1. Introduction

Currently, there is an urgent demand to incorporate numerous renewable energy sources to address issues such as greenhouse gas emissions, voltage quality problems, power supply reliability, network extensions, underserved remote areas, and power losses prevalent in conventional power plants [

1,

2,

3]. In Tunisia, the predominant electrical energy source is crude oil, except for certain countries relying on renewable sources [

4]. Investing in renewables, specifically solar power, reduces reliance on fossil fuels, like oil, and enhances the country's energy independence [

5,

6,

7,

8]. Furthermore, embracing renewable energies, particularly solar power, contributes to mitigating CO

2 emissions, offering both economic and environmental advantages [

9,

10,

11]. The adoption of renewable energies also directly benefits the environment by curbing CO

2 emissions and limiting pollution in air, water, and soil [

12,

13,

14,

15,

16]. As the world shifts towards sustainable and efficient transportation, Electric Vehicles (EVs) emerge as a key solution to combat environmental challenges posed by traditional fossil fuel-based vehicles [

17,

18,

19,

20]. This transition necessitates the development of a robust and eco-friendly charging infrastructure [

21,

22,

23,

24]. Integrating renewable energy sources, like Photovoltaic (PV) systems, and advanced technologies, such as fuel cells, becomes crucial. By combining the sun power through PV sources with the reliability of fuel cells, EV charging stations have the potential to operate independently of traditional energy grids, minimizing their carbon footprint [

25,

26]. One significant challenge in the widespread adoption of EVs is the demand for fast, efficient charging facilities with the aim of meeting the growing need. Implementing optimized algorithms, specifically Perturb and Observe (P&O), emerges as a noteworthy solution [

16,

27,

28,

29,

30]. The P&O algorithm, known for its effectiveness in maximizing solar energy system efficiency, shows promise when applied to the dynamic complexities of EV charging stations powered by both PV and fuel cell systems [

31,

32,

33,

34].

This comprehensive case study focuses on Tunisia's efforts to adopt sustainable energy practices and meet modern transportation needs. Leveraging Tunisia's abundant sunshine, the study explores integrating PV sources into EV charging stations. By examining the intricacies of integrating PV systems, fuel cell technology, and P&O optimization algorithms, the study aims to analyze the challenges, opportunities, and outcomes of maximizing charging efficiency in Tunisia's EV infrastructure. Through empirical data, simulation and theoretical frameworks, the analysis aims to provide a detailed blueprint addressing technical complexities, economic viability, and environmental impact. This exploration holds the potential to revolutionize the sustainable transport infrastructure in Tunisia, serving as a model for other regions facing similar challenges.

Wireless Energy Transfer (WET) represents a recent technological breakthrough with significant advances in research and manufacturing [

35,

36,

37]. Applicable across various fields, including everyday life optimization, Tesla's work in the early 1900s brought WET to fruition. Subsequent research focused on integrating the Wireless Power Transfer (WPT) technology into EVs, exploring prototypes for testing and marketing [

38]. Wireless transmission methods, categorized as near-field and far-field, offer advantages such as safe charging and easy integration into automated systems. While near-field technologies use inductive or capacitive coupling for short distances, far-field technologies employ electromagnetic radiation for longer distances. However, existing wireless transfer systems face efficiency challenges, particularly in the inductive coupling, which has a limited transfer range and efficiency drop with increased separation distance. The proposed magnetic Resonance WPT (RWPT) seeks to address these challenges while modeling for EV charging a wireless solar transfer chain [

39,

40]. The batter incorporates PV generators, hydrogen fuel cells, and the national grid, optimizing efficiency through class-ϕ2 inverters and circular spiral coils. concerning magnetic resonance transfer, the separation distance, or air gap, emerges as a critical factor influencing the overall system efficiency and performance. The paper aims to propose a model applicable to EV charging, aligning with the global trend towards renewable energy. The RWPT system requires an MHz resonant supply signal, utilizing a class-ϕ2 HF resonant inverter with GaN transistors for reduced switching losses and high efficiency [

13,

24,

41,

42]. The article also acknowledges the challenges faced by PV systems, emphasizing the importance of advanced energy storage technologies and high-efficiency solar cells.

Our suggested solution combines PV systems, hydrogen fuel cells, WPT, and energy storage for the creation of a more effective microgrid system. This approach aims to overcome the limitations associated with traditional PV systems and offers a comprehensive solution for EV charging stations. The project focuses on optimizing the PV source, the hydrogen fuel cell and the national grid using the MPPT algorithm, creating a resonance structure for 30-MHz signals and analyzing the electromagnetic properties of the transfer core through the use of spiral coils.

2. Approach

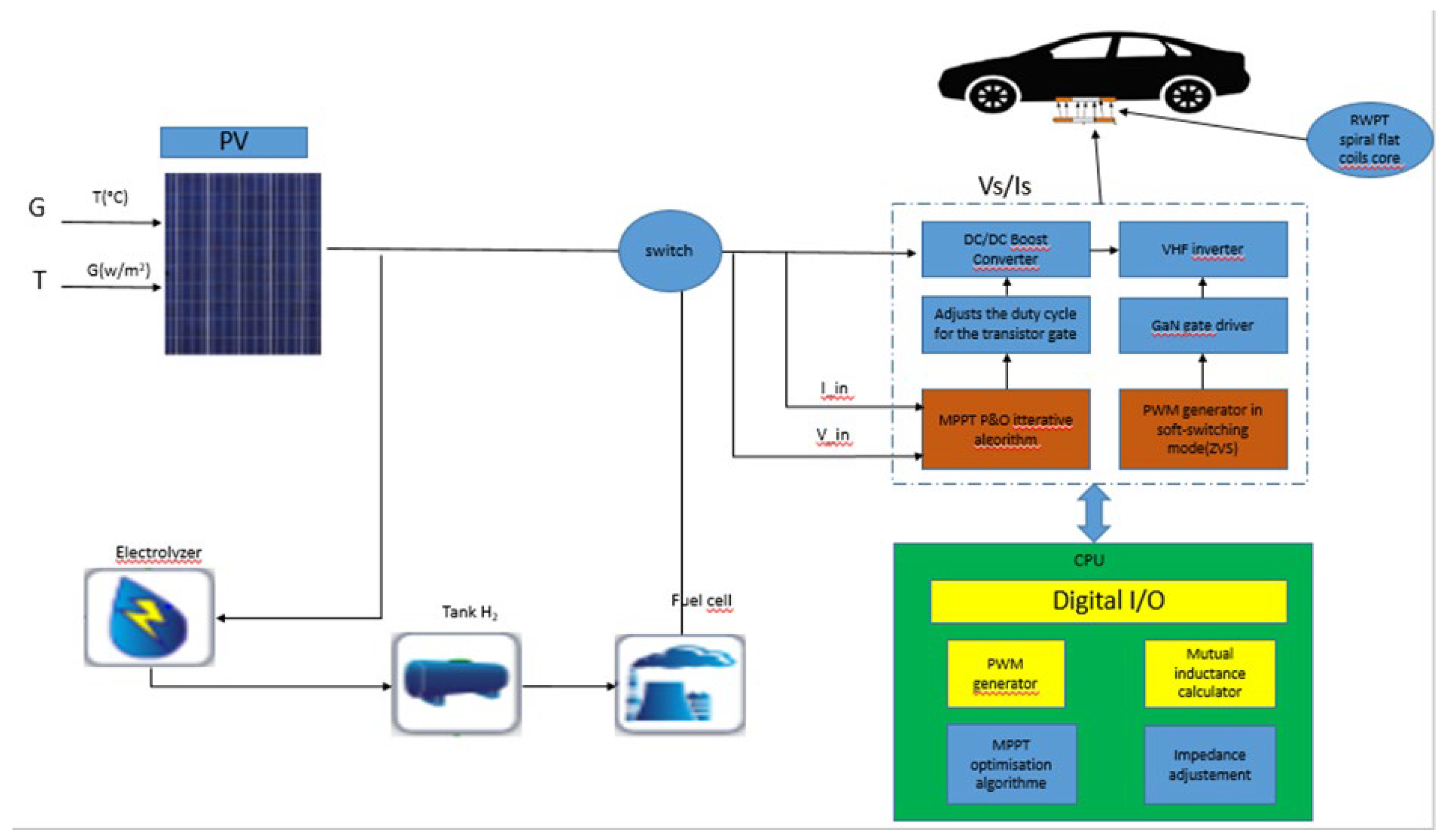

The proposed approach consists of designing a battery charging station powered by a PV source.

Figure 1 shows a synoptic diagram of the proposed approach. A PVP is used to charge the EV battery and to produce hydrogen. PVPs also be used to produce hydrogen by water electrolysis. we can storedhydrogen and use it after that in a fuel cell to produce electricity during periods when the sun is not shining.

The mutual inductance calculator facilitates the calculation of the mutual inductance between booth coils with the goal of obtaining the optimum M12 ratio for the maximum transfer point of the RWPT system. The adjustment impedance is represented by the optimized class-ϕ2 inverter’s input and output impedance. This step is used to adjust the input and output impedance to obtain maximal efficiency from the inverter. The inverter is powered by a PV Panel (PVP) and a fuel cell, which is optimized by applying the MPPT algorithm to the boost-converter. This pulse-width modulation generator is used to produce the control signals for the entire system (boost converter + ϕ2 class inverter). This stage is represented by the DSP card which delivers the control signals.

The energy management system can also decide how best to use the hydrogen produced, whether to feed it directly or store it for later use. This hybrid configuration enables a more sustainable use of energy resources by taking advantage of different renewable energy sources. It can also offer a degree of energy autonomy, reducing the total dependence on the electricity grid. The integration of an intelligent energy management system is essential to maximize the efficiency and optimization of available energy resources.

3. Mathematical Study and Electric Model Optimization for Advanced Energy Transfer Systems

The wireless charging system designed for EVs comprises three main components. The initial block integrates the solar generator, the hydrogen fuel cell and the Tunisian electricity grid, comprising a PVP, a fuel cell and the grid station, and utilizing a boost converter to enhance performance. In addition to that, the subsequent block concerns the resonance structure, as symbolized by one class-ϕ2 inverter. Ultimately, employing flat spiral coils, the wireless transformer is included in the last block.

It should be noted that the battery is initially assumed to be charged to 100% of its capacity. Meanwhile, the charger is precisely engineered in order to provide a maximal power of 3.3 kW. This should be done at 230 V with a current rate of 15 A. According to the literature, the maximum dischargeable state-of-charge value of this energy storage unit is around 30%, thus guaranteeing the battery's longevity. Various studies have also emphasized ensuring that the depth of discharge remains below 70% of the battery's maximum capacity, in order to preserve its health and ensure optimum service life, as demonstrated in several references [

30,

31,

32].

3.1. PV Model

The equation representing the maximum energy generated by solar PVPs (PV-max) can be formulated as follows:

In the given formula, GSR denotes the overall solar radiation, TP signifies the temperature of the PVPs, FR represents the irradiance flux, and P is a variable influenced by Joule effects, cleanliness, and the stability of the PV panels. Moreover, Pt is the temperature coefficient, while Tpref and PG-sdc correspond to the ambient temperature (25°C) and the rated power of the PV array in a standard test environment (1000W/m2), respectively.

The ambient temperature T

p is determined by the intensity of the Global Solar Radiation (GSR) and, the ambient temperature T

a which is set at 25°C. The calculation can be expressed as follows:

In this equation, SCOT represents the operating temperature under standard conditions. These conditions include an average 1m/s wind, an ambient 20°C temperature, and 800 W/m

2 irradiance. The ambient temperature T

p can be calculated using the relevant formula or a method applicable to your specific context or model [

25,

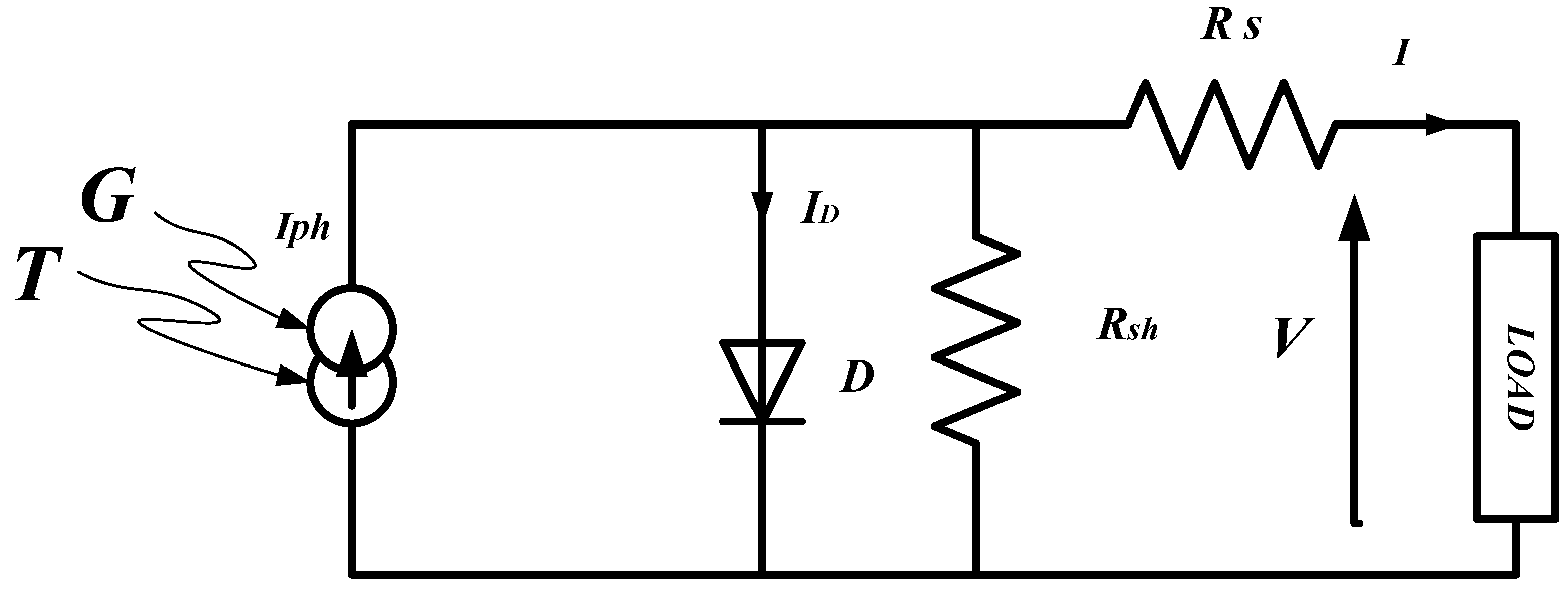

26]. Based on solar cells’ physical structure and output characteristics, as illustrated in

Figure 2, it is possible to electrically and equivalently represent an ideal solar cell consisting actually of one current source with a diode in parallel.

Photocurrent Iph is a function of the cell temperature T and the solar radiation Gs, as described in equation 3 we can express the mathematical relationship between voltage (V) and current (I) in an equivalent diode circuit by the following diode equation:

The dependence of the solar cell's reverse saturation current (I) on temperature (T) is expressed through the following relationship:

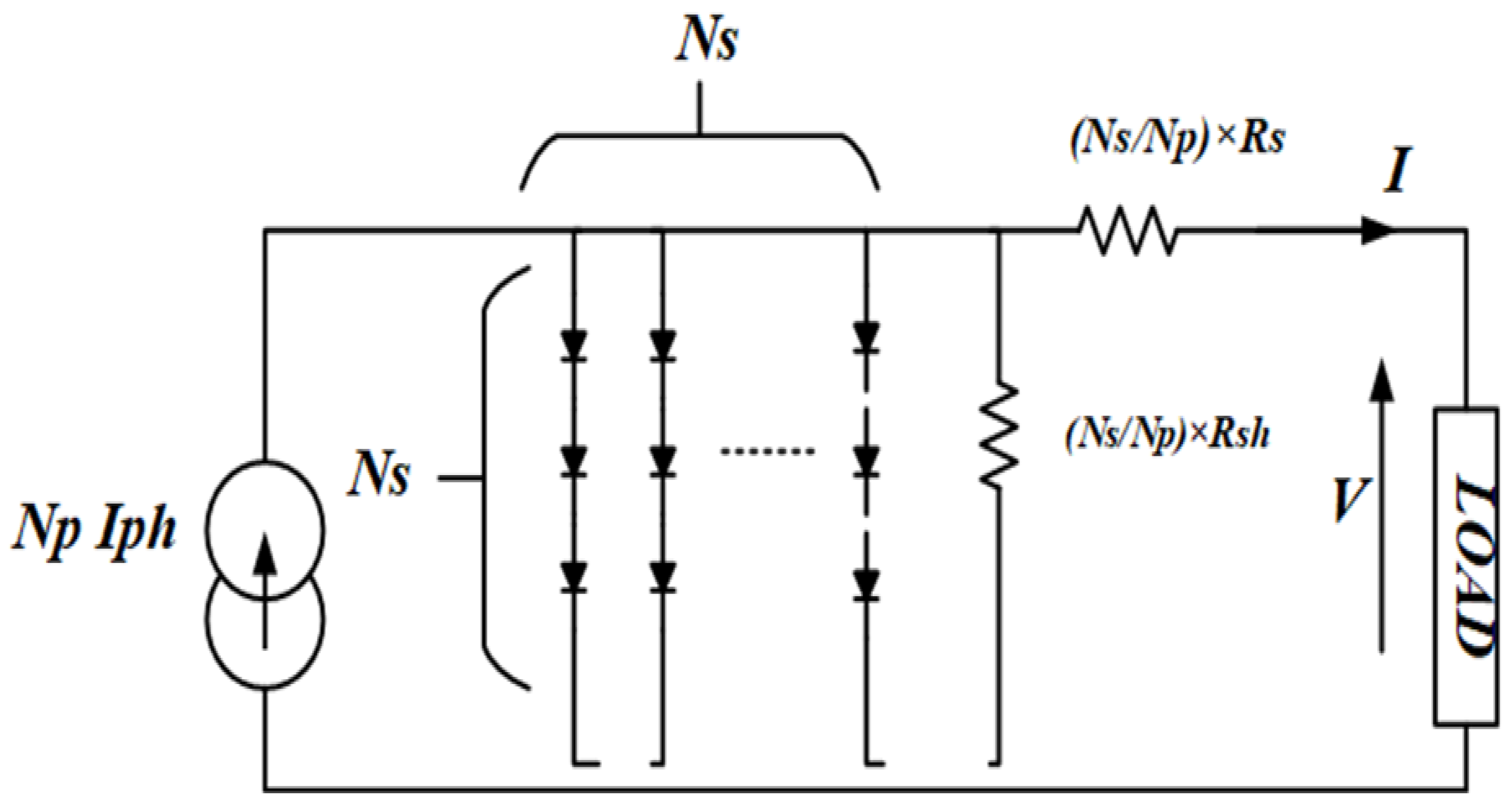

When PV Arrays are constructed by connecting solar cells in both series and parallel configurations, a common assumption is that these cells share identical characteristics.

Figure 3 shows the electrical equivalent circuit of a PV array.

In fact, the relationship in the PV grid between the voltage and the current, as well as the power produced, can be articulated in an equivalent circuit as follows:

Where the temperature coefficient (δ) is defined as -3.7×10⁻³ (1°C), Gs-ref represents solar irradiance under 25°C reference temperature (Tref) and standard (1000 W/m²) reference conditions, Gs is the solar irradiance, Pr represents rated power under reference conditions, and PPV(t) represents the PV output.

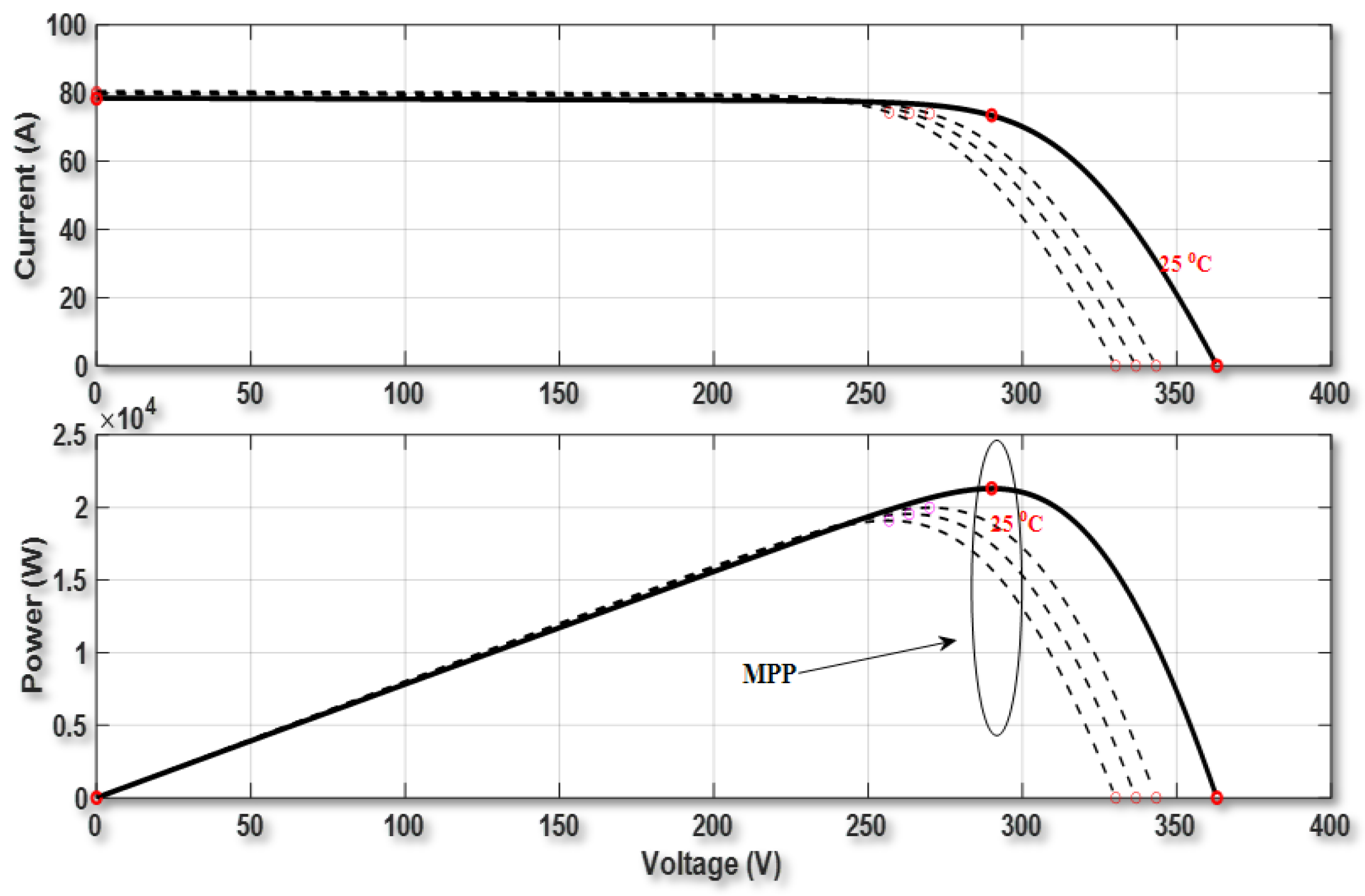

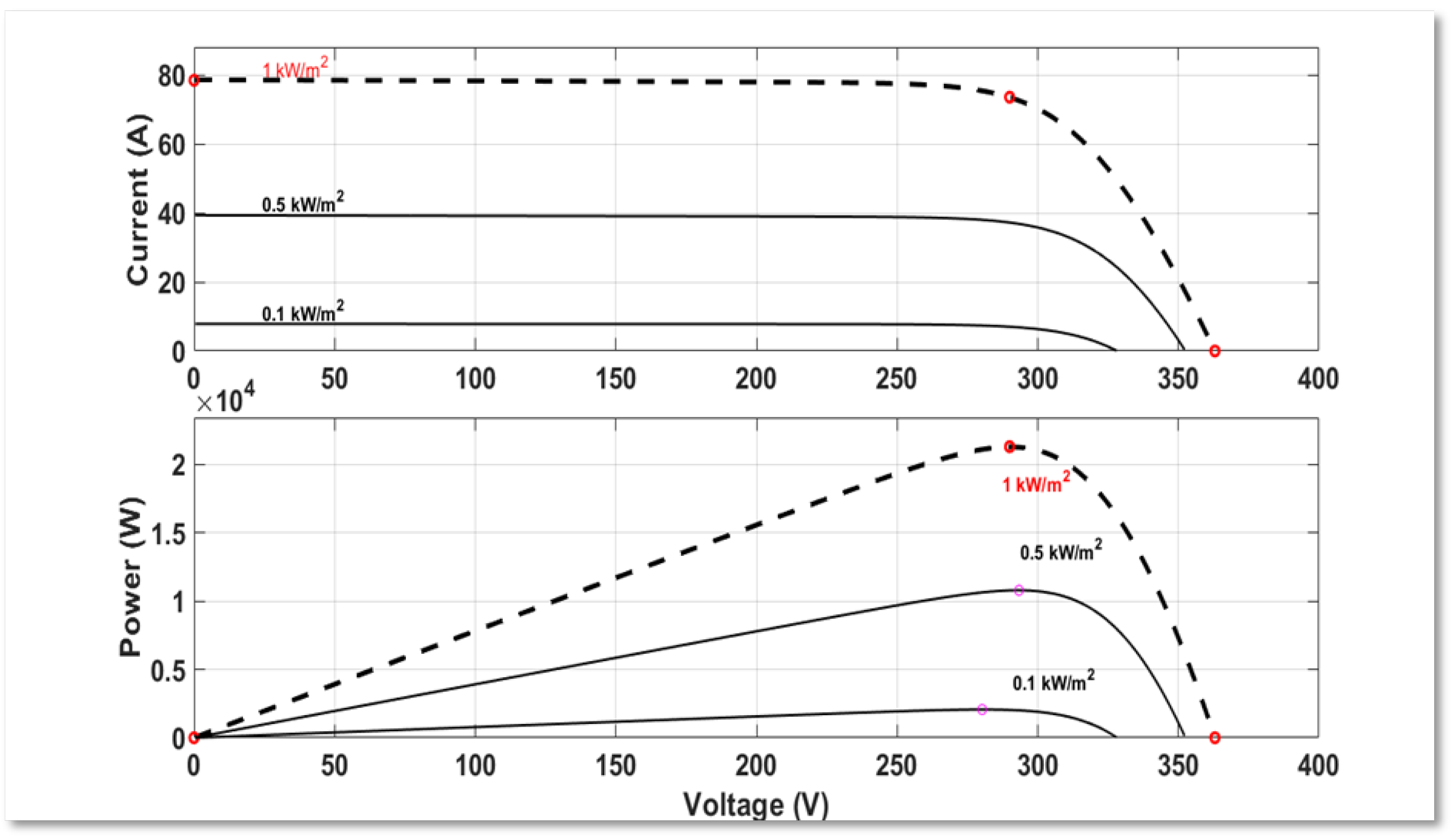

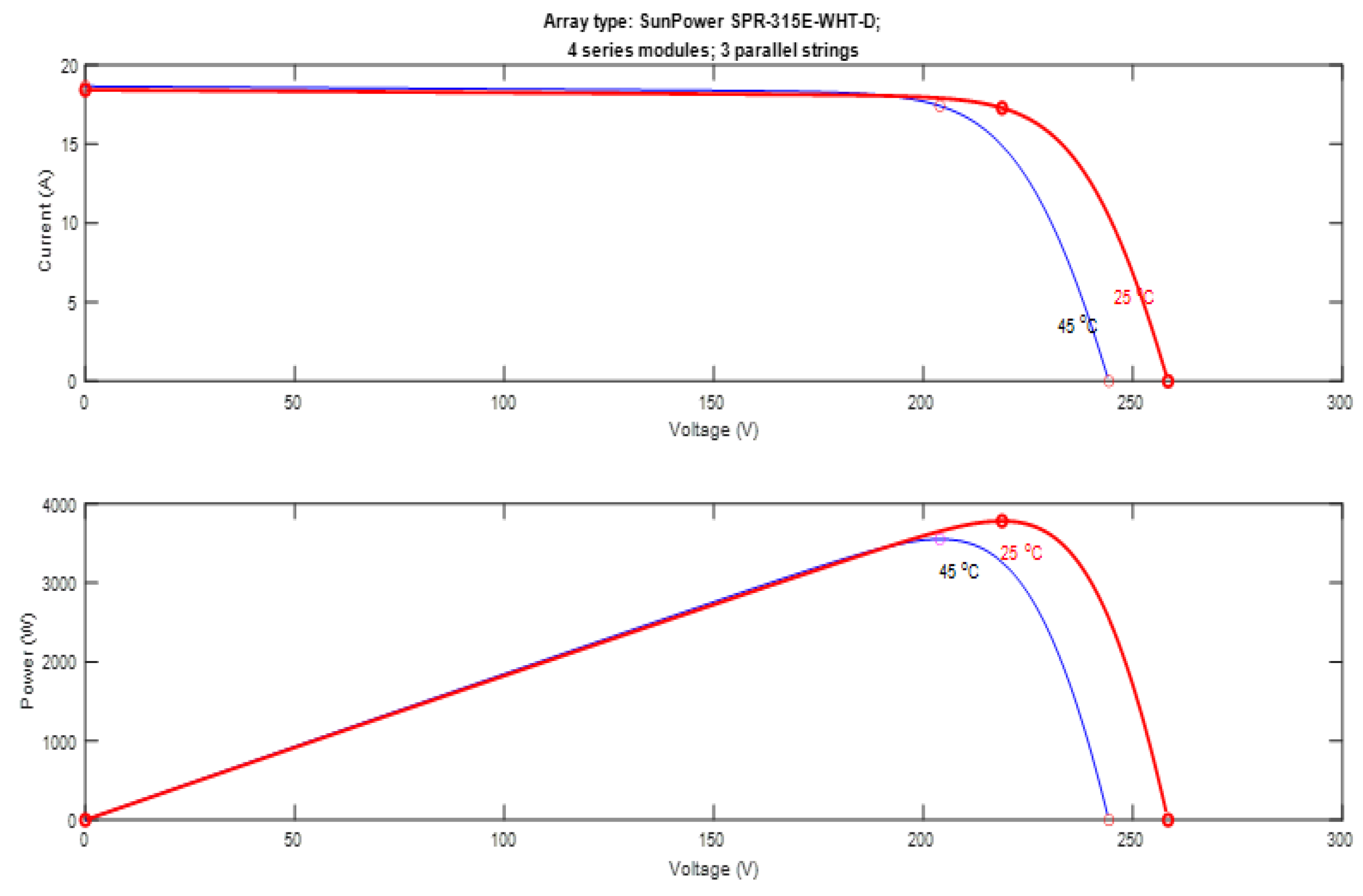

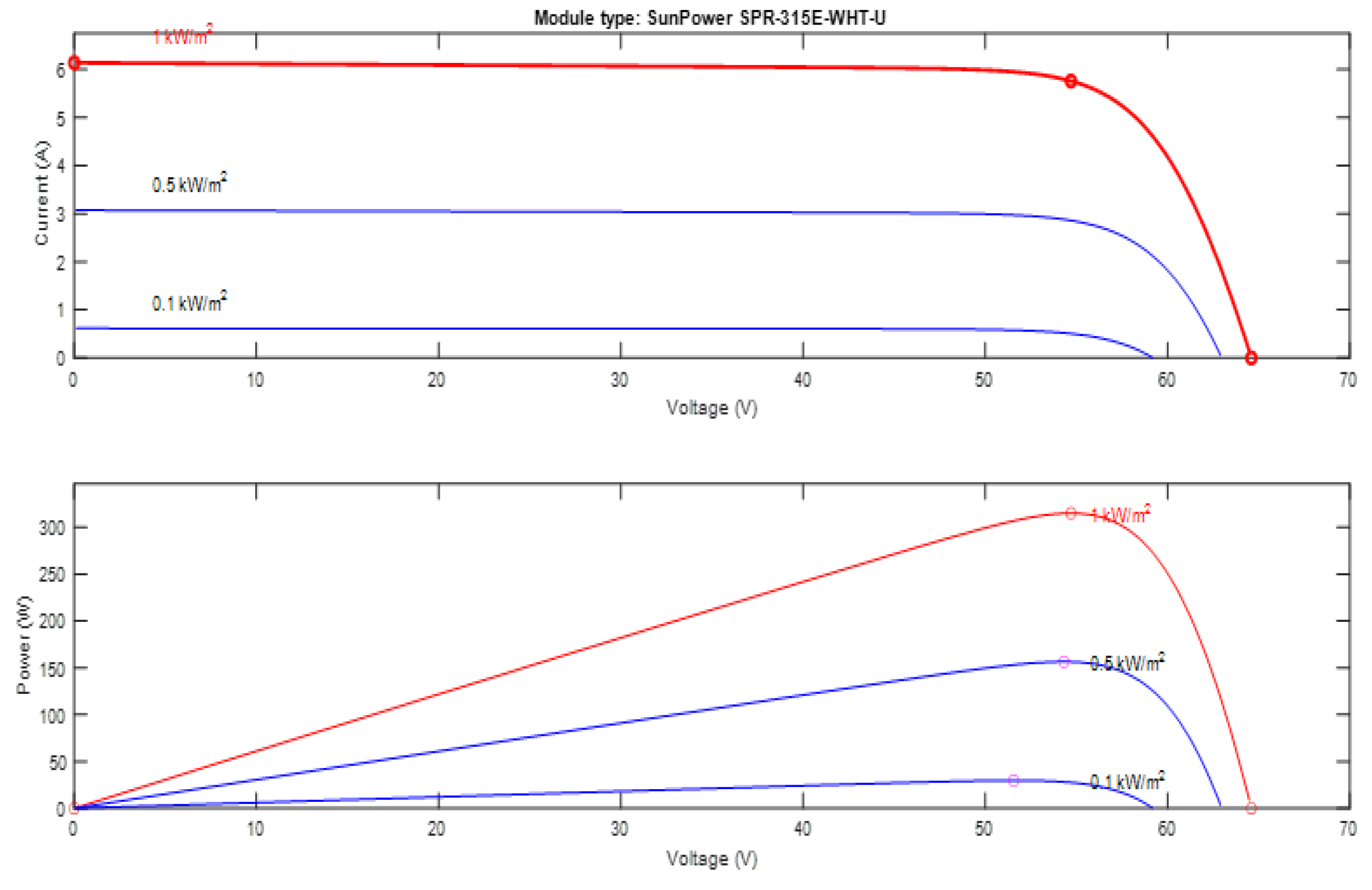

The challenge encountered by MPPT techniques lies in the automated determination of the optimal voltage (V

max) or current (I

max) at which a PV array should operate. As illustrated in

Figure 4 and

Figure 5, the attaining objective of this optimization is maximal output power (P

max) under specific temperature and solar radiation conditions depicted.

Figure 4 depicts the tracking of maximum power (P

max) for a constant solar radiation level (G

s), with a variation in T

ref. On the other hand,

Figure 5 shows the opposite situation, with a fixed T

ref and a variation in G

s.

3.2. Fuel Cell

The fuel cell represents an electrochemical device that is designed for directly converting chemical energy into electricity. The mathematical formula governing the fuel cell operations is expressed in terms of electrochemical potential, electric current, and voltage. The chemical reaction within a fuel cell is generally represented as follows, taking a hydrogen fuel cell as an example:

The general formula for the power (P) Generated by a fuel cell is given as follows:

where

The voltage V of a fuel cell is contingent upon various factors, including the reactants used in nature, the cell’s specific design, the pressure and the temperature. The precise formula for the voltage can be derived from fuel cell-specific thermodynamic and chemical kinetic equations.

It is crucial to highlight that the power generated by a fuel cell is additionally influenced by the efficiency of the electrochemical process, which can vary depending on the operating conditions of the cell. More detailed equations are often used in fuel cell models to take these specific factors into account.

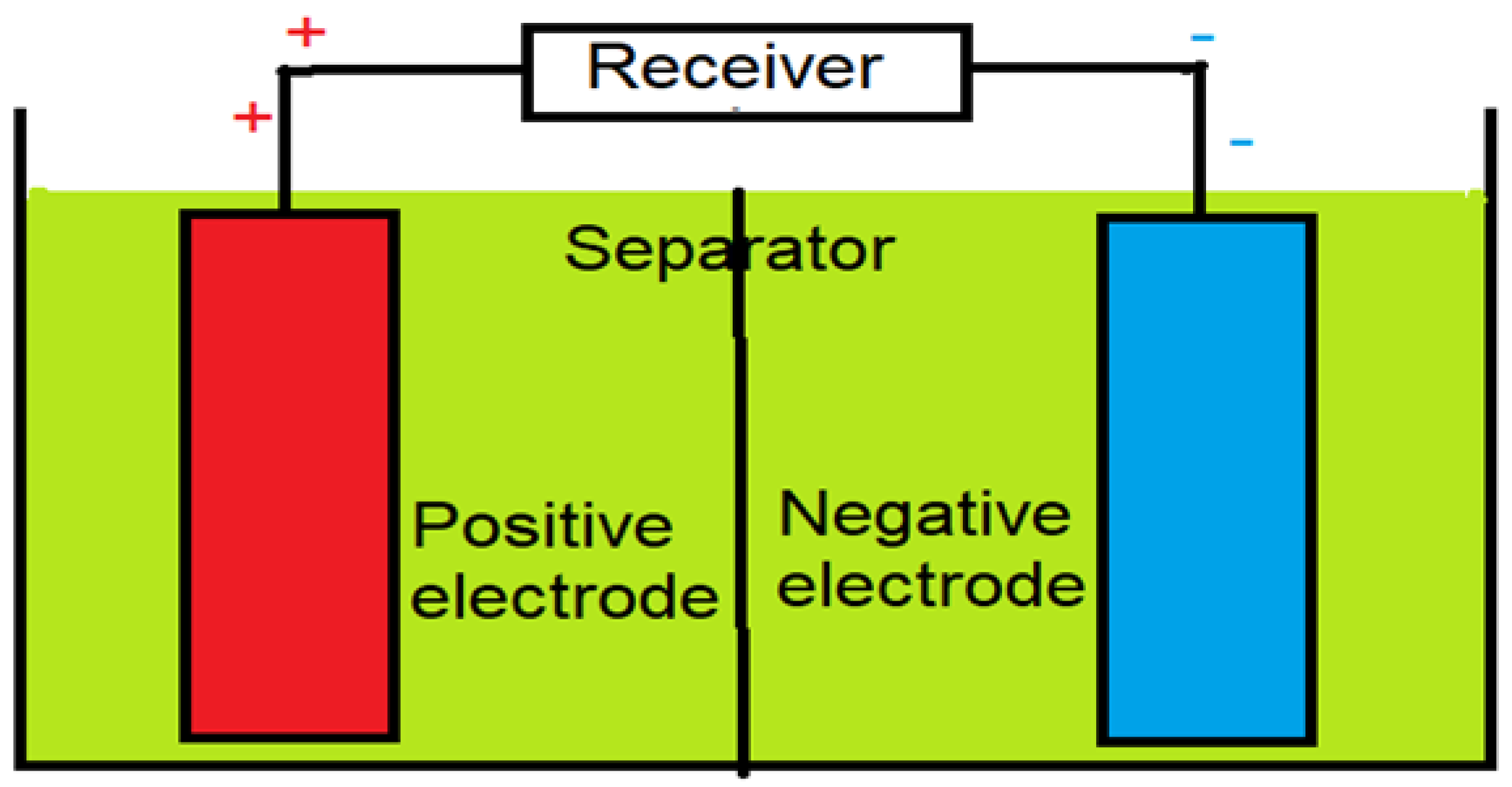

A fuel cell is an electrochemical device used for the direct conversion of chemical energy into electricity. This can be done using an electrochemical reaction between a fuel and an oxidant. It is frequently regarded as a clean and efficient energy source, as the main reaction produces electricity, water and heat as by-products. Here is a general explanation of how a fuel cell works: The chemical reaction at the heart of a fuel cell depends on the cell type. For example, in a hydrogen-oxygen fuel cell, specifically the Proton Exchange Membrane Fuel Cell (PEMFC), the reaction is as follows:

This reaction produces water H₂O and releases electricity.

Main components:

▪ Anode: the place where the fuel (e.g. hydrogen) is oxidized and releases electrons.

▪ Cathode: where the oxidizing agent (e.g. oxygen from the air) reacts with electrons and hydrogen ions (protons) to form water.

▪ Electrolyte: ion-conducting material that allows ions to pass between the anode and the cathode.

Electricity generation: When we supply hydrogen to the anode of the fuel cell, it splits the process while separating water molecules into protons (H⁺ ions) and electrons (e⁻). As a matter of fact, protons migrate through an electrolyte towards a cathode, and at the same time, electrons travel through an external circuit, as electricity is generated in the process.

Meeting of ions and electrons at the cathode: The convergence of ions and electrons occurs at the cathode, where protons and electrons combine with oxygen from the air to produce water H₂O. Applications: we use fuel cells in various applications, including EVs (hydrogen fuel cells for cars), backup power systems, industrial applications, and even space applications.

Fuel cell types: There exist different kinds of fuel cells, mainly PEMFCs, Solid Oxide Fuel Cells (SOFC), alkaline fuel cells, and more. Each type has its own advantages and disadvantages, tailored to specific applications. Fuel cells are good alternatives to traditional energy sources, particularly as we move towards a cleaner, more sustainable economy.

3.3. Boost Converter

Figure 6 shows a boost converter is an electronic circuit utilized for increasing increase the DC voltage of a power source to a higher value. It is commonly used in power supply applications to raise the voltage of a battery or renewable energy source to a level required to power other devices. The boost-converter operation is based on the principle of storing energy in an inductor (L) and subsequently transferring it to an output capacitor (C), which is achieved through the use of a switch, typically a transistor. Upon closing the switch, electric current does across the inductor, accumulating magnetic energy within it. When the switch opens, the energy stored within the inductor can be transposed into the output capacitor, increasing the voltage across it. As the switch is closed, the relationship between the switch duty cycle D, the output voltage (V

out), and the input voltage (V

int) can be expressed by the following formula:

Where D is the fraction of time this equation illustrates the correlation between the switch’s duty cycle and the output voltage. To enhance the output voltage, the duty cycle should be adjusted, accordingly.

The efficiency (η) of the boost converter is assessed by determining the output power ratio in order to input the power. Efficiency is calculated utilizing the following formula :

Where Iout and Iin are the output and input currents, respectively. Understanding these mathematical aspects is essential for designing and optimizing efficient boost converters in various electronic applications.

To enhance a solar PV system’s efficiency, the integration of one boost converter between the load and the generator is implemented. The voltage delivered to the load is regulated by the (DC-DC) converter. Indeed, this latter is controlled by an MPPT algorithm, through the use of a duty cycle(α)This algorithm directs the PV generator’s operating point towards the maximum power point (Pmax) as detected by the control system.

The boost converter derived’s equation can be based on its continuous operating model and is calculated as follows:

3.4. VHF Inverter

A Very-High-Frequency (VHF) inverter is an electrical device utilized to convert intoHigh-Frequacy AC voltage a Direct Current DC voltage. This inverter is often used in long-distance power transmission applications. The operation of an HF inverter is generally based on the principle of pulse-width modulation PWM, a common technique in power conversion.

The heart of the VHF inverter is a set of power transistors that switch rapidly between conducting and blocking states. The duty cycle of this switching, generally named as D, determines the width of the pulses generated by the output waveform. The output AC voltage (Vout) is defined using the following pulse-width modulation formula.

where V

dc is the input V

DC voltage. Through the adjustment of the duty cycle, the inverter effectively controls any output voltage.

To obtain an HF output voltage, HF inverters often use LC (inductor-capacitor) circuits that act as filters and limit unwanted harmonics. The switching frequency (fsw) is an important parameter in an inverter design and relates to the duty cycle by the following formula :

where Tsw is the switching period, and

VHF inverter efficiency is often evaluated by the efficiency (η), which represents the power ratio between the input and output powers. Efficiency is calculated using the following formula:

where I

int and I

out are respectively the input and output currents. Understanding these mathematical concepts is essential for designing efficient and reliable HF inverters in high-voltage power transmission systems.

3.5. RWPT System Modelization

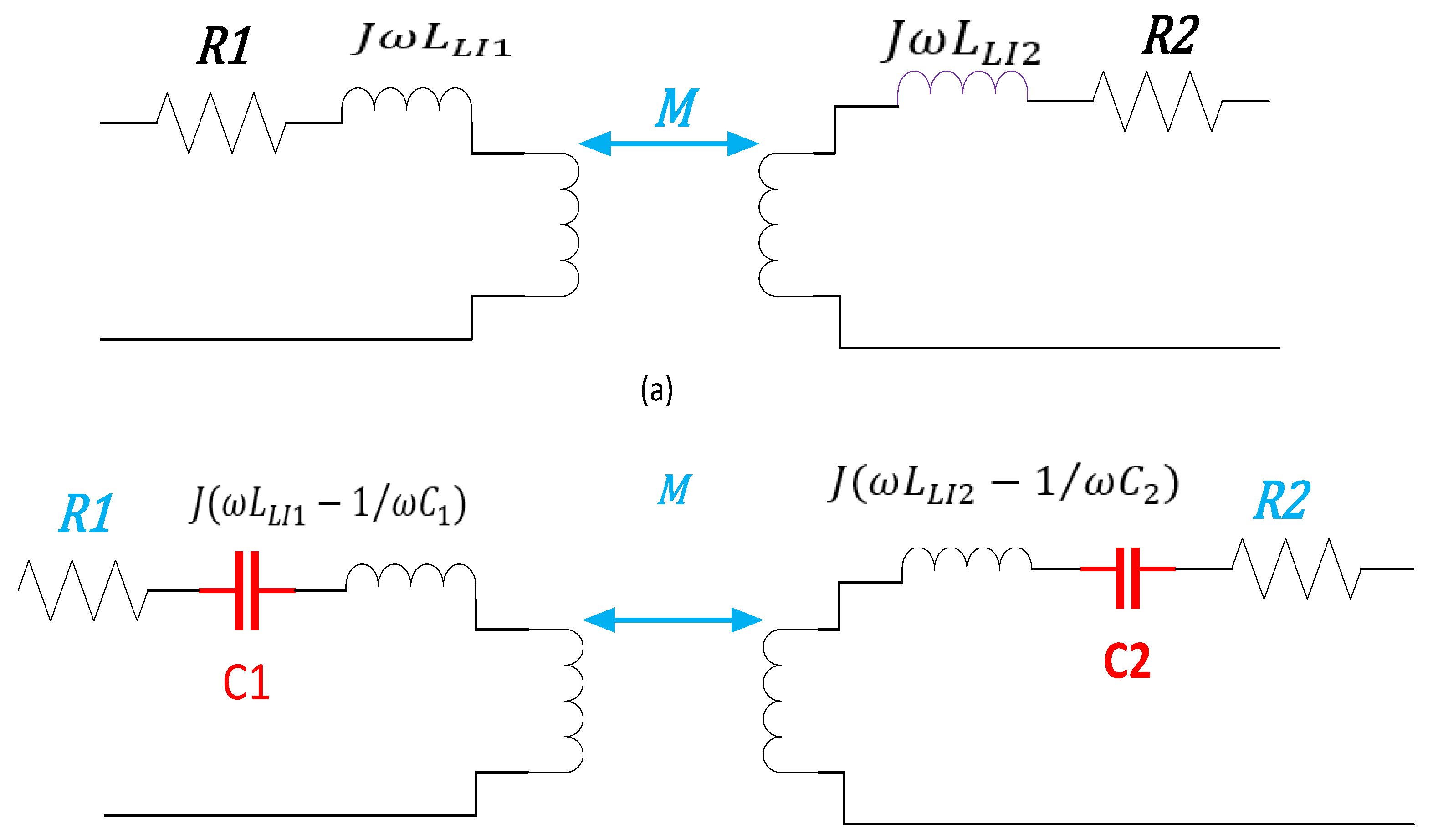

In 2008, MIT researchers developed the RWPT, a WPT system that world incorporates compensation capacitors within both the transmitter and the receiver. Function at their individual resonant frequencies. In general, adding these compensation capacitors represents a significant advancement for WPT, eliminating the imaginary impedance component perceived by the source. Thanks to this improvement, the RWPT achieves higher levels of output power and efficiency compared to conventional WPT.

This magnitude is observed at short and medium distances, relative to the size and shape of the coil. Not surprisingly, RWPT has found wide applications in recent years in a variety of technologies involving WET. Concrete examples include the integration of RWPT in several fields such as cellular phones and EV chargers, including those used in the innovative concept of road charging.

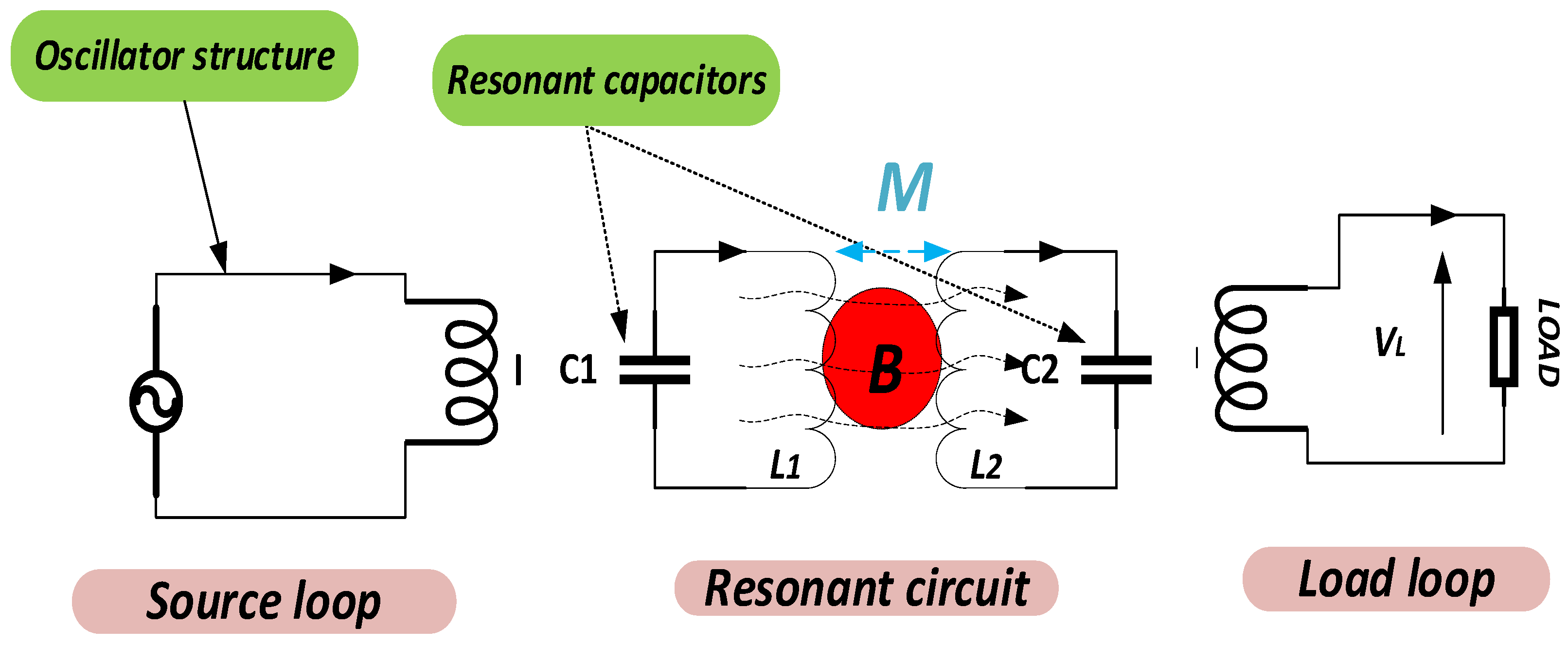

Figure 7.

Circuit representation equivalent to RWPT system.

Figure 7.

Circuit representation equivalent to RWPT system.

Equation 19 defines the coupling coefficient k. Generally, when the coupling constant k is higher, it means that there is increased transfer of magnetic flux to the receiver coil from the transmitter. Hence, it is clear that efficiency is linked to the coupling coefficient in a direct way.

When the coils are loosely coupled, the inductance becomes significant. To counteract or nullify the influence of this leakage inductance, a capacitor can be inserted in series. I let us examine two coils that are magnetically linked, as represented in

Figure 8(a). A one system with loose coupling, the leakage inductance can surpass the mutual inductance. As a result, the leakage reactance (L

LI) impedes the current flow to the output, particularly at elevated operating frequencies (where f=ω/2π). By introducing a series capacitor and tuning it to the LC resonator frequency (f

0). As depicted in

Figure 8(b) this concerns the two primary and secondary coils. Given fact, the leakage reactance can be compensated for, while effectively reducing the impedance along the energy path from the source into the circuit.

The operating frequency f

0 is defined as:

Here, C represents the capacitance of the resonant capacitor. Leveraging its negative reactance to offset the leakage inductance’s positive reactance represents one technique known as "impedance matching," which aims at minimizing the reactance along the energy flow path.

Figure 7 and

Figure 8 illustrate the link between the distance separating both coils and the k coupling factor k and the M mutual inductance, as outlined by equation 20. The relationship between M, k, and the distance between the coils is clearly one of inverse proportionality. Furthermore, when employing the mutual inductance M the commonly adopted closed-form solution. this inverse relationship exhibits a cubic nature. Thus, to achieve a sufficient coupling factor, it is advisable to position the coils as closely together as feasible, taking into account the desired degree of coupling.

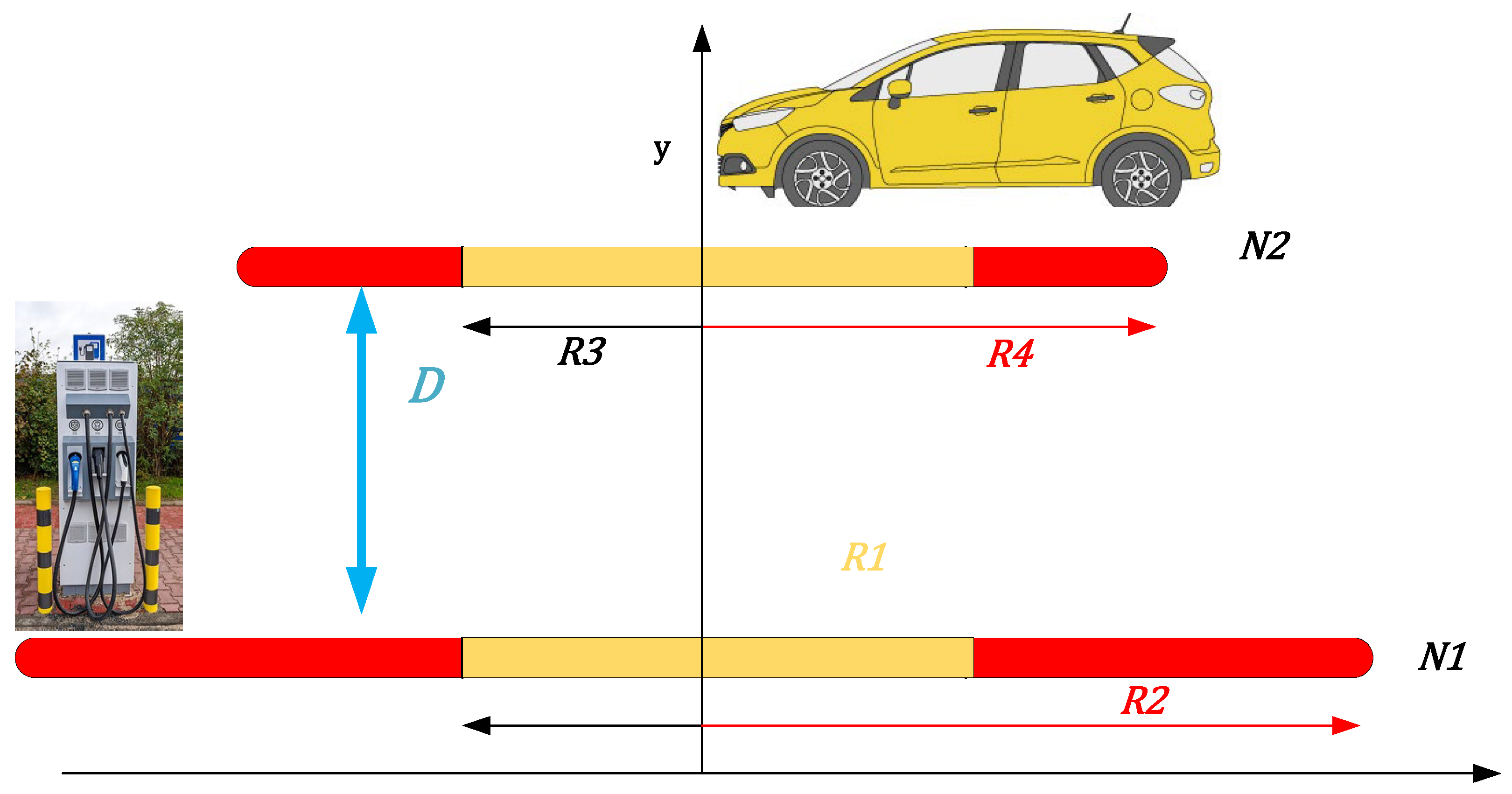

As depicted in

Figure 9 terms N1 and N2 represent the quantity of rotations made by both coils, while R2 and R4 designate the external dimensions of the coils, and R1 and R3 correspond to the doils’ inner racdii.

The efficiency of the system can be determined by employing the subsequent formula:

3.6. Size of Batteries

Sizing the battery of an EV is a critical step in the design of electric propulsion. In

Figure 10, several factors need to be taken into account to determine the battery capacity required to meet the specific needs of the vehicle. Here are some of the key factors to consider when sizing an EV battery:

Range required: The distance the vehicle must be able to cover between two charges determines the battery capacity. It is important to take into account the driving habits, the usual routes, and the needs of the vehicle owner.

Vehicle weight: The weight of the vehicle directly influences the amount of energy needed to move it. A heavier vehicle generally requires a higher-capacity battery to maintain an acceptable range.

System efficiency: The electric propulsion system’s overall efficiency, including the electric motor, the transmission, and the controller, can affect the amount of energy needed to travel a given distance. A more efficient system may allow a longer range with a lower battery capacity.

Environmental conditions: Environmental conditions, such as extreme temperatures, can have an impact on battery performance. Battery capacity can be reduced in cold weather, for example. Therefore, it is crucial to consider these factors when determining the appropriate size for the battery.

Battery life: Battery life is also an important factor. The higher the battery capacity, the greater the number of charge/discharge cycles it can withstand. However, higher-capacity batteries can be more expensive.

Cost: Battery cost is a critical element in the design of an EV. The sizing process needs to find a middle ground between the necessary battery capacity and the total cost.

Charging infrastructure: The availability and ease of access to charging stations can influence the size of the battery required. A well-developed recharging network may allow a smaller battery capacity, as drivers can recharge more frequently.

The physical dimensions of an EV battery are generally determined by the arrangement of the battery cells and the way they are assembled to form a battery pack. The specific mathematical formulas depend on the geometry chosen for the battery pack. Here are some basic elements that might be taken into account:

Battery volume: If the battery has a rectangular shape, the formula for volume V will be:

where L represents the length, l symbolizes the width, and h denotes the height.

Energy capacity: The energy capacity C of the battery is usually given in kilowatt-hours (kWh). This depends on both the energy density of the cells and the quantity of cells within the battery pack.

where n represents the cells’ number, and E signifies the individual energy capacity of a cell in kilowatt-hours (kWh).

Battery voltage: The Vbattery voltage of an Ncell series battery is the sum of the individual cell voltages. Vbattery=N×Vcell where the Vcell is the voltage of a cell.

Battery weight: The weight P of the battery depends on the density of the battery and the volume occupied by the battery.

where Density is the density of the battery.

4. Integrated System Modeling and Optimization Algorithms: Enhancing Efficiency and Performance

The selected panel model for system modeling in Simulink is the SunPower SPR -315E –WHT -U. The electrical specifications of this model are outlined in

Table 1.

Figure 11 and

Figure 12 illustrate the outcomes derived from simulating the model with an optimal parameterization aimed at achieving maximum output power, particularly at T=25°C and G=1000w/m

2.

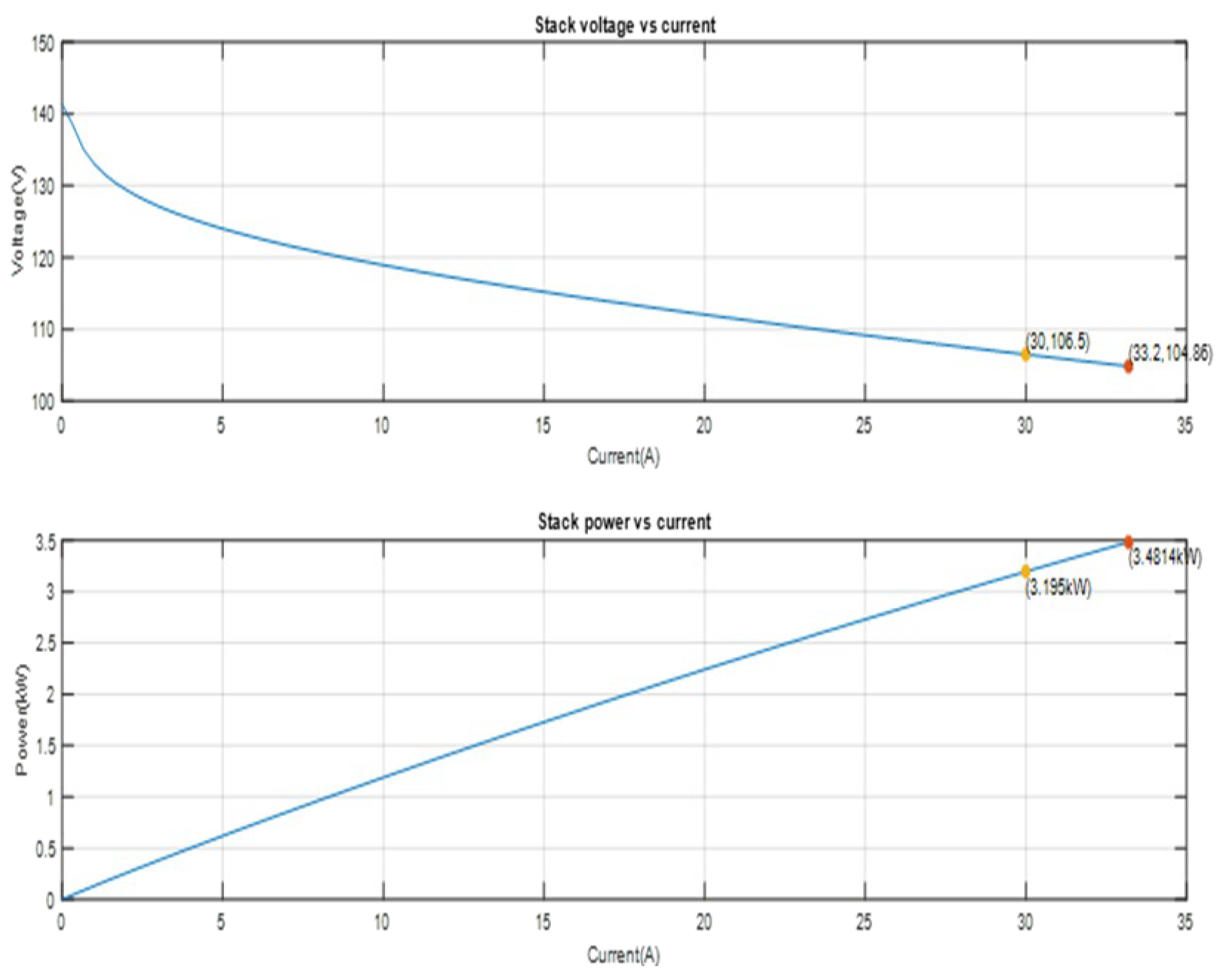

Table 2 provides a comprehensive overview of electrical parameters linked to the hydrogen fuel cell utilized in the simulation conducted on Simulink. The table encompasses crucial details, such as the voltage, the current, and other key electrical characteristics, offering a detailed insight into the behavior and performance of the hydrogen fuel cell within the simulation framework. This information serves as a valuable reference to understand the intricacies of the fuel cell's electrical properties, aiding in the analysis and interpretation of simulation results on Simulink.

Where

Figure 14 shows the results obtained from simulating the model under optimal parameterization, which achieves a maximal power output of the fuel cell generator.

To improve the capacity and performance of a PV array, a power converter can be actually introduced between the E-class inverter and the PV array, which acts as a resonant structure. Added to that, this "boost" DC-DC converter, which is basically governed by the iterative MPPT P&O algorithm nominally (controlled by the α: duty cycle), delivers appropriate voltage. Because of this fact, the MPPT algorithm achieves the maximum power, which is denoted as Pmax, from the PV. array. This is accomplished through a control system that monitors both V

pv and I

pv. In this context, parameter α varies within the interval [10%; 90%], as illustrated in

Figure 15.

4.1. Investigating the Impedance Characteristics of a VHF Inverter

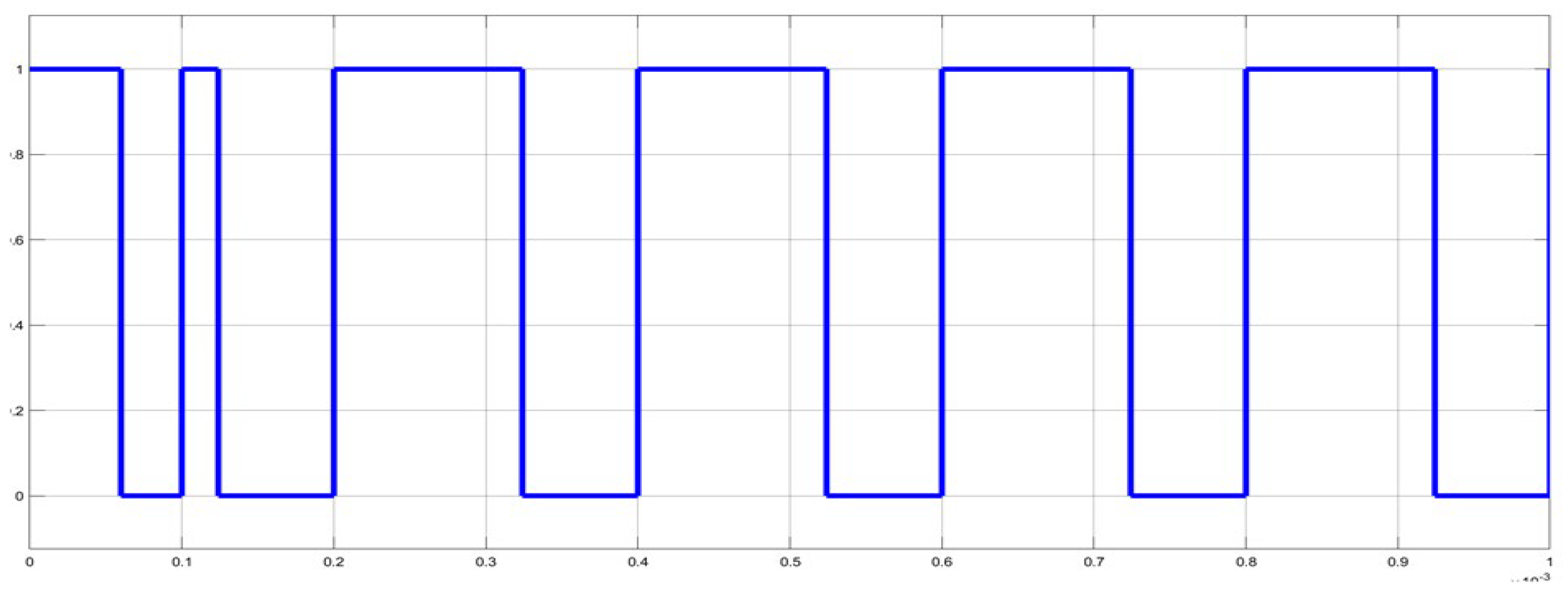

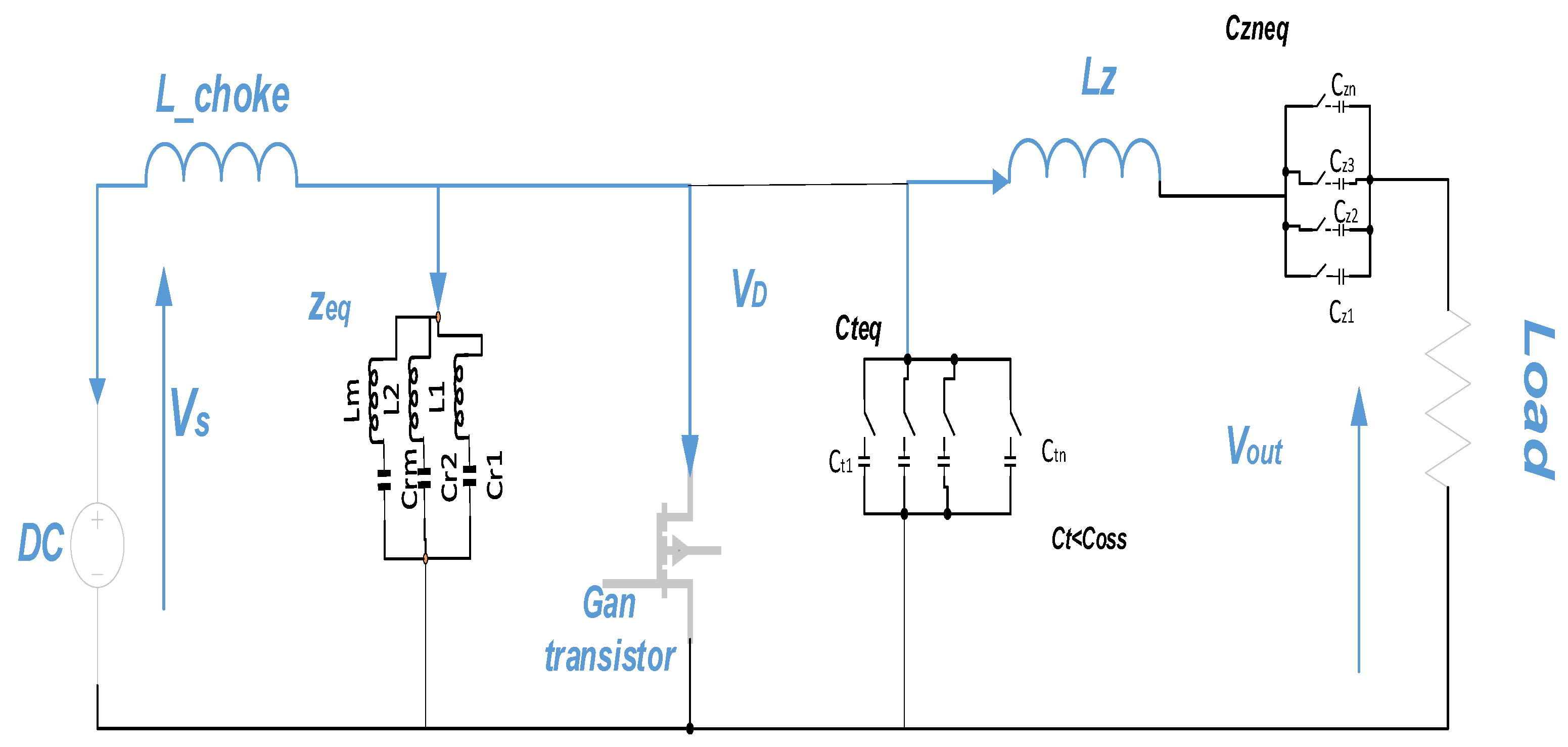

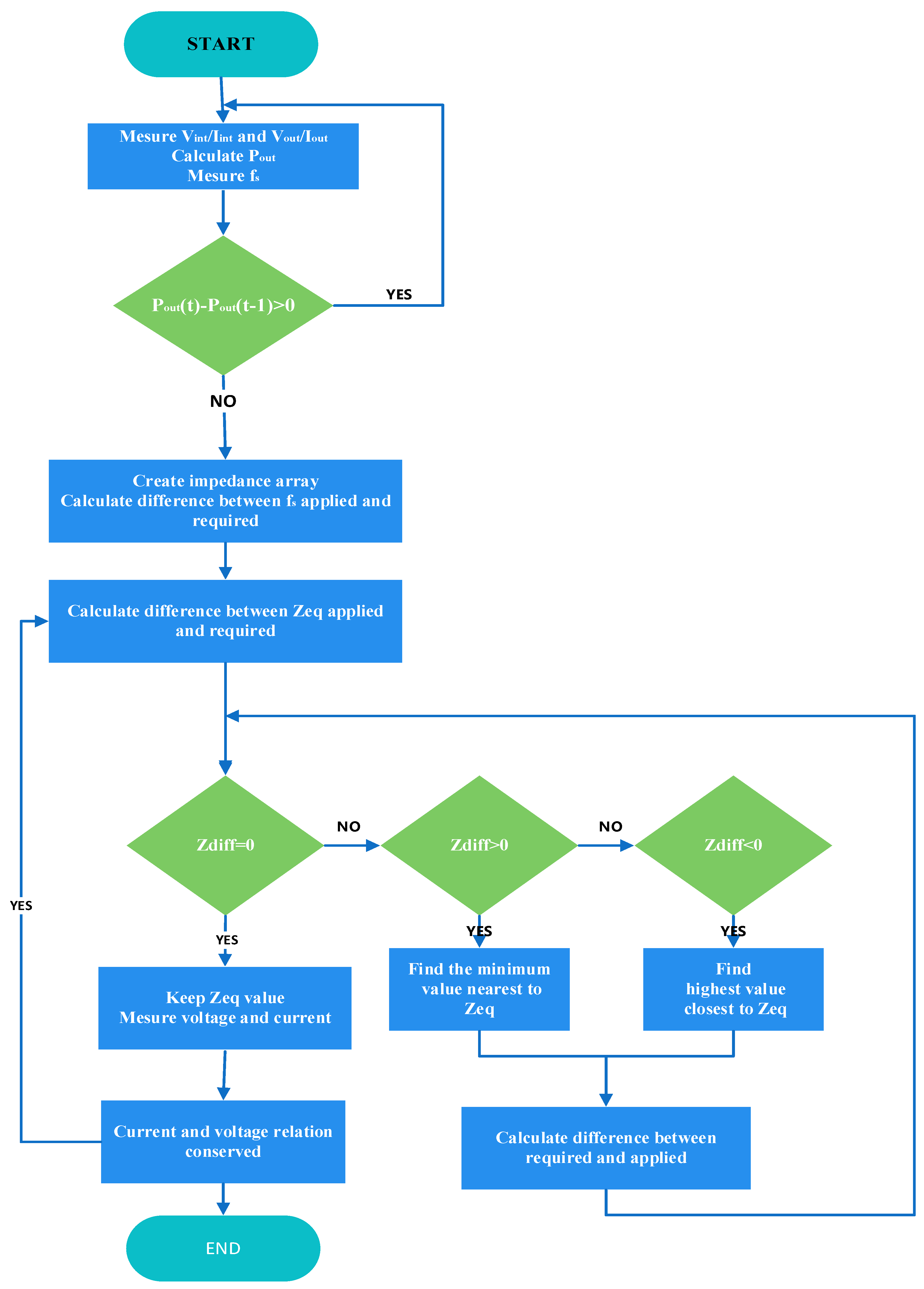

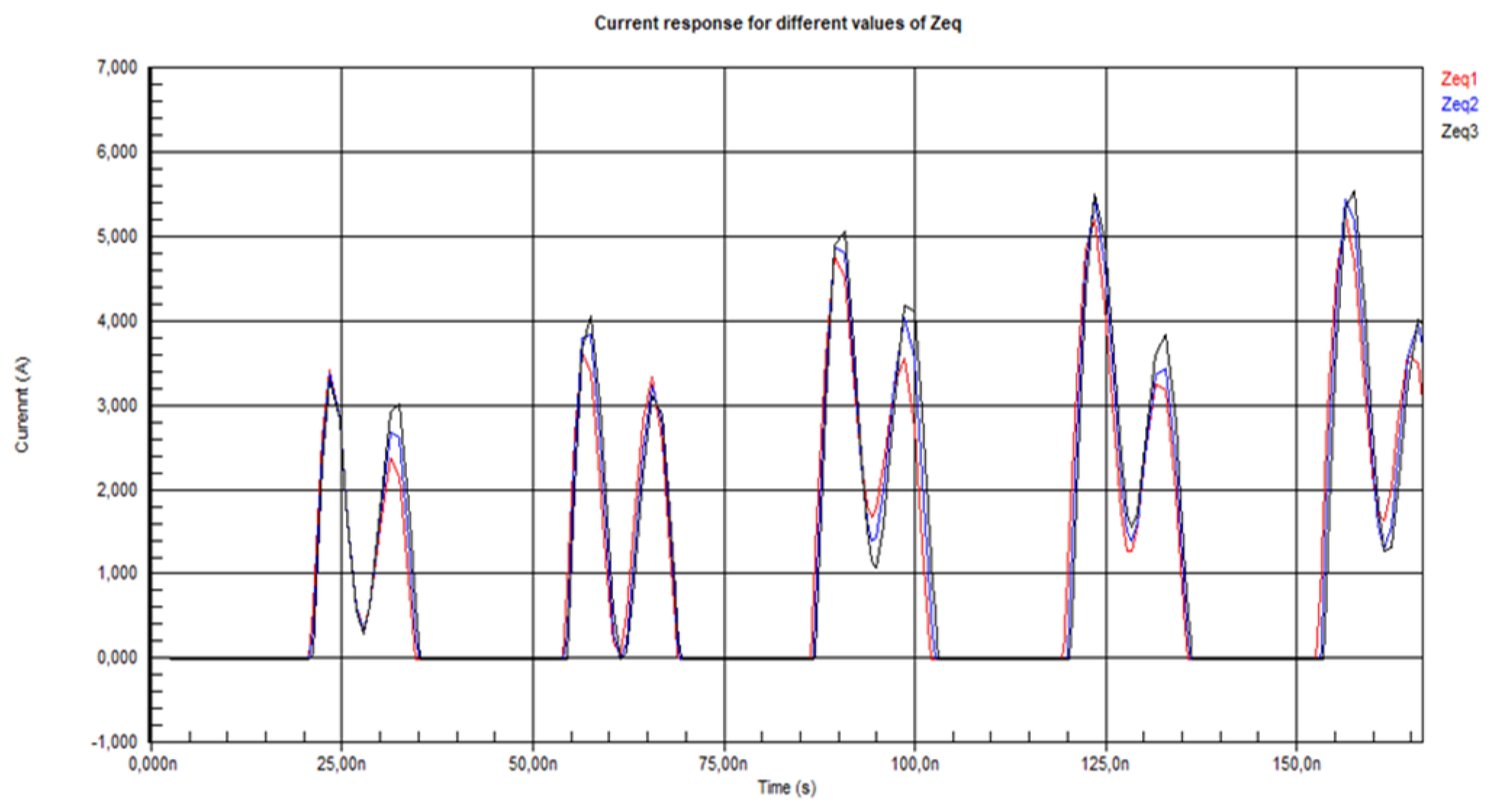

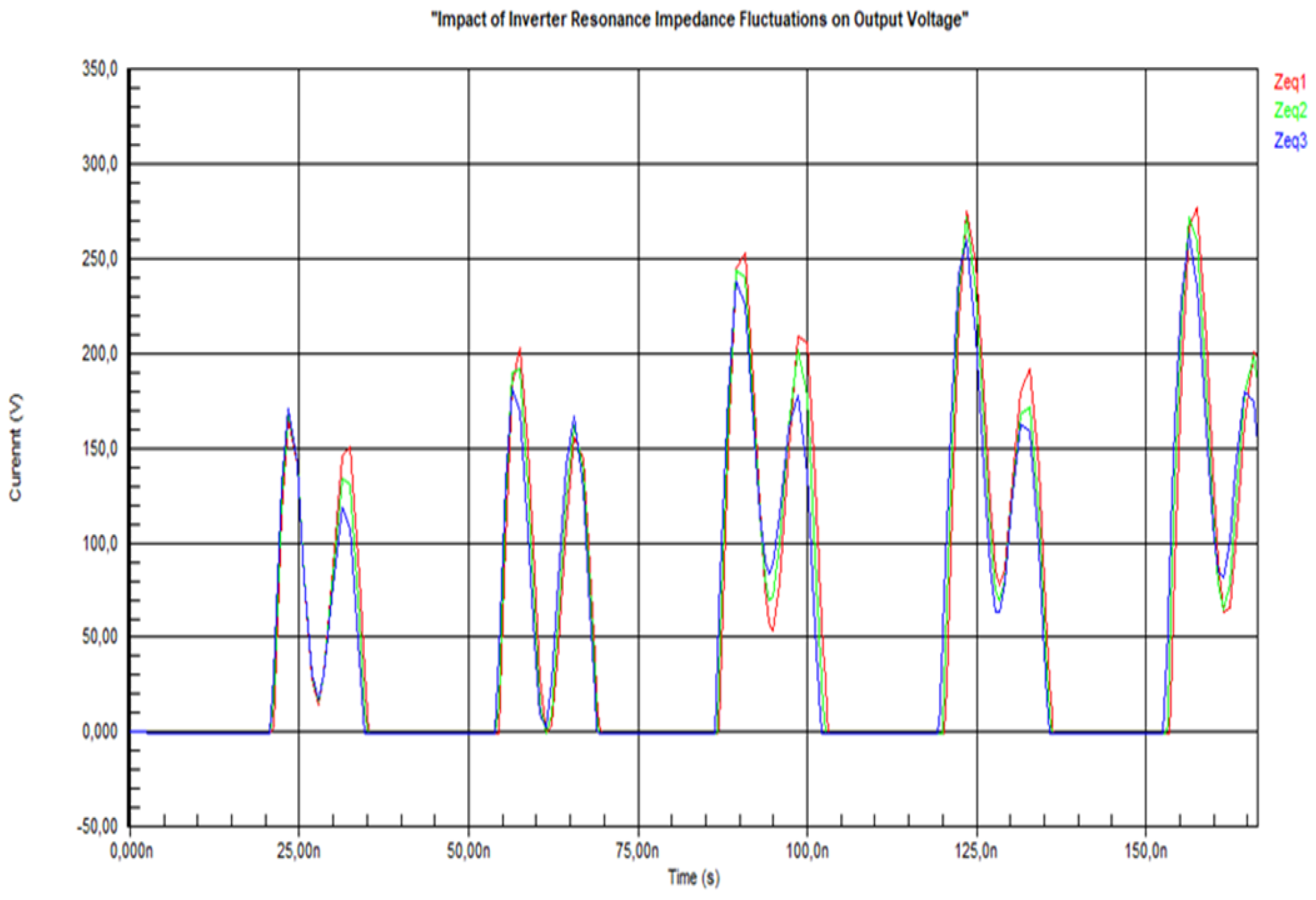

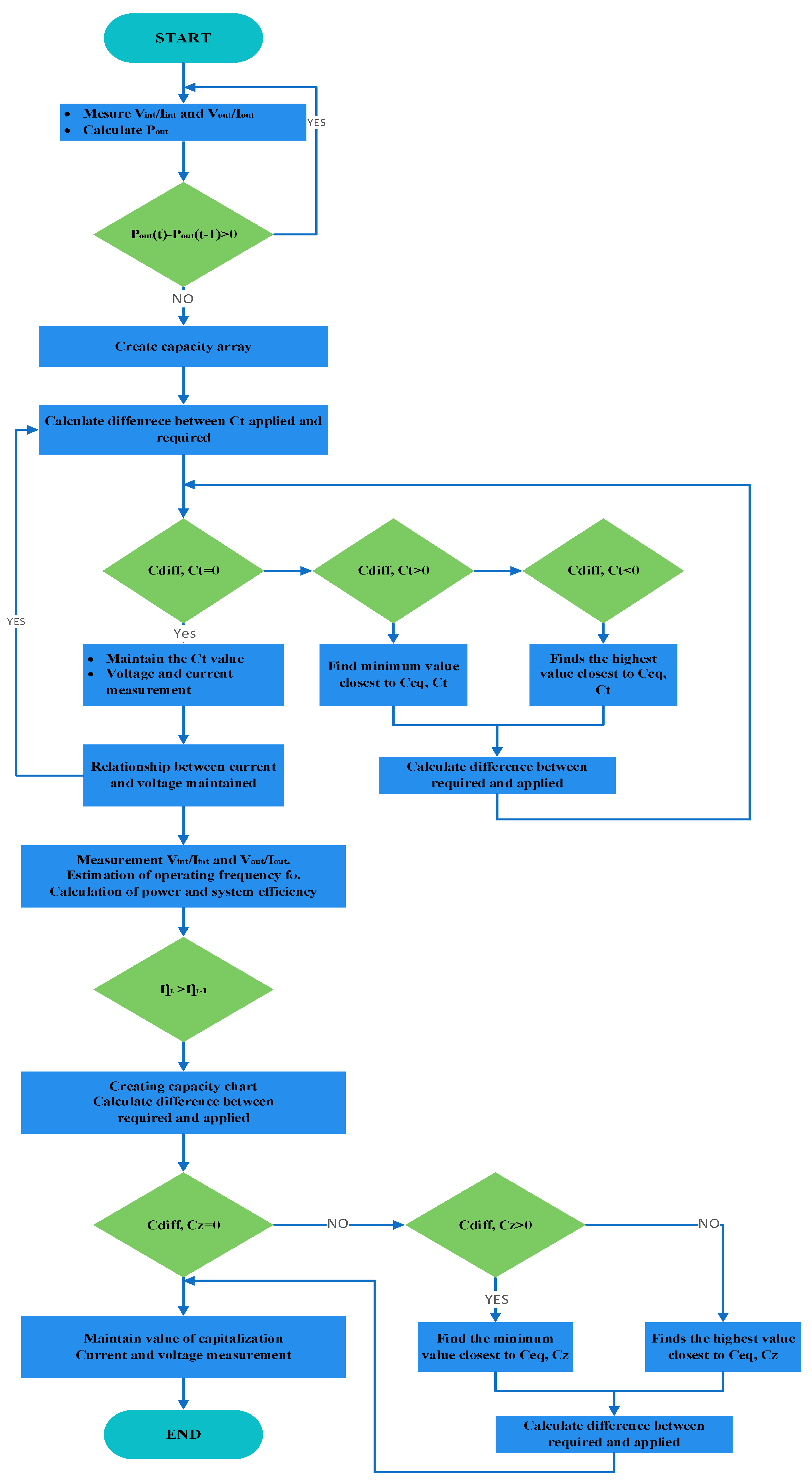

To provide comprehensive guidelines for designing the resonant characteristics of class-Ф2 conducted on the resonant parameters of the inverters undertaken to investigate modeling techniques specific to this class and to minimize the resonant current for analyzing magnitude and conduction losses in resonant power converters, we developed one analytic modeling approach for class-Ф2 inverters. Indeed such a method involves altering the inverter’s input impedance, while simultaneously overly employing one variable impedance (Zeq) with the purpose of tailoring and adjusting the resonance parameters and while considering key factors like the control signal emanating from the transistor response, the network signal quality and the DSP or driver module, as illustrated in

Figure 16 and

Figure 17. The capacitance at the output of the Gallium Nitride (GaN) transistor, often denoted as (Ct), is proportionally related to condition Ct < Coss, relative to the operating frequency of the inverter. The operational duration and manufacturing deviations of the transistor impact the (Coss) internal capacitance and as a consequence the overall system, necessitating careful consideration in the Ct selection.

Figure 17 outlines the algorithm for optimizing class-Ф2 inverters’operating mode using a capacitor array with the target of adjusting Ct optimally for Pout_max. Additionally, optimization trials between the RWPT system and the class-Ф2 inverters involve adjusting optimal operations achieved by balancing the input capacitance of RWPT (Cin) and output capacitance of inverter (Cz) for attaining maximum power at the secondary coil terminal (P

out_max) while minimizing losses (P

loss_min).

For enhancing the effectiveness and performance of inverters (of class-Φ2), the algorithm can be utilized to fine-tune the value of the resonant impedance, with a focus on obtaining maximum P

out The adjustment of the structure's resonance impedance directly impacts the inverter output signal’s second harmonic component, contributing to the reduction conduction losses and resonant current magnitude in resonant power converters.

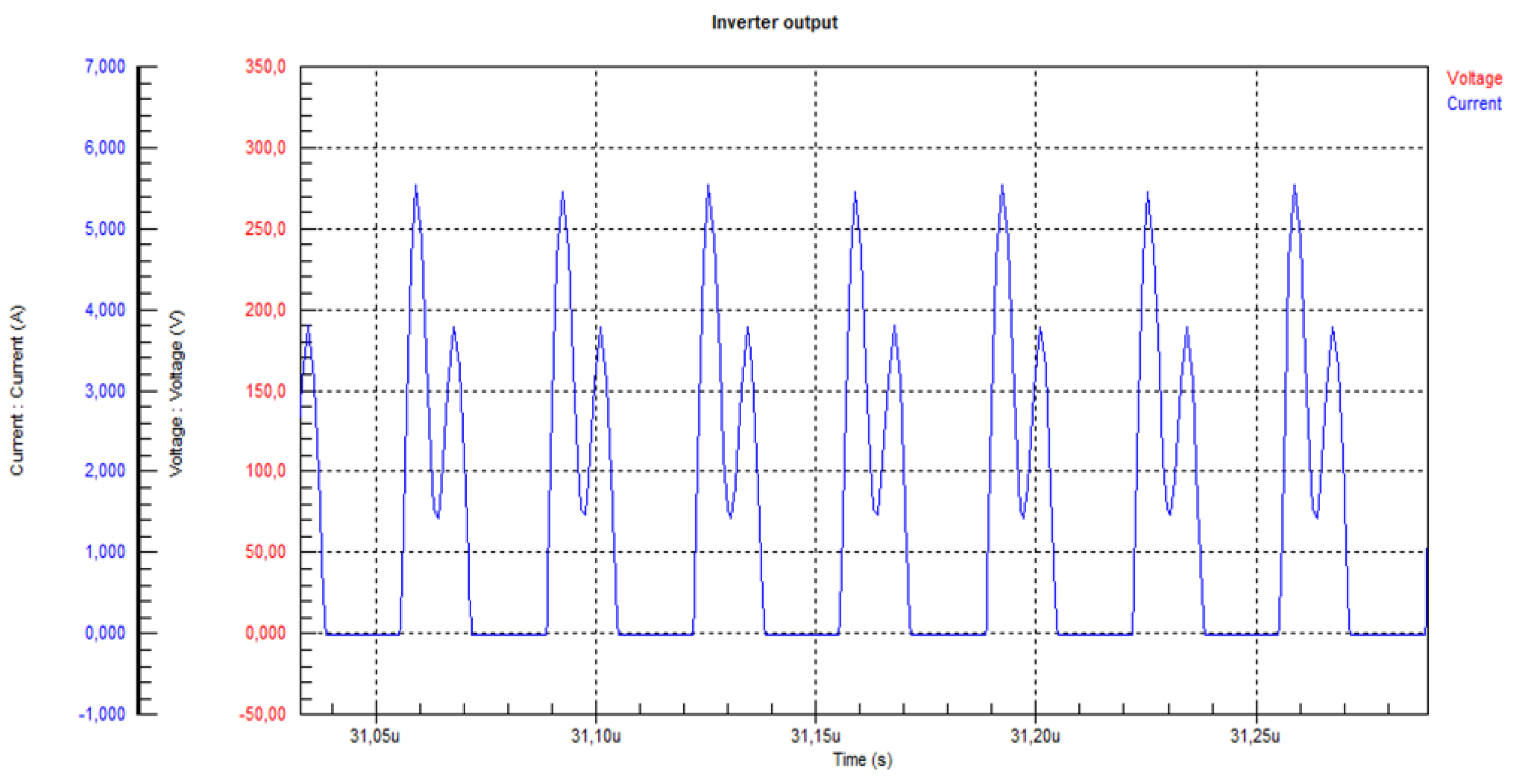

Figure 18 and

Figure 19 visually represent the current-voltage patterns observed in the resistive load terminal, illustrating the effectiveness of this optimization approach.

The capacitance value attributed to the output of the transistor (Ct) should be directly corresponding to the inverter’s operating frequency (Fs). Ct must adhere to the Ct < Coss condition, considering the influence of the operating time and manufacturing errors on the internal capacitance (Coss) of the transistor, as well as the frequency of the entire system. Consequently, selecting Ct should carefully consider these factors. The optimization process is outlined by the algorithm depicted in

Figure 20 for the operating mode of class-Φ2, utilizing one capacitor array with the objective of fine-tuning the optimal Ct value regarding P

out_max. Simultaneously, optimizing the system across a class-Φ2 inverter and the RWPT system necessitates adjustments to the inverter’s output capacitance (Cz), as well as to the input capacitance of RWPT (C

in). This guarantees the optimal operational structure range, aiming at achieving maximal power at the secondary coil’s terminal (P

out_max) while minimizing losses (P

loss_min).

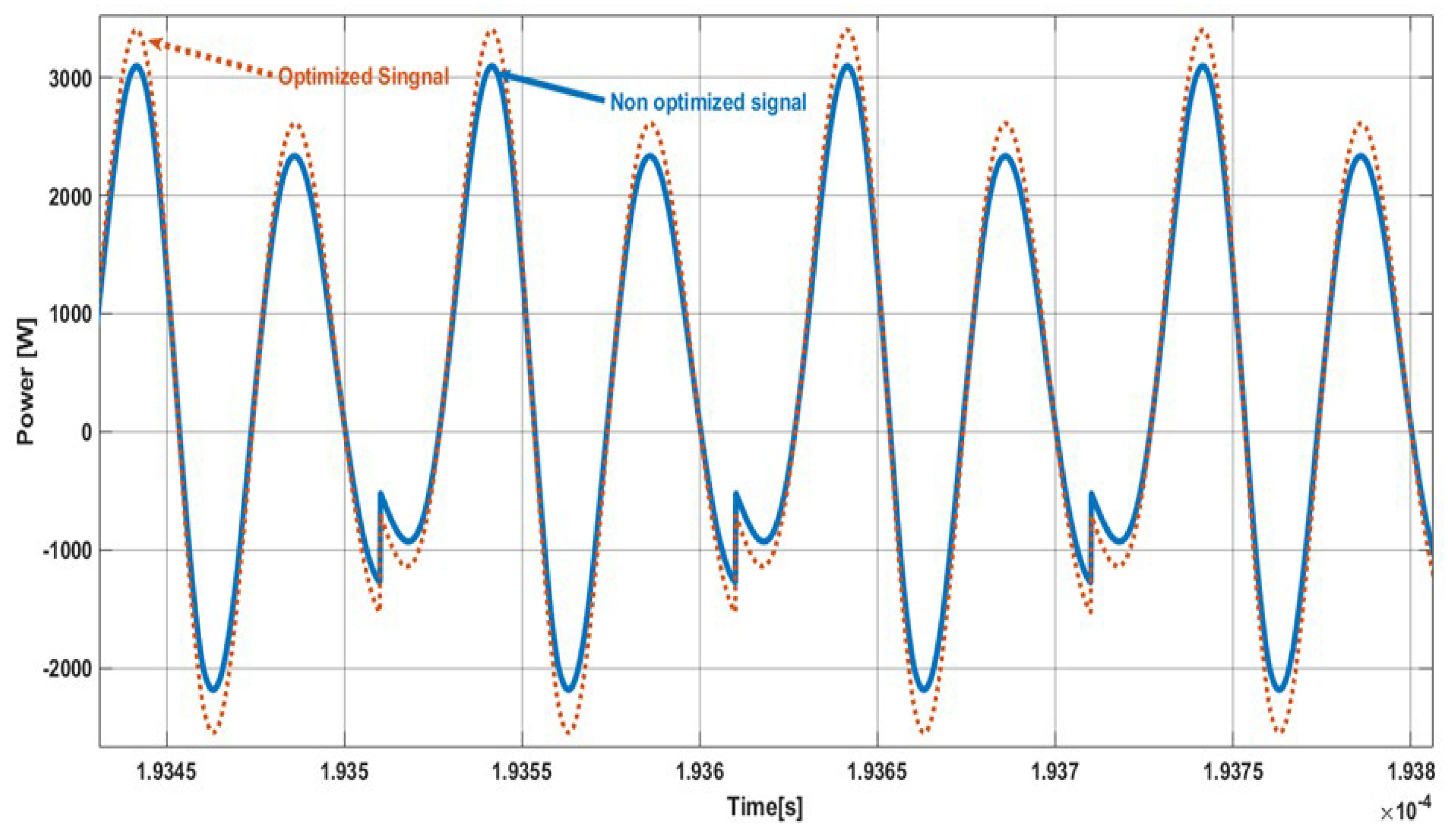

Figure 21 and

Figure 22 depict how changes in capacitance Ct and Cz affect the power P

out delivered by the inverter. Through the use of the previous algorithm, we can approximate those values of Ct and Cz to achieve at the inverter output the maximum power P

out_max.

Where

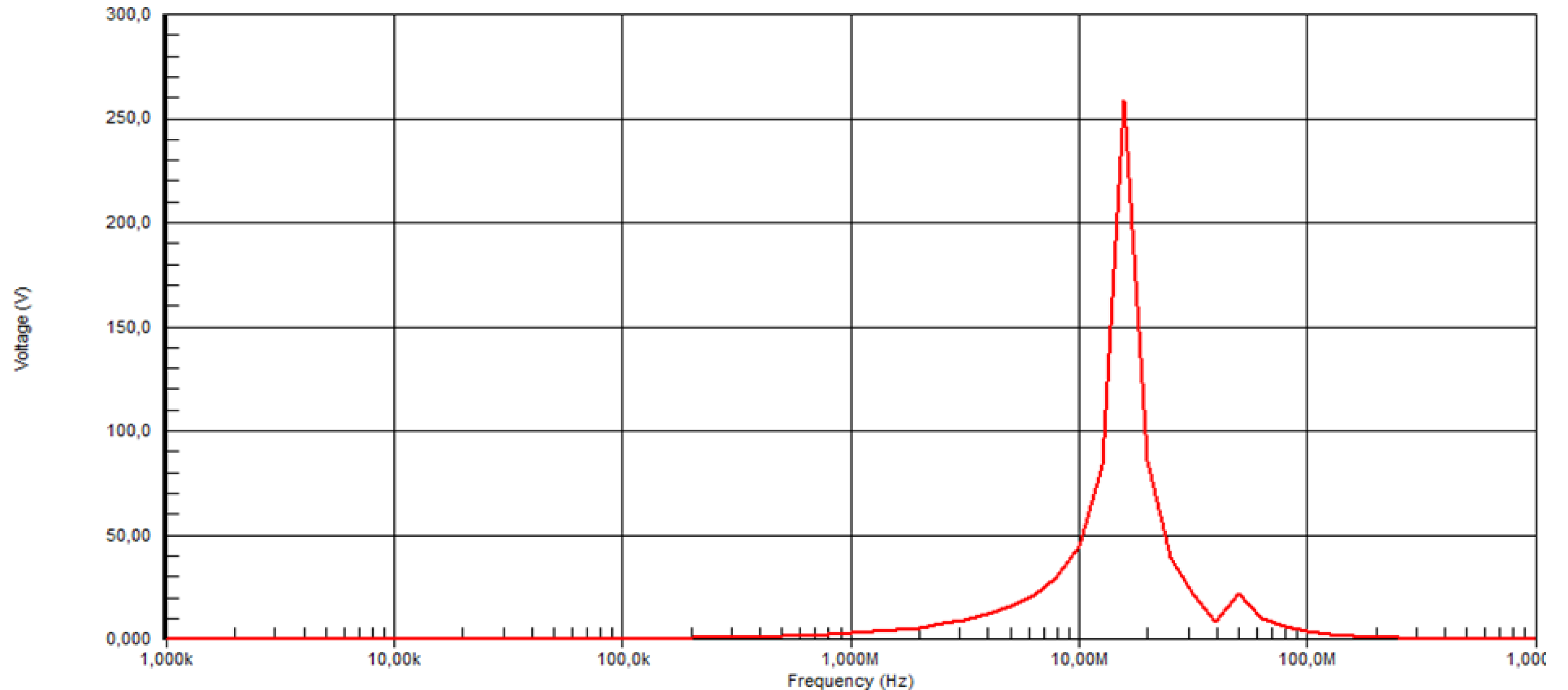

Figure 23 represents the system resonant frequency in an optimal work mode.

The VHF inverter model adheres to the following hypotheses:

The transistor can function like one switch with negligible switching times, an off-interval resistance approaching infinity, and a finite on-interval resistance (Rinv).

The shunt capacitance (Ct) remains unaffected by such switching voltage, including the transistor’s output capacitance.

We consider all passive elements as perfect and unchanging over time. In addition to that, the switch operates at any duty cycle (D) and any frequency (fs). In this case, we define the duty cycle as the switch-on time we divide this latter by (T = 1/fs) the switching period.

To achieve an optimal operation, the inverter structure necessitates soft switching, called ZVS, to minimize losses.

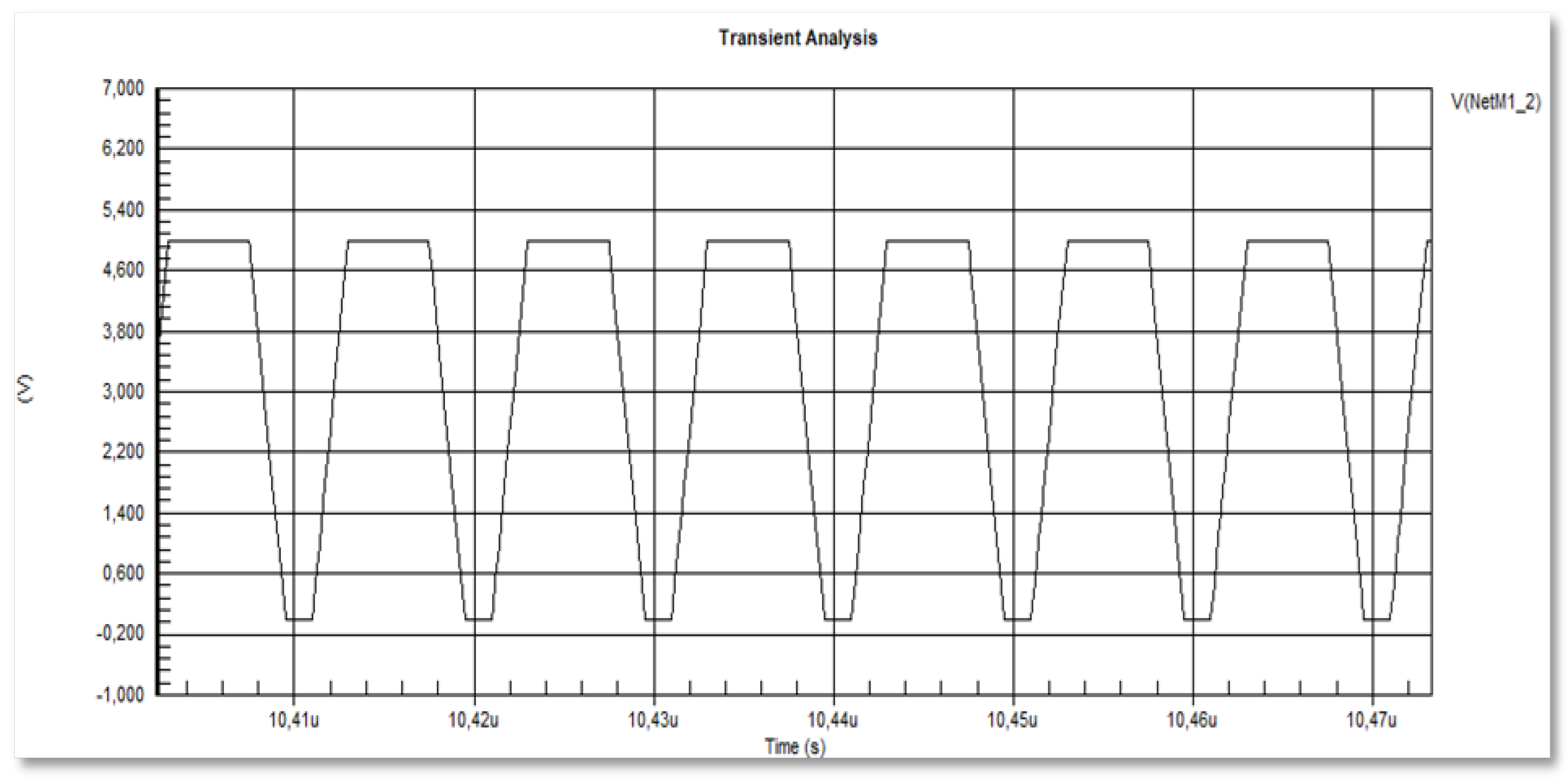

Figure 24 illustrates the control signal of class-Φ2 for specific parameters, including a duty cycle (D) of 45%, a fall time of 0.002us, a time delay of 0.001us, and a rise time of 0.002us.

5. Conclusions

In conclusion, this paper has introduced a groundbreaking hybrid EV charging station that leverages a hybrid power source, combining PVPs and a fuel cell. Operating at 240V and 14A, the system integrates the WPT technology and consists of five essential components. The optimization process, conducted in two stages, involves maximizing power generation through MPPT in the boost converter and employing a class-ϕ2 inverter at 30 MHz during the HF phase. Synchronized with the resonant frequency of RWPT coils, control is executed through a DSP card utilizing ZVS for an efficient operation. This innovative design optimizes power transfer, utilizing hybrid sources to contribute to the sustainability of EV charging solutions. Integrating renewable energy and advanced control techniques exemplifies a promising direction for the future of hybrid EV charging infrastructure, emphasizing efficiency, sustainability, and technological advancements.

Author Contributions

Conceptualization, C.B.S. and G. B.; methodology, C.B.S., G. B. and M. H. C; software, G. B.; validation, C.B.S., G. B. and M. H. C; formal analysis, C.B.S., G. B. and M. H. C; investigation, C.B.S., G. B. and M. H. C.; resources, C.B.S., G. B. and M. T.; data curation, G. B. and C.B.S; writing—original draft preparation, G. B. and C.B.S; writing—review and editing, C.B.S., G. B. and M. T.; visualization, C.B.S., G. B. and M. H. C.; supervision, C.B.S. and M. H. C; project administration, C.B.S and A. R.. All authors have read and agreed to the published version of the manuscript.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Agyeman, S.D.; Lin, B. Nonrenewable and Renewable Energy Substitution, and Low–Carbon Energy Transition: Evidence from North African Countries. Renew. Energy 2022, 194, 378–395. [Google Scholar] [CrossRef]

- Mahesh, A.; Chokkalingam, B.; Mihet-Popa, L. Inductive Wireless Power Transfer Charging for Electric Vehicles–A Review. IEEE Access 2021, 9, 137667–137713. [Google Scholar] [CrossRef]

- Huda, S.M.A.; Arafat, M.Y.; Moh, S. Wireless Power Transfer in Wirelessly Powered Sensor Networks: A Review of Recent Progress. Sensors 2022, 22, 2952. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.; Khan, Z.A.; Alvarez-Alvarado, M.S.; Zhang, Y.; Huang, Z.; Imran, M. A Critical Review of Sustainable Energy Policies for the Promotion of Renewable Energy Sources. Sustainability 2020, 12, 5078. [Google Scholar] [CrossRef]

- Khatun, E.; Hossain, M.M.; Ali, M.S.; Halim, M.A. A Review on Microgrids for Remote Areas Electrification-Technical and Economical Perspective. Int. J. Robot. Control Syst. 2023, 3, 627–642. [Google Scholar] [CrossRef]

- Rahim, S.; Wang, Z.; Ju, P. Overview and Applications of Robust Optimization in the Avant-Garde Energy Grid Infrastructure: A Systematic Review. Appl. Energy 2022, 319, 119140. [Google Scholar] [CrossRef]

- Sarkar, M.; Majumder, A.; Bhattacharya, S.; Sarkar, B. Optimization of Energy Cycle under a Sustainable Supply Chain Management. RAIRO - Oper. Res. 2023, 57, 2177–2196. [Google Scholar] [CrossRef]

- Chehab, M.H.; Ben Salah, C.; Falama, R.Z.; Tlija, M.; Rabhi, A. Comparative Analysis of Energy Storage Technologies for Microgrids. Int. Trans. Electr. Energy Syst. 2023, 2023, 1–24. [Google Scholar] [CrossRef]

- Gervet, C.; Atef, M. Optimal Allocation of Renewable Energy Parks: A Two–Stage Optimization Model. RAIRO - Oper. Res. 2013, 47, 125–150. [Google Scholar] [CrossRef]

- Abramov, E.; Peretz, M.M. Adaptive Self-Tuned Controller IC for Resonant-Based Wireless Power Transfer Transmitters. IEEE Trans. Power Electron. 2021, 36, 12413–12431. [Google Scholar] [CrossRef]

- Alshareef, M.J. An Effective Falcon Optimization Algorithm Based MPPT Under Partial Shaded Photovoltaic Systems. IEEE Access 2022, 10, 131345–131360. [Google Scholar] [CrossRef]

- Radhakrishnan, R.K.G.; Marimuthu, U.; Balachandran, P.K.; Shukry, A.M.M.; Senjyu, T. An Intensified Marine Predator Algorithm (MPA) for Designing a Solar-Powered BLDC Motor Used in EV Systems. Sustainability 2022, 14, 14120. [Google Scholar] [CrossRef]

- Chen, X.H.; Tee, K.; Elnahass, M.; Ahmed, R. Assessing the Environmental Impacts of Renewable Energy Sources: A Case Study on Air Pollution and Carbon Emissions in China. J. Environ. Manage. 2023, 345, 118525. [Google Scholar] [CrossRef] [PubMed]

- Bhattacharyya, D.; Pradhan, S. ; Shabbiruddin Barriers in Replacement of Conventional Vehicles by Electric Vehicles in India. Int. J. Decis. Support Syst. Technol. 2023, 15, 1–20. [Google Scholar] [CrossRef]

- Sundararaj, V.; Anoop, V.; Dixit, P.; Arjaria, A.; Chourasia, U.; Bhambri, P.; M R, R.; Sundararaj, R. CCGPA-MPPT: Cauchy Preferential Crossover-based Global Pollination Algorithm for MPPT in Photovoltaic System. Prog. Photovoltaics Res. Appl. 2020, 28, 1128–1145. [Google Scholar] [CrossRef]

- Falama, R.Z.; Dumbrava, V.; Saidi, A.S.; Houdji, E.T.; Salah, C. Ben; Doka, S.Y. A Comparative-Analysis-Based Multi-Criteria Assessment of On/Off-Grid-Connected Renewable Energy Systems: A Case Study. Energies 2023, 16, 1540. [Google Scholar] [CrossRef]

- Panov, Y.; Huber, L.; Jovanovic, M.M. Design Optimization and Performance Evaluation of Class Φ 2 VHF DC/DC Converter. In Proceedings of the 2020 IEEE Applied Power Electronics Conference and Exposition (APEC); IEEE, March 2020; pp. 2170–2177. [Google Scholar]

- Khare, V.; Chaturvedi, P. Design, Control, Reliability, Economic and Energy Management of Microgrid: A Review. e-Prime - Adv. Electr. Eng. Electron. Energy 2023, 5, 100239. [Google Scholar] [CrossRef]

- Jansen, I.; Petrova, S. Driving Towards Sustainability: Electric Vehicles’ Contribution to Environmental and Public Health. J. Sustain. Technol. Infrastruct. Plan. 2023, 7, 25–45. [Google Scholar]

- Ampah, J.D.; Afrane, S.; Agyekum, E.B.; Adun, H.; Yusuf, A.A.; Bamisile, O. Electric Vehicles Development in Sub-Saharan Africa: Performance Assessment of Standalone Renewable Energy Systems for Hydrogen Refuelling and Electricity Charging Stations (HRECS). J. Clean. Prod. 2022, 376, 134238. [Google Scholar] [CrossRef]

- Aijaz, I.; Ahmad, A. Electric Vehicles for Environmental Sustainability. In Smart Technologies for Energy and Environmental Sustainability. Green Energy and Technology; Agarwal, P., Mittal, M., Ahmed, J., Idrees, S.M., Eds.; Springer International Publishing: Cham, 2022; ISBN 978-3-030-80702-3. [Google Scholar]

- Mohsan, S.A.H.; Khan, M.A.; Mazinani, A.; Alsharif, M.H.; Cho, H.-S. Enabling Underwater Wireless Power Transfer towards Sixth Generation (6G) Wireless Networks: Opportunities, Recent Advances, and Technical Challenges. J. Mar. Sci. Eng. 2022, 10, 1282. [Google Scholar] [CrossRef]

- Pan, Z.; Quynh, N.V.; Ali, Z.M.; Dadfar, S.; Kashiwagi, T. Enhancement of Maximum Power Point Tracking Technique Based on PV-Battery System Using Hybrid BAT Algorithm and Fuzzy Controller. J. Clean. Prod. 2020, 274, 123719. [Google Scholar] [CrossRef]

- Yahia, I.; Salah, C. Ben; Saidi, A.S.; Mimouni, M.F.; Alshahrani, A. Contribution to Energy Management of Fuel Cell/Battery Hybrid Electric Vehicles. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2023, 237, 388–398. [Google Scholar] [CrossRef]

- Ye, Z.; Yang, M.; Chen, P.-Y. Multi-Band Parity-Time-Symmetric Wireless Power Transfer Systems for ISM-Band Bio-Implantable Applications. IEEE J. Electromagn. RF Microwaves Med. Biol. 2022, 6, 196–203. [Google Scholar] [CrossRef]

- Vanegas Cantarero, M.M. Of Renewable Energy, Energy Democracy, and Sustainable Development: A Roadmap to Accelerate the Energy Transition in Developing Countries. Energy Res. Soc. Sci. 2020, 70, 101716. [Google Scholar] [CrossRef]

- Gupta, R.S.; Tyagi, A.; Anand, S. Optimal Allocation of Electric Vehicles Charging Infrastructure, Policies and Future Trends. J. Energy Storage 2021, 43, 103291. [Google Scholar] [CrossRef]

- Ram, J.P.; Pillai, D.S.; Ghias, A.M.Y.M.; Rajasekar, N. Performance Enhancement of Solar PV Systems Applying P&O Assisted Flower Pollination Algorithm (FPA). Sol. Energy 2020, 199, 214–229. [Google Scholar] [CrossRef]

- Imanaka, M.; Toyoda, S.; Sugimoto, S.; Kato, T. Coordinated Control of Demand Response for Large Installation of Renewable Energy Sources in Isolated Islands. Int. J. Electr. Electron. Eng. Telecommun. 2022, 325–332. [Google Scholar] [CrossRef]

- Manoj, V. Towards Efficient Energy Solutions: MCDA-Driven Selection of Hybrid Renewable Energy Systems. Int. J. Electr. Electron. Eng. Telecommun. 2024, 13, 98–111. [Google Scholar] [CrossRef]

- Wong, J.; Lim, Y.S. Experimental Validation for Dynamic Fuzzy-Controlled Energy Storage System to Maximize Renewable Energy Integration. Int. J. Electr. Electron. Eng. Telecommun. 2018, 83–89. [Google Scholar] [CrossRef]

- Suman, A. Role of Renewable Energy Technologies in Climate Change Adaptation and Mitigation: A Brief Review from Nepal. Renew. Sustain. Energy Rev. 2021, 151, 111524. [Google Scholar] [CrossRef]

- Hao, D.; Qi, L.; Tairab, A.M.; Ahmed, A.; Azam, A.; Luo, D.; Pan, Y.; Zhang, Z.; Yan, J. Solar Energy Harvesting Technologies for PV Self-Powered Applications: A Comprehensive Review. Renew. Energy 2022, 188, 678–697. [Google Scholar] [CrossRef]

- Yap, K.Y.; Chin, H.H.; Klemeš, J.J. Solar Energy-Powered Battery Electric Vehicle Charging Stations: Current Development and Future Prospect Review. Renew. Sustain. Energy Rev. 2022, 169, 112862. [Google Scholar] [CrossRef]

- Chehab, M.H.; Khelil, M.; Salah, C. Ben; Tlija, M.; Rabhi, A. Photovoltaic Class-E Inverter for Resonance Wireless Power Transfer for Electric Vehicle Charging Applications with Optimization Algorithms. Energy Technol. 2023, 11. [Google Scholar] [CrossRef]

- Aguila-Leon, J.; Vargas-Salgado, C.; Chiñas-Palacios, C.; Díaz-Bello, D. Solar Photovoltaic Maximum Power Point Tracking Controller Optimization Using Grey Wolf Optimizer: A Performance Comparison between Bio-Inspired and Traditional Algorithms. Expert Syst. Appl. 2023, 211, 118700. [Google Scholar] [CrossRef]

- Serra, P.M.D.; A, E.-S. Sourcing Power with Microbial Fuel Cells: A Timeline. J. Power Sources 2021, 482, 228921. [Google Scholar] [CrossRef]

- Sun, Y. The Achievement, Significance and Future Prospect of China’s Renewable Energy Initiative. Int. J. Energy Res. 2020, 44, 12209–12244. [Google Scholar] [CrossRef]

- Asghar, R.; Sulaiman, M.H.; Mustaffa, Z.; Ullah, N.; Hassan, W. The Important Contribution of Renewable Energy Technologies in Overcoming Pakistan’s Energy Crisis: Present Challenges and Potential Opportunities. Energy Environ. 2023, 34, 3450–3494. [Google Scholar] [CrossRef]

- Eltoumi, F.M.; Becherif, M.; Djerdir, A.; Ramadan, H.S. The Key Issues of Electric Vehicle Charging via Hybrid Power Sources: Techno-Economic Viability, Analysis, and Recommendations. Renew. Sustain. Energy Rev. 2021, 138, 110534. [Google Scholar] [CrossRef]

- Nezamuddin, O.N.; Nicholas, C.L.; Santos, E.C. dos The Problem of Electric Vehicle Charging: State-of-the-Art and an Innovative Solution. IEEE Trans. Intell. Transp. Syst. 2022, 23, 4663–4673. [Google Scholar] [CrossRef]

- Parvez, M.; Pereira, A.T.; Ertugrul, N.; Weste, N.H.E.; Abbott, D.; Al-Sarawi, S.F. Wide Bandgap DC–DC Converter Topologies for Power Applications. Proc. IEEE 2021, 109, 1253–1275. [Google Scholar] [CrossRef]

Figure 1.

Illustration of a hybrid-powered wireless charging station for EVs.

Figure 1.

Illustration of a hybrid-powered wireless charging station for EVs.

Figure 1.

The equivalent electrical circuit of solar panel cell.

Figure 1.

The equivalent electrical circuit of solar panel cell.

Figure 3.

Electrical circuit representation corresponding to a single solar panel cell.

Figure 3.

Electrical circuit representation corresponding to a single solar panel cell.

Figure 4.

I-V (current-voltage) and P-V (power-voltage) characteristics of array presented under conditions of 1000 W/m² irradiance and specific temperature.

Figure 4.

I-V (current-voltage) and P-V (power-voltage) characteristics of array presented under conditions of 1000 W/m² irradiance and specific temperature.

Figure 5.

The I-V (current-voltage) and P-V (power-voltage) characteristics of the array graphically illustrated at the temperature of 25°C and designated level of irradiance.

Figure 5.

The I-V (current-voltage) and P-V (power-voltage) characteristics of the array graphically illustrated at the temperature of 25°C and designated level of irradiance.

Figure 6.

Circuit representation corresponding to boost converter.

Figure 6.

Circuit representation corresponding to boost converter.

Figure 8.

Equivalent circuit depicting magnetic coupling of two coils, with capacitors in series (a) and without capacitors (b).

Figure 8.

Equivalent circuit depicting magnetic coupling of two coils, with capacitors in series (a) and without capacitors (b).

Figure 9.

Centralized parallel positioning of two flat spiral coils.

Figure 9.

Centralized parallel positioning of two flat spiral coils.

Figure 11.

W=1000 and specified temperature.

Figure 11.

W=1000 and specified temperature.

Figure 12.

T=25 deg and specified irradiances.

Figure 12.

T=25 deg and specified irradiances.

Figure 13.

One module production.

Figure 13.

One module production.

Figure 14.

Fuel cell production.

Figure 14.

Fuel cell production.

Figure 15.

Boost-converter duty cycle with P&O Algorithm.

Figure 15.

Boost-converter duty cycle with P&O Algorithm.

Figure 16.

Optimized VHF inverter equivalent model.

Figure 16.

Optimized VHF inverter equivalent model.

Figure 17.

Suggested approach for creating an equivalent model of Zeq impedance layout.

Figure 17.

Suggested approach for creating an equivalent model of Zeq impedance layout.

Figure 18.

Influence of resonance impedance variation in inverter on output current curve.

Figure 18.

Influence of resonance impedance variation in inverter on output current curve.

Figure 19.

Influence of resonance impedance variation in inverter on to output voltage.

Figure 19.

Influence of resonance impedance variation in inverter on to output voltage.

Figure 20.

Suggested algorithm for the equivalent model of output inverter impedance layout.

Figure 20.

Suggested algorithm for the equivalent model of output inverter impedance layout.

Figure 21.

Effect of varying Ct and Cz on current and voltage curves.

Figure 21.

Effect of varying Ct and Cz on current and voltage curves.

Figure 22.

Effect of Ct and Cz variation’s onto output power.

Figure 22.

Effect of Ct and Cz variation’s onto output power.

Figure 23.

VHF inverter resonance frequency.

Figure 23.

VHF inverter resonance frequency.

Figure 24.

Command signal in ZVS mode.

Figure 24.

Command signal in ZVS mode.

Table 1.

SunPower SPR-315E-WHT-U.

Table 1.

SunPower SPR-315E-WHT-U.

| Max power (W) |

315.0721 |

| Number of cells per module |

96 |

| Series-connected modules per String |

4 |

| Parallel strings |

3 |

| Temp. Coef. of Isc(% / degC) |

0.0617743 |

| Temp. Coef. of Voc(% / degC) |

0.2727 |

| Current at Max. Power Imp( A ) |

5.76 |

| Voltage at Max. Power Vmp( V ) |

54.7 |

| Short circuit C. Isc( A ) |

6.14 |

| Open circuit V. Voc( V ) |

64.6 |

Table 2.

SOFC- 3KW- 100Vcd.

Table 2.

SOFC- 3KW- 100Vcd.

| Model Level: |

Detailed |

| Voltage at 1A and 0A [0, 1] (V) |

[14.34,133] |

| Nominal operating P. [I.nom(A), nom(V)] |

[30,106.5] |

| Nominal supply pressure [Fuel, Air] (bar) |

[1.35,1] |

| Nominal air flow R. (lpm) |

635 |

| Operating Temp. (Celsius) |

600 |

| Max. operating P. [I.end(A), V.end(V)] |

[33.2,104.86] |

| Numb. of cells |

119 |

| Nominal stack efficiency (%) |

52 |

| Nominal composition (%) [H2O2 H2O] (Air) |

[50,21,3] |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).