1. Introduction

1.1. Background

In 2022, the building and construction sector accounted for 34% of the global energy demand and 37% of the energy and process-related carbon emissions; despite a reduction of energy intensity, both those fractions increased by around 1% compared with 2021 because of the sheer increase in the number of buildings worldwide [

1]. As a significant part of the problem, the sector is crucial to achieving the decarbonization goals set by several countries and entities for the middle of this century. The European Union pledged to become climate-neutral by 2050 in its Green Deal [

2], writing into law the target and the intermediate steps in its European Climate Law [

3]. While solutions to achieve both carbon-neutral new buildings and a decarbonized building stock are already available [

4], the gap between the current state of emissions and the desired decarbonization path is significant and additional efforts are required to remain on track to meet the 2030 interim milestone and the 2050 goal [

1].

In this trajectory towards decarbonization, it is necessary to acknowledge that climate change is due to past emissions generated by developed countries, and that, at the same time, huge quantities of new building materials will be needed in the medium term to compensate for the housing deficit in the Global South, as well as for the construction of new infrastructure, much of which consists of carbon-intensive materials such as cement, steel and aluminum [

5]. It is therefore fair to consider that developed countries should not have a carbon budget to spend from now to 2050, and that they should rapidly transition to decarbonized practices together with additional investments in developing and promoting carbon capture and storage (CCS) technologies. Within this framework, new construction in Global North countries should be designed according to zero carbon standards [

6].

Radical and quick actions are required to correct the current trend, acting on the causes of emissions from the construction sector. Whereas in the past, emissions from the use, heating and/or cooling of buildings (so-called operational emissions) were dominant in the life cycle, their contribution has progressively become less relevant today, at least in those countries where increasingly stringent energy-saving requirements have been introduced [

7]. In contrast, material-related specific emissions, measured in kgCO

2-eq/kg or kgCO

2-eq/m

3, have not seen significant reductions over the years, other than those indirectly related to the decarbonization of the energy grid, and they are responsible of the “carbon spike”, a peak of carbon emission which occurs at the early stage of the building process [

8]. Reducing emissions for the production of materials is in fact more complex than containing operational emissions, where it is often sufficient to increase the level of thermal insulation of the building envelope and generate thermal energy with energy-efficient systems, possibly powered by renewable energy [

9]. At the same time, however, increasing the attention to the careful selection of materials opens opportunities to use buildings as carbon storage [

10], as repositories of materials to be reused in the future, or even as catalysts to reactivate a neighborhoods’ social and economic networks [

11].

Therefore, to achieve the goal of a decarbonized construction sector, one possible option is the change of the current “materials diet” [

6]. The most reasonable option implies that new buildings should be carbon neutral at every stage of the life cycle, i.e., zero net emissions and zero impact on emissions from building materials. A shift towards bio-based materials is needed to reduce the carbon intensity of materials processing, store biogenic CO

2 in the building elements, and quickly offset the initial emission through carbon restoration in soils [

12]. Bio-based materials are not only renewable in nature, but they naturally capture carbon dioxide from the atmosphere as they grow; the sequestered CO

2 is then stored as biogenic carbon during their use as a building product, with positive effects on the Earth’s climate. This effect is particularly pronounced if the biogenic material regenerates rapidly in the soil, e.g., through the regrowth of forests or plantations. The delayed emission of carbon previously stored in fast-growing biogenic materials – typically grass, such as straw, hemp, cane, bamboo, etc. – is completely captured by the regrowth of crops within a few years, which makes these materials more effective in mitigating climate change than wood products, which instead require long regrowth periods. Biogenic materials can be used as innovative components in different building elements; their availability and type are related to the specific geographical context. Thanks to their properties, bio-based materials must be part of the composition of carbon-neutral buildings, in a balanced quantity, in order to compensate for the positive emissions from high CO

2-emitting materials, e.g., cement and concrete, which are required in any case for the foundations and basements of buildings [

13].

As one of the global initiatives to control the emissions from the construction sector, the C40 global network of ninety-six among the world’s leading cities is committed to sharing best practices and implementing collaborative actions to cut their fair share of emissions in half by 2030 [

14]. The Reinventing Cities competition was established in 2017 by the C40 group to stimulate sustainable development and promote replicable models of low- or zero-carbon urban regeneration projects [

15], inviting professional, multi-disciplinary teams to submit proposals for underutilized sites in several cities worldwide [

16,

17]. The 2020 edition of the global competition included, among the other sites, several brownfield areas in Milan, Italy, which the municipality intended to regenerate as part of its city development plan to 2030. The goal of a low- or zero-carbon development, with a significant limitation of the onsite emissions, appears particularly important to a city which, for a combination of reasons, has one of the worst air quality indexes in Europe. This paper presents one of the proposals submitted for the site of the former Lambrate railway yard, now being decommissioned by the public rail network company, where a systematic methodology was applied to assess the impact of construction material selection on the achievement of the life cycle zero carbon target, comparing the design scenarios to the current construction standards and to existing carbon benchmarks.

1.2. Literature Review

While the need for the decarbonization of the building stock is evident, so far regulations have mostly focused on the limitation of operational energy; for example, the European Directive on the Energy Performance of Buildings (EPBD, 2010/31/UE) [

18] introduced the concept of Nearly Zero-Energy Buildings, but did not include any provision about the related carbon emissions, nor did it consider those deriving from other phases of the buildings’ life cycle, such as construction and demolition. The revision of the EPBD, that is currently in its final steps of formal adoption [

19], introduces, among other innovations, a new zero-emission standard for new buildings, requiring that all new residential and non-residential buildings have zero on-site emissions from fossil fuels, as of 1st January 2028 for publicly-owned buildings and as of 1st January 2030 for all other new buildings [

20].

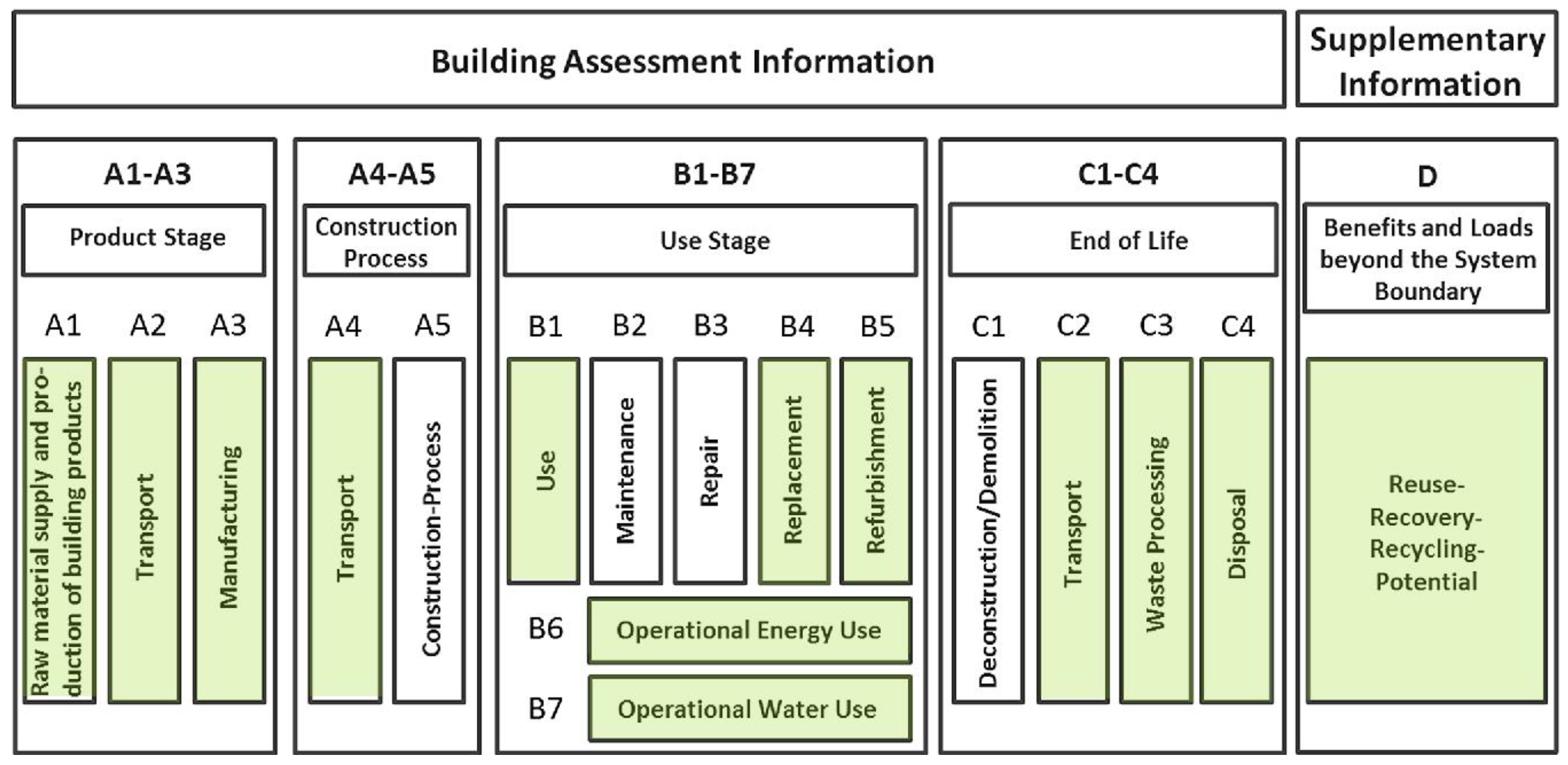

The mandatory part of the new version of the EPBD, however, still focuses exclusively on operational energy, while the whole life cycle emissions will have to be calculated only for information purposes. A more comprehensive approach to limit carbon emissions from the other phases of a building’s life cycle are typically included in green building rating systems [

21]; also, the European Commission’s framework for sustainable buildings, Level(s), includes greenhouse gas emissions along a building’s life cycle among its six macro-objectives [

22]. Conceived as an EU-wide system for assessing and reporting on the sustainability of buildings, the Level(s) framework adopts the Life cycle Global Warming Potential indicator (GWP, expressed in kgCO

2-eq) to provide information about the whole life carbon output as the design progresses.

The definition of numerical benchmarks at the European scale that would support mandatory or voluntary targets about the whole life carbon emissions of buildings has proven challenging, due to the large variability, among others, of climate (and therefore of operational energy needs), building type, and standard construction practices [

23]. Some targets to limit carbon emissions from the non-operational phases of a building’s life cycle have been introduced in recent years in some European countries [

24] but apply only in specific local contexts. To overcome, at least in part, these limitations, the “Carbon Heroes benchmark program” was launched a few years ago [

25]. The aim of the program is to set uniform embodied carbon emission benchmarks for common building types, based on the anonymized, verified data from thousands of buildings calculated through a standardized life cycle model. The results are reported in graphical forms, including a performance metric with seven bands (A to G from best to worst) equally distributed, and with the mean of results falling within band D; this scale can be used to assess the performance of any project against the Carbon Heroes benchmarks. A recent report published by the European Commission provides whole life carbon emission baselines for EU buildings through the modelling of building archetypes, as well as projections of emissions in 2050 according to three different scenarios [

26]. The study confirms the large variability of results; however, it also shows that the current best practice of low-carbon construction is already below the possible 2050 average for upfront embodied carbon. This suggests that even today there is a substantial potential to improve construction practices using available materials and strategies, and that low-carbon construction is already technically possible.

While Life Cycle Assessment (LCA) is now the standard methodology to estimate GWP values, among other environmental impacts, the assessment of biogenic carbon remains a point of contention [

27,

28]. Biogenic carbon is emitted to air as CO

2, CO or CH

4 as a result of the oxidation and/or reduction of biomass by means of its transformation or degradation (e.g., combustion, digestion, composting and landfilling). It can also be captured as CO

2 from the atmosphere through photosynthesis during biomass growth, a process commonly known as carbon sequestration [

29]. The main reason why it is often not considered in LCA [

30] has to do with the complex estimation of the time dependency of the cycles (emission-uptake) and their consequence on GWP values within standard “static” LCA analyses. Moreover, information about the real service life of building components, and the treatments of materials at their end of life, are difficult to predict at the time of design.

On the other hand, several studies stressed the importance of taking biogenic carbon into account. Bio-based products contain roughly 50% carbon in dry mass, creating an opportunity to store carbon in buildings constructed with biogenic materials (e.g., timber, hemp, straw, etc.) thanks to the uptake of carbon dioxide by its replacement via photosynthesis during the forest growth. In principle, this neutralizes the release of carbon from a biogenic product at the end of its life, leading the majority of LCA scholars and practitioners in the early 2000’s to use the “carbon neutral approach” when calculating biogenic carbon [

31]. The main criticism to this assumption is that it does not consider the timing of the carbon emissions and the influence of the rotation periods related to the biomass growth, i.e., when carbon is actually absorbed by the plants [

32]. Timber products (e.g., wood that has been processed into beams or planks) have a longer rotation period due to slow forest growth periods, so they cannot be considered as carbon neutral in a short time horizon. Conversely, fast-growing bio-based materials, such as straw and hemp, have a short rotation period and can provide an effective mitigation effect on carbon emissions by rapidly removing carbon from the atmosphere [

33]. The dynamic approach proposed by Levasseur et al. [

34] allows to take into account the different timing of emissions and uptake, allowing for a transparent assessment of biogenic construction materials, especially when long rotation species are used for products with an expected long service life [

35].

1.3. Scope of the Work

This paper introduces an integrated assessment method to identify a decarbonization strategy for achieving life cycle zero-carbon buildings, with a particular emphasis on the material selection process. The method is applied to the case study of the Scalo Lambrate district in Milan, Italy, developed as an entry for the 2020 edition of the C40 Reinventing Cities competition, where all carbon emissions, namely embodied, operational, maintenance and end-of-life, over the life cycle of the buildings are assessed.

2. Materials and Methods

2.1. General Framework

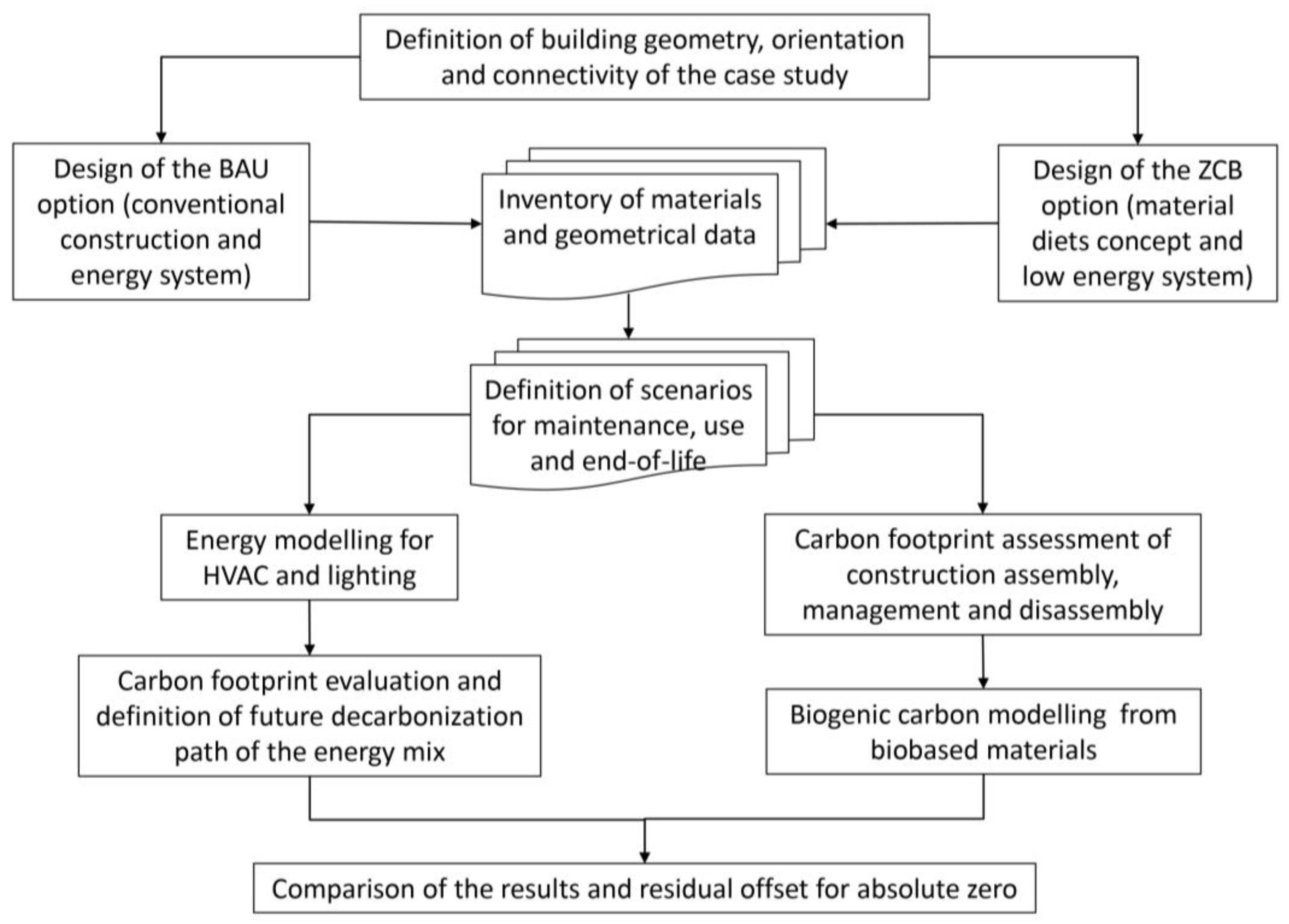

The methodology adopted is based on a comparative carbon footprint assessment applied to the case study of Scalo Lambrate in Milan, presented in

Section 2.2, which is aimed at identifying energy solutions and material combinations able to minimize both operational and embodied carbon over the life cycle of the building to achieve the absolute zero carbon target. As shown in

Figure 1, after the definition of the main geometrical proprieties of the building (shape, volume, number of floors, window to wall ratio, etc.), and connectivity, two main scenarios are identified for the selection of the construction solutions: i) Business As Usual (BAU), which considers conventional solutions for construction and energy systems according to the mandatory standard; ii) Zero-Carbon Building (ZCB), which is based on the identification of construction solutions and energy systems minimizing the embodied carbon from material processing and installation. The assessment of operational energy was based on dynamic energy models for both alternatives, providing the amount of primary energy required for heating, cooling, domestic hot water and all other electrical services during the use of the building as well as the renewable energy produced onsite by PV panels installed on the roofs.

An expected ordinary service life of 50 years was assumed for the BAU scenario, while for the ZCB alternative an extended service life of 100 years was assumed, with a refurbishment scenario including major renovation and material replacement at year 50. A linear regression method was applied to the carbon emission factor of the energy mix to estimate the sensitivity of future decarbonization strategies to energy generation, in line with the zero-carbon goal by 2050.

On the materials side, the main maintenance activities were estimated according to the expected service life of the selected construction products and the carbon emissions from replacement and waste processing were assessed through the LCA methodology. All benefits from urban greening and carbon storage in biobased materials, implemented in the ZCB design to reduce the carbon spike, were assessed and a semi-dynamic method adopted to include the contribution of biogenic carbon in the mitigation of the global warming potential (GWP). Finally, the residual CO2-eq values were defined and compensation instruments for carbon offset identified to reach the absolute-zero target.

2.2. Case Study Description

2.2.1. Background

The Scalo Lambrate project in Milan was developed as an entry for the fourth edition of the urban design and redevelopment competition called “Reinventing Cities”, organized by the C40 group. The goal of these competitions is to stimulate cities to build “ambitious” carbon-neutral developments in large urban areas that are currently abandoned or underused, promoting the cooperation between the public and private sectors and stimulating the implementation of design solutions (architecture, materials, construction technologies, etc.) that can be replicated in other projects on a global scale.

In order to achieve these objectives, the Reinventing Cities calls, organized in several cities at the same time, explicitly encourage the formation of multidisciplinary teams from the outset, with the capacity to represent the many necessary competences being part of the evaluation. The competition rules also require the appointment of three leading figures, representing the most important roles in the process: the architectural/urban designer, the environmental expert for sustainability and decarbonization, and the financial/real estate promoter.

An essential aspect, common to all the Reinventing Cities calls, are the “10 Climate Challenges”, covering different aspects of sustainability, and each measured through specific Key Performance Indicators (KPIs). Among these challenges, those with the most significant impact on carbon emissions are those on “Green buildings and energy efficiency” and on “Clean construction and building life cycle”, and to a lesser extent, or indirectly, those on “High-quality architecture and urban design”, “Low-carbon mobility”, “Climate resilience and adaptation” and “Green space, urban nature and biodiversity”. While the project had to take into account all the challenges and their complex interactions, this article mostly focuses on the first two.

2.2.2. Main Characteristics of the “Scalo Lambrate” Project

The Scalo Lambrate project proposed the urban regeneration of one of Milan’s former railway yards, used in the past for the handling and storage of goods in transit in the city. There are currently seven of these disused areas across the city, for a total surface of around 120 hectares that until recently remained essentially inaccessible to people, and that are now undergoing a complex process of rezoning and redevelopment that started back in 2007. The Lambrate railway yard is a 7-hectare area on Milan’s East side, where the city council stipulated that both private and public housing, student housing and a park should be realized. Besides the functional program, the design development also had to take into account several constraints related to the distance from live train tracks, to height limits due to the nearby airport, and to a requirement that 50% of the area should be dedicated to public green space.

To develop the proposal, a multidisciplinary team covering different areas of expertise was assembled. The three main figures requested by the competition were: Benedetta Tagliabue-EMBT Architects as the leader for architecture, Politecnico di Milano (Matteo Ruta of the Department of Architecture, Built Environment and Construction Engineering leading a team of twenty-five professors and researchers belonging to different departments) as the scientific expert for environmental aspects, and the Co-Inventing group as the developer. Several more experts, for a total of 170 consultants and stakeholders, took part in the design development, or were consulted during the process. To help validate decisions, building materials suppliers and construction companies were also part of the group. Part of the team – in particular the architect and the environmental expert – were already familiar with the area, since they took part in a previous workshop to develop visions about the transformation of Milan’s disused railway yards.

The team worked from January 2020 to March 2021 through an integrated design effort based on weekly meetings, where all the contact persons for each discipline discussed the advancement of the project and validated decisions based on technical and scientific aspects.

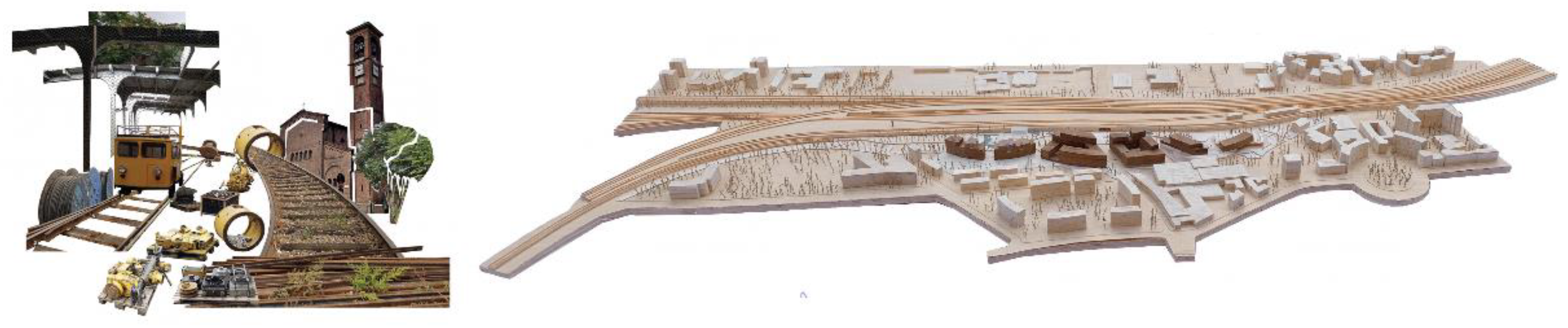

The plot, which is narrow and long, is characterized by a north-south orientation. The project developed from a focus on the public space, predominantly located between the high railway embankment and the new buildings, to create four new semi-circular public squares, with different functions, which also gave them their names: “railway”, “entertainment”, “water” and “flowers”. The architecture of the new buildings and their layout aim to reconnect the fabric of the former industrial district of Lambrate, characterized by disused factories and a few dwellings, with the rest of the city, also by connecting new and existing greenery, opening up new paths and viewpoints (

Figure 2).

Since the area is empty, the proposed buildings are all new; the only existing building on the site, a former warehouse building, was however preserved and integrated in the design as a memory of the district’s industrial past, but also to conserve resources.

Overall, the case study includes four buildings with a crescent layout, with different functions. Starting from the north, a first building, integrated with the preserved building, is a hostel, which is particularly useful since the neighborhood has a strong presence of students due to its proximity to two important universities. The second building is a student dormitory, and has an internal courtyard organization, which mitigates the climate and takes up a typically Milanese typology. The third building, also with a courtyard, is social housing. Finally, the fourth building, consisting of two separate single-story volumes, are other apartment buildings for the private market (

Figure 3).

All the buildings overlook green spaces and the new four squares or courtyards. The materials and colors used were chosen to integrate with both the neighborhood and the city of Milan. There was a desire to create diversified spaces, in terms of the size of the dwellings and also with different internal heights, to encourage the presence of different users, in terms of age and household composition (

Figure 4).

2.3. Construction System and Material Balance for Carbon Mitigation

2.3.1. Material Diets for Zero-Carbon Building

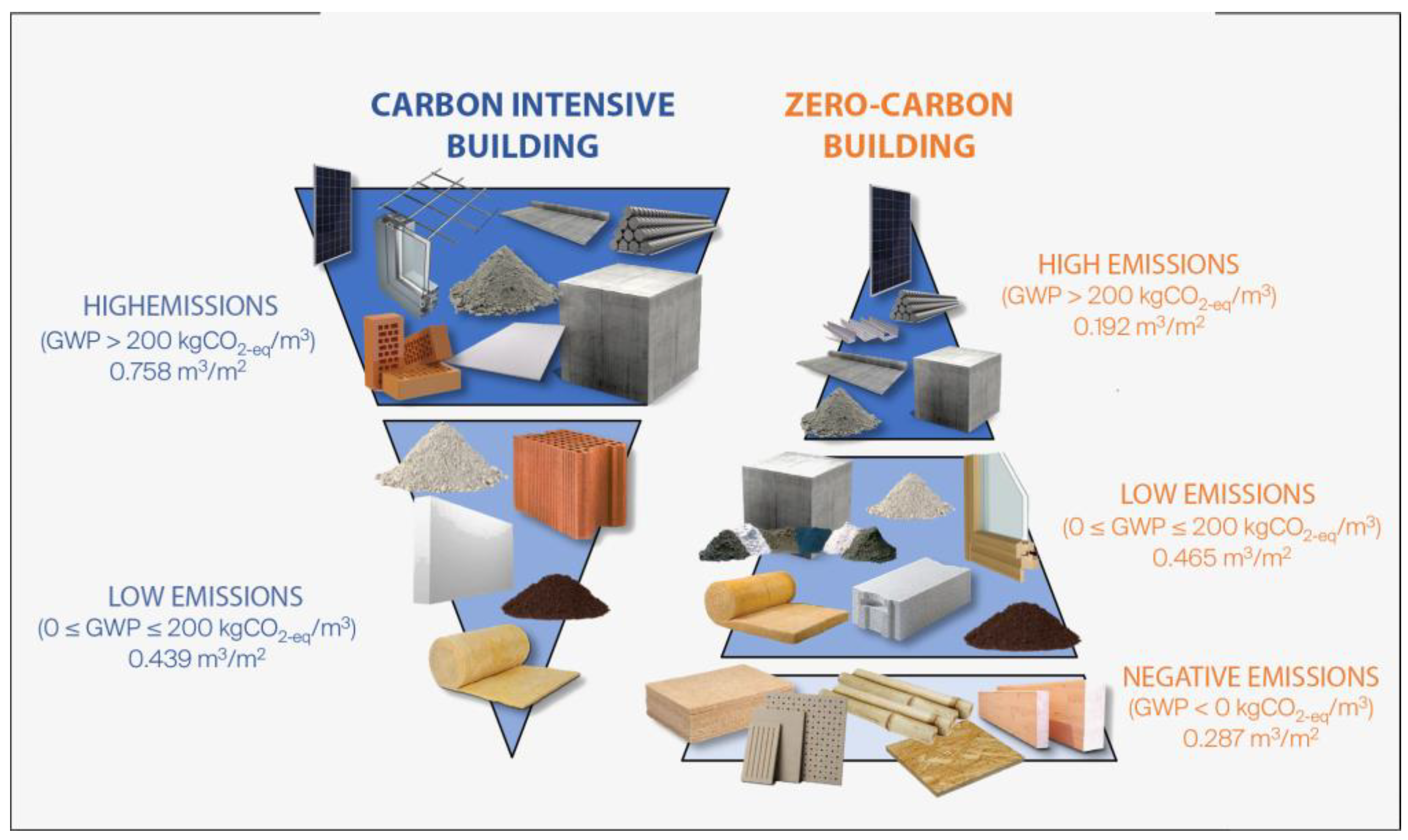

In ordinary buildings under a conventional business-as-usual scenario, a large amount of carbon intensive materials is used for construction, while the space for accommodating carbon-negative solutions, i.e., renewable materials able to restore the carbon in the land, e.g., wood, hemp, straw, etc., is limited to finishing and other marginal components. The resulting balance of material in a BAU scenario, as shown in

Figure 5, generates a clear hierarchy where at the top the carbon intensive materials take the major space, while the carbon-negative ones, able to regenerate the climate, take a marginal space. New material diets, where the amount of biobased solutions is increased in the building, allow to reverse the pyramid, generating a new hierarchy where carbon intensive materials are limited to components where no alternatives are possible (e.g., foundations, windows, PV panels, waterproof, etc.) and the biobased solutions are wide spread all over the rest of the building, able to compensate the positive carbon emissions and ideally achieve a zero-carbon target [

13].

Thus, the selection of the construction materials for the low-carbon building alternative was inspired by this material diets concept, which involves the identification of locally available negative carbon solutions, especially fast-growing biobased materials, able of removing CO

2 with the rapid regrowth of biomass in plantations [

36], to be largely adopted in the different building components.

2.3.2. Load-Bearing Structure

Usually, the load-bearing structure accounts for a significant share (around 40 percent) of the emissions from a building, because of the production of materials and its construction [

37]. Considering the whole structural system, the above-ground load-bearing components, such as floors, columns, and beams, constitute roughly 80-85% of the total material volumes [

38]. Consequently, considering the floor area of the buildings, the choice of the construction solution for the horizontal slabs is crucial for the reduction of the overall carbon footprint. In the selection process, a multi-criteria decision model was used considering the emission factor of each structural material, the duration of installation, the fire safety, and five S-KPIs - Structural Key Performance Indexes: i) HPI - Height Performance Index; ii) WPI - Weight Performance Index; iii) SPI - Span Performance Index; iv) CPI - Cost Performance Index; v) OPI: Overall Performance Index. As result, a mixed wood-concrete solution was selected, providing the required stiffness to respond to seismic stresses [

39] and significantly reducing the carbon footprint of the structure [

40]. Moreover, this structural solution allows to avoid the installation of suspended ceilings by keeping an exposed wood finish, resulting in additional material and carbon savings and reduced risk of indoor air pollution [

41]. Moreover, this construction system is suitable for covering large spans with a regular structural grid, allowing a flexible layout in case of future changes to the configuration of interior spaces.

Underground spaces were limited by design to minimize the mass of concrete used in the basement; slopes and appropriate landscaping, in particular, limited the extension of perimeter walls below grade. Similarly, the adoption of a system of basins and connecting channels for the collection and reuse of the water for greening and firefighting allowed to avoid the use of conventional underground concrete tanks for water storage. For all underground load-bearing elements, a large use of low-carbon concrete was assumed, based on the addition in the mixture of blended cement binders with low clinker content, which can decrease the carbon footprint by almost 40% compared to an ordinary Portland cement [

42]. The external elements, such as balconies, could not instead be built out of the mixed wood-concrete system described above; therefore, a slab solution with lightening elements was adopted, reducing the amount of material required by 18% compared to a traditional concrete slab. The use of this solution also ensures durability and reliability of mechanical performance over time, especially considering the outdoor exposure of those elements for an extended service life up to 100 years.

2.3.3. Building Envelope

For the envelope, a solid construction solution was selected in order to provide thermal storage, and therefore an effective dynamic control of the inbound energy flow during summer, in addition to a higher thermal resistance than the standard requires. Thus, the low carbon solution for the exterior walls consists of autoclaved aerated concrete blocks with the addition of a wood fiber insulation layer, storing carbon during the service life of the building. All leveling screeds used for the horizontal slabs are made of loose recycled hemp fibers, providing additional carbon storage.

2.3.4. Internal Partitions

On the contrary, lightweight construction solutions were preferred for the vertical internal partitions, in order to limit the extra-loads on the structures. The construction system consists of a modular, multi-layer drywall structure with timber frames and rigid panels made of recycled paper. Such a construction solution is extremely versatile, allowing different layout configuration to meet future living and working needs, which will inevitably change over an extended lifespan of 100 years. Thus, dynamic scenarios were assumed with the reconfiguration of the interior partitions while keeping the existing load-bearing structure intact. Thus, the embedded carbon in the load-bearing structure is preserved, resulting in substantial emissions savings due to demolition and reconstruction [

43]. In the definition of the interior elements, the principles of Design for Deconstruction (DfD) were taken into account to reduce the disturbance to the users. The materialization of this technological scenario within the project paves the way for industrial mass production of prefabricated components for interior elements, which can be used (and reused) for different functions and periods [

44]. Industrial production of components generates a major advantage in terms of environmental footprint, both from the production and the retrofit/replacement phases. Moreover, compared to other traditional construction solutions, they provide a fast installation, better integration of mechanical, electrical, and plumbing systems, reduced amount of waste, and higher safety during execution of onsite construction works. At the end of the service life, the modules can be easily decommissioned by disassembling the prefabricated elements, avoiding invasive demolition operations with consequential better management of the waste.

2.4. Material Processing and Transport

In the production phase (A1-3), the main processes to produce the main building materials used in the two configurations, carbon intensive building and zero-carbon building, were modeled. Secondary production data contained in the ecoinvent 3.8 database [

49] were considered for both scenarios and modelled within the LCA software SimaPro 9 [

50]. All processes used are reported in

Appendix A,

Table A1 for BAU and

Table A2 for ZCB scenario. The processes related to the innovative materials used in ZCB configuration, namely the laminated bamboo used as external cladding, the low-emission concrete, and the low-carbon stabilized earthen wattle used for external pavement of the park, are not included in the ecoinvent database; therefore, these were specifically modeled in SimaPro or obtained from EPDs or other sources, as in the case of the bamboo façade for which the reference was taken from INBAR [

51].

The transport phase was modeled considering a short-haul supply of materials, with a maximum distance traveled of 50 km, an assumption supported by the site’s proximity to the main distribution centers for building materials in the Milan hinterland. The transport mode was considered entirely by road according to the “Transport, freight, lorry 16-32 metric ton, EURO4” process of ecoinvent. All processes were considered according to the cut-off by classification allocation, and the classification adopted in the model is unit process (U).

2.5. Use of the Building and Maintenance

To achieve a very good energy performance during the use stage, the guiding principle in the design of Scalo Lambrate was to combine a high efficiency of building envelope solutions and mechanical systems with a significant energy production from renewable energy sources available on site. The adopted approach followed a consequential order of priority: i) passive solutions about orientation, massing and window to wall ratio; ii) appropriate technologies for construction elements and mechanical systems; iii) active systems for the production of energy from renewable sources, mainly located on the roof surfaces. The underlying ideas was that, thanks to the design choices of “i” and “ii”, it would be possible to cover most of the limited energy needs of a typical year through the renewable energy available locally, considering the practical limitations deriving from the architectural design (iii).

Since the site was elongated in the North-South direction, it was not possible to rely widely on passive solar gains for the winter period; therefore, the volumes are quite compact and with relatively small articulations to reduce heat losses through the envelope. The overall window to wall ratio has also been carefully controlled to limit heat losses and gains on the East and West fronts; moreover, the long Western facades, receiving a lot of solar radiation during summer afternoons, present shading devices and loggias to reduce the risk of overheating.

The thermal resistance of the building envelope (walls, windows and roofs) goes beyond the standard requirements of Italian regulation; in particular, the U-value of walls is 0.15 W/m2K (standard requirement: 0.26 W/m2K); the U-value of transparent elements (low-e insulating glazing) is instead 1.3 W/m2K (standard requirement: 1.4 W/m2K), with g-value below 0.3 including the shading devices.

To model the use and maintenance phase, the calculated operational energy needs were considered. Specifically, both the estimated annual electricity consumption to cover heat (B6), DHW (B7) and use (B1) needs, and the estimated annual production of the photovoltaic system installed on the roof and operational during the first 30 years of the district’s life were taken into account. An initial conversion factor (fc,p) of 0.432 kgCO2-eq/kWh for primary energy consumption from electrical sources and a conversion coefficient (fc,PV) of 0.081 kgCO2-eq/kWh for on-site electricity generation from solar sources were considered for estimating the related operational emissions. A linear decreasing function of the coefficient fc,p was also implemented in order to model a constant decarbonization of the electric grid to arrive at carbon-free power from the grid by 2050.

Modeling of module B4, on the other hand, was based on the assumption of replacement cycles of worn components to restore the expected performance. These included all interior wall and ceiling finishes, with repainting all surfaces with two coats of acrylic paint every 10 years; interior/exterior flooring and façade finishes, with replacement cycles of 25 years; and fixtures, assumed with a replacement cycle of 30 years. The photovoltaic system installed in the roofs, on the other hand, is removed 30 years after installation and no longer reinstalled, since complete decarbonization of electricity from the grid is assumed. Finally, for the ZCB scenario only, a deep retrofit is considered after 50 years from the construction in order to extend the useful life of the building by additional 50 years. This involves the replacement of the ETICS system, i.e., the insulation and exterior finish, and the ventilated facades, as well as the replacement and rehabilitation of all plumbing components, interior finishes, and vertical partition elements, with the possible reconfiguration of the interior room layout, thanks to the use of lightweight drywall systems.

2.6. End-of-Life and Final Disposal

The end-of-life of the buildings was assumed to be extended to 100 years for the ZCB configuration, with recycling of the waste produced as a result of selective demolition. In contrast, a partially selective demolition was assumed for the BAU configuration after 50 years of service life, with landfilling of all mineral components and recycling of reinforcement steel only. For all wood-based components, and in general biogenic material in the ZCB configuration, incineration with energy recovery was considered as reference scenario, while for all metal parts (steel rebars for concrete reinforcement and cold-formed aluminum profiles for the interior partition substructures) a recycling process with 100% efficiency was assumed. All GWP 100-year end-of-life values for each process are shown in

Appendix A,

Table A1 for BAU and

Table A2 for ZCB scenario.

2.7. Biogenic Carbon Accounting from Carbon Uptake and Storage

In Module D, all environmental benefits related to waste treatment and CO

2 sequestration related to carbon storage in building components and to vegetation planted in the urban park were accounted. Specifically, for storage calculations in wood-based and bamboo products, a carbon content of 50%of the dry biomass was assumed, with 20% moisture content for structural components and interior finishes, 25% for exterior finishes, and 10% for insulation fibers. All in-place densities were assumed from the values reported in ecoinvent 3.8 database, EPDs, and INBAR report [

51].

3. Results

3.1. Operational Carbon

Thanks to the design choices, the calculated thermal energy needs are on average around 50% lower than the reference scenario (

Table 1); to put this result in perspective, it is necessary to consider that the BAU benchmark was based on the same floor area and arrangement of volumes, but adopting standard values for the thermal performances of building components, the efficiency of mechanical systems and the contribution from renewable energy sources. These values are based on the national implementation of the EPBD 2010/31/EU as part of the Italian definition of Nearly Zero-Energy Building.

The reduced thermal loads make it possible to use heat pumps for all heating and cooling needs and the production of domestic hot water. While the specific distribution and control systems vary according to the function of each building, hot and cold water is always produced by water-to-water heat pumps exploiting groundwater as a heat sink: this way, it was possible to completely avoid the combustion of fossil fuels across the project site.

Building automation solutions and strategies to engage users in energy saving behaviors were also designed to improve the overall efficiency of the district, which runs entirely on electricity.

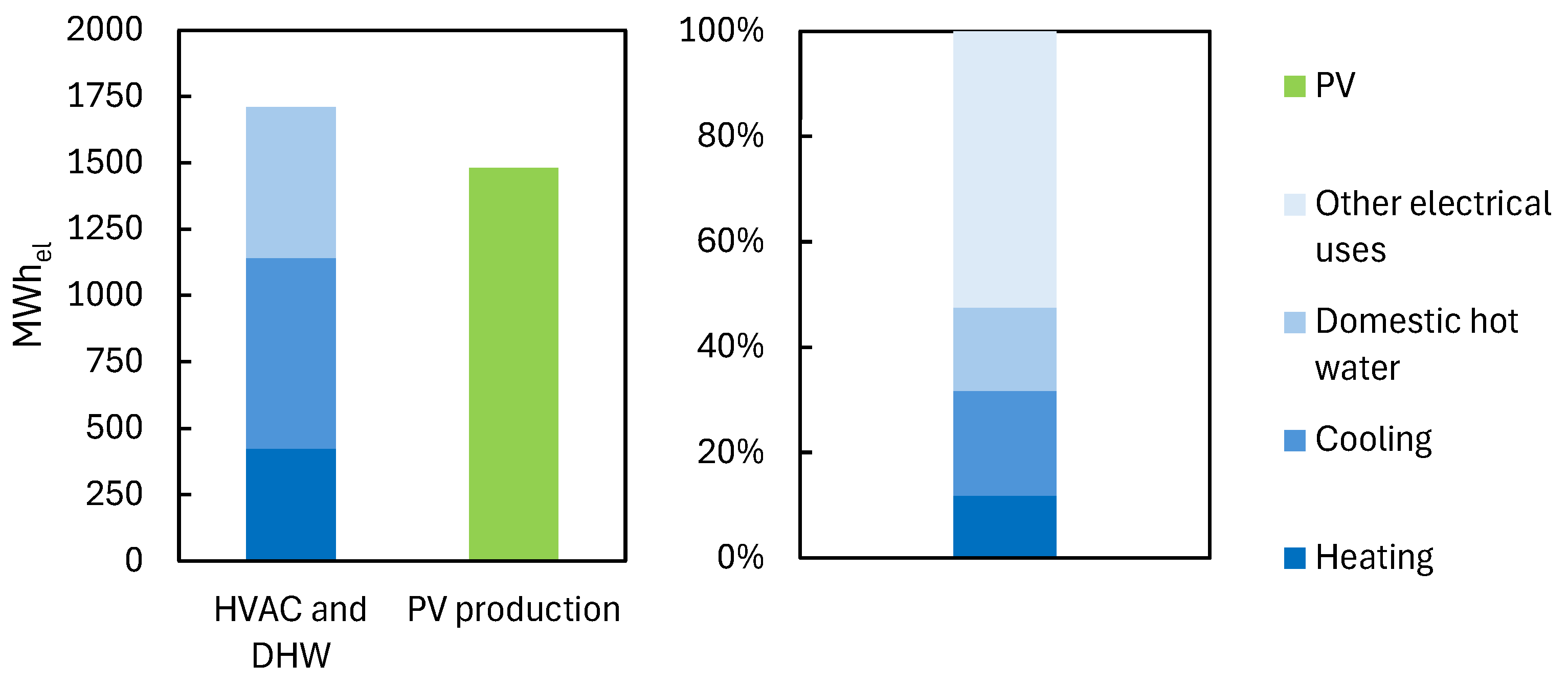

The total calculated energy use for all the buildings in the ZCB scenario, including heating, cooling, domestic hot water, and other electrical end-uses (e.g., artificial lighting and plug loads), is 3.5 MWh per year;

Table 2 shows a breakdown divided by end-use and function.

As the last step of the design process, photovoltaic (PV) panels were added on the roof of the buildings, since the East and West orientation of the main facades did not make vertical installations suitable. Also in this case, the goal was to install, compatibly with the available budget, a PV surface that would produce more energy than the standard requirement.

All the energy flows of the district would be managed by a local smart grid enabling the exchange of energy among buildings in case of surplus production.

The estimated energy production from the PV system is 1.5 MWh per year, i.e., 42% of the total electricity need as described above. The energy from PV panels covers 87% of the thermal energy need for heating and cooling and domestic hot water, well above the 60% fraction mandated by national regulations (

Figure 7).

To calculate the carbon emissions during the operational life of the buildings, the electricity needs for heating and cooling (phase B6), domestic hot water (phase B7) and other end-uses (phase B1) were converted into carbon emissions via a conversion coefficient fc,p = 0.432 kgCO2-eq/kWh for the use of electricity from the grid and another coefficient fc,PV = 0.081 kgCO2-eq/kWh for energy produced on site by PV panels.

The results show a significant decrease of yearly carbon emissions for the ZCB design scenario compared to the BAU scenario (

Table 3).

While these values were calculated considering the current energy mix in the national grid, to model the operational carbon emissions over a period of 30 years dynamic conversion coefficients were adopted, taking into account the progressive decarbonization of the electrical grid in the next decades. The assumption was a constant decrease of the carbon intensity of electricity taken from the grid, until a completely carbon-free situation is reached in 2050. In terms of operational energy, the project achieved a 38% reduction, equal to 10.6 MtCO2-eq, of total carbon emissions in 30 years compared to the BAU scenario.

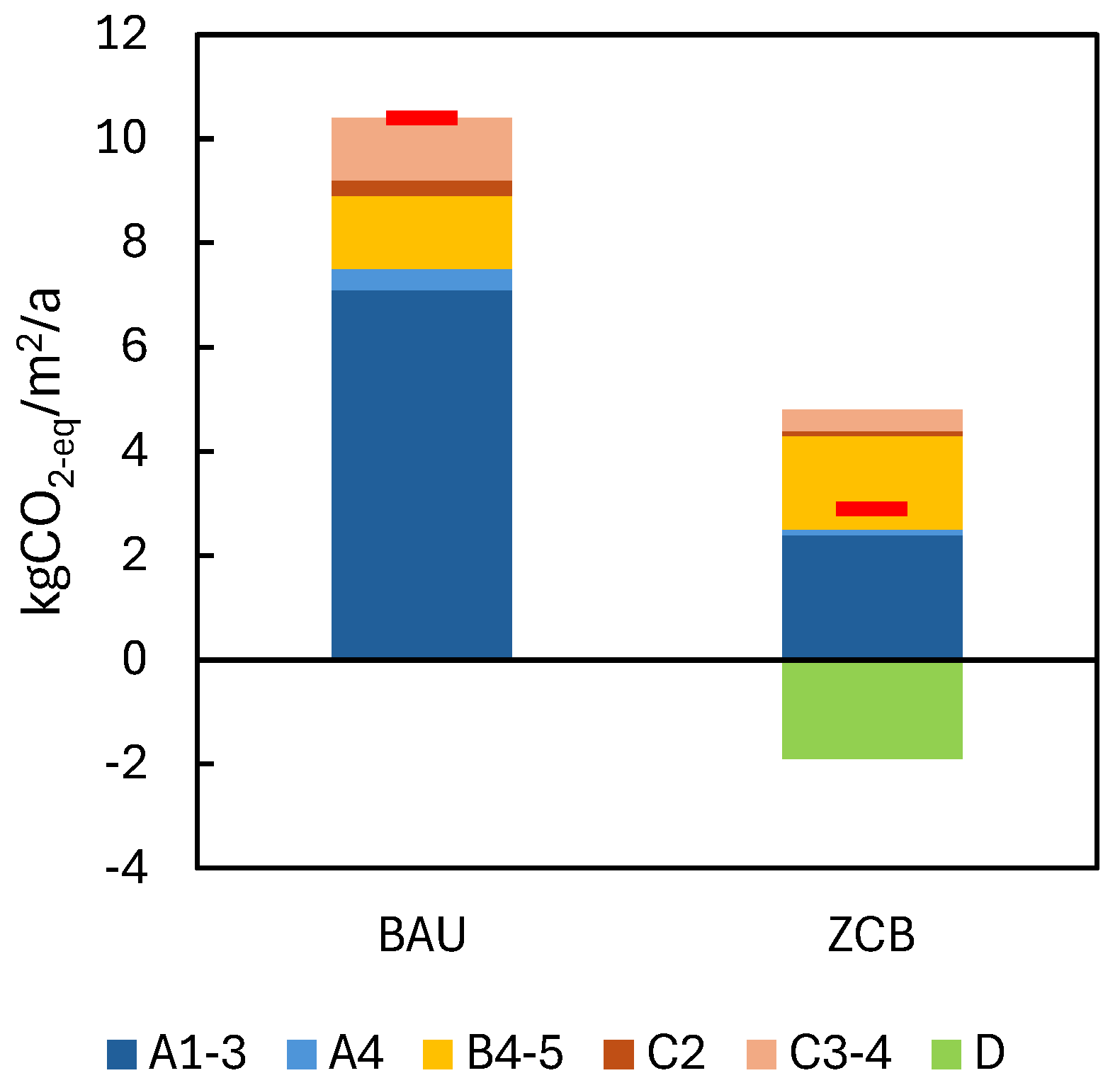

3.2. Embodied Carbon

The results of the carbon footprint assessment show the influence of the material selection under the two design options and the effect of the carbon compensation from a large share of biobased materials in the material diet adopted for the ZCB design. In particular, the choice of the mixed wood-concrete horizontal structures contributes to the sequestration of an amount of biogenic CO

2 equal to 2,500 tons. The adoption of bamboo as cladding for the ventilated façade contributes to reducing the carbon footprint for the production and installation phases by almost 75%. As shown in

Table 4, considering the carbon emissions from material processing (A1-3), transport (A4), maintenance/replacement and renovation (B4-5) and end-of-life (C2-4), the structure (ST) is the part of the building contributing the most to climate change, representing 32% of emissions for the BAU scenario and 22% for the ZCB one. However, when the contribution to GWP of the stored carbon in the hybrid wood-concrete structure for 100 years is taken into account, the net-GWP of ST drops to nearly 60 kgCO

2-eq/m

2, with 64% of net saving. Similarly, the use of fast-growing biobased fibers as lightening material for screed in the interior floors (IF) contributes to providing a nearly zero net-GWP, with a net saving of more than 90%. The lightweight multilayered interior walls, using a timber frame and recycled paper panels, further contributes to providing a negative net-GWP, saving nearly 70 kgCO

2-eq/m

2. The advanced energy systems adopted for the ZCB option as well as the additional PV installed on the roofs double instead the carbon emissions, compared to the BAU scenario. However, these extra burdens are fully compensated by the contribution of biobased materials in building components, which at the end contribute to drop the overall life cycle GWP by 45%. If the biogenic CO

2 is excluded from the calculation and only the fossil contribution is taken into account, the carbon saving between BAU and ZCB is only 9% in favor of the latter.

In

Figure 8, the annualized carbon emissions of the BAU solution are compared with the Zero-Carbon Building (ZCB) configuration. The effect of the material diet shows a reduction of about 50% of the carbon emissions compared to BAU. If the contribution of CO

2 sequestered in the biogenic materials is considered, this percentage is increased by an additional 20%, bringing the total carbon savings up to 70% over 100 years.

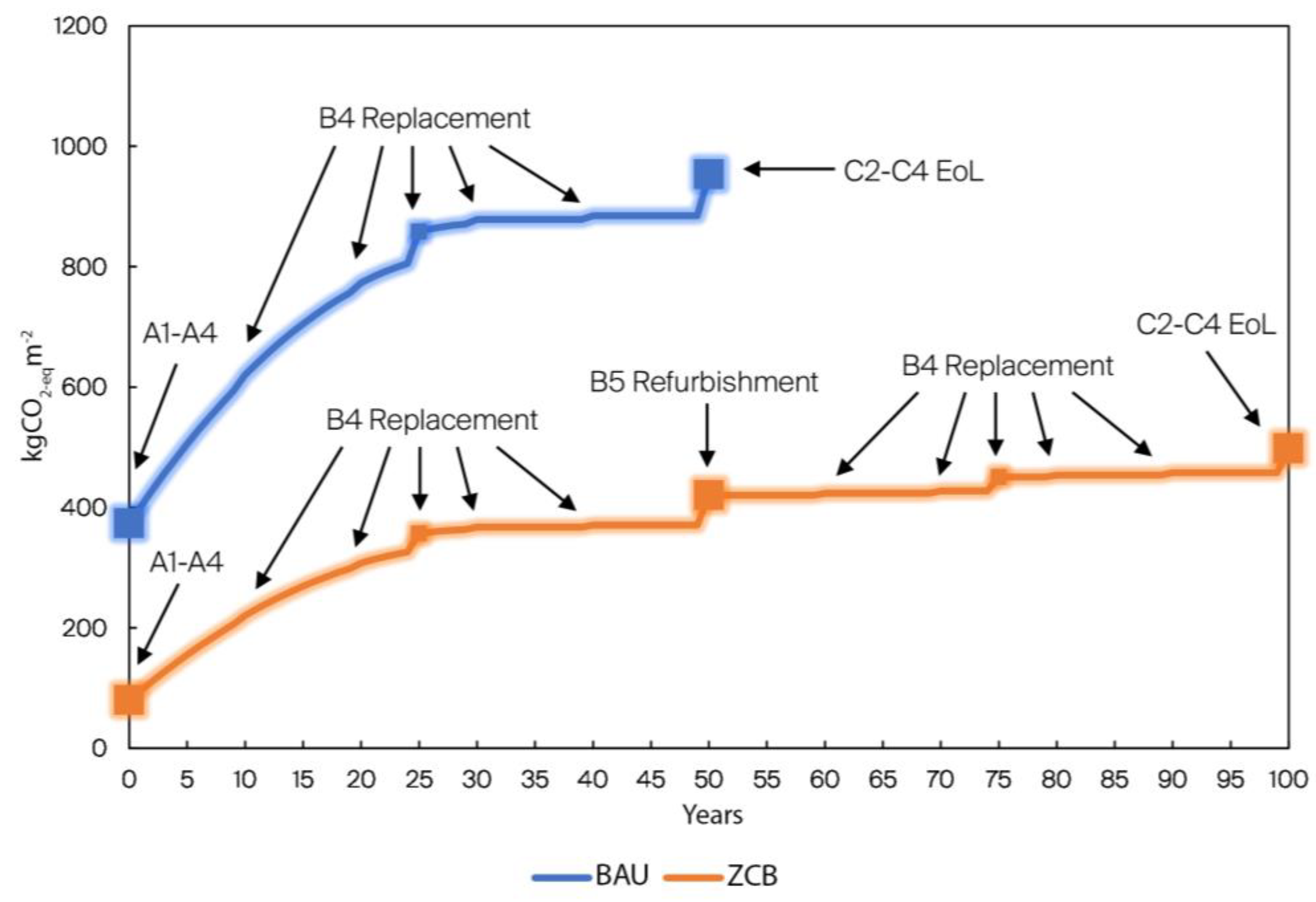

3.3. Life Cycle Zero-Carbon Building

To estimate the carbon mitigation effect deriving from the material selection, the time-depending emissions from embodied and operational carbon were evaluated over the whole life cycle of the building. As shown in

Figure 9, nearly 400 kgCO

2-eq are emitted per square meter under the BAU scenario. On the other hand, the initial carbon spike in case of the ZCB option is reduced by nearly 80%, mainly due to the fast carbon regeneration in the fast-growing materials used in the envelope and interior floors. After the construction, the annual emissions due to the operational energy need of the BAU more than double its GWP after 25 years. In this period the transition to zero-carbon energy, which is assumed to linearly decrease the emission factor of the electricity mix, is not fully completed and the low onsite production of solar energy only partially balances the positive emissions from the use of the buildings. On the other hand, the extra PV panels installed in the roof, as well the low carbon energy system adopted for the ZCB, limit the operational emissions, reducing the peak by 56%. From year 30, the operational energy is supposed to be carbon-free, and no additional contribution is expected till the end of the buildings’ service life. Consequently, the PV panels, which are assumed to have a lifespan equal to 30 years, are not replaced and a landfill scenario is assumed for both BAU and ZCB. While at year 50 the BAU scenario assumes a final disposal of the buildings, with most of the material demolished and sent to landfill, with the only exception of the metal components, in the ZCB option a refurbishment with a deep retrofit is assumed, with the replacement of all exhausted materials (i.e., finishing, external insulation, mechanical, electrical and plumbing systems (MEPs), doors and windows, etc.) and 10% of the concrete structure repaired with the replacement of heavily cracked parts.

The avoided demolition at year 50 and the extension of the buildings’ service life allows to save more than 50 kgCO2-eq/m2, with a relative saving of nearly 60% compared to BAU. Finally, the extended end-of-life of the ZCB scenario accounts for an additional 67 kgCO2-eq/m2, with a resulting GWP of 483 kgCO2-eq/m2 that, compared to 945 kgCO2-eq/m2 estimated for BAU, contributes to a total saving of nearly 50% of carbon emissions.

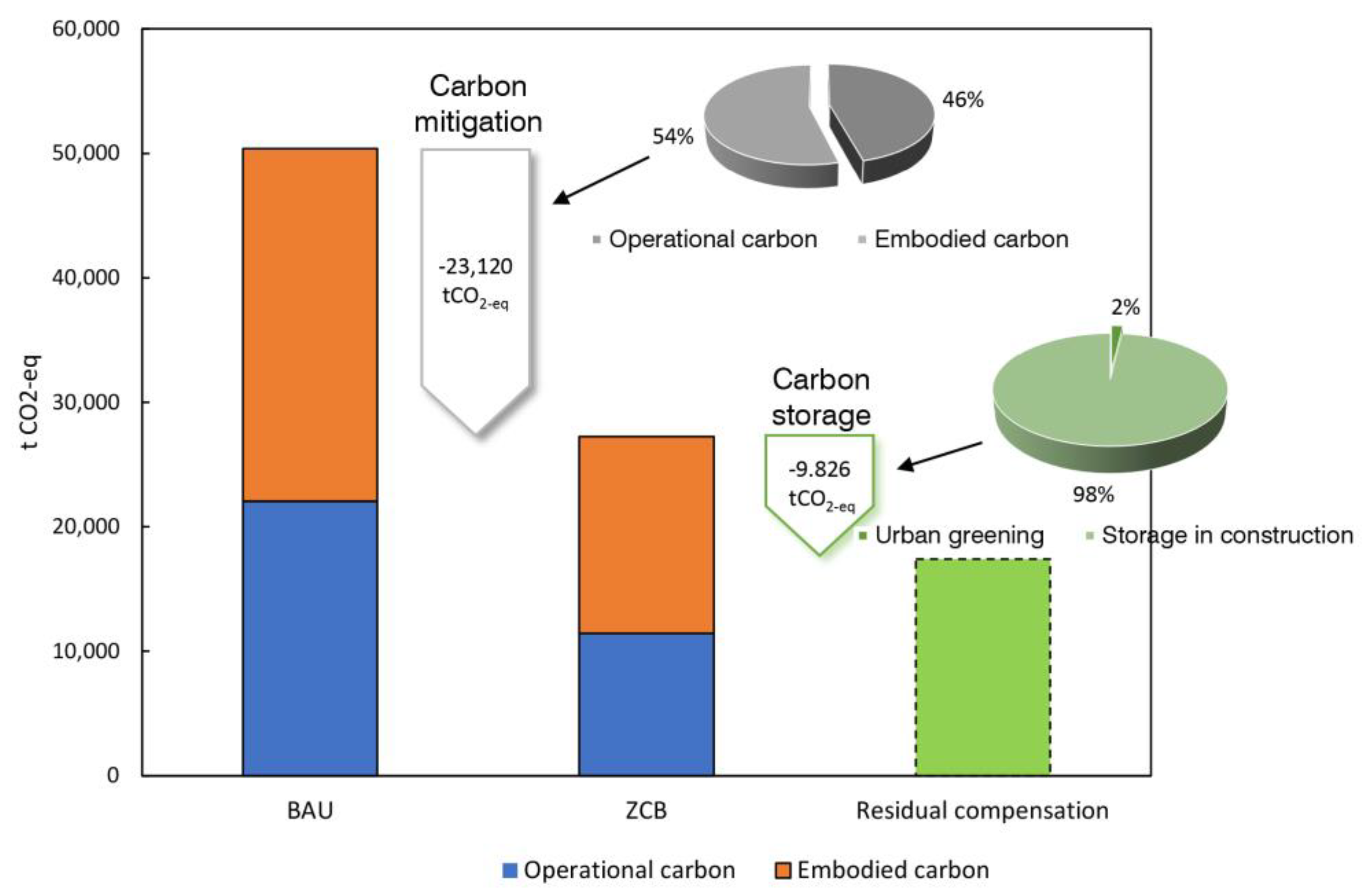

At the building scale, the total carbon emissions (operational + embodied carbon) for BAU were assumed equal to nearly 50 ktCO

2-eq. As shown in

Figure 10, the mitigation from material selection and energy efficiency allows to save more than 23 ktCO

2-eq, while the contribution of biogenic carbon storage and uptake in biomass regrowth and urban greening additionally saves nearly 10 ktCO

2-eq. The residual carbon emission, equal to nearly 20 ktCO

2-eq, which was not possible to avoid through additional onsite mitigation strategies, can be offset with the plantation of about 68 ha of coniferous forest, which corresponds to an area about 10-fold larger than the Scalo Lambrate site itself.

4. Discussion

4.1. The Influence of Future Energy Decarbonization on Embodied Carbon of Materials

The decarbonization of the energy grid is a pivotal aspect of global efforts to mitigate climate change and transition towards a sustainable future. Under 2050 zero-carbon scenarios, the focus lies on drastically reducing or eliminating greenhouse gas emissions associated with energy generation. This entails a shift away from fossil fuels towards renewable energy sources such as solar, wind, hydroelectric, and nuclear power, coupled with advancements in energy storage technologies and energy efficiency measures [

52].

One of the primary consequences of decarbonizing the energy grid is a significant reduction in emission factors associated with material manufacturing [

53,

54]. The construction sector is a major contributor to global carbon emissions due to energy-intensive processes and reliance on fossil fuels [

55]. However, as the energy grid becomes increasingly decarbonized, the emissions intensity of electricity used in manufacturing processes decreases. Renewable energy sources typically have lower carbon footprints compared to fossil fuels, as they produce minimal or no greenhouse gas emissions during electricity generation [

56]. This means that industries relying on electricity from the grid will inherently have lower emission factors associated with their manufacturing processes. For instance, the production of steel, cement, and chemicals—industries known for their high carbon emissions—can significantly reduce their environmental impact by transitioning to electricity derived from renewable sources [

57].

Moreover, the decarbonization of the energy grid enables the electrification of various industrial processes that were previously reliant on fossil fuels. This includes processes such as electric arc furnaces for steel production and electric boilers for heat generation in manufacturing facilities. By electrifying these processes with clean energy, emission factors can be further reduced, leading to significant environmental benefits. However, it is essential to consider the broader implications and challenges associated with decarbonizing the energy grid [

58]. This includes addressing intermittency issues of renewable energy sources, ensuring grid reliability and resilience, and managing the transition for industries heavily reliant on fossil fuels. Additionally, the adoption of low-carbon technologies in material manufacturing, such as carbon capture and utilization, will play a crucial role in further reducing emissions in sectors where complete electrification may be challenging, as cement industry [

59].

4.2. Barriers to Implementation of Biobased Construction Materials

The primary concerns associated with bio-based construction materials predominantly revolve around their aesthetic appeal, aging characteristics, durability, hydrothermal performance—particularly in humid conditions—and fire resistance [

60]. Furthermore, their integration into high-rise constructions remains restricted in various countries owing to regulatory limitations concerning fire safety. The crux of the matter lies in the appropriate application of these materials. The utilization and incorporation of bio-based materials into architectural design necessitate specialized expertise. For instance, opting for internal thermal insulation as opposed to external application mitigates the risk of compromising structural integrity and aesthetic appeal due to weather-induced deterioration. Enhancing reaction to fire and fire resistance can be achieved through the application of tailored coatings [

61]. However, realizing widespread adoption of such materials while concurrently ensuring sustainable forest and crop management requires a comprehensive political framework and incentivization [

62].

4.3. Land Use Issues

The predominant focus on greenhouse gas (GHG) emissions entails the potential risk of transferring burdens elsewhere. In addition to the climate crisis, numerous pressing environmental issues, such as biodiversity loss and water scarcity, necessitate attention [

63,

64]. A transition towards low-carbon materials and processes, exemplified by the shift from fossil to renewable energy sources, holds the promise of reducing GHG emissions. However, such a transition may inadvertently exacerbate pressures on other environmental fronts. In the case of renewable energy, the strain intensifies notably on biodiversity, land usage, and water resources [

65]. Certain resources may emerge as critical bottlenecks in the endeavor to achieve a low-carbon economy [

66,

67]. Consequently, merely meeting climate targets proves inadequate in attaining overall environmental sustainability.

5. Conclusions

This article presents a systematic methodology to assess the Global Warming Potential (GWP) of the project for the regeneration of one of Milan’s former railway yards into a neighborhood with several residential buildings and a public park. The project was submitted as an entry to the 2020 edition of the Reinventing Cities competition, organized by the C40 group. The methodology allowed to estimate the whole life cycle carbon emissions of the neighborhood over a time scale of 100 years, comparing the design scenario, based on the zero-carbon target, with a “business as usual” reference scenario, based on the current Italian regulations for Nearly Zero-Energy Buildings.

The results show that an appropriate combination of strategies to limit the emissions deriving from operational energy, together with the reversal of the material pyramid, using whenever possible fast-growing bio-based materials with negative carbon footprint, leads to a 70% reduction of the carbon emissions over the 100-year period; the remaining emissions can be offset with the afforestation of a 68-ha area. The project reaches the B class according to the Carbon Heroes Benchmark and is in line with the best practices for the embodied carbon of new builds in the EU.

These results are interesting because they prove the actual feasibility of zero-carbon neighborhoods also in situations with limited budget, such as developments mostly dedicated to affordable housing, where margins for the developer are low and it is not possible to use timber for structures and walls due to budget limitations. This work shows the opportunities for carbon storage offered by fast-growing biogenic products that can be used in secondary building components, such as finishings and fillers spread over wide surfaces such as horizontal floors and external facades.

At the same time, however, the results demonstrate that, with these constraints, the neighborhood still has residual carbon emissions, and that the on-site mitigation strategies such as the large public park are not sufficient to offset them. Only with the adoption of off-site mitigation measures, such as the afforestation of an area 10 times larger than the site itself, it is possible to achieve the zero-carbon target; this strategy, however, would open up significant issues about land use that may question its replicability at a larger scale.

Since the remaining opportunities to reduce carbon emissions deriving from operational energy appear limited, this work also clarifies the urgent need to implement policies and incentives for the introduction of bio-based materials in buildings thanks to the carbon storage potential they offer. Moreover, new standards should be developed to include dynamic methods for biogenic carbon accounting in building, matching more closely the peaks of emissions at the time of construction and maintenance and the carbon actually absorbed by vegetation during its growth.

Author Contributions

Conceptualization, M.R., F.P. and G.M.; methodology, F.P., G.M. and M.R.; software, F.P.; validation, G.M. and F.P.; formal analysis, F.P. and G.M.; investigation, F.P. and G.M.; resources, F.P. and G.M.; data curation, F.P. and G.M.; writing—original draft preparation, M.R., F.P. and G.M.; writing—review and editing, M.R. and G.M.; visualization, F.P.; supervision, G.M.; project administration, M.R.; funding acquisition, M.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Co-inventing Doria S.r.l. in its role as promoter of the project submitted to the Reinventing Cities competition.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

The authors would like to thank Studio Tecneas - Integrated Building Design and Dr. Eleonora Currò for the valuable insights provided for the consolidation of the construction and energy strategies. A special thanks to Benedetta Tagliabue - EMBT Architects for the inspiring contribution given during the design conceptualization.

Conflicts of Interest

The authors declare no conflicts of interest.

Appendix A

Table A1.

List of processes and GWP-100 values per FU adopted for LCA modelling of materials used for BAU configuration.

Table A1.

List of processes and GWP-100 values per FU adopted for LCA modelling of materials used for BAU configuration.

| Material |

Name of the process |

Source |

Functional Unit |

GWP-100 production |

GWP 100 end-of-life |

| (FU) |

kgCO2-eq/FU |

kgCO2-eq/FU |

| Steel profile |

Steel, low-alloyed {RER}| steel production, converter, low-alloyed | Cut-off, U |

ecoinvent |

kg |

0,734 |

0,000 |

| Asphalt |

Mastic asphalt {CH}| production | Cut-off, U |

ecoinvent |

kg |

25,800 |

2,340 |

| Reinforcing steel |

Reinforcing steel {RER}| production | Cut-off, U |

ecoinvent |

kg |

0,682 |

0,000 |

| Concrete |

Concrete, normal {CH}| unreinforced concrete production, with cement CEM II/A | Cut-off, U |

ecoinvent |

kg |

0,089 |

0,010 |

| Double glazing |

Glazing, double, U<1.1 W/m2K {RER}| production | Cut-off, U |

ecoinvent |

m2 |

44,900 |

2,980 |

| Drainage |

Polyethylene, high density, granulate {RER}| production | Cut-off, U |

ecoinvent |

kg |

2,380 |

3,030 |

| EPS |

Polystyrene foam slab for perimeter insulation {CH}| processing | Cut-off, U |

ecoinvent |

kg |

4,460 |

3,190 |

| Gypsum fibreboard |

Gypsum fibreboard {CH}| production | Cut-off, U |

ecoinvent |

kg |

0,527 |

0,009 |

| Woven geotextile |

Horticultural fleece {CH}| horticultural fleece production | Cut-off, U |

ecoinvent |

kg |

3,397 |

3,030 |

| Floor ventilation |

Polypropylene, granulate {RER}| production | Cut-off, U |

ecoinvent |

kg |

2,400 |

3,030 |

| Plaster |

Base plaster {CH}| production | Cut-off, U |

ecoinvent |

kg |

0,138 |

0,009 |

| Mineral wool |

Stone wool {CH}| stone wool production | Cut-off, U |

ecoinvent |

kg |

1,120 |

0,010 |

| Clay brick |

Clay brick {RER}| production | Cut-off, U |

ecoinvent |

kg |

0,249 |

0,009 |

| Waterproof membrane |

Fleece, polyethylene {RER}| production | Cut-off, U |

ecoinvent |

kg |

2,380 |

3,030 |

| PV panel |

Photovoltaic panel, single-Si wafer {RER}| production | Cut-off, U |

ecoinvent |

kWp |

2134,400 |

185,600 |

| Ceramic tile |

Ceramic tile {CH}| production | Cut-off, U |

ecoinvent |

kg |

0,768 |

0,009 |

| Light clay brick |

Light clay brick {DE}| production | Cut-off, U |

ecoinvent |

kg |

0,161 |

0,009 |

| Synthetic turf |

Polypropylene, granulate {RER}| production | Cut-off, U |

ecoinvent |

kg |

2,400 |

3,030 |

| Cement tile |

Cement tile {CH}| production | Cut-off, U |

ecoinvent |

kg |

0,050 |

0,009 |

| Glass fibre reinforced plastic |

Glass fibre reinforced plastic, polyester resin, hand lay-up {RER}| production | Cut-off, S |

ecoinvent |

kg |

0,682 |

0,000 |

| Screed |

Lean concrete {CH}| production, with cement CEM II/A | Cut-off, U |

ecoinvent |

kg |

0,050 |

0,009 |

| Polyethylene fleece |

Fleece, polyethylene {RER}| production | Cut-off, U |

ecoinvent |

kg |

2,760 |

2,580 |

| Aluminum frame |

Window frame, aluminum, U=1.6 W/m2K {RER}| production | Cut-off, U |

ecoinvent |

m2 |

191,000 |

25,700 |

| Sand |

Sand {CH}| gravel and quarry operation | Cut-off, U |

ecoinvent |

kg |

0,003 |

0,011 |

| Alkyd paint |

Alkyd paint, white, without water, in 60% solution state {RER}| Cut-off, S |

ecoinvent |

m2 |

0,877 |

0,719 |

Table A2.

List of processes and GWP-100 per FU adopted for LCA modelling of materials used for BAU configuration.

Table A2.

List of processes and GWP-100 per FU adopted for LCA modelling of materials used for BAU configuration.

| Material |

Name of the process |

Source |

Functional Unit |

GWP-100 production |

GWP 100 end-of-life |

| (FU) |

kgCO2-eq/FU |

kgCO2-eq/FU |

| Steel profile |

Steel, low-alloyed {RER}| steel production, converter, low-alloyed | Cut-off, U |

ecoinvent |

kg |

0,734 |

0,000 |

| Reinforcing steel |

Reinforcing steel {RER}| production | Cut-off, U |

ecoinvent |

kg |

0,682 |

0,000 |

| Reinforced soil |

85% Sand {CH}| gravel and quarry operation | Cut-off, U; 10% Polypropylene, fibers {RER}| production | Cut-off, U; 5% Cement, unspecified {CH}| cement, unspecified, import from Europe | Cut-off, U |

ecoinvent |

kg |

0,089 |

0,011 |

| Autoclaved aerated concrete block |

Autoclaved aerated concrete block {CH}| production | Cut-off, U |

ecoinvent |

kg |

0,408 |

0,009 |

| Concrete |

Concrete, normal {CH}| unreinforced concrete production, with cement CEM II/A | Cut-off, U |

ecoinvent |

kg |

0,089 |

0,010 |

| Low-carbon concrete |

15% Cement, pozzolana and fly ash 36-55%,non-US {Europe without Switzerland}| cement production, pozzolana and fly ash 36-55%, non-US | Cut-off, U; 37,7% Gravel, crushed {CH}| production | Cut-off, U; 37,7% Sand {CH}| gravel and quarry operation | Cut-off, U; 9,5% Tap water {CH}| market for | Cut-off, U; 0,1% Plasticiser, for concrete, based on sulfonated melamine formaldehyde {GLO}| market for | Cut-off, U |

ecoinvent |

kg |

0,053 |

0,010 |

| Double glazing |

Glazing, double, U<1.1 W/m2K {RER}| production | Cut-off, U |

ecoinvent |

m2 |

44,900 |

2,980 |

| Drainage |

Polyethylene, high density, granulate {RER}| production | Cut-off, U |

ecoinvent |

kg |

2,380 |

3,030 |

| Glued laminated timber |

Glued laminated timber, for indoor use {RER}| production | Cut-off, U |

ecoinvent |

kg |

0,365 |

0,121 |

| Wooden geotextile |

Horticultural fleece {CH}| horticultural fleece production | Cut-off, U |

ecoinvent |

kg |

3,397 |

3,030 |

| Gravel |

Gravel, round {CH}| gravel and sand quarry operation | Cut-off, S |

ecoinvent |

kg |

0,004 |

0,009 |

| Floor ventilation |

Polypropylene, granulate {RER}| production | Cut-off, U |

ecoinvent |

kg |

1,570 |

3,030 |

| Plaster |

Cover plaster, mineral {CH}| production | Cut-off, U |

ecoinvent |

kg |

0,138 |

0,009 |

| Wood wool |

Wood wool {RER}| production | Cut-off, U |

ecoinvent |

kg |

0,404 |

0,041 |

| Glass wool |

Glass wool mat {CH}| production | Cut-off, U |

ecoinvent |

kg |

1,120 |

0,010 |

| Gypsum plasterboard |

Gypsum plasterboard {CH}| production | Cut-off, U |

ecoinvent |

kg |

0,527 |

0,009 |

| Lightweight screed |

Lightweight concrete, expanded perlite {CH}| production | Cut-off, U |

ecoinvent |

kg |

0,223 |

0,010 |

| Kenaf textile |

Textile, kenaf {GLO}| market for | Cut-off, U |

ecoinvent |

kg |

1,120 |

0,221 |

| Waterproof membrane |

Fleece, polyethylene {RER}| production | Cut-off, U |

ecoinvent |

kg |

2,380 |

3,030 |

| PV panel |

Photovoltaic panel, single-Si wafer {RER}| production | Cut-off, U |

ecoinvent |

kWp |

2134,400 |

185,600 |

| Sawnwood |

Sawnwood, softwood, dried (u=10%), planed {RER}| production | Cut-off, U |

ecoinvent |

kg |

0,133 |

0,010 |

| OSB |

Oriented strand board {RER}| production | Cut-off, U |

ecoinvent |

kg |

0,487 |

0,127 |

| Laminated bamboo parquet |

Flattened bamboo (3 ply) (MOSO Bamboo Forest) |

INBAR |

kg |

0,620 |

0,077 |

| Ceramic tile |

Ceramic tile {CH}| production | Cut-off, U |

ecoinvent |

kg |

0,768 |

0,009 |

| Synthetic turf |

Polypropylene, granulate {RER}| production | Cut-off, U |

ecoinvent |

kg |

1,570 |

3,030 |

| Cement tile |

Cement tile {CH}| production | Cut-off, U |

ecoinvent |

kg |

0,050 |

0,009 |

| Cork insulation |

Cork slab {RER}| production | Cut-off, U |

ecoinvent |

kg |

1,120 |

0,221 |

| Glass fibre reinforced mash |

Glass fibre reinforced plastic, polyester resin, hand lay-up {RER}| production | Cut-off, U |

ecoinvent |

kg |

0,682 |

0,000 |

| Bamboo cladding |

Decking & Cladding (MOSO Bamboo X-treme) |

INBAR |

kg |

1,193 |

0,121 |

| Sand |

Sand {CH}| gravel and quarry operation | Cut-off, U |

ecoinvent |

kg |

0,003 |

0,011 |

| Lean concrete screed |

Lean concrete {CH}| production, with cement CEM II/A | Cut-off, U |

ecoinvent |

kg |

0,050 |

0,009 |

| Window timber frame |

Window frame, wood, U=1.5 W/m2K {RER}| production | Cut-off, U |

ecoinvent |

m2 |

109,000 |

19,600 |

| Alkyd paint |

Alkyd paint, white, without solvent, in 60% solution state {RER}| Cut-off, U |

ecoinvent |

m2 |

0,644 |

0,719 |

References

- UNEP, Global Status Report for Buildings and Construction: Beyond foundations - Mainstreaming sustainable solutions to cut emissions from the buildings sector, United Nations Environment Programme, Nairobi, 2024. [CrossRef]

- European Commission, Communication from the Commission - The European Green Deal, Official Journal of the European Union (2019). https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52019DC0640 (accessed April 16, 2024).

- European Commission, Establishing the framework for achieving climate neutrality and amending Regulations (EC) No 401/2009 and (EU) 2018/1999 (‘European Climate Law’), Official Journal of the European Union (2019). https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32021R1119 (accessed April 16, 2024).

- International Energy Agency, Net Zero Roadmap: A Global Pathway to Keep the 1.5 °C Goal in Reach - 2023 Update, Paris, 2023. www.iea.org/t&c/.

- D.B. Müller, G. Liu, A.N. Løvik, R. Modaresi, S. Pauliuk, F.S. Steinhoff, H. Brattebø, Carbon emissions of infrastructure development, Environ Sci Technol 47 (2013) 11739–11746. [CrossRef]

- R. Rovers, People vs Resources: restoring a world out of balance, Eburon Academic Publishers, 2019.

- M. Ritzen, R. Rovers, L. Gommans, C. Geurts, Insulation versus installation – an exploration towards maximization, in: Sustainable Building 13 - Implementing Sustainability - Barriers and Chances, Munich, Germany, 2013.

- D. Maierhofer, M. Röck, M. Ruschi Mendes Saade, E. Hoxha, A. Passer, Critical life cycle assessment of the innovative passive nZEB building concept ‘be 2226’ in view of net-zero carbon targets, Build Environ 223 (2022). [CrossRef]

- M. Röck, M. Ruschi Mendes Saade, M. Balouktsi, F. Nygaard, H. Birgisdottir, R. Frischknecht, G. Habert, T. Lützkendorf, Embodied GHG emissions of buildings – The hidden challenge for effective climate change mitigation, Appl Energy 131 (2019) 114107. [CrossRef]

- G. Churkina, A. Organschi, C.P.O. Reyer, A. Ruff, K. Vinke, Z. Liu, B.K. Reck, T.E. Graedel, H.J. Schellnhuber, Buildings as a global carbon sink, Nature Sustainability 2020 (2020) 1–8. [CrossRef]

- P.H. Brunner, Urban mining: a contribution to reindustrializing the city, J Ind Ecol 15 (2011) 339–341. [CrossRef]

- F. Pittau, F. Krause, G. Lumia, G. Habert, Fast-growing bio-based materials as an opportunity for storing carbon in exterior walls, Build Environ 129 (2018) 117–129. [CrossRef]

- Habert, L.E. Malighetti, F. Pittau, Material Diets for Climate-Neutral Construction, Environ Sci Technol 56 (2022) 5213–5223. [CrossRef]

- C40 Cities, A global network of mayors taking urgent climate action, (n.d.). https://www.c40.org/ (accessed April 16, 2024).

- C40, Reinventing Cities, (n.d.). https://www.c40reinventingcities.org/ (accessed April 16, 2024).

- Sedova, A. Celani, Urban Regeneration: What Are the Architectural Trends?, in: A. Ter-Martirosyan (Ed.), E3S Web of Conferences, 2023: p. 03016. [CrossRef]

- A. Campioli, E. Mussinelli, M. Lavagna, A. Tartaglia, Design Strategies and LCA of Alternative Solutions for Resilient, Circular, and Zero-Carbon Urban Regeneration: A Case Study, in: Regeneration of the Built Environment from a Circular Economy Perspective, 2020: pp. 205–215. [CrossRef]

- EU Parliament, Directive 2010/31/EU of the European Parliament and of the Council on the energy performance of buildings, Document 02010L0031-20210101 (2010). https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:02010L0031-20210101 (accessed April 16, 2024).

- EU Commission, Energy Performance of Buildings Directive, (2024). https://energy.ec.europa.eu/topics/energy-efficiency/energy-efficient-buildings/energy-performance-buildings-directive_en (accessed April 16, 2024).

- Directive of the European Parliament and of the Council on the energy performance of buildings, Document 52021PC0802 (2021). https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=COM:2021:802:FIN (accessed April 16, 2024).

- A.S. Cordero, S.G. Melgar, J.M.A. Márquez, Green building rating systems and the new framework level(s): A critical review of sustainability certification within Europe, Energies (Basel) 13 (2019). [CrossRef]

- EU Commission, Level(s) - European framework for sustainable buildings, (n.d.). https://environment.ec.europa.eu/topics/circular-economy/levels_en (accessed April 16, 2024).

- B. Izaola, O. Akizu-Gardoki, X. Oregi, Setting baselines of the embodied, operational and whole life carbon emissions of the average Spanish residential building, Sustain Prod Consum 40 (2023) 252–264. [CrossRef]

- S. Attia, M.C. Santos, M. Al-Obaidy, M. Baskar, Leadership of EU member States in building carbon footprint regulations and their role in promoting circular building design, in: IOP Conf Ser Earth Environ Sci, IOP Publishing Ltd., 2021. [CrossRef]

- P. Pasanen, R. Castro, Carbon Heroes Benchmark Program - Whole building embodied carbon profiling, in: IOP Conf Ser Earth Environ Sci, Institute of Physics Publishing, 2019. [CrossRef]

- EU commission, Supporting the development of a roadmap for the reduction of whole life carbon of buildings - Final technical report, 2024. [CrossRef]

- A. Levasseur, P. Lesage, M. Margni, R. Samson, Biogenic Carbon and Temporary Storage Addressed with Dynamic Life Cycle Assessment, J Ind Ecol 17 (2013) 117–128. [CrossRef]

- C. Breton, P. Blanchet, B. Amor, R. Beauregard, W.S. Chang, Assessing the climate change impacts of biogenic carbon in buildings: A critical review of two main dynamic approaches, Sustainability (Switzerland) 10 (2018). [CrossRef]

- M. Brandão, A. Levasseur, M. Kirschbaum, B. Weidema, A. Cowie, S. Jørgensen, M. Hauschild, D. Pennington, K. Chomkhamsri, Key issues and options in accounting for carbon sequestration and temporary storage in life cycle assessment and carbon footprinting, International Journal of Life Clycle Assessment 18 (2012) 230–240. [CrossRef]

- W. Liu, Z. Zhang, X. Xie, Z. Yu, K. Von Gadow, J. Xu, S. Zhao, Y. Yang, Analysis of the Global Warming Potential of Biogenic CO2 Emission in Life Cycle Assessments, Sci Rep 7 (2017) 1–8. [CrossRef]

- J.G. Vogtländer, N.M. Van Der Velden, P. Van Der Lugt, Carbon sequestration in LCA, a proposal for a new approach based on the global carbon cycle; Cases on wood and on bamboo, International Journal of Life Cycle Assessment 19 (2014) 13–23. [CrossRef]

- G. Habert, Fast-Growing Bio-Based Materials Can Heal the World, Buildings and Cities 4 (2021) 6.

- G. Verena, F. Freire, F. Pittau, Influence of material choice, renovation rate, and electricity grid to achieve a Paris Agreement-compatible building stock : A Portuguese case study, 195 (2021). [CrossRef]

- A. Levasseur, P. Lesage, M. Margni, L. Deschěnes, R. Samson, Considering time in LCA: Dynamic LCA and its application to global warming impact assessments, Environ Sci Technol 44 (2010) 3169–3174. [CrossRef]

- B. Lippke, E. Oneil, R. Harrison, K. Skog, L. Gustavsson, R. Sathre, Life cycle impacts of forest management and wood utilization on carbon mitigation: knowns and unknowns, Carbon Manag 2 (2011) 303–333. [CrossRef]

- F. Pittau, G. Lumia, N. Heeren, G. Iannaccone, G. Habert, Retrofit as a carbon sink: The carbon storage potentials of the EU housing stock, J Clean Prod (2019). [CrossRef]

- G. Habert, S.A. Miller, V.M. John, J.L. Provis, A. Favier, A. Horvath, K.L. Scrivener, Environmental impacts and decarbonization strategies in the cement and concrete industries, Nat Rev Earth Environ 1 (2020) 559–573. [CrossRef]

- B. D’Amico, F. Pomponi, On mass quantities of building frame structures, Journal of Building Engineering 31 (2020) 101426. [CrossRef]

- L. Boccadoro, A. Frangi, Experimental Analysis of the Structural Behavior of Timber-Concrete Composite Slabs made of Beech-Laminated Veneer Lumber, Journal of Performance of Constructed Facilities 28 (2014) 1–10. [CrossRef]

- S. Zingg, F. Pittau, A. Lammlein, Tobias Hajiesmaeili, P. Lura, E. Denarie, G. Habert, Environmental assessment of radical innovation in concrete structures, in: G. De Schutter, N. De Belie, A. Janssens, N. Van Den Bossche (Eds.), XIV DBMC – 14th International Conference on Durability of Building Materials and Components, RILEM Publications S.A.R.L., Ghent, Belgium, 2017: pp. 1–12. http://library1.nida.ac.th/termpaper6/sd/2554/19755.pdf.

- J.D. Spengler, Q. Chen, Indoor air quality factors in designing a healthy building, Annual Review of Energy and the Environment 25 (2000) 567–601. [CrossRef]

- A. Nazari, J.G. Sanjayan, Handbook of Low Carbon Concrete, Elsevier, Oxford, 2017. https://books.google.it/books?hl=en&lr=&id=3m1_CwAAQBAJ&oi=fnd&pg=PP1&dq=Low+CO2+concrete&ots=PJlCwyuig5&sig=AbK6ZAYoW-l8mL6mY3tbi70-ASo&redir_esc=y#v=onepage&q=Low CO2 concrete&f=false (accessed February 19, 2021).

- F. Pittau, D. Giacomel, G. Iannaccone, L.E. Malighetti, Environmental consequences of refurbishment vs. demolition and reconstruction: A comparative life cycle assessment of an Italian case study, Journal of Green Building 15 (2020) 155–172. [CrossRef]

- D.D. Tingley, B. Davison, Design for deconstruction and material reuse, Proceedings of Institution of Civil Engineers: Energy 164 (2011) 195–204. [CrossRef]

- IPCC, Climate change 2021: the physical science basis, 2021.

- A.E. Fenner, C.J. Kibert, J. Woo, S. Morque, M. Razkenari, H. Hakim, X. Lu, The carbon footprint of buildings: A review of methodologies and applications, Renewable and Sustainable Energy Reviews 94 (2018). [CrossRef]

- F. Cherubini, A.H. Strømman, E. Hertwich, Effects of boreal forest management practices on the climate impact of CO2 emissions from bioenergy, Ecol Modell 223 (2011) 59–66. [CrossRef]

- G. Guest, R.M. Bright, F. Cherubini, A.H. Strømman, Consistent quantification of climate impacts due to biogenic carbon storage across a range of bio-product systems, Environ Impact Assess Rev 43 (2013) 21–30. [CrossRef]

- ecoinvent, Database - ecoinvent, (n.d.). https://ecoinvent.org/database/ (accessed April 16, 2024).

- PRé Sustainability, SimaPro | LCA software for informed changemakers, (n.d.). https://simapro.com/ (accessed April 16, 2024).

- J.G. Vogtländer, P. Van der Lugt, The Environmental Impact of Industrial Bamboo Products: Life-cycle Assessment and Carbon Sequestration, 2013.

- IPCC (Intergovernmental Panel on Climate Change), IPCC - SR1.5 - Indicative linkages between mitigation options and sustainable development using SDGs (The linkages do not show costs and benefits), (2018) 5.

- K. Daehn, R. Basuhi, J. Gregory, M. Berlinger, V. Somjit, E.A. Olivetti, Innovations to decarbonize materials industries, Nat Rev Mater 7 (2021) 275–294. [CrossRef]

- J. Barrett, T. Cooper, G.P. Hammond, N. Pidgeon, Industrial energy, materials and products: UK decarbonisation challenges and opportunities, Appl Therm Eng 136 (2018) 643–656. [CrossRef]

- IEA, Global energy and process emissions from buildings, including embodied emissions from new construction, 2022. https://www.iea.org/data-and-statistics/charts/global-energy-and-process-emissions-from-buildings-including-embodied-emissions-from-new-construction-2021 (accessed February 5, 2023).

- REN21, Renewables 2024: Global Status Report - Global overview, 2024.

- European Environment Agency, The European environment : state and outlook 2020 : knowledge for transition to a sustainable Europe., Copenhagen, 2019. [CrossRef]

- Babatunde, J.L. Munda, Y. Hamam, Decarbonisation of Electricity Generation: Efforts and Challenges, Environmental Footprints and Eco-Design of Products and Processes (2019) 47–77. [CrossRef]

- M.L. Nehdi, A. Marani, L. Zhang, Is net-zero feasible: Systematic review of cement and concrete decarbonization technologies, Renewable and Sustainable Energy Reviews 191 (2024). [CrossRef]

- D. Jones, C. Brischke, Performance of bio-based building materials, Woodhead Publishing, 2017.

- A. Lucherini, Q.S. Razzaque, C. Maluk, Exploring the fire behaviour of thin intumescent coatings used on timber, Fire Saf J 109 (2019). [CrossRef]

- M.H. Ramage, H. Burridge, M. Busse-Wicher, G. Fereday, T. Reynolds, D.U. Shah, G. Wu, L. Yu, P. Fleming, D. Densley-Tingley, J. Allwood, P. Dupree, P.F. Linden, O. Scherman, The wood from the trees: The use of timber in construction, Renewable and Sustainable Energy Reviews 68 (2017) 333–359. [CrossRef]

- E.S. Brondízio, J. Settele, S. Díaz, H.T. Ngo, The global assessment report of the intergovernmental science-policy platform on biodiversity and ecosystem services, 2022.

- J. Rockström, O. Gaffney, J. Rogelj, M. Meinshausen, N. Nakicenovic, H.J. Schellnhuber, A Roadmap for Rapid Decarbonization, Science (1979) 355 (2017) 1269–1271. [CrossRef]

- H. Desing, D. Brunner, F. Takacs, S. Nahrath, K. Frankenberger, R. Hischier, A circular economy within the planetary boundaries: Towards a resource-based, systemic approach, Resour Conserv Recycl 155 (2020). [CrossRef]

- A. de Koning, R. Kleijn, G. Huppes, B. Sprecher, G. van Engelen, A. Tukker, Metal supply constraints for a low-carbon economy?, Resour Conserv Recycl 129 (2018) 202–208. [CrossRef]

- K. Nansai, K. Nakajima, S. Kagawa, Y. Kondo, S. Suh, Y. Shigetomi, Y. Oshita, Global flows of critical metals necessary for low-carbon technologies: The case of neodymium, cobalt, and platinum, Environ Sci Technol 48 (2014) 1391–1400. [CrossRef]

Figure 1.

General framework developed for achieving absolute zero-carbon building.

Figure 1.

General framework developed for achieving absolute zero-carbon building.

Figure 2.

Model of the proposed intervention (blocks in darker color) in its context.

Figure 2.

Model of the proposed intervention (blocks in darker color) in its context.

Figure 3.

Axonometric view of the building massing (above) and plan with the indication of the green and public spaces.

Figure 3.

Axonometric view of the building massing (above) and plan with the indication of the green and public spaces.

Figure 4.