Submitted:

24 April 2024

Posted:

25 April 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

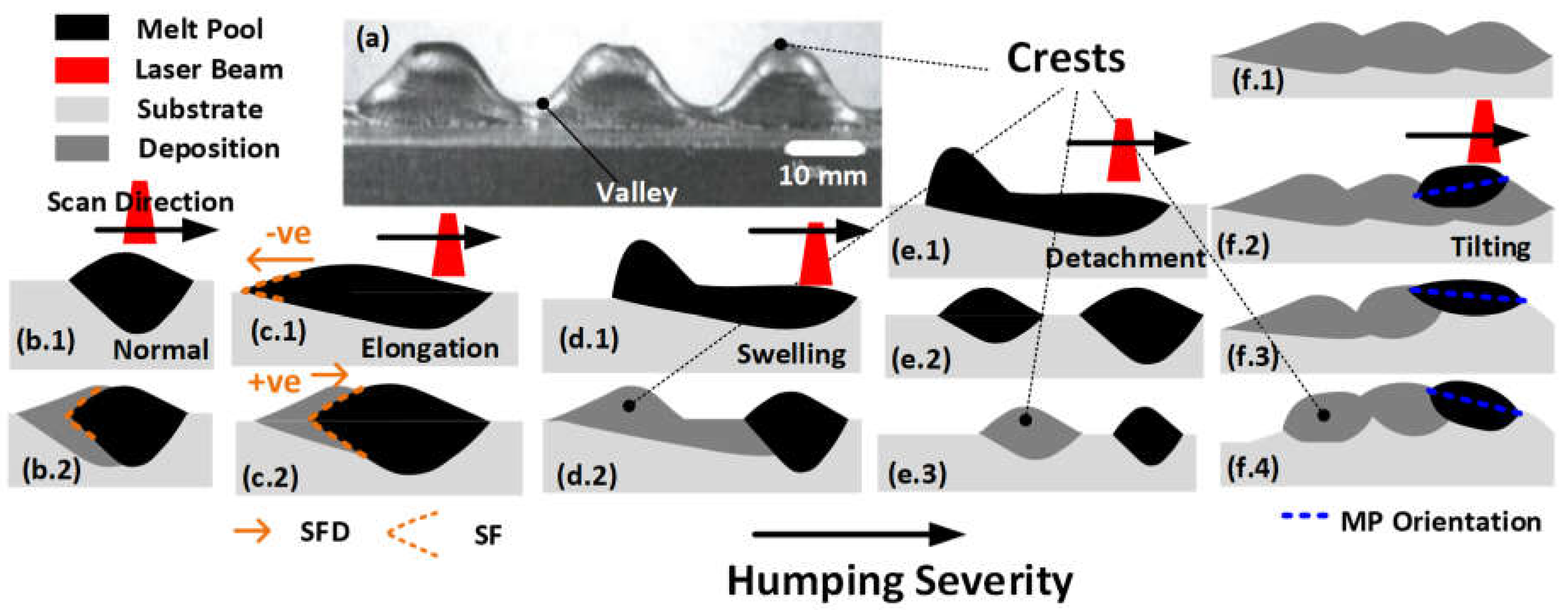

- Transform from reactive to proactive humping detection.

- Transform humping detection from spatial (i.e., detachment) to spatiotemporal (i.e., elongation) abnormalities.

- Practically track the variability in solidification front dynamics.

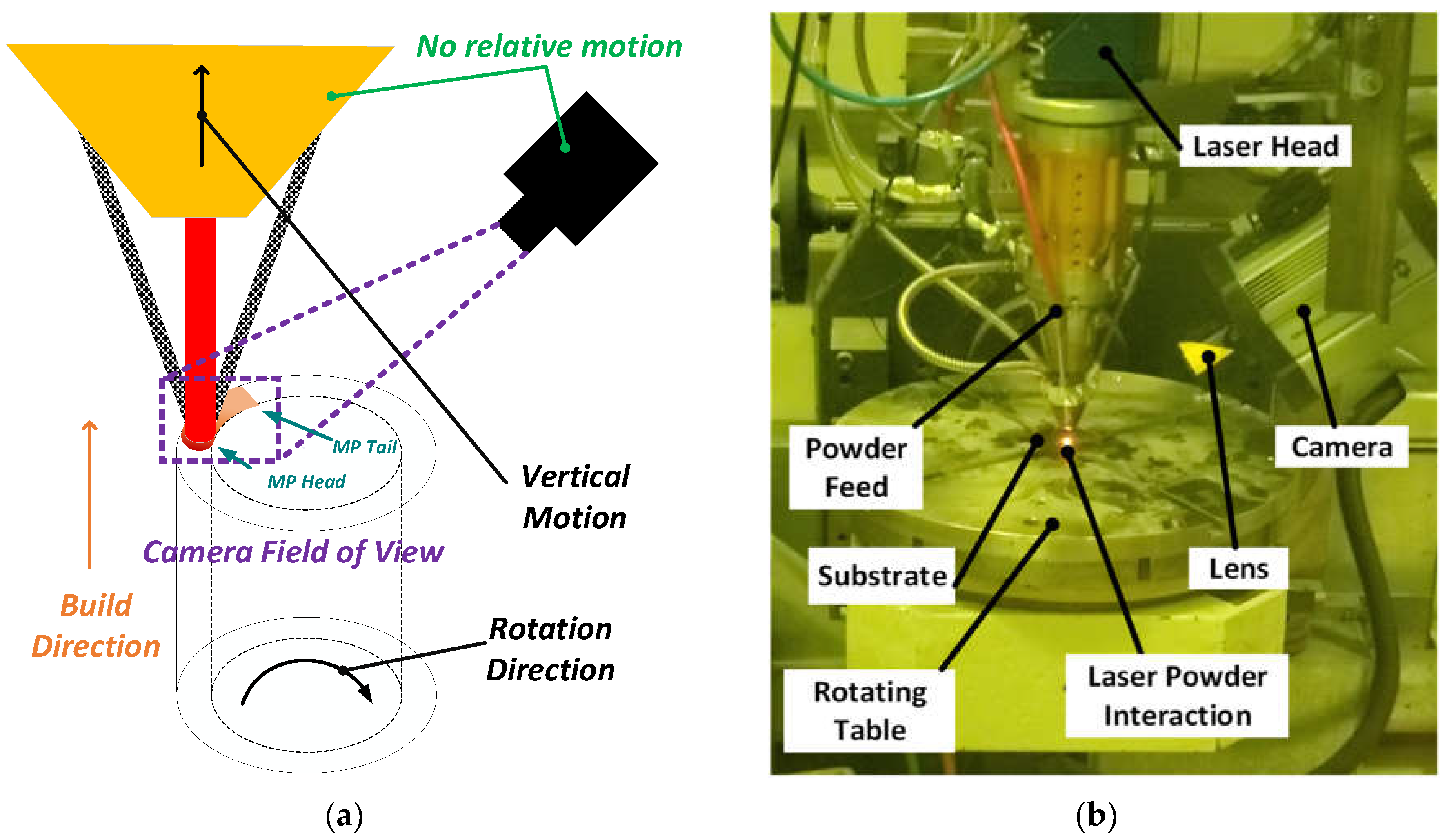

2. Experimental Setup

3. Signal Processing

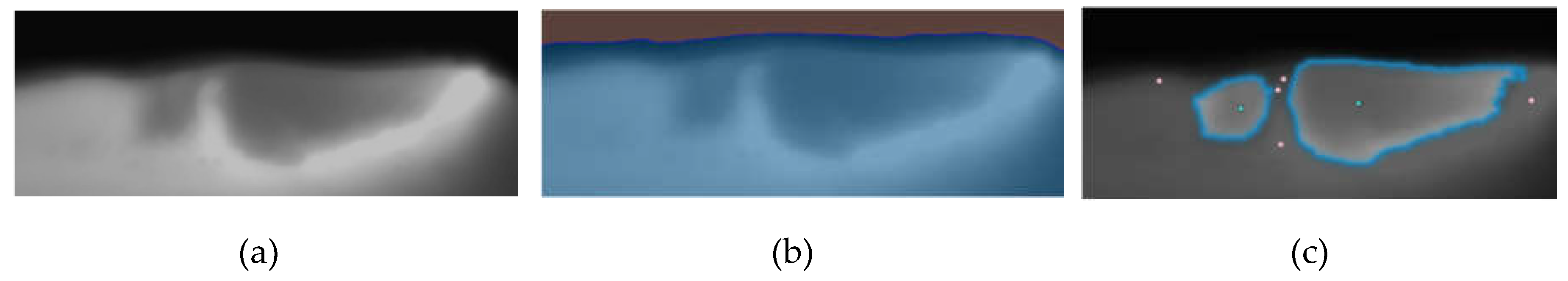

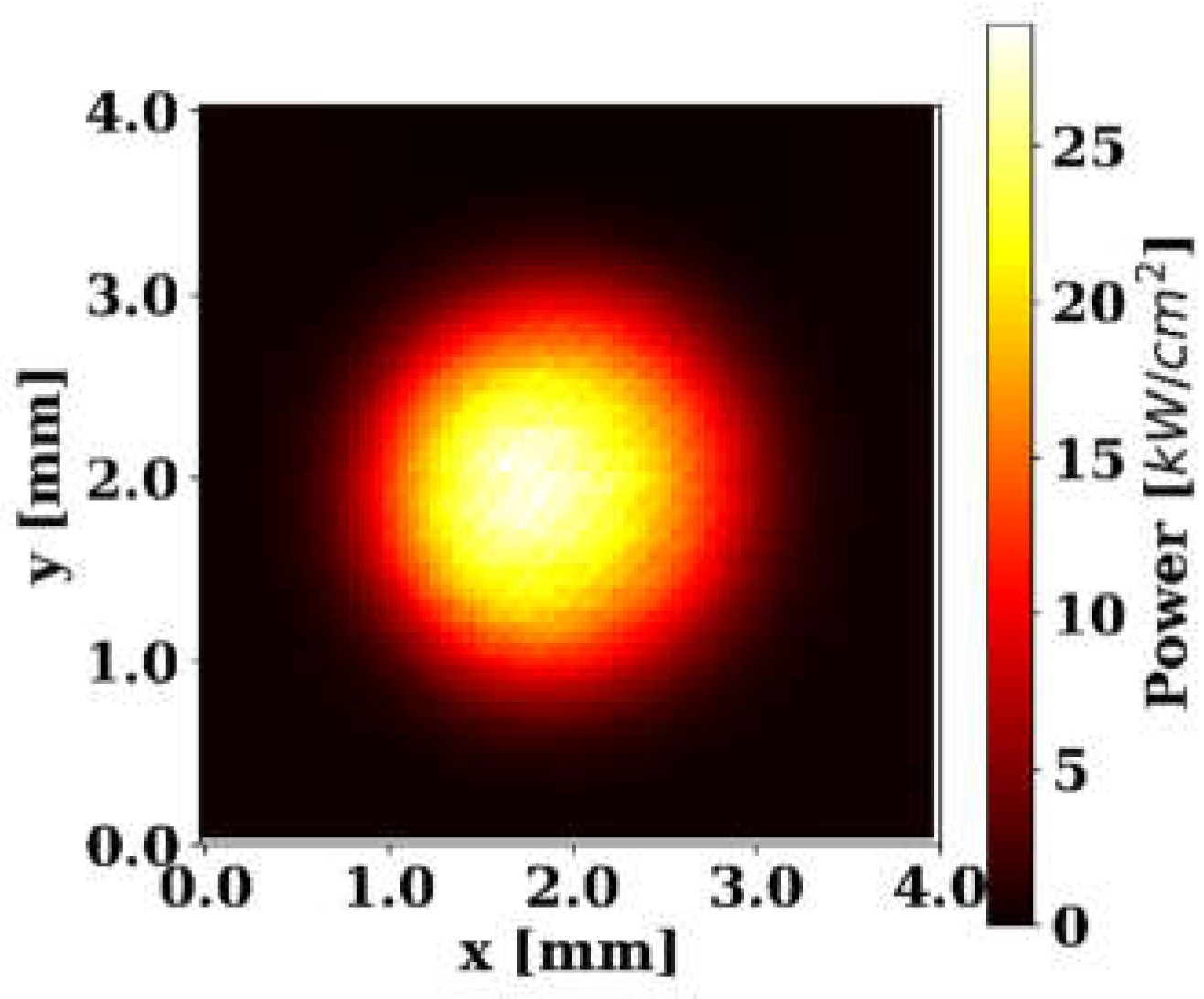

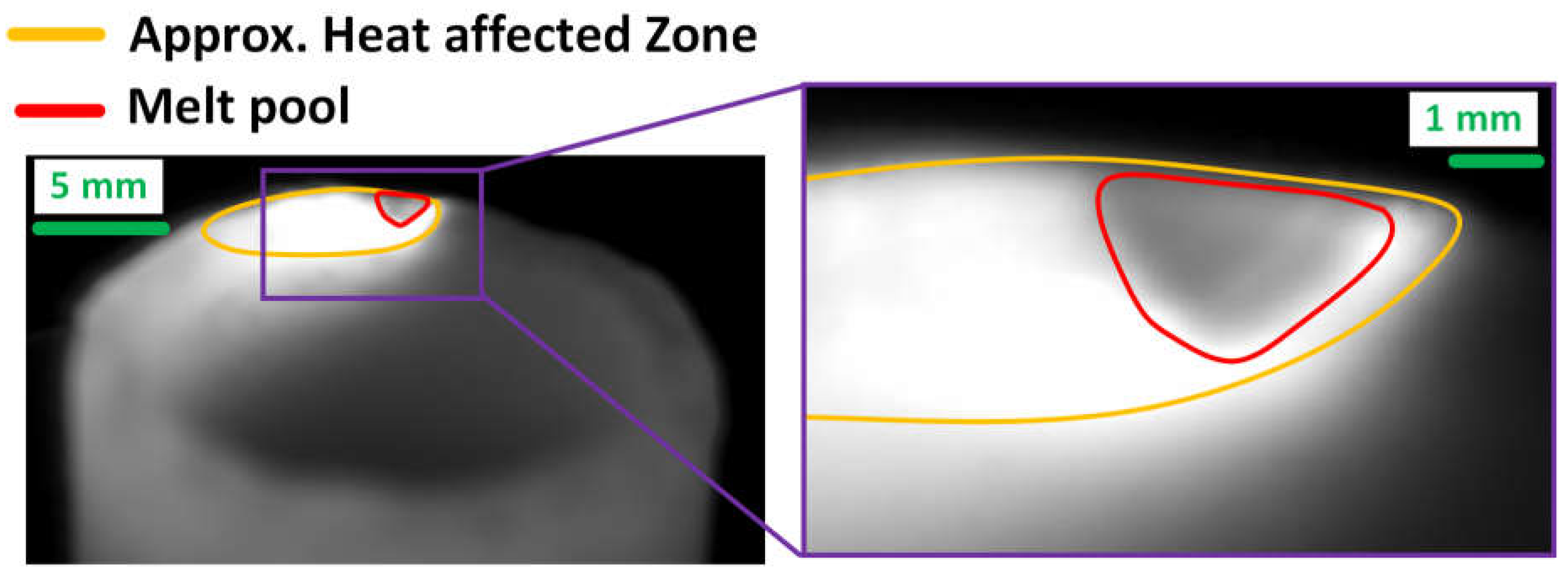

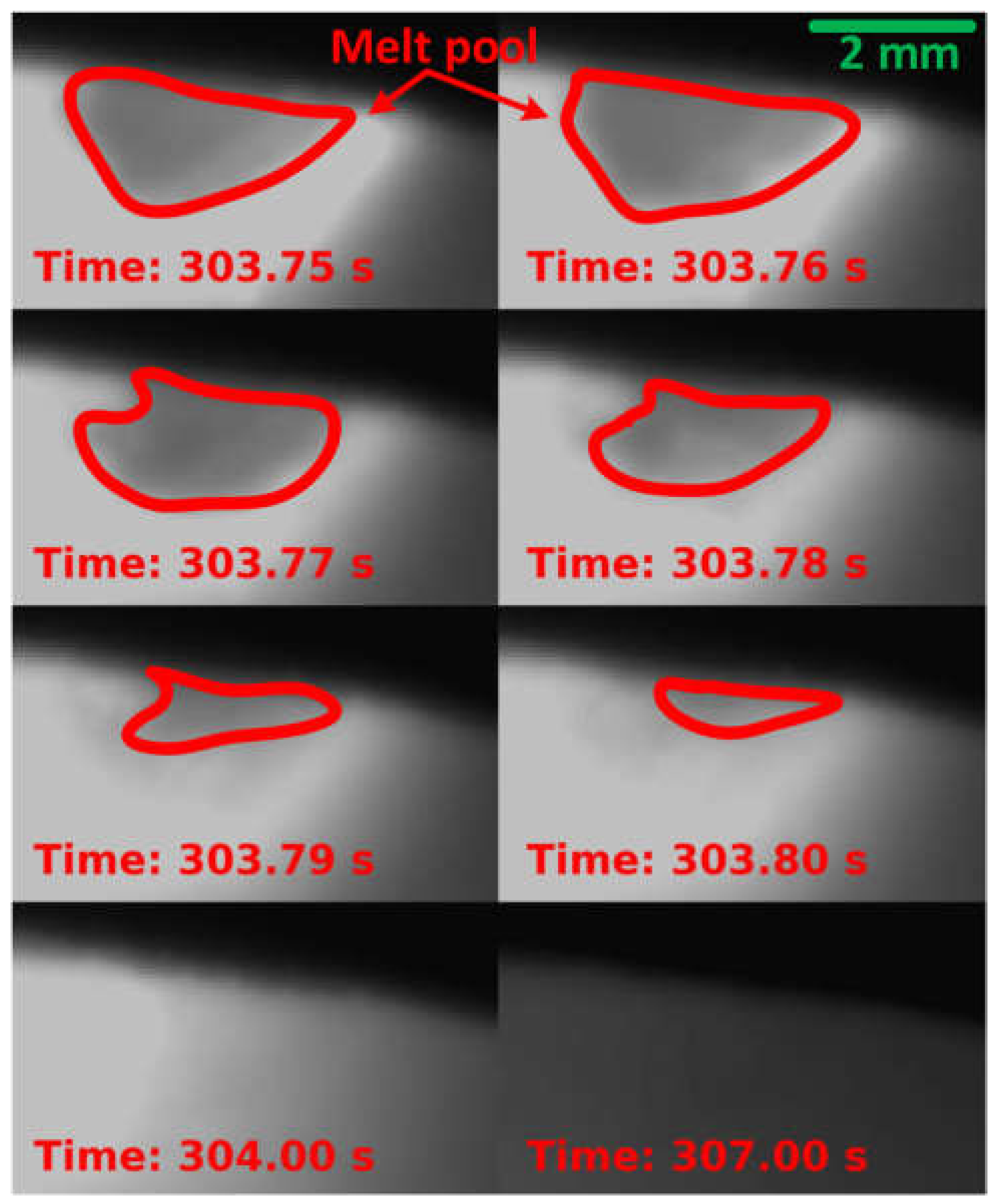

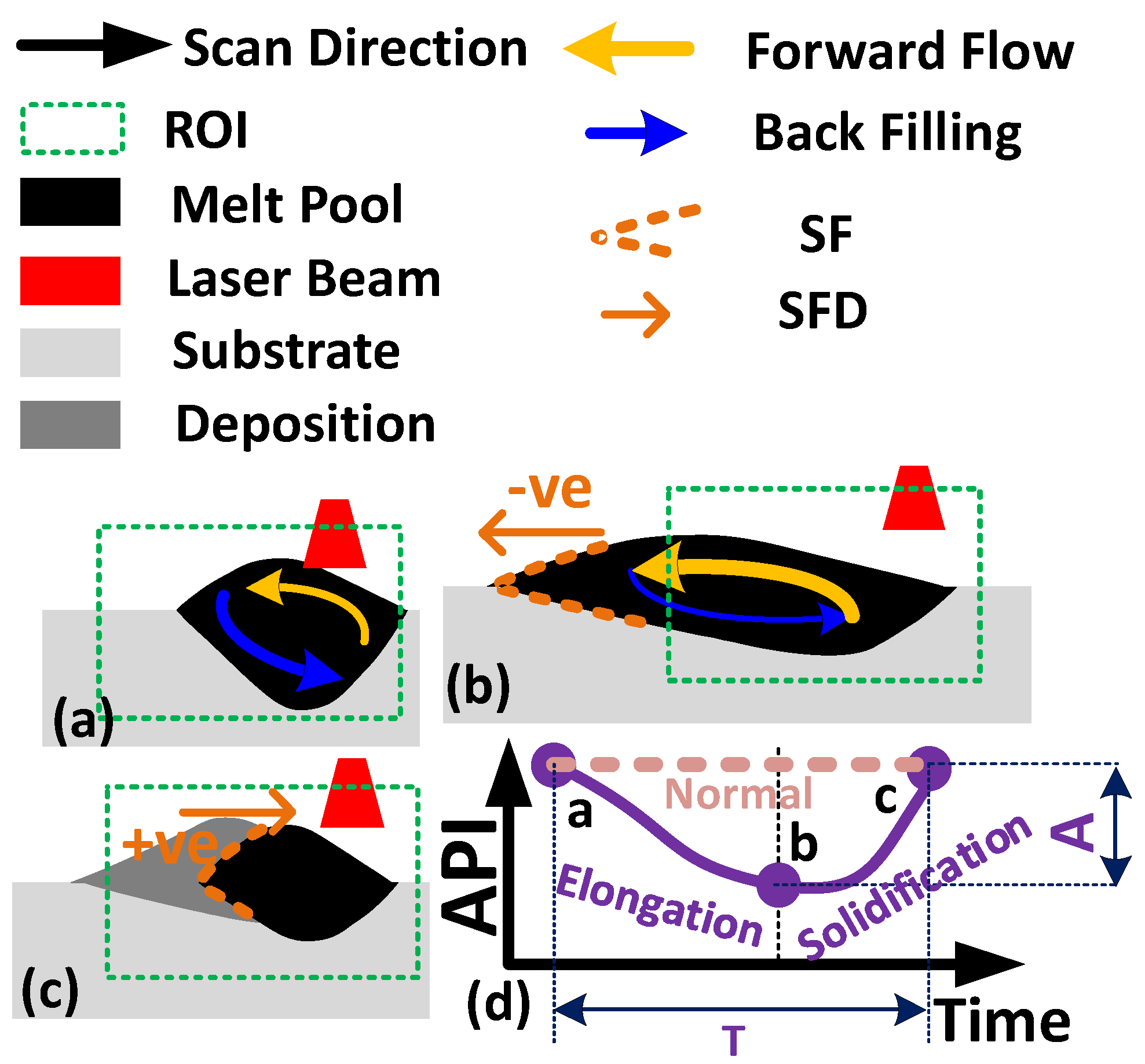

3.1. Pixel Intensity Physical Interpretation

3.2. Physics-Based Indicator

4. Results

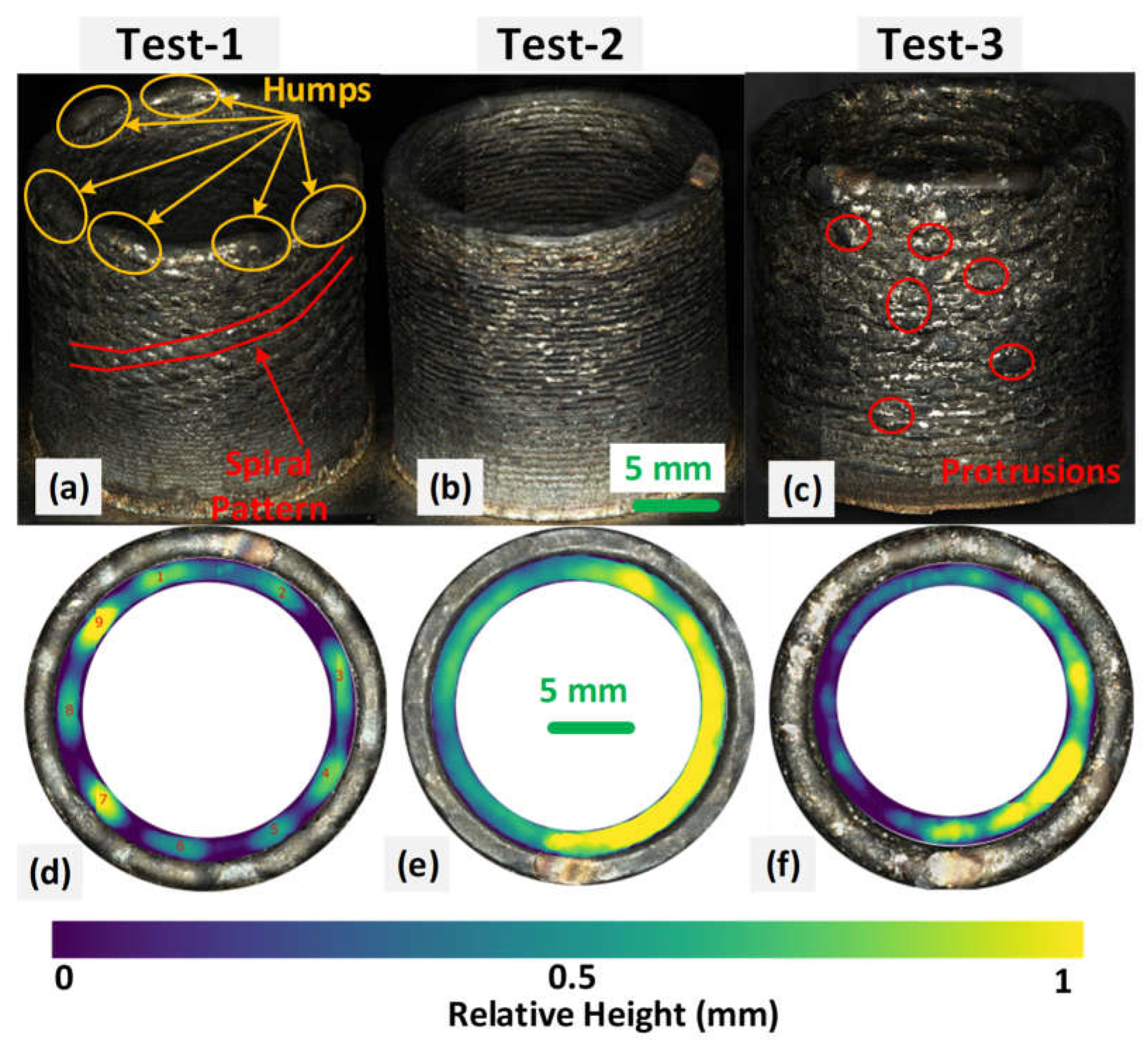

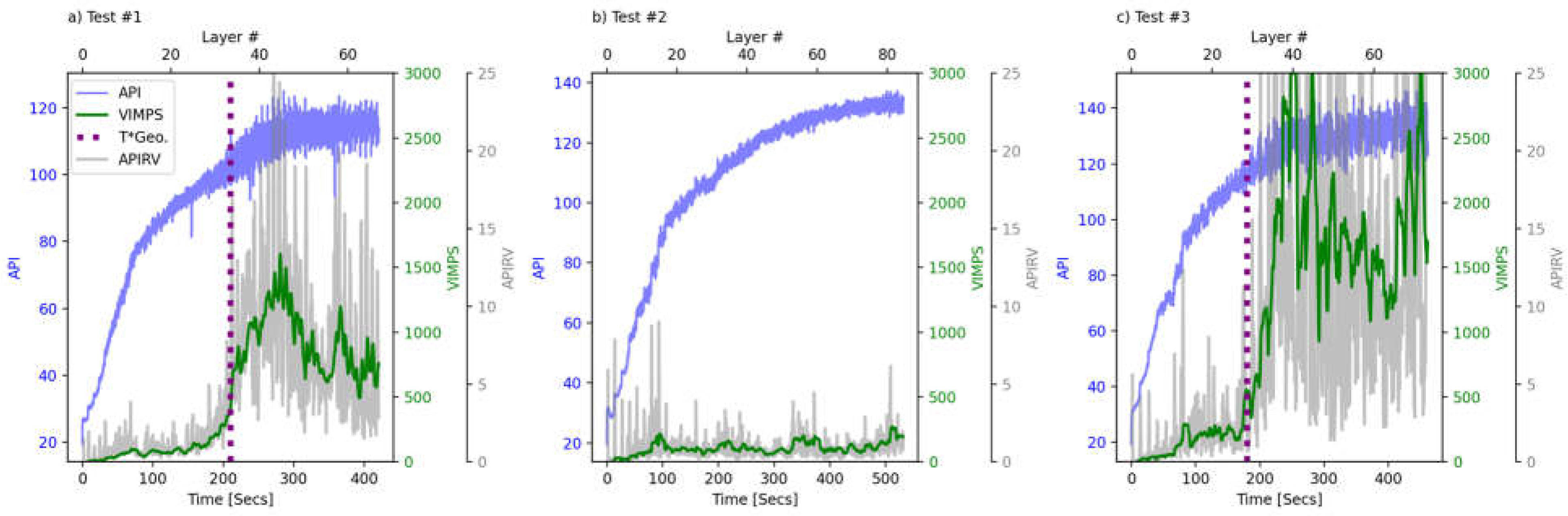

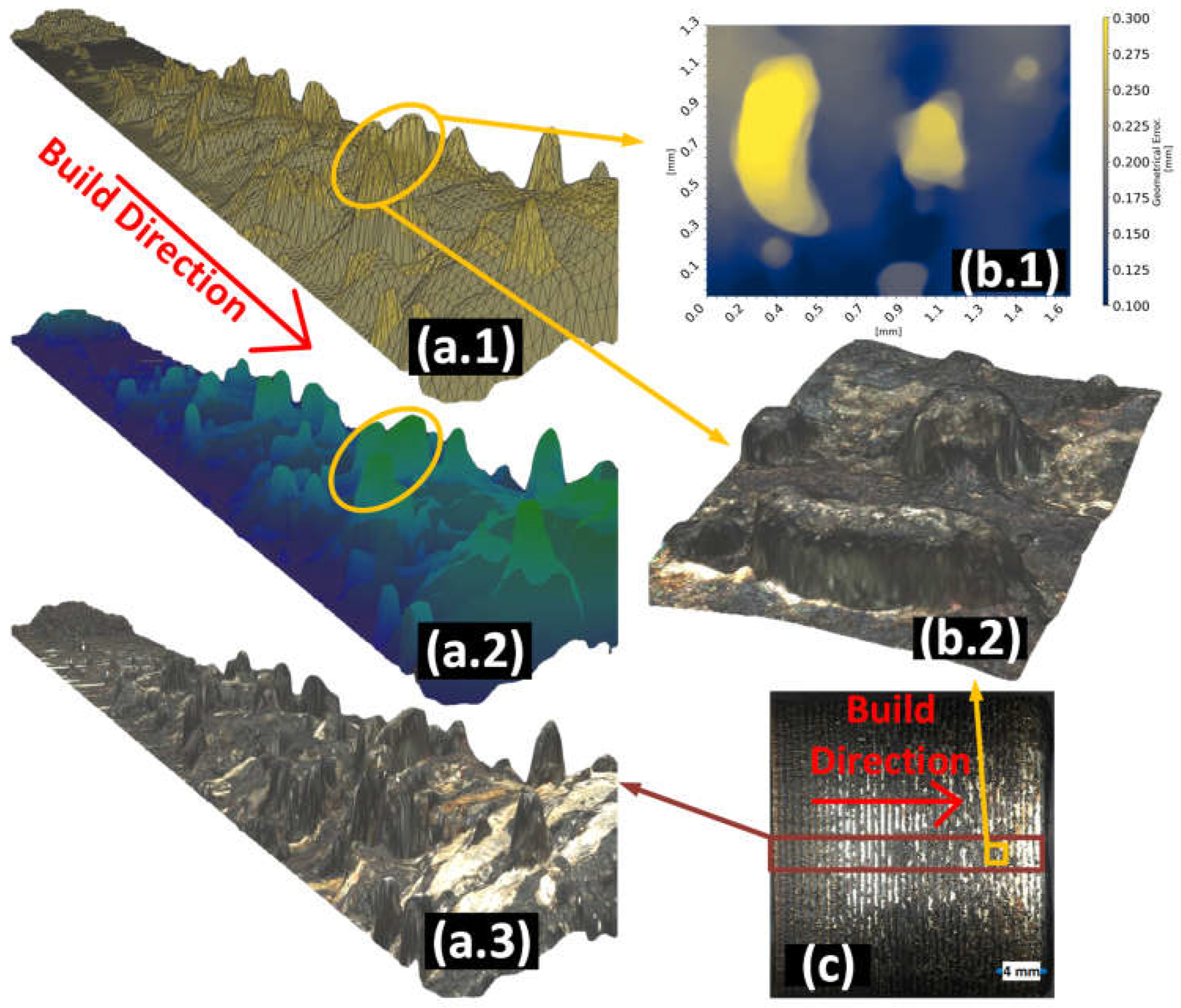

4.1. Geometrical Accuracy

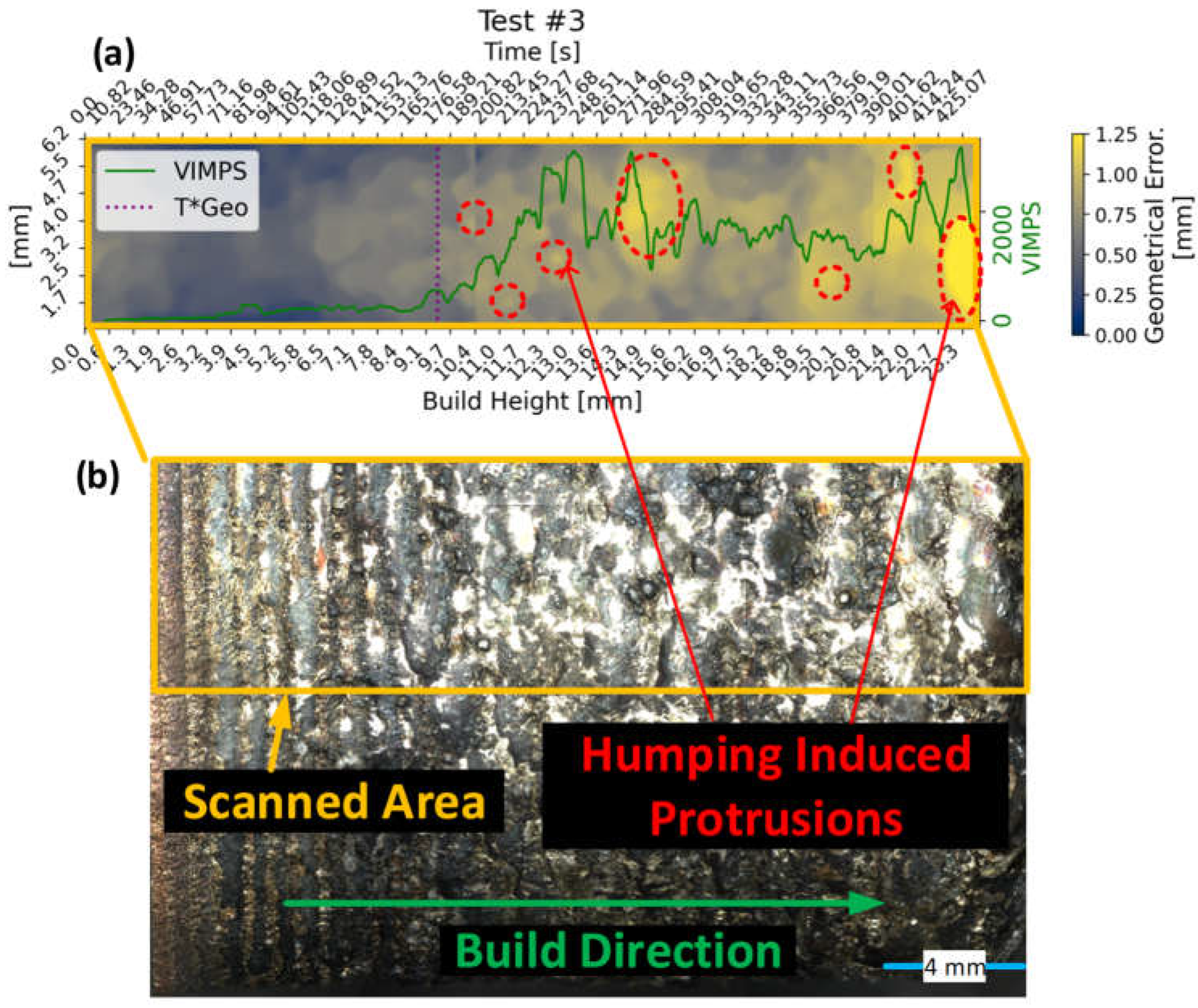

4.2. VIMPS Expressiveness of Geometrical Defects.

- It corrects the conceptual oversight related to the early stages of humping elongation modes.

- It acknowledges the temporal dynamics of humping, which are often overlooked.

- It avoids the complexity of segmentation, reducing potential errors.

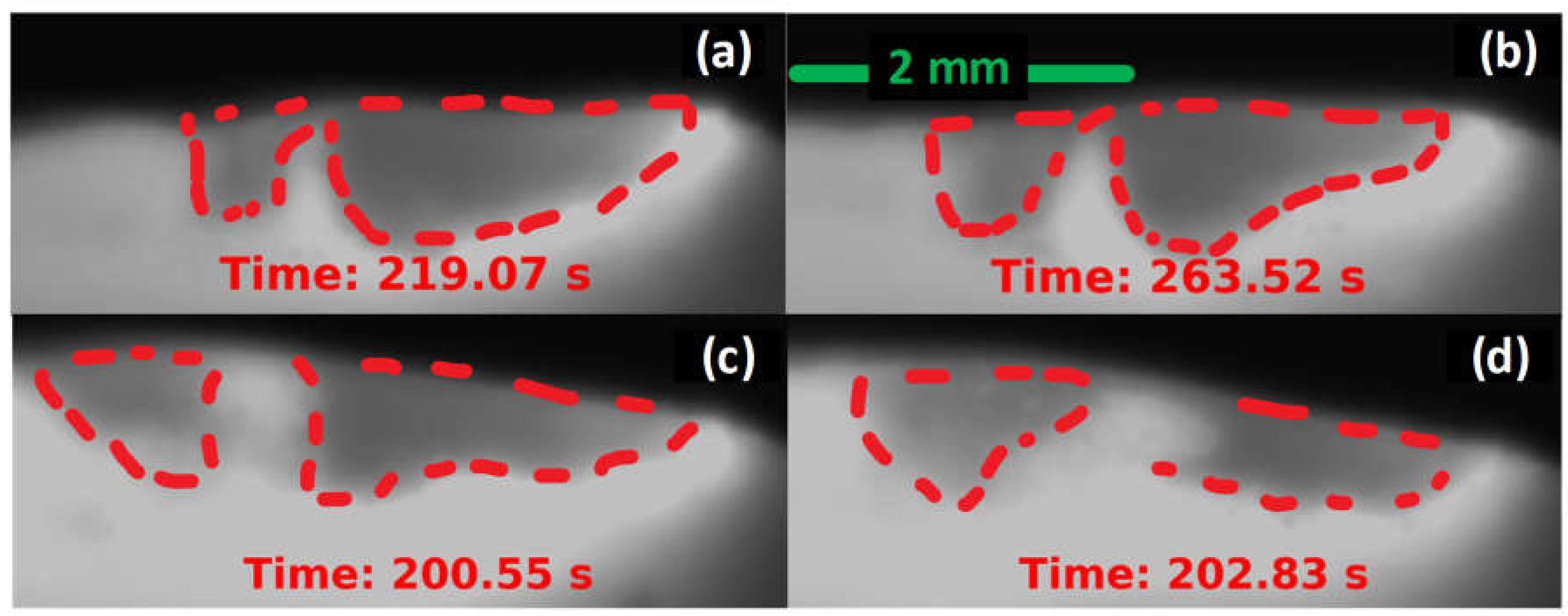

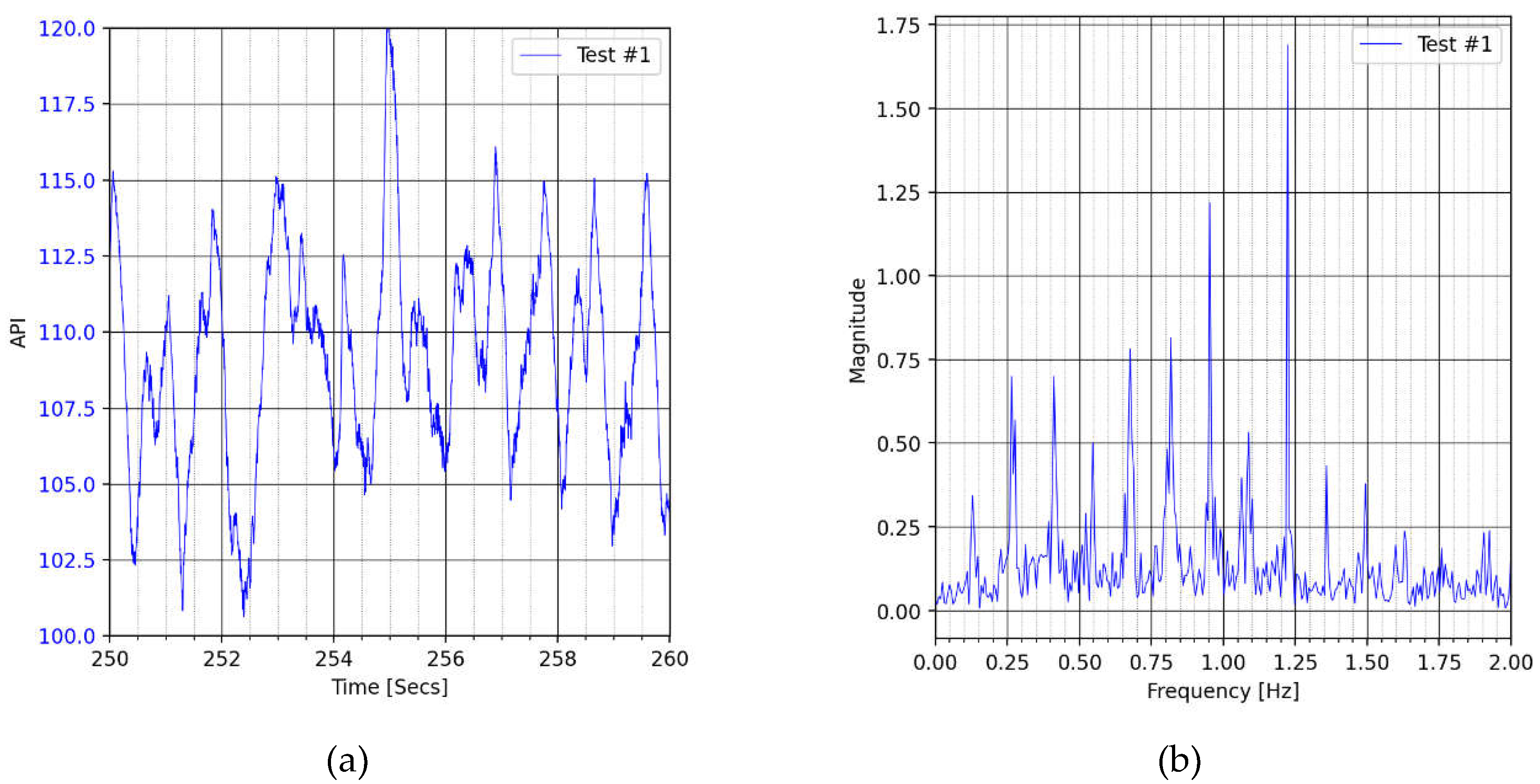

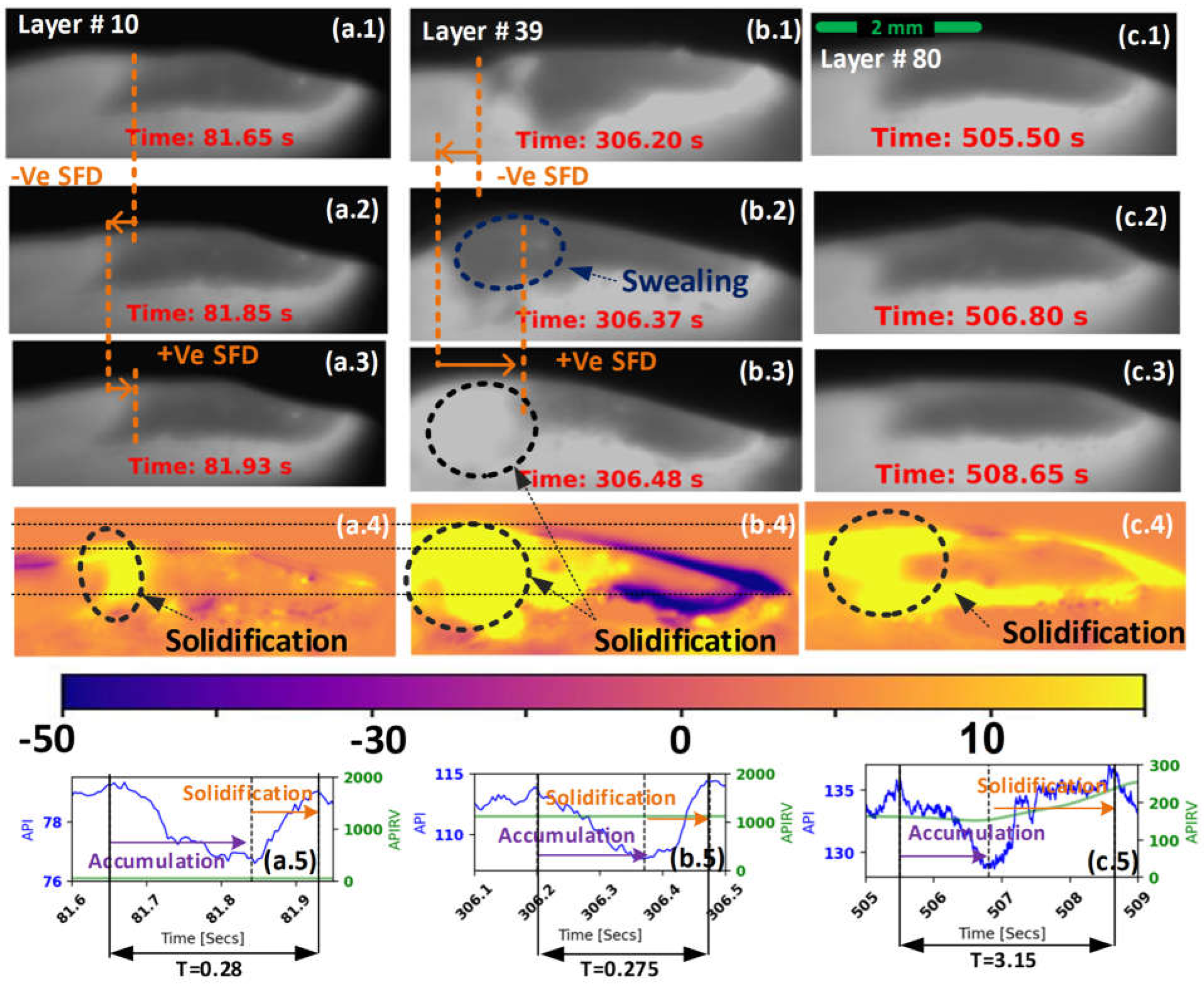

4.3. API Expressiveness of Solidification Spatiotemporal Dynamics.

5. Conclusions

Author Contributions

Funding

Competing Interests

Abbreviations

| SF | Solidification Front |

| SFD | Solidification Front Relative Velocity Direction |

| API | Average Pixel Intensity |

| VIMPS | Variability of Instantaneous Melt-Pool Solidification-Front Speed |

| DT | Dwell Time |

| MP | Melt pool |

| CDT | Continuous Deposition Time |

| A | The amplitude of the elongation cycle |

| T | Duration of the elongation cycle |

| LE | Linear Energy input |

Appendix A

| * | When the context is clear, the time index (t) is dropped from API(t) and PI(x,y,t) to avoid cluttered notation. But it should be clear that each of API, APIRV, APRIVM, APRIVxM and PI varies over time. |

References

- Z. Liu, B. He, T. Lyu, and Y. Zou, “A Review on Additive Manufacturing of Titanium Alloys for Aerospace Applications: Directed Energy Deposition and Beyond Ti-6Al-4V,” JOM, vol. 73, no. 6, pp. 1804–1818, Jun. 2021. [CrossRef]

- H. Chen, Z. Liu, X. Cheng, and Y. Zou, “Laser deposition of graded γ-TiAl/Ti2AlNb alloys: Microstructure and nanomechanical characterization of the transition zone,” J. Alloys Compd., vol. 875, p. 159946, Sep. 2021. [CrossRef]

- J. Ye, A. Bab-hadiashar, N. Alam, and I. Cole, “A review of the parameter-signature-quality correlations through in situ sensing in laser metal additive manufacturing,” Int. J. Adv. Manuf. Technol., vol. 124, no. 5–6, pp. 1401–1427, 2023. [CrossRef]

- T. Yu, L. Chen, Z. Liu, and P. Xu, “Research on the temperature control strategy of thin-wall parts fabricated by laser direct metal deposition,” Int. J. Adv. Manuf. Technol., vol. 122, no. 2, pp. 669–684, Sep. 2022. [CrossRef]

- Z. Mianji, A. Kholopov, I. Binkov, and K. Klimochkin, “Experimental and Numerical Study of Heat Transfer in Thin-Walled Structures Built by Direct Metal Deposition and Geometry Improvement via Laser Power Modulation,” Lasers Manuf. Mater. Process., vol. 10, no. 3, pp. 353–372, Sep. 2023. [CrossRef]

- D. Svetlizky et al., “Directed energy deposition (DED) additive manufacturing: Physical characteristics, defects, challenges and applications,” Mater. Today, vol. 49, pp. 271–295, Oct. 2021. [CrossRef]

- Z. jue Tang et al., “A review on in situ monitoring technology for directed energy deposition of metals,” Int. J. Adv. Manuf. Technol., vol. 108, no. 11–12, pp. 3437–3463, 2020. [CrossRef]

- Adebayo, J. Mehnen, and X. Tonnellier, “Limiting Travel Speed in Additive Layer Manufacturing,” 2013. [Online]. Available: https://api.semanticscholar.org/CorpusID:54218509.

- G. Turichin, E. Zemlyakov, O. Klimova, and K. Babkin, “Hydrodynamic instability in high-speed direct laser deposition for additive manufacturing,” Phys. Procedia, vol. 83, pp. 674–683, 2016. [CrossRef]

- T. C. Nguyen, D. C. Weckman, D. A. Johnson, and H. W. Kerr, “The humping phenomenon during high speed gas metal arc welding,” Sci. Technol. Weld. Join., vol. 10, no. 4, pp. 447–459, 2005. [CrossRef]

- E. Soderstrom and P. Mendez, “Humping mechanisms present in high speed welding,” Sci. Technol. Weld. Join., vol. 11, no. 5, pp. 572–579, 2006. [CrossRef]

- M. Zhang, T. Liu, R. Hu, Z. Mu, S. Chen, and G. Chen, “Understanding root humping in high-power laser welding of stainless steels: A combination approach,” Int. J. Adv. Manuf. Technol., vol. 106, no. 11–12, pp. 5353–5364, 2020. [CrossRef]

- P. Yinglei and S. Jiguo, “Understanding humping formation based on keyhole and molten pool behaviour during high speed laser welding of thin sheets,” Eng. Res. Express, vol. 2, no. 2, p. 025031, Jun. 2020. [CrossRef]

- Y. Ai et al., “Investigation of the humping formation in the high power and high speed laser welding,” Opt. Lasers Eng., vol. 107, no. May 2017, pp. 102–111, 2018. [CrossRef]

- Gullipalli, N. Thawari, and T. V. K. Gupta, “Humping defects in laser based direct metal deposition,” Mater. Today Proc., 2023. [CrossRef]

- J. Shi, F. Li, S. Chen, Y. Zhao, and H. Tian, “Effect of in-process active cooling on forming quality and efficiency of tandem GMAW–based additive manufacturing,” Int. J. Adv. Manuf. Technol., vol. 101, no. 5–8, pp. 1349–1356, 2019. [CrossRef]

- F. Montevecchi, G. Venturini, N. Grossi, A. Scippa, and G. Campatelli, “Heat accumulation prevention in Wire-Arc-Additive-Manufacturing using air jet impingement,” Manuf. Lett., vol. 17, pp. 14–18, 2018. [CrossRef]

- F. Montevecchi, G. Venturini, N. Grossi, A. Scippa, and G. Campatelli, “Idle time selection for wire-arc additive manufacturing: A finite element-based technique,” Addit. Manuf., vol. 21, no. January, pp. 479–486, 2018. [CrossRef]

- S. Singh, A. N. Jinoop, G. T. A. Tarun Kumar, I. A. Palani, C. P. Paul, and K. G. Prashanth, “Effect of interlayer delay on the microstructure and mechanical properties of wire arc additive manufactured wall structures,” Materials (Basel)., vol. 14, no. 15, 2021. [CrossRef]

- Turgut, U. Gürol, and R. Onler, “Effect of interlayer dwell time on output quality in wire arc additive manufacturing of low carbon low alloy steel components,” Int. J. Adv. Manuf. Technol., vol. 126, no. 11–12, pp. 5277–5288, 2023. [CrossRef]

- F. Dababneh and H. Taheri, “Investigation of the influence of process interruption on mechanical properties of metal additive manufacturing parts,” CIRP J. Manuf. Sci. Technol., vol. 38, pp. 706–716, 2022. [CrossRef]

- R. Denlinger, J. C. Heigel, P. Michaleris, and T. A. Palmer, “Effect of inter-layer dwell time on distortion and residual stress in additive manufacturing of titanium and nickel alloys,” J. Mater. Process. Technol., vol. 215, pp. 123–131, 2015. [CrossRef]

- S. C. A. Alfaro, J. A. R. Vargas, G. C. De Carvalho, and G. G. De Souza, “Characterization of ‘humping’ in the GTA welding process using infrared images,” J. Mater. Process. Technol., vol. 223, pp. 216–224, 2015. [CrossRef]

- B. Xue, B. Chang, and D. Du, “A vision based method for humping detection in high-speed laser welding,” J. Phys. Conf. Ser., vol. 1983, no. 1, p. 012074, Jul. 2021. [CrossRef]

- J. Lu, Z. Zhao, J. Han, and L. Bai, “Hump weld bead monitoring based on transient temperature field of molten pool,” Optik (Stuttg)., vol. 208, no. October 2019, p. 164031, Apr. 2020. [CrossRef]

- S. J. Altenburg, A. Straße, A. Gumenyuk, and C. Maierhofer, “In-situ monitoring of a laser metal deposition (LMD) process: Comparison of MWIR, SWIR and high-speed NIR thermography,” Quant. Infrared Thermogr. J., vol. 19, no. 2, pp. 97–114, Mar. 2022. [CrossRef]

- R. A. Felice and D. A. Nash, “Pyrometry of materials with changing, spectrally-dependent emissivity-Solid and liquid metals,” AIP Conf. Proc., vol. 1552 8, pp. 734–739, 2013. [CrossRef]

- “Emissivity Values for Metals.” https://www.flukeprocessinstruments.com/en-us/service-and-support/knowledge-center/infrared-technology/emissivity-metals (accessed Oct. 04, 2024).

- C. Slater, K. Hechu, C. Davis, and S. Sridhar, “Characterisation of the solidification of a molten steel surface using infrared thermography,” Metals (Basel)., vol. 9, no. 2, pp. 1–9, 2019. [CrossRef]

- Kirillov et al., “Segment Anything,” 2023, [Online]. Available: https://ai.facebook.com/research/publications/segment-anything/.

- J. Zhang et al., “Image Segmentation for Defect Analysis in Laser Powder Bed Fusion : Deep Data Mining of X - Ray Photography from Recent Literature,” Integr. Mater. Manuf. Innov., vol. 11, no. 3, pp. 418–432, 2022. [CrossRef]

- B. Blumenstiel, J. Jakubik, H. Kühne, and M. Vössing, “What a MESS: Multi-Domain Evaluation of Zero-Shot Semantic Segmentation,” Jun. 2023, Accessed: Apr. 14, 2024. [Online]. Available: https://arxiv.org/abs/2306.15521v3.

- M. A. Hassan, R. ElMallah, and C. G. Lee, “Approximate and Memorize (A&M): Settling opposing views in replay-based continuous unsupervised domain adaptation,” Knowledge-Based Syst., vol. 293, no. December 2023, p. 111653, 2024. [CrossRef]

- M. Abubakr, B. Akoush, A. Khalil, and M. A. Hassan, “Unleashing deep neural network full potential for solar radiation forecasting in a new geographic location with historical data scarcity: A transfer learning approach,” Eur. Phys. J. Plus, vol. 137, no. 4, 2022. [CrossRef]

- “Segment Anything | Meta AI.” https://segment-anything.com/ (accessed Apr. 14, 2024).

| Test No. | P (W) | V (mm/min) |

| 1 | 650 | 600 |

| 2 | 650 | 360 |

| 3 | 850 | 360 |

| MP size | SFD | API | |

| Accumulation in Figure 1c.1. | Increasing | Negative | Decreasing |

| Solidification in Figure 1c.2. | Decreasing | Positive | Increasing |

| Line | Pseudo Code |

| 1 | Define Region of Interest (ROI) |

| 2 | do: |

| 3 | Calculate Average Pixel Intensity (API) as per Equation 1 |

| 4 | Calculate API’s Rolling Mean (APIRM) as per Equation 2 |

| 5 | Calculate API’s Rolling Variance (APIRV) as per Equation 3 |

| 6 | Calculate APIRVxM as per Equation 4 |

| 7 | Calculate (VIMPS) as per Equation 5 |

| 8 | End For |

| Metric | VIMPS | SOTA’s Theoretical Upper bound |

||

| Test # | 1 | 3 | 1 | 3 |

| Detection Time | 200 | 170 | 219 | 200 |

| T*Geo Time | 210 | 180 | 210 | 180 |

| Detection Lead | 10 | 10 | -9 | -20 |

| Consistency | High | Low | ||

| Complexity | Low | High | ||

| Principle | Spatiotemporal | Spatial | ||

| Mode | Elongation | Detachment | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).