Submitted:

24 March 2024

Posted:

25 March 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

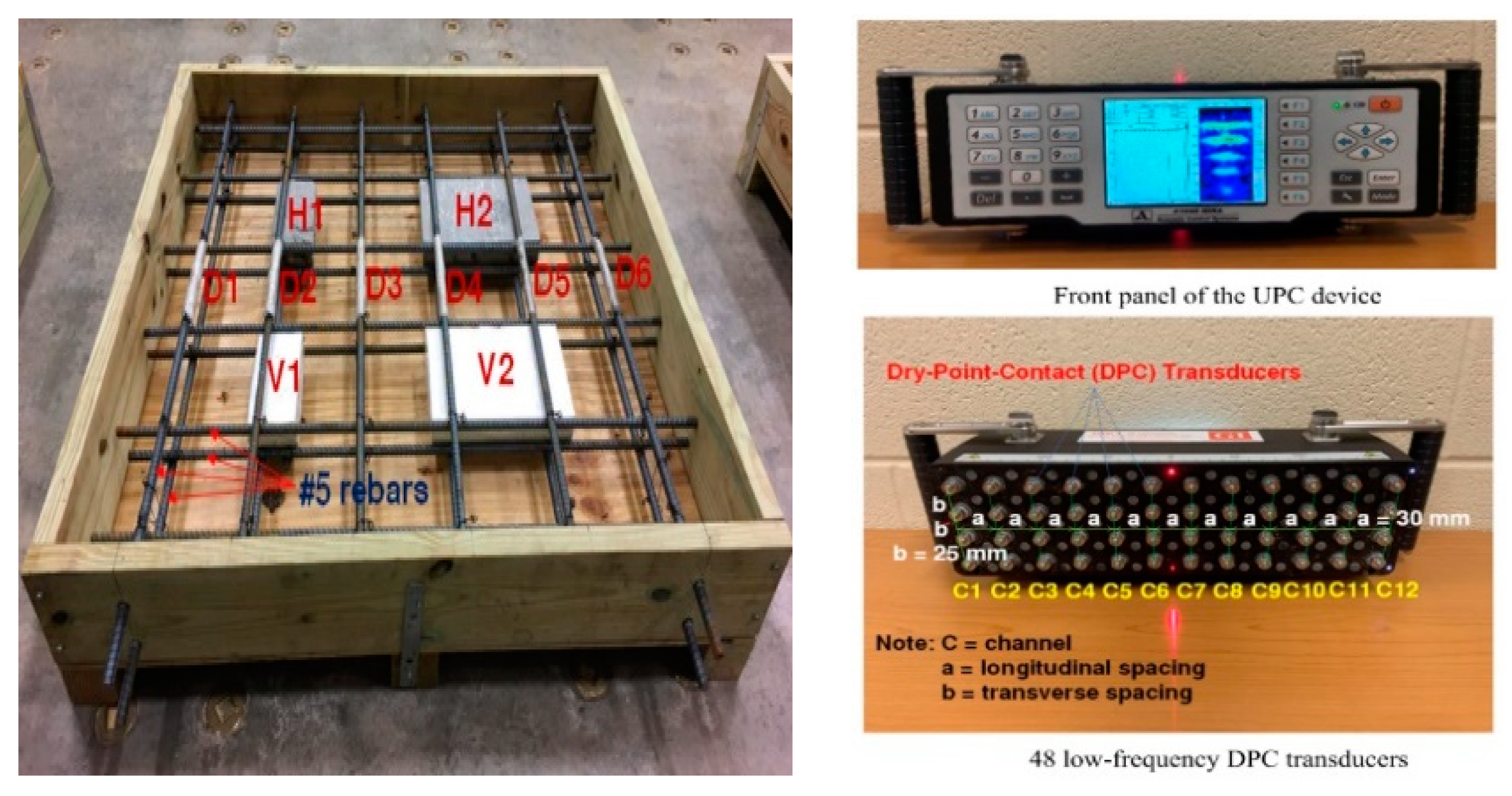

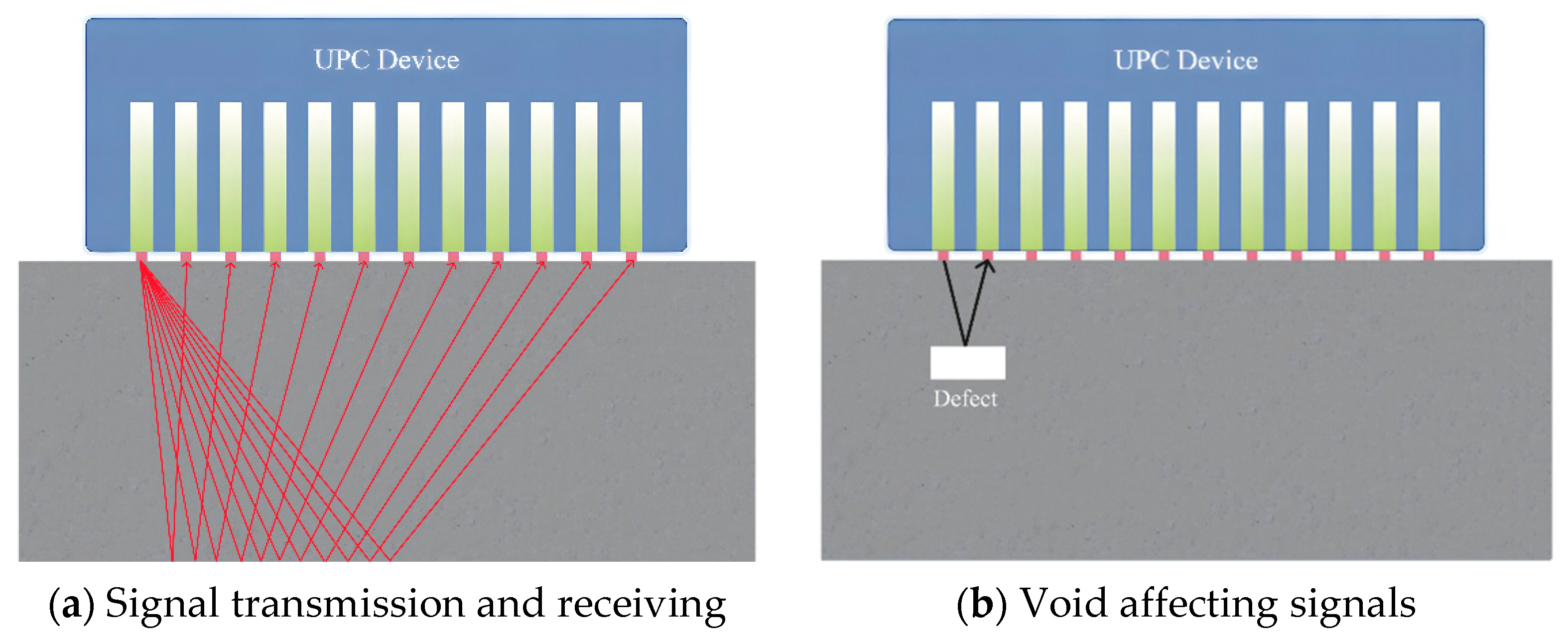

2. Experimental Setup

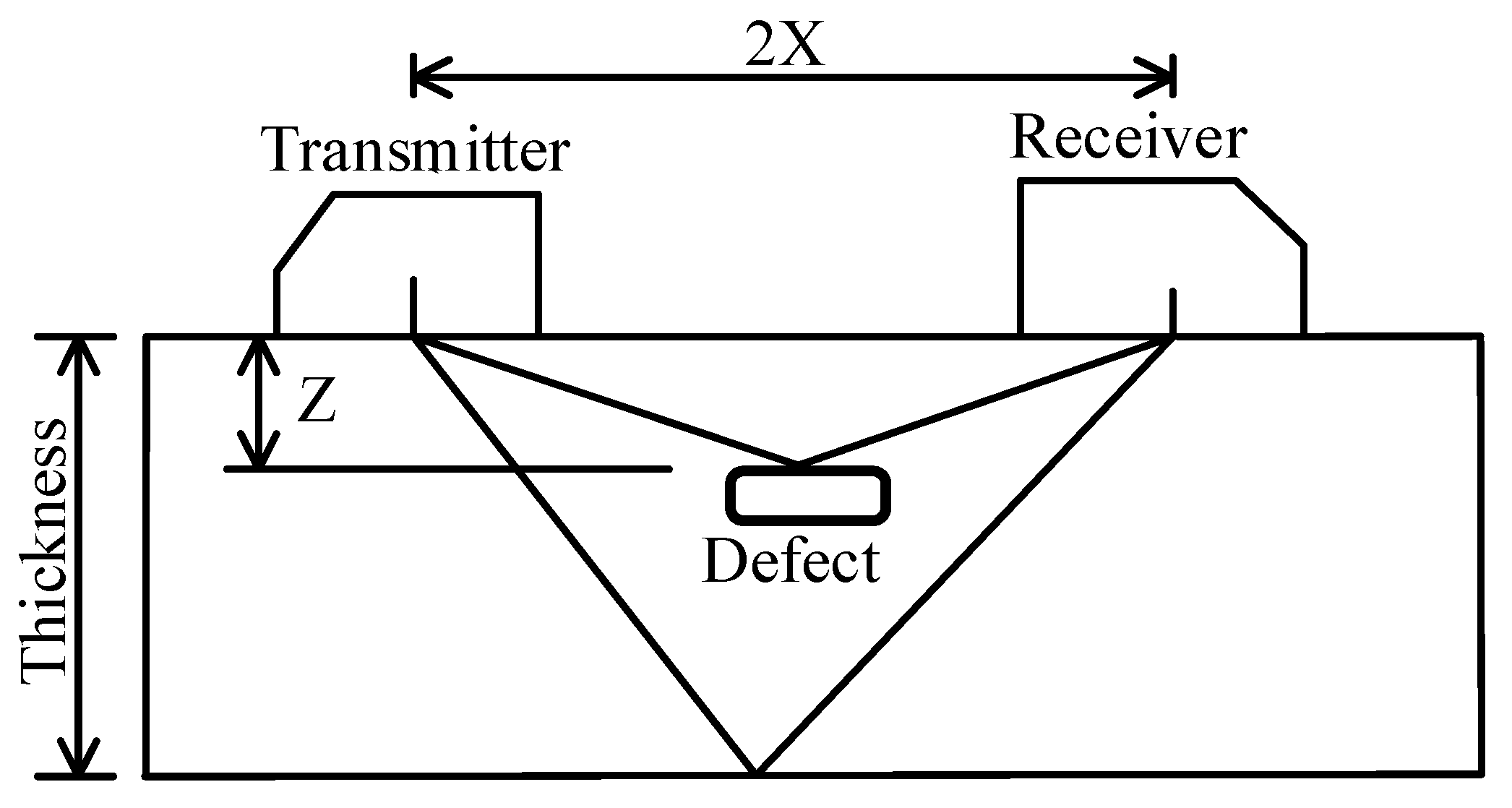

3. Formulation for Accurate Assessment of Defects and Voids

- (1)

- To accurately process the input signal, we must initially identify all local maxima and minima, along with their respective positions and amplitudes. Following this, we can employ cubic spline interpolation to generate an upper envelope consisting of the local maxima and a lower envelope using the local minima.

- (2)

- After calculating these envelopes, the envelope mean signal, known as , can be determined by taking their mean. Lastly, to finalize the processing, we need to subtract the envelope mean signal from the original input signal (Equation 4).

- (3)

- Check if meets the IMF requirements. Treat the data as new data and repeat the process if it does not meet the IMF requirements (Equation 5).

- (4)

- Repeat the sifting procedure k times until the resulting component is an IMF, which becomes the first IMF (Equation 6).

- (5)

- A standard method for extracting and analyzing a signal's underlying components is residual analysis. This process involves subtracting the component from the input signal and defining the resulting remainder as the first residual. Given that the first residual may contain information relating to longer-period components, it is treated as a new data stream. The procedure is repeated for this new signal. This process may be iterated j times, resulting in the generation of j residuals. By following this approach, it is possible to obtain a refined understanding of the signal and identify the underlying components contributing to its overall structure.

- (6)

- The sifting process is interrupted once either of the two criteria mentioned above is fulfilled: firstly, when the component or the residual is reduced to such a minuscule size that it can be regarded as insignificant, or secondly, when the residual (R) becomes a monotonic function that precludes the extraction of the IMF—the objective IMF can be obtained by adding Equations (4) and (5). The original signal can be expressed as a combination of IMFs and a residual, producing significant implications in signal processing and analysis. This observation has been accepted in the academic community.

- (7)

- EMD-based denoising, similar to other decomposition-based denoising techniques like wavelet transforms, requires a reliable and robust threshold to distinguish between noise and authentic signal components. In cases where irregularity or noise is present in a time series, the Hurst exponent plays a crucial role in determining the irregularity in the signal. This methodology is more efficient than traditional approaches such as autocorrelation, ANOVA, and spectral analysis in many applications. The Hurst exponent value, whether greater or less than 0.5, indicates the pattern of the nonlinearity of the data set. Some white noise signals have a flat spectrum and are determined by the Hurst exponent H. The autocorrelation function for a zero-mean Gaussian stationary process is expressed as:

- (8)

- Equation 10 represents the interdependence of process variance (σ), Hurst exponent (H), and correlation lag (k). Notably, when H equals 0.5, the process is classified as uncorrelated white noise, whereas for other H values, it is labeled as colored Gaussian noise. Moreover, when a generalized white noise signal is subjected to EMD, it acts as a dyadic filter bank. It is important to note that the log-variance of the IMFs follows a simple linear model, which the Hurst exponent of the process ultimately governs.

- (9)

- The energy of each of the IMFs, for k≥ 2 and ρH ≈ 2, can be parameterized as a function of the first IMF energy (Equation 11). The energy of the first IMF is given by Equation 12.

- (10)

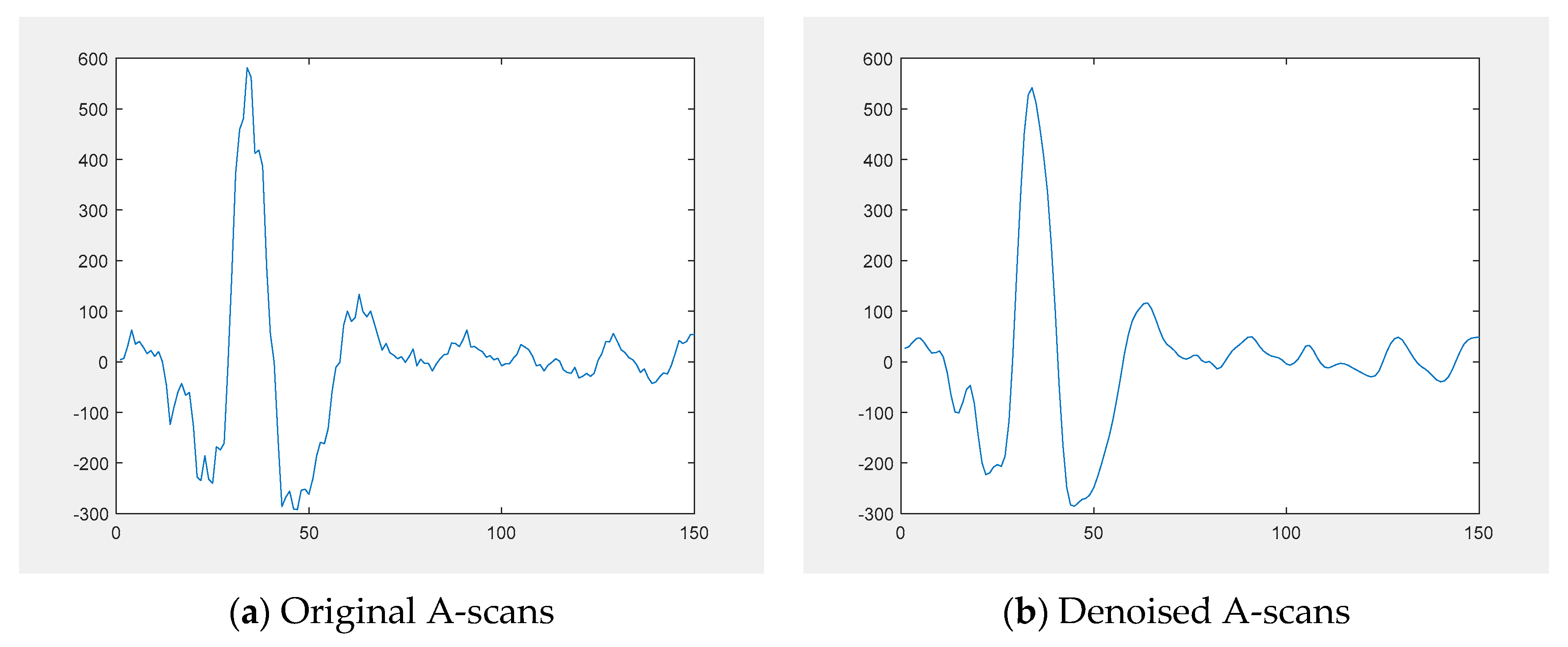

- This particular model can execute denoising BMD-based techniques. The process entails breaking down the noisy signal into IMFs and gauging their energy levels about the estimated noise-only IMF energies derived from Equation10. From there, the signal reconstruction is accomplished by adding up the IMFs whose energy levels deviate from the expected noise model.

- (11)

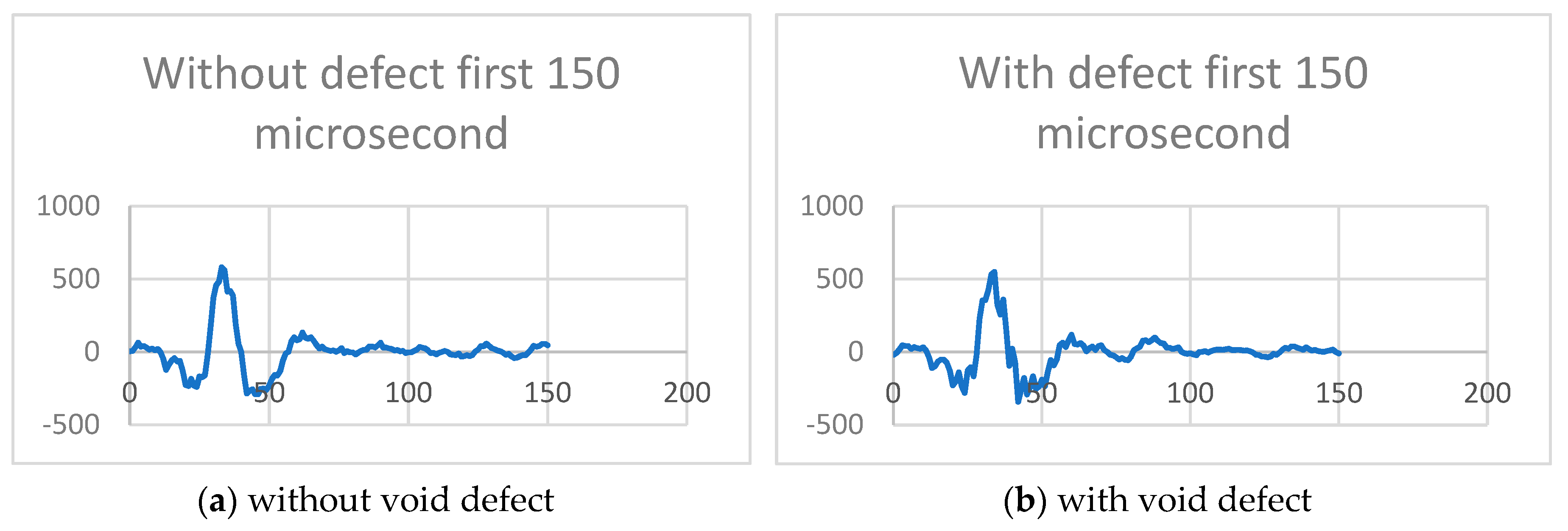

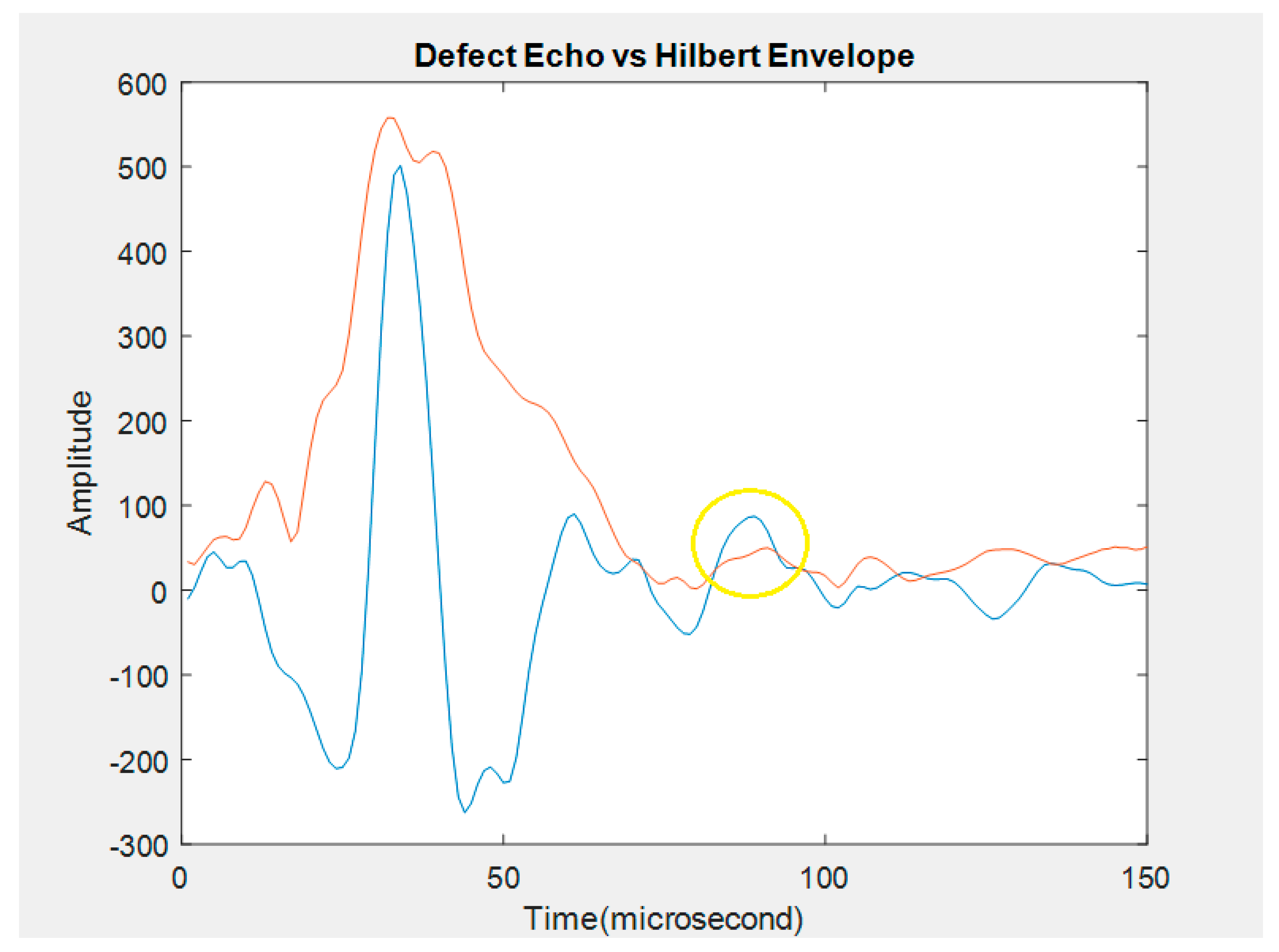

- Peak detection techniques are typically employed to estimate TOF, thereby differentiating between the reflection signal from the front surface and the reflection signal from the defect. Despite the denoising process, the defect echo signals may still exhibit dispersion and weakness, requiring specialized methods for identification and estimation. Techniques such as filtering, cross-correlation, envelop moment analysis, and matching pursuit decomposition with dispersion compensation are necessary for accurate defect detection in such scenarios. The envelope of an echo signal constitutes a vital characteristic that can be employed to extract information regarding the location of the echo waveform.

- (12)

- In Equation 14, j is the imaginary number, while H[·] denotes the Hilbert transform operation. In the time domain, the Hilbert transform is defined as the convolution of a(t) with 1/πt, where â(t)= H[a(t)]. The envelope of a signal is the magnitude of the analytical signal, which is the same as the magnitude of the real signal. The complex signal ã(t) is formed by the Hilbert transform, a(t), and â(t) as shown in Equation 15. Then, the envelope of the real signal can be given by Equation 16.

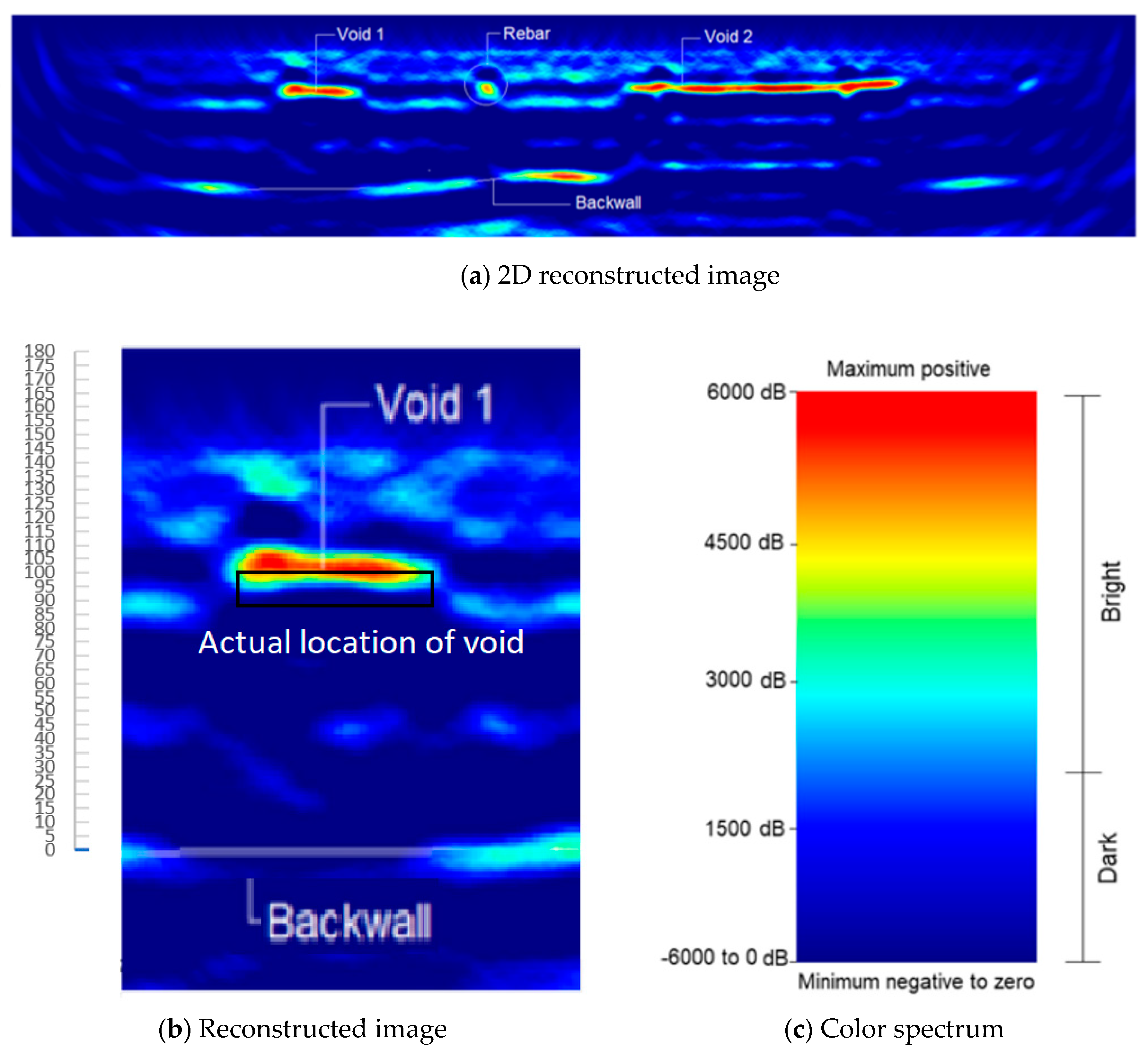

4. Results and Discussion

5. Conclusions

Acknowledgments

References

- ACI Committee 228, Nondestructive Test Methods for Evaluation of Concrete in Structures (ACI 228.2R-13), American Concrete Institute Farmington Hills, MI, 2013, 82 pp.

- Hosseini, Z., Momayez, M., Hassani, F., Lévesque, D.; Thompson, D.; and Chimenti, D. E., Detection of Inclined Cracks inside Concrete Structures by Ultrasonic SAFT, AIP Conference Proceedings, V. 975, 2008, pp. 1298-1304. [CrossRef]

- Tong, J. H., Chiu, C. L., and Wang, C. Y., Improved Synthetic Aperture Focusing Technique by Hilbert-Huang Transform for Imaging Defects inside a Concrete Structure, IEEE Transactions on Ultrasonics, Ferroelectrics, and Frequency Control, 2010., V. 57, No. 11.

- De La Haza, A., Samokrutov, A., and Samokrutov, P., Assessment of Concrete Structures Using the Mira and Eyecon Ultrasonic Shear Wave Devices and the SAFT-C Image Reconstruction Technique, Construction and Building Materials, V. 38, 2013, pp. 1276–1291. [CrossRef]

- Felice, M., and Fan, Z., Sizing of Flaws using Ultrasonic Bulk Wave Testing: A Review, Ultrasonics, Volume 88,2018, pp. 26–42.

- Blitz, J., and Simpson, G. Ultrasonic Methods of Nondestructive Testing, Springer: Berlin/Heidelberg, Germany, 1995.

- Karaiskos, G.; Deraemaeker, A.; Aggelis, D.; Van Hemelrijck, D. Monitoring of Concrete Structures using the Ultrasonic Pulse Velocity Method. Smart Mater. Struct. 2015, 24, 113001. [Google Scholar] [CrossRef]

- Hoegh, K.; Khazanovich, L.; Maser, K.; Tran, N. Evaluation of Ultrasonic Technique for Detecting Delamination in Asphalt Pavements, Transportation Research Record. Journal of the Transportation Research Board 2012, 2306, 105–110. [Google Scholar] [CrossRef]

- Hoegh, K., Khazanovich, L., Ferraro, C., and Clayton, D., Ultrasonic Linear Array Validation via Concrete Test Blocks, AIP Conference Proceedings 1650, 83 (2015). [CrossRef]

- Samokrutov, A., Bishko, A., and Shevaldykin, V., Ultrasonic Echo-Pulse Tomography of Concrete Using Shear Waves Low-Frequency Phased Antenna Arrays, NDT.net Issue: 2008-11, Special Issue of e-Journal of Nondestructive Testing, 2008, Vol. 13(11).

- Bishko, A., Samokrutov, A., and Shevaldykin, V., Ultrasonic Echo-Pulse Tomography of Concrete Using Shear Waves Low-Frequency Phased Antenna Arrays, 17th World Conference on Nondestructive Testing, 2008, pp. 25–28, Shanghai, China.

- Zhao, H., Song, P., Urban, M., Kinnick, R., Yin, M., Greenleaf, J., and Chen Shigao, S., Bias Observed in Time-of-Flight Shear Wave Speed Measurements Using Radiation Force of a Focused Ultrasound Beam, Ultrasound in Medicine and Biology, 2011, 37(11), pp. 1884-1892.

- Deng, Y., Rouze, N., Palmeri, M., and Nightingale, K., System Dependent Sources of Error in Time-of-Flight Shear Wave Speed Measurements, 2015 IEEE International Ultrasonics Symposium (IUS), Taipei, Taiwan, 2015, pp. 1–4. [CrossRef]

- Haslinger, S., Lowe, M., Huthwaite, P., Craster, R., and Shi, F., Elastic Shear Wave Scattering by Randomly Rough Surfaces, Journal of the Mechanics and Physics of Solids, V. 137, 2020, 103852.

- Yufeng Deng, Ned C. Rouze, Mark L. Palmeri, and Kathryn R. Nightingale, On System Dependent Sources of Uncertainty and Bias in Ultrasonic Quantitative Shear Wave Imaging, IEEE Trans Ultrason Ferroelectr Frequency Control. 2016, 63(3), pp. 381–393.

- De La Haza, A., Samokrutov, A., and Samokrutov, P., Assessment of Concrete Structures using the Mira and Eyecon Ultrasonic Shear Wave Devices and the SAFT-C Image Reconstruction Technique, Construction and Building Materials, 38, 2013, pp.1276–1291.

- Lin, S.; Shams, S., Choi, H., and Azari, H., Ultrasonic Imaging of Multi-Layer Concrete Structures, NDT & E International, Volume 98, 2018, pp. 101–109.

- Kwon, H.; Joh, c.; Chin, W. Pulse Peak Delay-Total Focusing Method for Ultrasonic Tomography on Concrete Structure. Appl. Sci. 2021, 11, 1741. [Google Scholar] [CrossRef]

- Harshit, J.; Patankar, V. Advances in Ultrasonic Instrumentation for Inspection of Concrete/RCC Structures; Elsevier: Amsterdam, the Netherlands, 2019. [Google Scholar]

- Zatar, A., Nguyen, H., and Nghiem, h., Ultrasonic Pitch and Catch Technique for Non-destructive Testing of Reinforced Concrete Slabs, Journal of Infrastructure Preservation and Resilience, 2020, pp. 1–12.

- Ohara, Y.; Kikuchi, K.; Tsuji, T.; Mihara, T. Development of Low-Frequency Phased Array for Imaging Defects in Concrete Structures. Sensors 2021, 21, 7012. [Google Scholar] [CrossRef]

- San Emeterio, J., and Rodriguez-Hernandez, M., Wavelet Denoising of Ultrasonic A-Scans for Detection of Weak Signals, 2012, 19th International Conference on Systems, Signals and Image Processing (IWSSIP), Vienna, Austria, 2012, pp. 48–51.

- Hoseini, M., Zuo, M., and Wang, X., Denoising Ultrasonic Pulse-echo Signal using Two-dimensional Analytic Wavelet Thresholding, Measurement, Vol. 45, Issue 3, 2012, pp. 255–267.

- Sharma, G., Kumar, A., and Jayakumar, T., Ensemble Empirical Mode Decomposition-Based Methodology for Ultrasonic Testing of Coarse Grain Austenitic Stainless Steels, Ultrasonics, 2015, 57: pp. 167–178.

- Traitement du Signal, Vol. 36, No. 2, 2019, pp. 139-145.

- Orcid, Z., Xu, H., Jiang, B., and Han, F., Wavelet Threshold Ultrasound Echo Signal Denoising Algorithm Based on CEEMDAN, Electronics, 2023, 12(14), 3026.

- Bouchair, A., Selouani, S.A., AND Amrouche, A., Improved Empirical Mode Decomposition Using Optimal Recursive Averaging Noise Estimation for Speech Enhancement, Circuits System Signal Process 41, 2022, pp. 196–223. [CrossRef]

- Zhang, Z., Xie, H., Tong, X., Zhang, H., Liu Y., and Li, B., Denoising for Satellite Laser Altimetry Full-waveform Data Based on EMD-Hurst Analysis, International Journal of Digital Earth, 2020, 13:11, pp. 1212–1229.

- Luo, H., Fang, X., and Ertas, B., Hilbert Transform and its Engineering Applications, AIAA Journal, 2009, 47(4), pp. 923–932.

- Yoo, J.; Cho, S. Advanced Synchronization Check Method Using Hilbert Transform-based Voltage Envelope Analysis. Journal of Electrical Engineering Technology 2023, 18, 4463–4471. [Google Scholar] [CrossRef]

- Zhang, M., and Wei, G., An Integrated EMD Adaptive Threshold Denoising Method for Reduction of Noise in ECG. PLoS One, 2020, 15;15(7):e0235330. [CrossRef]

- Feng, W.; Zhou, X.; Zeng, X.; Yang, C. Ultrasonic Flaw Echo Enhancement Based on Empirical Mode Decomposition. Sensors 2019, 19, 236. [Google Scholar] [CrossRef]

- Duan, D., Ma, H., Yan, Y., and Yang, Q., A Fault Diagnosis Scheme Using Hurst Exponent for Metal Particle Faults in GIL/GIS, Sensors, 2022, 22(3), 862.

- Haider, N., Respiratory sound denoising using Empirical Mode Decomposition, Hurst analysis and Spectral Subtraction, Biomedical Signal Processing and Control, 2021, Volume 64, 102313.

- Zhu, W.; Chen, X.; Li, Z.; Meng, X.; Fan, G.; Shao, W.; Zhang, H. A SAFT Method for the Detection of Void Defect inside a Ballastless Track Structure Using Ultrasonic Array Sensors. Sensors 2019, 19, 4677. [Google Scholar] [CrossRef] [PubMed]

| Method | Experimental specimen | UPE device | New method |

|---|---|---|---|

| Distance from surface (mm) | 83 | 70-75 | 82 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).