Submitted:

02 May 2024

Posted:

07 May 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

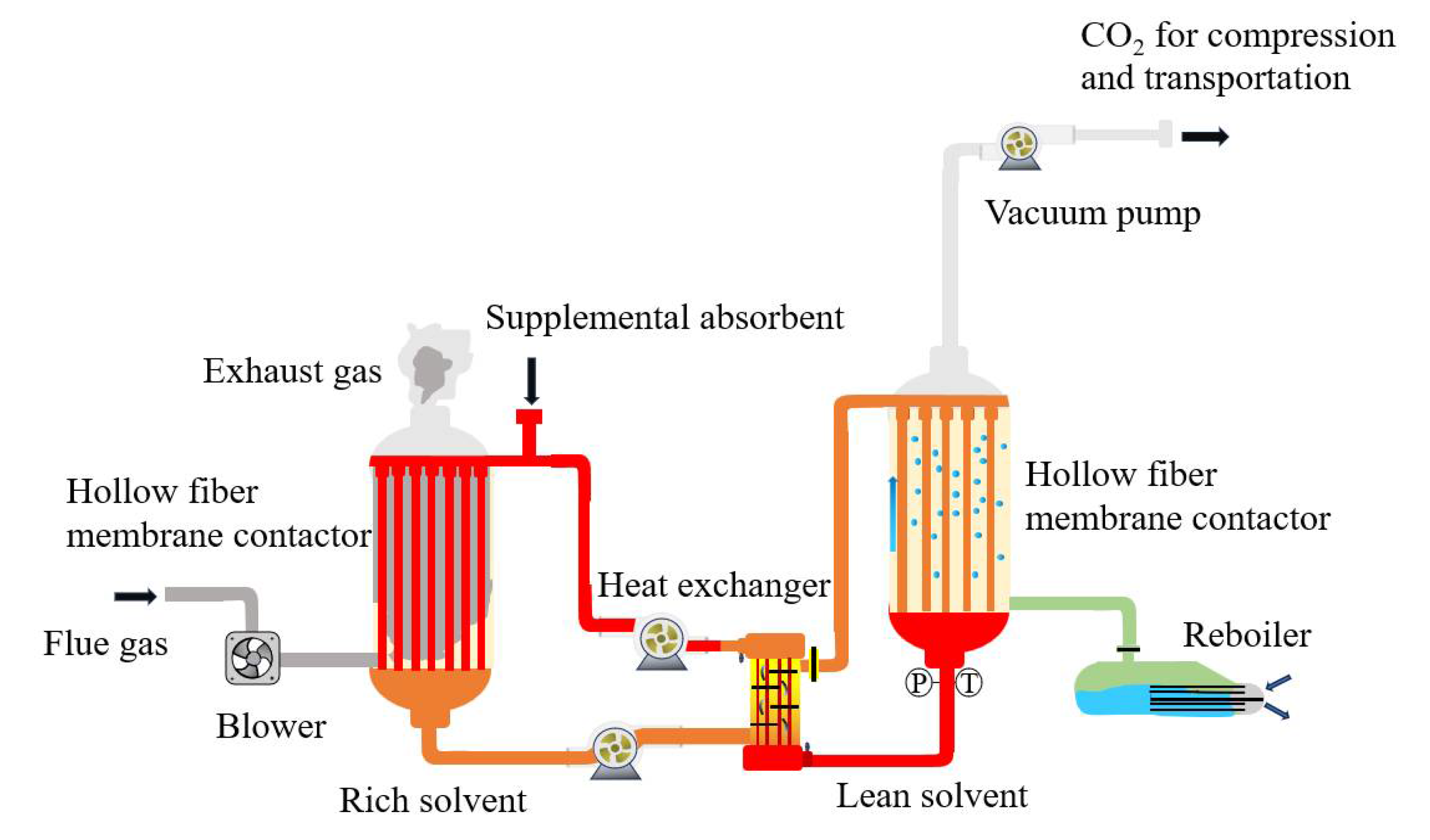

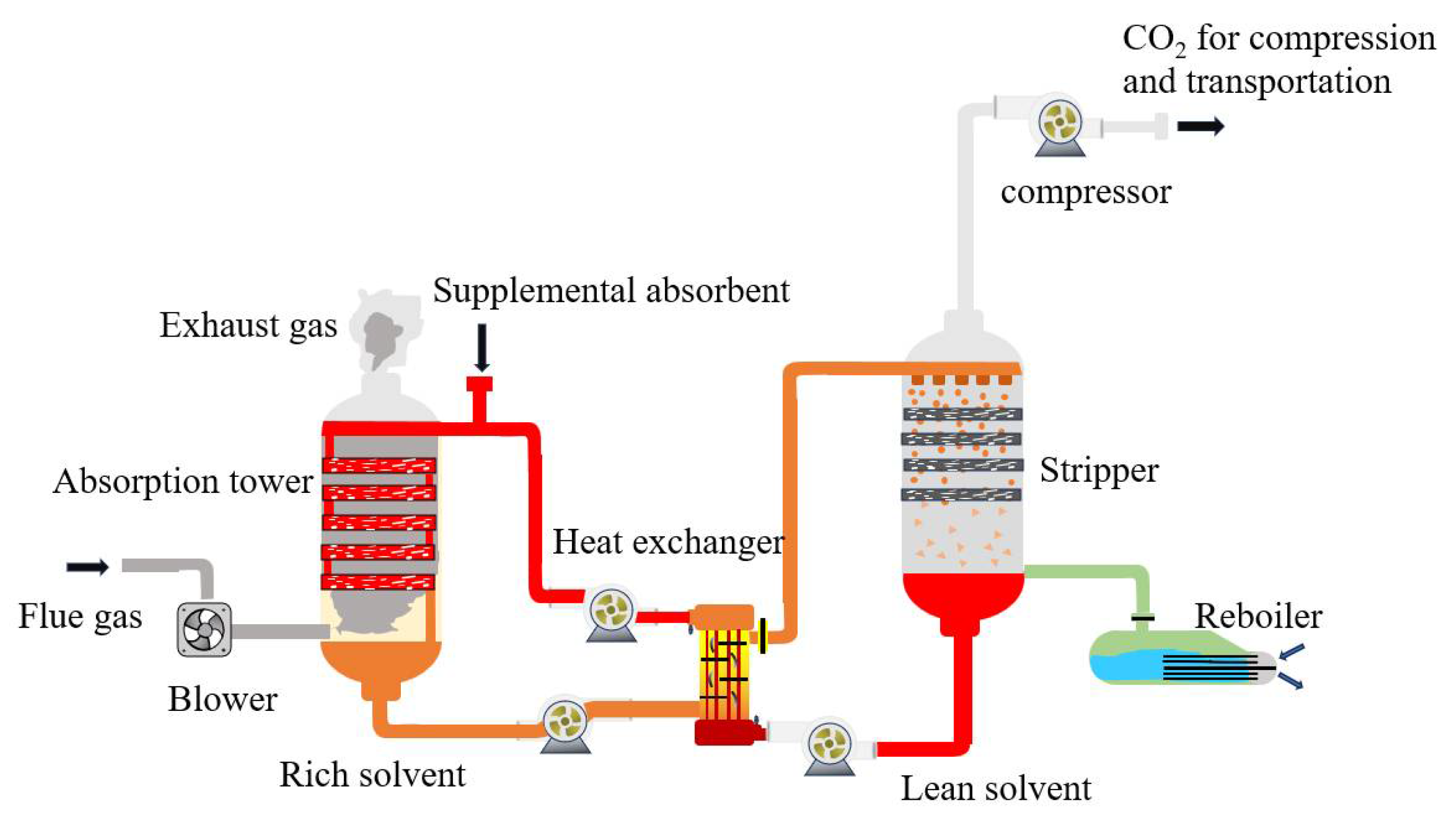

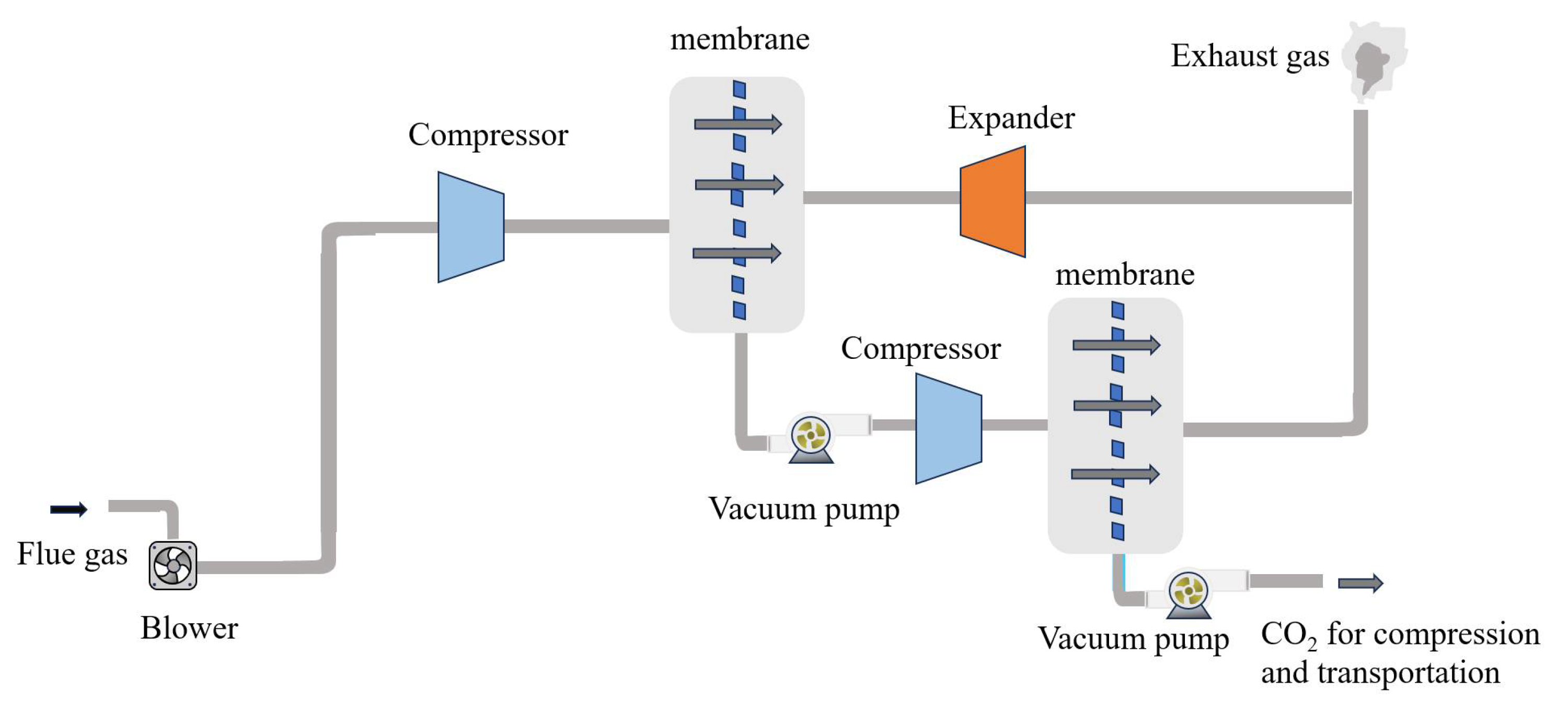

2. Materials and Methods

3. Life Cycle Assessment Methodology

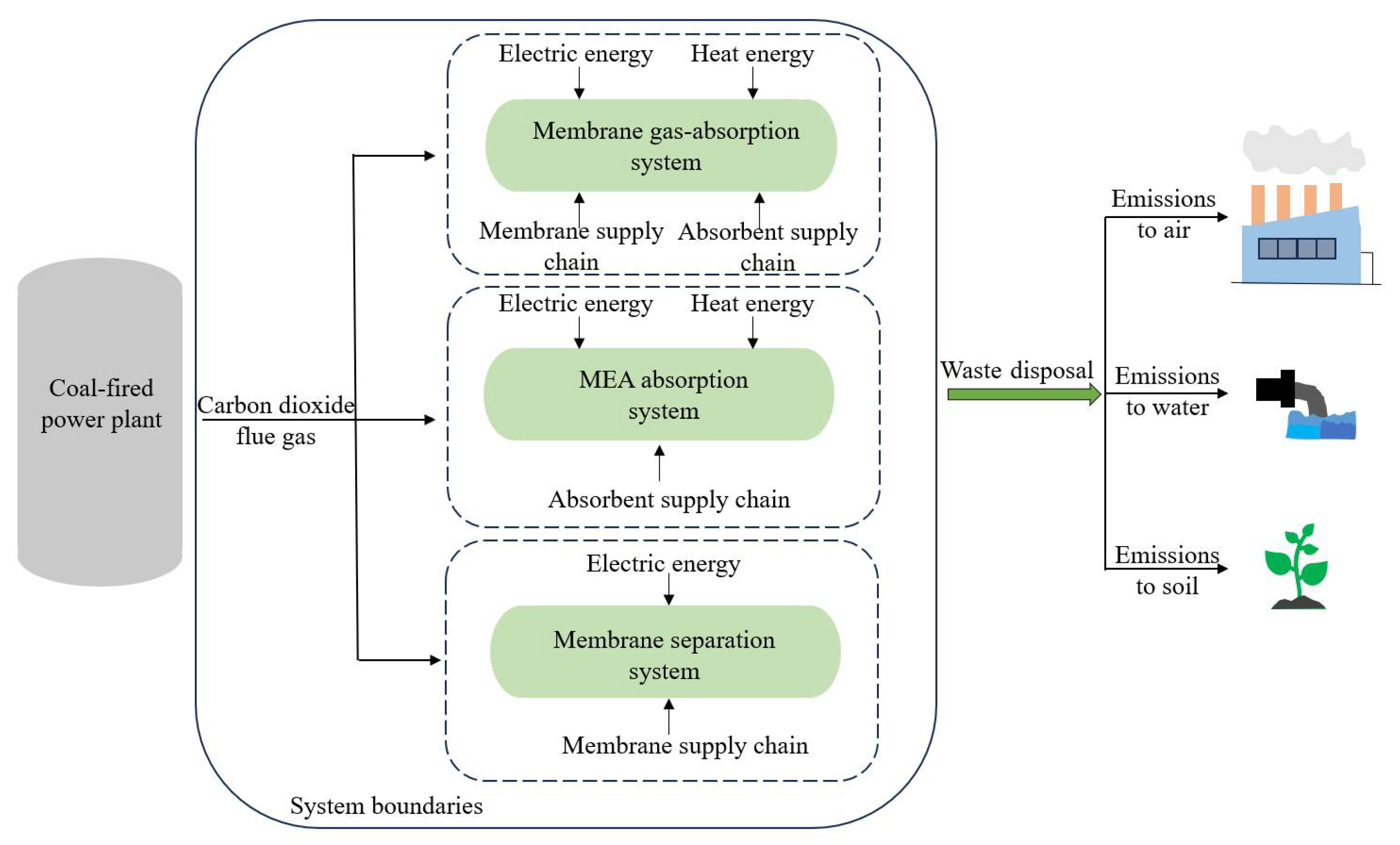

3.1 Goal and Scope Definition

3.2 Life Cycle Inventory

| System parameters | Unit | Value |

|---|---|---|

| Membrane gas absorption [29] | ||

| MEA consumption | kg/t CO2 | 0.9 |

| Membrane area | 103 m2 | 4400 |

| Regeneration heat | GJ/ t CO2 | 2 |

| Compressor | kWh/t CO2 | 83.3 |

| Auxiliary equipment | kWh/t CO2 | 67.96 |

| Chemical absorption [24] | ||

| MEA consumption | kg/t CO2 | 1.44 |

| Regeneration heat | GJ/ t CO2 | 3.2 |

| Compressor | kWh/t CO2 | 64.5 |

| Auxiliary equipment | kWh/t CO2 | 33.8 |

| Membrane gas separation system [24] | ||

| Membrane area | 103 m2 | 2828.5 |

| Compressor | kWh/t CO2 | 77.1 |

| Auxiliary equipment | kWh/t CO2 | 230.4 |

| Unit | Value | ||

|---|---|---|---|

| Input | Water, unspecified natural origin | L | 3000 |

| Oxygen | kg | 32.8 | |

| Water, deionized | kg | 3.2 | |

| 2,4-dichlorophenol | kg | 75.2 | |

| Benzene | kg | 79.2 | |

| Bisphenol | kg | 28.8 | |

| Electricity | kg | 2871.84 | |

| Heat | kg | 72.27 | |

| Carbon dioxide, liquid | kg | 161.59 | |

| Ethylene oxide | kg | 160.17 | |

| Nitrogen | L | 0.561 | |

| Output | Hollow fiber membrane | m2 | 1000 |

| Wastewater, average | L | 5000 | |

| Ethylene oxide | kg | 0.08 | |

| Carbon dioxide, fossil | kg | 1.7 | |

| Spent catalyst base from ethylene oxide production | kg | 1.6 | |

| Phenol | kg | 0.056 | |

| Phenol, 2,4-dichloro | kg | 0.16 | |

| Water | m3 | 0.96 |

| Unit | Amount | ||

|---|---|---|---|

| Input | Ethylene oxide | g | 816 |

| Ammonia | g | 788 | |

| Electricity | kWh | 0.333 | |

| Natural gas | MJ | 2 | |

| Transport (truck and train) | t×km | 11.23 | |

| Infrastructure chemical plant | p | 4×1010 | |

| Output | Monoethanolamine | kg | 1 |

| Waste heat | MJ | 1.2 | |

| Ethylene oxide to air | g | 1.63 | |

| Ethylene oxide to water | g | 1.47 | |

| Ammonia to air | g | 1.58 | |

| Ammonium to water | g | 3.04 | |

| CO2 | g | 26.5 | |

| Nitrate (NO2) to water | g | 6.97 | |

| COD.BOD | g | 21.3 | |

| TOC.DOC | g | 8.02 |

3.3. Life Cycle Impact Assessment

3.4. Interpretation

4. Results and Discussion

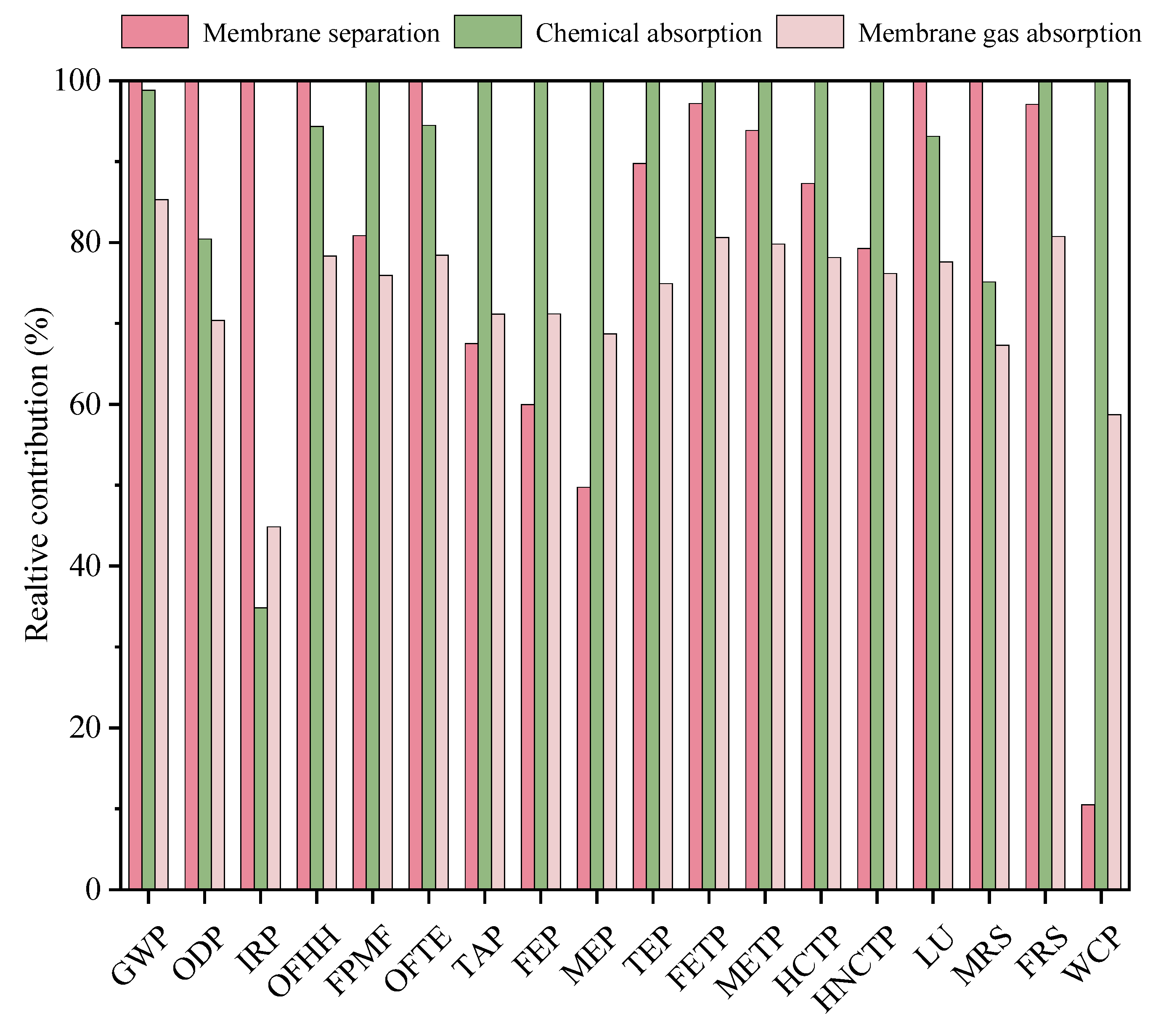

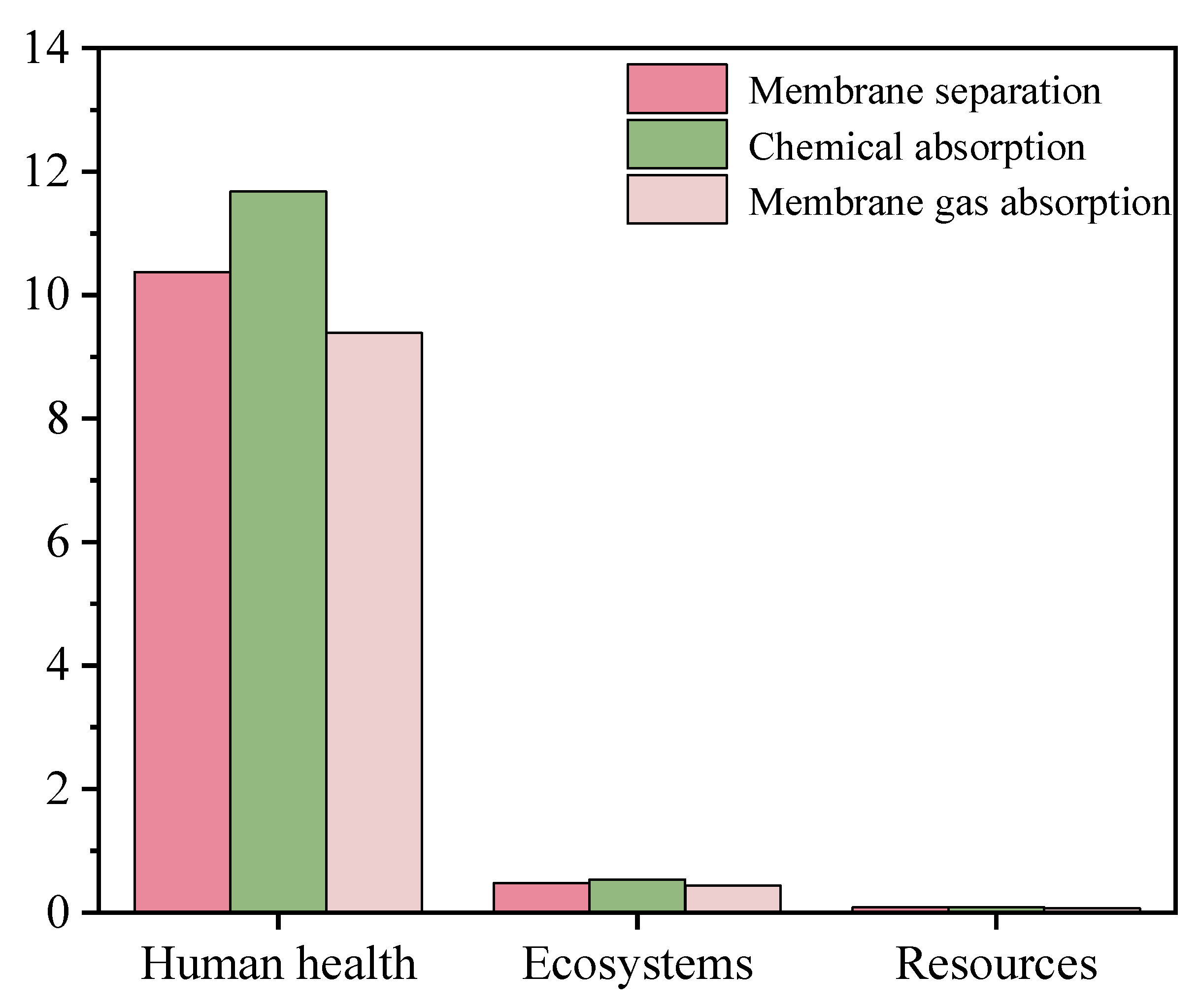

4.1. Environmental Impact Comparison of Different CO2 Capture Systems

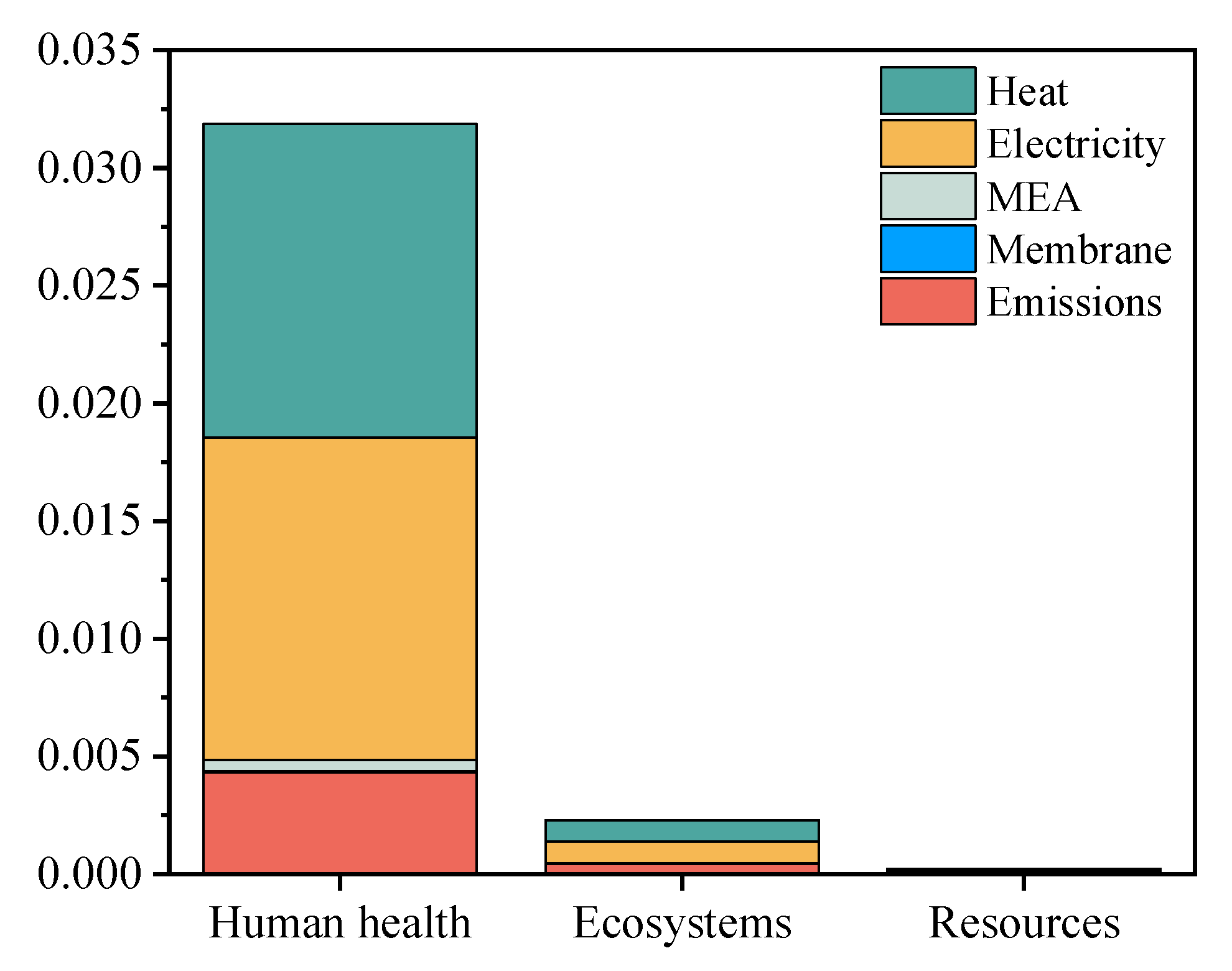

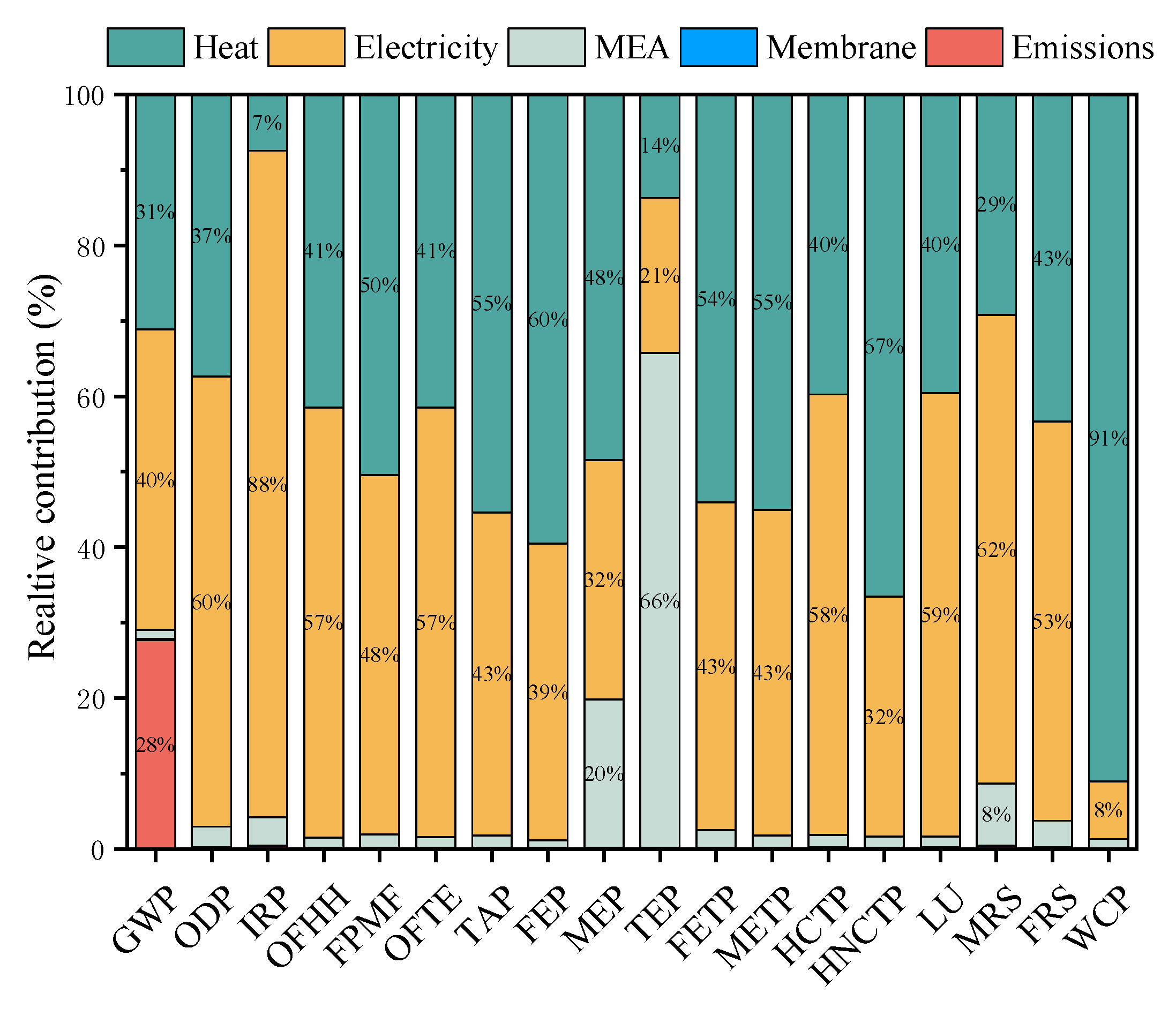

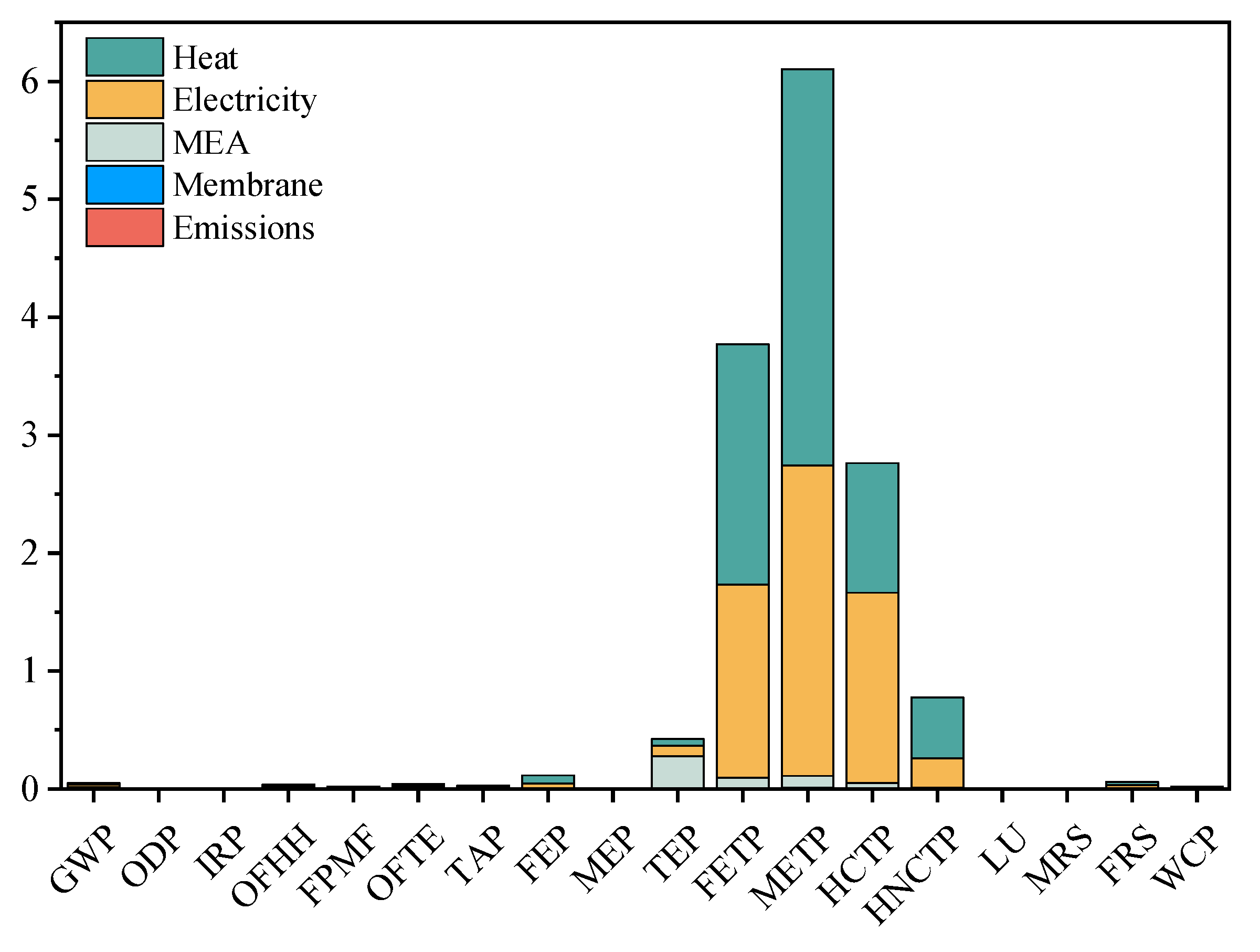

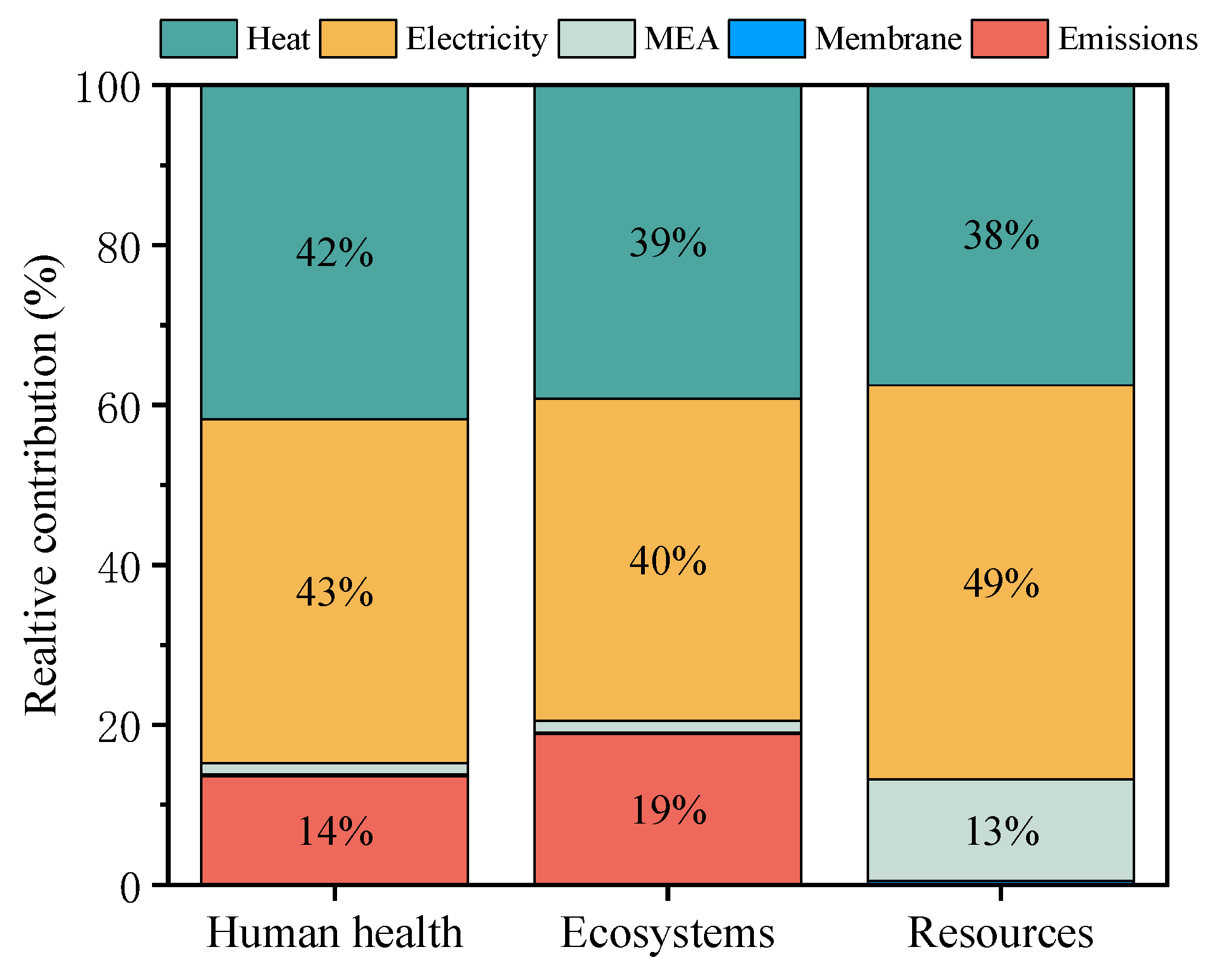

4.2. Process Contribution Analysis of Membrane Gas Absorption System

5. Sensitivity Analysis

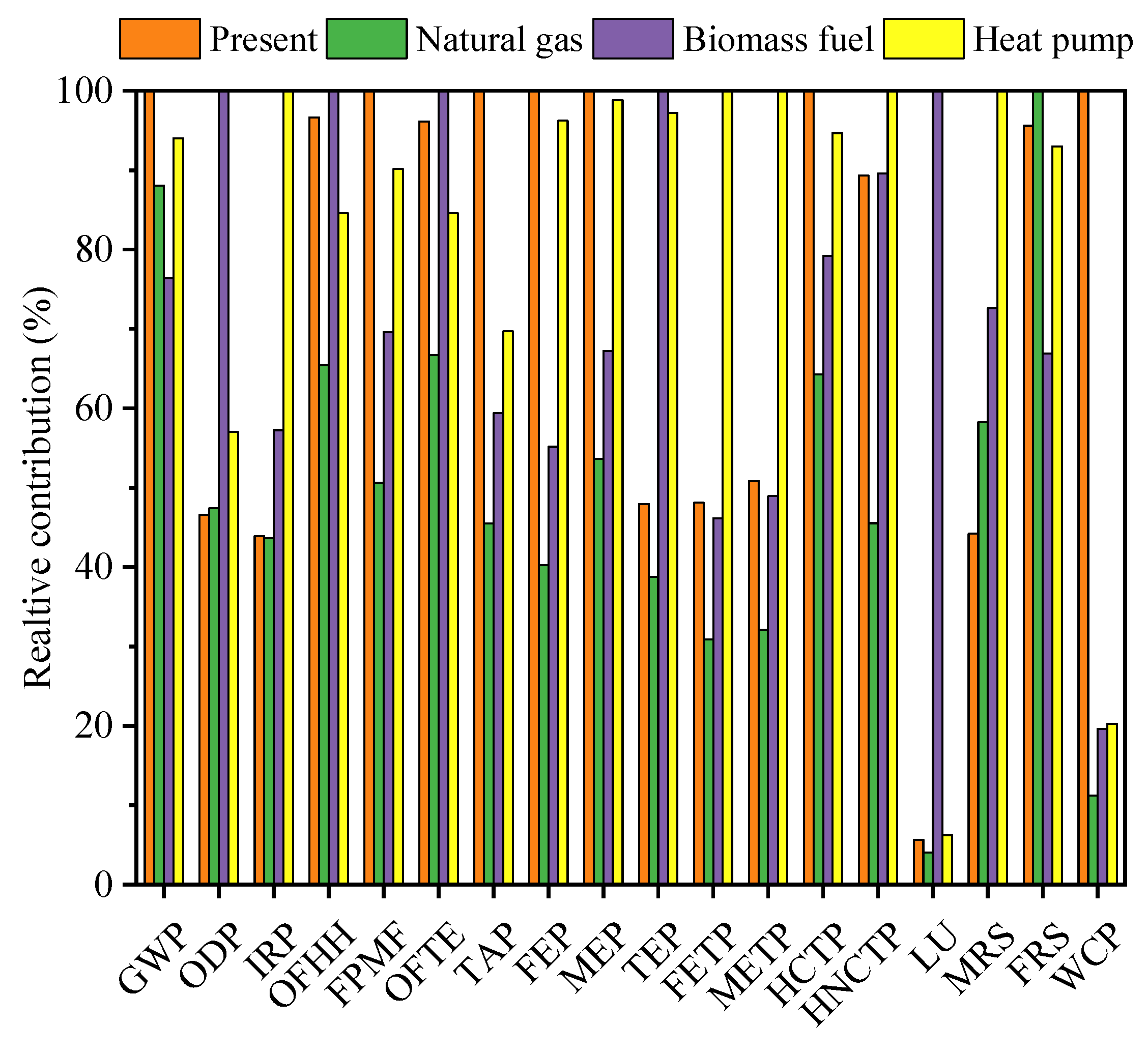

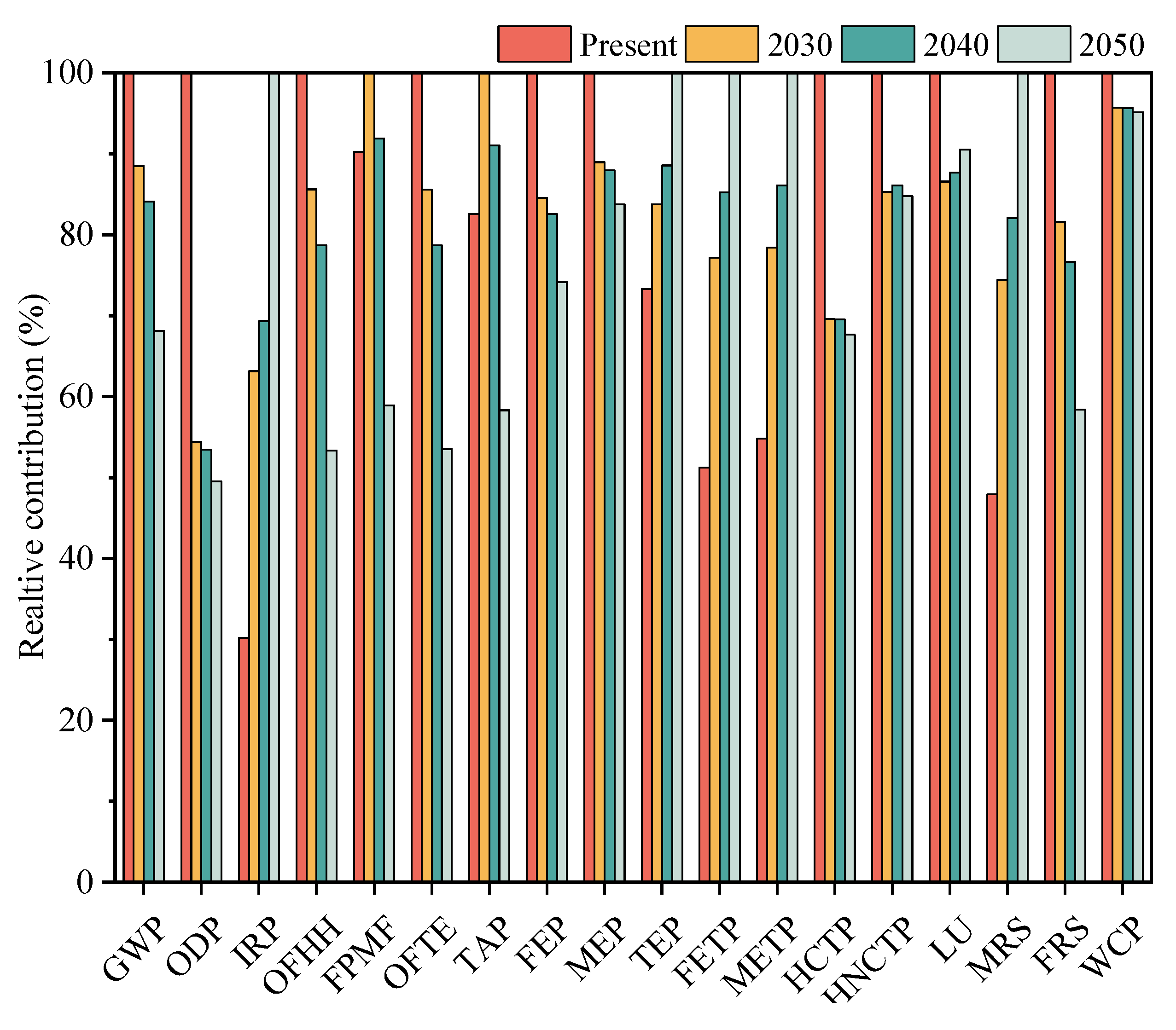

5.1. Sensitivity Analysis on Heat Supply Source

6. Conclusions

- (1)

- At the given function unit of 1 ton CO2 captured from the power plant, the membrane gas absorption system exhibits the lowest environmental impacts across the majority evaluated categories in comparison with chemical absorption and membrane gas separation system. Specially, the GWP indicator values are 393 kgCO2 eq., 456 kgCO2 eq. and 461 kgCO2 eq. for membrane gas absorption, chemical absorption and membrane gas separation systems, respectively. Furthermore, membrane gas separation exhibits the lowest environmental impact over water-related impact categories such as WCP, TAP, FEP and MEP.

- (2)

- For the membrane gas absorption system, the contribution of electricity supply and heat consumption are the primary sources of environmental impact within the system life cycle, varying from 8% to 88%, and from 7% to 91%, respectively. Electricity consumption leads to significant impacts in IRP, which contributes 88% of this impact category. Heat consumption contribution in water consumption potential is more than 90%, due to large amount of water consumed during the heat production and supply process. The impact of heat consumption on human health, ecosystems, and resource consumption accounts for 42%, 39%, and 38%, respectively, while the impact of electricity consumption corresponds to 43%, 40%, and 49%, respectively.

- (3)

- Sensitivity analysis results show that, switching the heat supply from coal-fired steam to natural gas can reduce the majority of the impact categories, with GWP reduction by 12%. The most observable reduction WCP is reduced nearly by 90%, but the SOP and FFP indicators are increased by 15% and 5%, respectively. Considering the power structure decarbonization from 2030 to 2050 in China, the global warming potential, fossil resource consumption and ozone formation can be signficiantly reduced by increasing utilization of renewable energy. However, the ecological and environmental issues are also caused due to mineral resource extraction.

Acknowledgements

References

- The Intergovernmental Panel on Climate Change. Available online: https://www.ipcc.ch/sr15/. (Accessed on October 26, 2023).

- EU Action. Available online: https://climate.ec.europa.eu/eu-action/european-climate-law_en. (Accessed on October 26, 2023).

- Silva Herran, D.; Fujimori, S. Beyond Japanese NDC: energy and macroeconomic transitions towards 2050 in emission pathways with multiple ambition levels. Sustainability Science. 2021, 16: 489-501. [CrossRef]

- The Long-Term Strategy of the United States. Available online: https://www.whitehouse.gov/wp-content/uploads/2021/10/us-long-term-strategy.pdf. (Accessed on November 8, 2023).

- China’s Route to Carbon Neutrality: Perspectives and the Role of Renewables. Available online: https://www.irena.org/publications/2022/Jul/Chinas-Route-to-Carbon-Neutrality. (Accessed on October 26, 2023).

- Fariba Zarei; Peyman Keshavarz. High performance CO2 Absorption/Desorption using Amine-Functionalized magnetic nanoparticles. Separation and Purification Technology. 2023, 323: 124438. [CrossRef]

- Baihe Guo; Jingchao Zhang; Yanlin Wang; Xiaolei Qiao; Jun Xiang; Yan Jin. Study on CO2 adsorption capacity and kinetic mechanism of CO2 adsorbent prepared from fly ash. Energy. 2023, 263, Part B: 125764. [CrossRef]

- Nandakishora Y.; Ranjit K. Sahoo; Murugan S.; Sai Gu. 4E analysis of the cryogenic CO2 separation process integrated with waste heat recovery. Energy. 2023, 278, Part A: 127922. [CrossRef]

- Farhad Ahmadijokani; Hossein Molavi; Salman Ahmadipouya; Mashallah Rezakazemi; Ahmadreza Ghaffarkhah; Milad Kamkar; Akbar Shojaei; Mohammad Arjmand. Polyurethane-based membranes for CO2 separation: A comprehensive review. Progress in Energy and Combustion Science. 2023, 97: 101095. [CrossRef]

- Usman Khan; Chukwuma C. Ogbaga; Okon-Akan Omolabake Abiodun; Adekunle A. Adeleke; Peter P. Ikubanni; Patrick U. Okoye; Jude A. Okolie. Assessing absorption-based CO2 capture: Research progress and techno-economic assessment overview. Carbon Capture Science & Technology. 2023, 8: 100125. [CrossRef]

- Han Yang; Yang Yutong; W.S. Winston Ho. Recent progress in the engineering of polymeric membranes for CO2 capture from flue gas. Membranes 2020, 10, 365. [CrossRef]

- K. Villeneuve; D.A. Albarracin Zaidiza; D. Roizard; S. Rode. Modeling and simulation of CO2 capture in aqueous ammonia with hollow fiber composite membrane contactors using a selective dense layer. Chemical Engineering Science. 2018, 190: 345-360. [CrossRef]

- Mun-Gi Jang; Seokwon Yun; Jin-Kuk Kim. Process design and economic analysis of membrane-integrated absorption processes for CO2 capture. Journal of Cleaner Production. 2022. 368: 133180. [CrossRef]

- Cristhian Molina-Fernández; Tom Renson; Victor Deveen; Carla Martín-Chinarro; Gauthier Chaplier; Giuseppe Vitola; Rosalinda Mazzei; Lidietta Giorno; Patricia Luis. Immobilization of carbonic anhydrase on poly(ionic liquid) composite membranes for CO2 absorption by gas-liquid membrane contactors. Journal of Membrane Science. 2023, 687: 122011. [CrossRef]

- Masoud Eskandari; Seyed Amir Nezam Khaksar; Peyman Keshavarz. CO2 absorption using benzylamine as absorbent and promoter in a hollow fiber membrane contactor: A numerical study. Journal of CO2 Utilization. 2022, 66: 102287. [CrossRef]

- Mohammadhossein Vaezi; Hamidreza Sanaeepur; Abtin Ebadi Amooghin; Ali Taghvaie Nakhjiri. Modeling of CO2 absorption in a membrane contactor containing 3-diethylaminopropylamine (DEAPA) solvent. International Journal of Greenhouse Gas Control. 2023, 127: 103938. [CrossRef]

- Kwanghwi Kim; Heejun Lee; Hyun Sic Park; Hojun Song; Suhan Kim. Surface modification of polypropylene hollow fiber membranes using fluorosilane for CO2 absorption in a gas-liquid membrane contactor. Heliyon. 2023. 9(9): e19829. [CrossRef]

- Aniqa Imtiaz; Mohd Hafiz Dzarfan Othman; Asim Jilani, Imran Ullah Khan; Roziana Kamaludin; Muhammad Ayub; Ojo Samuel; Tonni Agustiono Kurniawan; NurAwanis Hashim; Mohd Hafiz Puteh. A critical review in recent progress of hollow fiber membrane contactors for efficient CO2 separations. Chemosphere. 2023. 325: 138300. [CrossRef]

- Arman Shiravi; Mohammad Salehi Maleh; Ahmadreza Raisi; Mika Sillanpää. Hollow fiber membrane contactor for CO2 capture: A review of recent progress on membrane materials, operational challenges, scale-up and economics. Carbon Capture Science & Technology. 2024. 10: 100160. [CrossRef]

- Seungju Kim; Colin A. Scholes; Daniel E. Heath; Sandra E. Kentish. Gas-liquid membrane contactors for carbon dioxide separation: A review. Chemical Engineering Journal. 2021. 411: 128468. [CrossRef]

- Joris Koornneef; Tim van Keulen; André Faaij; Wim Turkenburg. Life cycle assessment of a pulverized coal power plant with post-combustion capture, transport and storage of CO2. International Journal of Greenhouse Gas Control. 2008, 2(4): 448-467. [CrossRef]

- Letitia Petrescu; Davide Bonalumi; Gianluca Valenti; Ana-Maria Cormos; Calin-Cristian Cormos. Life Cycle Assessment for supercritical pulverized coal power plants with post-combustion carbon capture and storage. Journal of Cleaner Production. 2017, 157: 10-21. [CrossRef]

- Surprenant R. Comparison of life-cycle assessment between bio-catalyzed and promoted potassium carbonate processes and amine-based carbon capture technologies. International Journal of Greenhouse Gas Control. 2019. 88, 134-155. [CrossRef]

- Lorena Giordano; Denis Roizard; Eric Favre. Life cycle assessment of post-combustion CO2 capture: A comparison between membrane separation and chemical absorption processes. International Journal of Greenhouse Gas Control. 2018. 68: 146-163. [CrossRef]

- Wang Y; Pan Z; Zhang WX; Huang SC; Yu GJ; Soltanian MR; Lichtfouse E; Zhang ZE. Higher efficiency and lower environmental impact of membrane separation for carbon dioxide capture in coal power plants. Environmental Chemistry Letters. 2023. 21: 1951-1958. [CrossRef]

- Akan AP; Chau J; Gullu G; Sirkar KK. Life Cycle Assessment of Post-Combustion CO2 Capture and Recovery by Hydrophobic Polypropylene Cross-Flow Hollow Fiber Membrane Contactors with Activated Methyldiethanolamine. Atmosphere. 2023. 14(3): 490-513. [CrossRef]

- R.E. James III; D. Kearins; M. Turner; M. Woods; N. Kuehn; A. Zoelle. Cost and performance baseline for fossil energy plants volume 1: bituminous coal and natural gas to electricity, NETL, 2019.

- Scholes; Colin A. Membrane contactors modelled for process intensification post combustion solvent regeneration. International Journal of Greenhouse Gas Control, 2019, 87: 203-210. [CrossRef]

- Nguyen K; Iliuta I; Bougie F; et al. Techno-economic assessment of enzymatic CO2 capture in hollow fiber membrane contactors with immobilized carbonic anhydrase. Separation and Purification Technology, 2023, 307: 122702. [CrossRef]

- Jelena Lillepärg; Prokopios Georgopanos; Sergey Shishatskiy. Stability of blended polymeric materials for CO2 separation. Journal of Membrane Science. 2014. 467: 269-278. [CrossRef]

- Available at: https://ecoinvent.org/the-ecoinvent-database/. (Accessed on October 26, 2023).

- Yadav P; Ismail N, Essalhi M; Tysklind M. Assessment of the environmental impact of polymeric membrane production. Journal of Membrane Science, 2021, 622: 118987. [CrossRef]

- Koornneef J; van Keulen T; Faaij A; Turkenburg W. Life cycle assessment of a pulverized coal power plant with post-combustion capture, transport and storage of CO2[J]. International journal of greenhouse gas control, 2008, 2(4): 448-467. [CrossRef]

- Huijbregts; M.A.J.; Steinmann; Z.J.N.; Elshout; P.M.F. et al. ReCipe2016: a harmonised life cycle impact assessment method at midpoint and endpoint level. The International Journal of Life Cycle Assessment. 2017. 22: 138–147. [CrossRef]

- China Energy Outlook. Available online: https://international.lbl.gov/china-energy-outlook-0. (Accessed on October 26, 2023).

| Parameters | Value |

|---|---|

| Fiber inner diameter (m) | 3.0×10-4 |

| Fiber outer diameter (m) | 5.0×10-4 |

| Pore diameter (m) | 1.0×10-7 |

| Porosity | 0.5 |

| Outer specific area (m2/m3) | 1500 |

| Inner specific area (m2/m3) | 900 |

| Gas velocity (m/s) | 1.0 |

| Liquid velocity (m/s) | 0.07 |

| Number of absorber contactors Number of desorber contactors |

100 |

| 100 | |

| Effective height (m) | 4.0 |

| Membrane material | Polysulfone |

| Name of the impact category | Expression in equivalent unit | Abbreviation |

|---|---|---|

| ReCipe 2016 Midpoint indicators | ||

| Global warming potential | kg CO2 to air eq. | GWP |

| Ozone layer depletion potential | kg CFC-11 eq. | ODP |

| Ionizing radiation potential | kBq Cobalt-60 to air eq. | IRP |

| Ozone formation, Human health | kg NOx eq. | OFHH |

| Fine particulate matter formation | kg PM2.5 to air eq. | FPMF |

| Ozone formation terrestrial ecosystems | kg NOx eq. | OFTE |

| Terrestrial acidification potential | kg SO2 eq. | TAP |

| Freshwater eutrophication potential | kg P eq. | FEP |

| Marine eutrophication potential | kg N eq. | MEP |

| Terrestrial ecotoxicity potential | kg 1,4-DCB to industrial soil eq. | TEP |

| Freshwater ecotoxicity potential | kg 1,4-DCB to freshwater eq. | FETP |

| Marine ecotoxicity potential | kg 1,4-DCB to marine water eq. | METP |

| Human carcinogenic toxicity potential | kg 1,4-DCB eq. | HCTP |

| Human non-carcinogenic toxicity potential | kg 1,4-DCB eq. | HNCTP |

| Land use | m2×yr annual cropland eq. | LU |

| Mineral resource scarcity | kg Cu eq. | MRS |

| Fossil resource scarcity | kg oil-eq. | FRS |

| Water consumption potential | m3 water-eq. consumed | WCP |

| ReCipe 2016 Endpoint indicators | ||

| Damage to human health | points | |

| Damage to ecosystem quality | points | |

| Damage to resources | points |

| 2020 | 2025 | 2030 | 2035 | 2040 | 2045 | 2050 | |

|---|---|---|---|---|---|---|---|

| Coal | 55% | 54% | 52% | 42% | 34% | 20% | 5% |

| Natural gas | 4% | 5% | 5% | 5% | 5% | 6% | 5% |

| Hydro | 21% | 19% | 17% | 16% | 15% | 16% | 18% |

| Nuclear | 6% | 7% | 8% | 10% | 11% | 13% | 16% |

| Wind | 8% | 11% | 13% | 18% | 22% | 25% | 29% |

| Solar | 5% | 4% | 6% | 9% | 13% | 19% | 27% |

| Electricity GWP kgCO2eq/kWh | 0.724 | 0.714 | 0.691 | 0.586 | 0.482 | 0.329 | 0.143 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).