1. Introduction

The quality and reliability of modern machines are largely determined by the correct consideration in the design of friction characteristics in various critical frictional interfaces. In each friction pair, in the initial period of the process of contact interaction, the geometric parameters of the friction surfaces change so called running-in or breaking-in [

1]. Widespread practice shows that the operation of a friction pair begins only after the completion of the running-in. Therefore, information about the completion of running-in is the most important characteristic of this process.

To date, standard methods for determining the running-in have not yet been developed. Information about the end of the running-in process directly in the process of friction can be obtained only when conducting laboratory tests, for example, according to data on the stabilization of the friction coefficient or stabilization of the temperature in the contact area. Therefore, there is an urgent need to develop methods for directly determining the run-in time at a working facility. One of such methods can be Acoustic Emission (AE) testing.

The using of ceramic materials in modern friction units further enhances the problem of the relevance of the study of running-in. The fact is that ceramics, having such very useful properties as strength, hardness, high wear resistance, the ability to work at high temperatures and in an aggressive environment, have a significantly negative property - brittleness. The tendency of ceramics to unexpected destruction requires the organization of continuous monitoring of their properties during operation. Therefore, the running-in of such materials must be continuously monitored.

An analysis of the literature has shown that when wear-resistant ceramic and brittle materials are used in friction units, the initial stage of the process in dry friction is practically not studied. There are several explanations for this: firstly, because the friction process is non-equilibrium and fast; secondly, access to the contact gap for direct research is difficult; thirdly, there are no convenient instrumental methods of research. It is obvious that the running-in mechanism has not been sufficiently studied yet, because always, first of all, most research is focused purely on applied applications. However, only by understanding the physical causes of the phenomenon, one can choose ways to control it over time. In this regard, it is of interest to use the AE method to control the running-in of movable parts.

2. Background

Friction usually accompanies the mechanism of energy dissipation (dissipation) in the process of relative motion of two bodies [

2]. Also, as a result of the frictional interaction of the surfaces, the initial values of the roughness and waviness parameters change in such a way that during further work under the same conditions, there is no noticeable change in their values [

3]. A high coefficient of friction does not necessarily entail intense wear, since the frictional interaction energy entering the system is divided in different ways. It can be used, for example, for the formation of oxides, the growth of cracks, the formation of grooves, surface heating, and also for the formation of layers of sheared particles. Thus, two systems may have the same coefficients of friction, but one may have more wear than the other [

4].

When friction is initiated, there is a certain transitional period called running-in, during which friction and wear rate decrease to their constant values [

5]. The term running-in is used mostly in Europe and Great Britain, while in the United States the term breaking-in is predominantly used [

6]. During the running-in process, the surfaces adapt to each other, leading to a more ordered state, lower energy dissipation rates, and exhibit friction-induced self-organization [

7]. Practice shows that, despite the large number of currently available criteria for the end of running-in, there are no standard methods for assessing the running-in of machine-building materials [

8]. In this regard, it is of interest to use movable mates to control the running-in using the AE method. One of the criteria for the end of running-in is the stabilization of the selected parameters at a certain level [

9]. Other indirect methods can be used to determine whether burn-in is complete, such as the concentration of wear particles in the lubricant, the vibration characteristics in the bearings, and the temperature of the bearing body [

6].

Acoustic emission is a natural phenomenon observed by man from early times. AE is also sometimes called stress wave emission [

10]. The oldest natural sources of emission are earthquakes and rock bursts (sudden rock collapse) in mines [

11]. The first documented observation of audible acoustic emission was made in the 8th century AD. Arab alchemist Abu Musa Jabir Ibn Hayyan Al-Azdi, also known by the Latinized name Geber. In his work ‘Summa perfectionis magisterii’, published in Latin in 1545, he described the ‘harsh sound’ of tin (Jupiter) and the ‘sounds much’ of iron (Mars) in forging. In the Middle Ages, tin smelters tested the samples given to them for melting for the presence of impurities by bending them, since the sound emitted when pure tin was bent (the ‘cry of tin’) made it possible to judge the absence of impurities, such as lead or zinc, which reduce the luster of the casting [

12]. Classical AE sources are the result of deformation processes: crack growth and plastic deformation. The author [

13] argues that there are only a few main sources of AE that generate the characteristic parameter of ultrasound. In his opinion, more complex sources of AE can be the result of a combination of different types of simple sources.

The physical basis of the AE phenomenon during friction is that the frictional interaction causes a dynamic local change in the fields of mechanical stresses in contacting media, which manifests itself in the appearance of stress waves [

14], by registering which, one can judge the course of processes and their parameters. Widespread studies of AE during friction in the former Soviet Union (USSR) fall on the beginning of the 80s and are described in the following works [

15,

16,

17,

18,

19]. Several research papers have been carried out to confirm or disprove the existence of any type of connection between the AE method and friction. For example, in [

20], AE was measured in metal samples under conditions of intense sliding friction. This study showed that there is a relationship between dry sliding friction and AE. Also, certain external variables were found, on which the AE count rate depends. The relationship between AE and friction confirms the fact that AE can be used for modern diagnostics of a technical condition.

Methods for analyzing AE signals, depending on the equipment used, can be divided into two main groups: 1) based on the analysis of signal parameters (classical); 2) based on waveform analysis (quantitative). The reason for the existence of two methods was the rapid development of microelectronics over the past few decades, since it was previously impossible to record and store a large number of waveforms in a relatively short period of time. Both methods are successfully used today [

21]. When monitoring AE in real time, the use of temporal (classical) analysis is common. The measured AE parameters in this case are: an acoustic emission event; number of acoustic emission pulses; acoustic emission count rate; maximum amplitude and energy of acoustic emission [

10,

22]. Using the so-called quantitative AE technology, it is possible to record and store as many signals as needed, along with their shape, by converting the signals from analog to digital form. This method provides better data interpretation capabilities than the previous one, allowing the use of Digital Signal Processing (DSP) techniques to extract the signal from the noise. As a result, it is possible to perform a more comprehensive, but at the same time more time-consuming data analysis, usually performed in post-processing [

21].

The main disadvantage of the second method is the generation of a large amount of data, since the frequency range of AE waves can vary from several Hertz to Megahertz, then in order to cover the weight of this volume of frequencies, in accordance with the Nyquist-Shannon theorem or the sampling theorem, the sampling frequency should be at least twice the maximum signal frequency [

23,

24]. Due to high sampling rates, signals of even short duration will be large. But, despite this disadvantage, this method is widely used because of its advantages in signal processing.

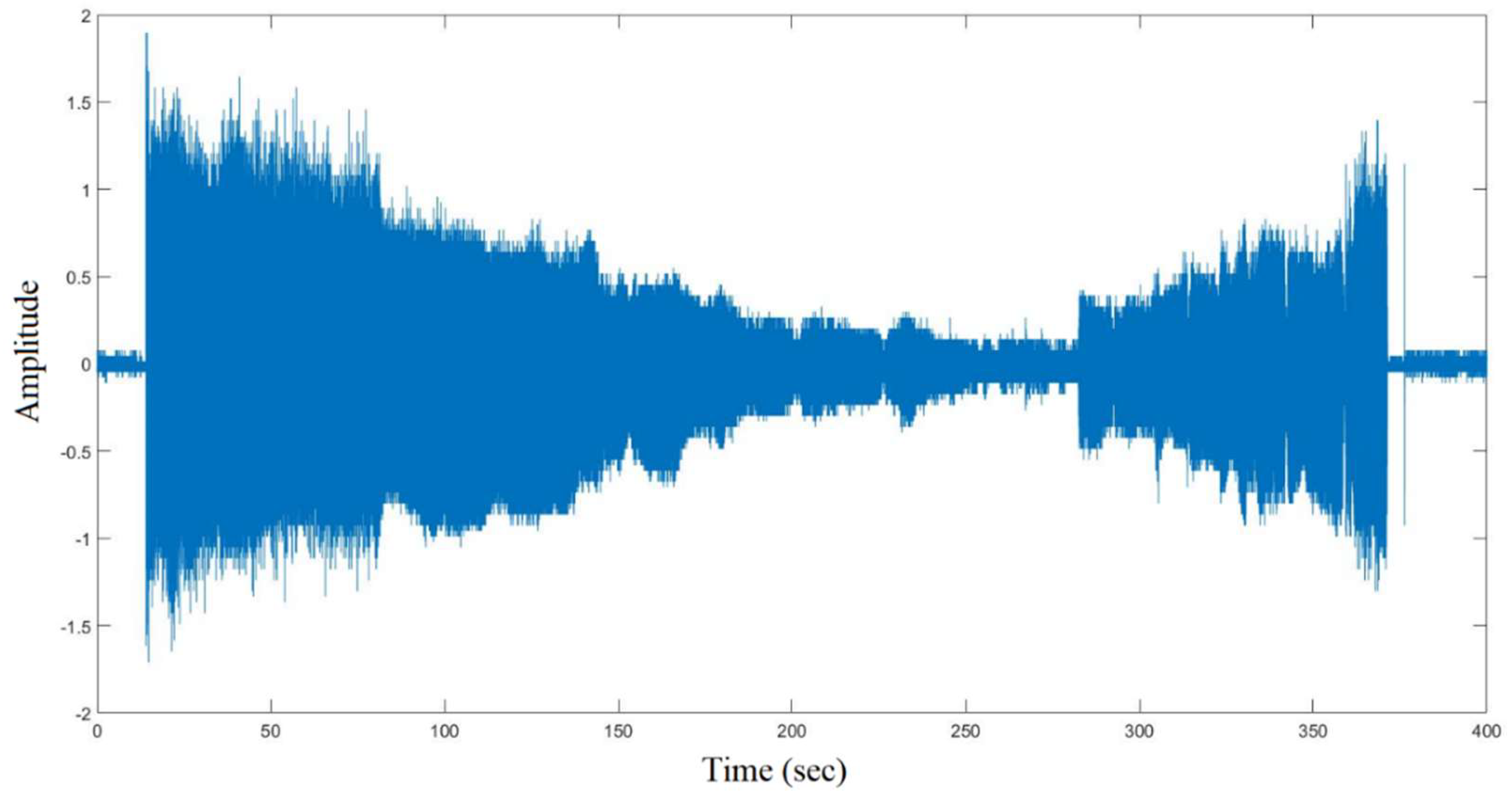

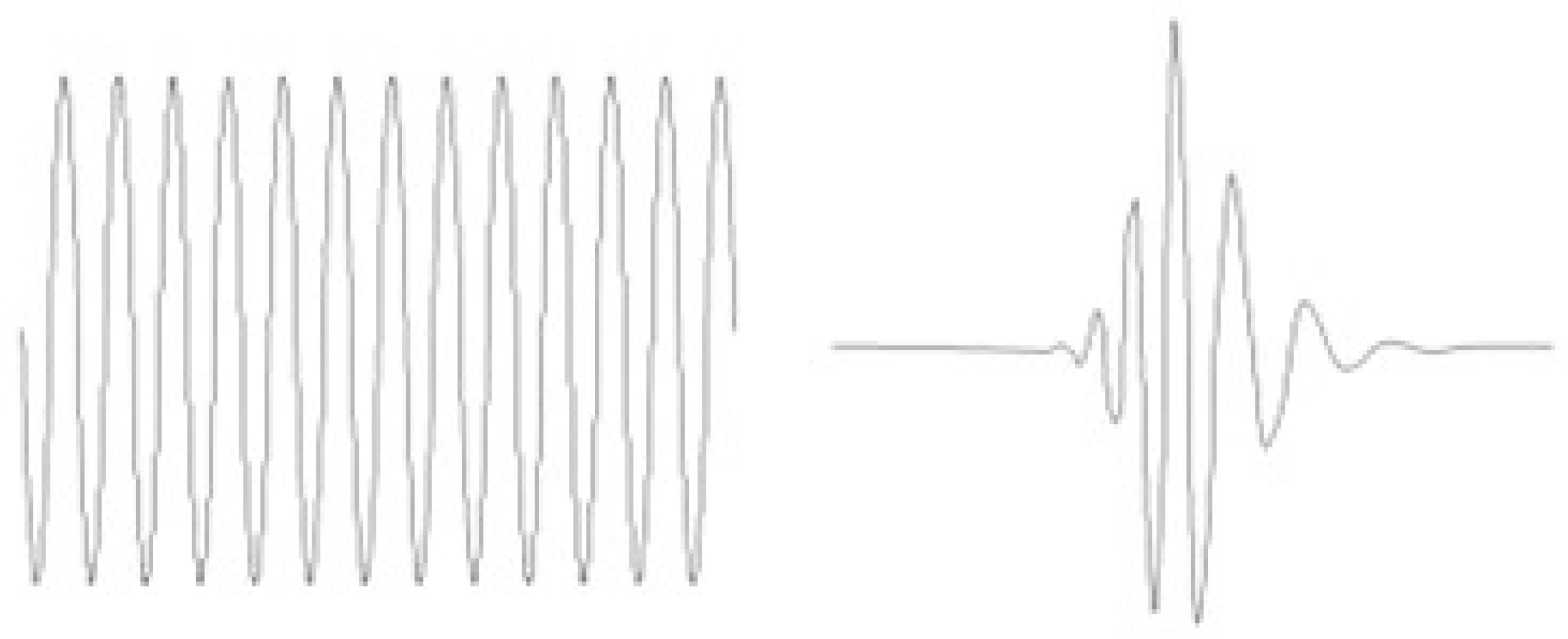

Figure 1 depicts a typical example of the AE signal waveform collected in real time by the AE sensors of the AE monitoring system during the friction.

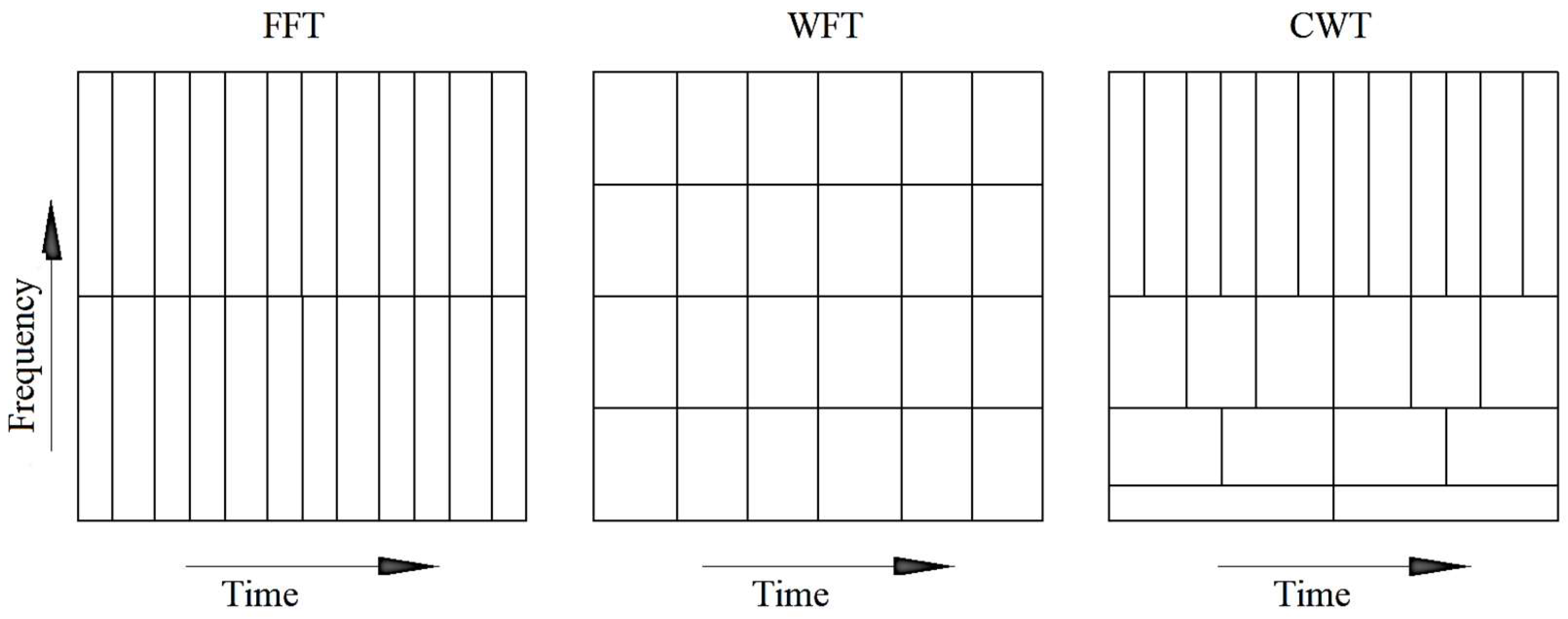

Currently, there are several methods for analyzing waveform based acoustic emission: 1) amplitude-time; 2) frequency; 3) frequency-time; 4) others. The applicability of time or frequency types of analysis is significantly limited for non-stationary signals, which include AE signals, therefore, various time-frequency analysis methods are used [

25]: Gabor transform or windowed (local) Fourier Transform (FT); Wigner-Wille transform and Wavelet Transform (WT). Analysis of the frequency characteristics of signals is usually performed using the Discrete Fourier Transform (DFT) and its calculation algorithm, called the Cooley-Tukey algorithm [

24]. A modified version of this algorithm, known as the Fast Fourier Transform (FFT), mathematically transforms the time domain of AE signals into a sequence of discrete frequency components - spectral analysis. However, the use of the Fourier transform for the spectral analysis of AE signals has two main drawbacks. First, Fourier transform does not give us any information about the time of occurrence of a particular frequency component. Secondly, the signal must be stationary, which is not suitable for the studied AE signals. One way to overcome these shortcomings is to use the WT as one of the frequency-time analysis techniques. In fact, WT is a timescale method because it transforms a function from the time domain to the timescale domain. WT is a reversible transformation that allows reconstruction or estimation of certain signal components, even if the inverse transformation may not be orthogonal [

26].

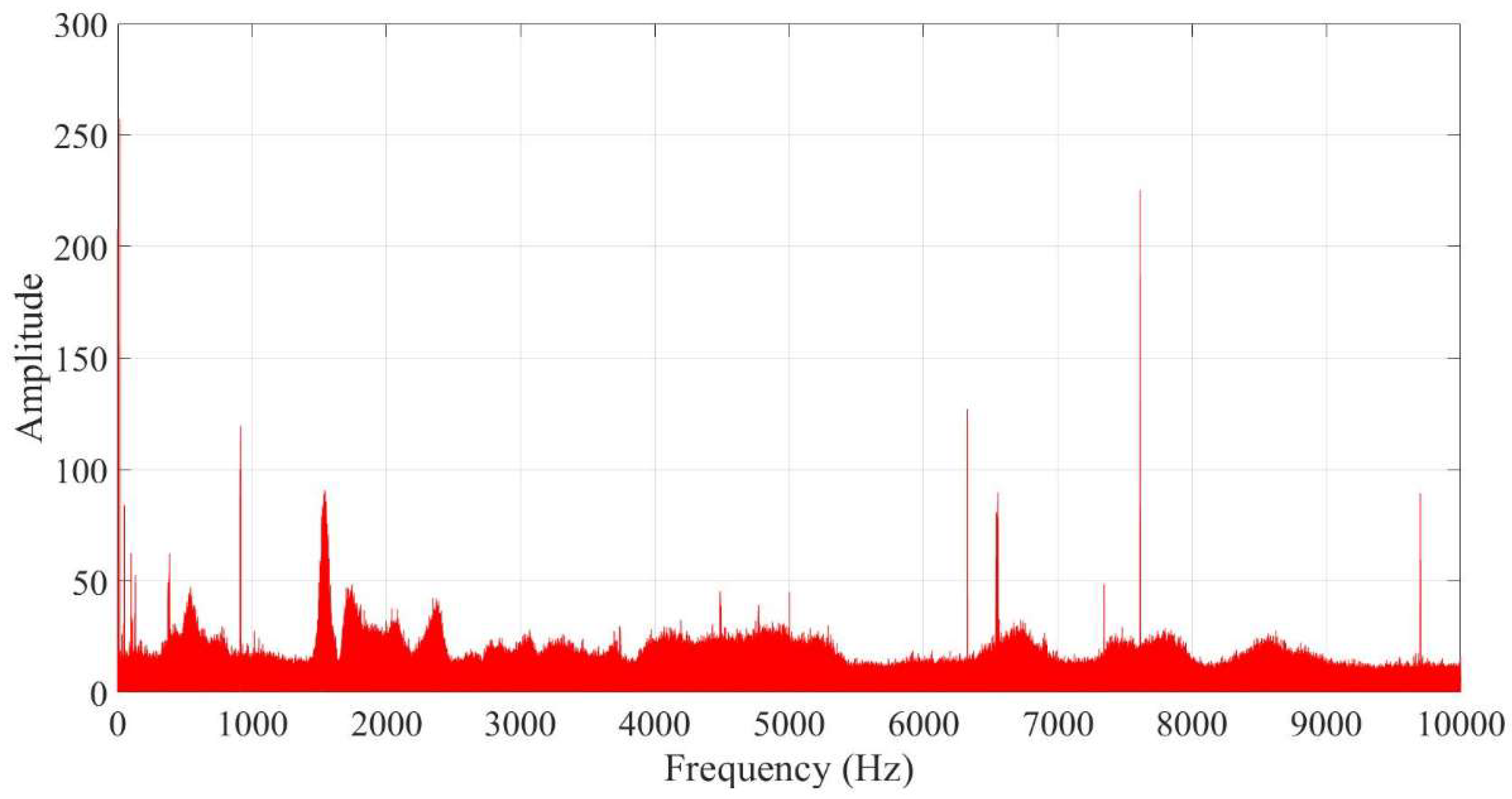

For example,

Figure 2 shows the FFT result for a typical raw AE signal. Knowing the frequency range of the AE sensors, we can initially determine the dominant frequency ranges. However, from the presented figure it is obvious that we cannot unambiguously determine the specific moments in time of the occurrence of one or another frequency component present in the signal. Therefore, in this study, when analyzing AE signals, we concentrate on the criteria of wavelet energy and wavelet entropy, since a different distribution of energy at each frequency component of the signal can be associated with a certain stage of destruction. By analogy with the Fourier transform, wavelet entropy can provide additional useful information underlying the dynamic process of the signal under study.

According to the definition of information entropy introduced by Shannon [

27], entropy is a measure of the information of any distribution in the analysis and comparison of probability distributions, that is, it is a measure of the quantitative uncertainty of the system. Moreover, Kolmogorov and Sinai have transformed Shannon's information theory into a powerful tool for the study of dynamical systems [

28,

29]. The entropy value of a signal reflects the degree of complexity that the signal has. A more disordered signal shows more entropy. By analogy with the wavelet transform, the wavelet transform based entropy is called wavelet entropy and can provide additional useful information underlying the dynamic process of the signal under study. This idea is theoretically clarified below.

4. Experimental Set-Up and Test Procedure

4.1. Experimental Set-Up

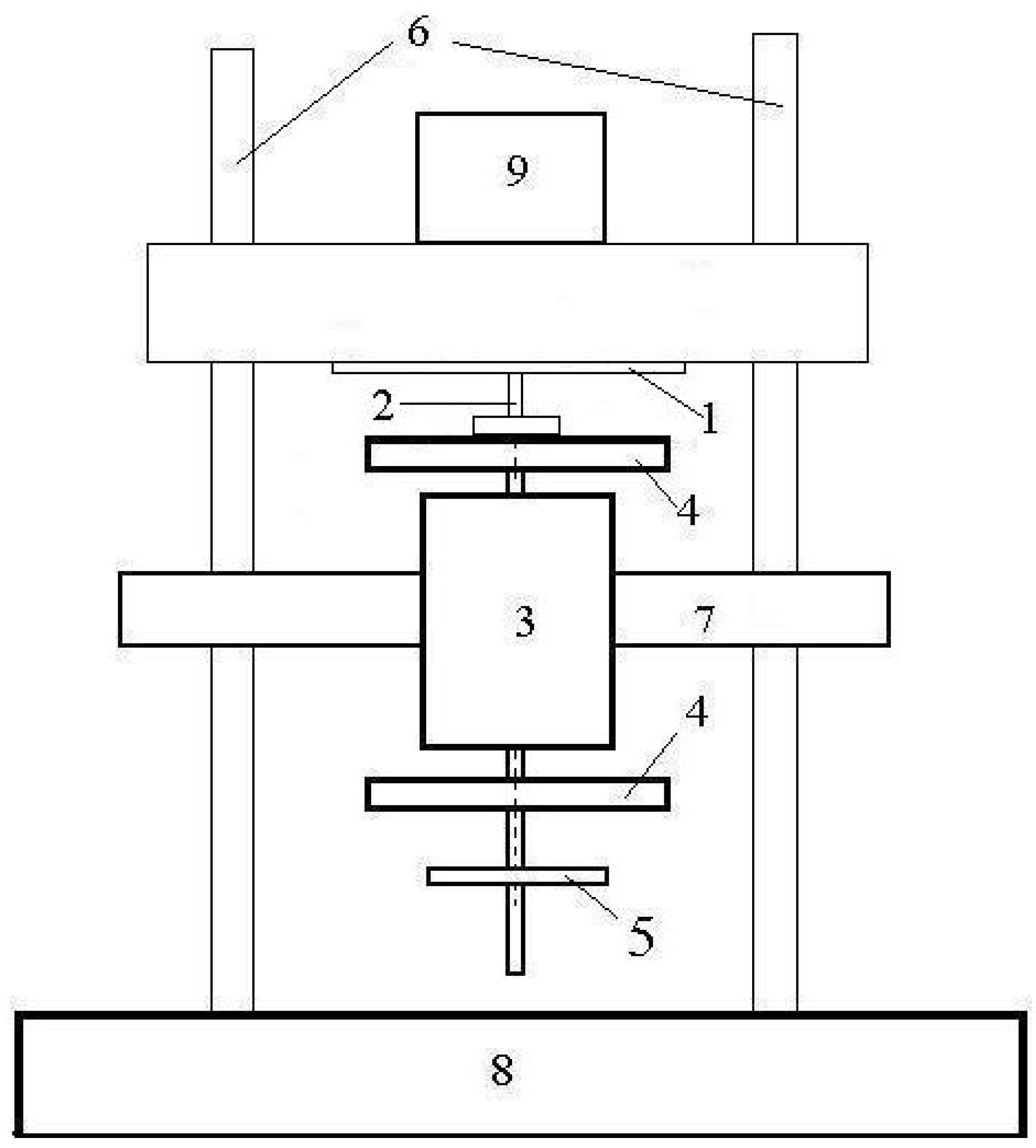

Experimental studies on the study of the initial stage of contact of solids were carried out on various tribological pairs composed of different materials: ceramics, metals, and their combinations. The process of friction of model samples was studied on several types of tribometers operating according to various geometric contact patterns. The variety of materials made it possible to select the optimal model pairs for the respective studies. The choice of equipment and approaches to research is due to the main goal of the work - to obtain information directly during the friction process. The most convenient for friction testing turned out to be a setup with flywheels was a variant of the movable / fixed ring scheme. It can operate both in continuous mode and under braking conditions. A general view of the installation is shown in

Figure 9.

Figure 9.

Experimental setup for the study of friction: 1 – stationary sample of the material under study; 2 – rotating specimen; 3 – electromotor; 4 – flywheels; 5 – photoelectric speed sensor; 6 – guides; 7 – motor mount; 8 – frame; 9 – load.

Figure 9.

Experimental setup for the study of friction: 1 – stationary sample of the material under study; 2 – rotating specimen; 3 – electromotor; 4 – flywheels; 5 – photoelectric speed sensor; 6 – guides; 7 – motor mount; 8 – frame; 9 – load.

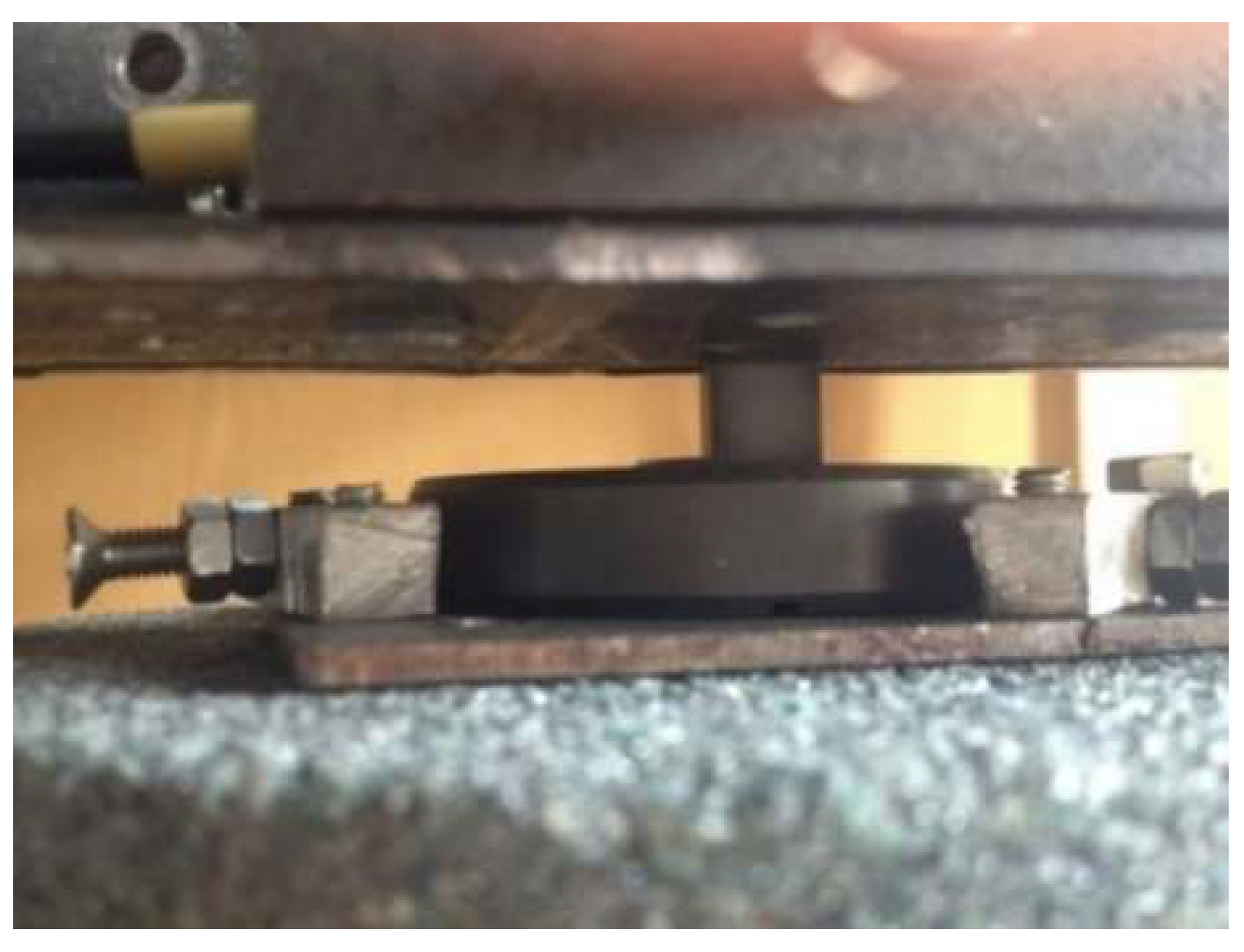

Figure 10.

Friction unit: movable sample is a disk; fixed sample is a pin.

Figure 10.

Friction unit: movable sample is a disk; fixed sample is a pin.

The setup is very effective for rapid express analysis of the tribological properties of materials and testing in liquid media. There are no special requirements for sample dimensions. A movable sample in the form of a disk, rod, ring, tube or even a bar, together with flywheels, can be accelerated by an electric motor up to a maximum angular velocity of 50 rpm. The stationary sample may be in the form of a plate, a ring, a cylinder, or an arbitrary shape with a flat area. Loads (maximum load 200 N) located on the movable traverse provide contact pressure during friction. The initial deceleration rate, depending on the configuration of the friction pair samples, can reach 25 m/s. During braking, each revolution is registered by a photoelectronic speed sensor. Data from photoelectric sensors, as well as other measuring devices (thermocouples, vibration sensors, microphones, etc.) installed as necessary on the device, are transmitted to the ACK-3107 virtual oscilloscope. When processing data, both the total number of revolutions and the duration of each of them can be determined.

The friction coefficient is calculated using the following formula [

45]:

where

is the moment of inertia of the rotating masses;

is a deceleration path, on which the angular velocity changed from

to

and

is a load.

4.2. Data Recording and Acquisition

The experimental setup for studying acoustic emission signals consisted of two main instruments. One of the devices was created on the basis of blocks of the standard AF-15 equipment and is designed to record classical high-frequency (HF) acoustic emissions in the range from 200 kHz to 1 MHz, while the other device, on the contrary, provides low-frequency (LF) registration of acoustic signals with a frequency of up to 20 kHz using the ACK-3107 virtual oscilloscope, a Personal computer (PC) Based USB Oscilloscope, which allows recording the waveform of the AE signal. Each channel of the ACK-3107 has its own analog-to-digital converter (ADC).

The high-frequency path of the installation consisted of: 1) a source of wave; 2) piezoelectric transducer; 2) preamplifier; 3) main amplifier; 4) filters; 5) data processing unit. From the HF processing unit, the AE signal enters the National Instruments PCI-6023e Multifunction I/O DAQ Board, which converts the original analog signal into a sequence of counts. Counts are taken at regular intervals

this is the so-called sampling period (or interval, sampling step), which is the inverse of sampling frequency (

) [

46,

47,

48,

49]:

At the output of the board, signals event, amplitude, oscillations are formed. After the event pulse arrives at the computing device, the time of its arrival is determined and a serial number is assigned to it. The amplitude of the AE signal in this work is understood as the maximum value of the amplitude in the radio pulse. This amplitude is measured by a peak detector. Counting the intersections of a certain voltage level by a damped AE pulse gives the signal oscillations. Thus, an array of data is formed in the computer. Based on these data, one can judge how the material wear process changes over time [

50].

The low-frequency path consisted of a virtual oscilloscope ACK-3107 and AE sensors of the P113 type made from TsTS-19 piezoceramics, as well as GT-200-01 and GT-205-01. Analogue AE signals arising during the friction were recorded by piezoelectric sensors and transmitted to the ACK-3107 virtual oscilloscope connected to a PC, where they are digitized with a sampling frequency of 20 kHz (see

Figure 11), which was determined by the capabilities of the PC.

For experimental registration of wave phenomena, standard acoustic emission equipment is usually used, but if low-pass filters are removed from the amplification path, then the range can be significantly expanded towards lower frequencies. Usually, when using AE to study the destruction of structural materials, they try to avoid the noise of the test equipment and put low-pass filters. In the case of studying the destruction of surface layers of materials during friction, low-frequency interactions are the main ones. It can be assumed that during friction there will be not only wave phenomena associated with the interaction of individual roughness (contact spots), but also larger-scale phenomena associated with the waviness of the surfaces themselves. All this is directly related to the running-in of surfaces.

4.3. Results Correlations and Analysis

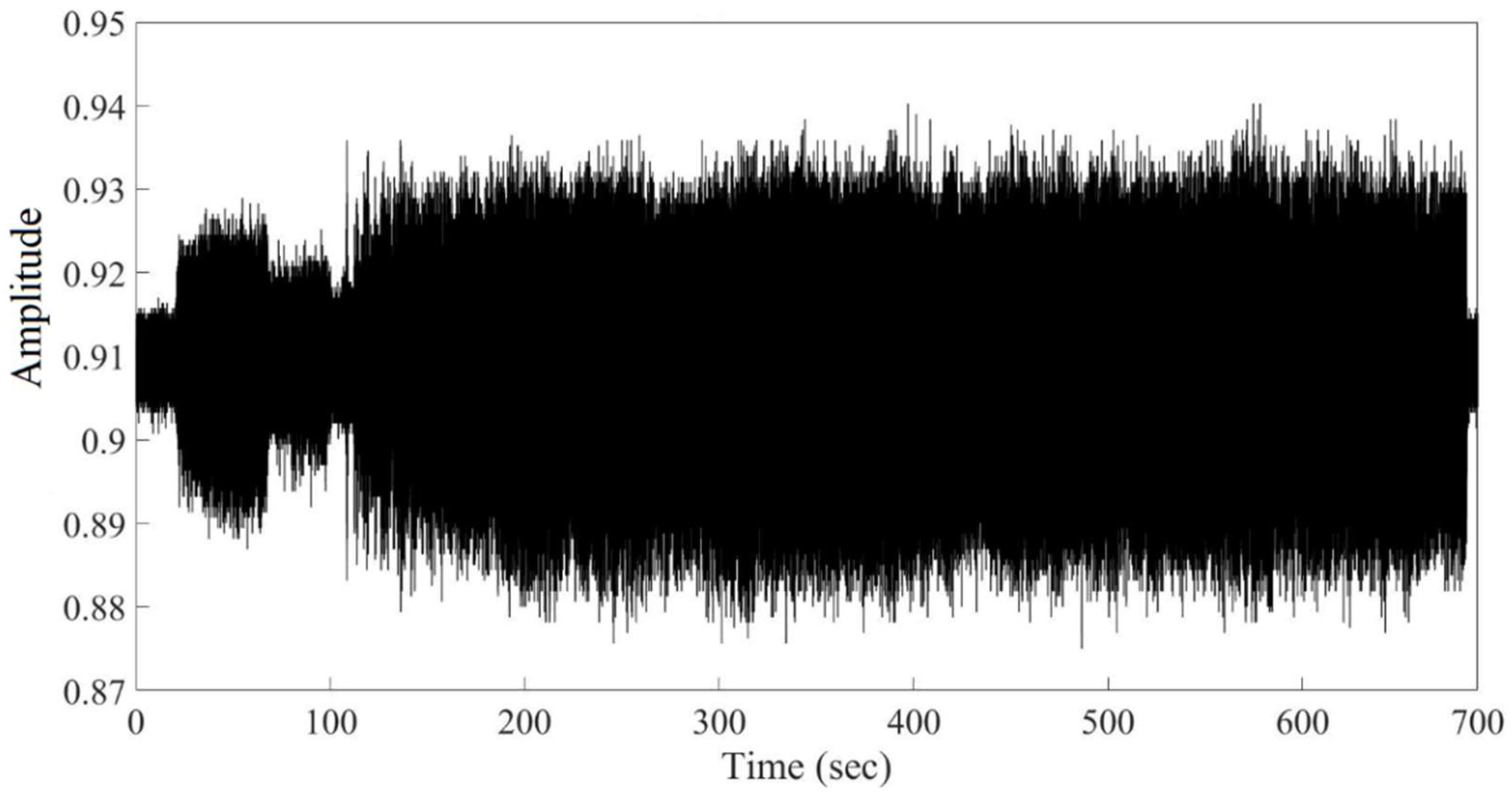

The dry friction behavior of Alumina ceramics (Al₂O₃) against steel was investigated in air at room temperature, and a constant load 10 N using the equipment described in the subsection 4.1. The coefficient of friction calculated by the formula from subsection 4.2 was 0.24. To analyze the waveform of AE signal recorded during the friction, see

Figure 12, the MATLAB programming platform was chosen as having numerous options and allowing you to create your own code corresponding to the application. The developed code was used to perform the Fourier transform and wavelet analysis of acoustic emission signals.

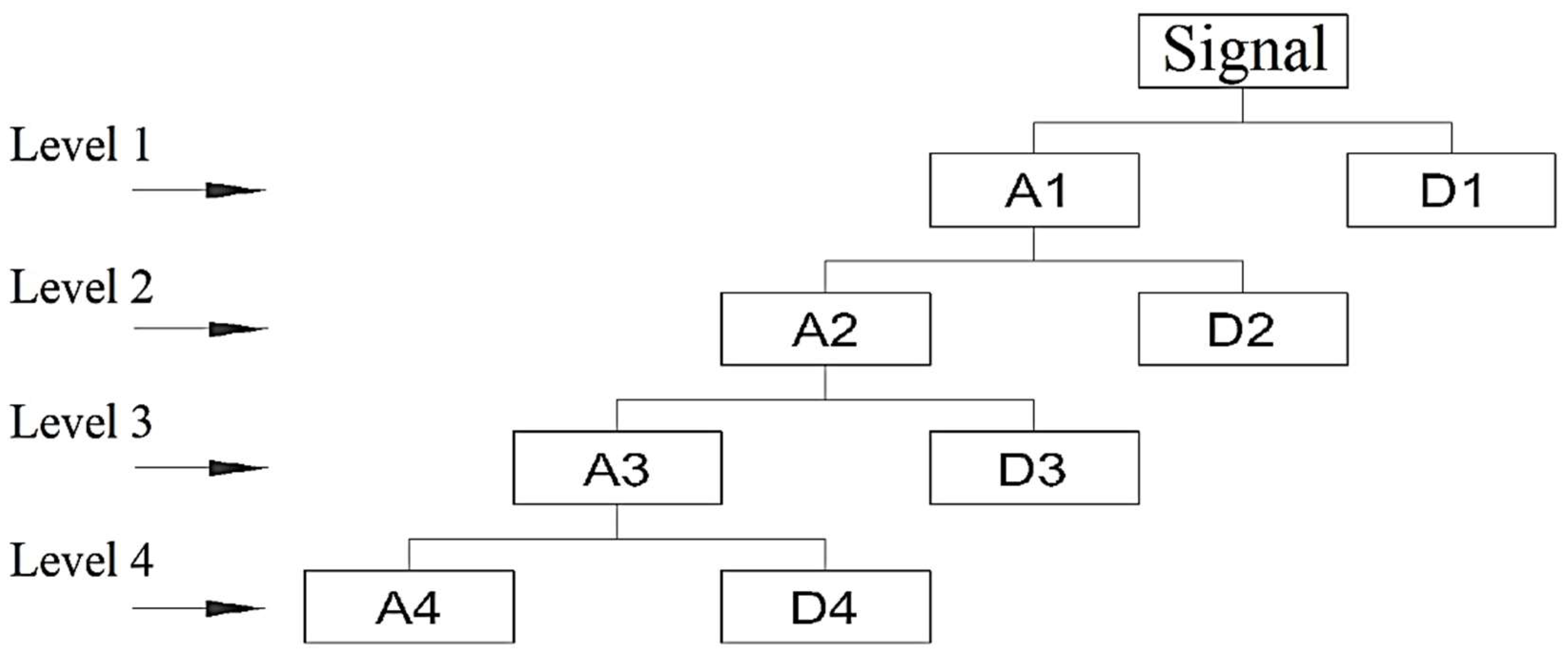

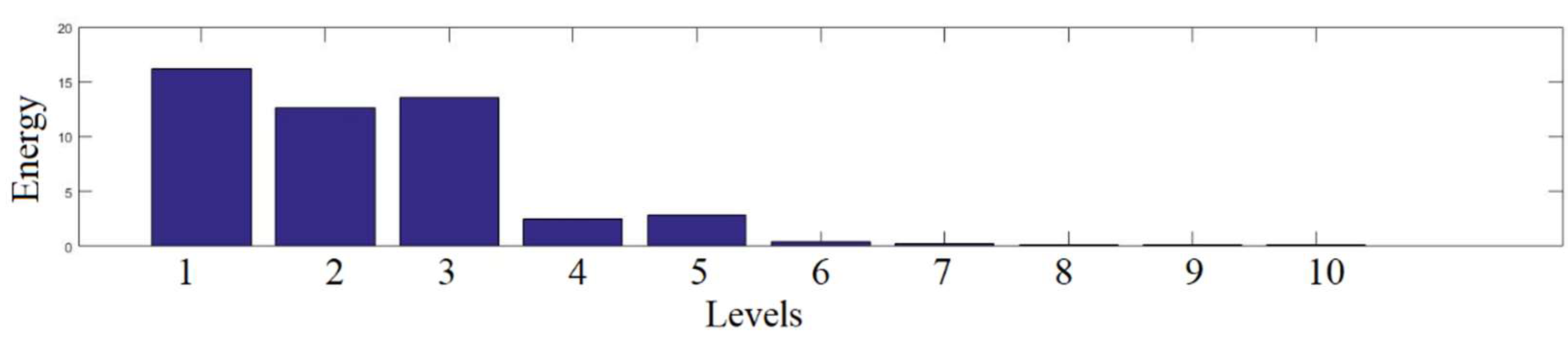

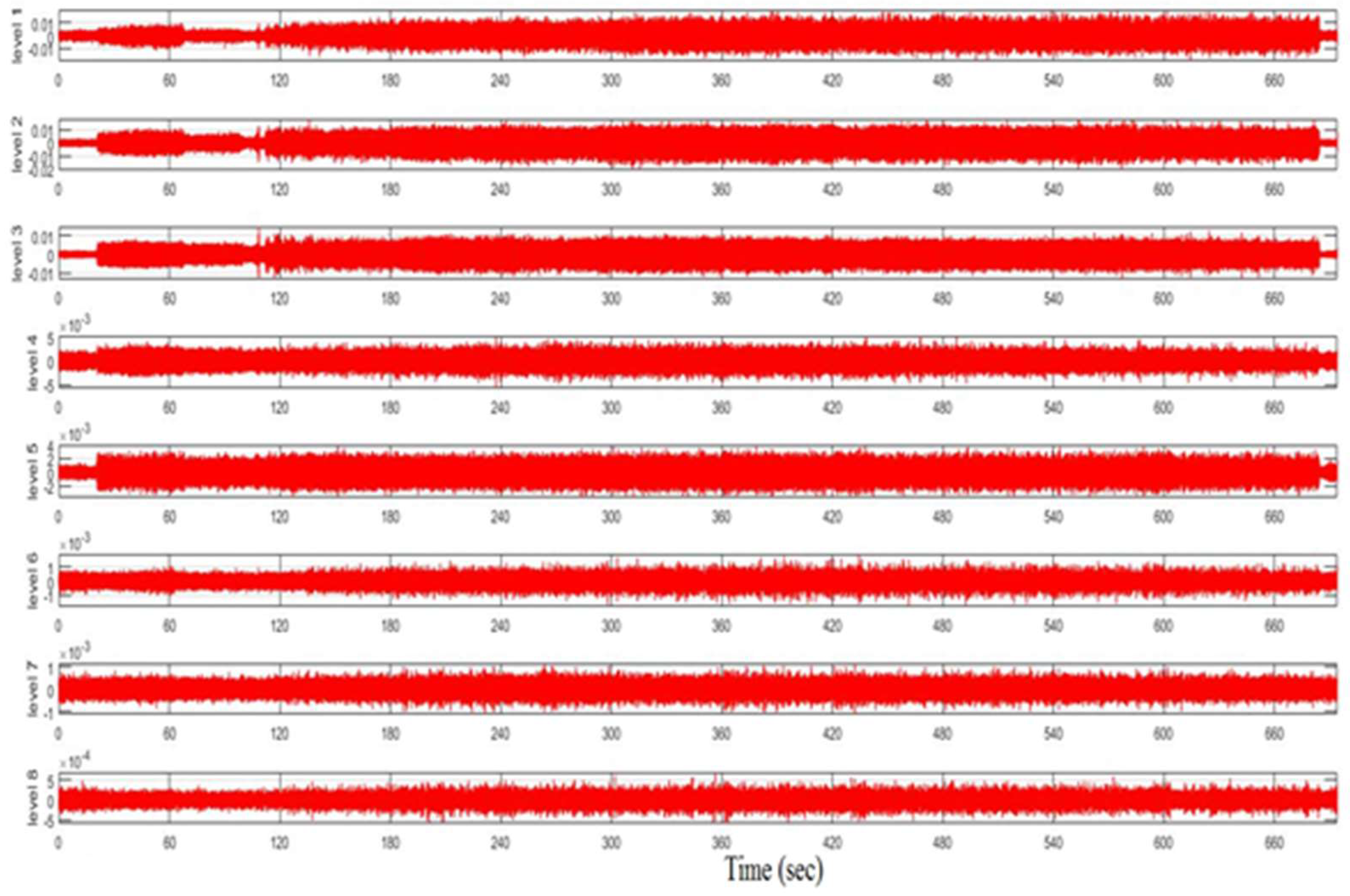

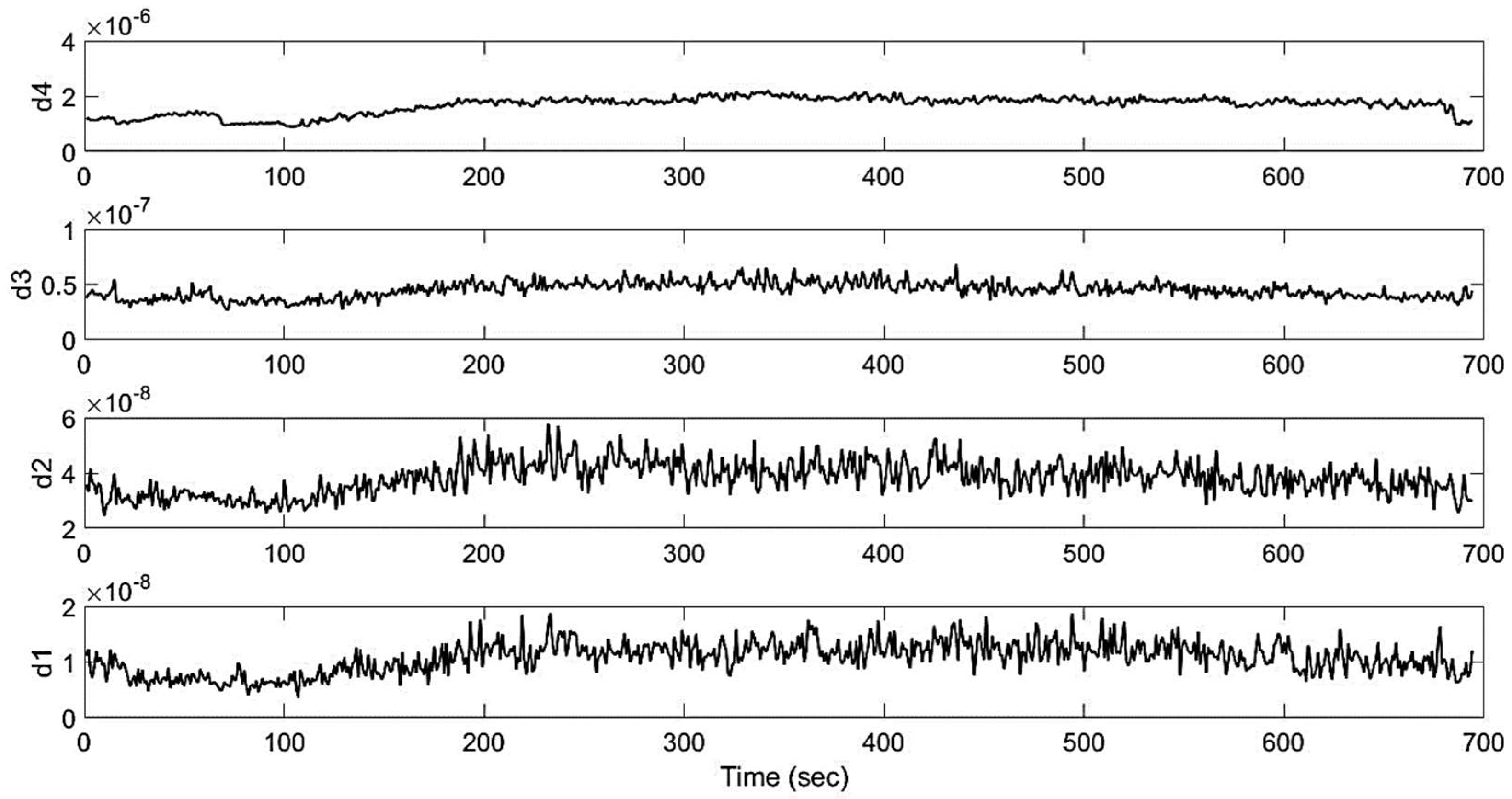

Having chosen the mother wavelet (in our case, the Meyer wavelet), the AE signal was decomposed into 8 levels, see

Figure 13. The result of the wavelet transform was a sequence of wavelet coefficients at each level of decomposition, ordered by a hierarchical scheme (see the multi-scale analysis described in the previous section). For each moment of time, the wavelet function is related to the waveform of the signal under study at a given position. Such a correlation is a measure of how the position of the wavelet at a given decomposition level corresponds to the waveform signal under study. Each level of decomposition corresponded to a certain frequency range, see

Table 3. The results obtained show that the maximum amount of energy is concentrated on the first level, and the energy of the wavelet coefficients contained from levels 4 to 8 is less than 15% of the total energy of the wavelet coefficients of the studied AE signal, see

Table 3.

Thus, it is obvious that the maximum amount of information is contained in the first three decomposition levels, which confirms the correctness of the preliminary choice of eight decomposition levels instead of maximum possible amount is ten (see

Figure 13).

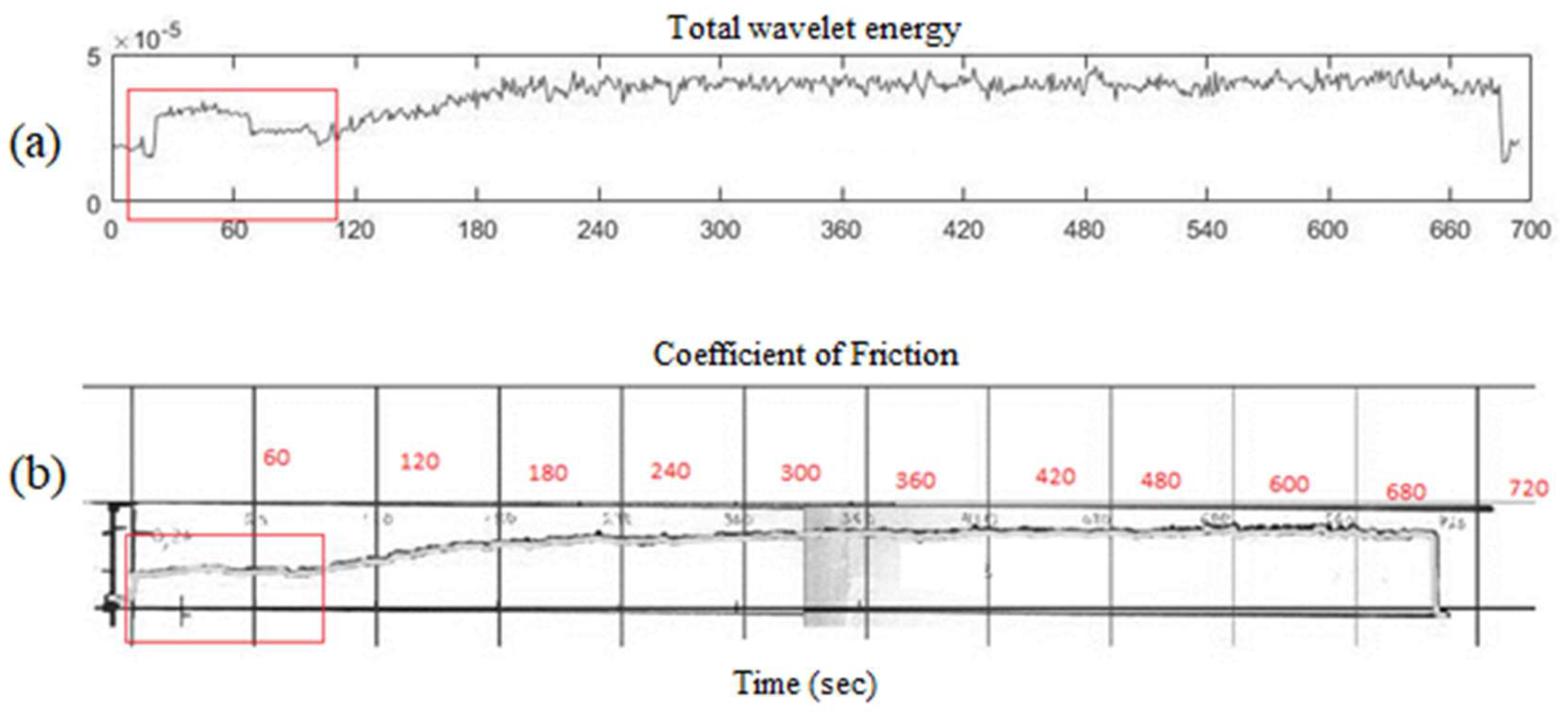

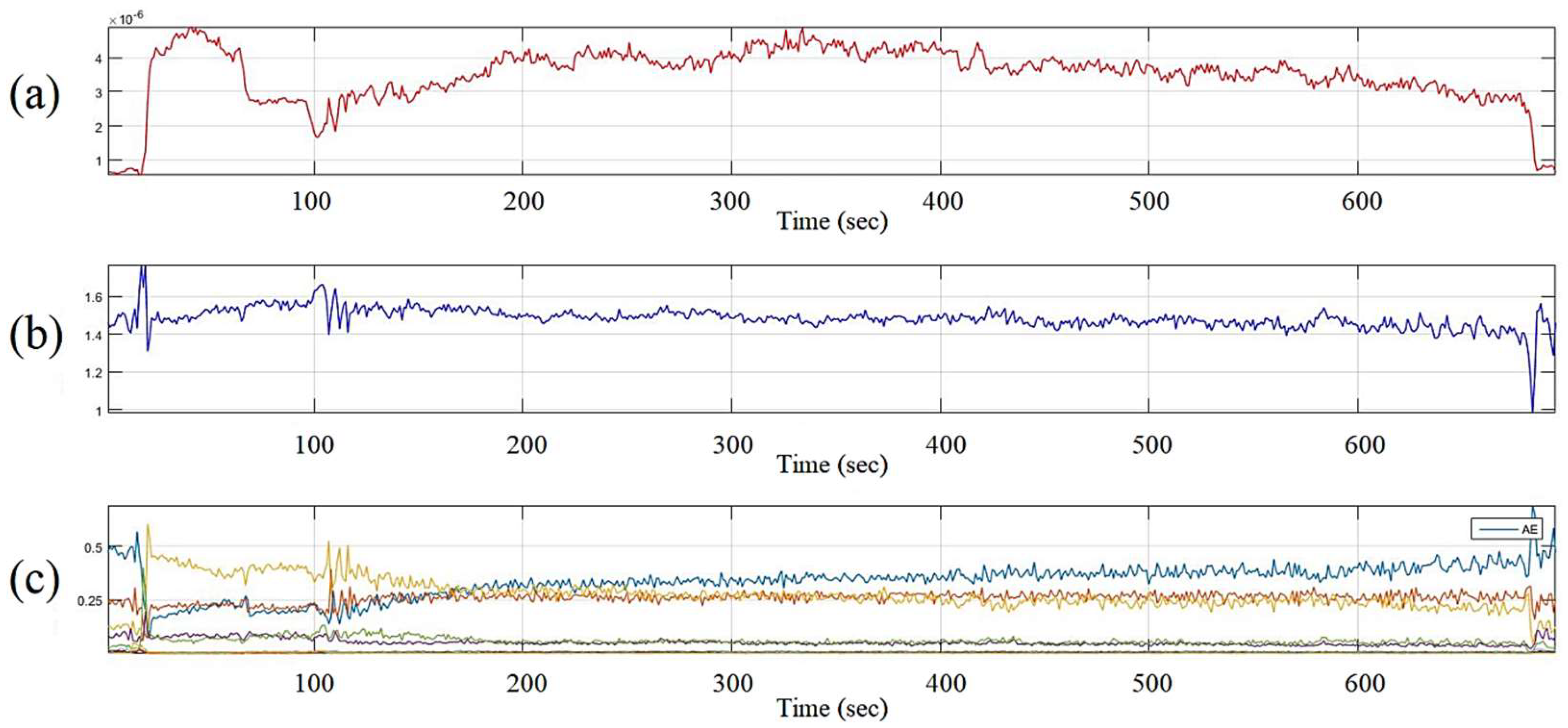

Figure 14 depicts that the initial stage of friction is associated with low-frequency oscillations, which are close to the rotational speed of the tribometer motor and, apparently, are due to the waviness of the rubbing surfaces. As the irregularities caused by the waviness are removed, the surfaces become more and more smooth and smaller protrusions come into contact. These protrusions provide a higher AE generation frequency. It is interesting that the moment of time of about 100 seconds, see Figure 19, corresponding to the end of AE generation at the 3rd level of decomposition, already goes beyond the stage of a sharp change in the friction coefficient. It can even be said that the friction coefficient has already passed into a stable stage and this corresponds to the traditional ideas about the completion of running-in [

1]. In fact, the running-in process continues at a higher structural level and finally, for this particular example, ends at 200 seconds, see Figure 19. Further, the detail coefficient takes a stable value.

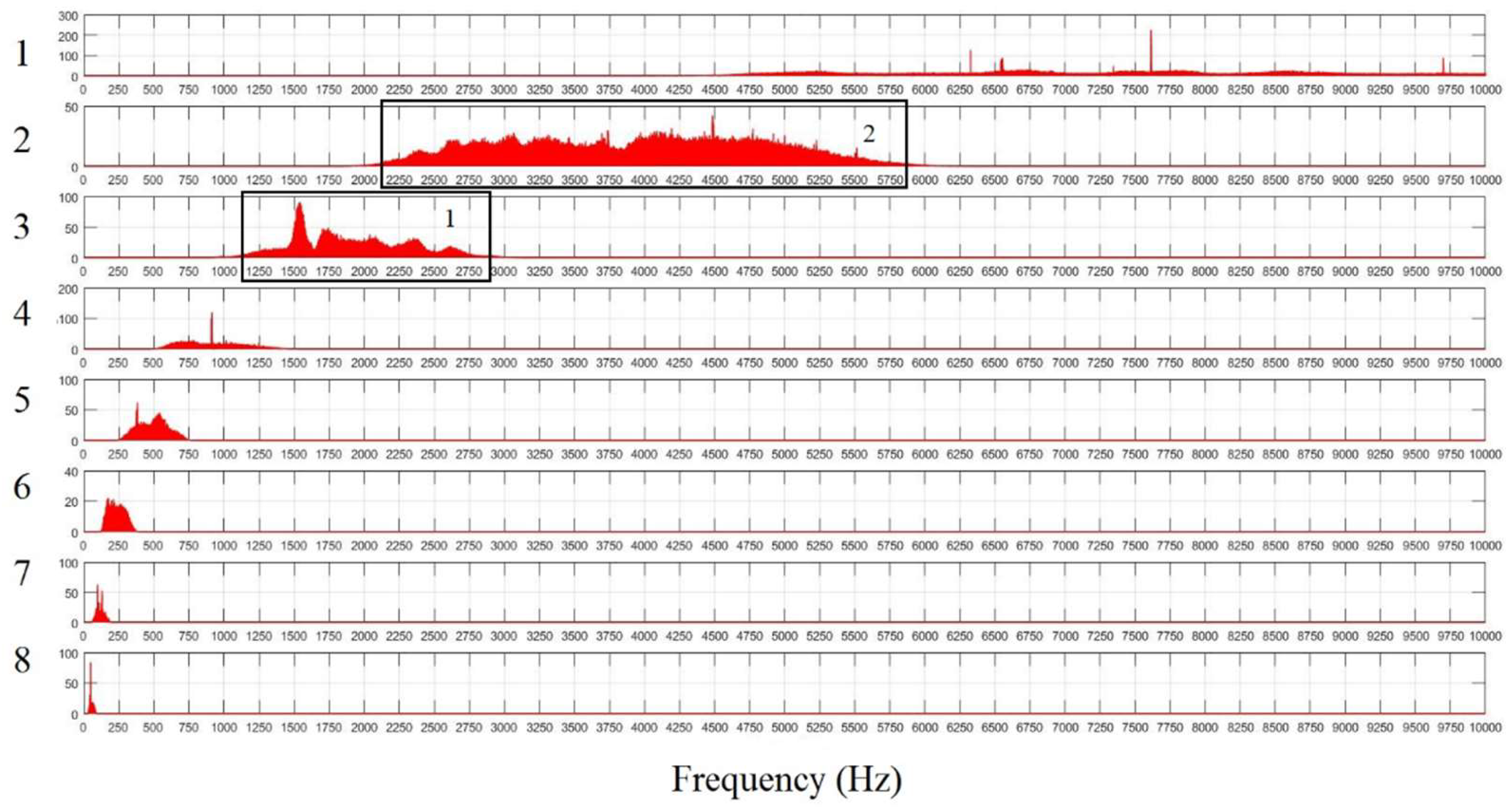

Due to its time-frequency nature, the WT does not show or use frequency responses embedded in the signal resulting from the periodic nature of signal shaping. Therefore, a subsequent spectral analysis of the wavelet coefficients is performed, showing the frequencies hidden in the signal. The spectrum of wavelet coefficients of the decomposed AE signal is shown in

Figure 15. Even a cursory look at the resulting spectrum, several characteristic frequency zones are visible, with their own types of amplitude-frequency characteristics that occur at different periods of the friction process. As shown in

Figure 15, the frequency range in the running-in zone is within 1250 ... 2750 Hz. The highest intensity of the spectrum power (100 rel. u.) is in the frequency range ~1500 Hz. In the zone of stable (steady friction) the frequency range of the AE signal consists of a range of frequencies 2250...5500 Hz with different amplitudes. The highest spectrum power intensity of this frame is twice as low as that of the frame in the running-in area of a tribo-unit. Significant changes in the values of the friction coefficient and AE signals are typical for running-in, (‘zone 1’, see Fig. 16). The increase in the amplitudes of the AE signal is due to the increase in the number of deformation events that occur during running-in, as well as the destruction, separation and flaking of wear particles in the tribological conjugation zone. In the region of stable friction (‘zone 2’, see

Figure 15), small changes in the friction coefficient and the AE signal were registered.

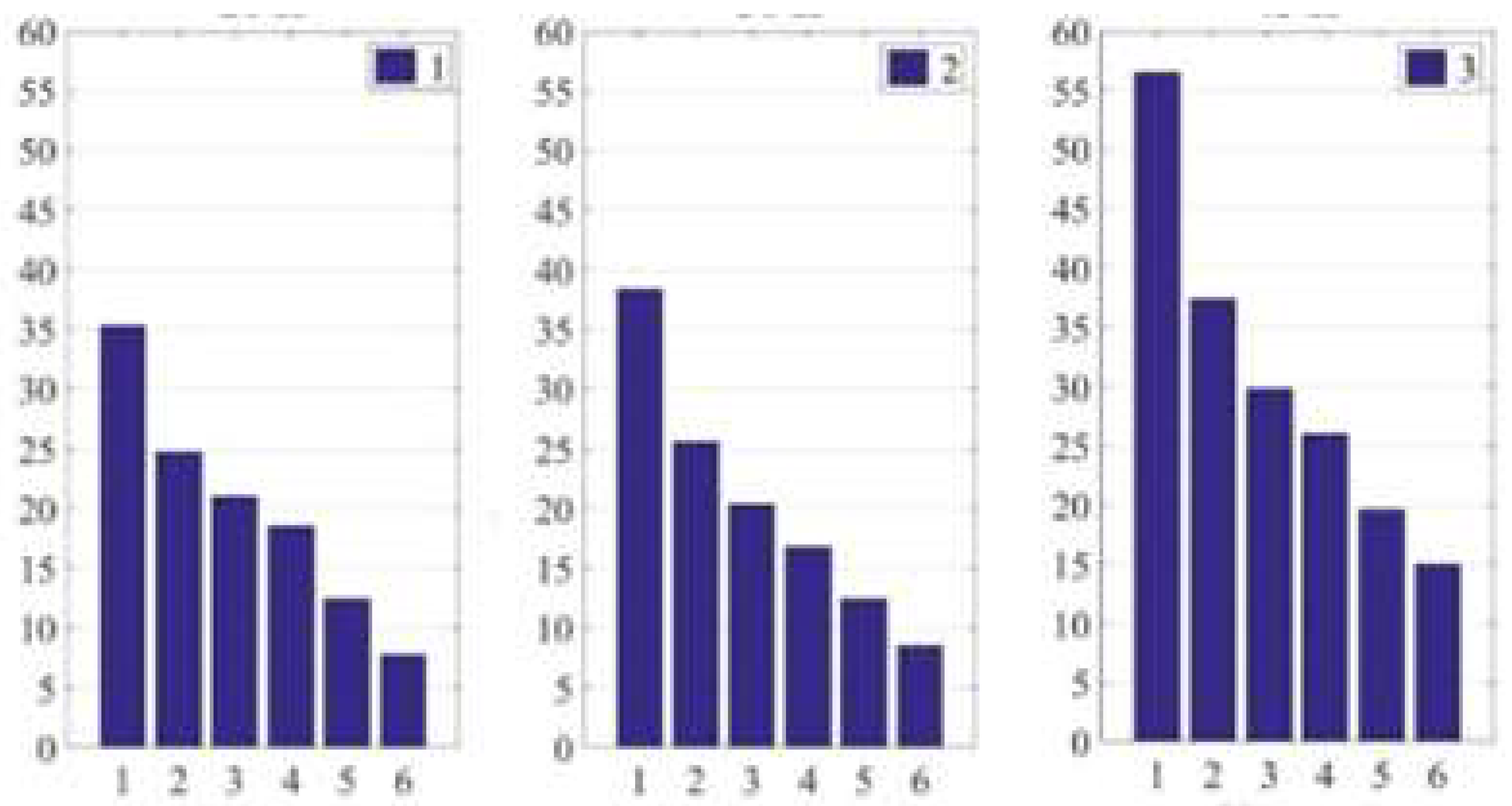

Figure 16 shows the results of calculating the energy distribution of the wavelet coefficients of several AE signals calculated by formulas at various loads. From this figure, it is obvious that a change in the applied load leads to an increase in the energy amplitudes of the wavelet coefficients, while the distribution of the prevailing frequency ranges responsible for certain processes that occur directly in the friction process remains unchanged. This means that the increase in energy caused by the increase in load is absorbed predominantly in the first decomposition level.

Conclusions

It has been established that during sliding friction of ceramics with speeds less than 10 m/s, the interaction of surface roughness occurs at frequencies up to 5 kHz and is accompanied by audible acoustic emission. The use of a wavelet transform for audible acoustic emission makes it possible to establish the beginning and end of a change in the frequency ranges of roughness interaction. It has been found that by investigating the running-in process using the wavelet transform, one can obtain information about the kinetics of the interaction of roughness of different levels at different points in time.

Spectral analysis of wavelet coefficients can be used to identify zones or stages that occur during friction, in particular, we can talk about the end of running-in. However, further research is needed to understand the reasons for the differences in the frequency spectrum. Thus, it is obvious that the spectral analysis of the wavelet coefficients is more efficient than the traditional Fourier transform or the classical wavelet transform, thereby providing a more detailed visual representation of the change in the frequency characteristics of the AE signal over the entire period of its registration.

The greatest interest is the use of the proposed approach for estimating the surface roughness in the process of friction of practically important brittle materials. Such materials include ceramics, monocrystals, and some types of composites. These materials, as a rule, have a greater hardness than glass, and ground surfaces also have a greater roughness than glass. When tested with such loads as described above, the friction track is not visible under normal observations, and the standard roughness tester is not applicable, while the acoustic emission is fixed quite reliably. Thus, for the first time, it became possible to estimate some friction parameters directly during the experiment.

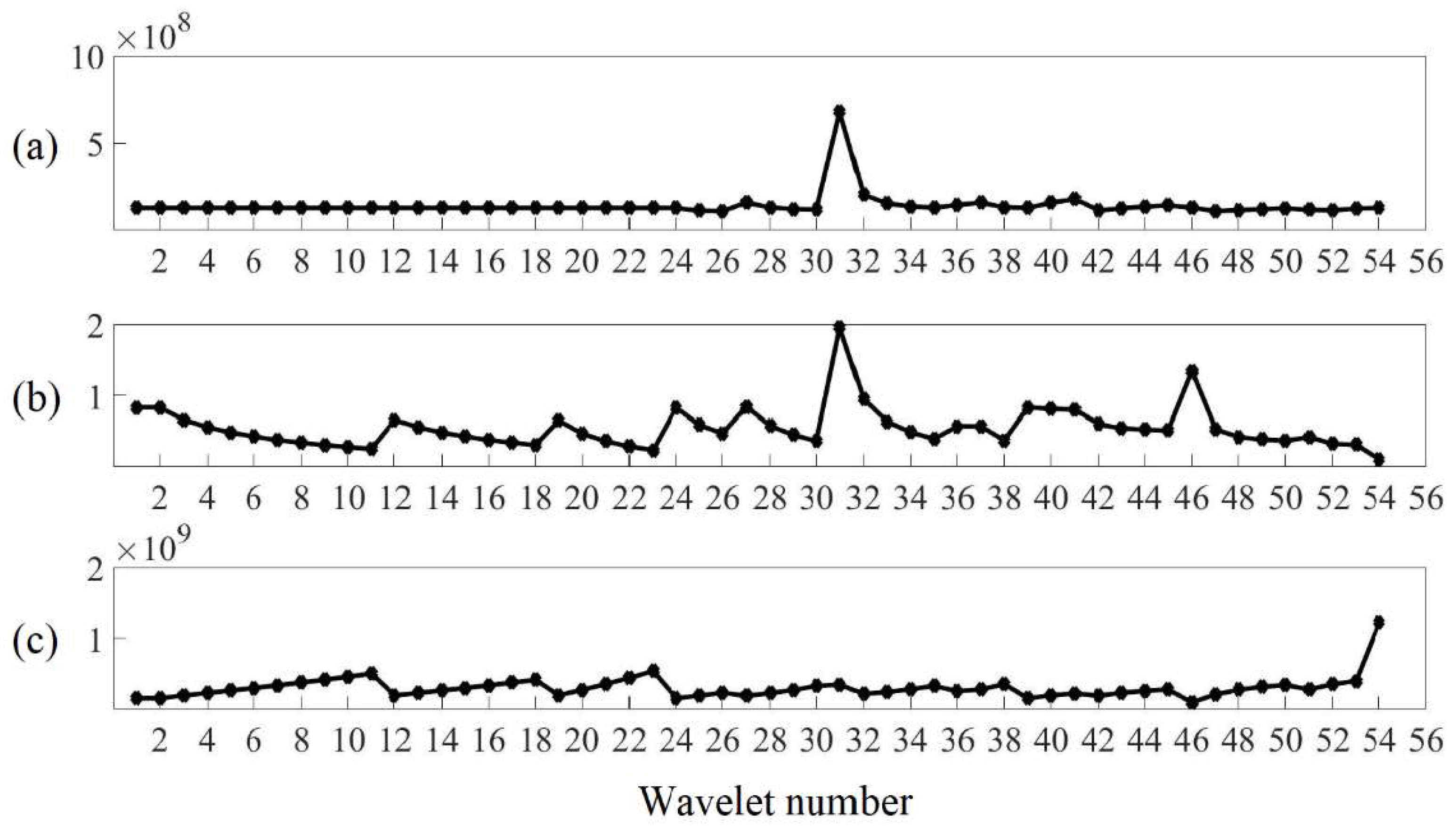

If the frequency investigate range of the AE signal is not known in advance, then to automate the determination of the sufficiency of decomposition levels, a mathematical criterion based on the criterion for the distribution of the energy of wavelet coefficients can be used. In addition, the use of such mathematical criteria as maximum wavelet energy, Shannon entropy minimum, and maximum energy-to-Shannon entropy ratio can be one of the criteria for the automated determination of the optimal mother wavelet, which was demonstrated in this work.

Figure 1.

A typical raw AE signal waveform recorded during friction.

Figure 1.

A typical raw AE signal waveform recorded during friction.

Figure 2.

Frequency analysis of the raw AE signal.

Figure 2.

Frequency analysis of the raw AE signal.

Figure 3.

Schematic illustration of the difference between a wave and a wavelet.

Figure 3.

Schematic illustration of the difference between a wave and a wavelet.

Figure 4.

Frequency and time resolution of the Wavelet analysis compared to FFT [

38].

Figure 4.

Frequency and time resolution of the Wavelet analysis compared to FFT [

38].

Figure 5.

Structure tree of the 4-level decomposition [

41].

Figure 5.

Structure tree of the 4-level decomposition [

41].

Figure 6.

The 54 preliminary candidates for the mother wavelet.

Figure 6.

The 54 preliminary candidates for the mother wavelet.

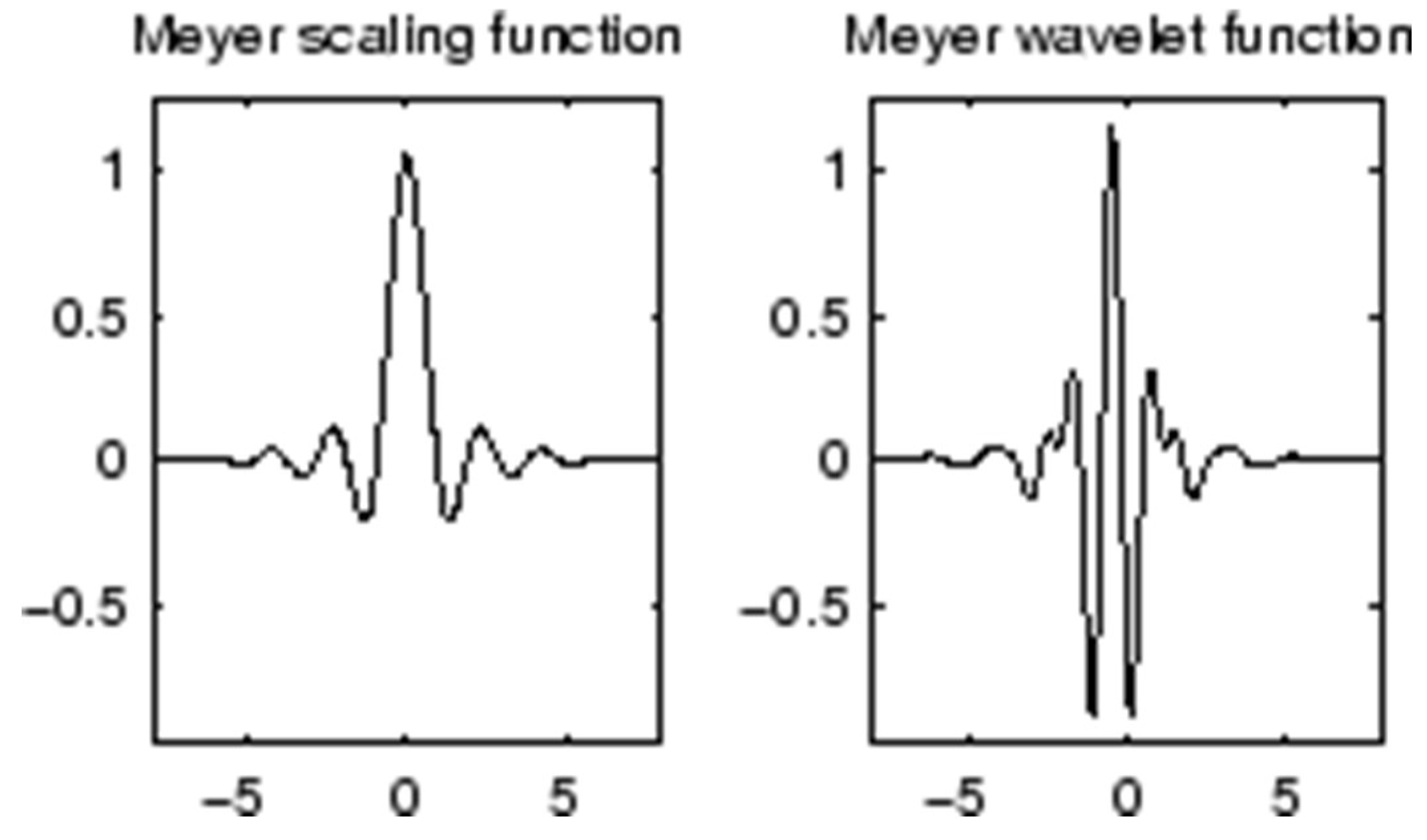

Figure 7.

Meyer scaling function and Meyer wavelet function [

39].

Figure 7.

Meyer scaling function and Meyer wavelet function [

39].

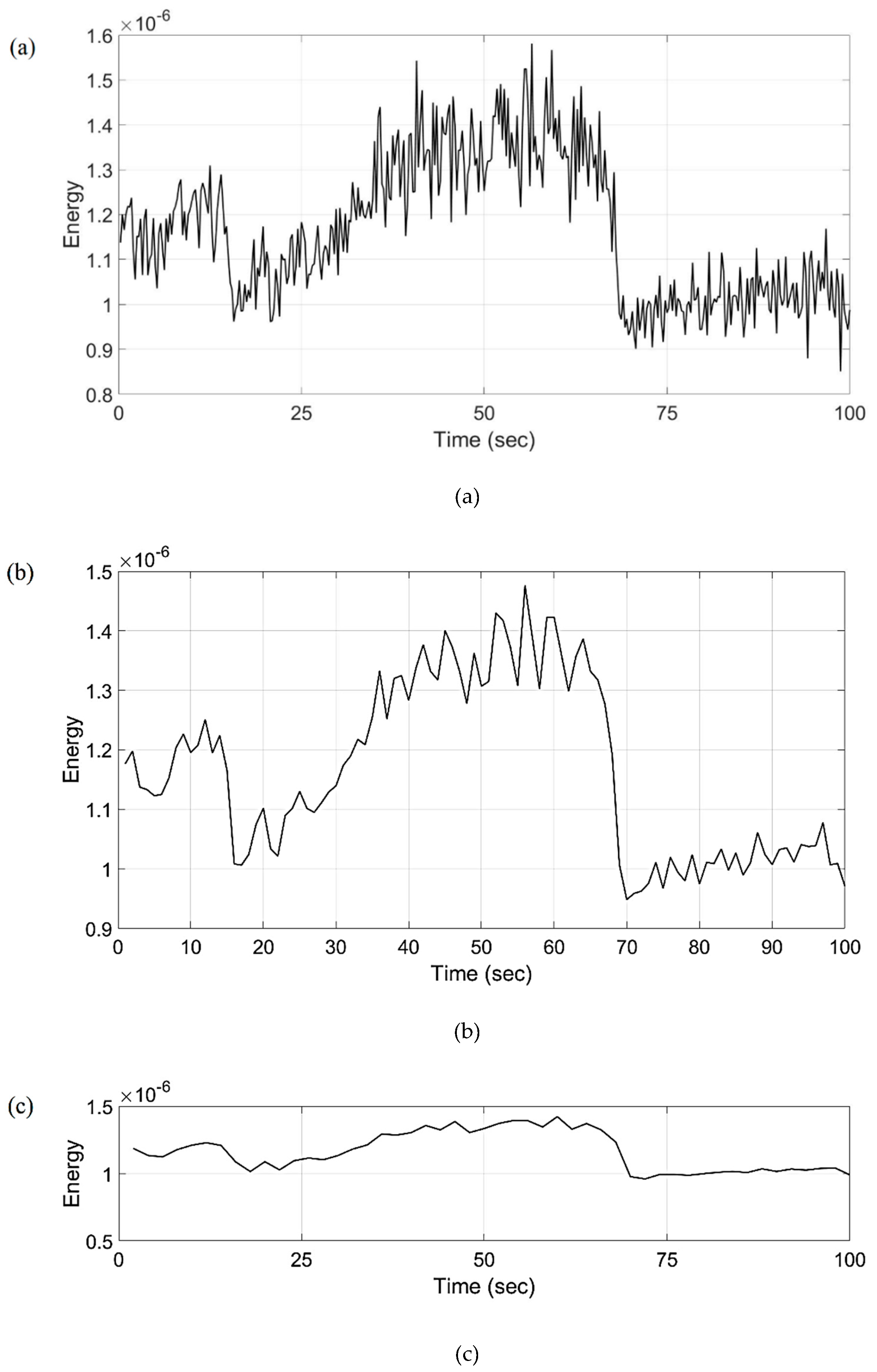

Figure 8.

(a) 0.25 seconds; (b) 1 second; (c) 2 seconds.

Figure 8.

(a) 0.25 seconds; (b) 1 second; (c) 2 seconds.

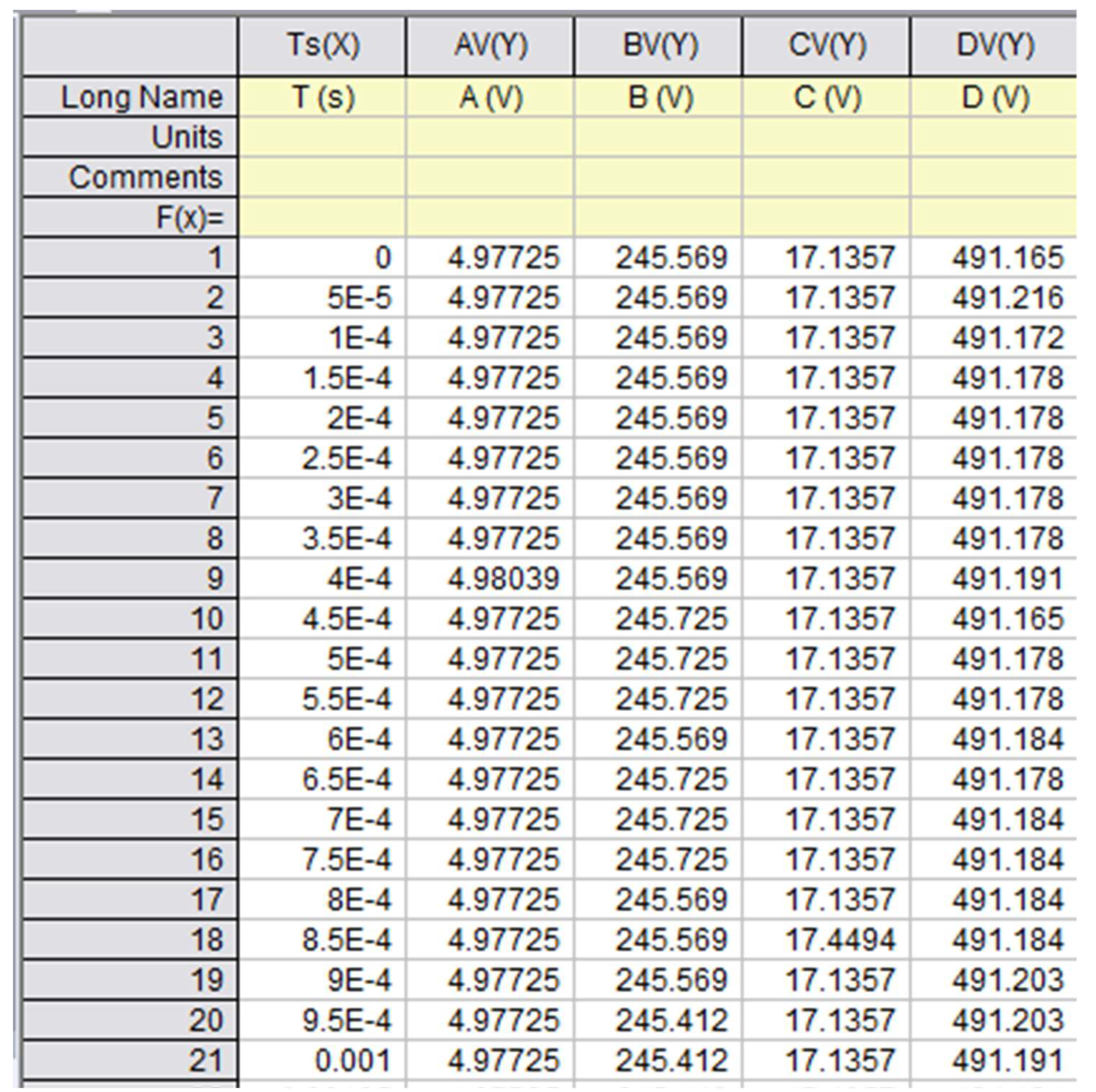

Figure 11.

Fragment of raw AE data collected using ACK-3107.

Figure 11.

Fragment of raw AE data collected using ACK-3107.

Figure 12.

Original waveform of AE signal recorded during the friction (Amplitude vs. Time).

Figure 12.

Original waveform of AE signal recorded during the friction (Amplitude vs. Time).

Figure 13.

Histogram of the AE energy at each frequency band.

Figure 13.

Histogram of the AE energy at each frequency band.

Figure 14.

Decomposition of the AE signal at eight levels using the proposed wavelet transform.

Figure 14.

Decomposition of the AE signal at eight levels using the proposed wavelet transform.

Figure 15.

Frequency response of the detail coefficients at 8 level for AE signal.

Figure 15.

Frequency response of the detail coefficients at 8 level for AE signal.

Figure 16.

Energy distribution of wavelet coefficients by decomposition levels during friction of ceramics based on Al2O3 and corresponding loads: (1) 20 N; (2) 30 N; (3) 45N.

Figure 16.

Energy distribution of wavelet coefficients by decomposition levels during friction of ceramics based on Al2O3 and corresponding loads: (1) 20 N; (2) 30 N; (3) 45N.

Figure 17.

Relative wavelet energy of wavelet coefficients corresponding to four wavelet resolution levels.

Figure 17.

Relative wavelet energy of wavelet coefficients corresponding to four wavelet resolution levels.

Figure 18.

(a) total wavelet energy of wavelet coefficients; (b) coefficient of friction Alumina ceramics (Al₂O₃) against steel.

Figure 18.

(a) total wavelet energy of wavelet coefficients; (b) coefficient of friction Alumina ceramics (Al₂O₃) against steel.

Figure 19.

(a) total wavelet energy of the wavelet coefficients; (b) total wavelet entropy of the wavelet coefficients; (c) relative wavelet energy of wavelet coefficients.

Figure 19.

(a) total wavelet energy of the wavelet coefficients; (b) total wavelet entropy of the wavelet coefficients; (c) relative wavelet energy of wavelet coefficients.

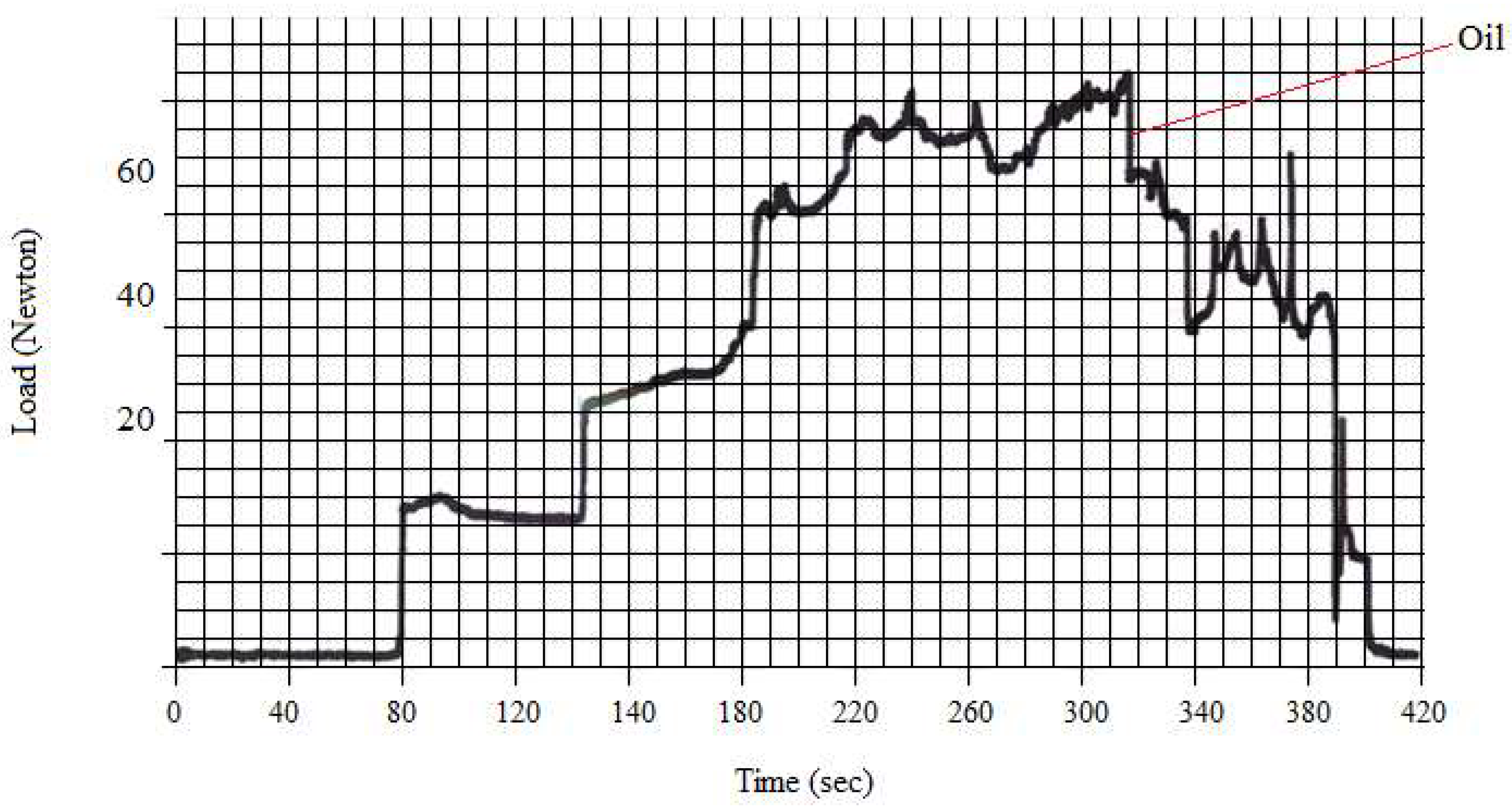

Figure 20.

Coefficient of friction aluminum against steel.

Figure 20.

Coefficient of friction aluminum against steel.

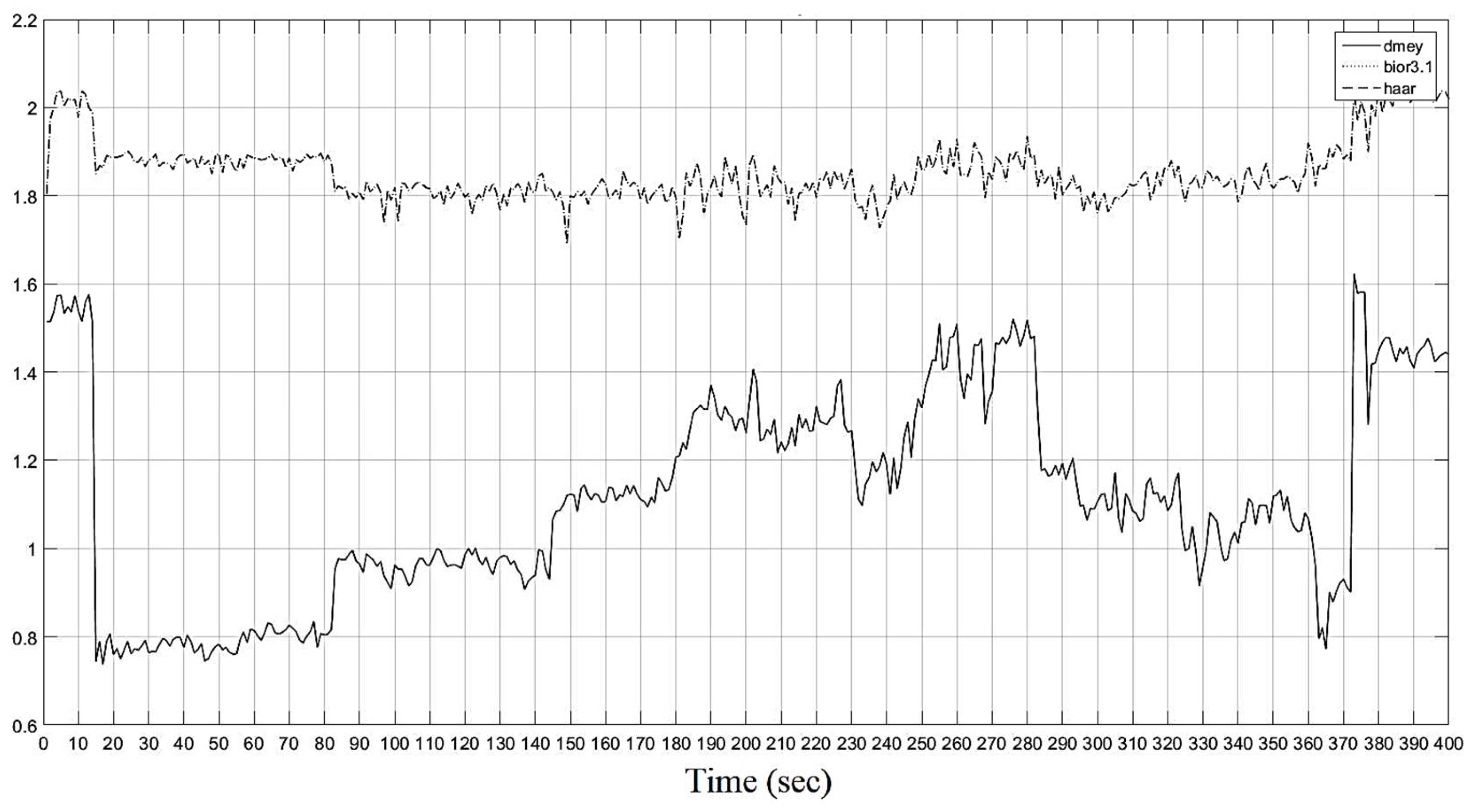

Figure 21.

Total wavelet entropy of the wavelet coefficients for three types of the mother wavelets.

Figure 21.

Total wavelet entropy of the wavelet coefficients for three types of the mother wavelets.

Table 1.

Frequency bands.

Table 1.

Frequency bands.

| Levels |

Components |

Frequency (Hz) |

| 1 |

d1 |

5000 – 10000 |

| 2 |

d2 |

2500 – 5000 |

| 3 |

d3 |

1250 – 2500 |

| 4 |

d4 |

625 – 1250 |

| 5 |

d5 |

312.5 – 625 |

| 6 |

d6 |

156.25 – 312.5 |

| 7 |

d7 |

78.125 – 156.25 |

| 8 |

d8 |

39 – 78.125 |

| 9 |

d9 |

19.53125 – 39.0625 |

| 10 |

d10 |

9.765625 – 19.53125 |

Table 2.

Studied wavelet families.

Table 2.

Studied wavelet families.

| No |

Mother wavelet |

No |

Mother wavelet |

No |

Mother wavelet |

No |

Mother wavelet |

| 1 |

haar |

15 |

sym5 |

29 |

bior2.6 |

43 |

rbio2.4 |

| 2 |

db1 |

16 |

sym6 |

30 |

bior2.8 |

44 |

rbio2.6 |

| 3 |

db2 |

17 |

sym7 |

31 |

bior3.1 |

45 |

rbio2.8 |

| 4 |

db3 |

18 |

sym8 |

32 |

bior3.3 |

46 |

rbio3.1 |

| 5 |

db4 |

19 |

coif1 |

33 |

bior3.5 |

47 |

rbio3.3 |

| 6 |

db5 |

20 |

coif2 |

34 |

bior3.7 |

48 |

rbio3.5 |

| 7 |

db6 |

21 |

coif3 |

35 |

bior3.9 |

49 |

rbio3.7 |

| 8 |

db7 |

22 |

coif4 |

36 |

bior4.4 |

50 |

rbio3.9 |

| 9 |

db8 |

23 |

coif5 |

37 |

bior5.5 |

51 |

rbio4.4 |

| 10 |

db9 |

24 |

bior1.1 |

38 |

bior6.8 |

52 |

rbio5.5 |

| 11 |

db10 |

25 |

bior1.3 |

39 |

rbio1.1 |

53 |

rbio6.8 |

| 12 |

sym2 |

26 |

bior1.5 |

40 |

rbio1.3 |

54 |

dmey |

| 13 |

sym3 |

27 |

bior2.2 |

41 |

rbio1.5 |

|

|

| 14 |

sym4 |

28 |

bior2.4 |

42 |

rbio2.2 |

|

|

Table 3.

Percentage of the energy distribution amongst decomposition levels.

Table 3.

Percentage of the energy distribution amongst decomposition levels.

| Level of wavelet decomposition |

Frequency range (Hz) |

Percentage (%) |

| d1 |

5000 – 10000 |

37.57 |

| d2 |

2500 – 5000 |

23.4 |

| d3 |

1250 – 2500 |

24.25 |

| d4 |

625 – 1250 |

6.8 |

| d5 |

312,5 – 625 |

5.87 |

| d6 |

156,25 – 312,5 |

1 |

| d7 |

78,125 – 156,25 |

0.86 |

| d8 |

39 – 78,125 |

0.24 |