Submitted:

04 May 2024

Posted:

06 May 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

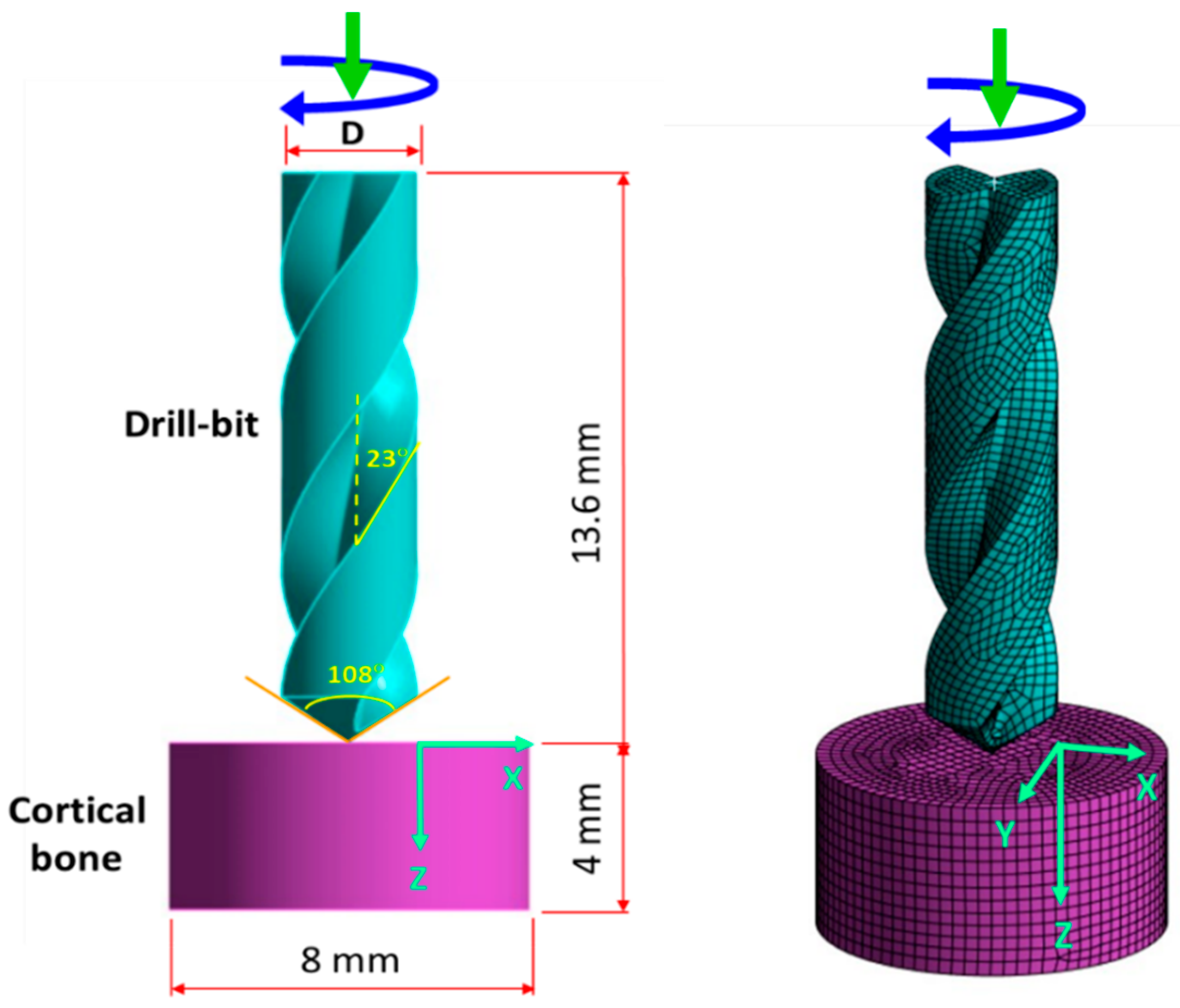

2. Finite Element (FE) Modelling

2.1. Construction of FE Model

2.2. Material Properties and Boundary Conditions

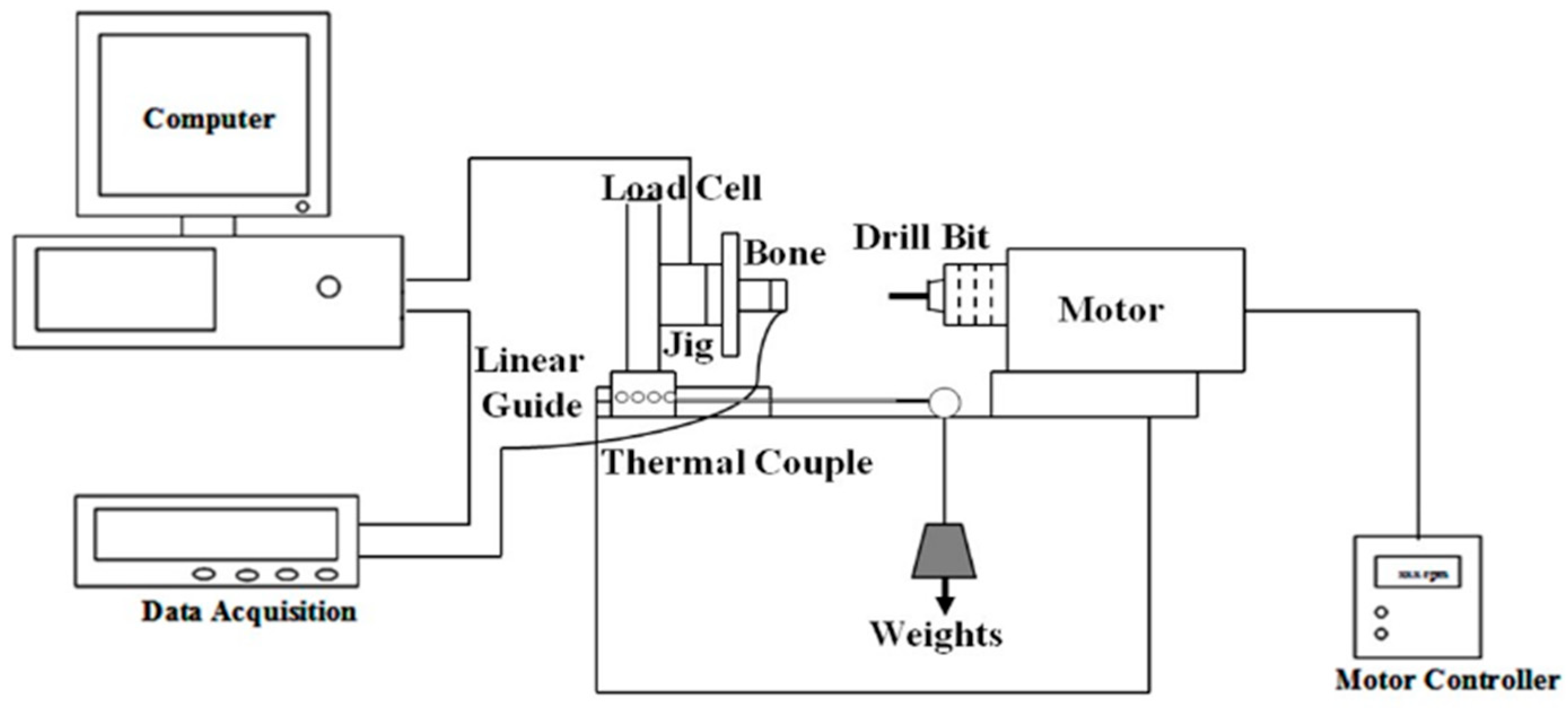

3. Bone Drilling Experiment

4. Results

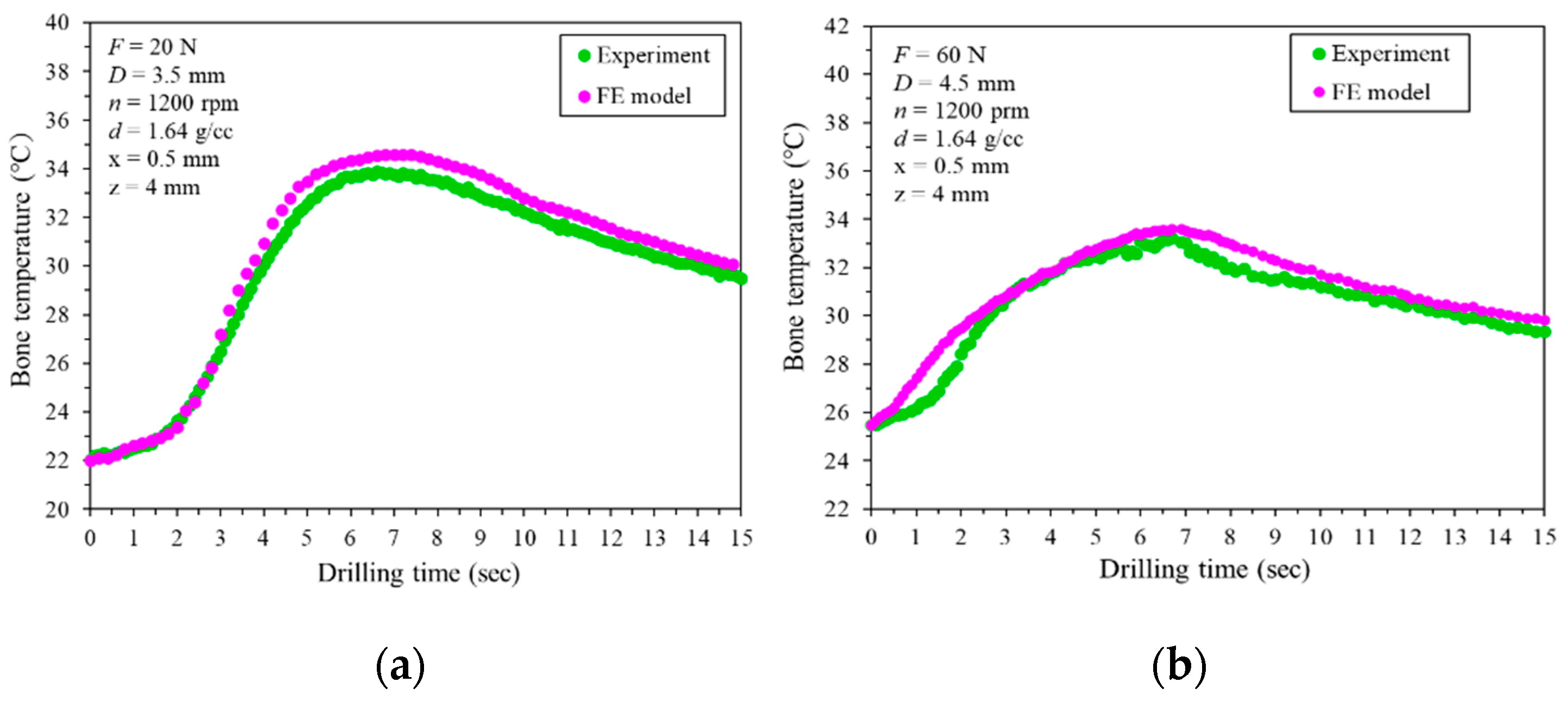

4.1. Validation of the FE Model

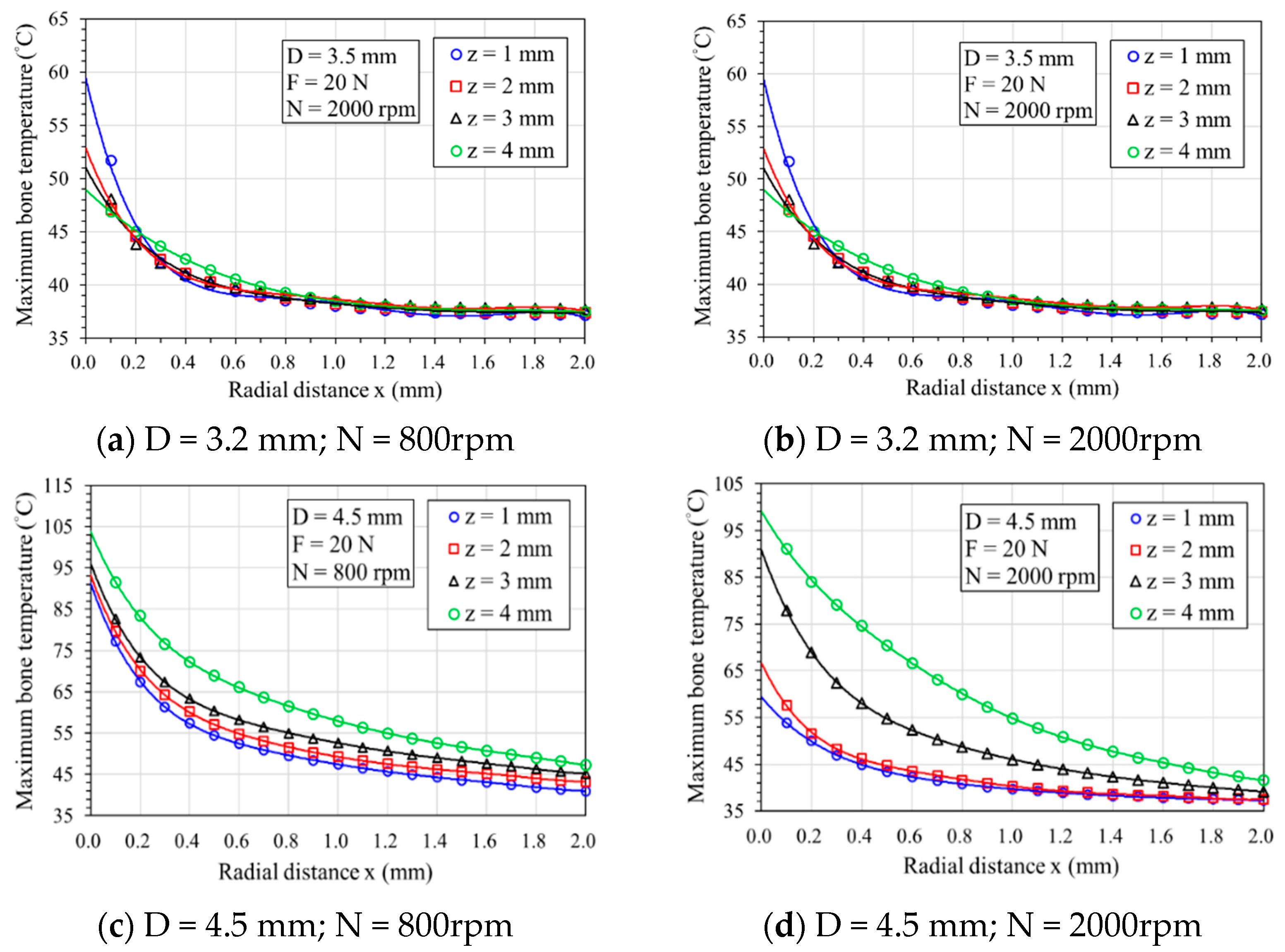

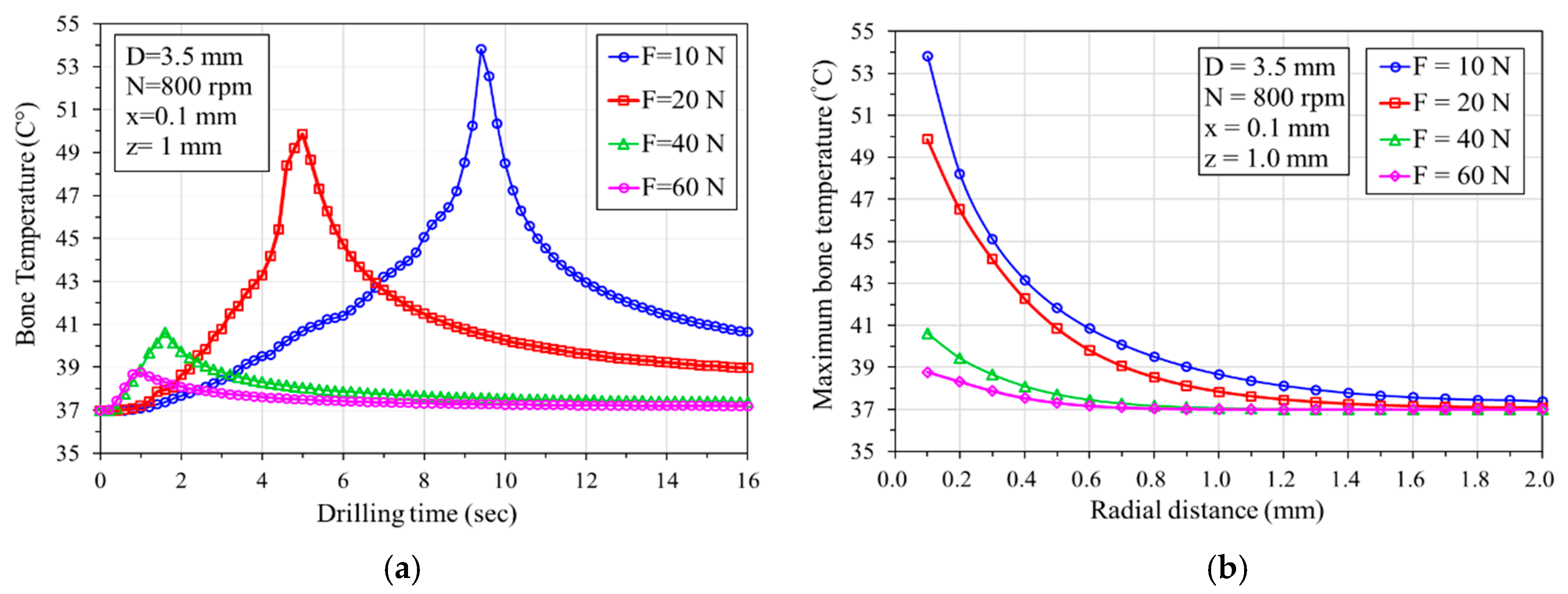

4.2. Maximum Temperature with Radial Distance

4.3. Effects of Feeding Force on Bone Temperature

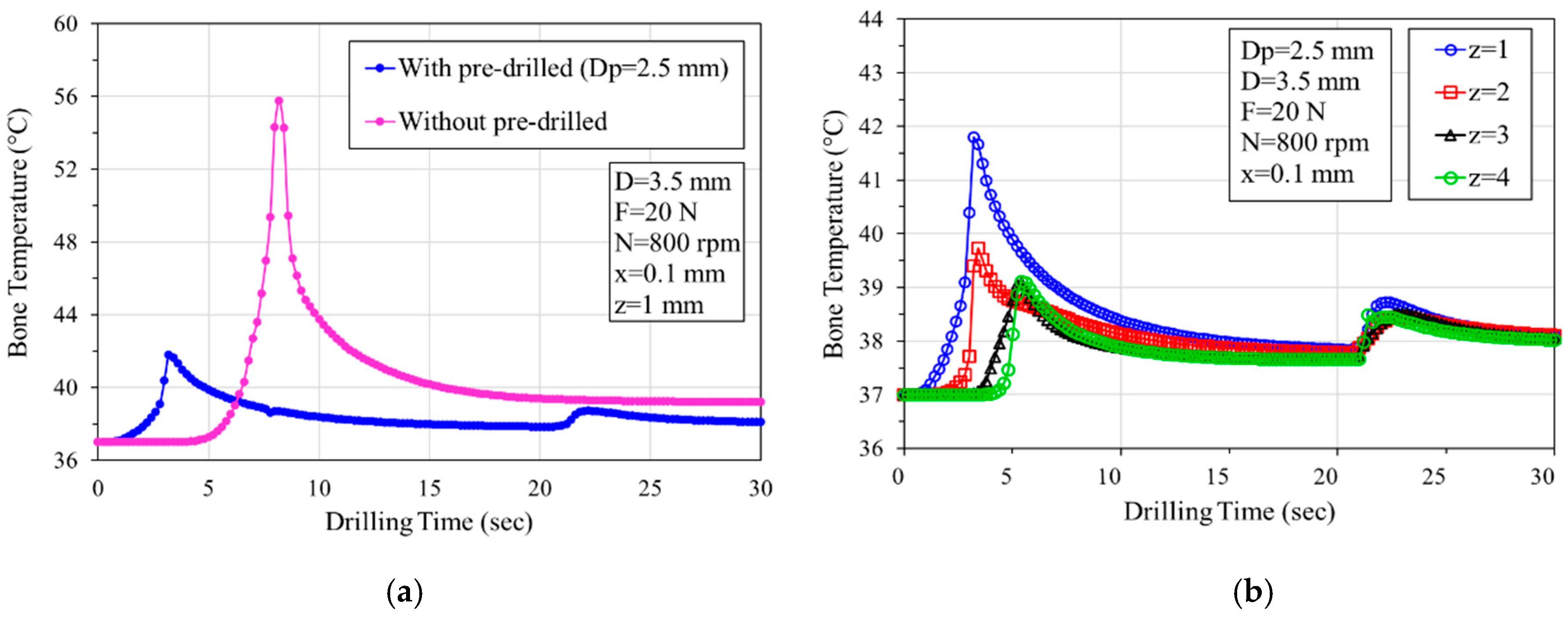

4.4. Effects of the Predrilled Hole on Bone Temperature

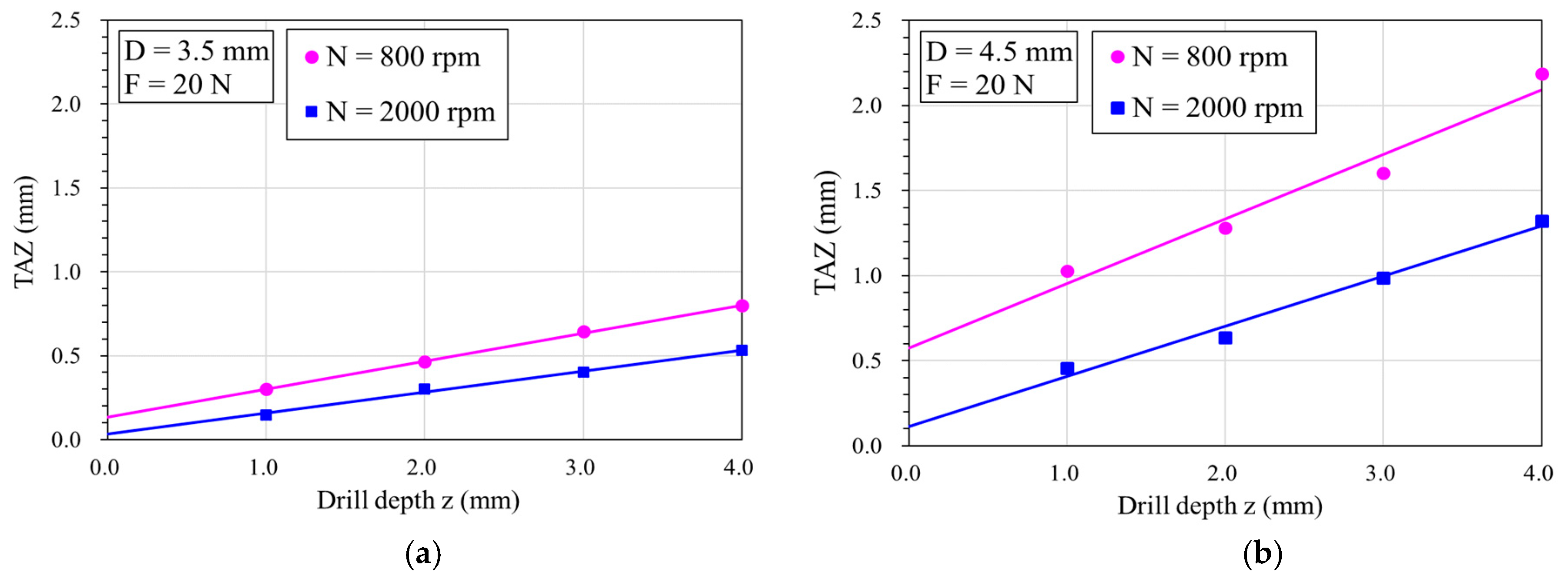

4.5. Effects of Rotational Speed on Thermal Affecting Zone

5. Discussion

6. Conclusions

- Our three-dimensional FE model was experimentally validated and can effectively assess temperature elevation and the thermally affected zone (TAZ) during bone drilling. This is valuable for identifying optimal drilling parameters, designing drill handpieces, and implementing robot-assisted bone drilling.

- Higher rotational speeds may reduce bone temperature and decrease the TAZ; however, the TAZ increases with drill depth, feed force, and drill bit diameter.

- Implementing a two-stage drilling process can minimize frictional heat, thereby reducing temperature during bone drilling. This approach may be considered an effective method for mitigating bone temperature elevation during drilling.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bonfield, W.; Li, C.H. The temperature dependence of the deformation of bone. J Biomechanics 1968, 1, 323–9. [Google Scholar] [CrossRef]

- Thompson, H.C. Effect of drilling on bone. Journal of Oral Surgery 1958, 16, 22–30. [Google Scholar]

- Eriksson, R.A.; Albertson, T. The effect of heat on bone regeneration: an experimental study in the rabbit using the bone growth chamber. Journal of Oral and Maxillofacial Surgery 1984, 42, 705–711. [Google Scholar] [CrossRef] [PubMed]

- Eriksson, A.R.; Albrektsson, T.; Albrektsson, B. Heat caused by drilling cortical bone. Temperature measured in vivo in patients and animals. Acta Orthop Scand 1984, 55, 629–31. [Google Scholar] [CrossRef] [PubMed]

- Cordioli, G.; Majzoub, Z. Heat generation during Implant site preparation: an in vitro study. Journal of Oral and Maxillofacial Implants 1997, 12, 186–193. [Google Scholar]

- Matthews, L.S.; Hirsch, C. Temperatures measured in human cortical bone when drilling. J Bone Joint Surg [Am]. 1972, 54-A, 297–308. [Google Scholar] [CrossRef]

- Brisman, D.L. The effect of speed, pressure, and time on bone temperature during the drilling of implant sites. Int J Oral Maxillofac Impl. 1996, 11, 35–7. [Google Scholar]

- Tehemar, S.H. Factors affecting heat generation during implant site preparations: a review of biologic observations and future considerations. International Journal of Oral and Maxillofacial Implants 1999, 14, 127–136. [Google Scholar]

- Alevizakos, V.; Mosch, R.; von See, C. Influence of Multiple Used Implant Drills on Their Cutting Performance and Fracture Resistance. Materials (Basel) 2023, 16, 5271. [Google Scholar] [CrossRef] [PubMed]

- Lundskog, J. Heat and bone tissue. An experimental investigation of the thermal properties of bone and threshold levels for thermal injury. Scand J Plast Reconstr Surg. 1972, 9, 1–80. [Google Scholar]

- Hillery, M.T.; Shuaib, I. Temperature Effects in the Drilling of Human and Bovine Bone. Journal of Materials Processing Technology 1999, 92-93, 302–308. [Google Scholar] [CrossRef]

- Ardan, N.I.; Janes, J.M.; Herrick, J.F. Ultrasonic Energy and Surgically Produced Defects in Bone. Journal of Bone and Joint Surgery 1957, 39A, 394–402. [Google Scholar] [CrossRef]

- Mortiz, A.R.; Henrique, F.C. Studies of Thermal Injuries. Journal of Pathol. 1947, 23, 695–719. [Google Scholar]

- Mortiz, A.R.; Henrique, F.C. The Relative Importance of Time and Surface Temperature in the Causation of Cutaneous Burns. Journal of Physiology 1947, 23, 695–719. [Google Scholar]

- Eriksson, A.; Albrektsson, T.; Grace, B.; McQueen, O. Thermal Injury to Bone. A vital Microscopic description of Heat Effects. Journal of Oral Surgery 1982, 11, 115–121. [Google Scholar]

- Davidson, S.R.; James, D.F. Drilling in Bone: Modeling Heat Generation and Temperature Distribution. Journal of Biomechanical Engineering 2003, 125, 305–314. [Google Scholar] [CrossRef] [PubMed]

- Akhbar, M.F.A.; Sulong, A.W. Surgical Drill Bit Design and Thermomechanical Damage in Bone Drilling: A Review. Ann. Biomed. Eng. 2021, 49, 29–56. [Google Scholar] [CrossRef] [PubMed]

- Sezek, S.; Aksakal, B.; Karaca, F. Influence of drill parameters on bone temperature and necrosis: A FEM modelling and in vitro experiments. Computational Materials Science 2012, 60, 13–8. [Google Scholar] [CrossRef]

- Tuijthof1, G. J. M.; Frühwirt, C.; Kment, C. Influence of tool geometry on drilling performance of cortical and trabecular bone. Med Eng Phys. 2013, 35, 1165–72. [Google Scholar] [CrossRef]

- Pourgiv, S.; Mosavar, A.; Jamshidi, N.; Mohammadi, A. Ultrasonic-assisted drilling of cortical and cancellous bone in a comparative point of view. Heliyon 2024, 10, e26248. [Google Scholar] [CrossRef]

- Pazarcı, Ö.; Gündoğdu, F. Temperature change during orthopedic drilling procedures: An experimental surgical internal fixation simulation study. J. Orthop. 2023, 46, 58–63. [Google Scholar] [CrossRef] [PubMed]

- Lang, Z.; Wang, Q.L.; He, D.; Liu, Y.J.; Tian, W. Study on parameters of robot-assisted ultrasonic drilling on bovine vertebral body. Zhonghua Yi Xue Za Zhi 2022, 102, 370–377. [Google Scholar]

- Karaca, F.; Aksakal, B.; Kom, M. Influence of orthopaedic drilling parameters on temperature and histopathology of bovine tibia: an in vitro study. Med Eng Phys. 2011, 33, 1221–7. [Google Scholar] [CrossRef] [PubMed]

- Jung, O.; Lindner, C.; Pantermehl, S.; Barbeck, M. Heat Development During Medical Drilling: Influencing Factors and Examination Methods - Overview and First Results. In Vivo. 2021, 35, 3011–3017. [Google Scholar] [CrossRef] [PubMed]

- Aquilanti, L.; Antognoli, L.; Rappelli, G.; Di Felice, R.; Scalise, L. Heat Generation During Initial Osteotomy for Implant Site Preparation: An In Vitro Measurement Study. J. Maxillofac. Oral. Surg. 2023, 22, 313–320. [Google Scholar] [CrossRef] [PubMed]

- Shawary, M.; Misch, C.E.; Weller, N.; Tehemar, S. Heat generation during implant drilling: the significance of motor speed. J Oral Maxillofac Surg. 2002, 1160, 1169–260. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Gozen, B. A.; Ozdoganlar, O. B. Modeling and Experimentation of Bone Drilling Forces. J. Biomech. 2012, 45, 1076–1083. [Google Scholar] [CrossRef] [PubMed]

- Strbac, G.D.; Giannis, K.; Unger, E.; Mittlböck, M.; Watzek, G.; Zechner, W. A novel standardized bone model for thermal evaluation of bone osteotomies with various irrigation methods. Clin. Oral. Implants Res. 2014, 25, 622–631. [Google Scholar] [CrossRef] [PubMed]

- Delgado-Ruiz, R.A.; Velasco, O.E.; Romanos, G.E.; Gerhke, S.; Newen, I.; Calvo-Guirado, J.L. Slow drilling speeds for single-drill implant bed preparation. Experimental in vitro study. Clin. Oral. Investig. 2018, 22, 349–359. [Google Scholar] [CrossRef]

- Salomó-Coll, O.; Auriol-Muerza, B.; Lozano-Carrascal, N.; Hernández-Alfaro, F.; Wang, H.L; Gargallo-Albiol, J. Influence of bone density, drill diameter, drilling speed, and irrigation on temperature changes during implant osteotomies: an in vitro study. Clin. Oral. Investig. 2020, 25, 1047–1053. [Google Scholar] [CrossRef]

- Gaspar, J.; Borrecho, G.; Oliveira, P.; Salvado, F.; Martins dos Santos, J. Osteotomy at low-speed drilling without irrigation versus high-speed drilling with irrigation: an experimental study. Acta Medica Port. 2013, 26, 231–236. [Google Scholar]

- Varghai, K.; Wang, R.; Eppell, S.J. Effect of drilling speed on dental implant insertion torque. J. Oral Implantol. 2020, 46, 467–474. [Google Scholar] [CrossRef] [PubMed]

- Gehrke, S.; Bettach, R.; Taschieri, S.; Boukhris, G.; Corbella, S.; Del Fabbro, M. Temperature Changes in Cortical Bone after Implant Site Preparation Using a Single Bur versus Multiple Drilling Steps: An In Vitro Investigation. Clin. Implant Dent. Relat. Res. 2015, 17, 700–707. [Google Scholar] [CrossRef]

- Lee, J.; Chavez, C.; Park, J. Parameters affecting mechanical and thermal responses in bone drilling: A review. J. Biomech. 2018, 71, 4–21. [Google Scholar] [CrossRef] [PubMed]

- Alam, K.; Mitrofanov, A.V.; Silberschmidt, V.V. Thermal analysis of orthogonal cutting of cortical bone using finite element simulations. Int. J. Exp. Comput Biomech. 2010, 1, 236–251. [Google Scholar] [CrossRef]

- Khurshid, A.; Issam, M.B.; Naseer, A. Cortical bone drilling: An experimental and numerical study. Technol. Health Care. 2014, 23, 1–12. [Google Scholar]

- Waqas, A.L.; Kaddour, B.M.; Ian, A. Drilling in cortical bone: a finite element model and experimental investigations. J. Mech. Behav. Biomed. Mater. 2015, 42, 32–42. [Google Scholar]

- Kutay, A.; Korhan, Ö.; Levent, U. An analytical and numerical approach to the determination of thermal necrosis in cortical bone drilling. Int. J. Numer. Method. Biomed. Eng. 2022, 38, e3640. [Google Scholar]

- Chen, Y.C.; Tu, Y.K. Zhuang, J.Y.; Tsai, Y.J.; Yen, C.Y.; Hsiao, C.K. Evaluation of the parameters affecting bone temperature during drilling using a three-dimensional dynamic elastoplastic finite element model. Med. Biol. Eng. Comput. 2017, 55, 1949–57. [Google Scholar] [CrossRef]

- Chen, Y.C.; Tu, Y.K.; Tsai, Y.J.; Tsai, Y.S.; Yen, C.Y.; Yang, S.C.; Hsiao, C.K. Assessment of thermal necrosis risk regions for different bone qualities as a function of drilling parameters. Comput Methods Programs Biomed. 2018, 162, 253–261. [Google Scholar]

- Prabhu, N.; Shetty, D.K.; Naik, N. Application of finite element analysis to evaluate optimal parameters for bone/tooth drilling to avoid thermal necrosis, cogent. Engineering. 2021, 8, 1876582. [Google Scholar]

- Bachus, K.N.; Rondina, M.T.; Hutchinson, D.T. The effects of drilling force on cortical temperatures and their duration: an in vitro study. Med. Eng. Phys. 2000, 22, 685–691. [Google Scholar] [CrossRef] [PubMed]

- Davidson, S.R.H.; James, D.F. Measurement of thermal conductivity of bovine cortical bone. Medical Engineering and Physics. 2000, 22, 741–7. [Google Scholar] [CrossRef]

- Akhbar, M.F.A.; Yusoff, A.R. Comparison of bone temperature elevation in drilling of human, bovine and porcine bone. 17th CIRP Conference on Modelling of Machining Operations. Procedia CIRP 2000, 82, 411–414. [Google Scholar] [CrossRef]

- Inan, M.; Mizrak, B.; Ertem, K.; Harma, A.; Elmali, N.; Ayan, I. The factors effecting thermal necrosis secondary to teh application of teh Ilizarov transosseous wire. Acta Orthop Traumatol Turc. 2005, 39, 70–5. [Google Scholar] [PubMed]

- Mustafa, B. , David, F.J. Measurements of Shaft Speed While Drilling through Bone. Journal of Oral and Maxillofacial Surgery 1995, 53, 1308–1315. [Google Scholar]

- Staroveski, T.; Brezak, D.; Udiljak, T. Drill wear monitoring in cortical bone drilling. Med. Eng. Phys. 2015, 37, 560–6. [Google Scholar] [CrossRef] [PubMed]

- Augustin, G.; Davila, S.; Udilljak, T.; Staroveski, T.; Brezak, D.; Babic, S. Temperature changes during cortical bone drilling with a newly designed step drill and an internally cooled drill. Int. Orthop. 2012, 2012. 36, 1449–56. [Google Scholar] [CrossRef]

- Augustin, G.; Davila, S.; Mihoci, K.; Udiljak, T.; Vedrina, D.S.; Antabak, A. Thermal osteonecrosis and bone drilling parameters revisited. Arch. Orthop. Trauma. Surg. 2008, 128, 71–7. [Google Scholar] [CrossRef] [PubMed]

- Abdul-Rashid, M.L.; Ta, H.L.; Pancharatnam, D. Assessment of Coolant Delivery Techniques for Irrigation During Bone Drilling: A Cadaveric Observation. Malays. Orthop. J. 2020, 14, 206–207. [Google Scholar]

- Tuce, R.A.; Neagu, M.; Pupazan, V.; Neagu, A.; Arjoca, S. The 3D Printing and Evaluation of Surgical Guides with an Incorporated Irrigation Channel for Dental Implant Placement. Bioengineering (Basel) 2023, 10, 1168. [Google Scholar] [CrossRef]

- Parvizi, S.; Cameron, A.; Tadakamadla, S.; Figueredo, C.M.S.; Reher, P. A Novel Irrigation System to Reduce Heat Generation during Guided Implantology: An In Vitro Study. J. Clin. Med. 2023, 12, 3944. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).