Submitted:

01 May 2024

Posted:

01 May 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

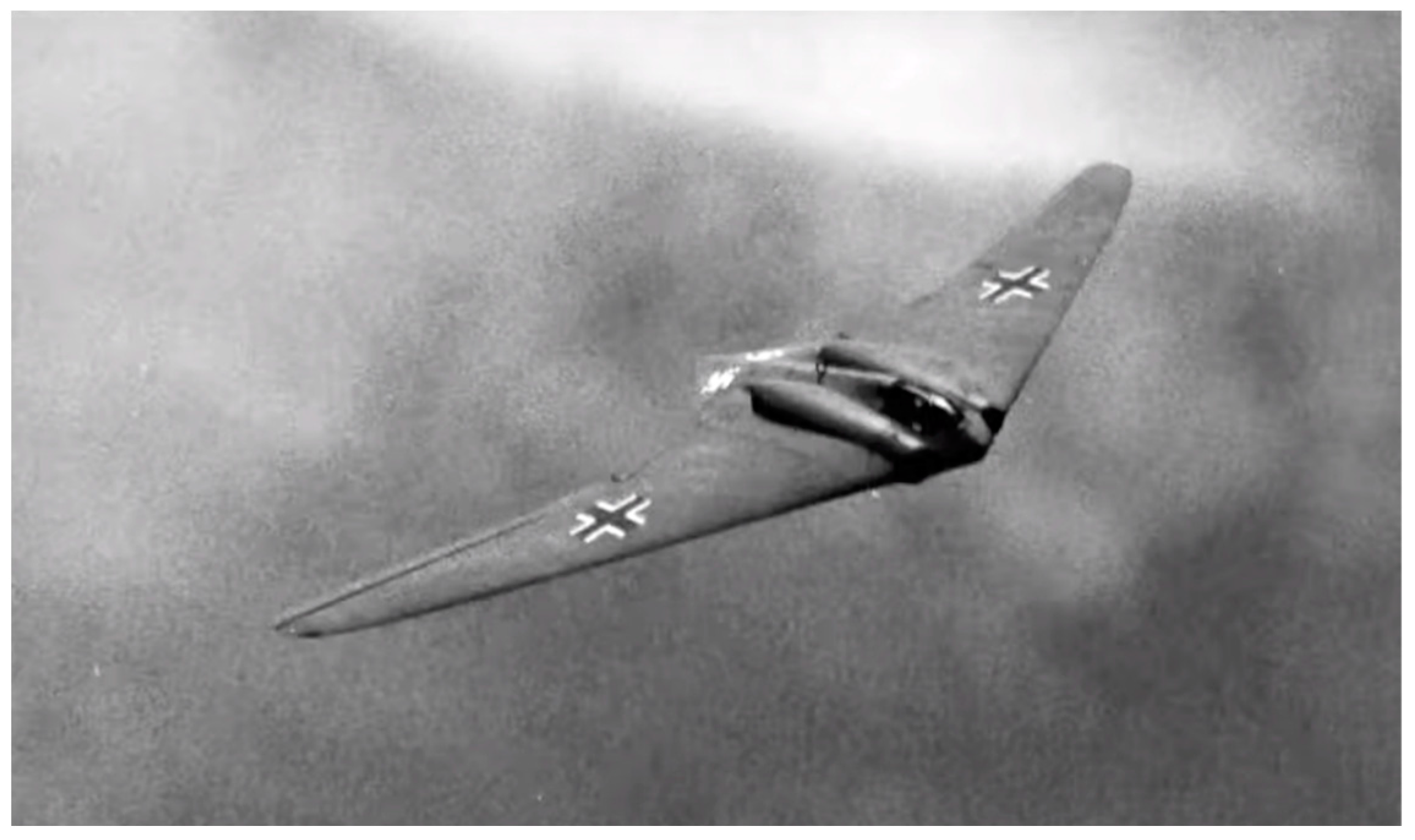

1.1. Brief History of Flying Wing Designs

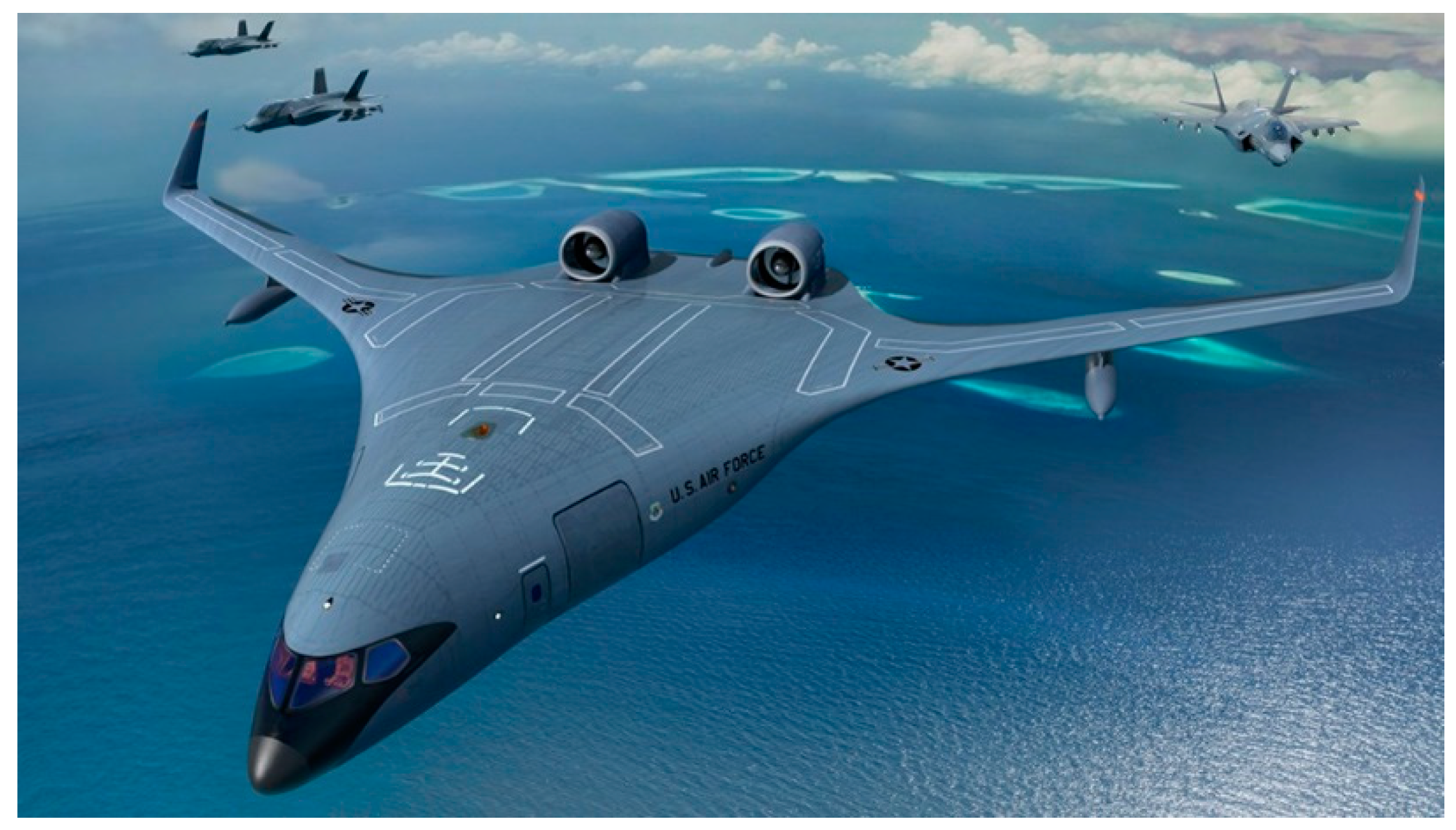

1.2. The USAF NGAS Program

1.3. Structure of the Present Work

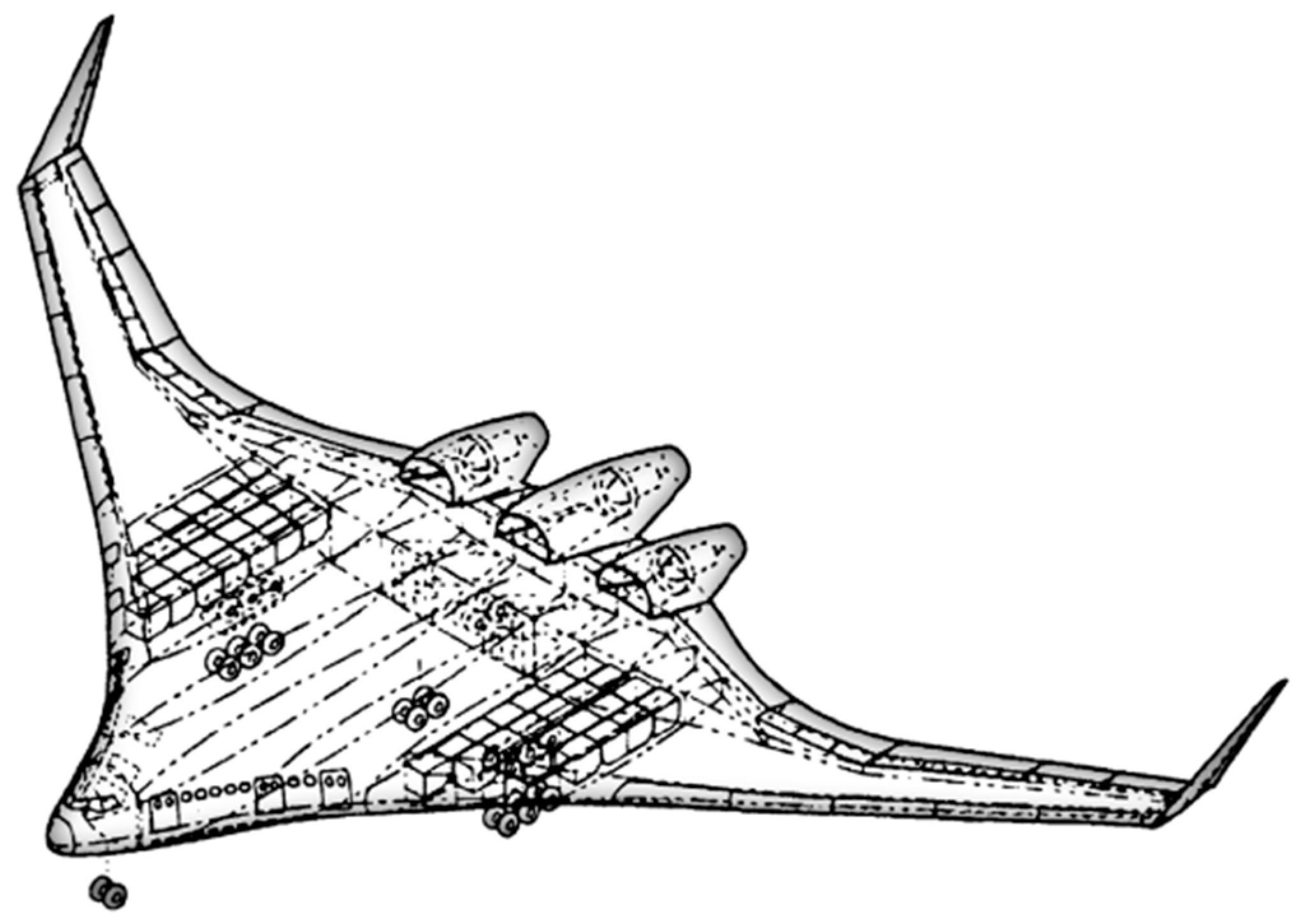

2. Potentials and Challenges of the Blended Wing Body Design

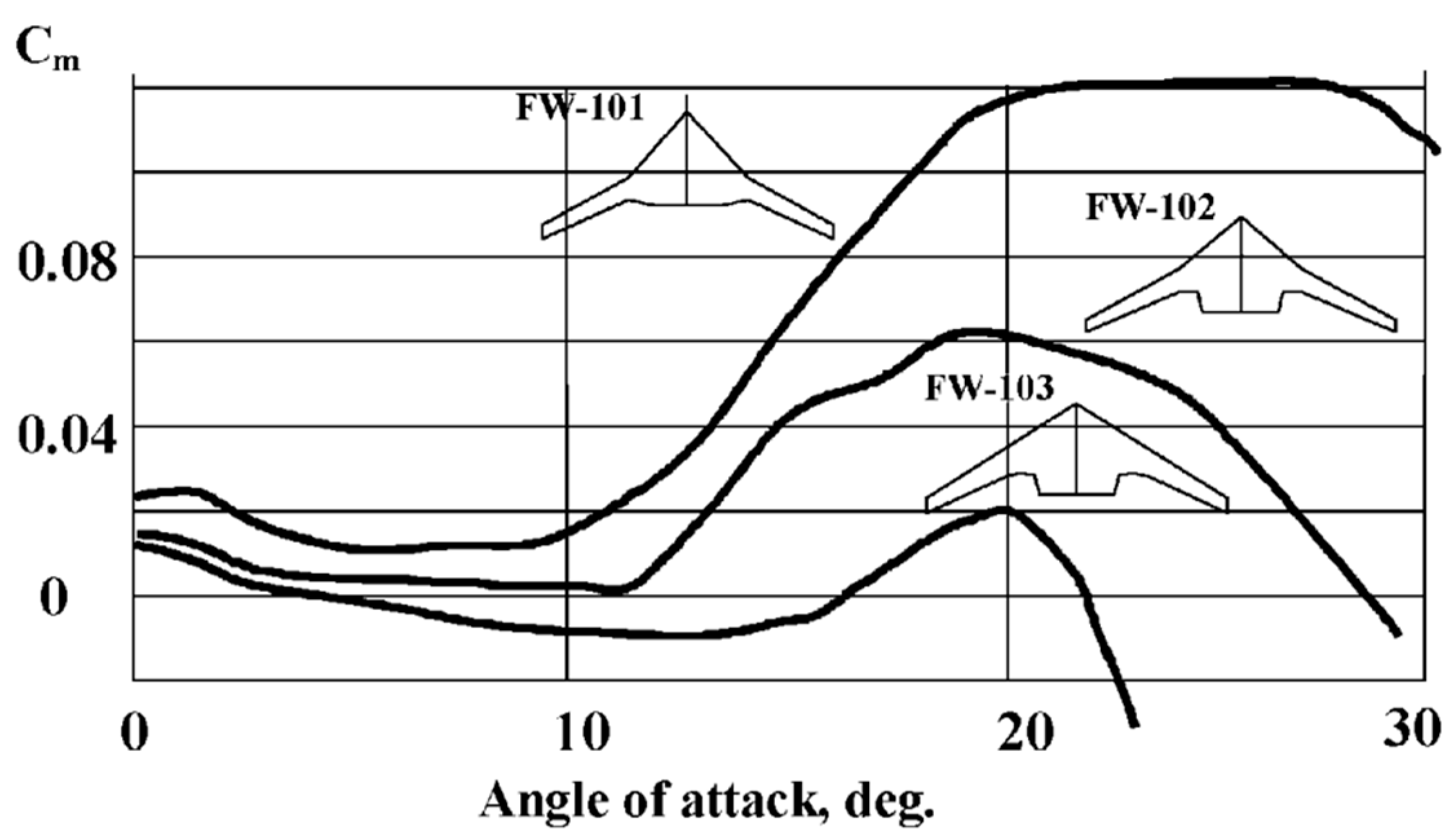

2.1. Aerodynamic Considerations

2.1.1. Aerodynamic Considerations in Light of the NGAS Program

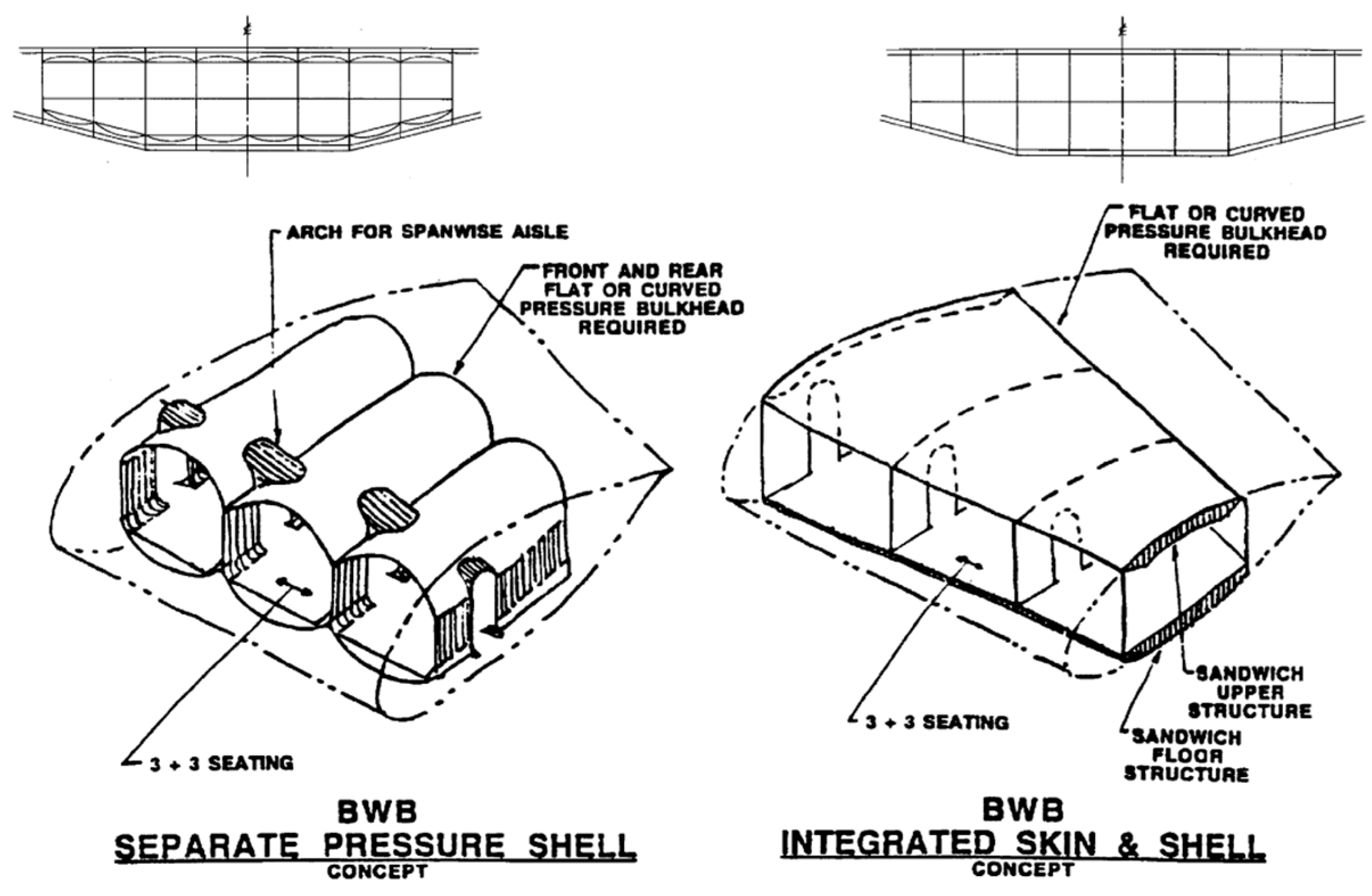

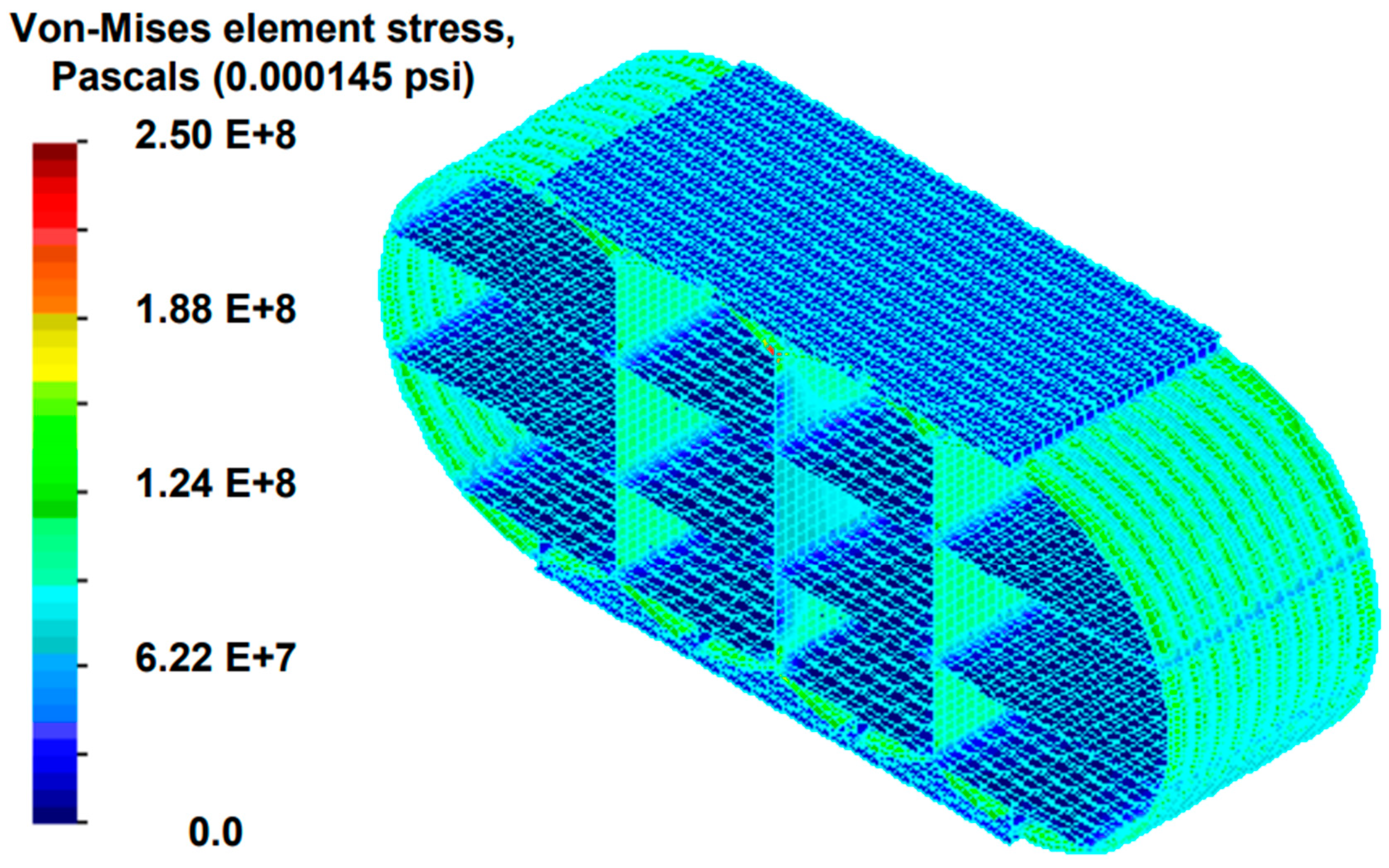

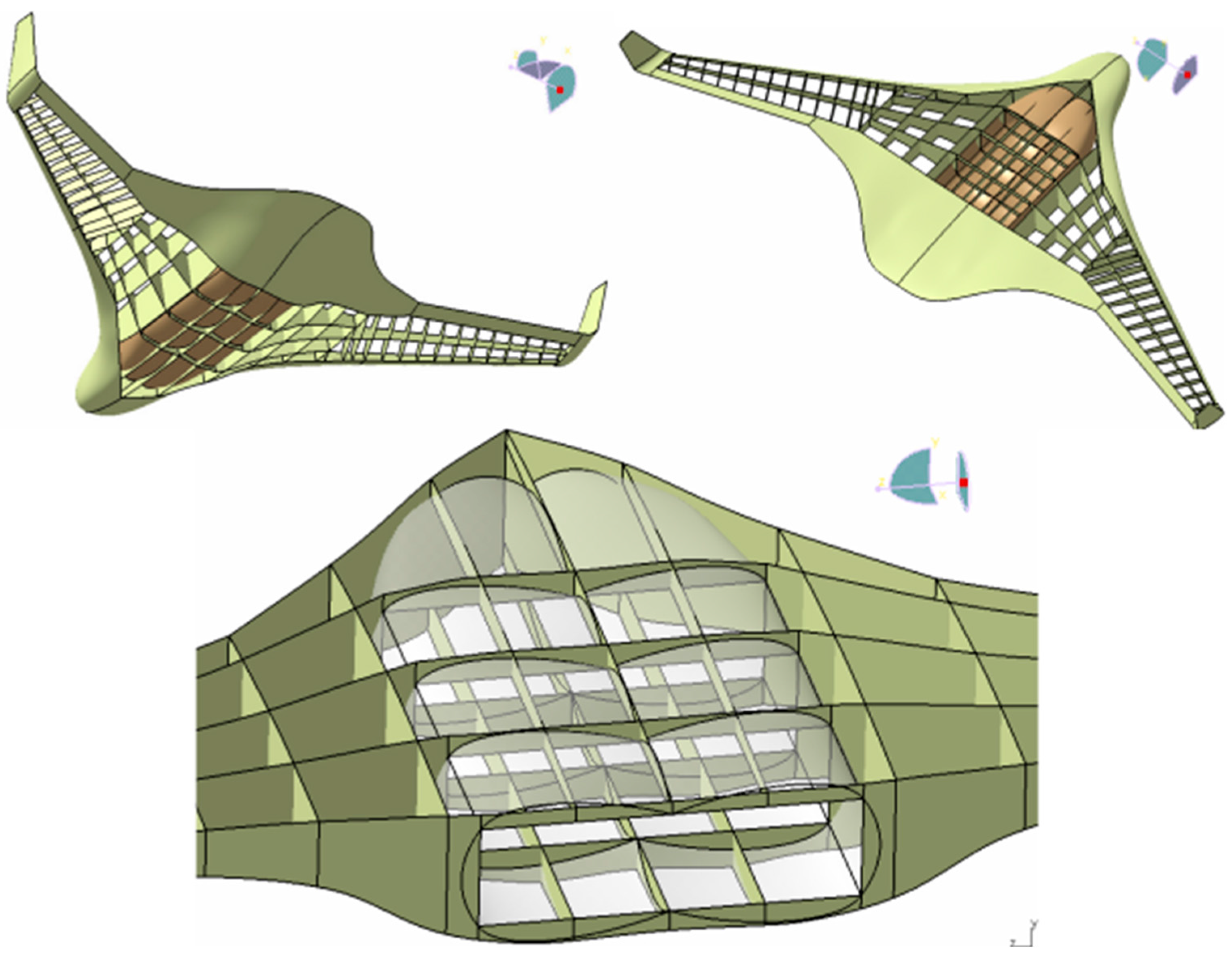

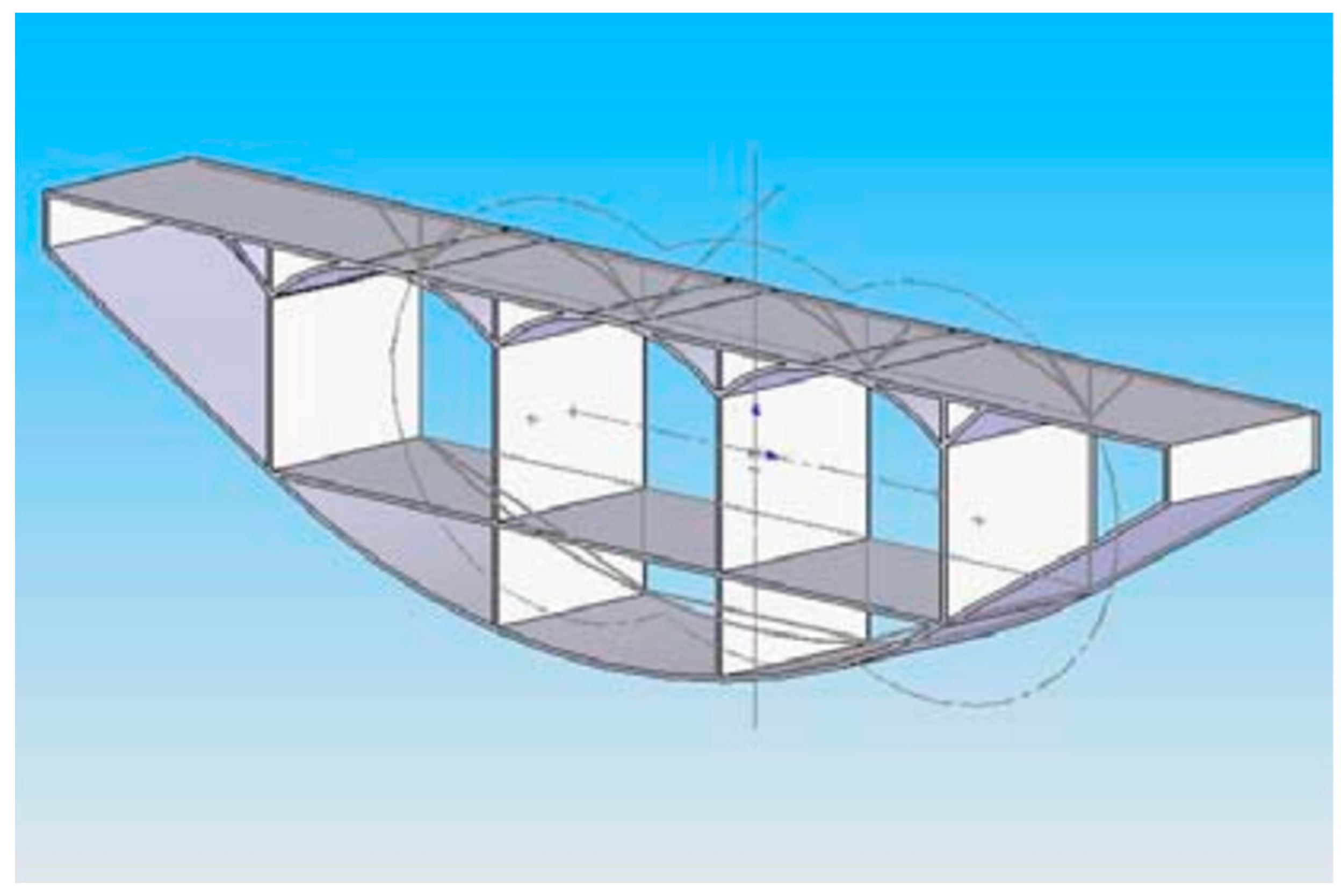

2.2. Structure and Manufacturing

2.2.1. Structural Considerations in Light of the NGAS Program

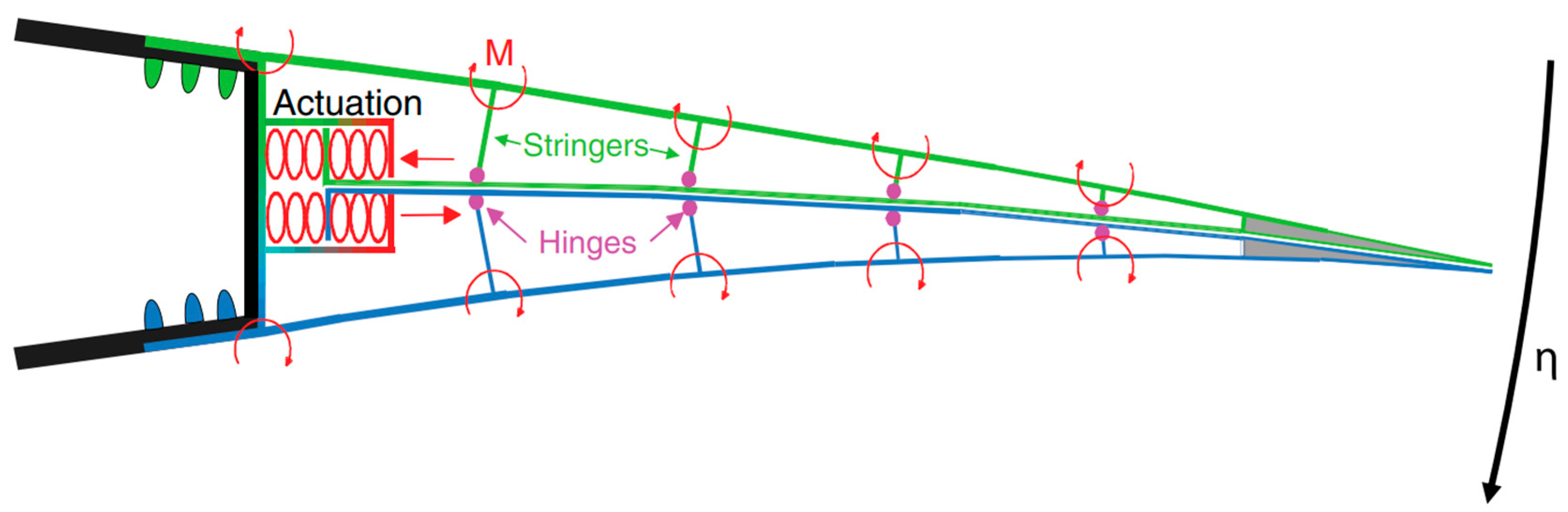

2.3. Stability and Control

2.3.1. Stability and Control Considerations in Light of the NGAS Program

2.4. Noise

2.4.1. Noise Considerations in Light of the NGAS Program

2.5. Miscellaneous

2.5.1. Propulsion

2.5.2. Stealth

2.5.3. Aircraft Safety, Passenger Comfort and Emergency Egress

3. Conclusion

References

- R. Wood and X. Bauer, “Flying wings/flying fuselages,” in 39th Aerospace Sciences Meeting and Exhibit, Reno, NV, U.S.A.: American Institute of Aeronautics and Astronautics, Jan. 2001. [CrossRef]

- H. [complied by] and R. D. A. [editor] Lukins, The book of Westland aircraft, First Edition. Aircraft Technical Pub, 1944.

- J. M. Campbell and G. R. Pape, Northrop Flying Wings: A History of Jack Northrop’s Visionary Aircraft, 1st edition. Atglen, PA: Schiffer Military History, 1997.

- D. Donald, The Encyclopedia of World Aircraft, 0 edition. Leicester: Bookmart, 1997.

- “The WW2 flying wing decades ahead of its time.” Accessed: Feb. 03, 2024. [Online]. Available: https://www.bbc.com/future/article/20160201-the-wwii-flying-wing-decades-ahead-of-its-time.

- D. Myhra, The Horten Brothers and Their All-Wing Aircraft, 1st ed. edition. Atglen, PA: Schiffer Military History, 1997.

- H. Griffiths, “The Horten Ho-229 Aircraft [History Column],” IEEE Aerospace and Electronic Systems Magazine, vol. 36, no. 1, pp. 61–61, Jan. 2021. [CrossRef]

- S. Magazine and R. Maksel, “Restoring Germany’s Captured ‘Bat Wing,’” Smithsonian Magazine. Accessed: Feb. 13, 2024. [Online]. Available: https://www.smithsonianmag.com/air-space-magazine/horten-flying-wing-180960066/.

- T. Coleman and R. Wenkam, Jack Northrop and the Flying Wing: The Story Behind the Stealth Bomber, First Edition. Paragon House, 1988.

- GAO/NSIAD-97-181, “B-2 Bomber: Cost and Operational Issues.” [Online]. Available: https://www.gao.gov/products/nsiad-97-181.

- J. Tirpak, “Second B-21 Under Construction as Bomber Moves Toward First Flight,” Air & Space Forces Magazine. Accessed: Feb. 03, 2024. [Online]. Available: https://www.airandspaceforces.com/second-b-21-under-construction-as-bomber-moves-toward-first-flight/.

- “The B-21 Raider: Designed For Low Risk | Aviation Week Network.” Accessed: Feb. 03, 2024. [Online]. Available: https://aviationweek.com/defense-space/aircraft-propulsion/b-21-raider-designed-low-risk.

- G. Times, “China’s long-range stealth bomber outlined in PLA Air Force recruitment video - Global Times.” Accessed: Feb. 03, 2024. [Online]. Available: https://www.globaltimes.cn/page/202101/1211986.shtml.

- B. I. Larrimer, Beyond tube-and-wing: The X-48 blended wing-body and NASA’s quest to reshape future transport aircraft. in NASA aeronautics book series. Washington, DC: NASA, 2020.

- R. H. Liebeck, “Design of the Blended Wing Body Subsonic Transport,” Journal of Aircraft, vol. 41, no. 1, pp. 10–25, 2004. [CrossRef]

- R. Martinez-Val, “Flying Wings. A New Paradigm for Civil Aviation?,” Acta Polytechnica, vol. 47, no. 1, Art. no. 1, Jan. 2007. [CrossRef]

- P. Okonkwo and H. Smith, “Review of evolving trends in blended wing body aircraft design,” Progress in Aerospace Sciences, vol. 82, pp. 1–23, Apr. 2016. [CrossRef]

- “Next Generation Air-refueling System (NGAS) Request for Information (RFI).” Accessed: Feb. 13, 2024. [Online]. Available: https://sam.gov/opp/b4a602a266e4450f861242c45e71fb07/view.

- J. Tirpak, “Air Force Launches New Stealthy Tanker Program, with Delivery Projected for 2040,” Air & Space Forces Magazine. Accessed: Oct. 08, 2023. [Online]. Available: https://www.airandspaceforces.com/air-force-launches-new-stealthy-tanker-program-with-delivery-projected-for-2040/.

- D. Roza, “As USAF Considers a Blended-Wing Body Tanker, New Startup Reveals Its Concept,” Air & Space Forces Magazine. Accessed: Oct. 08, 2023. [Online]. Available: https://www.airandspaceforces.com/air-force-blended-wing-body-tanker-jetzero/.

- “Start-up gets $235M investment from U.S. Air Force to help build sleek, futuristic-looking aircraft,” Fortune. Accessed: Oct. 08, 2023. [Online]. Available: https://fortune.com/2023/08/17/jetzero-us-air-force-investment/.

- G. Fernandes et al., “Conceptual Design of a Semi Blended Wing Body for the Air Force Next-Generation Air-Refueling System,” in AIAA SCITECH 2024 Forum, American Institute of Aeronautics and Astronautics. [CrossRef]

- R. Liebeck, M. Page, and B. Rawdon, “Blended-wing-body subsonic commercial transport,” in 36th AIAA Aerospace Sciences Meeting and Exhibit, in Aerospace Sciences Meetings. , American Institute of Aeronautics and Astronautics, 1998. [CrossRef]

- M. Kozek and A. Schirrer, Modeling and Control for a Blended Wing Body Aircraft: A Case Study. 2015. [CrossRef]

- R. Liebeck, “Blended Wing Body Design Challenges,” in AIAA International Air and Space Symposium and Exposition: The Next 100 Years, in International Air and Space Symposium (Evolution of Flight). , American Institute of Aeronautics and Astronautics, 2003. [CrossRef]

- D. Roman, R. Gilmore, and S. Wakayama, “Aerodynamics of High-Subsonic Blended-Wing-Body Configurations,” in 41st Aerospace Sciences Meeting and Exhibit, American Institute of Aeronautics and Astronautics, Jan. 2003. [CrossRef]

- L. Bolsunovsky et al., “Flying wing—Problems and decisions,” Aircraft Design, vol. 4, no. 4, pp. 193–219, Dec. 2001. [CrossRef]

- R. Liebeck, “Design of the Blended-Wing-Body subsonic transport,” in 40th AIAA Aerospace Sciences Meeting & Exhibit, American Institute of Aeronautics and Astronautics, Jan. 2002. [CrossRef]

- H. Smith, “College of Aeronautics Blended Wing Body Development Programme,” presented at the ICAS Congress, 2000.

- Morris, “MOB A European Distributed Multi-Disciplinary Design and Optimisation Project,” in 9th AIAA/ISSMO Symposium on Multidisciplinary Analysis and Optimization, American Institute of Aeronautics and Astronautics, Sep. 2002. [CrossRef]

- Morris, P. Arendsen, G. LaRocca, M. Laban, R. Voss, and H. Hönlinger, “MOB – A EUROPEAN PROJECT ON MULTIDISCIPLINARY DESIGN OPTIMISATION,” presented at the 24TH INTERNATIONAL CONGRESS OF THE AERONAUTICAL SCIENCES, 2004.

- M. Hepperle, “VELA 1 Baseline Configuration.” [Online]. Available: https://www.dlr.de/as/en/PortalData/5/Resources/dokumente/projekte/vela/The_VELA_Project.pdf.

- N. Qin, “Aerodynamic Studies for Blended Wing Body Aircraft,” in 9th AIAA/ISSMO Symposium on Multidisciplinary Analysis and Optimization, in Multidisciplinary Analysis Optimization Conferences. , American Institute of Aeronautics and Astronautics, 2002. [CrossRef]

- L. Moreno, R. Palma, and L. P. Pascual, “Aerodynamic study of a blended wing body, comparison with a conventional transport airplane.,” presented at the ICAS, Sep. 2006.

- P. Roysdon and M. Khalid, “Lateral-Directional Stability Investigation of a Blended-Wing Body,” in 10th AIAA Aviation Technology, Integration, and Operations (ATIO) Conference, in Aviation Technology, Integration, and Operations (ATIO) Conferences. , American Institute of Aeronautics and Astronautics, 2010. [CrossRef]

- J. Hileman, Z. Spakovszky, M. Drela, and M. Sargeant, “Aerodynamic and Aeroacoustic Three-Dimensional Design for a ‘Silent’ Aircraft,” in 44th AIAA Aerospace Sciences Meeting and Exhibit, in Aerospace Sciences Meetings. , American Institute of Aeronautics and Astronautics, 2006. [CrossRef]

- J. I. Hileman, Z. S. Spakovszky, M. Drela, M. A. Sargeant, and A. Jones, “Airframe Design for Silent Fuel-Efficient Aircraft,” Journal of Aircraft, vol. 47, no. 3, pp. 956–969, May 2010. [CrossRef]

- J. E. Green, “Greener by Design — the technology challenge,” The Aeronautical Journal, vol. 106, no. 1056, pp. 57–113, Feb. 2002. [CrossRef]

- S. Siouris and N. Qin, “Study of the effects of wing sweep on the aerodynamic performance of a blended wing body aircraft,” Proceedings of the Institution of Mechanical Engineers, Part G: Journal of Aerospace Engineering, vol. 221, no. 1, pp. 47–55, Jan. 2007. [CrossRef]

- S. Cho, C. Bil, and J. Bayandor, “Structural Design and Analysis of a BWB Military Cargo Transport Fuselage,” in 46th AIAA Aerospace Sciences Meeting and Exhibit, in Aerospace Sciences Meetings. , American Institute of Aeronautics and Astronautics, 2008. [CrossRef]

- D. Jung and M. Lowenberg, “Stability and Control Assessment of a Blended-Wing-Body Airliner Configuration,” presented at the AIAA Atmospheric Flight Mechanics Conference and Exhibit, American Institute of Aeronautics and Astronautics, Aug. 2005. [CrossRef]

- L. U. Hansen, W. Heinze, and P. Horst, “Blended wing body structures in multidisciplinary pre-design,” Struct Multidisc Optim, vol. 36, no. 1, pp. 93–106, Jul. 2008. [CrossRef]

- V. Mukhopadhyay, “Blended Wing Body (BWB) Fuselage Structural Design for Weight Reduction,” in 46th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, Austin, Texas: American Institute of Aeronautics and Astronautics, Apr. 2005. [CrossRef]

- V. Mukhopadhyay, J. Sobieszczanski-Sobieski, I. Kosaka, G. Quinn, and G. N. Vanderplaats, “Analysis, Design, and Optimization of Noncylindrical Fuselage for Blended-Wing-Body Vehicle,” Journal of Aircraft, vol. 41, no. 4, pp. 925–930, Jul. 2004. [CrossRef]

- S. H. Cho, C. Bil, and J. Bayandor, “BWB Military Cargo Transport Fuselage Design and Analysis,” presented at the ICAS, 2008.

- M. Blair, G. Bharatram, and R. Canfield, “Designing a blended composite wing and fuselage,” presented at the 6th Symposium on Multidisciplinary Analysis and Optimization, American Institute of Aeronautics and Astronautics, 1996. [CrossRef]

- Velicki and P. Thrash, “Blended wing body structural concept development,” The Aeronautical Journal, vol. 114, no. 1158, pp. 513–519, Aug. 2010. [CrossRef]

- R. Vos, F. J. J. M. M. Geuskens, and M. F. M. Hoogreef, “A New Structural Design Concept for Blended Wing Body Cabins,” presented at the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, Honolulu, Hawaii: American Institute of Aeronautics and Astronautics, Apr. 2012. [CrossRef]

- R. J. H. Wanhill, “Chapter 15 - Aerospace Applications of Aluminum–Lithium Alloys,” in Aluminum-lithium Alloys, N. Eswara Prasad, A. A. Gokhale, and R. J. H. Wanhill, Eds., Boston: Butterworth-Heinemann, 2014, pp. 503–535. [CrossRef]

- J. P. Moran, F. S. Bovard, J. D. Chrzan, and P. Vandenburgh, “Corrosion Performance of New Generation Aluminum-Lithium Alloys for Aerospace Applications,” in ICAA13 Pittsburgh, H. Weiland, A. D. Rollett, and W. A. Cassada, Eds., Cham: Springer International Publishing, 2016, pp. 425–430. [CrossRef]

- R. Langton, C. Clark, M. Hewitt, L. Richards, I. Moir, and A. Seabridge, Aircraft Fuel Systems, 1st edition. Chichester, U.K: Wiley, 2009.

- Y. Denieul, J. Bordeneuve, D. Alazard, C. Toussaint, and G. Taquin, “Multicontrol Surface Optimization for Blended Wing–Body Under Handling Quality Constraints,” Journal of Aircraft, vol. 55, no. 2, pp. 638–651, 2018. [CrossRef]

- W. Tung and B.-C. Song, “Aerodynamic Performance Study of a Modern Blended-Wing-Body Aircraft Under Severe Weather Situations,” in 49th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, in Aerospace Sciences Meetings. , American Institute of Aeronautics and Astronautics, 2011. [CrossRef]

- T. Wan and H. Yang, “Aerodynamic Performance Investigation of a Modern Blended-Wing-Body Aircraft Under the Influence of Heavy Rain Condition,” presented at the ICAS, 2010.

- D. Cameron and N. Princen, “Control allocation challenges and requirements for the Blended Wing Body,” in AIAA Guidance, Navigation, and Control Conference and Exhibit, in Guidance, Navigation, and Control and Co-located Conferences. , American Institute of Aeronautics and Astronautics, 2000. [CrossRef]

- “Final Report Summary - NACRE (New aircraft concepts research) | FP6,” CORDIS | European Commission. Accessed: Feb. 03, 2024. [Online]. Available: https://cordis.europa.eu/project/id/516068/reporting.

- M. Voskuijl, G. L. Rocca, and F. Dircken, “Controllability of Blended Wing Body Aircraft,” presented at the ICAS, 2008.

- R. Nangia and M. Palmer, “Flying-Wings (Blended Wing Bodies) with Aft & Forward Sweep, Relating Design Camber & Twist to Longitudinal Control,” presented at the AIAA Atmospheric Flight Mechanics Conference and Exhibit, American Institute of Aeronautics and Astronautics, Aug. 2002. [CrossRef]

- Wildschek, T. Havar, and K. Plötner, “An all-composite, all-electric, morphing trailing edge device for flight control on a blended-wing-body airliner,” Proceedings of The Institution of Mechanical Engineers Part G-journal of Aerospace Engineering - PROC INST MECH ENG G-J A E, vol. 224, pp. 1–9, Jan. 2010. [CrossRef]

- S. M. Waters, M. Voskuijl, L. L. M. Veldhuis, and F. J. J. M. M. Geuskens, “Control allocation performance for blended wing body aircraft and its impact on control surface design,” Aerospace Science and Technology, vol. 29, no. 1, pp. 18–27, Aug. 2013. [CrossRef]

- Y. Staelens, R. Blackwelder, and M. Page, “Novel Pitch Control Effectors for a Blended Wing Body Airplane in Takeoff and Landing Configuration,” presented at the 45th AIAA Aerospace Sciences Meeting and Exhibit, American Institute of Aeronautics and Astronautics, Jan. 2007. [CrossRef]

- Schirrer, C. Westermayer, M. Hemedi, and M. Kozek, “LQ-based design of the inner loop lateral control for a large flexible BWB-type aircraft,” in 2010 IEEE International Conference on Control Applications, Sep. 2010, pp. 1850–1855. [CrossRef]

- Valiyff and M. Arjomandi, “An Investigation Into the Aerodynamic Efficiency of Tailles Aircraft,” presented at the 47th AIAA Aerospace Sciences Meeting including The New Horizons Forum and Aerospace Exposition, American Institute of Aeronautics and Astronautics, Jan. 2009. [CrossRef]

- R. Martínez-Val, E. Pérez, P. Alfaro, and J. Pérez, “Conceptual design of a medium size flying wing,” Proceedings of the Institution of Mechanical Engineers, Part G: Journal of Aerospace Engineering, vol. 221, no. 1, pp. 57–66, Jan. 2007. [CrossRef]

- Agarwal, A. P. Dowling, H.-C. Shin, W. Graham, and S. Sefi, “Ray Tracing Approach to Calculate Acoustic Sheilding by a Flying Wing Airframe,” AIAA Journal, vol. 45, no. 5, pp. 1080–1090, May 2007. [CrossRef]

- L. Clark and C. Gerhold, “Inlet noise reduction by shielding for the blended-wing-body airplane,” in 5th AIAA/CEAS Aeroacoustics Conference and Exhibit, Bellevue,WA,U.S.A.: American Institute of Aeronautics and Astronautics, May 1999. [CrossRef]

- G. A. Hill and R. H. Thomas, “Challenges and Opportunities for Noise Reduction Through Advanced Aircraft Propulsion Airframe Integration and Configurations,” presented at the 8th CEAS Workshop, 2004.

- G. Hill, S. Brown, K. Geiselhart, and C. Burg, “Integration of Propulsion-Airframe-Aeroacoustic Technologies and Design Concepts for a Quiet Blended-Wing-Body Transport,” in AIAA 4th Aviation Technology, Integration and Operations (ATIO) Forum, Chicago, Illinois: American Institute of Aeronautics and Astronautics, Sep. 2004. [CrossRef]

- Diedrich, J. Hileman, D. Tan, K. Willcox, and Z. Spakovszky, “Multidisciplinary Design and Optimization of the Silent Aircraft,” in 44th AIAA Aerospace Sciences Meeting and Exhibit, in Aerospace Sciences Meetings. , American Institute of Aeronautics and Astronautics, 2006. [CrossRef]

- L. T. Leifsson, “Multidisciplinary Design Optimization of Low-Noise Transport Aircraft,” Virginia Tech University, Blacksburg, VA, 2005.

- Y. Guo, C. L. Burley, and R. H. Thomas, “On Noise Assessment for Blended Wing Body Aircraft,” in 52nd Aerospace Sciences Meeting, National Harbor, Maryland: American Institute of Aeronautics and Astronautics, Jan. 2014. [CrossRef]

- S. Wakayama, “Blended-wing-body optimization problem setup,” presented at the 8th Symposium on Multidisciplinary Analysis and Optimization, American Institute of Aeronautics and Astronautics, Sep. 2000. [CrossRef]

- Quayle, A. Dowling, H. Babinsky, H.-C. Shin, W. Graham, and P. Sijtsma, “Landing Gear for a Silent Aircraft,” presented at the 45th AIAA Aerospace Sciences Meeting and Exhibit, American Institute of Aeronautics and Astronautics, Jan. 2007. [CrossRef]

- D. Crichton, E. de la Rosa Blanca, T. Law, and J. Hileman, “Design and Operation for Ultra Low Noise Take-Off,” in 45th AIAA Aerospace Sciences Meeting and Exhibit, in Aerospace Sciences Meetings. , American Institute of Aeronautics and Astronautics, 2007. [CrossRef]

- “Silent Aircraft Initiative Concept Risk Assessment - NASA Technical Reports Server (NTRS).” Accessed: Feb. 01, 2024. [Online]. Available: https://ntrs.nasa.gov/citations/20080012497.

- T. Law and A. Dowling, “Optimisation of Traditional and Blown Liners for a Silent Aircraft,” in 12th AIAA/CEAS Aeroacoustics Conference (27th AIAA Aeroacoustics Conference), Cambridge, Massachusetts: American Institute of Aeronautics and Astronautics, May 2006. [CrossRef]

- Reimann, A. Tinetti, and M. Dunn, “Noise Scattering by the Blended Wing Body Airplane: Measurements and Prediction,” in 12th AIAA/CEAS Aeroacoustics Conference (27th AIAA Aeroacoustics Conference), in Aeroacoustics Conferences. , American Institute of Aeronautics and Astronautics, 2006. [CrossRef]

- K. Sakaliyski, J. Hileman, and Z. Spakovszky, “Aero-Acoustics of Perforated Drag Plates for Quiet Transport Aircraft,” in 45th AIAA Aerospace Sciences Meeting and Exhibit, in Aerospace Sciences Meetings. , American Institute of Aeronautics and Astronautics, 2007. [CrossRef]

- P. Shah, D. Mobed, and Z. Spakovszky, “Engine Air-Brakes for Quiet Air Transport,” presented at the 45th AIAA Aerospace Sciences Meeting and Exhibit, American Institute of Aeronautics and Astronautics, Jan. 2007. [CrossRef]

- M. Herr and W. Dobrzynski, “Experimental Investigations in Low-Noise Trailing Edge Design.,” AIAA Journal, vol. 43, no. 6, pp. 1167–1175, Jun. 2005. [CrossRef]

- R. H. Thomas, C. L. Burley, and E. D. Olson, “Hybrid Wing Body Aircraft System Noise Assessment with Propulsion Airframe Aeroacoustic Experiments,” International Journal of Aeroacoustics, vol. 11, no. 3–4, pp. 369–409, Sep. 2012. [CrossRef]

- Y. Guo and R. H. Thomas, “System Noise Assessment of Blended-Wing-Body Aircraft with Open Rotor Propulsion,” in 53rd AIAA Aerospace Sciences Meeting, Kissimmee, Florida: American Institute of Aeronautics and Astronautics, Jan. 2015. [CrossRef]

- M. D. Guynn, J. E. Freeh, and E. D. Olson, “Evaluation of a Hydrogen Fuel Cell Powered Blended-Wing-Body Aircraft Concept for Reduced Noise and Emissions,” 2004.

- Guynn and E. D. Oison, “Reduced Noise and Emissions,” NASA Langley Research Center, Technical Memorandum 20020079419, Sep. 2002. [Online]. Available: https://ntrs.nasa.gov/citations/20020079419.

- Hall and D. Crichton, “Engine And Installation Configurations For A Silent Aircraft,” presented at the XVII International Symposium on Air Breathing Engines, Munich, Germany, Sep. 2005.

- L. Nickol, “Silent Aircraft Initiative Concept Risk Assessment,” NASA Langley Research Center, Technical Memorandum 20080012497, Feb. 2008. [Online]. Available: https://ntrs.nasa.gov/citations/20080012497.

- Reimann, A. Tinetti, and M. Dunn, “Noise Prediction Studies for the Blended Wing Body Using the Fast Scattering Code,” in 11th AIAA/CEAS Aeroacoustics Conference, in Aeroacoustics Conferences. , American Institute of Aeronautics and Astronautics, 2005. [CrossRef]

- Proudman and G. I. Taylor, “The generation of noise by isotropic turbulence,” Proceedings of the Royal Society of London. Series A. Mathematical and Physical Sciences, vol. 214, no. 1116, pp. 119–132, Jan. 1997. [CrossRef]

- R. Pieren et al., “Perception-based noise assessment of a future blended wing body aircraft concept using synthesized flyovers in an acoustic VR environment—The ARTEM study,” Aerospace Science and Technology, vol. 144, p. 108767, Jan. 2024. [CrossRef]

- N. Gandur et al., “Conceptual Design of a Single Core Mixed Pressure Flow Hybrid Electric Turbine Engine,” in AIAA SCITECH 2024 Forum, American Institute of Aeronautics and Astronautics. [CrossRef]

- M. B. Carter, R. L. Campbell, O. C. Pendergraft, D. M. Friedman, and L. Serrano, “Designing and Testing a Blended Wing Body with Boundary-Layer Ingestion Nacelles,” Journal of Aircraft, vol. 43, no. 5, pp. 1479–1489, Sep. 2006. [CrossRef]

- R. T. Kawai, D. M. Friedman, and L. Serrano, “Blended Wing Body (BWB) Boundary Layer Ingestion (BLI) Inlet Configuration and System Studies,” NASA/CR-2006-214534, Dec. 2006. Accessed: Feb. 28, 2024. [Online]. Available: https://ntrs.nasa.gov/citations/20070006754.

- Hileman, Z. Spakovszky, M. Drela, and M. Sargeant, “Airframe Design for ‘Silent Aircraft,’” in 45th AIAA Aerospace Sciences Meeting and Exhibit, Reno, Nevada: American Institute of Aeronautics and Astronautics, Jan. 2007. [CrossRef]

- Q. Yang, Y. Zheng, and T. Streit, “Aerodynamic Design for Wing-Body Blended and Inlet,” presented at the ICAS, 2006.

- M. Li, J. Bai, L. Li, X. Meng, Q. Liu, and B. Chen, “A gradient-based aero-stealth optimization design method for flying wing aircraft,” Aerospace Science and Technology, vol. 92, pp. 156–169, Sep. 2019. [CrossRef]

- N. Shirke, V. Ghase, and V. Jamdar, “Recent advances in stealth coating,” Polym. Bull., Feb. 2024. [CrossRef]

- S. P. Mahulikar, H. R. Sonawane, and G. Arvind Rao, “Infrared signature studies of aerospace vehicles,” Progress in Aerospace Sciences, vol. 43, no. 7, pp. 218–245, Oct. 2007. [CrossRef]

- H. B. Srivastava, Y. B. Limbu, R. Saran, and A. Kumar, “Airborne Infrared Search and Track Systems,” Defence Science Journal, vol. 57, no. 5, Art. no. 5, Sep. 2007. [CrossRef]

- “Bundesheer - TRUPPENDIENST - Ausgabe 6/2008 - Der Eurofighter ‘Typhoon’ (VII).” Accessed: Feb. 29, 2024. [Online]. Available: https://www.bmlv.gv.at/truppendienst/ausgaben/artikel.php?id=807.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).