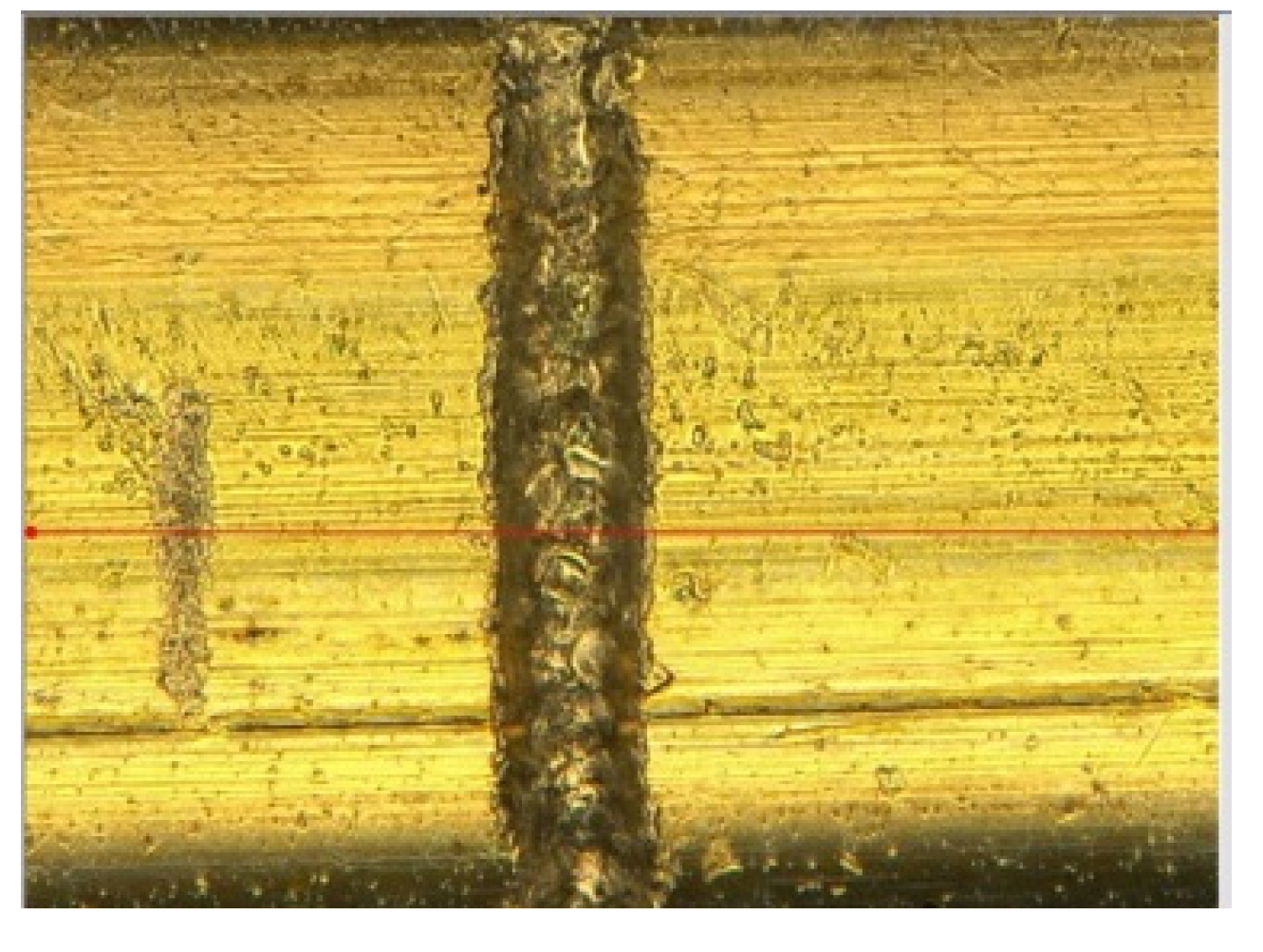

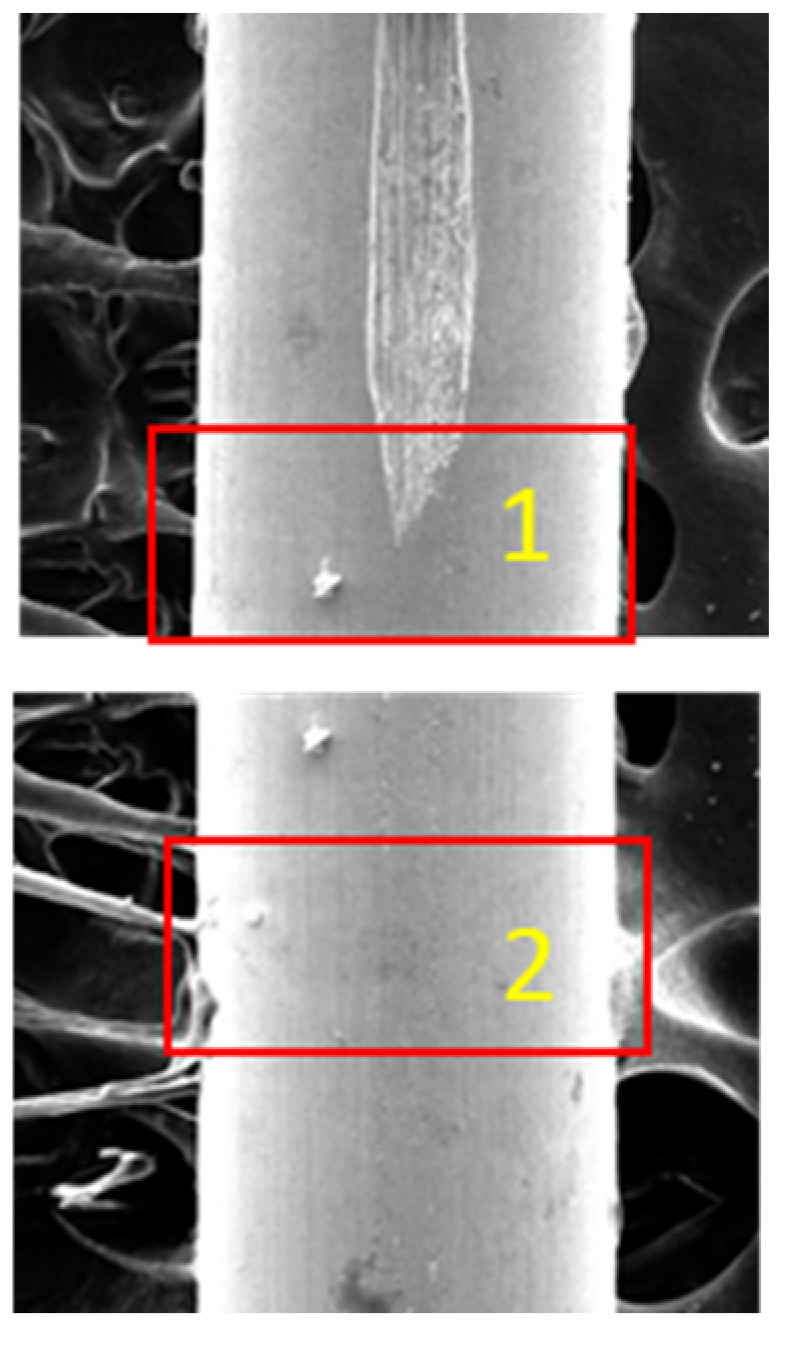

3.1. Verification of the Composition Inside and Outside of Microdefects

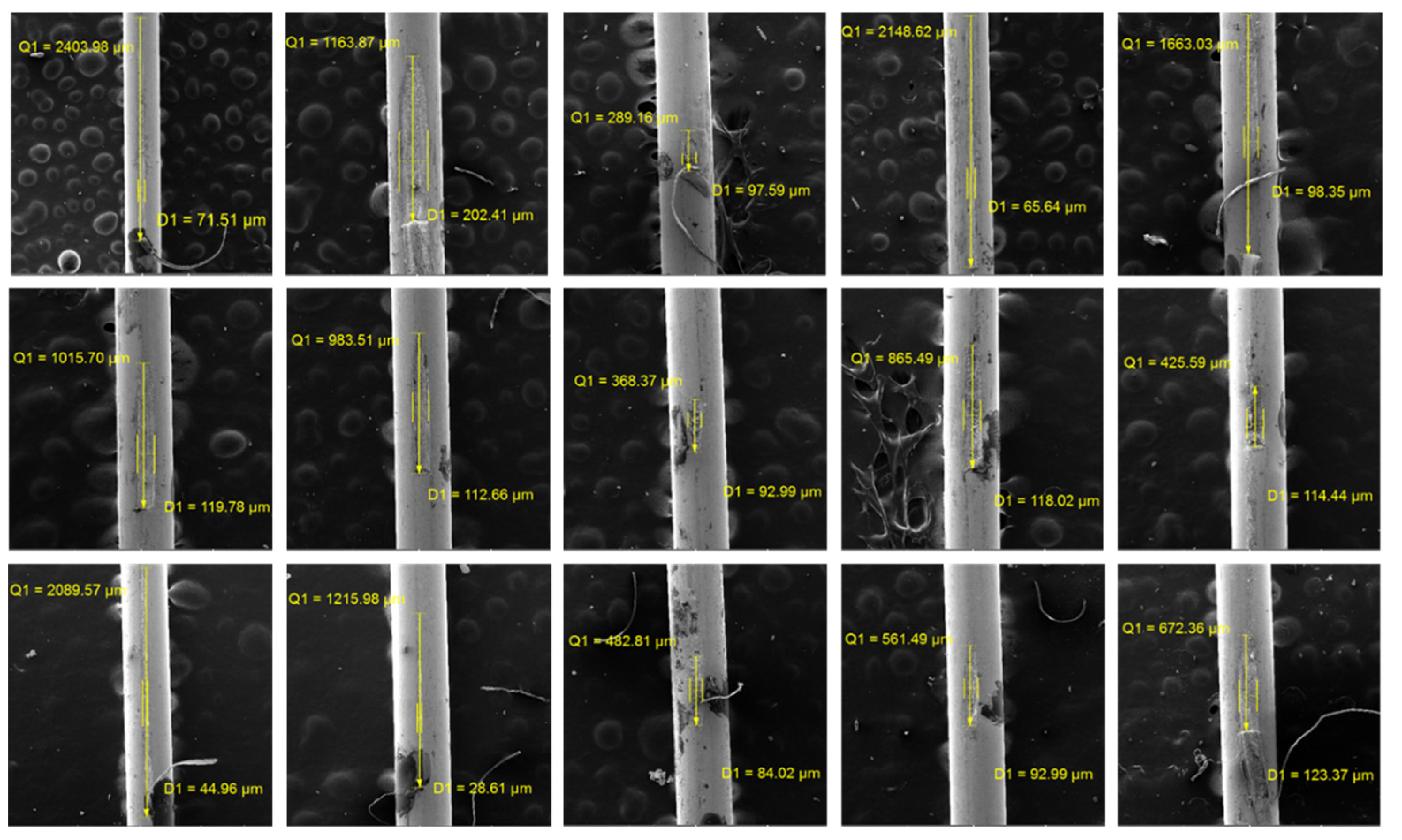

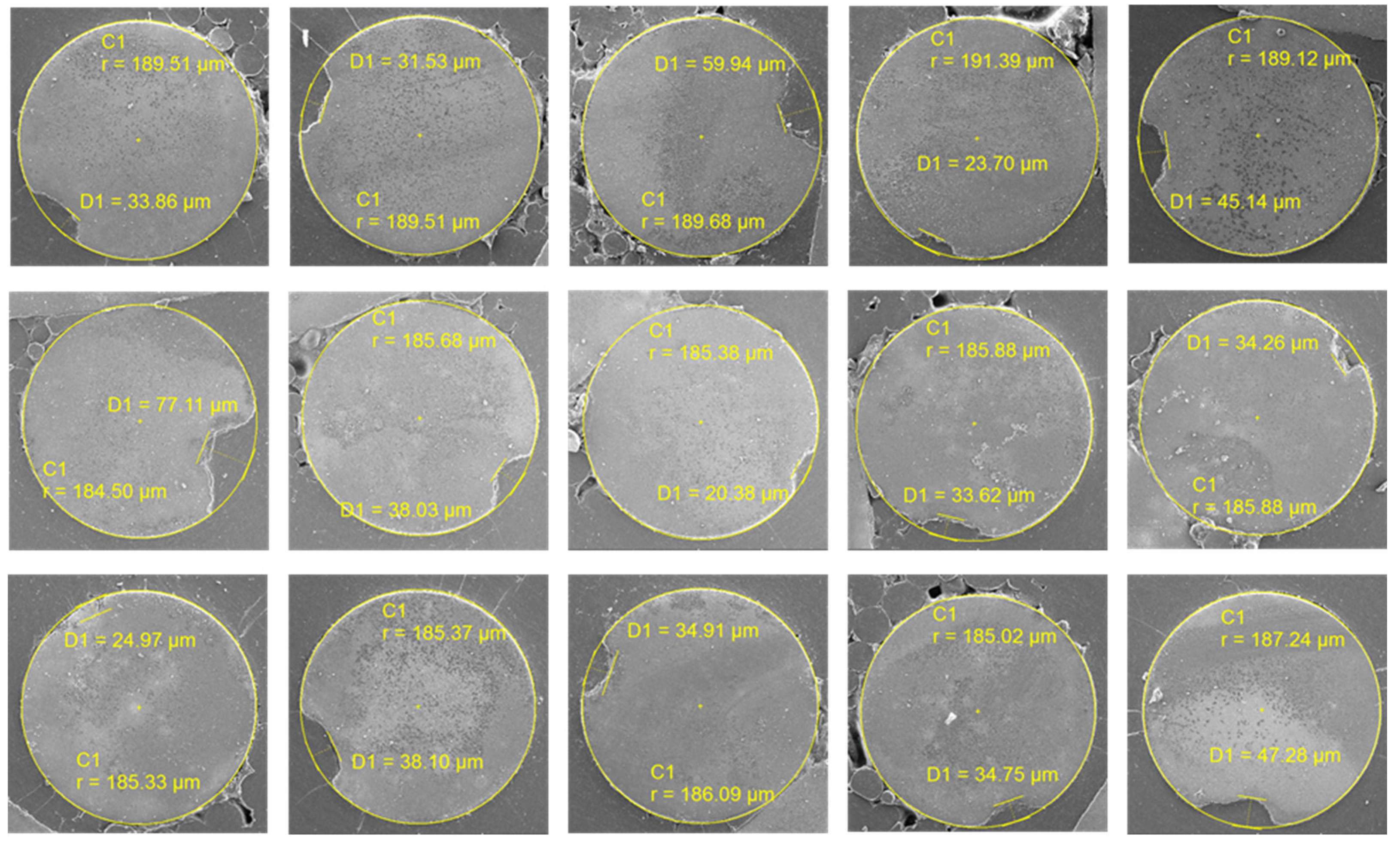

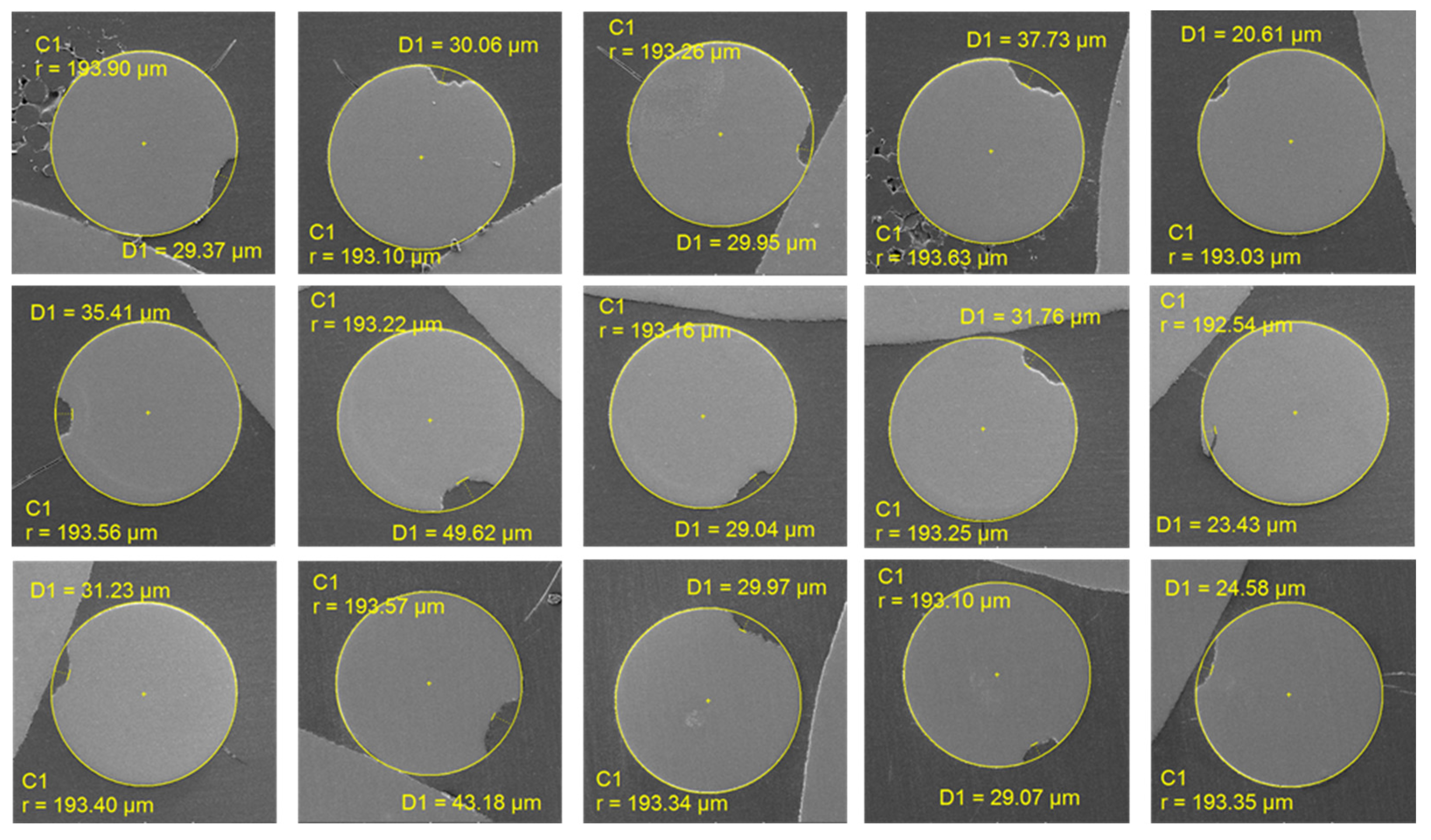

3.2. Measurement of Defect’s Depth

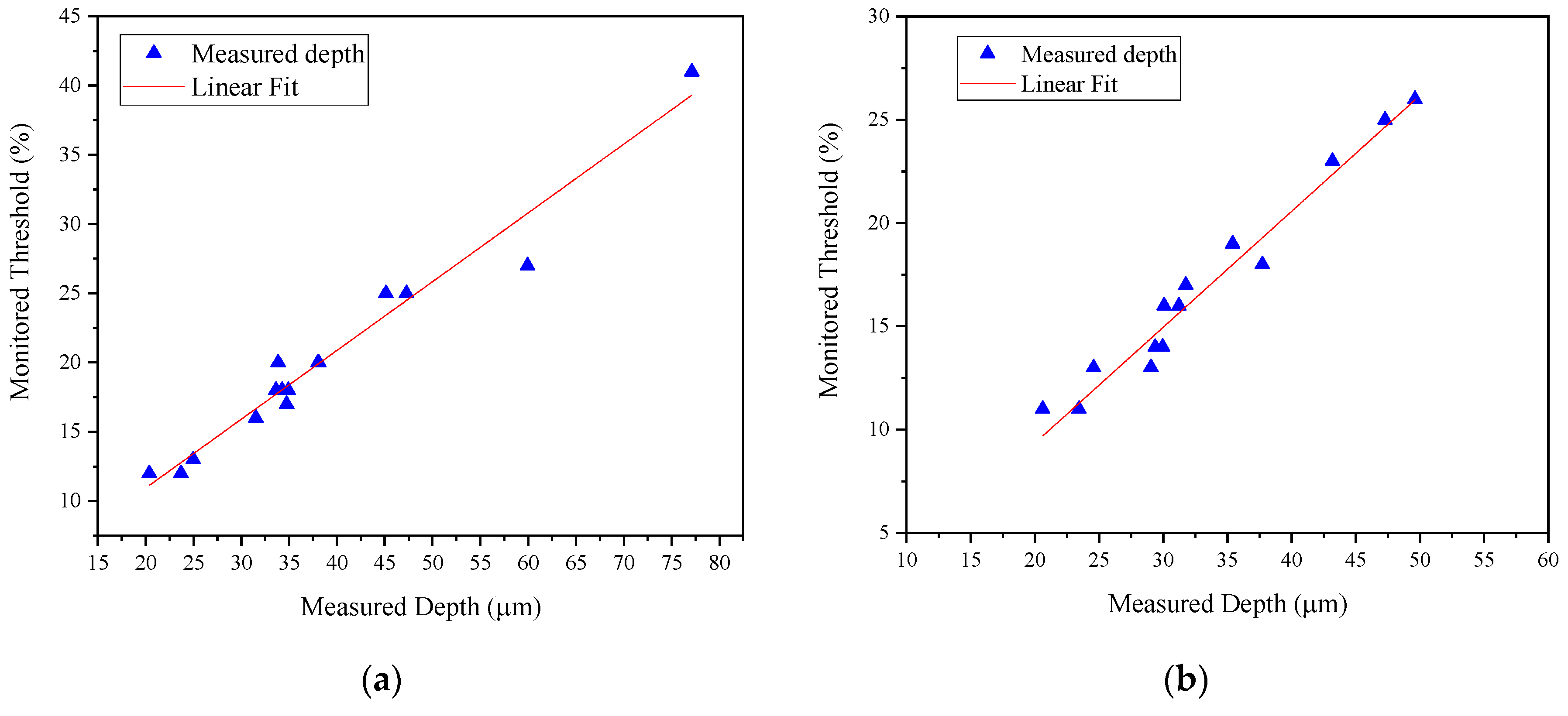

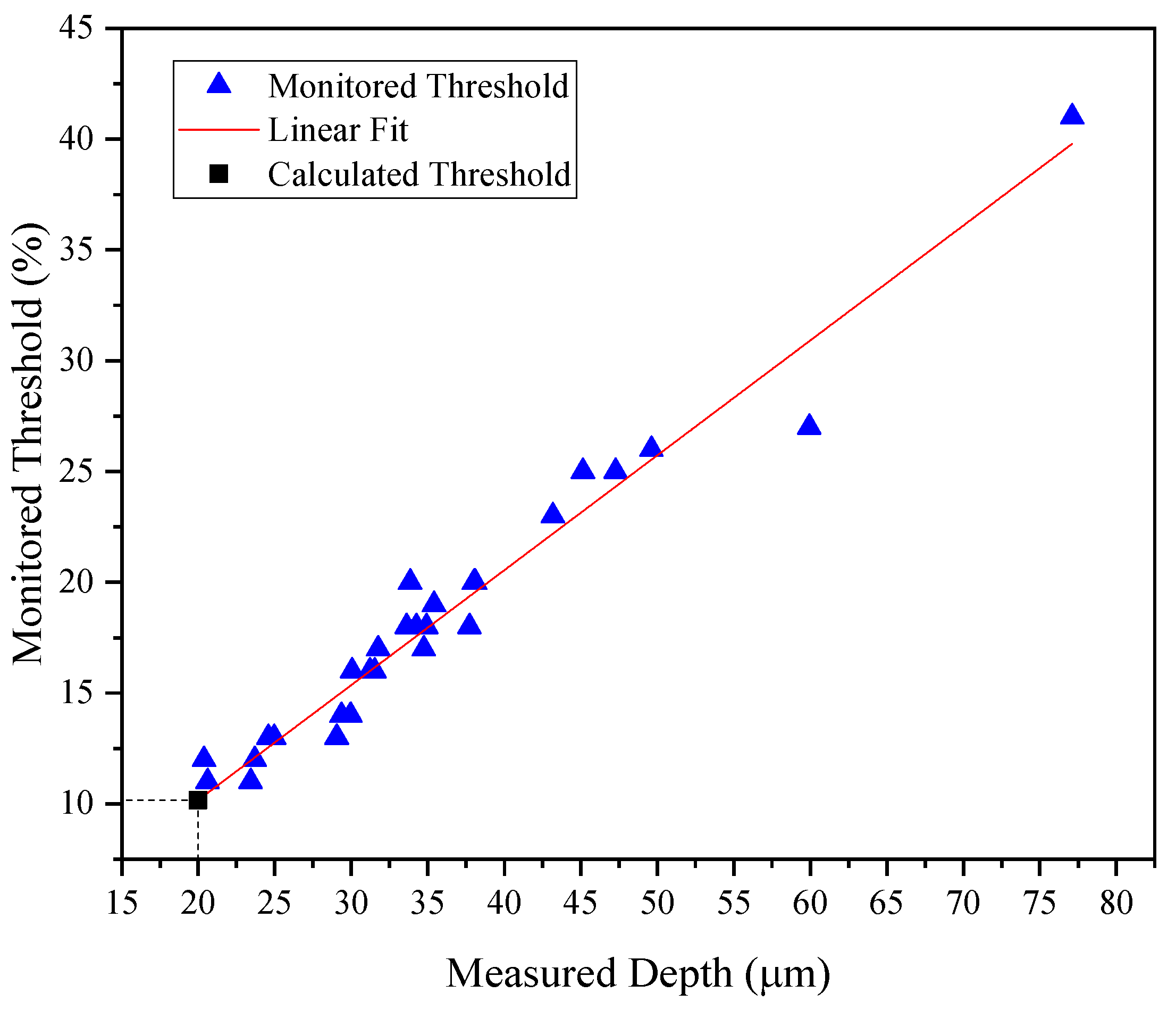

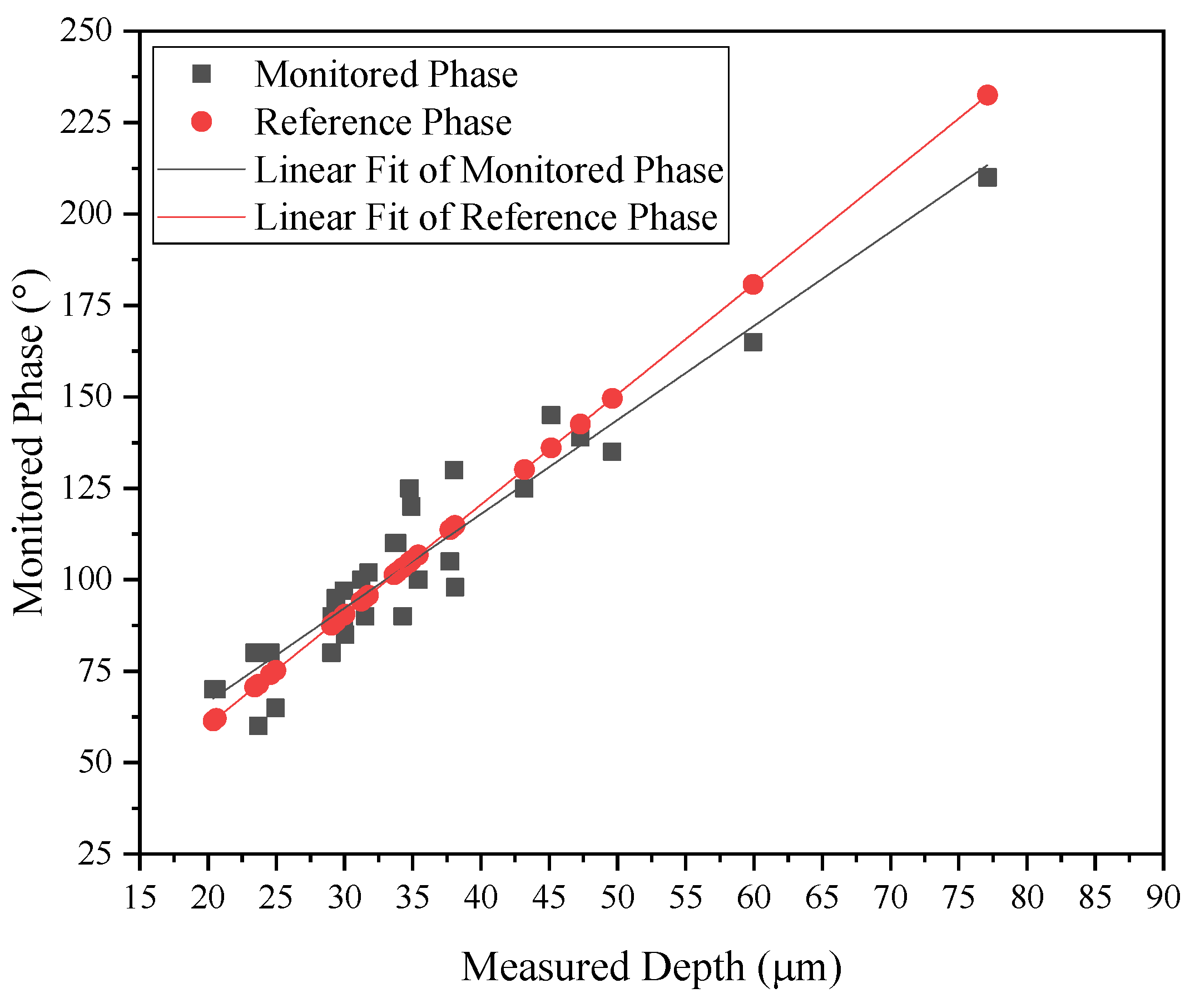

3.3. Signal Amplitude and Defective Depth

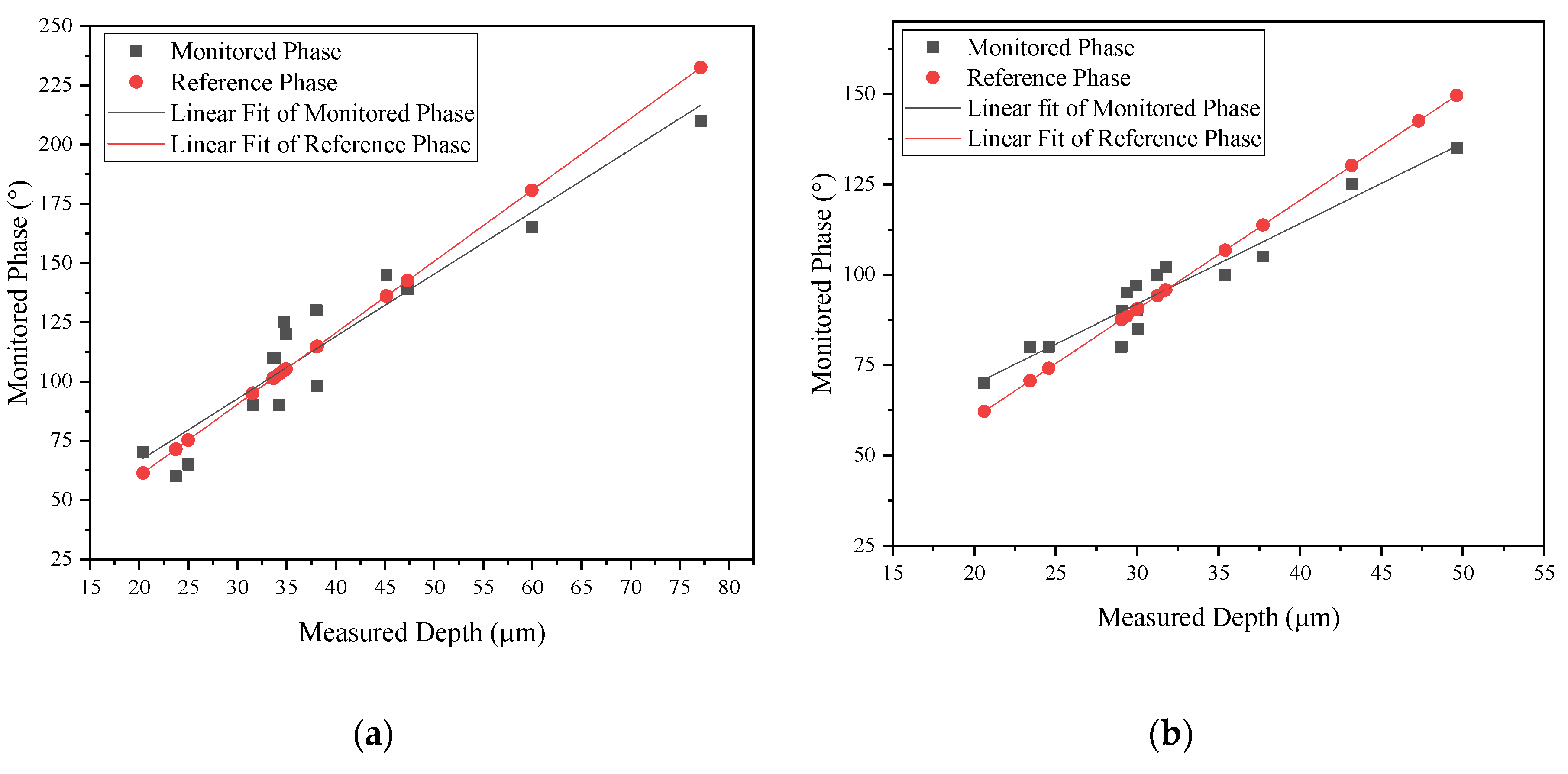

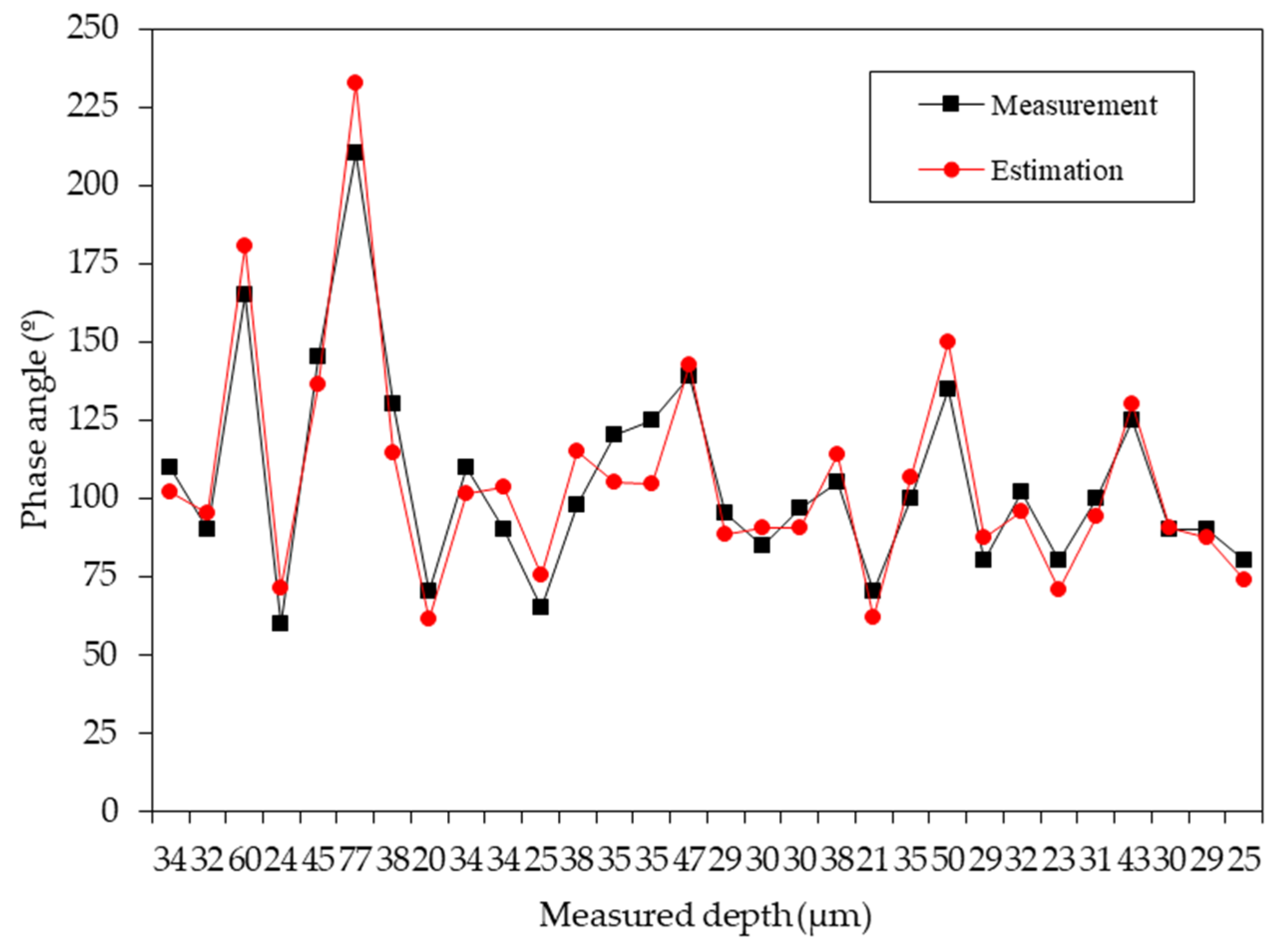

3.4. Comparison Phase Angle Signal

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Antony, J.; Swarnakar, V.; Gupta, N.; Kaur, J.; Jayaraman, R.; Tortorella, G.L.; Cudney, E. Critical success factors for operational excellence initiatives in manufacturing: a meta-analysis. Total Quality Management & Business Excellence 2023, 34, 1152–1172. [Google Scholar]

- Ehrampoosh, A.; Shirinzadeh, B.; Pinskier, J.; Smith, J.; Moshinsky, R.; Zhong, Y. A force-feedback methodology for teleoperated suturing task in robotic-assisted minimally invasive surgery. Sensors 2022, 22, 7829. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Zhang, Q.; Tan, Z.; Wang, L.; Li, Z.; Ma, G. Investigation of steel wire mesh reinforcement method for 3D concrete printing. Archives of Civil and Mechanical Engineering 2021, 21, 1–18. [Google Scholar] [CrossRef]

- Hamta, N.; Ehsanifar, M.; Babai, A.; Biglar, A. Improving the Identification and prioritization of the most important risks of safety equipment in FMEA with a hybrid multiple criteria decision-making technique. Journal of applied research on industrial engineering 2021, 8, 1–16. [Google Scholar]

- Lampman, S.; Mulherin, M.; Shipley, R. Nondestructive testing in failure analysis. Journal of Failure Analysis and Prevention 2022, 22, 66–97. [Google Scholar] [CrossRef]

- Rudenko, S.; Berladir, K.V.; Trojanowska, J.; Varenyk, S.; Shvetsov, D.; Kravets, V. Application of FMEA for assessment of the polymer composite materials quality. 2021, 8, 12–18.

- Kumpati, R.; Skarka, W.; Ontipuli, S.K. Current trends in integration of nondestructive testing methods for engineered materials testing. Sensors 2021, 21, 6175. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Guo, F.; Gao, H.; Li, M.; Zhang, Y.; Zhou, H. Defect detection of injection molding products on small datasets using transfer learning. Journal of manufacturing processes 2021, 70, 400–413. [Google Scholar] [CrossRef]

- Supapan, J.; Chutima, P. Defect reduction in the manufacturing process of in-mould decoration of injection moulded components. In Proceedings of the Materials Science Forum; 2019; pp. 181–188. [Google Scholar]

- Chuenyindee, T.; Prasetyo, Y.T. Roller chains quality enhancement using Six Sigma and failure mode and effects analysis (FMEA). In Proceedings of the Proceedings of the 2020 2nd International Conference on Management Science and Industrial Engineering, 2020; pp. 219–224.

- Baynal, K.; Sarı, T.; Akpınar, B. Risk management in automotive manufacturing process based on FMEA and grey relational analysis: A case study. Advances in Production Engineering & Management 2018, 13, 69–80. [Google Scholar]

- Du, Z.; Tang, K.; Ferro, P. Quantitative analyses on geometric shape effect of microdefect on fatigue accumulation in 316L stainless steel. Engineering Fracture Mechanics 2022, 269, 108517. [Google Scholar] [CrossRef]

- Xiao, Z.; Xu, C.; Xiao, D.; Peng, G.; Li, X. Ultrasonic Adaptive Detection for Aerospace Components with Varying Thickness. Mathematical Problems in Engineering 2017, 2017. [Google Scholar] [CrossRef]

- Tran, K.; Phan, H.; Lee, H.; Kim, Y.; Park, H. Blocking force of a piezoelectric stack actuator made of single crystal layers (PMN-29PT). Smart Materials and Structures 2016, 25, 095038. [Google Scholar] [CrossRef]

- Cao, H.; Jiang, M.; Jia, L.; Ma, M.; Sun, L.; Zhang, L.; Tian, A.; Liang, J. An ultrasonic signal processing method to improve defect depth estimation in composites based on empirical mode decomposition. Measurement Science and Technology 2021, 32, 115112. [Google Scholar] [CrossRef]

- Moskovchenko, A.; Švantner, M.; Vavilov, V.; Chulkov, A. Analyzing probability of detection as a function of defect size and depth in pulsed IR thermography. NDT & E International 2022, 130, 102673. [Google Scholar]

- Cheshideh, H.; Nasirpouri, F.; Mardangahi, B.; Jabbarpour, A. Failure analysis and preventive recommendations against corrosion of steel tubes of gas risers in natural gas urban distribution lines. Engineering Failure Analysis 2021, 122, 105240. [Google Scholar] [CrossRef]

- Ammar, M.M.A.; Shirinzadeh, B.; Zhao, P.; Shi, Y. An approach for damage initiation and propagation in metal and carbon fiber hybrid composites manufactured by robotic fiber placement. Composite Structures 2021, 268. [Google Scholar] [CrossRef]

- Ito, K.; Kusano, M.; Demura, M.; Watanabe, M. Detection and location of microdefects during selective laser melting by wireless acoustic emission measurement. Additive Manufacturing 2021, 40, 101915. [Google Scholar] [CrossRef]

- Amado, J.Q. Manufacture and testing of lightweight tubes for rocketry and centrifuges. In Lightweight composite structures in transport; Elsevier: 2016; pp. 421–437.

- Xu, R.; Xu, Q. A Survey of Recent Developments in Magnetic Microrobots for Micro-/Nano-Manipulation. Micromachines 2024, 15, 468. [Google Scholar] [CrossRef] [PubMed]

- Safri, S.N.A.B.; Sultan, M.; Jawaid, M. Damage analysis of glass fiber reinforced composites. In Durability and life prediction in biocomposites, fibre-reinforced composites and hybrid composites; Elsevier: 2019; pp. 133–147.

- Armendáriz, I.; Millán, J.S.; Encinas, J.M.; Olarrea, J. Strategies for dynamic failure analysis on aerospace structures. In Handbook of Materials Failure Analysis with Case Studies from the Aerospace and Automotive Industries; Elsevier: 2016; pp. 29–55.

- Schwalb, W.; Shirinzadeh, B.; Smith, J. A force-sensing surgical tool with a proximally located force/torque sensor. The International Journal of Medical Robotics and Computer Assisted Surgery 2017, 13, e1737. [Google Scholar] [CrossRef]

- Batty, T.; Ehrampoosh, A.; Shirinzadeh, B.; Zhong, Y.; Smith, J. A transparent teleoperated robotic surgical system with predictive haptic feedback and force modelling. Sensors 2022, 22, 9770. [Google Scholar] [CrossRef]

- Park, C.; Choi, S.; Won, S. Vision-based inspection for periodic defects in steel wire rod production. Optical Engineering 2010, 49, 017202–017202. [Google Scholar]

- Chen, Z.; Deng, J.; Zhu, Q.; Wang, H.; Chen, Y. A systematic review of machine-vision-based leather surface defect inspection. Electronics 2022, 11, 2383. [Google Scholar] [CrossRef]

- Tran, K.S.; Shirinzadeh, B.; Ehrampoosh, A.; Zhao, P.; Shi, Y. Detection, Verification and Analysis of Micro Surface Defects in Steel Filament Using Eddy Current Principles, Scanning Electron Microscopy and Energy-Dispersive Spectroscopy. Sensors 2023, 23, 8873. [Google Scholar] [CrossRef] [PubMed]

- Echeta, I.; Dutton, B.; Leach, R.K.; Piano, S. Finite element modelling of defects in additively manufactured strut-based lattice structures. Additive Manufacturing 2021, 47, 102301. [Google Scholar] [CrossRef]

- Menzies, I.; Koshy, P. In-process detection of surface porosity in machined castings. International Journal of Machine Tools and Manufacture 2009, 49, 530–535. [Google Scholar] [CrossRef]

- Damon, J.; Dietrich, S.; Gorantla, S.; Popp, U.; Okolo, B.; Schulze, V. Process porosity and mechanical performance of fused filament fabricated 316L stainless steel. Rapid Prototyping Journal 2019, 25, 1319–1327. [Google Scholar] [CrossRef]

- Zhang, X.; Krewet, C.; Kuhlenkötter, B. Automatic classification of defects on the product surface in grinding and polishing. International Journal of Machine Tools and Manufacture 2006, 46, 59–69. [Google Scholar] [CrossRef]

- Simoneau, A.; Ng, E.; Elbestawi, M. Surface defects during microcutting. International Journal of Machine Tools and Manufacture 2006, 46, 1378–1387. [Google Scholar] [CrossRef]

- Wu, B.; Wang, Y.J.; Liu, X.C.; He, C.F. A novel TMR-based MFL sensor for steel wire rope inspection using the orthogonal test method. Smart Materials and Structures 2015, 24. [Google Scholar] [CrossRef]

- Gao, Y.; Tian, G.Y.; Wang, P.; Wang, H.; Gao, B.; Woo, W.L.; Li, K. Electromagnetic pulsed thermography for natural cracks inspection. Scientific reports 2017, 7, 42073. [Google Scholar] [CrossRef]

- Zhou, P.; Zhou, G.; Wang, S.; Wang, H.; He, Z.; Yan, X. Visual Sensing Inspection for the Surface Damage of Steel Wire Ropes With Object Detection Method. IEEE Sensors Journal 2022, 22, 22985–22993. [Google Scholar] [CrossRef]

- Saludes-Rodil, S.; Baeyens, E.; Rodriguez-Juan, C.P. Unsupervised classification of surface defects in wire rod production obtained by eddy current sensors. Sensors (Basel) 2015, 15, 10100–10117. [Google Scholar] [CrossRef] [PubMed]

- Clark, L.; Shirinzadeh, B.; Tian, Y.; Oetomo, D. Laser-based sensing, measurement, and misalignment control of coupled linear and angular motion for ultrahigh precision movement. IEEE/ASME Transactions on Mechatronics 2014, 20, 84–92. [Google Scholar] [CrossRef]

- Zhang, W.; Bu, J.; Li, D.; Zhang, K.; Zhou, M. Coupling Interference between Eddy Current Sensors for the Radial Displacement Measurement of a Cylindrical Target. Sensors 2022, 22, 4375. [Google Scholar] [CrossRef] [PubMed]

- García-Martín, J.; Gómez-Gil, J.; Vázquez-Sánchez, E. Non-destructive techniques based on eddy current testing. Sensors 2011, 11, 2525–2565. [Google Scholar] [CrossRef]

| Symbols | Unit | Definition | Value |

|---|---|---|---|

| σ | S/m | Electrical conductivity | |

| μ | H/m | Magnetic permeability | |

| ω | Radian/second | Frequency |

| Sample No. | Defect depth Batch 1 (μm) |

Defect depth Batch 2 (μm) |

Sample No. | Defect depth Batch 1 (μm) |

Defect depth Batch 2 (μm) |

|---|---|---|---|---|---|

| 1 | 33.86 | 29.37 | 9 | 33.62 | 31.76 |

| 2 | 31.53 | 30.06 | 10 | 34.26 | 23.43 |

| 3 | 59.94 | 29.95 | 11 | 24.97 | 31.23 |

| 4 | 23.70 | 37.73 | 12 | 38.10 | 43.18 |

| 5 | 45.14 | 20.61 | 13 | 34.91 | 29.97 |

| 6 | 77.11 | 35.41 | 14 | 34.75 | 29.07 |

| 7 | 38.03 | 49.62 | 15 | 47.28 | 24.58 |

| 8 | 20.38 | 29.04 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).