Submitted:

26 April 2024

Posted:

28 April 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Methods

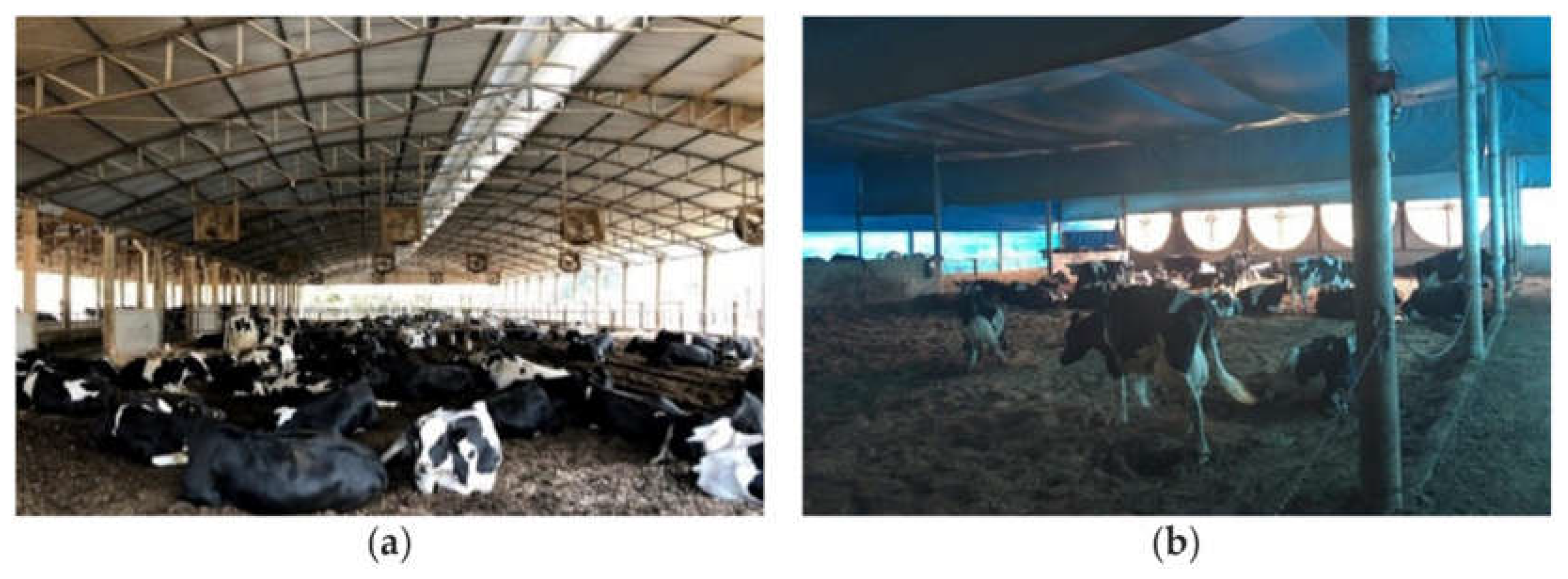

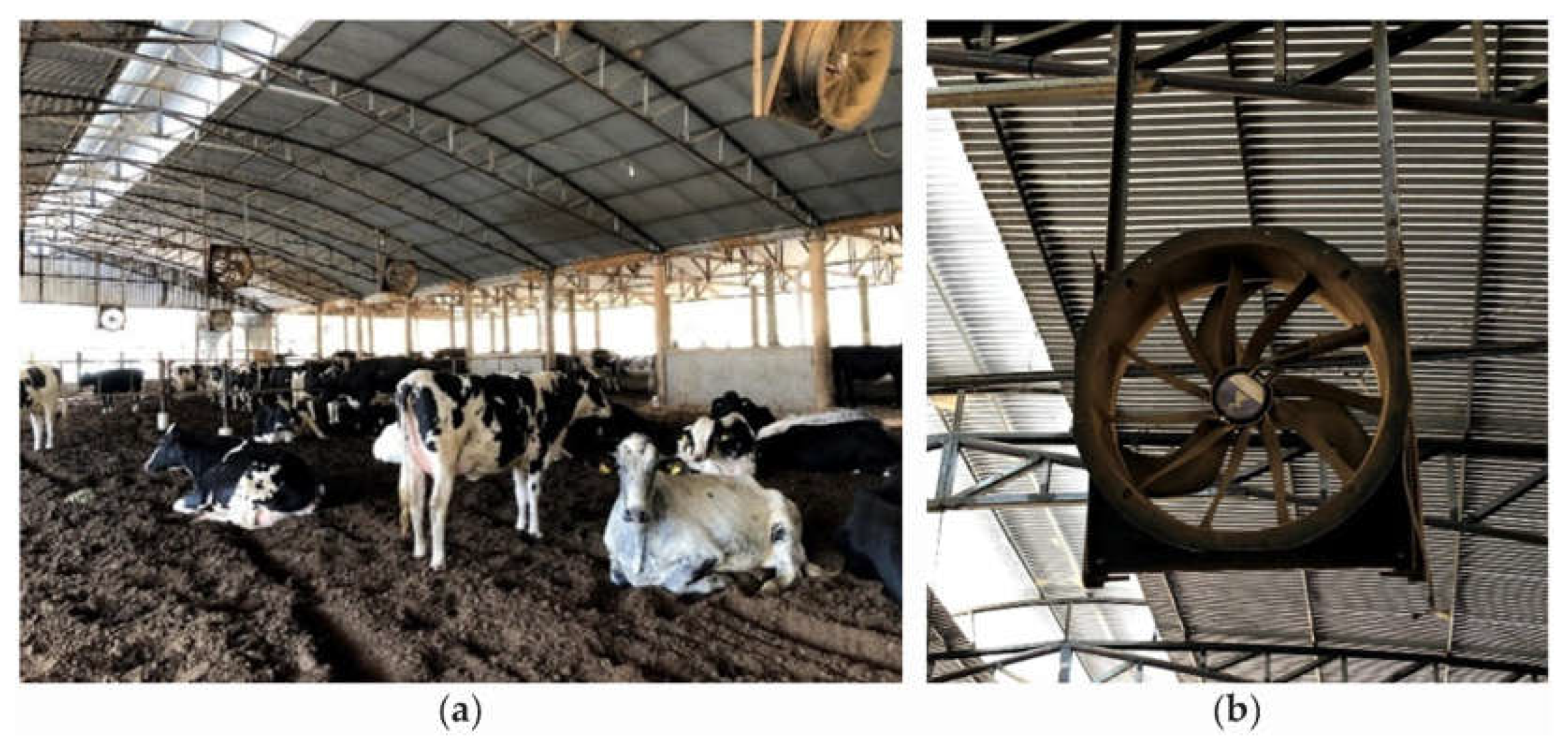

3. Compost-Bedded Pack Barn Systems

3.1. Implementation of Compost-Bedded Pack Barn Systems

3.1.1. Globally

3.1.2. In Brazil

3.2. Bedding for Compost-Bedded Pack Barn Systems

3.2.1. Materials

3.2.2. Animal Bed Surface

3.2.3. Management Practices

3.3. Construction and Architectural Characteristics in Brazil

3.4. Effects of the Environment on the Thermal Comfort and Welfare of Dairy Cows

3.5. Ambient Thermal Conditioning System Used in Compost-Bedded Pack Barn Facilities

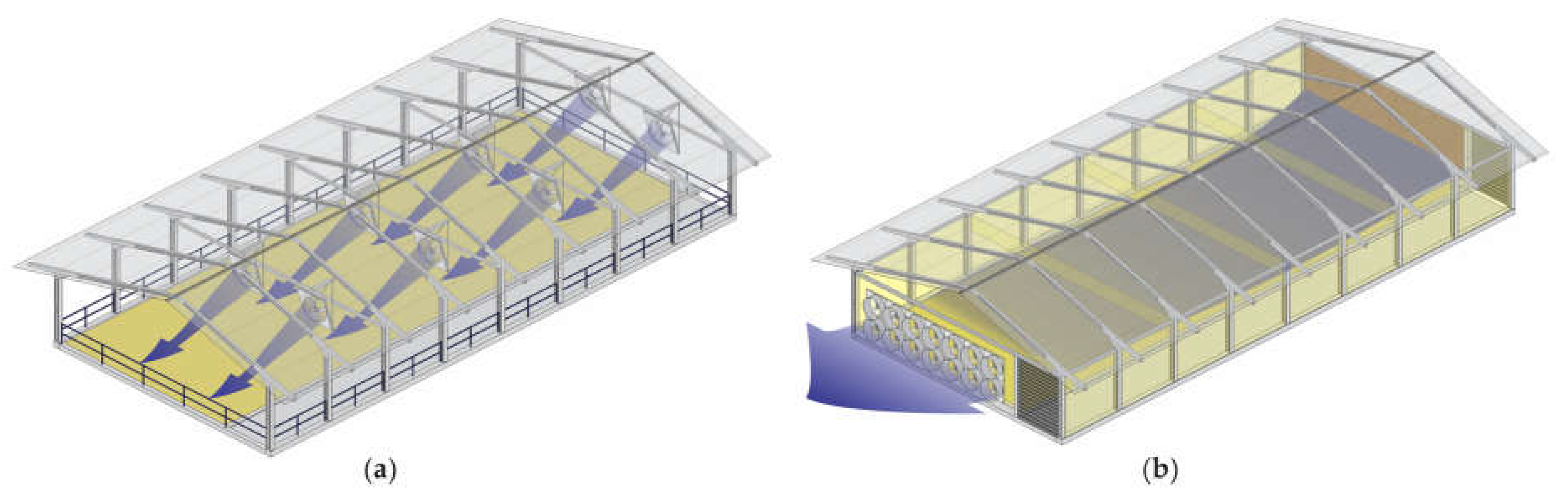

- a)

- CBP systems designed in open facilities, in which internal air renewal naturally occurs through natural ventilation or supplemented with positive pressure ventilation (Figure 2a).

- a)

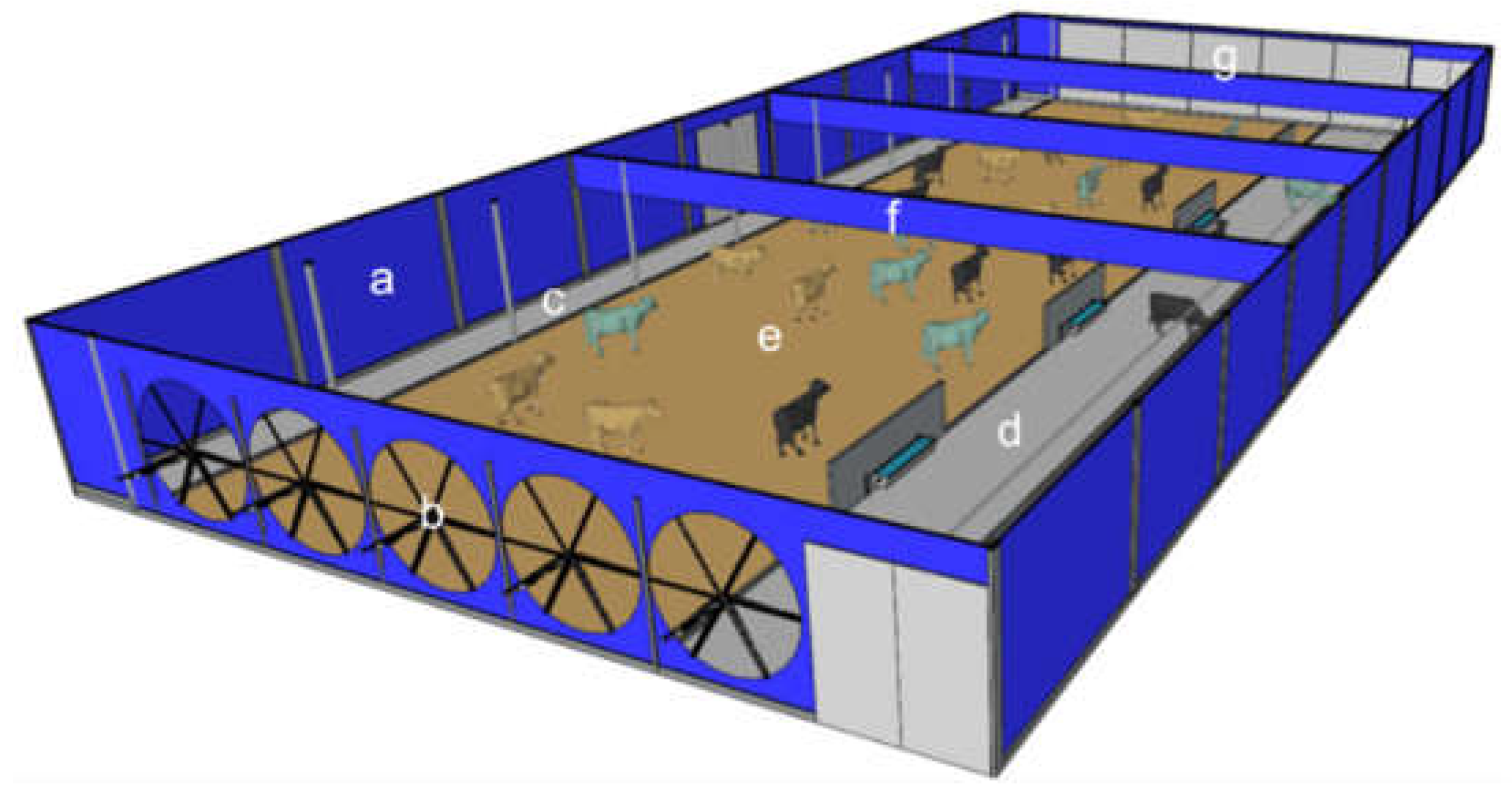

- CBP systems designed in closed facilities, where the sides are closed, and the volume of internal air, as well as the volume and flow of air that enters and leaves, are controlled. The ventilation is achieved through a negative pressure system (Figure 2b).

3.5.1. Positive Pressure Ventilation Systems

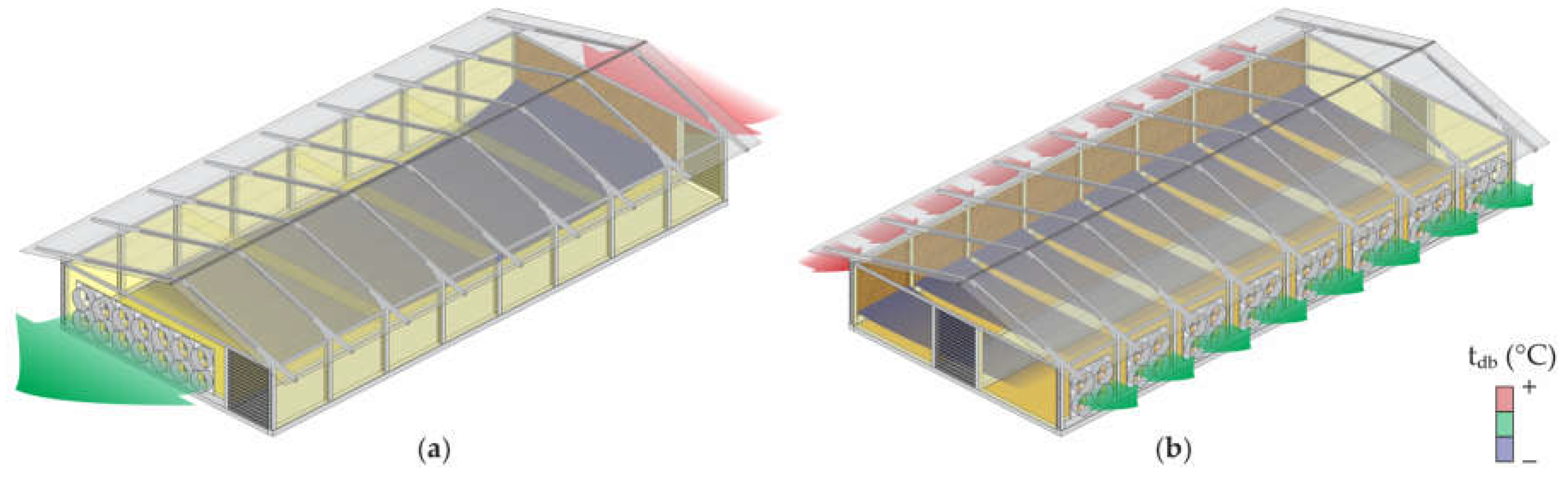

3.5.2. Negative Pressure Ventilation Systems

3.5.3. Evaporative Adiabatic Cooling Process

4. Conclusions and Future Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Leso, L.; Barbari, M.; Lopes, M.A.; Damasceno, F.A.; Galama, P.; Taraba, J.L.; Kuipers, A. Invited Review: Compost-Bedded Pack Barns for Dairy Cows. J. Dairy Sci. 2020, 103, 1072–1099. [Google Scholar] [CrossRef] [PubMed]

- Kuipers, A.; Galama, P.; Leso, L.; Bruegemann, K.; Klopčič, M. A Composting Bedding System for Animals as a Contribution to the Circular Economy. Processes 2022, 10, 518. [Google Scholar] [CrossRef]

- Galama, P.J.; Ouweltjes, W.; Endres, M.I.; Sprecher, J.R.; Leso, L.; Kuipers, A.; Klopčič, M. Symposium Review: Future of Housing for Dairy Cattle. J. Dairy Sci. 2020, 103, 5759–5772. [Google Scholar] [CrossRef] [PubMed]

- Lassen, J.; Sandøe, P.; Forkman, B. Happy Pigs Are Dirty! – Conflicting Perspectives on Animal Welfare. Livest. Sci. 2006, 103, 221–230. [Google Scholar] [CrossRef]

- Barberg, A.E.; Endres, M.I.; Janni, K.A. Compost Dairy Barns in Minnesota: A Descriptive Study. Appl. Eng. Agric. 2007, 23, 231–238. [Google Scholar] [CrossRef]

- Bewley, J.M.; Robertson, L.M.; Eckelkamp, E.A. A 100-Year Review: Lactating Dairy Cattle Housing Management. J. Dairy Sci. 2017, 100, 10418–10431. [Google Scholar] [CrossRef] [PubMed]

- Pilatti, J.A.; Vieira, F.M.C.; Rankrape, F.; Vismara, E.S. Diurnal Behaviors and Herd Characteristics of Dairy Cows Housed in a Compost-Bedded Pack Barn System under Hot and Humid Conditions. Animal 2019, 13, 399–406. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, C.E.A.; Damasceno, F.A.; Ferraz, G.A.S.; Nascimento, J.A.C.; Vega, F.A.O.; Titôco, I.F.F.; Andrade, R.R. Assessment of Spatial Variability of Bedding Variables in Compost Bedded Pack Barns with Climate Control System. An. Acad. Bras. Cienc. 2021, 93, 20200384. [Google Scholar] [CrossRef]

- Emanuelson, U.; Brügemann, K.; Klopčič, M.; Leso, L.; Ouweltjes, W.; Zentner, A.; Blanco-Penedo, I. Animal Health in Compost-Bedded Pack and Cubicle Dairy Barns in Six European Countries. Animals 2022, 12, 396. [Google Scholar] [CrossRef]

- Yameogo, B.; Andrade, R.R.; Teles Júnior, C.G.S.; Laud, G.S.; Becciolini, V.; Leso, L.; Rossi, G.; Barbari, M. Analysis of Environmental Conditions and Management in a Compost-Bedded Pack Barn with Tunnel Ventilation. Agron. Res. 2021, 19, 1195–1204. [Google Scholar] [CrossRef]

- Shane, E.M.; Endres, M.I.; Janni, K.A. Alternative Bedding Materials for Compost Bedded Pack Barns in Minnesota: A Descriptive Study. Appl. Eng. Agric. 2010, 26, 465–473. [Google Scholar] [CrossRef]

- Valente, B.S.; Xavier, E.G.; Morselli, T.B. . G.A.; Jahnke, D.S.; Brum Jr., B.; Cabrera, B.R.; Moraes, P.; Lopes, D.C.N. Fatores Que Afetam o Desenvolvimento Da Compostagem de Resíduos Orgânicos. Arch. Zootec. 2009, 58, 59–85. [Google Scholar] [CrossRef]

- Andrade, R.R.; Tinôco, I.F.F.; Damasceno, F.A.; Ferraz, G.A.S.; Freitas, L.C.S.R.; Ferreira, C.F.S.; Barbari, M.; Baptista, F.J.F.; Coelho, D.J.R. Spatial Distribution of Bed Variables, Animal Welfare Indicators, and Milk Production in a Closed Compost-Bedded Pack Barn with a Negative Tunnel Ventilation System. J. Therm. Biol. 2022, 105, 103111. [Google Scholar] [CrossRef] [PubMed]

- Klaas, I.C.; Bjerg, B.S.; Friedmann, S.; Bar, D. Cultivated Barns for Dairy Cows - An Option to Promote Cattle Welfare and Environmental Protection in Denmark? Dansk Veterinaertidsskrift 2010, 93, 20–29. [Google Scholar]

- Balcells, J.; Fuertes, E.; Seradj, A.R.; Maynegre, J.; Villalba, D.; de la Fuente, G. Study of Nitrogen Fluxes across Conventional Solid Floor Cubicle and Compost-Bedded Pack Housing Systems in Dairy Cattle Barns Located in the Mediterranean Area: Effects of Seasonal Variation. J. Dairy Sci. 2020, 103. [Google Scholar] [CrossRef] [PubMed]

- Black, R.A.; Taraba, J.L.; Day, G.B.; Damasceno, F.A.; Bewley, J.M. Compost Bedded Pack Dairy Barn Management, Performance, and Producer Satisfaction. J. Dairy Sci. 2013, 96, 8060–8074. [Google Scholar] [CrossRef]

- Leso, L.; Uberti, M.; Morshed, W.; Barbari, M. A Survey of Italian Compost Dairy Barns. J. Agric. Eng. 2013, 44, 17. [Google Scholar] [CrossRef]

- Fávero, S.; Portilho, F.V.R.; Oliveira, A.C.R.; Langoni, H.; Pantoja, J.C.F. Factors Associated with Mastitis Epidemiologic Indexes, Animal Hygiene, and Bulk Milk Bacterial Concentrations in Dairy Herds Housed on Compost Bedding. Livest. Sci. 2015, 181, 220–230. [Google Scholar] [CrossRef]

- Lazzarini, B.; Baudracco, J.; Tuñon, G.; Gastaldi, L.; Lyons, N.; Quattrochi, H.; Lopez-Villalobos, N. Review: Milk Production from Dairy Cows in Argentina: Current State and Perspectives for the Future. Appl. Anim. Sci. 2019, 35, 426–432. [Google Scholar] [CrossRef]

- Bran, J.A.; Costa, J.H.C.; von-Keyserlingk, M.A.G.; Hötzel, M.J. Factors Associated with Lameness Prevalence in Lactating Cows Housed in Freestall and Compost-Bedded Pack Dairy Farms in Southern Brazil. Prev. Vet. Med. 2019, 172, 104773. [Google Scholar] [CrossRef]

- Vieira, F.M.C.; Soares, A.A.; Herbut, P.; Vismara, E.S.; Godyń, D.; dos Santos, A.C.Z.; Lambertes, T.S.; Caetano, W.F. Spatio-Thermal Variability and Behaviour as Bio-Thermal Indicators of Heat Stress in Dairy Cows in a Compost Barn: A Case Study. Animals 2021, 11, 1197. [Google Scholar] [CrossRef]

- Méndez, M.N.; Grille, L.; Mendina, G.R.; Robinson, P.H.; Adrien, M. de L.; Meikle, A.; Chilibroste, P. Performance of Autumn and Spring Calving Holstein Dairy Cows with Different Levels of Environmental Exposure and Feeding Strategies. Animals 2023, 13, 1211. [Google Scholar] [CrossRef] [PubMed]

- Silveira, R.M.F.; Ferreira, J.; Busanello, M.; Vasconcelos, A.M.; Valente, F.L.J.; Façanha, D.A.E. Relationship between Thermal Environment and Morphophysiological, Performance and Carcass Traits of Brahman Bulls Raised on Tropical Pasture: A Canonical Approach to a Set of Indicators. J. Therm. Biol. 2021, 96, 102814. [Google Scholar] [CrossRef] [PubMed]

- Andrade, R.R.; Tinôco, I.F.F.; Damasceno, F.A.; Ferraz, G.A.S.; Freitas, L.C.S.R.; Ferreira, C.F.S.; Barbari, M.; Teles Junior, C.G.S. Spatial Analysis of Microclimatic Variables in Compost-Bedded Pack Barn with Evaporative Tunnel Cooling. An. Acad. Bras. Cienc. 2022, 94, e20210226. [Google Scholar] [CrossRef] [PubMed]

- Ferraz, P.F.P.; Ferraz, G.A.S.; Leso, L.; Klopčič, M.; Barbari, M.; Rossi, G. Properties of Conventional and Alternative Bedding Materials for Dairy Cattle. J. Dairy Sci. 2020, 103, 8661–8674. [Google Scholar] [CrossRef]

- Oliveira, V.C.; Damasceno, F.A.; Oliveira, C.E.A.; Ferraz, P.F.P.; Ferraz, G.A.S.; Saraz, J.A.O. Compost-Bedded Pack Barns in the State of Minas Gerais: Architectural and Technological Characterization. Agron. Res. 2019, 17, 2016–2028. [Google Scholar] [CrossRef]

- Oliveira, C.E.A.; Tinôco, I.F.F.; Oliveira, V.C.; Rodrigues, P.H.M.; Silva, L.F.; Damasceno, F.A.; Andrade, R.R.; Sousa, F.C.; Barbari, M.; Bambi, G. Spatial Distribution of Bedding Attributes in an Open Compost-Bedded Pack Barn System with Positive Pressure Ventilation in Brazilian Winter Conditions. Animals 2023, 13, 786. [Google Scholar] [CrossRef]

- Radavelli, W.M.; Danieli, B.; Zotti, M.L.A.N.; Gomes, F.J.; Endres, M.I.; Schogor, A.L.B. Compost Barns in Brazilian Subtropical Region (Part 1): Facility, Barn Management and Herd Characteristics. Res. Soc. Dev. 2020, 9, e445985198. [Google Scholar] [CrossRef]

- Fournel, S.; Ouellet, V.; Charbonneau, É. Practices for Alleviating Heat Stress of Dairy Cows in Humid Continental Climates: A Literature Review. Animals 2017, 7, 37. [Google Scholar] [CrossRef]

- Barberg, A.E.; Endres, M.I.; Salfer, J.A.; Reneau, J.K. Performance and Welfare of Dairy Cows in an Alternative Housing System in Minnesota. J. Dairy Sci. 2007, 90, 1575–1583. [Google Scholar] [CrossRef]

- Eckelkamp, E.A.; Taraba, J.L.; Akers, K.A.; Harmon, R.J.; Bewley, J.M. Understanding Compost Bedded Pack Barns: Interactions among Environmental Factors, Bedding Characteristics, and Udder Health. Livest. Sci. 2016, 190, 35–42. [Google Scholar] [CrossRef]

- Oliveira, C.E.A.; Tinôco, I.F.F.; Souza, C.F.; Baêta, F.C.; Andrade, R.R.; Vieira, F.M.C.; Barbari, M.; Bambi, G. Physicochemical Bedding Quality in Compost-Bedded Pack Barn Systems for Dairy Cows: A Systematic Review. Appl. Sci. 2023, 13, 9832. [Google Scholar] [CrossRef]

- Black, R.A.; Taraba, J.L.; Day, G.B.; Damasceno, F.A.; Newman, M.C.; Akers, K.A.; Wood, C.L.; McQuerry, K.J.; Bewley, J.M. The Relationship between Compost Bedded Pack Performance, Management, and Bacterial Counts. J. Dairy Sci. 2014, 97, 2669–2679. [Google Scholar] [CrossRef]

- Silva, K.H.; Teixeira, M.C.; Stracke, M.P.; Girardello, V.C.; Knob, D.; Lenz, R.L.S.; Huber, E.; Backes, T.R. Evaluation of the Compost Barn System of Milk Producers from Cooperatives in the Mission Region. Brazilian J. Dev. 2021, 7, 27227–27241. [Google Scholar] [CrossRef]

- Janni, K.A.; Endres, M.I.; Reneau, J.K.; Schoper, W.W. Compost Dairy Barn Layout and Management Recommendations. Appl. Eng. Agric. 2007, 23, 97–102. [Google Scholar] [CrossRef]

- Llonch, L.; Gordo, C.; López, M.; Castillejos, L.; Ferret, A.; Balanyà, T. Agronomic Characteristics of the Compost-Bedded Pack Made with Forest Biomass or Sawdust. Processes 2021, 9, 546. [Google Scholar] [CrossRef]

- Llonch, L.; Castillejos, L.; Mainau, E.; Manteca, X.; Ferret, A. Effect of Forest Biomass as Bedding Material on Compost-Bedded Pack Performance, Microbial Content, and Behavior of Nonlactating Dairy Cows. J. Dairy Sci. 2020, 0. [Google Scholar] [CrossRef]

- De-Boer, H.C.; Wiersma, M. Thermophilic Composting of the Pack Can Reduce Nitrogen Loss from Compost-Bedded Dairy Barns. Biosyst. Eng. 2021, 210, 20–32. [Google Scholar] [CrossRef]

- Mota, V.C.; Campos, A.T.; Damasceno, F.A.; Resende, E.A.M.; Rezende, C.P.A.; Abreu, L.R.; Vareiro, T. Confinamento Para Bovinos Leiteiros: Histórico e Características. Pubvet 2017, 11, 433–442. [Google Scholar] [CrossRef]

- Leso, L.; Conti, L.; Rossi, G.; Barbari, M. Criteria of Design for Deconstruction Applied to Dairy Cows Housing: A Case Study in Italy. Agron. Res. 2018, 16, 794–805. [Google Scholar] [CrossRef]

- Biasato, I.; D’Angelo, A.; Bertone, I.; Odore, R.; Bellino, C. Compost Bedded-Pack Barn as an Alternative Housing System for Dairy Cattle in Italy: Effects on Animal Health and Welfare and Milk and Milk Product Quality. Ital. J. Anim. Sci. 2019, 18, 1142–1153. [Google Scholar] [CrossRef]

- Silva, M.V.; Pandorfi, H.; Almeida, G.L.P.; Jardim, A.M.R.F.; Batista, P.H.D.; Silva, R.A.B.; Lopes, I.; Oliveira, M.E.G.; Silva, J.L.B.; Moraes, A.S. Spatial Variability and Exploratory Inference of Abiotic Factors in Barn Compost Confinement for Cattle in the Semiarid. J. Therm. Biol. 2020, 94, 102782. [Google Scholar] [CrossRef] [PubMed]

- Kogima, P.A.; Diesel, T.A.; Vieira, F.M.C.; Schogor, A.L.B.; Volpini, A.A.; Veloso, G.J.; Ferraz, P.F.P.; Zotti, M.L.A.N. The Welfare of Dairy Cows in Pasture, Free Stall, and Compost Barn Management Systems in a Brazilian Subtropical Region. Animals 2022, 12, 2215. [Google Scholar] [CrossRef]

- Mondaca, M.R.; Choi, C.Y.; Cook, N.B. Understanding Microenvironments within Tunnel-Ventilated Dairy Cow Freestall Facilities: Examination Using Computational Fluid Dynamics and Experimental Validation. Biosyst. Eng. 2019, 183, 70–84. [Google Scholar] [CrossRef]

- Mrema, G.C.; Gumbe, L.O.; Chapete, H.J.; Agullo, J.O. Rural Structures in the Tropics: Design and Development; 1st ed.; FAO: Roma, 2011; ISBN 9789251070475. [Google Scholar]

- Menconi, M.E.; Grohmann, D. Model Integrated of Life-Cycle Costing and Dynamic Thermal Simulation (MILD) to Evaluate Roof Insulation Materials for Existing Livestock Buildings. Energy Build. 2014, 81, 48–58. [Google Scholar] [CrossRef]

- Smith, T.R.; Chapa, A.; Willard, S.; Herndon, C.; Williams, R.J.; Crouch, J.; Riley, T.; Pogue, D. Evaporative Tunnel Cooling of Dairy Cows in the Southeast. II: Impact on Lactation Performance. J. Dairy Sci. 2006, 89, 3915–3923. [Google Scholar] [CrossRef]

- Damasceno, F.A.; Day, G.B.; Taraba, J.L.; Oliveira, C.E.A.; Andrade, R.R.; Frigeri, K.D.-M.; Vieira, F.M.C.; Barbari, M.; Bambi, G. Compost Dairy Barn Layout and Management Recommendations in Kentucky: A Descriptive Study. Anim. 2022, Vol. 12, Page 3324 2022, 12, 3324. [Google Scholar] [CrossRef]

- Lobeck, K.M.; Endres, M.I.; Shane, E.M.; Godden, S.M.; Fetrow, J. Animal Welfare in Cross-Ventilated, Compost-Bedded Pack, and Naturally Ventilated Dairy Barns in the Upper Midwest. J. Dairy Sci. 2011, 94, 5469–5479. [Google Scholar] [CrossRef]

- Yameogo, B.; Andrade, R.R.; Teles-Júnior, C.G.S.; Laud, G.S.; Becciolini, V.; Leso, L.; Rossi, G.; Barbari, M. Behavioural Patterns of Cows Housed in Two Different Typologies of Compost-Bedded Pack Barns. Agron. Res. 2021, 19, 1205–1215. [Google Scholar] [CrossRef]

- Andrade, R.R.; Tinôco, I.F.F.; Damasceno, F.A.; Barbari, M.; Valente, D.A.; Vilela, M.O.; Souza, C.F.; Conti, L.; Rossi, G. Lighting and Noise Levels in Compost Dairy Barns with Natural and Forced Ventilation. Agron. Res. 2020, 18, 689–698. [Google Scholar] [CrossRef]

- Blanco-Penedo, I.; Ouweltjes, W.; Ofner-Schröck, E.; Brügemann, K.; Emanuelson, U. Symposium Review: Animal Welfare in Free-Walk Systems in Europe. J. Dairy Sci. 2020, 103, 5773–5782. [Google Scholar] [CrossRef]

- Marcondes, M.I.; Mariano, W.H.; De Vries, A. Production, Economic Viability and Risks Associated with Switching Dairy Cows from Drylots to Compost Bedded Pack Systems. Animal 2020, 14, 399–408. [Google Scholar] [CrossRef] [PubMed]

- Burgstaller, J.; Raith, J.; Kuchling, S.; Mandl, V.; Hund, A.; Kofler, J. Claw Health and Prevalence of Lameness in Cows from Compost Bedded and Cubicle Freestall Dairy Barns in Austria. Vet. J. 2016, 216, 81–86. [Google Scholar] [CrossRef]

- Vilela, M.O.; Gates, R.S.; Martins, M.A.; Barbari, M.; Conti, L.; Rossi, G.; Zolnier, S.; Teles, C.G.S.; Zanetoni, H.H.R.; Andrade, R.R.; et al. Computational Fluids Dynamics (CFD) in the Spatial Distribution of Air Velocity in Prototype Designed for Animal Experimentation in Controlled Environments. Agron. Res. 2019, 17, 890–899. [Google Scholar] [CrossRef]

- Pilatti, J.A.; Vieira, F.M.C. Environment, Behavior and Welfare Aspects of Dairy Cows Reared in Compost Bedded Pack Barns System. J. Anim. Behav. Biometeorol. 2017, 5, 97–105. [Google Scholar] [CrossRef]

- Smith, J.F.; Harner, J.; Zulovich, J.; Pohl, S.; Fulhage, C.; Nicoli, D.; Hetchler, B.; Jacobson, L.; Brouk, M. Comprehensive Evaluation of a Low-Profile Cross-Ventilated Freestall Barn. In Proceedings of the Proceedings of the 8th Western Dairy Management Conference; pp. 2007127–147.

- Arcidiacono, C. Engineered Solutions for Animal Heat Stress Abatement in Livestock Buildings. Agric. Eng. Int. CIGR J. 2018, 1–22. [Google Scholar]

- Vega, F.A.O.; Ríos, A.P.M.; Saraz, J.A.O.; Andrade, R.R.; Damasceno, F.A.; Barbari, M. CFD Study of a Tunnel-Ventilated Compost-Bedded Pack Barn Integrating an Evaporative Pad Cooling System. Animals 2022, 12, 1776. [Google Scholar] [CrossRef] [PubMed]

- Lobeck, K.M.; Endres, M.I.; Janni, K.A.; Godden, S.M.; Fetrow, J. Environmental Characteristics and Bacterial Counts in Bedding and Milk Bulk Tank of Low Profile Cross-Ventilated, Naturally Ventilated, and Compost Bedded Pack Dairy Barns. Appl. Eng. Agric. 2012, 28, 117–128. [Google Scholar] [CrossRef]

- Harner, J.P.; Smith, J.F.; Marti, M.H.; Sheffield, R.E.; Zulovich, J.M.; Pohl, S.H.; Pasikanti, S.; Fulhage, C.D.; Nicoli, R.E.; Hetchler, B.; et al. Characteristics of Low-Profile Cross-Ventilated Freestalls. In Proceedings of the 6th International Dairy Housing Conference Proceeding; American Society of Agricultural and Biological Engineers: Minneapolis, 2007; pp. 1–9. [Google Scholar]

- Oliveira, C.E.A.; Tinôco, I.F.F.; Sousa, F.C.; Damasceno, F.A.; Andrade, R.R.; Maciel, F.F.; Barbari, M.; Martins, M.A. Analysis of Heat and Mass Transfer in Compost-Bedded Pack Barns for Dairy Cows Using Computational Fluid Dynamics: A Review. Appl. Sci. 2023, Vol. 13, Page 9331 2023, 13, 9331. [Google Scholar] [CrossRef]

- Tyson, T.; McFarland, D.F.; Graves, R.E. Tunnel Ventilation for Tie Stall Dairy Barns; Penn State Extension: State College, PA, USA, 2014. [Google Scholar]

- Melo Júnior, J.C.M.; Bamberg, J.V.M.; Machado, N.S.; Caldas, E.N.G.; Rodrigues, M.S. Evaporative Cooling Efficiency of Pads Consisting of Vegetable Loofah. Comun. Sci. 2019, 10, 38–44. [Google Scholar] [CrossRef]

- Liao, C.M.; Chiu, K.H. Wind Tunnel Modeling the System Performance of Alternative Evaporative Cooling Pads in Taiwan Region. Build. Environ. 2002, 37, 177–187. [Google Scholar] [CrossRef]

- Smith, J.F.; Bradford, B.J.; Harner, J.P.; Potts, J.C.; Allen, J.D.; Overton, M.W.; Ortiz, X.A.; Collier, R.J. Effect of Cross Ventilation with or without Evaporative Pads on Core Body Temperature and Resting Time of Lactating Cows. J. Dairy Sci. 2016, 99, 1495–1500. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).