Submitted:

13 June 2024

Posted:

13 June 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Literature Review

- (1)

- A Lagrange relaxation approach for CLSP is implemented.

- (2)

- A stepping-stone algorithm is developed for solving the resulting transportation problem.

- (3)

- A fix-up heuristic is proposed for obtaining feasible solutions.

- (4)

- A local neighborhood search heuristic is used for further searching for high-quality solutions, which increases the chance of finding the optimal solution.

3. Solution Approach

3.1. Lagrange Relaxation

3.2. Obtaining Feasible Solutions

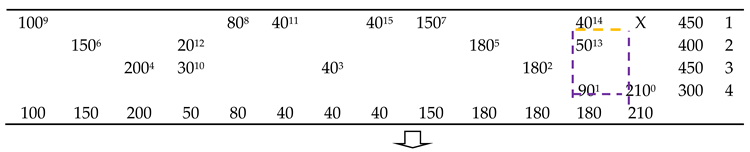

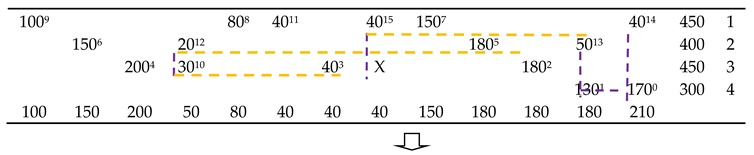

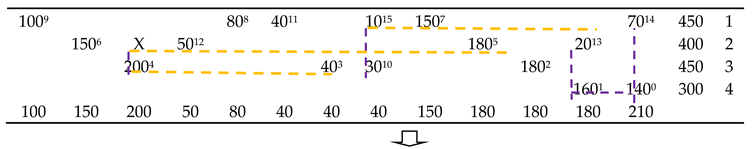

| Algorithm 1: Stepping-stone algorithm |

|

3.3. Fix-up Heuristic

| Algorithm 2: Fix-up heuristic |

|

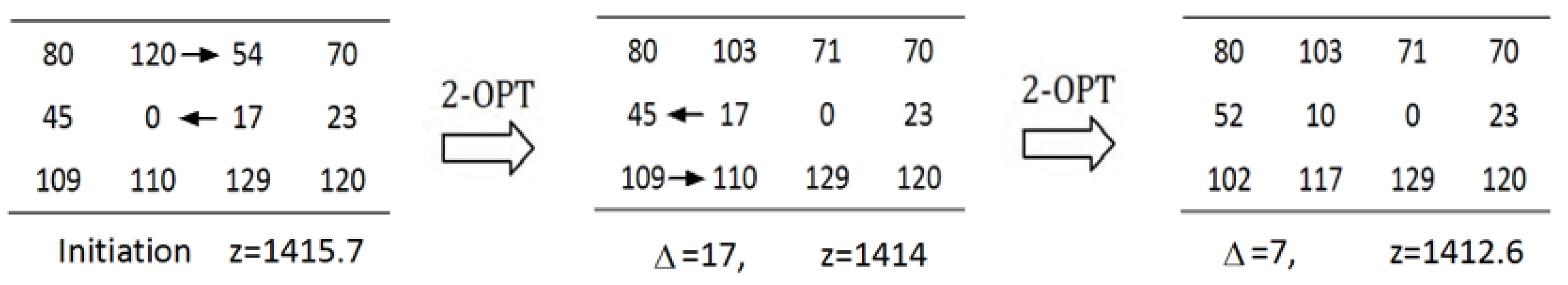

3.4. Local Neighborhood Search Algorithm

- (1)

- The neighborhood of the lot-move

- (2)

- The neighborhood of the 2-opt lot-exchanges

3.5. Subgradient Algorithm

| Algorithm 3: Subgradient algorithm |

| 1: given a Lagrangian multiplier uk, k = 0; 2: loop 3: Arbitrarily select a subgradient from ∂(zu), If any of the termination criteria are met then stop; else uk+1 = max {0, uk + θksk}; 4: k=k+1; 5: if k > N then stop; 6: end loop |

- θk = θ0ρk, 0<ρ<1;

- ;

- 3

- Iterations: N,

- 4

- sk = 0 or,

- 5

- |zUBk - zLBk| < ε

- 6

- uk or z(uk) does not change within a given number of iterations (e.g., 7).

3.6. Overview of the Lagrange Relaxation Algorithm

| Algorithm 4: Lagrangian relaxation main procedure |

| // Initialization 1: k =0 2: LB = -1E+10 // a sufficiently small lower bound 3: UB = 1E+10 // a sufficiently large upper bound 4: Gap = 1E-2 // dual gap percentage 5: K = 5000 // the maximum number of iterations 6: ηk = 2.0 // step-size 7: uk = 0 // Lagrangian multipliers 8: loop // main cycle beginning 9: Solve the Lagrangian relaxation LR (uk) by the W-W dynamic programming, and calculate the current lower bound ZLB (uk) 10: Solve the resulting transportation problem by the stepping-stone algorithm for the y from the solution of the current LR to obtain a ZUB (uk) if it is feasible else { Execute fix-up heuristic Solve the corresponding transportation problem using the stepping-stone algorithm } 11: Execute the local neighborhood search algorithm for raising solution quality 12: if ZLB (uk) < ZLB, ZLB = ZLB (uk) // update low bounds 13: if ZUB (uk) >ZUB, ZUB = ZUB (uk) // update upper bounds 14: if [ (ZUBk – ZLBk) / ZUBk] ≤ Gap, then stop 15: k++, if k >= K then stop; 16: Update Lagrangian multipliers with the subgradient algorithm 17: ηk =1/2*ηk; // update step-size 18: end loop // main cycle ending |

4. Computational Results

4.1. Comparison Study

4.2. Large-Sized Problems

- (1)

- The number of time periods, |T| and the number of items, |I|.

- (2)

- Tightness of the capacity utilization: .

- (1)

- the maximal number of items is set to 512;

- (2)

- the number of periods is set to 48;

- (3)

- the maximal utilization ratio is set to 93%.

5. Conclusions

Conflicts of Interest:

Author Contributions

Funding

Data Availability Statement

References

- Drexl, A.; Kimms, A. Lot sizing and scheduling — Survey and extensions. Eur. J. Oper. Res. 1997, 99, 221–235. [Google Scholar] [CrossRef]

- Maes, J.; Van Wassenhove, L.N. Multi-item single-level capacitated dynamic lot-sizing heuristics: a general review. Journal of the Operational Research Society 1988, 39, 991–1004. [Google Scholar] [CrossRef]

- Karimi, B.; Ghomi, S.F.; Wilson, J. The capacitated lot sizing problem: a review of models and algorithms. Omega 2003, 31, 365–378. [Google Scholar] [CrossRef]

- Florian, M.; Lenstra, J.K.; Rinnooy Kan, A.H. G Deterministic production planning algorithms and complexity. Management Science 1980, 26, 669–679. [Google Scholar] [CrossRef]

- Tang, L.; Meng, Y.; Liu, J. An improved Lagrangean relaxation algorithm for the dynamic batching decision problem: Lot sizing and scheduling: new models and solution approaches to address industrial extensions. International Journal of Production Research 2011, 49, 2501–2517. [Google Scholar] [CrossRef]

- Gao, Z.; Tang, L.; Jin, H.; Xu, N. An Optimization Model for the Production Planning of Overall Refinery. Chin. J. Chem. Eng. 2008, 16, 67–70. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, R.; Ren, J.; Gui, Q. Adaptive Fractional Image Enhancement Algorithm Based on Rough Set and Particle Swarm Optimization. Fractal Fract. 2022, 6, 100. [Google Scholar] [CrossRef]

- Jans, R.; Degraeve, Z. Modeling industrial lot sizing problems: a review. Int. J. Prod. Res. 2008, 46, 1619–1643. [Google Scholar] [CrossRef]

- Buschkühl, L.; Sahling, F.; Helber, S.; Tempelmeier, H. Dynamic capacitated lot-sizing problems: a classification and review of solution approaches. OR Spectr. 2008, 32, 231–261. [Google Scholar] [CrossRef]

- Harris, F.W. How many parts to make at once, Factory – The Magazine of Management, 1913, 10, 135–136+152.

- Gorham, T. Dynamic order quantities. Prod. Inventory Manag. J. 1968, 9, 75–79. [Google Scholar]

- DeMatteis, J.J. An economic lot-sizing technique, I: The part-period algorithm. IBM Syst. J. 1968, 7, 30–38. [Google Scholar] [CrossRef]

- Mendoza, A.G. An economic lot-sizing technique. II: Mathematical analysis of the part period algorithm. IBM Systems Journal 1968, 739–746. [Google Scholar] [CrossRef]

- Silver, E.A.; Meal, H.C. A heuristic for selecting lot size quantities for the case of a deterministic time varying demand rate and discrete opportunities for replenishment. Production and Inventory Management 1973, 14, 64–74. [Google Scholar]

- Lambrecht, M.R.; Vanderveken, H. Heuristics procedures for the single operation, multi-item loading problem, AIIE Transactions 1979, 11, 319–326.

- Dixon, P.S.; Silver, E.A. A heuristics solution procedure for multi-item, single-level, limited capacity, lot-sizing problem, Journal of Operations Management 1981, 2, 23–39.

- Eisenhut, P.S. A Dynamic Lot Sizing Algorithm with Capacity Constraints. A I I E Trans. 1975, 7, 170–176. [Google Scholar] [CrossRef]

- Wagner, H.M.; Whitin, T.M. Dynamic Version of the Economic Lot Size Model. Manag. Sci. 1958, 5, 89–96. [Google Scholar] [CrossRef]

- Barany, I.; Van Roy, T.J.; Wolsey, L.A. Strong Formulations for Multi-Item Capacitated Lot Sizing. Manag. Sci. 1984, 30, 1255–1261. [Google Scholar] [CrossRef]

- Lasdon, L.S.; Terjung, R.C. An Efficient Algorithm for Multi-Item Scheduling. Oper. Res. 1971, 19, 946–969. [Google Scholar] [CrossRef]

- Bahl, H.C. Column Generation Based Heuristic Algorithm for Multi-Item Scheduling. IIE Trans. 1983, 15, 136–141. [Google Scholar] [CrossRef]

- Hindi, K. Computationally efficient solution of the multi-item, capacitated lot-sizing problem. Comput. Ind. Eng. 1995, 28, 709–719. [Google Scholar] [CrossRef]

- Thizy, J.M.; Van Wassenhove, L.N. Lagrangian relaxation for the multi-item capacitated lot-sizing problem, a heuristics approach. AIIE Transactions 1985, 17, 308–313. [Google Scholar]

- Held, M.; Wolfe, P.; Crowder, H.P. Validation of subgradient optimization. Math. Program. 1974, 6, 62–88. [Google Scholar] [CrossRef]

- Trigeiro, W.W.; Thomas, L.J.; McClain, J.O. Capacitated Lot Sizing with Setup Times. Manag. Sci. 1989, 35, 353–366. [Google Scholar] [CrossRef]

- Diaby, M.; Bahl, Karwan, H. M.; Zionts, S. Capacitated lot-sizing and scheduling by Lagrangean relaxation. European Journal of Operational Research 1992, 59, 444–458. [Google Scholar] [CrossRef]

- Xie, J.; Dong, J. Heuristic genetic algorithms for general capacitated lot-sizing problems. Comput. Math. Appl. 2002, 44, 263–276. [Google Scholar] [CrossRef]

- Gaafar, L. Applying genetic algorithms to dynamic lot sizing with batch ordering. Comput. Ind. Eng. 2006, 51, 433–444. [Google Scholar] [CrossRef]

- Gaafar, L.K.; Nassef, A.O.; Aly, A.I. Fixed-quantity dynamic lot sizing using simulated annealing. Int. J. Adv. Manuf. Technol. 2008, 41, 122–131. [Google Scholar] [CrossRef]

- Hindi, K.S. Solving the CLSP by a tabu search heuristic, Journal of the Operational Research Society 1996, 47, 151–161.

- Jans, R.; Degraeve, Z. Meta-heuristics for dynamic lot sizing: A review and comparison of solution approaches. Eur. J. Oper. Res. 2007, 177, 1855–1875. [Google Scholar] [CrossRef]

- Fisher, M.L. The Lagrangian Relaxation Method for Solving Integer Programming Problems. Manag. Sci. 1981, 27, 1–18. [Google Scholar] [CrossRef]

- Fisher, M.L. An Applications Oriented Guide to Lagrangian Relaxation. INFORMS J. Appl. Anal. 1985, 15, 10–21. [Google Scholar] [CrossRef]

- Charnes, A.; Cooper, W.W. The Stepping Stone Method of Explaining Linear Programming Calculations in Transportation Problems. Manag. Sci. 1954, 1, 49–69. [Google Scholar] [CrossRef]

- Glover, F.; Klingman, D. Letter to the Editor—Locating Stepping-Stone Paths in Distribution Problems Via the Predecessor Index Method. Transp. Sci. 1970, 4, 220–225. [Google Scholar] [CrossRef]

| Item | period | ||||

| 1 | 2 | 3 | 4 | ||

| 1 | 20 | 30 | 40 | 10 | demands |

| 2 | 20 | 10 | 10 | 10 | |

| 3 | 25 | 30 | 30 | 30 | |

| capacity | 450 | 400 | 450 | 300 | |

| Item | pi | ai | si | hi |

| 1 | - | 5 | 70 | 3 |

| 2 | - | 4 | 90 | 4 |

| 3 | - | 6 | 200 | 5 |

| production | demands | |T|t | ||||||||||||

| 100 | 150 | 200 | 50 | 80 | 40 | 40 | 40 | 150 | 180 | 180 | 180 | 210 | ||

| 450 | 0 | .6 | 1.2 | 1.8 | 0 | 1 | 2 | 3 | 0 | 5/6 | 5/3 | 2.5 | 0 | 1 |

| 400 | X | 0 | .6 | 1.2 | X | X | X | X | X | 0 | 5/6 | 5/3 | 0 | 2 |

| 450 | X | X | 0 | .6 | X | X | 0 | 1 | X | X | 0 | 5/6 | 0 | 3 |

| 300 | X | X | X | X | X | X | X | X | X | X | X | 0 | 0 | 4 |

| |T|×|I|+1 | τ=1,2,3,4; i=1 | τ=1,2,3,4; i=2 | τ=1,2,3,4; i=3 | dummy | ||||||||||

|

|

|

|

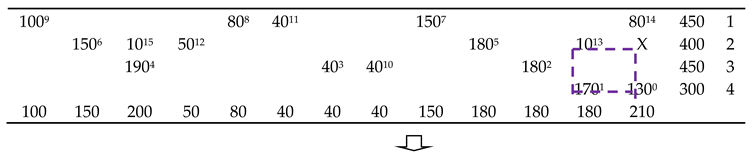

| 1009 | 808 | 4011 | 1507 | 8014 | 450 | 1 | ||||||||

| 1506 | 1015 | 5012 | 1805 | 1013 | 400 | 2 | ||||||||

| 1904 | 403 | 4010 | 1802 | 450 | 3 | |||||||||

| 1801 | 1200 | 300 | 4 | |||||||||||

| 100 | 150 | 200 | 50 | 80 | 40 | 40 | 40 | 150 | 180 | 180 | 180 | 210 |

| item | hi | si | period | TBO | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | ||||

| 1 | 1 | 100 | - | 70 | 50 | 100 | 20 | 80 | - | 100 | 2 |

| 2 | 1 | 200 | 20 | 40 | 50 | 10 | 30 | - | 40 | 50 | 3.65 |

| 3 | 1 | 200 | 40 | 50 | - | 100 | 40 | 80 | 90 | 160 | 2.33 |

| 4 | 1 | 300 | - | 100 | 100 | 150 | 160 | 90 | 100 | 100 | 2.5 |

| 5 | 1 | 400 | 50 | - | 20 | 40 | 10 | 10 | 20 | 10 | 6.32 |

| 6 | 1 | 250 | 70 | 40 | 40 | 40 | 100 | 20 | 40 | 50 | 3.16 |

| 7 | 1 | 500 | - | 20 | 50 | 10 | 20 | 60 | 40 | 40 | 5.77 |

| 8 | 1 | 300 | 10 | 20 | - | - | 10 | 10 | 20 | 30 | 6.93 |

| Available demand | 190 | 340 | 310 | 450 | 390 | 350 | 350 | 540 | Total demand 2920 |

||

| TVW1 | 350 | 350 | 350 | 400 | 400 | 400 | 400 | 500 | 3150 (93%) | ||

| TVW2 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 3200 (91%) | ||

| TVW3 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 4000 (73%) | ||

| TVW4 | 600 | 600 | 600 | 600 | 600 | 600 | 600 | 600 | 4800 (61%) | ||

| Problem ID | LP Relaxation | Optimal solution With CPLEX |

LR | LRFN | DS | LV |

| TVW1 | 7996.67 | 8430 | 8710 | 8520 | 8710 | 8970 |

| TVW2 | 7722.27 | 7910 | 7930 | 7910 | 7930 | 8800 |

| TVW3 | 7534.17 | 7610 | 7610 | 7610 | 7970 | 7970 |

| TVW4 | 7446.17 | 7520 | 7520 | 7520 | 8000 | 8000 |

| Problem No. |

Problem size (items × periods) |

LB | Optimal solution | Iteration found |

Gap (%) | CPU time (S) |

| 1 | 5×36 | 82131.54 | 85374 | 201 | 3.95 | 68.73 |

| 2 | 5×48 | 111368.25 | 115136 | 215 | 3.38 | 215 |

| 3 | 10×10 | 84904.29 | 88094 | 2 | 3.76 | 5.33 |

| 4 | 10×15 | 67167.7 | 67906 | 49 | 1.1 | 1.5 |

| 5 | 10×15 | 71694.02 | 71705 | 8 | 0.02 | 0.03 |

| 6 | 10×20 | 151859.54 | 157470 | 87 | 3.69 | 40.75 |

| 7 | 10×20 | 85426.11 | 85619 | 1 | 0.23 | 2.47 |

| 8 | 15×20 | 160088.16 | 161128 | 14 | 0.65 | 7.4 |

| 9 | 10×24 | 103383.29 | 103866 | 10 | 0.47 | 82.97 |

| 10 | 15×36 | 57341.8 | 58184 | 40 | 1.47 | 66.08 |

| 11 | 10×36 | 220486.05 | 224047 | 214 | 1.62 | 380.94 |

| 12 | 10×30 | 224231.93 | 226571 | 7 | 1.04 | 161.01 |

| 13 | 20×20 | 261226.71 | 267422 | 2 | 2.37 | 16.65 |

| 14 | 20×30 | 379853.7 | 383533 | 3 | 0.97 | 50.51 |

| 15 | 10×48 | 358551 | 392750 | 1 | 9.54 | 1147.91 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).