Submitted:

17 April 2024

Posted:

18 April 2024

You are already at the latest version

Abstract

Keywords:

Introduction

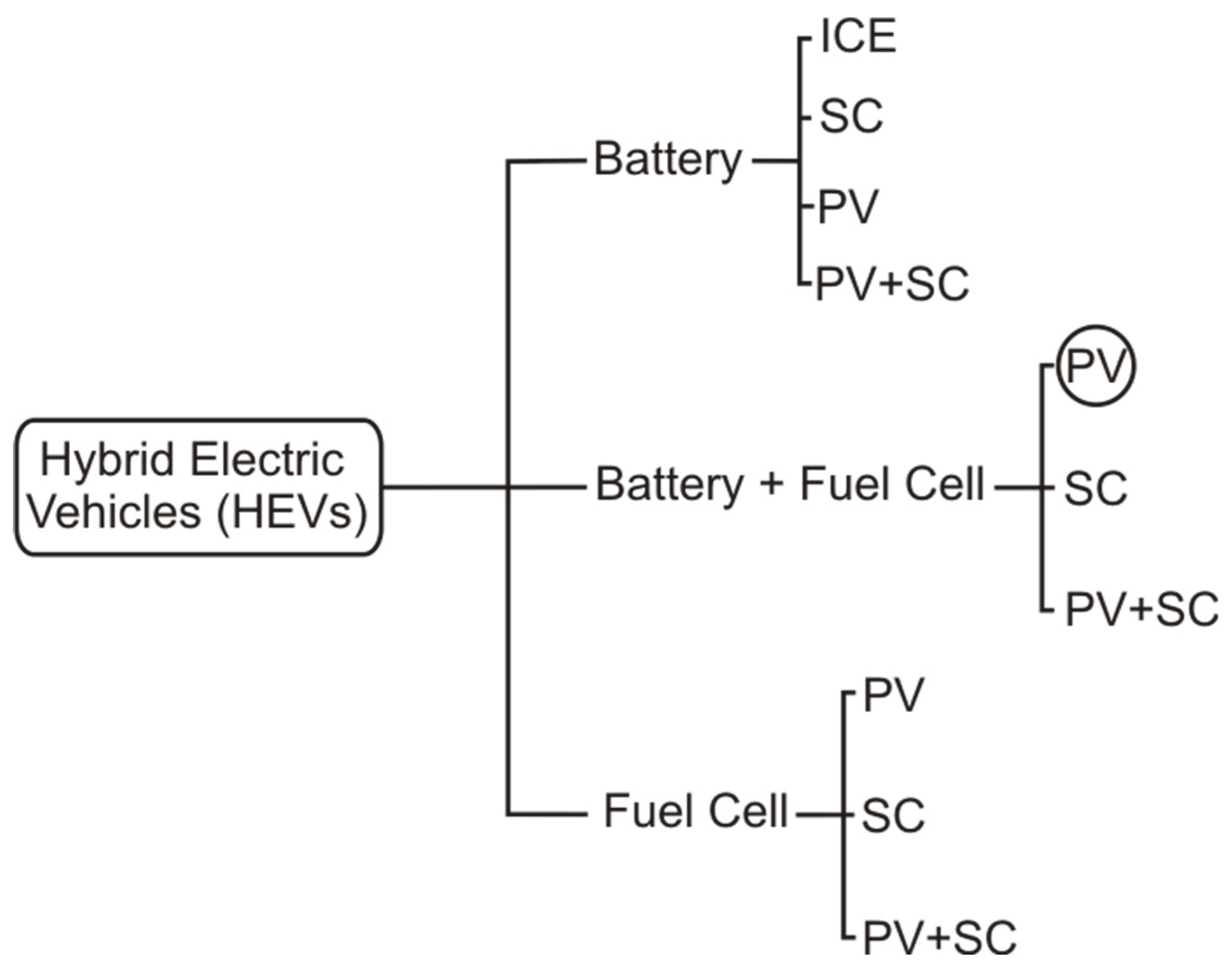

Electric Vehicle Prototype Topology

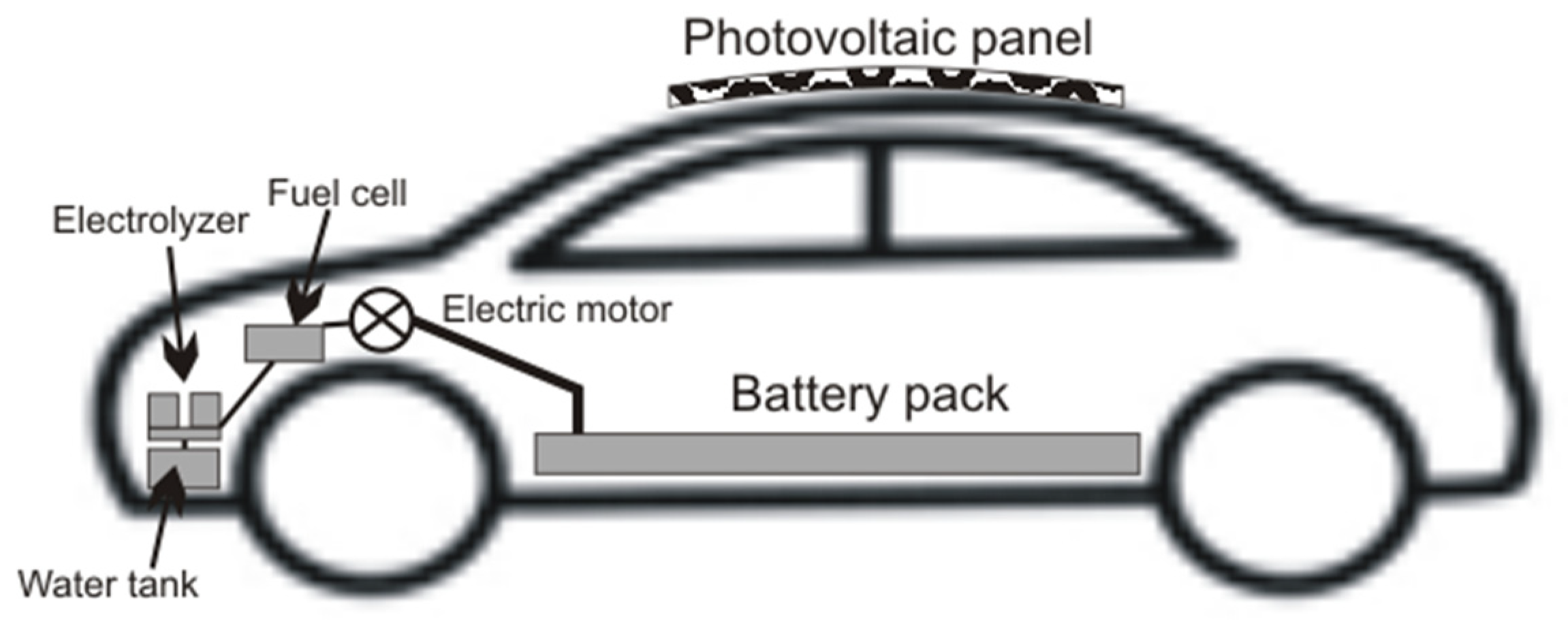

Hybrid System Characteristics

- a)

- Photovoltaic panel

- b)

- Lithium battery

- c)

- Fuel cell

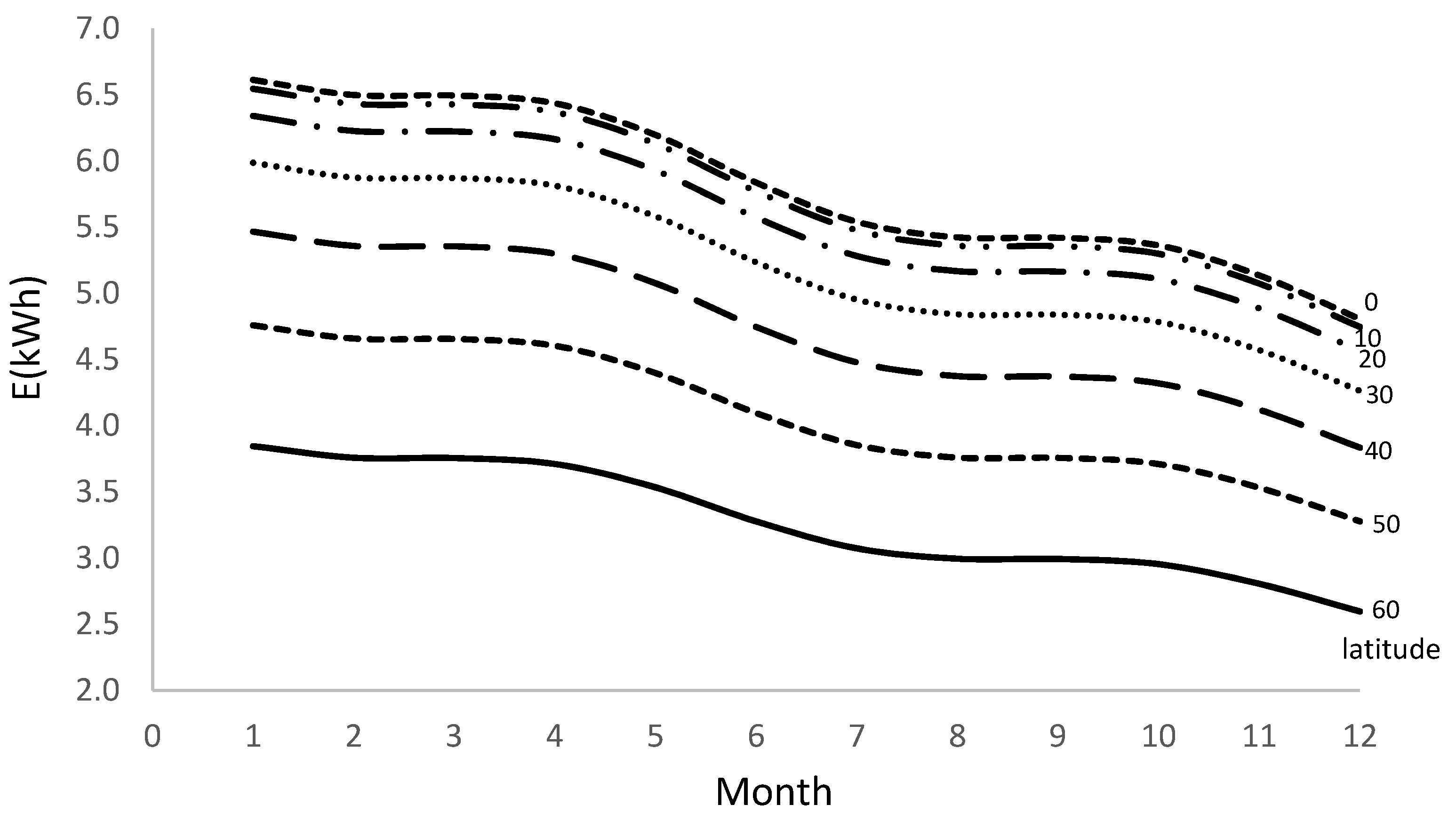

Energy Balance

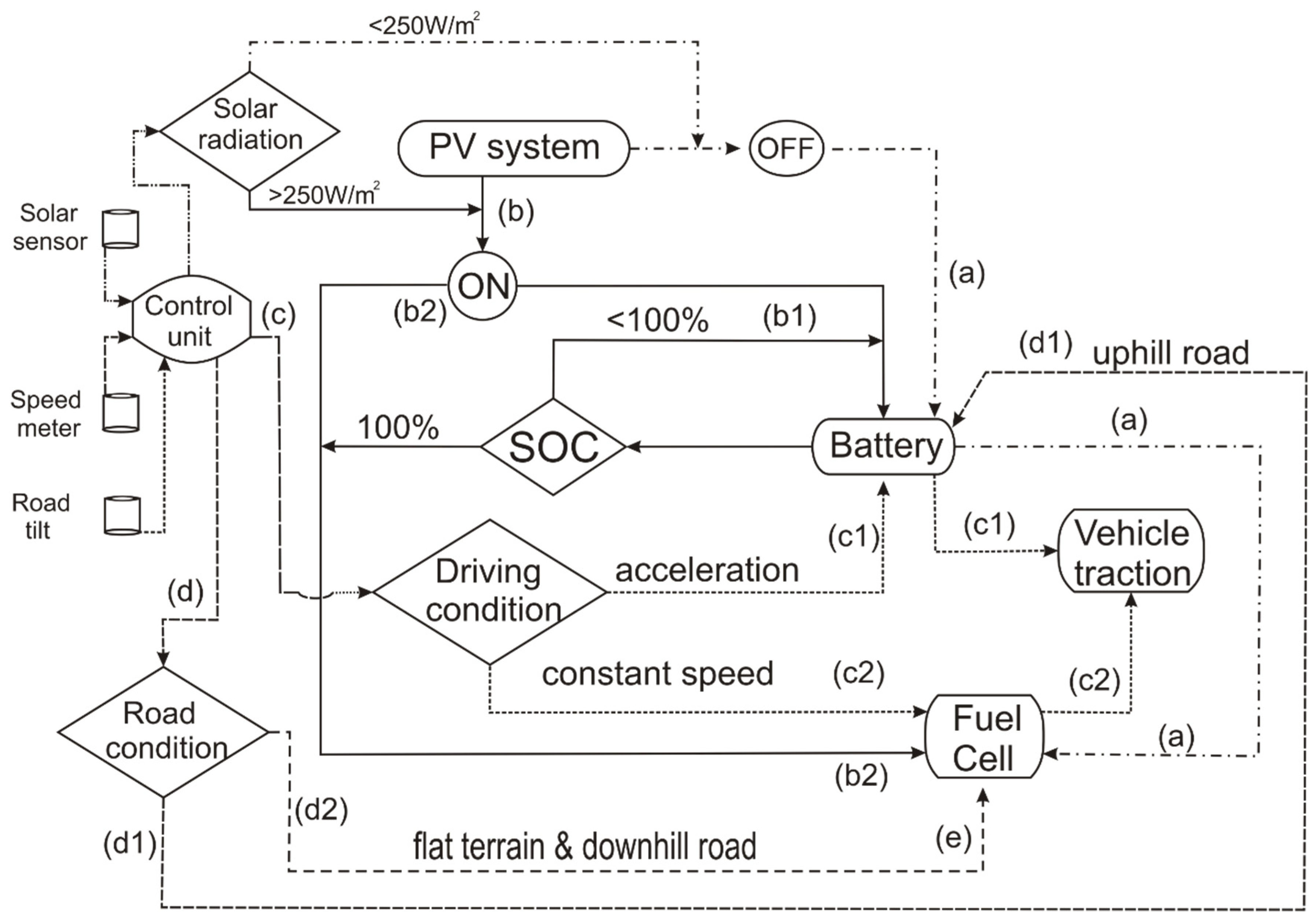

Control System

- The solar sensor detects solar radiation and sends the signal to the control unit, which evaluates the intensity of solar radiation

- If the level of solar radiation is less than 250 W/m2, the control unit deactivates the photovoltaic system as an energy source and activates the battery to supply energy to the fuel cell (a) and to drive the vehicle (c1)

- If the solar radiation level is higher than 250 W/m2, the control unit activates the photovoltaic system (b) and detects the battery state of charge (SOC)

- If the battery is fully charged (SOC=100%), the control unit diverts the photovoltaic energy supply to the fuel cell (b2); otherwise, it switches the PV system to charge the battery to the 100% state of charge (b1) at which point the control unit returns to the initial state and the PV system supplies power to the fuel cell again (b2)

- In parallel, the control unit detects the driving and road conditions by receiving the vehicle speed and road inclination signal

- The control unit determines the acceleration from the moment the vehicle speed changes, using the classic dynamic equation

- If the acceleration exceeds a configured threshold, currently set at the conservative value (1 m/s2), the control unit interprets that the vehicle is accelerating and switches the energy source to the battery (c1), which powers the electric motor to drive the vehicle

- If the acceleration is lower than the configuration threshold or zero, the control unit switches the power supply to the fuel cell (c2), which powers the vehicle’s electric traction motor

- The control system continuously monitors road conditions (d); when it detects an uphill segment from the road inclination sensor, it switches the power supply to the battery (d1), regardless of the driving conditions encountered; otherwise, it maintains the fuel cell as a power source (d2) until driving or road conditions change

Driving Range Evaluation

Economic Analysis

Conclusions

References

- Weldon, P., Morrissey, P., & O’Mahony, M. (2018). Long-term cost of ownership comparative analysis between electric vehicles and internal combustion engine vehicles. Sustainable Cities and Society, 39, 578-591. [CrossRef]

- Ağbulut, Ü., & Bakir, H. (2019). The investigation on economic and ecological impacts of tendency to electric vehicles instead of internal combustion engines. Düzce Üniversitesi Bilim ve Teknoloji Dergisi, 7(1), 25-36. [CrossRef]

- Wilken, D., Oswald, M., Draheim, P., Pade, C., Brand, U., & Vogt, T. (2020). Multidimensional assessment of passenger cars: Comparison of electric vehicles with internal combustion engine vehicles. Procedia Cirp, 90, 291-296. [CrossRef]

- Woo, J., & Magee, C. L. (2020). Forecasting the value of battery electric vehicles compared to internal combustion engine vehicles: the influence of driving range and battery technology. International Journal of Energy Research, 44(8), 6483-6501. [CrossRef]

- Ding, N., Prasad, K., & Lie, T. T. (2017). The electric vehicle: a review. International Journal of Electric and Hybrid Vehicles, 9(1), 49-66. [CrossRef]

- Poullikkas, A. (2015). Sustainable options for electric vehicle technologies. Renewable and Sustainable Energy Reviews, 41, 1277-1287. [CrossRef]

- Hannan, M. A., Azidin, F. A., & Mohamed, A. (2014). Hybrid electric vehicles and their challenges: A review. Renewable and Sustainable Energy Reviews, 29, 135-150. [CrossRef]

- Pramuanjaroenkij, A., & Kakaç, S. (2023). The fuel cell electric vehicles: The highlight review. International Journal of Hydrogen Energy, 48(25), 9401-9425. [CrossRef]

- Sorlei, I. S., Bizon, N., Thounthong, P., Varlam, M., Carcadea, E., Culcer, M., ... & Raceanu, M. (2021). Fuel cell electric vehicles—A brief review of current topologies and energy management strategies. Energies, 14(1), 252. [CrossRef]

- Das, H. S., Tan, C. W., & Yatim, A. H. M. (2017). Fuel cell hybrid electric vehicles: A review on power conditioning units and topologies. Renewable and Sustainable Energy Reviews, 76, 268-291. [CrossRef]

- Yang, W. C. (2000). Fuel cell electric vehicles: Recent advances and challenges.Thomas, C. E. (2009). Fuel cell and battery electric vehicles compared. international journal of hydrogen energy, 34(15), 6005-6020. [CrossRef]

- Maggetto, G., & Van Mierlo, J. (2001, July). Electric vehicles, hybrid electric vehicles and fuel cell electric vehicles: state of the art and perspectives. In Annales de Chimie Science des Materiaux (Vol. 26, No. 4, pp. 9-26). No longer published by Elsevier.

- Tanç, B., Arat, H. T., Baltacıoğlu, E., & Aydın, K. (2019). Overview of the next quarter century vision of hydrogen fuel cell electric vehicles. International Journal of Hydrogen Energy, 44(20), 10120-10128. [CrossRef]

- Muthukumar, M., Rengarajan, N., Velliyangiri, B., Omprakas, M. A., Rohit, C. B., & Raja, U. K. (2021). The development of fuel cell electric vehicles–A review. Materials Today: Proceedings, 45, 1181-1187. [CrossRef]

- Raja, V. B., Raja, I., & Kavvampally, R. (2021, December). Advancements in battery technologies of electric vehicle. In Journal of Physics: Conference Series (Vol. 2129, No. 1, p. 012011). IOP Publishing. [CrossRef]

- Manzetti, S., & Mariasiu, F. (2015). Electric vehicle battery technologies: From present state to future systems. Renewable and Sustainable Energy Reviews, 51, 1004-1012. [CrossRef]

- Rezvanizaniani, S. M., Liu, Z., Chen, Y., & Lee, J. (2014). Review and recent advances in battery health monitoring and prognostics technologies for electric vehicle (EV) safety and mobility. Journal of power sources, 256, 110-124. [CrossRef]

- Andwari, A. M., Pesiridis, A., Rajoo, S., Martinez-Botas, R., & Esfahanian, V. (2017). A review of Battery Electric Vehicle technology and readiness levels. Renewable and Sustainable Energy Reviews, 78, 414-430. [CrossRef]

- Thomas, C. E. (2009). Fuel cell and battery electric vehicles compared. international journal of hydrogen energy, 34(15), 6005-6020. [CrossRef]

- Schuss, C., Fabritius, T., Eichberger, B., & Rahkonen, T. (2019). Impacts on the output power of photovoltaics on top of electric and hybrid electric vehicles. IEEE Transactions on Instrumentation and Measurement, 69(5), 2449-2458. [CrossRef]

- Ben Said-Romdhane, M., & Skander-Mustapha, S. (2021). A review on vehicle-integrated photovoltaic panels. Advanced Technologies for Solar Photovoltaics Energy Systems, 349-370. [CrossRef]

- Abdul Rauf Bhatti, Zainal Salam, Mohd Junaidi Bin Abdul Aziz, Kong Pui Yee, Ratil H. Ashique, Electric vehicles charging using photovoltaic: Status and technological review, Renewable and Sustainable Energy Reviews, Volume 54, 2016, Pages 34-47, ISSN 1364-0321. [CrossRef]

- Ben Said-Romdhane, M., Skander-Mustapha, S. (2021). A Review on Vehicle-Integrated Photovoltaic Panels. In: Motahhir, S., Eltamaly, A.M. (eds) Advanced Technologies for Solar Photovoltaics Energy Systems. Green Energy and Technology. Springer, Cham. [CrossRef]

- Vehicle Integrated Photovoltaics (VIPV). Fraunhofer ISE. Vehicle-Integrated Photovoltaics - Fraunhofer ISE [Accessed online: 10/04/2024].

- Vehicle-integrated PV for heavy-duty trucks. PV Magazine. Vehicle-integrated PV for heavy-duty trucks – pv magazine International (pv-magazine.com) [Accessed online: 10/04/2024].

- Sagaria, S., Duarte, G., Neves, D., & Baptista, P. (2022). Photovoltaic integrated electric vehicles: Assessment of synergies between solar energy, vehicle types and usage patterns. Journal of Cleaner Production, 348, 131402. [CrossRef]

- Pollet, B. G., Staffell, I., & Shang, J. L. (2012). Current status of hybrid, battery and fuel cell electric vehicles: From electrochemistry to market prospects. Electrochimica Acta, 84, 235-249. [CrossRef]

- Khaligh, A., & Li, Z. (2010). Battery, ultracapacitor, fuel cell, and hybrid energy storage systems for electric, hybrid electric, fuel cell, and plug-in hybrid electric vehicles: State of the art. IEEE transactions on Vehicular Technology, 59(6), 2806-2814. [CrossRef]

- Das, H. S., Tan, C. W., & Yatim, A. H. M. (2017). Fuel cell hybrid electric vehicles: A review on power conditioning units and topologies. Renewable and Sustainable Energy Reviews, 76, 268-291. [CrossRef]

- Armenta-Déu, C. (2024) Control Device for Dual Battery Block and Fuel Cell Hybrid Power System for Electric Vehicles. Preprints.org, Preprints ID: preprints-95366. [CrossRef]

- Mokrani, Z., Rekioua, D., & Rekioua, T. (2014). Modeling, control and power management of hybrid photovoltaic fuel cells with battery bank supplying electric vehicle. International Journal of Hydrogen Energy, 39(27), 15178-15187. [CrossRef]

- Mohamed, N., Aymen, F., Altamimi, A., Khan, Z. A., & Lassaad, S. (2022). Power management and control of a hybrid electric vehicle based on photovoltaic, fuel cells, and battery energy sources. Sustainability, 14(5), 2551. [CrossRef]

- Huang, Z., Zhang, C., Zeng, T., Lv, C., & Chan, S. H. (2019). Modeling and energy management of a photovoltaic-fuel cell-battery hybrid electric vehicle. Energy Storage, 1(3), e61. [CrossRef]

- Park, B., & Kim, Y. (2023). Reenacting the hydrogen tank explosion of a fuel-cell electric vehicle: An experimental study. International Journal of Hydrogen Energy, 48(89), 34987-35003. [CrossRef]

- Bedir, F., Kayfeci, M., & Elmas, U. (2015). Safety Rules and Measures to Be Taken Where Hydrogen Gas Is Stored. Progress in Clean Energy, Volume 2: Novel Systems and Applications, 551-565.

- Rivard, E., Trudeau, M., & Zaghib, K. (2019). Hydrogen storage for mobility: A review. Materials, 12(12), 1973. [CrossRef] [PubMed]

- Paster, M. D., Ahluwalia, R. K., Berry, G., Elgowainy, A., Lasher, S., McKenney, K., & Gardiner, M. (2011). Hydrogen storage technology options for fuel cell vehicles: well-to-wheel costs, energy efficiencies, and greenhouse gas emissions. International Journal of Hydrogen Energy, 36(22), 14534-14551. [CrossRef]

- Rasul, M. G., Hazrat, M. A., Sattar, M. A., Jahirul, M. I., & Shearer, M. J. (2022). The future of hydrogen: Challenges on production, storage and applications. Energy Conversion and Management, 272, 116326. [CrossRef]

- Penina, N., Turygin, Y. V., & Racek, V. (2010, June). Comparative analysis of different types of hybrid electric vehicles. In 13th Mechatronika 2010 (pp. 102-104). IEEE.

- Vidyanandan, K. V. (2018). Overview of electric and hybrid vehicles. Energy Scan, 3, 7-14.

- Kebriaei, M., Niasar, A. H., & Asaei, B. (2015, October). Hybrid electric vehicles: An overview. In 2015 International Conference on Connected Vehicles and Expo (ICCVE) (pp. 299-305). IEEE.

- Pistoia, G. (Ed.). (2010). Electric and hybrid vehicles: Power sources, models, sustainability, infrastructure and the market. Elsevier.

- Chau, K. T., & Wong, Y. S. (2001). Hybridization of energy sources in electric vehicles. Energy Conversion and Management, 42(9), 1059-1069. [CrossRef]

- Maggetto, G., & Van Mierlo, J. (2001, July). Electric vehicles, hybrid electric vehicles and fuel cell electric vehicles: state of the art and perspectives. In Annales de Chimie Science des Materiaux (Vol. 26, No. 4, pp. 9-26). No longer published by Elsevier.

- Fathabadi, H. (2018). Novel fuel cell/battery/supercapacitor hybrid power source for fuel cell hybrid electric vehicles. Energy, 143, 467-477. [CrossRef]

- Thomas, C. E., Kuhn Jr, I. F., James, B. D., Lomax Jr, F. D., & Baum, G. N. (1998). Affordable hydrogen supply pathways for fuel cell vehicles. International Journal of Hydrogen Energy, 23(6), 507-516. [CrossRef]

- Zhao, Y., Liu, Y., Liu, G., Yang, Q., Li, L., & Gao, Z. (2022). Air and hydrogen supply systems and equipment for PEM fuel cells: A review. International Journal of Green Energy, 19(4), 331-348. [CrossRef]

- Lototskyy, M. V., Tolj, I., Pickering, L., Sita, C., Barbir, F., & Yartys, V. (2017). The use of metal hydrides in fuel cell applications. Progress in Natural Science: Materials International, 27(1), 3-20. [CrossRef]

- Davids, M. W., Lototskyy, M., Malinowski, M., Van Schalkwyk, D., Parsons, A., Pasupathi, S., ... & Van Niekerk, T. (2019). Metal hydride hydrogen storage tank for light fuel cell vehicle. International Journal of Hydrogen Energy, 44(55), 29263-29272. [CrossRef]

- Smaragdakis, A., Kamenopoulos, S., & Tsoutsos, T. (2020). How risky is the introduction of fuel cell electric vehicles in a Mediterranean town?. International Journal of Hydrogen Energy, 45(35), 18075-18088. [CrossRef]

- Park, J., Yoo, Y., Ryu, J., & Lee, H. (2022). Study on the explosion of the hydrogen fuel tank of fuel cell electric vehicles in semi-enclosed spaces. Energies, 16(1), 241. [CrossRef]

- Shen, Y., Lv, H., Hu, Y., Li, J., Lan, H., & Zhang, C. (2023). Preliminary hazard identification for qualitative risk assessment on onboard hydrogen storage and supply systems of hydrogen fuel cell vehicles. Renewable Energy, 212, 834-854. [CrossRef]

- Hirose, K. (2010). Handbook of hydrogen storage: new materials for future energy storage. John Wiley & Sons.

- Durbin, D. J., & Malardier-Jugroot, C. (2013). Review of hydrogen storage techniques for on board vehicle applications. International journal of hydrogen energy, 38(34), 14595-14617. [CrossRef]

- Hassan, I. A., Ramadan, H. S., Saleh, M. A., & Hissel, D. (2021). Hydrogen storage technologies for stationary and mobile applications: Review, analysis and perspectives. Renewable and Sustainable Energy Reviews, 149, 111311. [CrossRef]

- Prigent, M. (1997). On board hydrogen generation for fuel cell powered electric cars. A review of various available techniques. Revue de l’Institut français du pétrole, 52(3), 349-360. [CrossRef]

- Avcı, A. K., Önsan, Z. İ., & Trimm, D. L. (2003). On-board hydrogen generation for fuel cell-powered vehicles: the use of methanol and propane. Topics in catalysis, 22, 359-367. [CrossRef]

- Bansal, R. C. (2017). Electric vehicles. In Handbook of automotive power electronics and motor drives (pp. 55-96). CRC Press.

- Why Electric Car Needs the High-Voltage Battery. How Do Electric Car Batteries Work. GO-TO U. https://go-tou.com/en/news/how-electric-car-batteries-work [Accessed online: 10/04/2024].

- High Voltage Vehicles: Why 800-Volts EVs are on the Rise. Engineering.com https://www.engineering.com/story/high-voltage-vehicles-why-800-volt-evs-are-on-the-rise [Accessed online: 10/04/2024].

- Electric Vehicle Motors: Battery and Supply Voltage. Tech Tips. Matsusada Precision. https://www.matsusada.com/column/ev-power.html [Accessed online: 10/04/2024].

- Kamamura, Atsuo., Miguchi, Yasuhiko., Setiadi, Hadi., Obara, Hidemine (2022) Survey of 99.9% Class Efficiency DC-AC Power Conversion and Technical Issues. Transactions on Electrical and Electronics Engineering (IEEJ). Institute of Electrical Engineers of Japan. Volume 18, Issue 1, pages 6-14. [CrossRef]

- Mikhaylov, Konstantin & Tervonen, Jouni & Fadeev, Dmitry. (2012). Development of Energy Efficiency Aware Applications Using Commercial Low Power Embedded Systems. 10.5772/38171.

- How much energy is wasted when converting DC power to AC and then back to DC?. Quora. https://www.quora.com/How-much-energy-is-wasted-when-converting-DC-power-to-AC-and-then-back-to-DC [Accessed online: 10/04/2024].

- Solar Photovoltaic Panel Sizes: A Complete Guide. Skills Training Course. https://www.skillstg.co.uk/blog/solar-photovoltaic-panel-sizes/#:~:text=Most%20residential%20solar%20panels%27%20standard,different%20levels%20of%20energy%20output. [Accessed online:11/04/2024].

- Solar Panels Dimensions. AIRIS Solutions. https://airisenergy.us/solar-panels-dimensions/#:~:text=The%20standard%20solar%20panel%20size,3.25%20feet%20by%205.5%20feet.&text=The%20average%2072-cell%20solar,60-cell%20standard%20size%20panels. [Accessed online: 11/4/2024].

- Passenger car roof area and curvature. Research Gate. https://www.researchgate.net/figure/Passenger-car-roof-area-and-curvature_fig3_349656294#:~:text=The%20roof%20area%20of%20an,for%20larger%20vehicles.%20... [Accessed online: 11/04/2024].

- Kim, Sehyeon & Holz, Markus & Park, Soojin & Yoon, Yongbeum & Cho, Eunchel & Yi, Junsin. (2021). Future Options for Lightweight Photovoltaic Modules in Electrical Passenger Cars. Sustainability. 13. 2532. [CrossRef]

- An Introduction to Solar Radiation. Muhammad Iqbal. Academic Press. 1983. ISBN: 978-0-12-373750-2. [CrossRef]

- Thomas, C.E. (Sandy) (2009) Fuel Cell and Battery Electric Vehicles Compared. Department of Energy (DOE). US. 3/27/2009. https://www.energy.gov/eere/fuelcells/articles/fuel-cell-and-battery-electric-vehicles-compared [Accessed online: 11/04/2024].

- Pethaiah, S. & Sadasivuni, Kishor kumar & Jayakumar, Arunkumar & Ponnamma, Deepalekshmi & Tiwary, Chandra & Sasikumar, Gangadharan. (2020). Methanol Electrolysis for Hydrogen Production Using Polymer Electrolyte Membrane: A Mini-Review. Energies. 13. [CrossRef]

- Armenta-Déu, C., Coulaud, T. (2023) Design of a Control System for Determining the Autonomy of Electric Vehicles. Journal of Mechatronics and Automation, Volume 9, Issue 2, pages 1-16.

- Kühlwein, Jörg (2016) Driving Resistances of Light-Duty Vehicles in Europe: Present Situation, Trends and Scenarios for 2025. The International Council on Clean Transportation (ICCT). Berlin.

- Cross Slope. Safety. Federal Highway Administration. U.S. Department Transportation. https://safety.fhwa.dot.gov/geometric/pubs/mitigationstrategies/chapter3/3_crossslope.cfm#:~:text=On%20high-speed%20roadways%2C%20normal,centerline%20not%20exceeding%204%20percent. [Accessed online: 11/04/2024].

- Carlier, Mathilde. Average speed in Europe’s most congested cities in 2017, based on congested level. Transportation & Logistics. Vehicles & Road Traffic. Statista. Posted on Apr. 20, 2022 https://www.statista.com/statistics/264703/average-speed-in-europes-15-most-congested-cities/ [Accessed online: 11/04/2024].

- Speed limits by country. Wikipedia. https://www.statista.com/statistics/264703/average-speed-in-europes-15-most-congested-cities/ [Accessed online: 11/04/2024].

- Ligth-duty Vehicle. Engine Testing. First Edition (2021) Science Direct. https://www.sciencedirect.com/topics/engineering/light-duty-vehicle [Accessed online: 11/04/2024].

- T. Hofman, C.H. Dai (2010) Energy Efficiency Analysis and Comparison of Transmission Technologies for an Electric Vehicle. Technische Universiteit Eindhoven (TU/e) Department of Mechanical Engineering, Control Systems Technology Group, PO BOX 512, 5600 MB Eindhoven, The Netherlands https://www.iri.upc.edu/people/riera/VPPC10/vppc2010.univ-lille1.fr/uploads/PDF/papers/RT4/95-43218-final.pdf [Accessed online: 07/04/2024].

- Boloor, Madhur; Valderrama, Patricia; Statler, Ada; Garcia, Samuel What are electric vehicles? Efficient, for one. Electric Vehicle Basics. Posted on July31, 2019 https://www.nrdc.org/bio/madhur-boloor/electric-vehicle-basics#:~:text=Electric%20motors%20makes%20vehicles%20substantially,for%20a%20gas%20combustion%20engine. [Accessed online: 07/04/2024].

- Lacock, Stephan, Armand André du Plessis, and Marthinus Johannes Booysen. 2023. “Electric Vehicle Drivetrain Efficiency and the Multi-Speed Transmission Question” World Electric Vehicle Journal 14, no. 12: 342. [CrossRef]

- Energy losses in EV drivetrain. Department of Energy (DOE). https://www.google.com/search?client=opera&q=efficiency+of+an+electric+motor+transmission&sourceid=opera&ie=UTF-8&oe=UTF-8#ip=1 [Accessed online: 07/04/2024].

- Drivetrain losses (efficiency). X-engineer. https://x-engineer.org/drivetrain-losses-efficiency/#:~:text=Overall%20efficiency%20of%20the%20drivetrain&text=This%20means%20that%20around%2015.9,which%20have%20a%20central%20differential. [Accessed online: 07/04/2024].

- BU-808c: Coulombic and Energy Efficiency with the Battery. Battery University. https://batteryuniversity.com/article/bu-808c-coulombic-and-energy-efficiency-with-the-battery [Accessed online: 07/04/2024].

- Armenta-Déu, C., Boucheix, B. (2023) Evaluation of Lithium-Ion Battery Performance under variable climatic conditions: Influence on the Driving Range of Electric Vehicles. Future Transportation 2023, 3(2), 535-551. [CrossRef]

- WLTP. https://es.wikipedia.org/wiki/WLTP [Accessed online: 11/04/2024].

- Jacobs-Crisioni, Chris & Kompil, Mert & Baranzelli, Claudia & Lavalle, Carlo. (2015). Indicators of urban form and sustainable urban transport: Introducing simulation-based indicators for the LUISA modelling platform. [CrossRef]

- Armenta-Déu, C., Carriquiry, J.P., Guzmán, S. (2019) Capacity correction factor for Li-ion batteries: Influence of the discharge rate. Journal of Energy Storage, Volume 25, October 2019, 100839. [CrossRef]

- Handbook of Fuel Cells: Fundamentals, Technology, Applications, 4 Volume Set. Wolf Vielstich (Editor), Arnold Lamm (Editor), Hubert A. Gasteiger (Editor). John Wiley and Sons. May 2003. New York, NY, USA. ISBN: 978-0-471-49926-8.

- Methanol Physical Properties. Centiner Engineer Corporation. https://www.cetinerengineering.com/Properties.htm [Accessed online: 14/04/2024].

- Properties of water. Wikipedia. https://en.wikipedia.org/wiki/Properties_of_water [Accessed online: 14/04/2024].

- Armenta-Déu, C. (2024) Battery Management for Improved Performance in Hybrid Electric Vehicles. Preprints.org https://www.preprints.org/manuscript/202407.0747.v1. [CrossRef]

- Kruse, Bjørnar. ”Hydrogen Status og muligheter” (PDF). bellona.org/. Bellona Norway. Retrieved 22 April 2018.

- Bernholz, Jan (September 13, 2018). ”RWE’s former, current and possible future energy storage applications” (PDF). RWE. p. 10.

- “ITM – Hydrogen Refuelling Infrastructure – February 2017” (PDF). level-network.com. Archived (PDF) from the original on 17 April 2018. Retrieved 17 April 2018.

- “Cost reduction and performance increase of PEM electrolysers” (PDF). www.fch.europa.eu. Fuel Cells and Hydrogen Joint Undertaking. Retrieved 17 April 2018.

- Useable battery capacity of full electric vehicles. Electric Vehicle Database. Useable battery capacity of full electric vehicles cheatsheet - EV Database (ev-database.org) [Accessed online: 15/04/2024].

- What Is The Average Size Of A Car Gas Tank?”. www.mechanicbase.com. 19 September 2022. Retrieved 4 January 2023 [Accessed online: 16/04/2024].

- What is the Capacity of a Car’s Gas Tank? https://www.way.com/blog/car-gas-tank-capacity/ [Accessed online: 15/04/2024].

- Energy consumption of full electric vehicles. Electric Vehicle Database. https://ev-database.org/cheatsheet/energy-consumption-electric-car [Accessed online: 14/04/2024].

- Energy consumption and driving range of an electric vehicle. https://www.kbc.be/corporate/en/mobility/energy-consumption-electric-car.html [Accessed online: 11/04/2024].

- Mark Singer, Caley Johnson, Edward Rose, Erin Nobler, and Luna Hoopes. Electric Vehicle Efficiency Ratios for Light-Duty Vehicles Registered in the United States. National Renewable Energy Laboratory (NREL). Technical Report NREL/TP-5400-84631 March 2023.

- Mark Singer, Caley Johnson, Edward Rose, Erin Nobler, and Luna Hoopes. Electric Vehicle Efficiency Ratios for Light-Duty Vehicles Registered in the United States. National Renewable Energy Laboratory (NREL). Technical Report NREL/TP-5400-84631 March 2023.

- Armenta-Déu, C., Rincón, C. (2024) Reduction of GHG Emissions: Air Quality Improvement in Urban Areas. Current Research in Environmental Science and Ecology Letters, Volume 1, Issue 1, pages 1-16.

- Armenta-Déu, C., Cortés, H. (2022) Advanced Method to Calculate Real Driving Range for Electric Vehicles. Journal of Automobile Engineering and Applications, Volume 9, Issue 3, pages 1-19.

- Armenta-Déu, C. (2024) Improving Sustainability in Urban and Road Transportation: Control Device for Dual Battery Block and Fuel Cell Hybrid Power System for Electric Vehicles, Sustainability 16(5), 2110 https://www.mdpi.com/2071-1050/16/5/2110/pdf.

- Toyota. https://www.toyota.com [Accessed online: 16/04/2024].

- KIA. https://www.kia.com/es/ [Accessed online: 16/04/2024].

- Jennifer Kurtz, Sam Sprik, Genevieve Saur, and Shaun Onorato. Fuel Cell Electric Vehicle Driving and Fueling Behavior. National Renewable Energy Laboratory (NREL). Technical Report NREL/TP-5400-73010 March 2019.

- Hydrogen Fuel Cell Electric Cars. DriveClean. California Air Resources Board. ca.gov https://driveclean.ca.gov/hydrogen-fuel-cell#:~:text=Fueling,a%20standard%20car%27s%20gas%20tank [Accessed online: 16/04/2024].

- Electric car mileage range. https://www.resultsdistributor.com/web?gad_source=5&gclid=EAIaIQobChMIhNL3lY7HhQMVsEtBAh2lhQDmEAAYASAAEgL3ovD_BwE&o=1670601&q=electric+car+mileage+range&qo=semQuery&ag=fw59&an=google_s&tt=rmd&ad=semA&akid=1000000261rdb162625861411kwd-302323592798c20881938655 [Accessed online: 16/04/2024].

- Find Electric Car Mileage Range https://www.discovertoday.co/web?gad_source=5&gclid=EAIaIQobChMI9_fi247HhQMVD0RBAh0hHQu4EAAYAiAAEgKzSPD_BwE&o=1669776&q=electric+car+mileage+range&qo=semQuery&ag=fw&an=google_s&tt=rmd&ad=semA&akid=1000000104dto159233523724kwd-302323592798c20923517895 [Accessed online: 16/04/2024].

- Esmaeili Shayan, M., Najafi, G., Ghobadian, B., Gorjian, S., Mazlan, M., Samami, M., & Shabanzadeh, A. (2022). Flexible photovoltaic system on non-conventional surfaces: a techno-economic analysis. Sustainability, 14(6), 3566. [CrossRef]

- Gambhir, A., Sandwell, P., & Nelson, J. (2016). The future costs of OPV–A bottom-up model of material and manufacturing costs with uncertainty analysis. Solar Energy Materials and Solar Cells, 156, 49-58. [CrossRef]

- Hegedus, S. (2006). Thin film solar modules: the low cost, high throughput and versatile alternative to Si wafers. Progress in photovoltaics: research and applications, 14(5), 393-411. [CrossRef]

- Li, Q., & Zanelli, A. (2021). A review on fabrication and applications of textile envelope integrated flexible photovoltaic systems. Renewable and Sustainable Energy Reviews, 139, 110678. [CrossRef]

- Thomas, C. E. (2009). Fuel cell and battery electric vehicles compared. international journal of hydrogen energy, 34(15), 6005-6020. [CrossRef]

- Offer, G. J., Howey, D., Contestabile, M., Clague, R., & Brandon, N. P. (2010). Comparative analysis of battery electric, hydrogen fuel cell and hybrid vehicles in a future sustainable road transport system. Energy policy, 38(1), 24-29. [CrossRef]

- Ruffini, E., & Wei, M. (2018). Future costs of fuel cell electric vehicles in California using a learning rate approach. Energy, 150, 329-341. [CrossRef]

- Bekel, K., & Pauliuk, S. (2019). Prospective cost and environmental impact assessment of battery and fuel cell electric vehicles in Germany. The International Journal of Life Cycle Assessment, 24, 2220-2237. [CrossRef]

- Battery and fuel cell future cost comparison. Technology Trends Team. Advanced Propulsion Centre. UK. March 2023. https://www.apcuk.co.uk/wp-content/uploads/2023/02/Battery-and-Fuel-Cell-Cost-Comparison-report.pdf [Accessed online: 17/04/2024].

- Charles Kubert. Fuel Cell Technology. A Clean, Reliable Source for Stationary Power. Clean Energy States Alliance (CESA). May 2010. https://www.cesa.org/wp-content/uploads/CESA-fuelcelltechnology-may2010.pdf [Accessed online: 17/04/2024].

- 8 Types of Fuel Cell by Price Point. Horizon Educational. https://www.horizoneducational.com/8-types-of-fuel-cell-by-price-point/ [Accessed online: 16/04/2024].

- Manufacturing Cost Analysis of PEM Fuel Cell Systems for 5- and 10-kW Backup Power Applications. Battelle Memorial Institute. US. Department of Energy (DOE). October 2016. https://www.energy.gov/eere/fuelcells/articles/manufacturing-cost-analysis-pem-fuel-cell-systems-5-and-10-kw-backup-power [Accessed online: 17/04/2024].

- Electric vehicles and batteries. The Economist. Dec. 23rd, 2021. https://www.economist.com/espressochart/2021-12-23?utm_medium=cpc.adword.pd&utm_source=google&ppccampaignID=18151738051&ppcadID=&utm_campaign=a.22brand_pmax&utm_content=conversion.direct-response.anonymous&gad_source=1&gclid=CjwKCAjww_iwBhApEiwAuG6ccMD66O_YH9jvynEp8Y3gic1OrB-w6MJdJMR7CTfnDcDbuY_38FA9GRoCzzQQAvD_BwE&gclsrc=aw.ds [Accessed online: 17/04/2024].

- Trends in batteries. Global EV Outlook 2023. International Energy Agency (IEA). https://www.iea.org/reports/global-ev-outlook-2023/trends-in-batteries [Accessed online: 17/04/2024].

- What’s the lifecycle of an electric vehicle battery?. Drax. Posted on 19th August 2022. What’s the lifecycle of an electric vehicle battery? | Drax [Accessed online: 17/04/2024].

- Electricity price statistics. Eurostat. Statistics Explained. Updated in October 2023. Electricity price statistics - Statistics Explained (europa.eu) [Accessed online: 17/04/2024].

- Average retail electricity prices in the United States in selected years from 1990 to 2023. Energy & Environment. Energy. Statista. Updated in March 2024. Historical electricity prices U.S. 1990-2023 | Statista [Accessed online: 17/04/2024].

| Photovoltaic System | Battery | Fuel Cell | |||

|---|---|---|---|---|---|

| Power (kW) | Energy (kWh) | Power (kW) | Energy (kWh) | Power (kW) | Energy (kWh) |

| 1.152 | 5.2 | 92.3 | 6.27 | 15.5 | 14.27 |

| Topology | Standard Energy Consumption Rate | Reduced Energy Consumption Rate | ||

|---|---|---|---|---|

| Maximum | Average | Minimum | ||

| Battery only | 317.1 | 275.7 | 248.1 | 324.4 |

| Fuel cell only | 640.0 | 520.0 | 480.0 | 528.7 |

| Battery + Fuel cell | n.a. | n.a. | n.a. | 728.5 |

| Energy consumption rate | |||

|---|---|---|---|

| Optimum | Average | Minimum | |

| Prototype | 728.5 | 728.5 | 728.5 |

| Simulated | 601.3 | 490.7 | 452.2 |

| Gain | 127.2 | 237.8 | 276.3 |

| Cost | ||

|---|---|---|

| System | USD | € |

| Lithium battery | 7170.0 | 6750.8 |

| Fuel Cell | 9737.5 | 9168.1 |

| Hybrid | 8311.8 | 7825.8 |

| Cost | ||

|---|---|---|

| System | USD | € |

| Lithium battery | 8526.4 | 8984.7 |

| Hybrid | 8311.8 | 7825.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).