Submitted:

03 June 2024

Posted:

04 June 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Plugs Preparation

- Offshore Plugs

- Onshore Plugs

2.2.2. Mechanical Tests

- Compressive Strength

- Adhesion

2.2.3. Plugs Interaction with Formation Waters

3. Results and Discusion

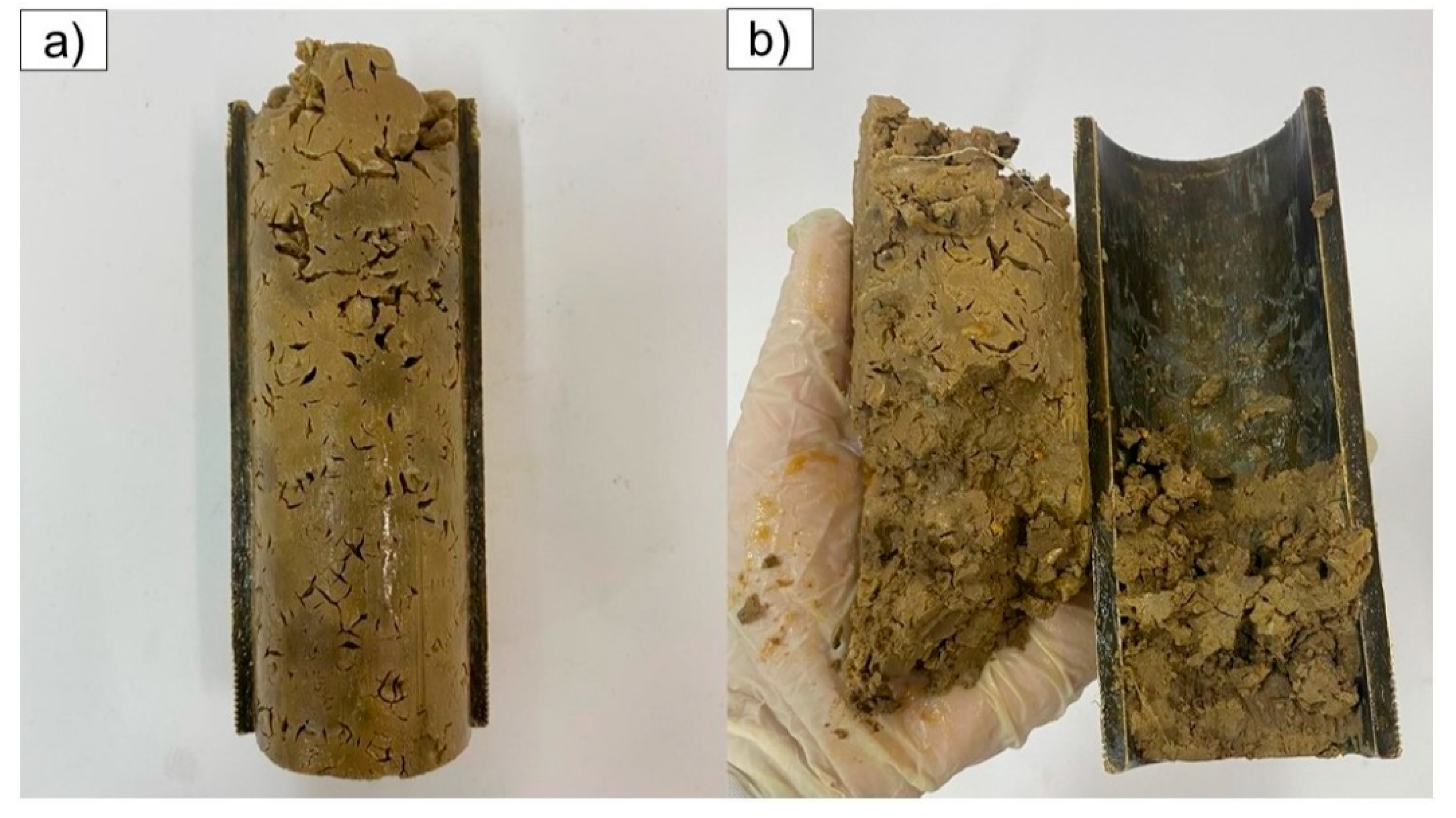

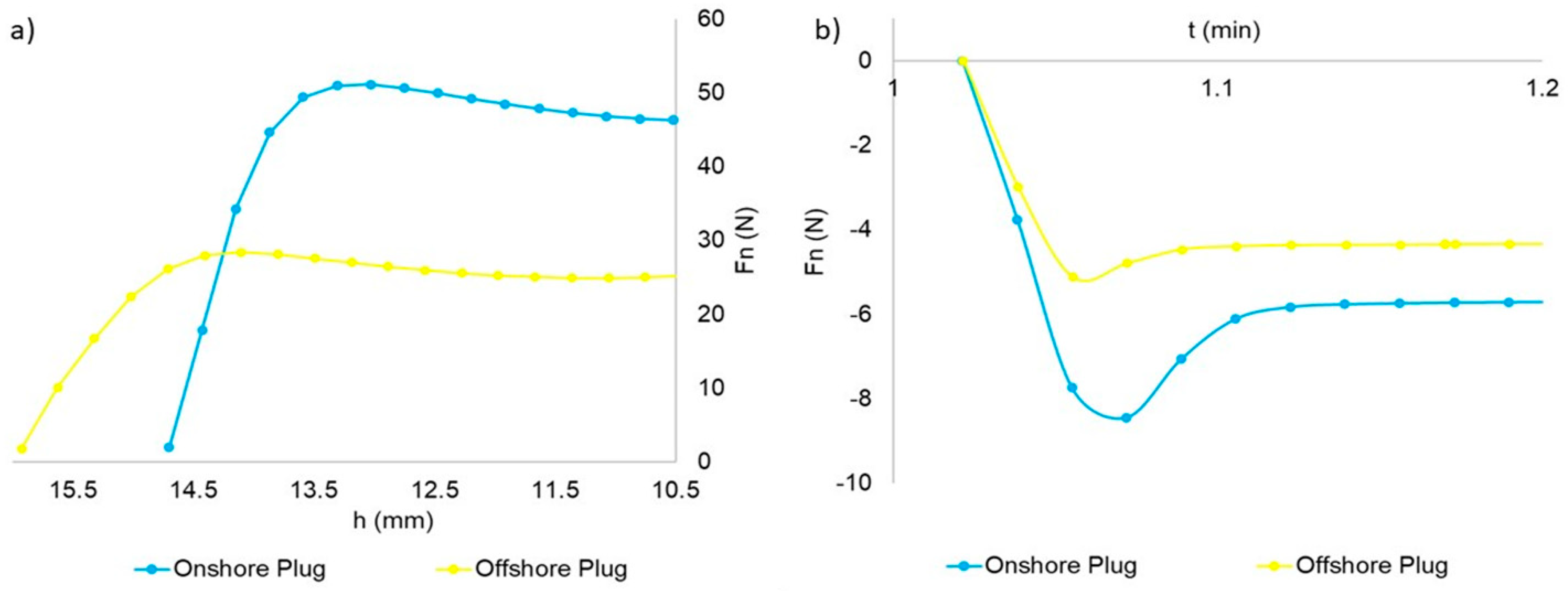

3.1. Aspect and Mechanical Properties of Offshore and Onshore Plugs

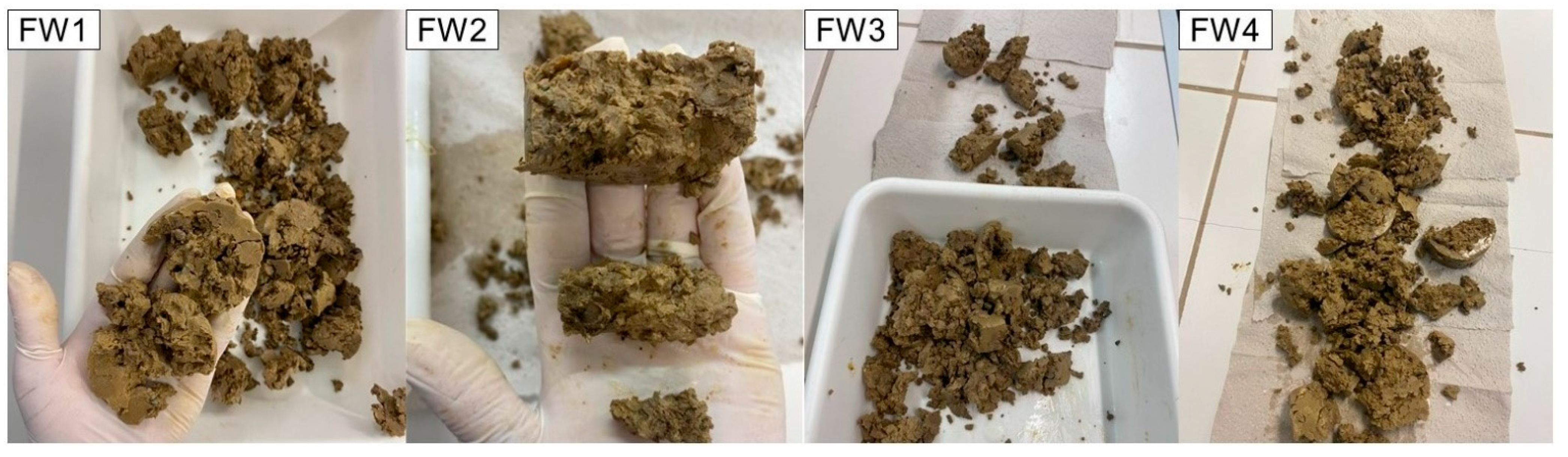

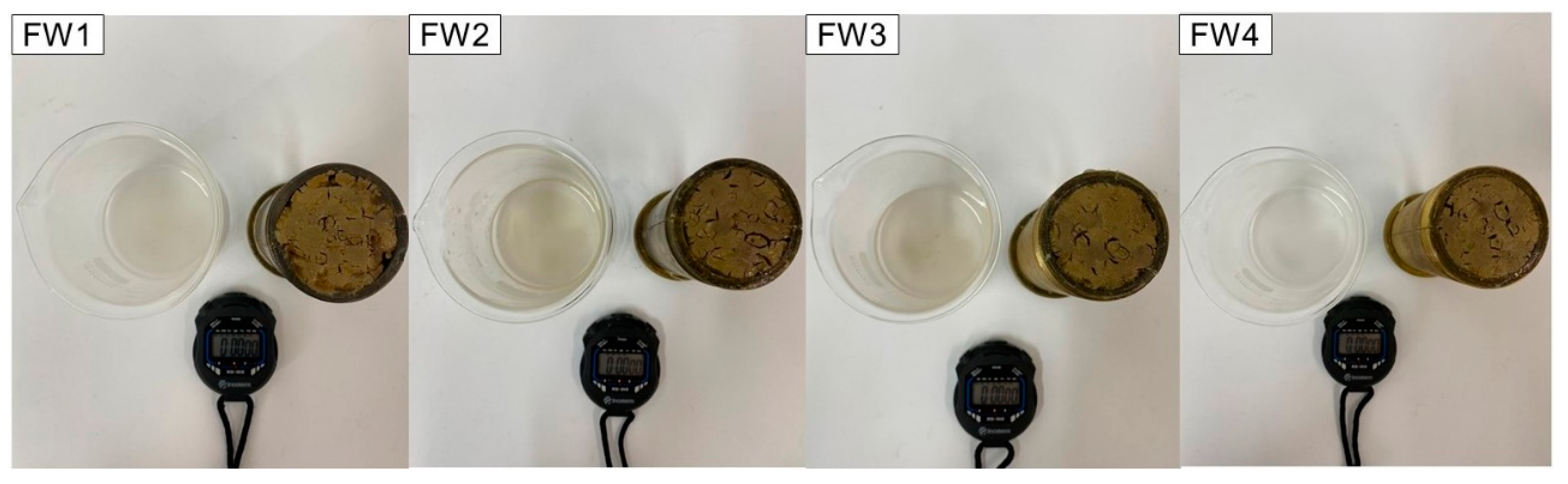

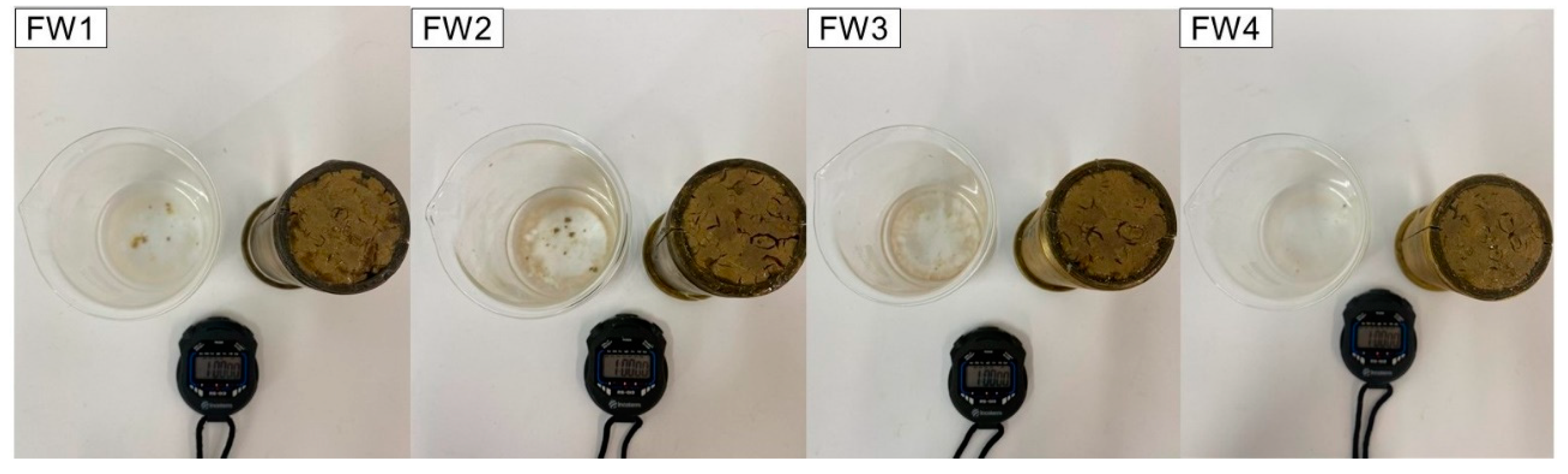

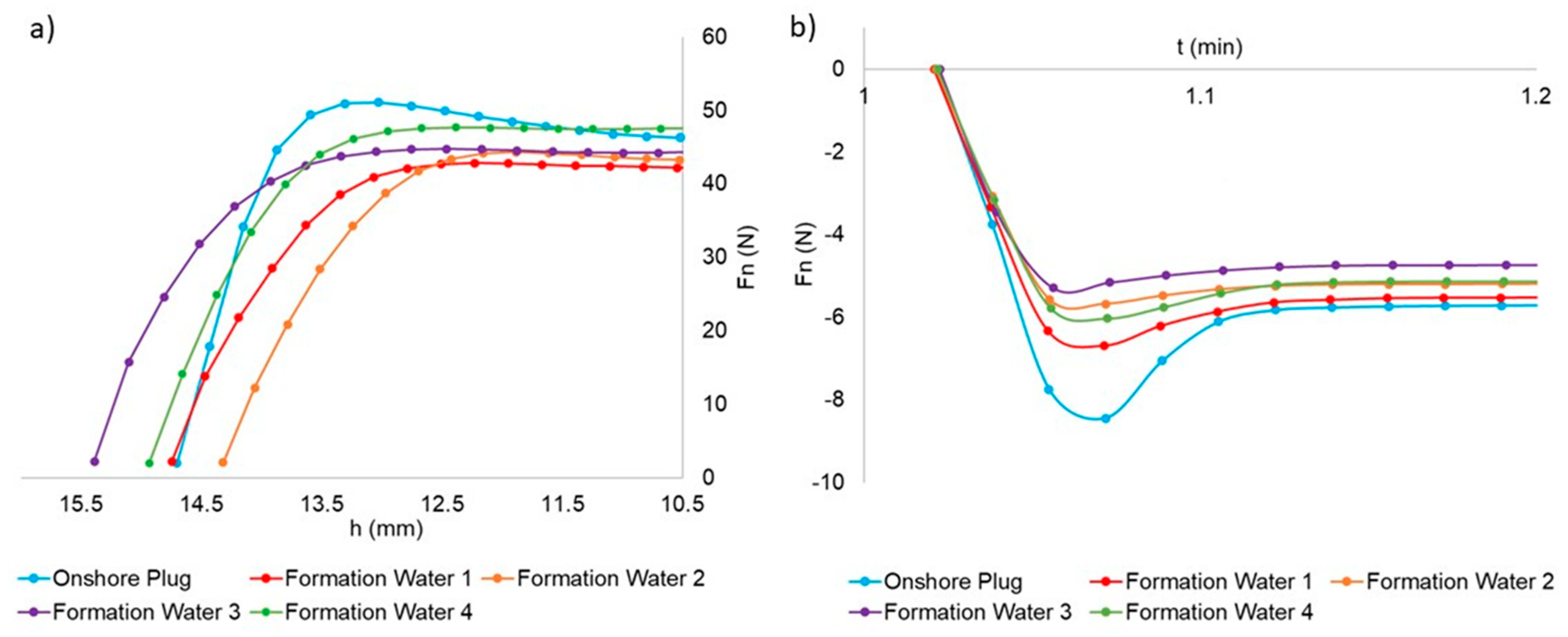

3.2. Aspect and Mechanical Properties of Plugs after Interaction with Formation Waters

4. Conclusions

- Prior analysis of mechanical properties of the plug is a determining factor in the appropriate choice of the operational procedure and, in the case of offshore wells, of the type of displacement fluid used to dispose the pellets inside the well in the design of abandonment operations;

- Contact with organic fluids used to displace the pellets in offshore wells reduces the mechanical properties of bentonite plugs, however, this reduction compromises significantly only the stability of plugs formed by pellets previously immersed in olefin, so that plugs formed by pellets previously immersed in diesel are promising alternatives for offshore wells abandonment;

- The onshore plug presents satisfactory mechanical resistance to contact with formation waters, so that the plug's capacity to support loads, represented by compressive strength, is minimally affected by this condition, although the adhesion property presents more pronounced reductions;

- The salinity of the formation water has a significant influence on the mechanical properties of the bentonite plug, adversely affecting these parameters, especially the adhesion properties.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Leporini, M.; Marchetti, B.; Corvaro, F.; Polonara, F. Reconversion of offshore oil and gas platforms into renewable energy sites production: Assessment of different scenarios. Renew. Energy 2019, 135, 1121–1132. [Google Scholar] [CrossRef]

- Colaleo, G.; Nardo, F.; Azzellino, A.; Vicinanza, D. Decommissioning of offshore platforms in Adriatic Sea: The total removal option from a life cycle assessment perspective. Energies 2019, 15, 9325. [Google Scholar] [CrossRef]

- Bull, A. S.; Love, M. S. Worldwide oil and gas platform decommissioning: A review of practices and reefing options. Ocean. Coast. Manage. 2018, 168, 274–306. [Google Scholar] [CrossRef]

- Wang, C.; Liu, Y.; Lian, X.; Luo, J.; Liang, C.; Ma, H. Dynamic risk assessment of plugging and abandonment operation process of offshore wells based on Dynamic Bayesian Network. Ocean Eng. 2023, 270, 113625. [Google Scholar] [CrossRef]

- Ruivo, F. M.; Morooka, C. K. Decommissioning Offshore Production Facilities. In Engineering Technology Conference on Energy, Houston, TX, USA, 4-5 February 2002. [CrossRef]

- Mainguy, M.; Longuemare, P.; Audibert, A.; Lécolier, E. Analyzing the risk of well plug failure after abandonment. Oil Gas Sci. Technol. 2007, 62, 311–324. [Google Scholar] [CrossRef]

- Towler, B.F.; Firouzi, M.; Mortezapour, A.; Hywel-Evans, P.D. Plugging CSG wells with bentonite: Review and preliminary lab results. In Proceedings of the SPE Asia Pacific Unconventional Resources Conference and Exhibition, Brisbane, Australia, 9–11 November 2015. [Google Scholar] [CrossRef]

- Magalhães, E.S.; Lemos, M. J. A thermal study of a new oil well plugging & abandonment operation. Int. J. Therm. Sci. 2020, 155, 106421. [Google Scholar] [CrossRef]

- Towler, B.F.; Firouzi, M.; Holl, H.G.; Gandhi, R.; Thomas, A. Field trials of plugging oil and gas wells with hydrated bentonite. In Proceedings of the SPE Asia Pacific Oil & Gas Conference and Exhibition, Perth, Australia, 25–27 October 2016. [Google Scholar] [CrossRef]

- Achang, M.; Yanyao, L.; Radonjic, M. A review of past, present, and future technologies for permanent plugging and abandonment of wellbores and restoration of subsurface geologic barriers. Environ. Eng. Sci. 2020, 37, 395–408. [Google Scholar] [CrossRef]

- Vrålstad, T.; Saasen, A.; Fjær, E.; Øia, T.; Ytrehus, J. D.; Khalifeh, M. Plug & abandonment of offshore wells: Ensuring long-term well integrity and cost-efficiency. J. Pet. Sci. Eng. 2019, 173, 478–491. [Google Scholar] [CrossRef]

- Willis, B. M.; Strutt, J. E.; Eden, R. D. Long Term Well Plug Integrity Assurance–A Probabilistic Approach. In: Offshore Technology Conference, Houston, Texas, USA, 6-9 May 2019. [CrossRef]

- James, M.C. Using coarse ground bentonite to plug abandoned holes. Water Well J. 1996, 50, 44–47. [Google Scholar]

- Yoon, S.; Cho, W.; Lee, C.; Kim, G. Y. Thermal conductivity of Korean compacted bentonite buffer materials for a nuclear waste repository. Energies 2018, 11, 2269. [Google Scholar] [CrossRef]

- Kale, R.C.; Ravi, K. A review on the impact of thermal history on compacted bentonite in the context of nuclear waste management. Environ. Technol. Inno. 2021, 23, 101728. [Google Scholar] [CrossRef]

- Clarck, J.; Salsbury, B. Well Abandonment Using Highly Compressed Sodium Bentonite-An Australian Case Study. In Exploration and Production Environmental Conference, San Antonio, Texas, USA, 10-12 March 2003. [CrossRef]

- Bell, S.T.; Opitz, L.A.; Sundstrom, E.; Taylor, J.F. Plugging Wells with Hydrated Bentonite, Part 3: Further Lab Results. University of Wyoming Unpublished Senior Design Report, 2009.

- Ogden, F. L.; Ruff, J. F. Strength of bentonite water-well annulus seals in confined aquifers. J. Irrig. Drain. Eng. 1993, 119, 242–250. [Google Scholar] [CrossRef]

- Towler, B.F.; Ehlers, G.C. Friction factors for hydrated bentonite plugs. In Proceedings of the SPE Rocky Mountain Regional Meeting, Casper, WY, USA, 18–21 May 1997. [Google Scholar] [CrossRef]

- Khalifeh, M.; Hodne, H.; Saasen, A.; Vralstad, T. Techniques and materials for North Sea plug and abandonment operations. In Offshore Technology Conference, Houston, Texas, USA, 6-9 May 2013. [CrossRef]

- Costa, W. R. P.; Oliveira, L. R. C.; Nóbrega, K. C.; Costa, A. C. A.; Gonçalves, R. L. N.; Lima, M. C. S.; Nascimento, R.C.A.M.; Souza, E.A.; Oliveira, T.A. , Barros, M.; Amorim, L. V. Evaluation of Saline Solutions and Organic Compounds as Displacement Fluids of Bentonite Pellets for Application in Abandonment of Offshore Wells. Processes 2023, 11, 3375. [Google Scholar] [CrossRef]

- Worden, R. H.; Manning, D. A. C.; Bottrell, S. H. Multiple generations of high salinity formation water in the Triassic Sherwood Sandstone: Wytch Farm oilfield, onshore UK. Appl. Geochem. 2006, 21, 455–475. [Google Scholar] [CrossRef]

- Towler, B.F.; Hywel-Evans, D.; Firouzi, M. Failure modes for hydrated bentonite plugs used in well decommissioning operations. Appl. Clay Sci. 2020, 184, 105385. [Google Scholar] [CrossRef]

- Bolaji, T. A.; Oti, M. N.; Onyekonwu, M. O.; Bamidele, T.; Osuagwu, M.; Chiejina, L; Elendu, P. Preliminary geochemical characterization of saline formation water from Miocene reservoirs, offshore Niger Delta. Heliyon <bold>2021</bold>, 7. [CrossRef]

- Costa, W.R.P.; Amorim, L.V.; Nobrega, K.C. , Nascimento, R. C. A. M., Costa, A. C. A., Duarte, A. B. M.; Lima, M. C. S. (2022). Stability of inverse olefin emulsions: influence of the incorporation of fine solids of different chemical natures. J. Dispers. Sci. Technol. 2022, 43, 1709–1716. [Google Scholar] [CrossRef]

- Glazacheva, E. N.; Uspenskaya, M. V.; Strelnikova, I. E. Bentonite acrylic copolymers modified as effective oil absorbents. WIT Trans. Ecol. Environ. 2015, 196, 529–535. [Google Scholar] [CrossRef]

- Taheri, S.; Ebadi, T.; Maknoon, R.; Amiri, M. Predicting variations in the permeability and strength parameters of a sand-bentonite mixture (SBM) contaminated simultaneously with lead (II) and diesel. Appl. Clay Sci. 2018, 157, 102–110. [Google Scholar] [CrossRef]

- Komine, H.; Yasuhara, K.; Murakami, S. Reply to Discussion by Kaya et al. on “Swelling characteristics of bentonite in artificial seawater”. Can. Geotech. J. 2009, 46, 1239–1242. [Google Scholar] [CrossRef]

- Xu, Z.; Sun, Y.; Niu, Z.; Xu, Y.; Wei, X.; Chen, X.; Pan, D.; Wu, W. Kinetic determination of sedimentation for GMZ bentonite colloids in aqueous solution: Effect of pH, temperature and electrolyte concentration. Appl. Clay Sci. 2020, 184, 105393. [Google Scholar] [CrossRef]

- Ye, W.M.; Zheng, Z.J.; Chen, B.; Chen, Y.G.; Cui, Y.J.; Wang, J. Effects of pH and temperature on the swelling pressure and hydraulic conductivity of compacted GMZ01 bentonite. Appl. Clay Sci. 2014, 101, 192–198. [Google Scholar] [CrossRef]

- Mcbride, M. Environmental Chemistry of Soils; Oxford University Press: New York, USA, 1994; pp. 63–116. [Google Scholar]

- Santamarina, J. C. Soil behavior at the microscale: particle forces. In Soil behavior and soft ground construction, American Society of Civil Engineers, Massachussets, USA, 05-06 October 2001. [CrossRef]

- Mitchell, J.K. . Fundamentals of Soil Behavior; John Wiley & Sons: New York, USA, 1976; pp. 283–338. [Google Scholar]

- Corina, A. N.; Wollenweber, J.; Fischer, H.; Van der Valk, K.; Castelein, K.; Moghadam, A.; Heerens, G. J. Evaluation of Bentonite Application for the Abandonment of Deep Geo-energy Wells. Rock Mech. Rock Eng. 2023, 56, 301–317. [Google Scholar] [CrossRef]

| FW1 | FW2 | FW3 | FW4 | |

| Chemical compound | Concentration (mg/L) |

Concentration (mg/L) |

Concentration (mg/L) | Concentration (mg/L) |

| NaCl | 31001,00 | 158176,75 | 116391,32 | 32945,00 |

| CaCl2 | 1603,70 | 2693,34 | 0 | 1009,00 |

| NaHCO3 | 6590,00 | 436,44 | 996,79 | 4806,35 |

| MgCl2 | 1478,89 | 0 | 0 | 1112,75 |

| MgO | 60,06 | 829,22 | 575,54 | 0 |

| Ca(OH)2 | 0 | 43,02 | 959,44 | 0 |

| HCl | 0 | 25,00 | 62,00 | 0 |

| KCl | 1359,00 | 3622,63 | 3769,45 | 1940,96 |

| NaOH | 0 | 0 | 851,37 | 0 |

| CaCO3 | 0 | 0 | 0 | 780,70 |

| Formation water | FW1 | FW2 | FW3 | FW4 |

| Absorbed Volume (mL) | 3.5 | 4.5 | 4.0 | 3.5 |

| Onshore Plug | Formation Water 1 | Formation Water 2 | Formation Water 3 | Formation Water 4 | |

| Compressive strength (N) | 51.1 | 42.9 | 44.6 | 44.8 | 47.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).