1. Introduction

Reducing energy consumption and minimizing environmental pollution are significant concerns globally, with the building industry being a major contributor to energy use and carbon emissions [

1]. According to the “China Building Energy Consumption and Carbon Emission Research Report” (2023) [

2], in 2021, the operational energy consumption of buildings in China was 1.15 billion tce, accounting for 21.9% of the total national energy consumption, with northern winter heating constituting a significant portion of this. Currently, traditional heating methods are commonly used in rural winter heating in China’s cold regions, such as burning coal, wood, and using sunrooms on the southern side of houses. However, burning fuels results in high energy consumption and pollution, affecting residents’ health [

3]. Sunrooms have large temperature fluctuations and limited heating effects. Some buildings use new heating methods such as solar energy, air source heat pumps (ASHP), and ground source heat pumps (GSHP) [

4]. However, GSHPs have high costs and site limitations [

5], and solar thermal systems can face issues like pipeline freezing and cracking in low-temperature environments. ASHPs face serious frosting issues and high operational costs in low-temperature environments. Considering equipment cost, system complexity, and operational stability, ASHP systems have significant potential for winter heating in cold regions [

6].

ASHPs generally use compression-type heat pumps, relying on the Carnot cycle theorem, using outdoor air as the heat source, and consuming a small amount of high-grade energy such as electricity to produce a large amount of low-grade heat energy, thus achieving energy savings [

7]. The heating performance of ASHPs in winter in cold regions is mainly limited by ambient temperature. In low temperatures, the coefficient of performance (COP) and heating capacity of the heat pump are affected [

8]. To solve these issues, many scholars have conducted research and attempts through various methods. In recent years, many researchers have proposed schemes to couple ASHPs with solar energy to mitigate and reduce the impact of environmental temperature on ASHP heating [

9]. Li et al. [

10] compared the performance of ASHP coupled with solar vacuum tube water heaters and micro-heat pipe PV/T systems, finding that the MHP-PV/T-ASHP heating system performed better than the SETWH-ASHP system, with solar energy utilization increasing by 19%, system energy efficiency ratio increasing by 2.2%, and primary energy saving rate increasing by 12.3%. Han et al. [

11] studied the performance of a combined solar and heat pump heating system, showing significant energy savings compared to traditional distributed coal heating and hot water supply, up to 43.55%. Ni et al. [

12] conducted experimental research on the annual operation of a solar and ASHP heating system using a three-pipe energy storage heat exchanger. They found that the higher the temperature and flow rate of the hot water on the solar side, the higher the system’s heating energy efficiency. Although the heating performance of solar-coupled heat pump systems has been widely discussed, current combined heating systems mainly use water for heat storage.

In addition, some scholars have found that combining phase change heat storage (PCHS) with ASHP systems can achieve peak electricity regulation and provide better low-temperature adaptability for the heat pump [

13]. These approaches include combining phase change materials (PCM) with the evaporative side, condensing side, or heat exchanger of ASHPs [

14]. J. Gao et al. [

15] proposed a solar-coupled ASHP system with phase change heat storage, showing that the average power consumption of the compressor was 1.87 kW, reducing by 21.1%, and the system’s average COP was 5.42, 143.0% higher than the original system. Mazo et al. [

16] found that when the heating load reached 25 kWh, continuous heat storage for 7 hours was required, with a heat storage capacity of 1116 liters in the PCHS unit. They developed a radiant heating terminal based on PCHS and combined it with an ASHP system for combined heating. The results showed that this approach could meet the heating needs of buildings throughout the day. Zou et al. [

17] designed a new water-PCM heat storage device for ASHP water heaters, showing that the volume of the heat storage container increased by only 6%, while the total heat storage capacity increased by 14%.

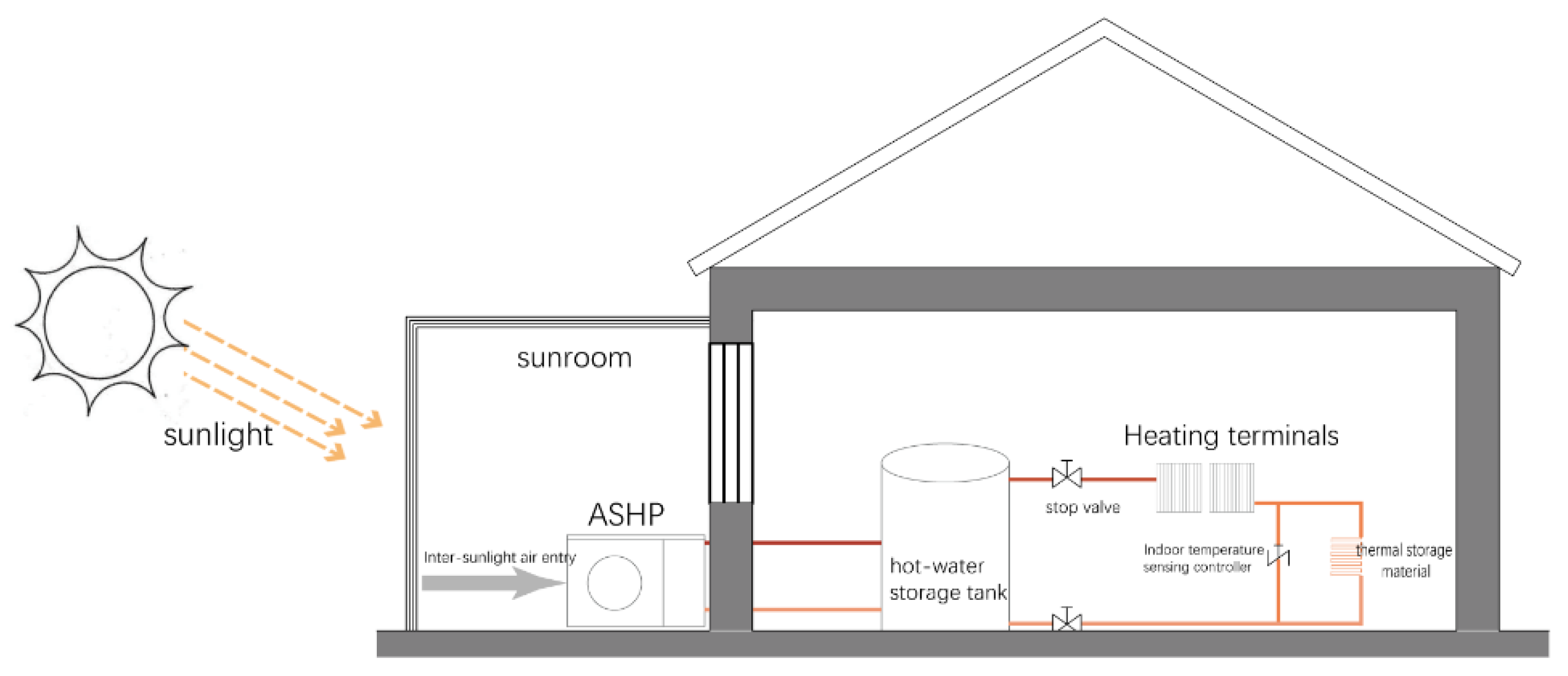

Existing literature shows that many researchers have extensively studied and optimized ASHP systems. The above research content has solved some of the winter heating problems of ASHPs in cold climates to varying degrees. However, the complexity and operational stability of various systems remain insufficient. Addressing these issues, we propose a coupled heating scheme of ASHP and passive heating. This system mainly consists of an ASHP unit, a heat storage water tank, a heating terminal, and a passive sunroom. The ASHP is used as the heating equipment for the building, and the sunroom provides suitable working conditions for the ASHP. During winter days, the sunroom collects solar energy, raising the internal temperature, providing a good working environment for the ASHP [

18]. The high-temperature air inside the sunroom acts as the heat source for the ASHP, requiring less air than outdoor operation to obtain the same amount of heat, significantly improving the heating efficiency of the ASHP. Additionally, the suitable ambient temperature reduces the frosting probability of the ASHP evaporator pump. To address the lack of solar energy at night, phase change materials and heat storage media are proposed to be used in the building to store excess heat during the day and release it at night, thus meeting the heating needs throughout the day. The working principle of the system is shown in

Figure 1. This paper uses DesignBuilder, Trnsys, and other software for simulation and mathematical analysis, comparing the coupled scheme with traditional schemes to explore the heating situation and energy-saving effects of the ASHP and passive heating coupled system in rural homes in Harbin, China’s cold regions.

2. Methods

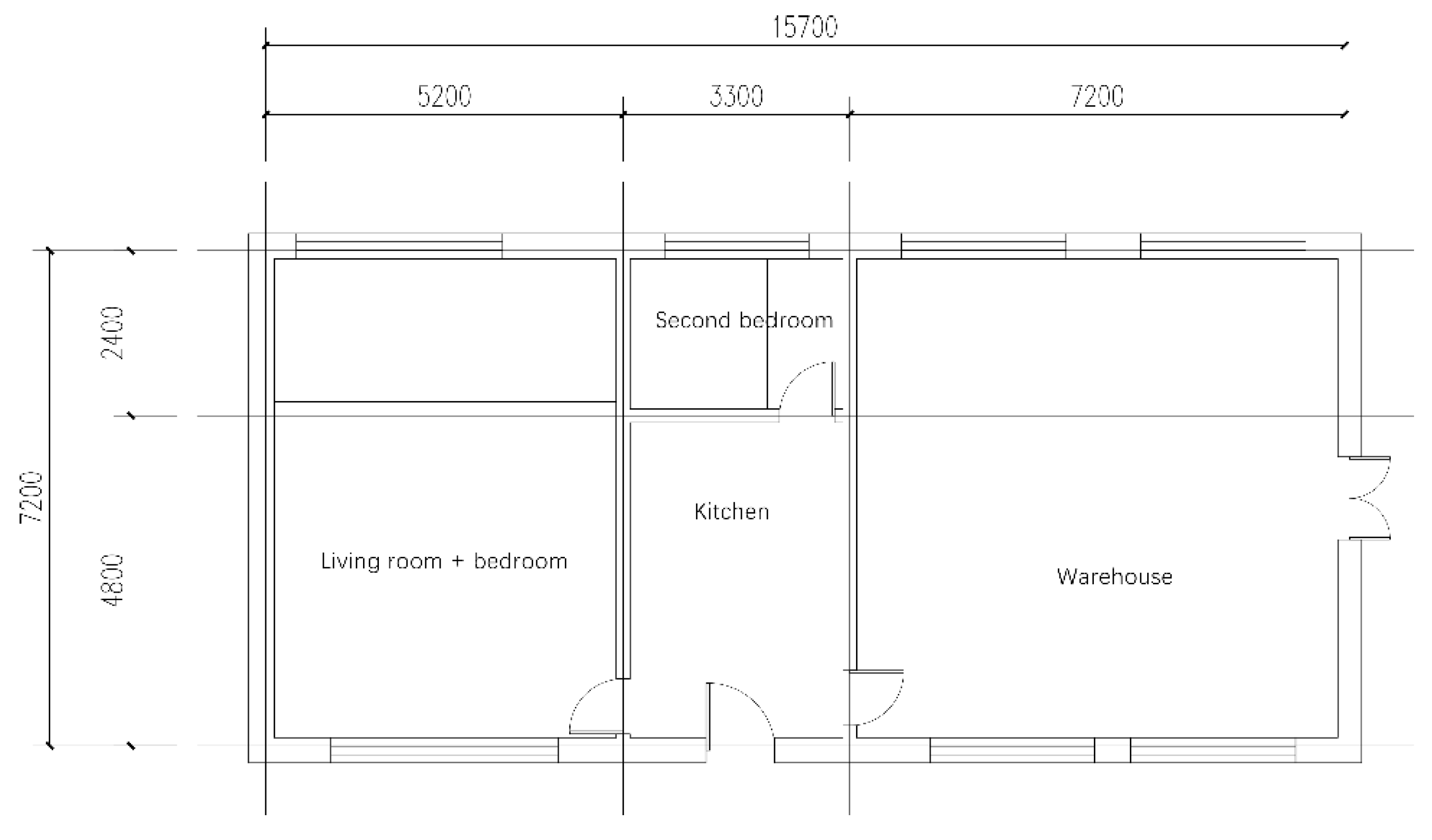

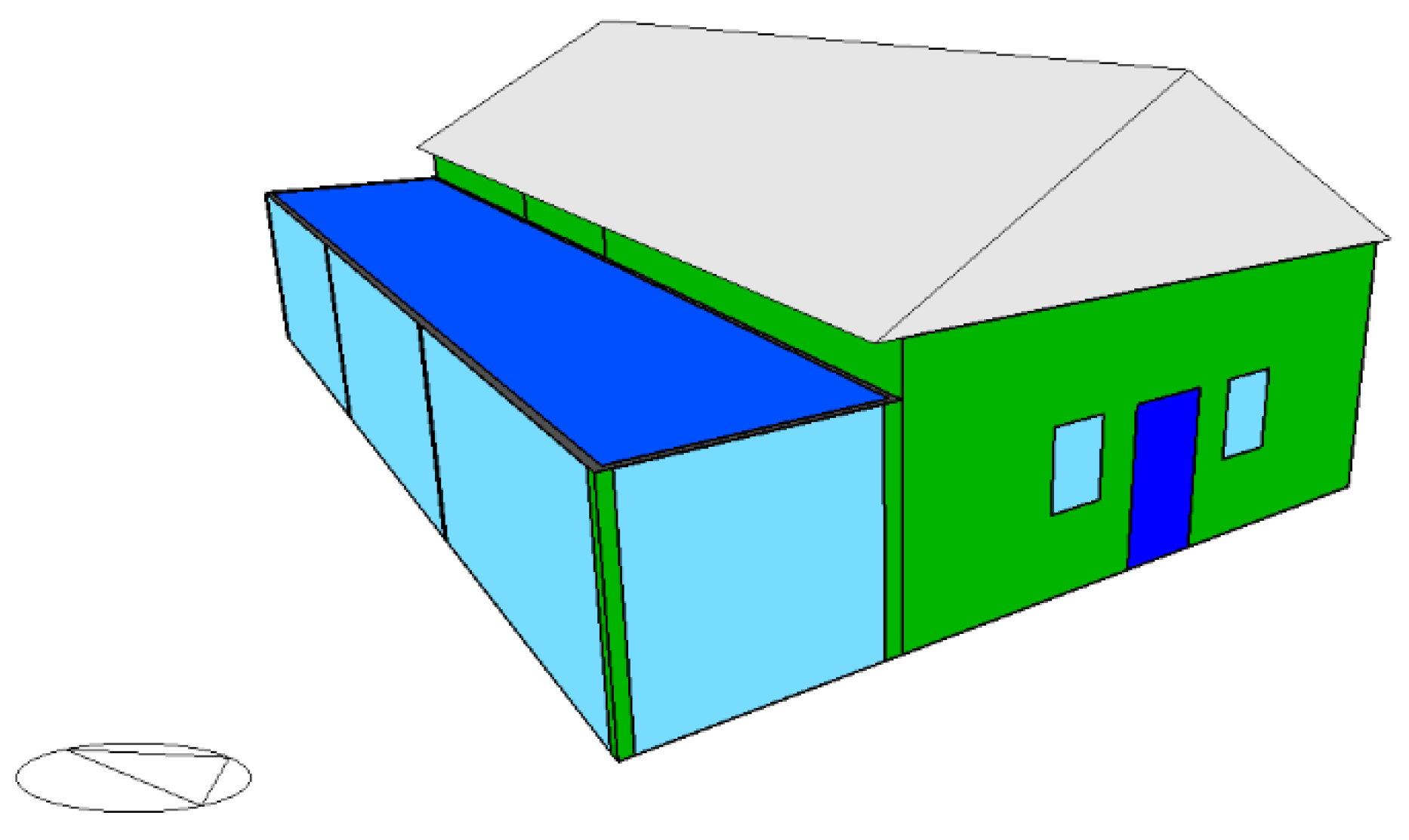

The study focuses on a single-story farmhouse in Harbin, China (latitude: 46.5°, longitude: 128.44°), as shown in

Figure 2. Located in the severe cold region of China’s thermal design zones, the building has an east-west length of 15.7 meters, a north-south width of 7.2 meters, and a floor height of 3.3 meters. The main bedroom and living area are combined and located on the southwest side of the building. The east side is used for storage, and the middle section houses the kitchen and secondary bedroom. An additional sunroom is attached to the south side of the building, measuring 15.7 meters by 3 meters with a height of 2.7 meters. The sunroom features double-glazed transparent glass and an aluminum frame on its east, west, and south sides, as well as on the roof. The south exterior wall of the living room has a window measuring 3.3 meters by 1.5 meters with a sill height of 0.9 meters. The north exterior wall has a window measuring 3.0 meters by 1.5 meters. The south side of the kitchen has an exterior door measuring 0.9 meters by 2.0 meters, and the north side of the secondary bedroom has a window measuring 2.4 meters by 1.5 meters. There are internal doors measuring 0.8 meters by 2 meters between the living room and the kitchen, and between the kitchen and the secondary bedroom. The floor plan of the farmhouse is shown in

Figure 3.

2.1. Building Model Establishment

The basic information of the farmhouse is shown in

Table 1:

The designed indoor temperature for heating in the room is 20.0℃. The lighting power density is 5W/m2, and the internal personnel density is 0.11 people/㎡. The airtight infiltration is set to 0.7arc/h. The room is also equipped with some electrical appliances, with an average electrical load of 0.650KW. The building’s envelope heat transfer coefficients are shown in

Table 2, meeting the requirements of the “Rural Residential Building Energy Saving Design Standards” (GB/T 50824-2013)[

19].

Based on the above building information, a typical rural residential building model was established in the DB software, and parameter settings for the envelope structure’s thermal performance were configured. The model is shown in

Figure 4:

2.2. Air Source Heat Pump Model Establishment

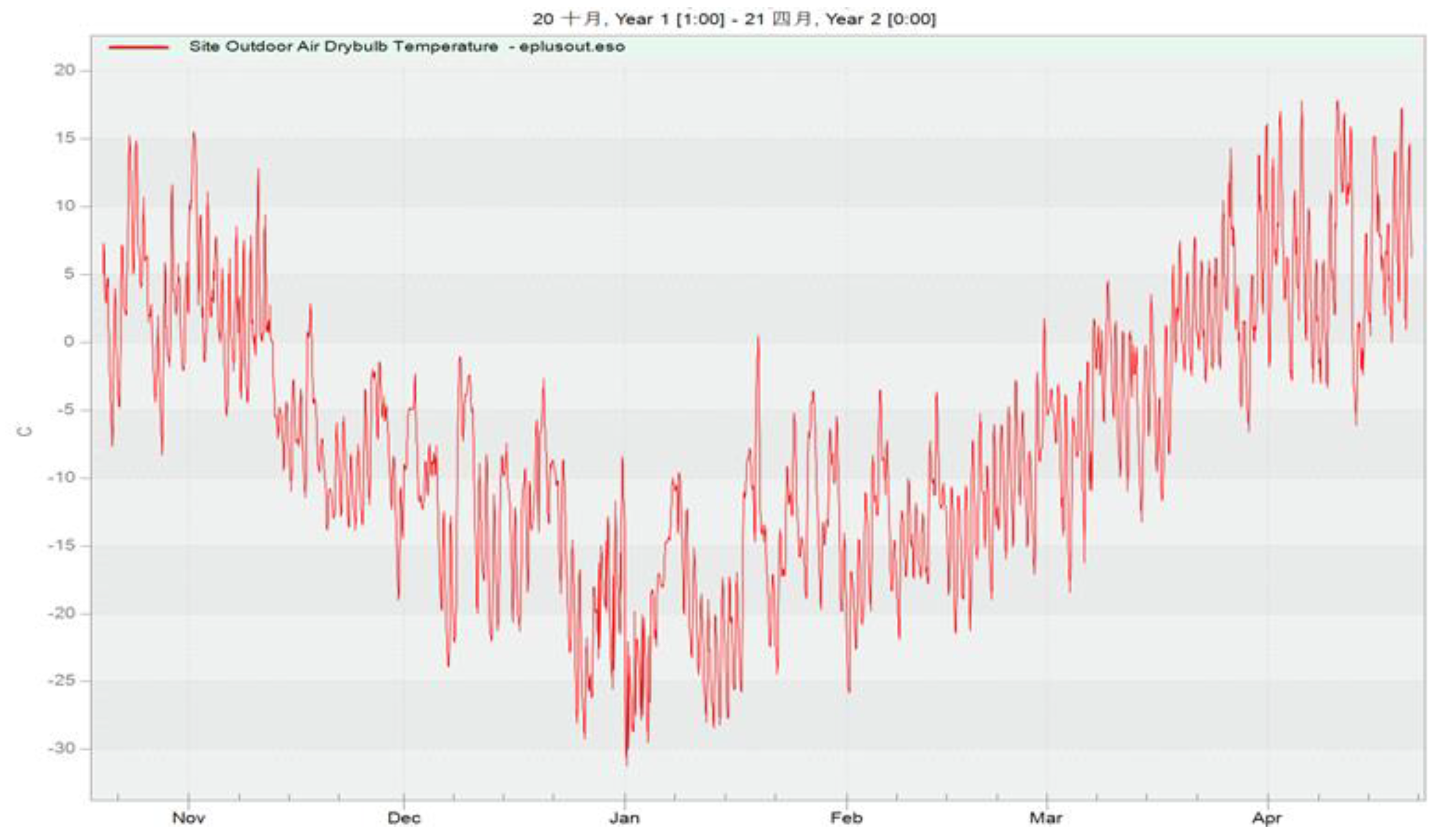

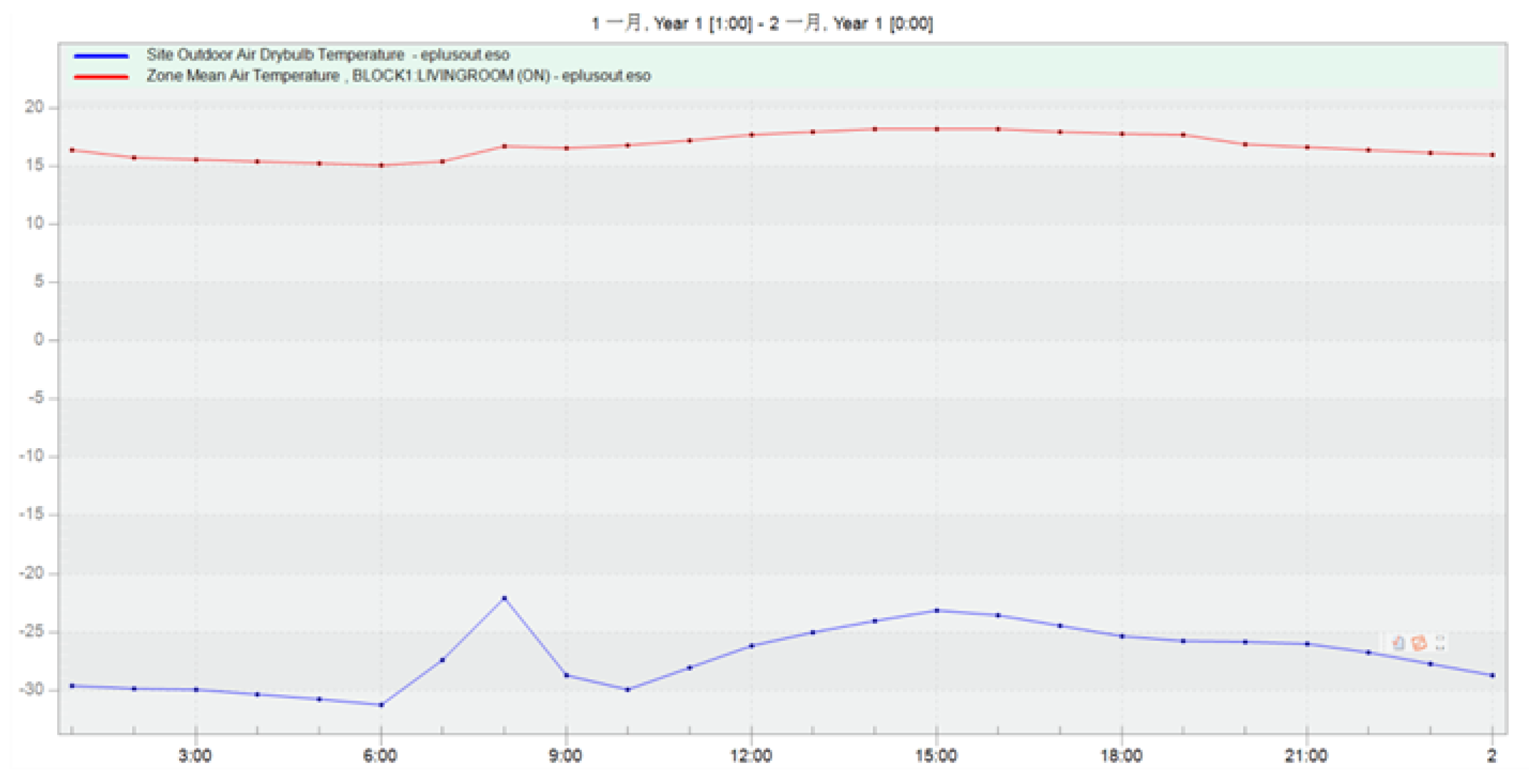

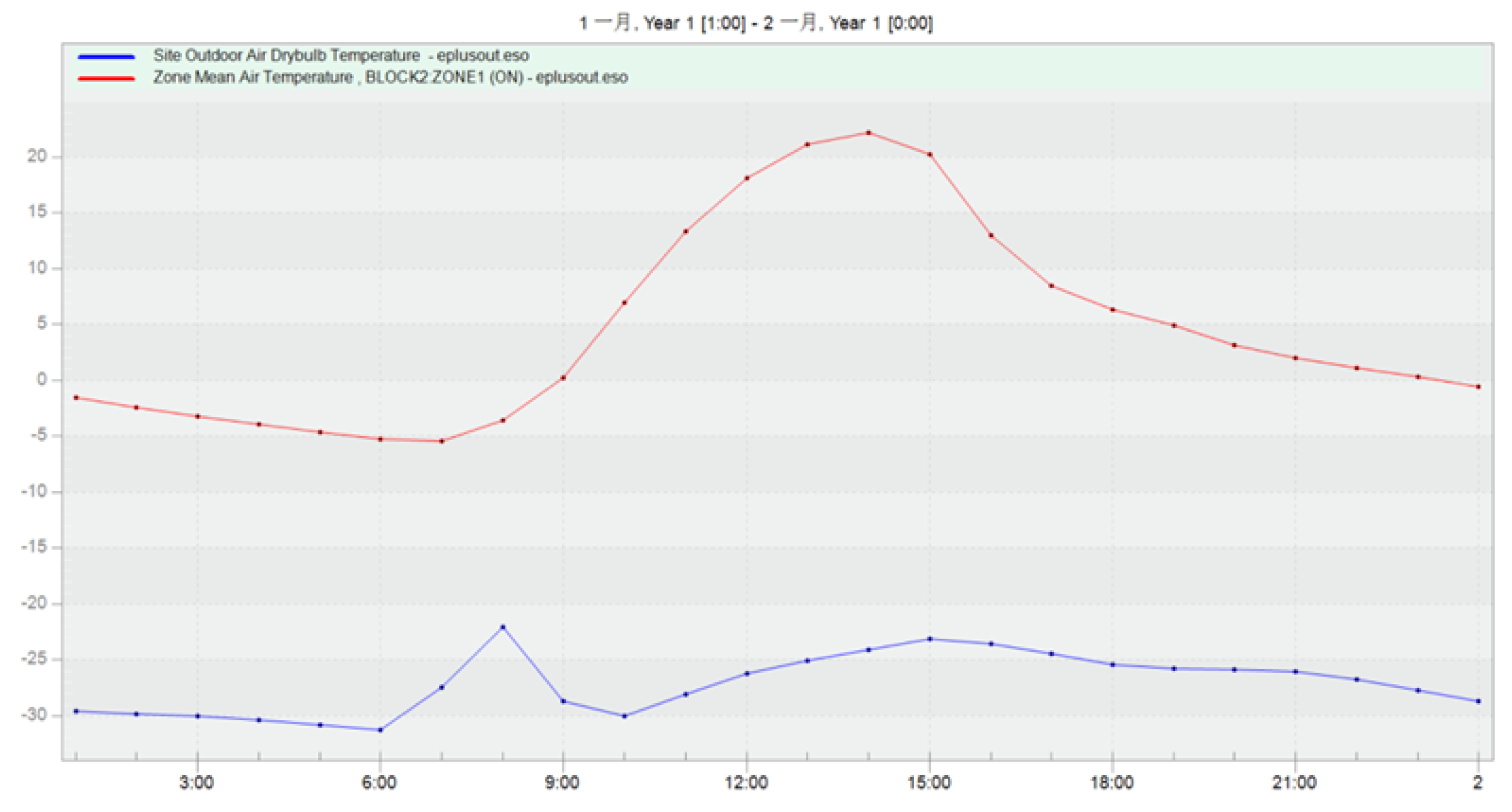

Based on typical meteorological conditions in Harbin, the simulation period is set for the coldest month of January (January 1 to January 31). Typical hourly dry-bulb temperatures for a typical year in Harbin were extracted from EnergyPlus, as shown in

Figure 5, with an average temperature of -7.12°C and the lowest temperature on January 1, with a daily average temperature of -26.99°C.

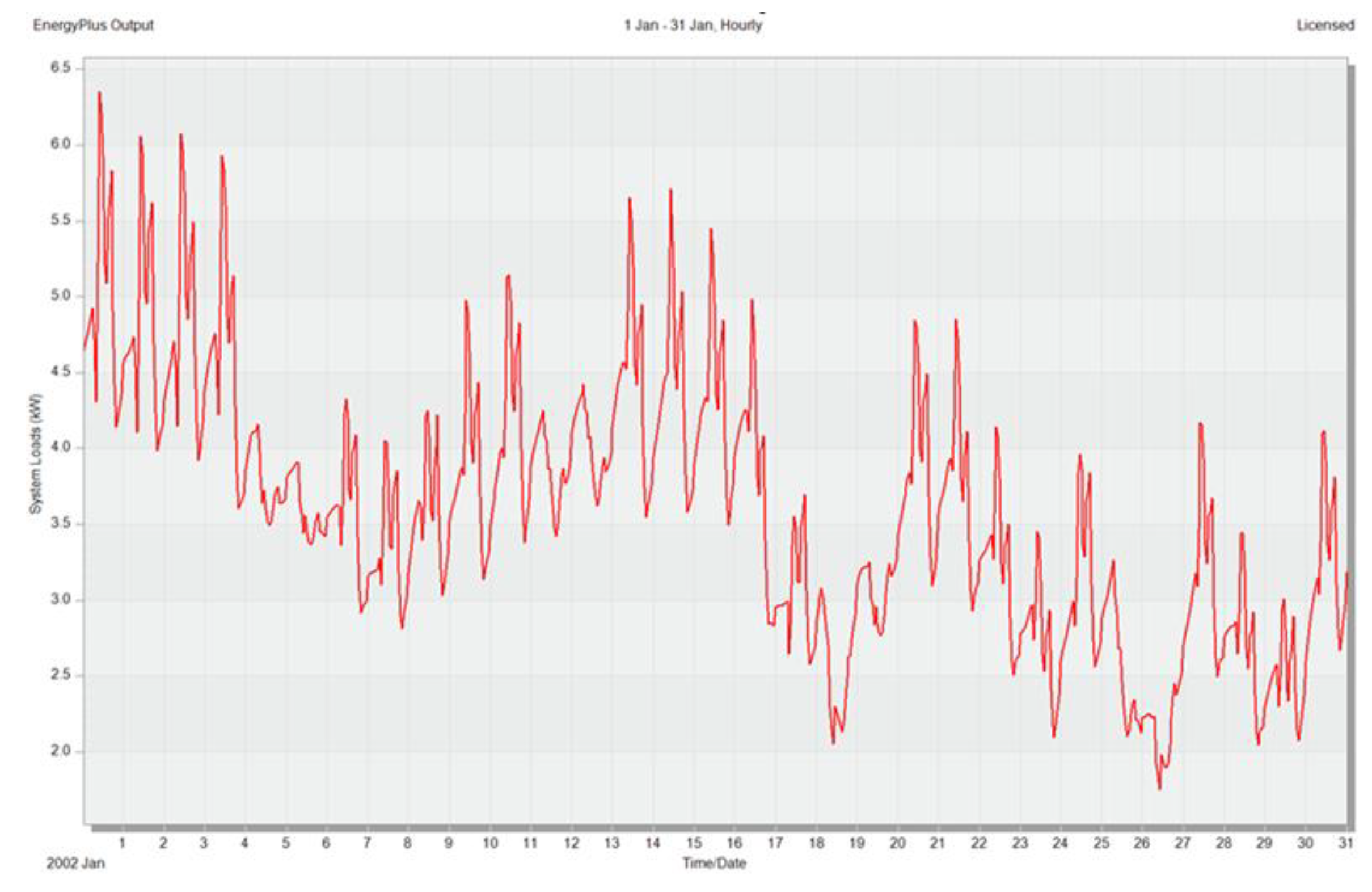

Simulation analysis of the building’s heating load during the heating period was conducted using DesignBuilder software to aid in the selection and calculation of the air source heat pump. The hourly heating load of the building is shown in

Figure 6, with a cumulative heating load of 2677.569kWh and a maximum hourly heating load of 6.35kWh during the operational period.

Based on the above building parameters and thermal load data analysis, this study selected a low-temperature air source heat pump from a particular brand, model RY14-NcPB5U1, with a design supply and return water temperature of 45/40°C, and a minimum operating temperature of -25°C. Radiant heating is used as the terminal heating method. Specific parameters of the heat pump system are shown in

Table 3. The parameters of the air source heat pump were set and modeled in DB software as shown in

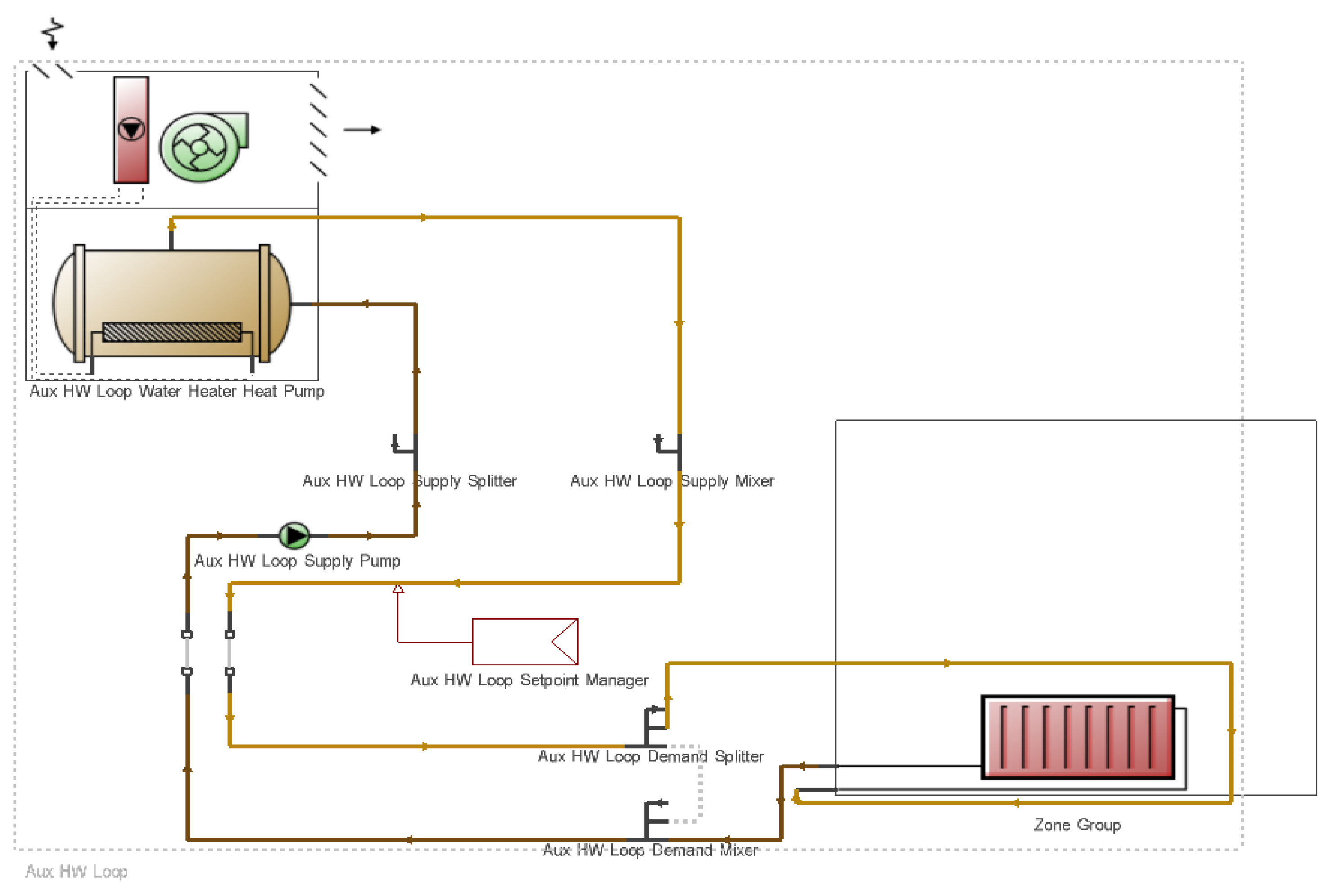

Figure 7.

2.3. Simulation and Analysis

This study involves two operational conditions: Mode 1 and Mode 2. Mode 1 involves the traditional air source heat pump (ASHP) placed outdoors for heating, while Mode 2 combines the ASHP with a passive heating system. The operational efficiency and energy consumption of both modes are compared to analyze the feasibility and energy consumption of the ASHP combined with the passive heating system.

2.3.1. Simulation and Analysis of Traditional Mode (Mode I)

Using the simulation system built in DB, the outdoor unit of the air source heat pump is placed outside the building to operate at the outdoor dry bulb temperature. The operation of the heat pump is controlled by the indoor temperature, starting when the indoor temperature is below 20°C and stopping when it is above 20°C. Additionally, electric heating of the water tank is used as auxiliary heating when the outdoor temperature is too low for the heat pump to provide sufficient heat, with a cyclic control mode and an electric heating efficiency of 90%.

Using the above data, the coldest day of the winter, January 1, was selected for analysis. If the heating demand is met on the coldest day, it can be assumed to be sufficient for other days as well. The hourly temperature comparison between the heated room and the outdoor temperature on this day is shown in

Figure 8.

2.3.2. ASHP and Passive Heating Coupled System Simulation and Analysis (Mode 2)

Mode 2 involves a coupled ASHP and passive heating system. In this system, the ASHP outdoor unit is placed inside the passive solar sunroom, with other conditions remaining the same as in Mode 1. The mathematical model and external files are used for calculations, as traditional simulation software cannot execute the operation of placing the ASHP outdoor unit in the sunroom. The building model is still built using DesignBuilder software, with parameters consistent with Mode 1.

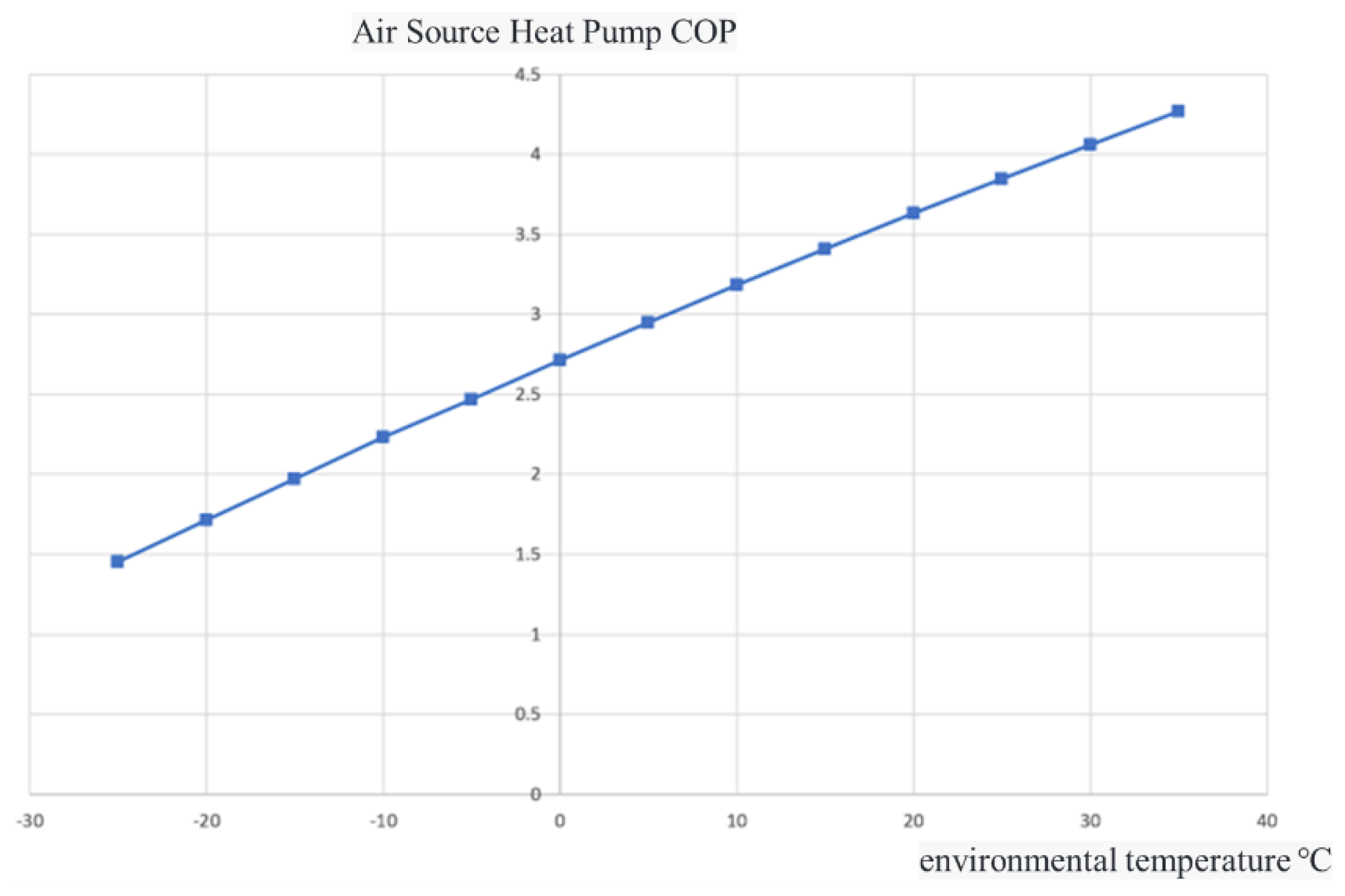

The same ASHP model RY14-NcPB5U1 as in Mode 1 is used. The ASHP model is built using Trnsys software, with the supply and return water temperature set to 45/40°C. The relationship curve between the COP (Coefficient of Performance) and ambient temperature for this ASHP model is shown in

Figure 9.

The energy efficiency of the air source heat pump is primarily determined by the COP value, which is essentially the ratio of the heating capacity achieved by the heat pump system to the input power. By using the simulated analysis results of the heat pump’s COP and the building’s heat load, the input power of the air source heat pump can be calculated. The calculation formula is as follows:

In the formula: COP is the coefficient of performance of the air source heat pump; is the heating capacity of the air source heat pump, in kWh; is the input electrical energy of the air source heat pump, in kWh.

Additionally, based on the calculated heating capacity and input electrical energy of the heat pump, the input heat to the heat pump from the surrounding environment can be determined. The calculation formula is as follows:

In the formula: is the input heat of the air source heat pump, in kWh.

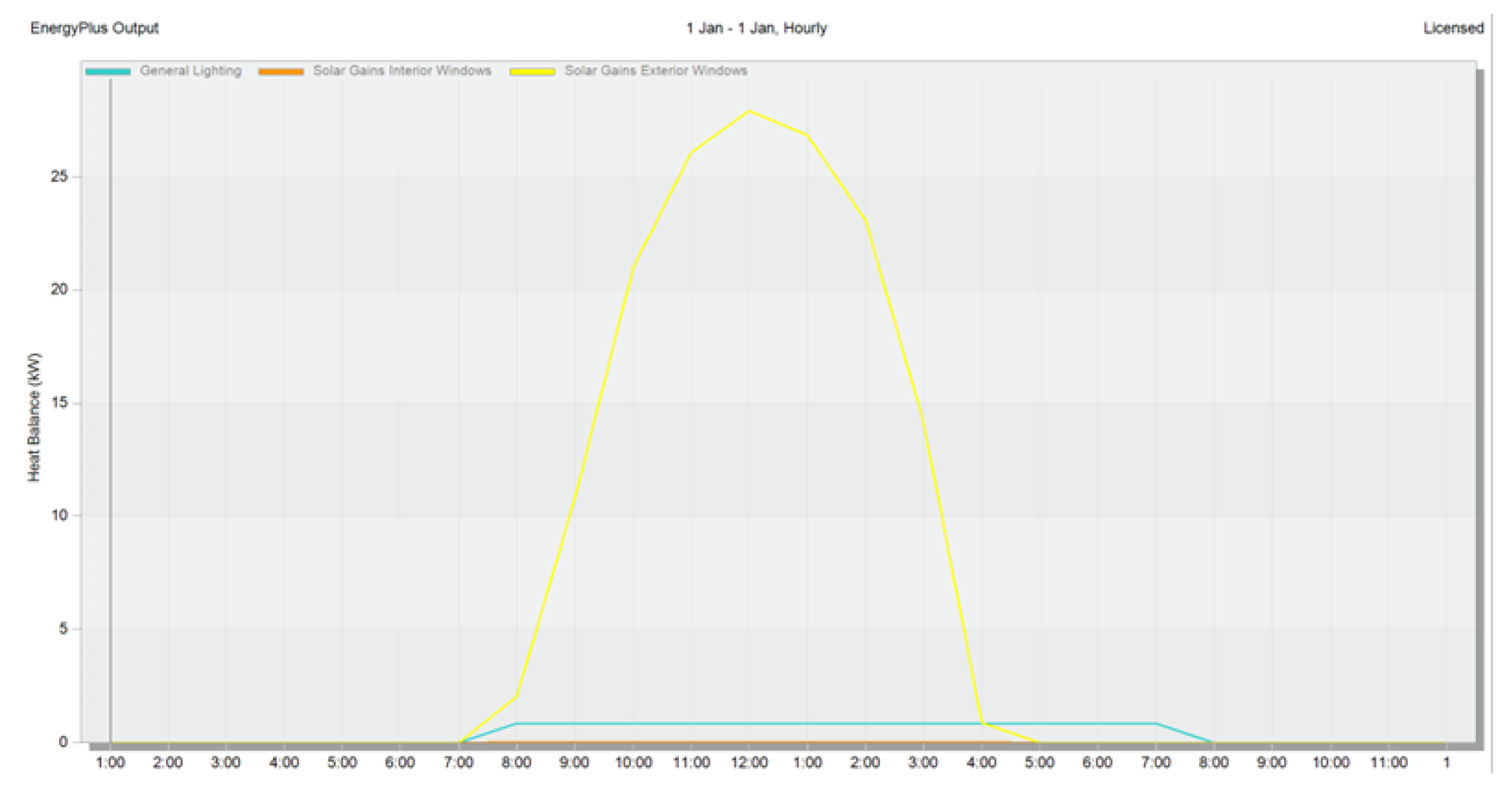

Using the DB software, the internal temperature simulation results of the passive solar sunroom (without heating terminal in the sunroom) on the coldest day, January 1, are shown in

Figure 10. The hourly solar energy gain curve of the sunroom is shown in

Figure 11.

Based on the simulation results, the sunroom receives solar energy from 8:00 AM to 5:00 PM. At 9:00 AM, the temperature in the sunroom reaches 0.22°C. Assuming the ASHP starts operating at 9:00 AM and converts all the solar energy obtained by the sunroom into heat for indoor heating, the sunroom temperature is maintained at 0.22°C. According to the relationship curve between the ASHP COP and ambient temperature, the COP of the heat pump is approximately 2.69 at this temperature. The maximum heating capacity of this ASHP model is 14 kW, and the maximum hourly heat absorption by the heat pump is calculated to be 8.8 kWh. The hourly heat gain of the sunroom is shown in

Table 4, with a total solar energy gain of 152.76 kWh throughout the day.

3. Results and Discussions

3.1. Analysis and Discussion of Operational Results for Mode 1 and Mode 2

The simulation results for Mode 1 are summarized in

Table 5. During the set time period, the indoor temperature consistently reached above 16°C, with an average temperature of 16.74°C, which is 3.26°C lower than the design temperature of 20°C. Under the operational conditions, the electric heating consumption of the water tank was 109.24 kWh, far exceeding the air source heat pump’s electricity consumption of 2.35 kWh. The heat output of the ASHP could not meet the building’s heating load, with most of the heating provided by the electric heating water tank, consuming a total of 111.59 kWh and generating 64.88 kWh of heat.

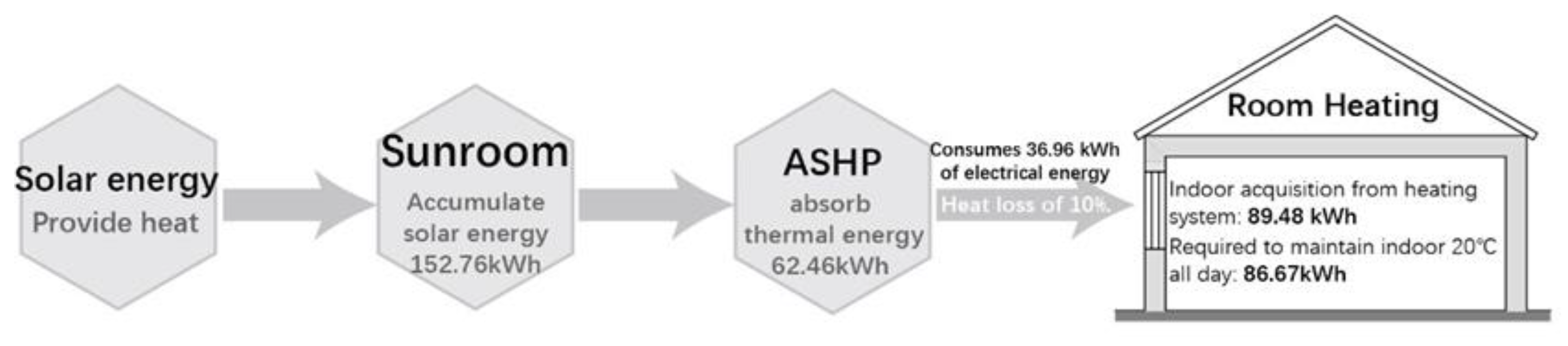

In Mode 2, the ASHP coupled with the sunroom system absorbed approximately 62.46 kWh of heat throughout the day, providing about 99.41 kWh of heat to the indoor space. Assuming a 10% heat loss during the process, the indoor heat gain would be around 89.48 kWh, exceeding the required energy to maintain an indoor temperature of 20°C, which is 86.67 kWh. The total electricity consumption of the system was 36.96 kWh. The analysis is as follows:

In Mode 1, when the outdoor temperature is higher than -25°C, meeting the minimum operating conditions for the ASHP, it can perform heating work. However, at lower temperatures, the heating efficiency of the heat pump decreases. The heating system relies on both the ASHP and the electric heating water tank. When the outdoor temperature drops below -25°C, the ASHP cannot operate, and only the electric heating water tank provides heating;

In Mode 2, the sunroom continuously captures solar energy during the day, maintaining the temperature within the sunroom and providing energy for the ASHP to heat. The entire heating load required by the building is supplied by the ASHP, achieving the design target indoor temperature of 20°C. The heat input to the ASHP is less than the heat gain from the sunroom, indicating that under the given conditions, the heat input to the ASHP can be fully supplied by the sunroom, as shown in

Figure 12;

Mode 2 significantly reduces energy consumption compared to Mode 1. The average electricity consumption is reduced by 74.63 kWh, a decrease of 66.88%. Mode 2 is also simpler to operate by placing the ASHP outdoor unit in the sunroom. Therefore, in practical applications, the ASHP and passive heating coupled system have great prospects for use in extremely cold regions.

3.2. All-Weather Operational Design Strategy and Application

To achieve all-weather use of the air source heat pump (ASHP) in extremely cold regions, the focus is on maintaining indoor thermal comfort during nighttime when solar energy is not available. Therefore, excess heat transported by the ASHP during the day should be stored, and a medium should provide heat for heating during the night. Based on this concept, two feasible solutions are proposed.

Method 1: The ASHP transfers heat to water, using water as a medium to distribute heat to various room terminals for heating. When the indoor temperature reaches the target (20°C), excess heat is stored in the water tank. After the ASHP stops working at night, the water tank continues to provide heating. This method relies on the heat storage capacity of water (or other high specific heat capacity media). To meet the entire night’s heating demand, the water tank must have a sufficiently large volume, which should be selected based on the heating area during the design stage.

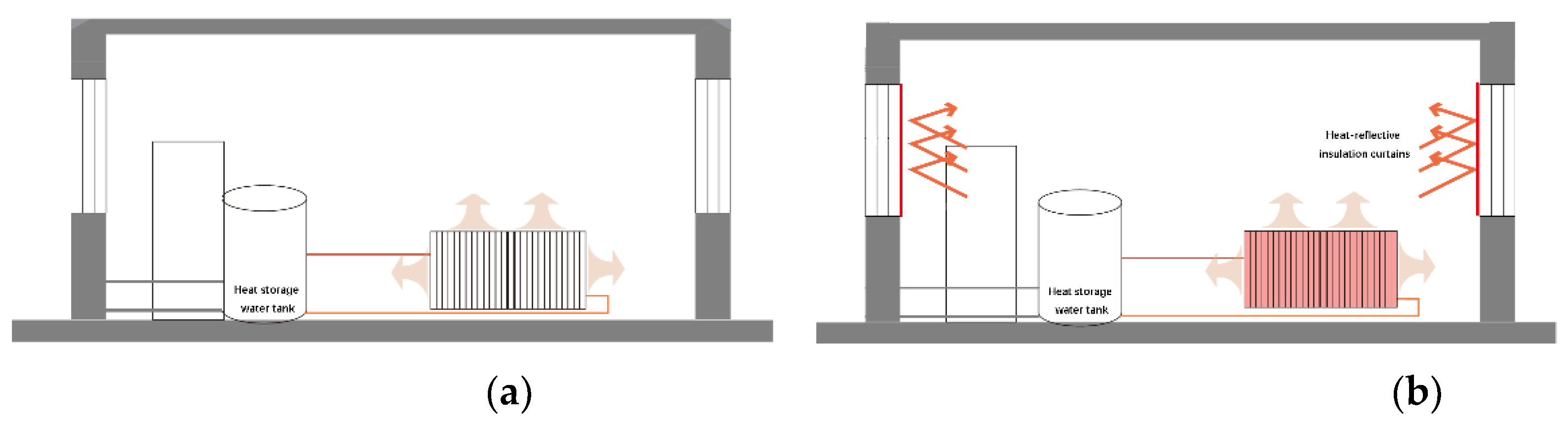

Method 2: Based on Method 1, phase change materials (PCMs) are applied in the building. When the indoor temperature is lower than the PCM temperature, the PCM releases the absorbed heat, thereby slowing down the drop in indoor temperature and reducing heating power and energy consumption [

20]. When the indoor temperature is higher than the PCM temperature, the PCM will reabsorb heat, maintaining the temperature. The application methods of phase change heat storage technology in buildings mainly include the following:

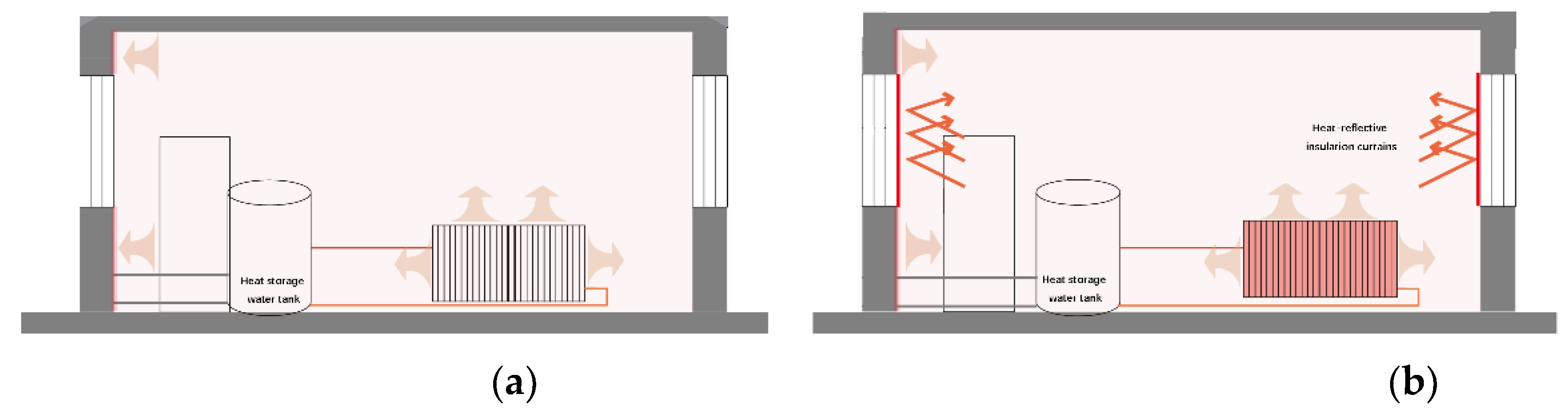

Co-location of PCM and Heating Equipment: The PCM absorbs or releases heat to achieve energy-saving heating. When the heating system is working, the PCM absorbs heat; when the heating system stops operating, the PCM releases the absorbed heat, slowing the drop in indoor temperature [

21], as shown in

Figure 13;

Figure 13.

Co-location of PCM and Heating Equipment: (a) Application during winter day; (b) Application during winter night.

Figure 13.

Co-location of PCM and Heating Equipment: (a) Application during winter day; (b) Application during winter night.

Application of PCM in Building Enclosures of Heating Spaces: The PCM is affected by indoor temperature. When the indoor temperature is higher than the PCM temperature, it absorbs heat; when the indoor temperature is lower than the PCM temperature, it releases the absorbed heat [

22], as shown in

Figure 14;

Figure 14.

Application of PCM in Building Enclosures of Heating Spaces: (a) Application during winter day; (b) Application during winter night.

Figure 14.

Application of PCM in Building Enclosures of Heating Spaces: (a) Application during winter day; (b) Application during winter night.

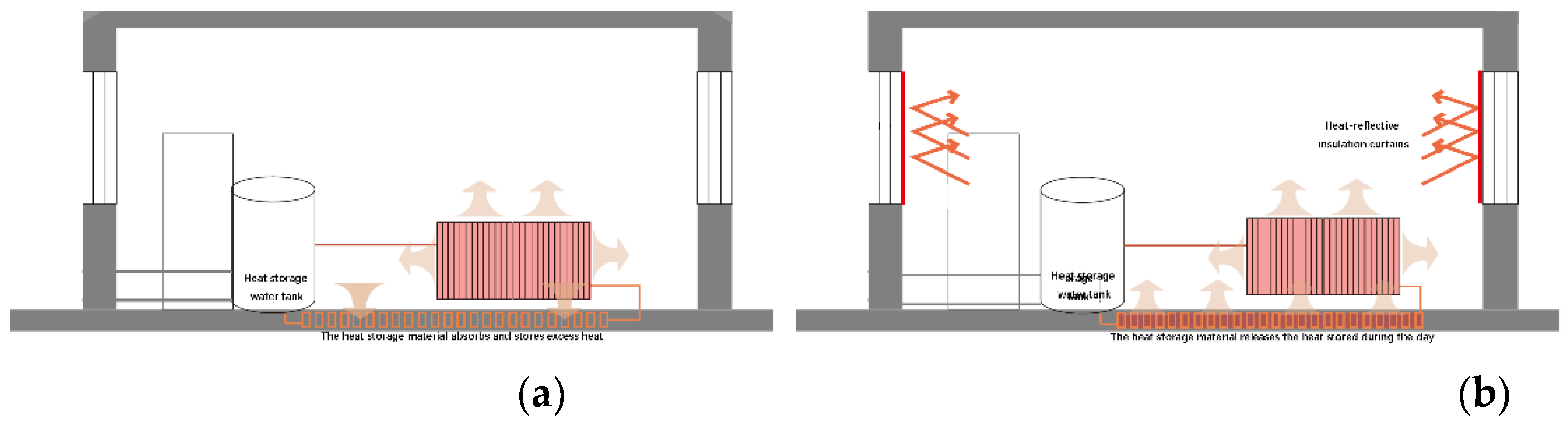

Incorporation of PCM in the Floor: Adding phase change heat storage materials in the floor can also enhance heating efficiency. When the heat medium flows back to the water tank from the heating terminal, it flows through the PCM inside the floor. At night, when the system stops heating, the PCM releases the absorbed heat [

23], as shown in

Figure 15.

Figure 15.

Incorporation of PCM in the Floor: (a) Application during winter day; (b) Application during winter night.

Figure 15.

Incorporation of PCM in the Floor: (a) Application during winter day; (b) Application during winter night.

Compared to Method 1, the addition of PCM can reduce the heating power during the operation of the ASHP, saving heating energy consumption. Secondly, it can slow down the rate of indoor temperature drop, improving the building’s insulation performance.

By adopting suitable methods to temporarily store excess heat and release it when needed, it is possible to rely solely on the ASHP and passive systems for heating during the heating period in extremely cold regions. The design should consider the relationship between the heating area, the heat pump power, and the size of the water tank to maximize cost savings and reduce heating losses.

4. Conclusions

This study investigated the feasibility of coupling an air source heat pump (ASHP) with a passive heating system for heating in extremely cold regions. The performance of two modes was analyzed through simulation: Mode 1 being the traditional ASHP system, and Mode 2 the ASHP combined with passive heating.

(1)Heating Capacity in Extreme Cold Conditions: Under the coldest day conditions in extremely cold regions, the combined ASHP and passive heating system provided a total heating capacity of 99.41 kWh, which is sufficient to maintain an indoor temperature of 20°C throughout the day, requiring 86.67 kWh.

(2)Efficiency Improvement with Sunroom: Placing the ASHP outdoor unit inside a passive sunroom utilizes the higher ambient temperature within the sunroom, significantly improving the COP (Coefficient of Performance) of the ASHP, thereby reducing its electricity consumption. Compared to the traditional system, the combined system’s average electricity consumption decreased by 66.88%, demonstrating excellent energy-saving effects.

(3)Daytime Heat Storage for Nighttime Heating: The study suggests storing excess heat from the passive heating system during the day for use at night, addressing the issue of not being able to capture solar energy at night. This approach achieves stable heating and energy savings. Compared to traditional heating methods, this system greatly reduces energy consumption while maintaining comfort, further quantifying the application potential of ASHPs in cold regions.

Due to the limitations of this study in simulating the working state of the ASHP in the additional sunroom, continuous dynamic simulation over time was not achieved. The traditional mathematical calculation method used in this study blurred the fluctuations and losses in heat transfer. Future research should focus on the detailed design and simulation of heat storage and release, and optimize the system design through real-world experimental platform simulations.

Funding

This research received no external funding.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The author declares no conflict of interest.

References

- Xu, X.; Yu, H.; Sun, Q.; et al. A critical review of occupant energy consumption behavior in buildings: How we got here, where we are, and where we are headed. Renewable and Sustainable Energy Reviews, 2023, 182, 113396. [Google Scholar] [CrossRef]

- China Building Energy Consumption and Carbon Emissions Research Report (2023). Architecture, 2024, (02): 46-59.

- Li, C.; Li, Z.; Bai, L.; et al. Estimating air pollutant emissions from burning straw for heating in rural Northeast China: Based on the heat load for building heating. Journal of Building Engineering, 2023, 72, 106642. [Google Scholar] [CrossRef]

- Chen, X.; Li, Z.; Dai, L.; et al. Occupant Heating Patterns of Low-Temperature Air-to-Air Heat Pumps in Rural Areas during Different Heating Periods. Buildings, 2023, 13, 679. [Google Scholar] [CrossRef]

- Luo, J.; Zhang, Q.; Liang, C.; et al. An overview of the recent development of the Ground Source Heat Pump (GSHP) system in China. Renewable Energy, 2023, 210, 269–279. [Google Scholar] [CrossRef]

- Di, Y.; Zhao, C.; Lian, X.; et al. Study on the Performance of a New Ultra-Low Temperature Air Source Heat Pump (ASHP) Unit in Cold Regions. Buildings, 2023, 13, 2107. [Google Scholar] [CrossRef]

- Ma, L.; Wang, F.; Wang, Z.; et al. Thermodynamic mechanism of high energy performance of air source heat pump with coupled liquid-storage to gas-liquid separator. Solar Energy, 2023, 255, 497–506. [Google Scholar] [CrossRef]

- Gollamudi, S.; Fauchoux, M.; Krishnan, E.; et al. Methodology to evaluate design modifications intended to eliminate frosting and high discharge temperatures in air-source heat pumps (ASHPs) in cold climates. Energy and Buildings, 2024, 312, 114209. [Google Scholar] [CrossRef]

- Sezen, K.; Gungor, A. Comparison of solar assisted heat pump systems for heating residences: A review. Solar Energy, 2023, 249, 424–445. [Google Scholar] [CrossRef]

- Li, J.; Sun, X.; Zhu, J.; et al. Performance comparison of air source heat pump coupling with solar evacuated tube water heater and that with micro heat pipe PV/T. Energy, 2024, 300, 131600. [Google Scholar] [CrossRef]

- Han, Z.; Liu, Y.; Zhong, M.; et al. Influencing factors of domestic waste characteristics in rural areas of developing countries. Waste management, 2018, 72, 45–54. [Google Scholar] [CrossRef]

- Ni, L.; Qv, D.; Yao, Y.; et al. An experimental study on performance enhancement of a PCM based solar-assisted air source heat pump system under cooling modes. Applied thermal engineering, 2016, 100, 434–452. [Google Scholar] [CrossRef]

- Osterman, E.; Stritih, U. Review on compression heat pump systems with thermal energy storage for heating and cooling of buildings. Journal of Energy Storage, 2021, 39, 102569. [Google Scholar] [CrossRef]

- Huang, R.; Mahvi, A.; James, N.; et al. Evaluation of phase change thermal storage in a cascade heat pump. Applied Energy, 2024, 359, 122654. [Google Scholar] [CrossRef]

- Gao, J.; Li, S.; Wu, F.; et al. Study on efficient heating method by solar coupled air source heat pump system with phase change heat storage in severe cold region. Applied Energy, 2024, 367, 123206. [Google Scholar] [CrossRef]

- Mazo, J.; Delgado, M.; Marin, J.M.; et al. Modeling a radiant floor system with Phase Change Material (PCM) integrated into a building simulation tool: Analysis of a case study of a floor heating system coupled to a heat pump. Energy and Buildings, 2012, 47, 458–466. [Google Scholar] [CrossRef]

- Zou, D.; Ma, X.; Liu, X.; et al. Experimental research of an air-source heat pump water heater using water-PCM for heat storage. Applied Energy, 2017, 206, 784–792. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, K.; Zhou, D.; et al. Improvement of Human Comfort in Rural Cave Dwellings via Sunrooms in Cold Regions of China. Buildings, 2024, 14, 734. [Google Scholar] [CrossRef]

- Rural Residential Building Energy Efficiency Design Standards. Brick & Tile World, 2014, (01): 45-56.

- Gu, H.; Chen, Y.; Yao, X.; et al. Review on heat pump (HP) coupled with phase change material (PCM) for thermal energy storage. Chemical Engineering Journal, 2023, 455, 140701. [Google Scholar] [CrossRef]

- Gao, L.; Zhang, X.; Hua, W. Recent progress in photovoltaic thermal phase change material technology: A review. Journal of Energy Storage, 2023, 65, 107317. [Google Scholar] [CrossRef]

- Gao, L.; Zhang, X.; Hua, W. Recent progress in photovoltaic thermal phase change material technology: A review. Journal of Energy Storage, 2023, 65, 107317. [Google Scholar] [CrossRef]

- Rebelo, F.; Figueiredo, A.; Vicente, R.; et al. Innovation and progress in the incorporation of phase change materials into radiant floor systems. Journal of Energy Storage, 2023, 74, 109495. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).