Submitted:

15 March 2024

Posted:

18 March 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

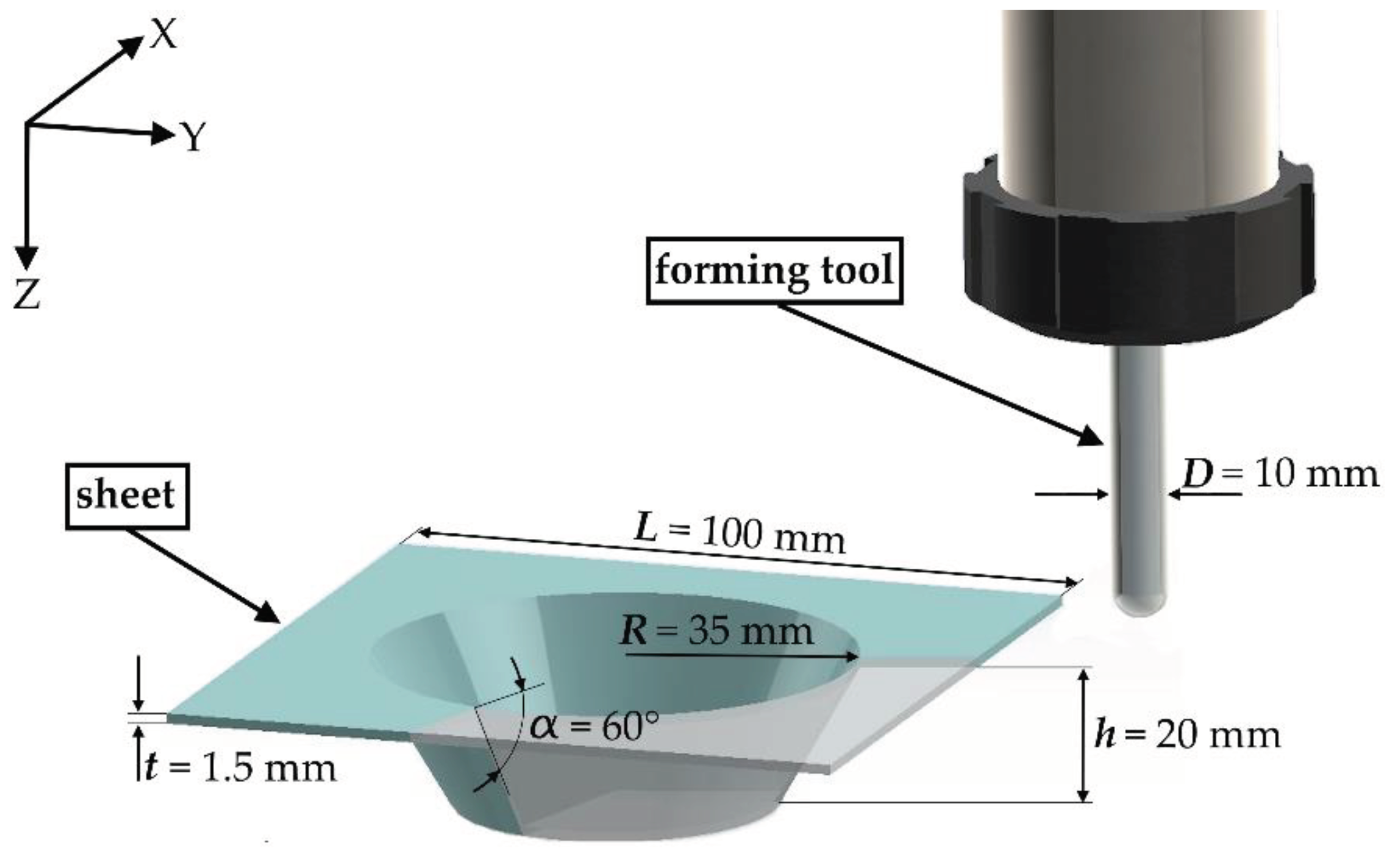

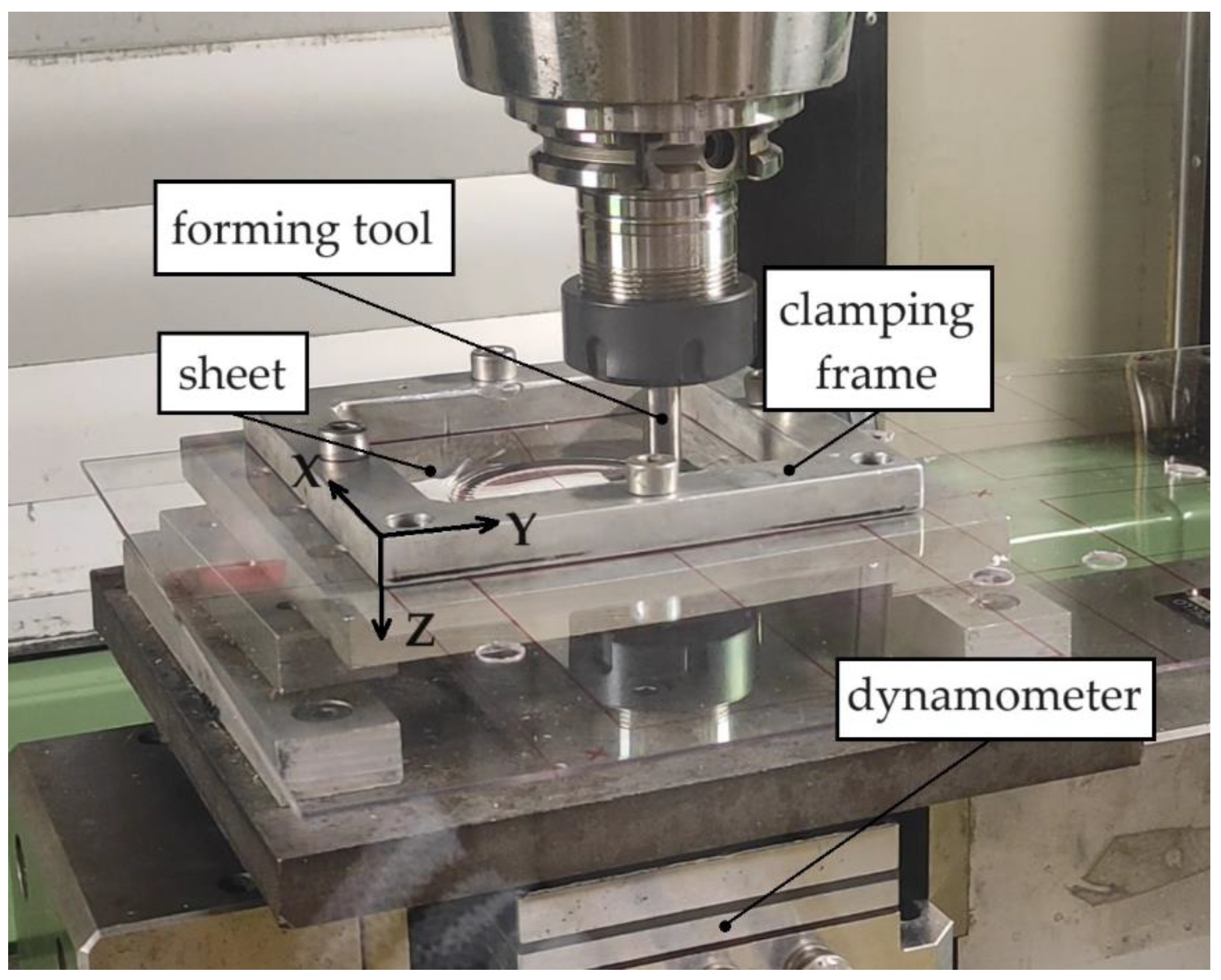

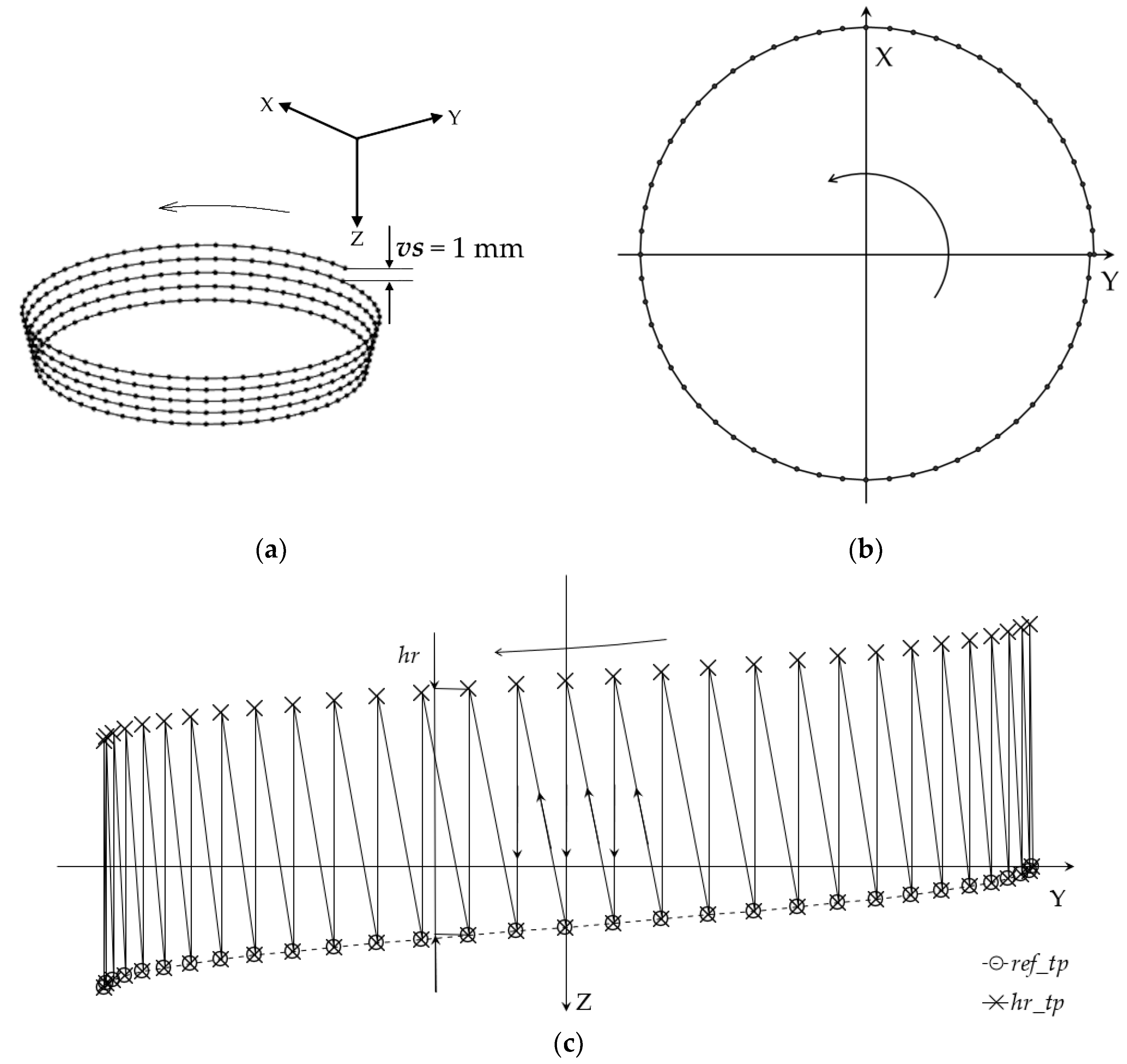

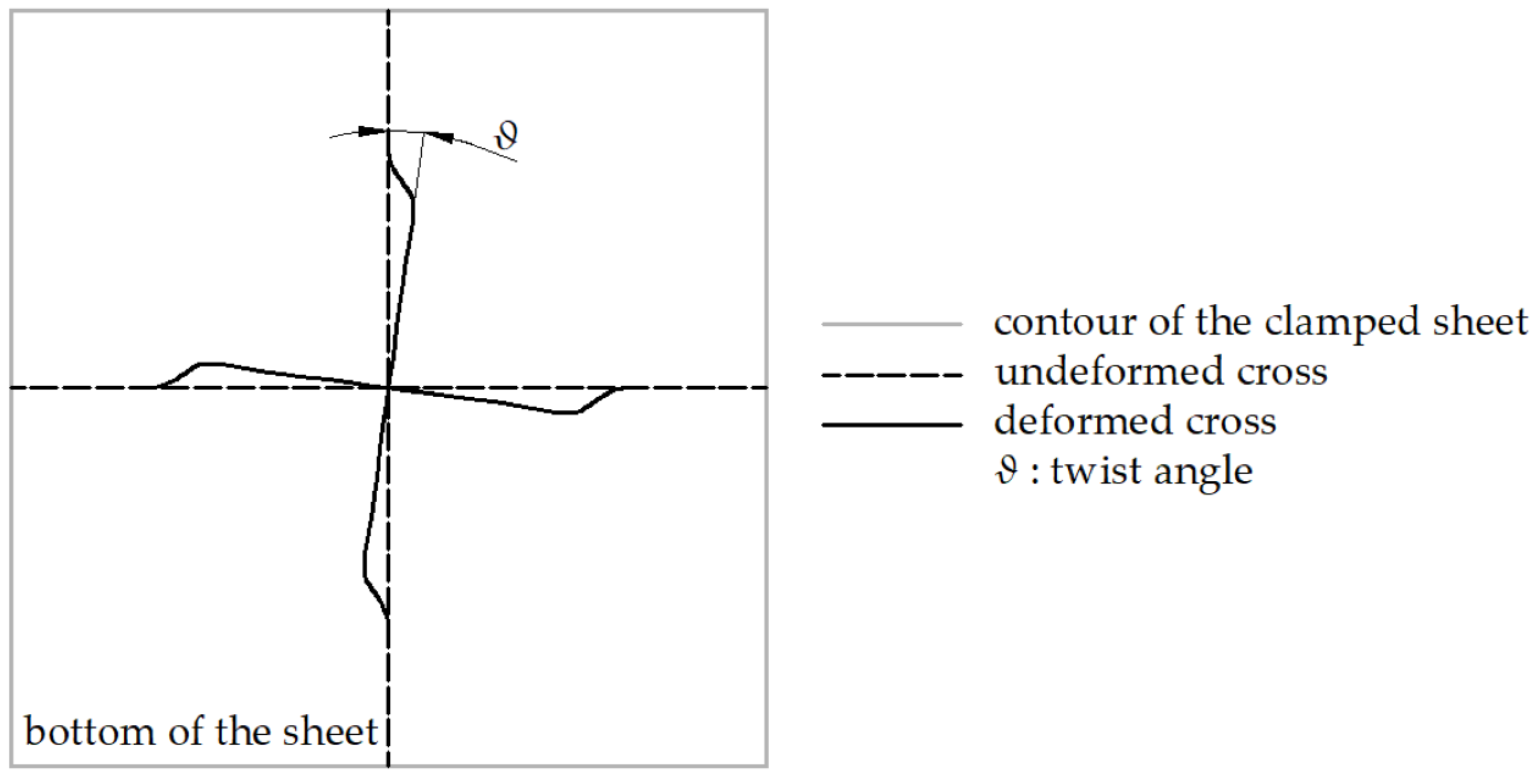

2. Materials and Methods

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rosa-Sainz, A.; Centeno, G.; Silva, M.B.; Vallellano, C. Experimental Failure Analysis in Polycarbonate Sheet Deformed by Spif. J. Manuf. Process. 2021, 64, 1153–1168. [Google Scholar] [CrossRef]

- Rosa-Sainz, A.; Centeno, G.; Silva, M.B.; Andrés López-Fernández, J.; Jesus Martínez-Donaire, A.; Vallellano, C. On the Determination of Forming Limits in Polycarbonate Sheets. Materials (Basel). 2020, 13, 928. [Google Scholar] [CrossRef]

- Shaw, M.T. Cold Forming of Polymeric Materials. Annu. Rev. Mater. Sci. 1980, 10, 19–42. [Google Scholar] [CrossRef]

- Bagudanch, I.; Centeno, G.; Vallellano, C.; Garcia-Romeu, M.L. Revisiting Formability and Failure of Polymeric Sheets Deformed by Single Point Incremental Forming. Polym. Degrad. Stab. 2017, 144, 366–377. [Google Scholar] [CrossRef]

- Tofail, S.A.M.; Koumoulos, E.P.; Bandyopadhyay, A.; Bose, S.; O’Donoghue, L.; Charitidis, C. Additive Manufacturing: Scientific and Technological Challenges, Market Uptake and Opportunities. Mater. Today 2018, 21, 22–37. [Google Scholar] [CrossRef]

- Bertini, L.; Kubit, A.; Al-Sabur, R.; Gradzik, A.; Ochał, K.; Slota, J.; Korzeniowski, M. Investigating Residual Stresses in Metal-Plastic Composites Stiffening Ribs Formed Using the Single Point Incremental Forming Method. Materials (Basel). 2022, 15, 8252. [Google Scholar] [CrossRef]

- Behera, A.K.; de Sousa, R.A.; Ingarao, G.; Oleksik, V. Single Point Incremental Forming: An Assessment of the Progress and Technology Trends from 2005 to 2015. J. Manuf. Process. 2017, 27, 37–62. [Google Scholar] [CrossRef]

- Jeswiet, J.; Micari, F.; Hirt, G.; Bramley, A.; Duflou, J.; Allwood, J. Asymmetric Single Point Incremental Forming of Sheet Metal. CIRP Ann. 2005, 54, 88–114. [Google Scholar] [CrossRef]

- Bagudanch, I.; Garcia-Romeu, M.L.; Sabater, M. Incremental Forming of Polymers: Process Parameters Selection from the Perspective of Electric Energy Consumption and Cost. J. Clean. Prod. 2016, 112, 1013–1024. [Google Scholar] [CrossRef]

- Franzen, V.; Kwiatkowski, L.; Martins, P.A.F.; Tekkaya, A.E. Single Point Incremental Forming of PVC. J. Mater. Process. Technol. 2009, 209, 462–469. [Google Scholar] [CrossRef]

- Martins, P.A.F.; Kwiatkowski, L.; Franzen, V.; Tekkaya, A.E.; Kleiner, M. Single Point Incremental Forming of Polymers. CIRP Ann. 2009, 58, 229–232. [Google Scholar] [CrossRef]

- Le, V.S.; Ghiotti, A.; Lucchetta, G. Preliminary Studies on Single Point Incremental Forming for Thermoplastic Materials. Int. J. Mater. Form. 2008, 1, 1179–1182. [Google Scholar] [CrossRef]

- Marques, T.A.; Silva, M.B.; Martins, P.A.F. On the Potential of Single Point Incremental Forming of Sheet Polymer Parts. Int. J. Adv. Manuf. Technol. 2012, 60, 75–86. [Google Scholar] [CrossRef]

- Bagudanch, I.; Garcia-Romeu, M.L.; Centeno, G.; Elías-Zúñiga, A.; Ciurana, J. Forming Force and Temperature Effects on Single Point Incremental Forming of Polyvinylchloride. J. Mater. Process. Technol. 2015, 219, 221–229. [Google Scholar] [CrossRef]

- Davarpanah, M.A.; Mirkouei, A.; Yu, X.; Malhotra, R.; Pilla, S. Effects of Incremental Depth and Tool Rotation on Failure Modes and Microstructural Properties in Single Point Incremental Forming of Polymers. J. Mater. Process. Technol. 2015, 222, 287–300. [Google Scholar] [CrossRef]

- Martínez-Donaire, A.J.; García-Lomas, F.J.; Vallellano, C. New Approaches to Detect the Onset of Localised Necking in Sheets under Through-Thickness Strain Gradients. Mater. Des. 2014, 57, 135–145. [Google Scholar] [CrossRef]

- Durante, M.; Formisano, A.; Boccarusso, L.; Langella, A. Influence of Cold-Rolling on Incremental Sheet Forming of Polycarbonate. Mater. Manuf. Process. 2020, 35, 328–336. [Google Scholar] [CrossRef]

- Formisano, A.; Lambiase, F.; Durante, M. Polymer Self-Heating during Incremental Forming. J. Manuf. Process. 2020, 58, 1189–1199. [Google Scholar] [CrossRef]

- Formisano, A.; Boccarusso, L.; Capece Minutolo, F.; Carrino, L.; Durante, M.; Langella, A. Negative and Positive Incremental Forming: Comparison by Geometrical, Experimental, and FEM Considerations. Mater. Manuf. Process. 2017, 32, 530–536. [Google Scholar] [CrossRef]

- Zhu, H.; Ou, H.; Popov, A. Incremental Sheet Forming of Thermoplastics: A Review. Int. J. Adv. Manuf. Technol. 2020, 111, 565–587. [Google Scholar] [CrossRef]

- Durante, M.; Formisano, A.; Lambiase, F. Incremental Forming of Polycarbonate Sheets. J. Mater. Process. Technol. 2018, 253, 57–63. [Google Scholar] [CrossRef]

- Chang, Z.; Chen, J. Mechanism of the Twisting in Incremental Sheet Forming Process. J. Mater. Process. Technol. 2020, 276, 116396. [Google Scholar] [CrossRef]

- Duflou, J.R.; Vanhove, H.; Verbert, J.; Gu, J.; Vasilakos, I.; Eyckens, P. Twist Revisited: Twist Phenomena in Single Point Incremental Forming. CIRP Ann. 2010, 59, 307–310. [Google Scholar] [CrossRef]

- Formisano, A.; Durante, M.; Boccarusso, L.; Memola Capece, F. A Numerical Approach to Optimize the Toolpath Strategy for Polymers Forming. Mater. Res. Proc. 2023, 28, 1697–1702. [Google Scholar] [CrossRef]

- Formisano, A.; Boccarusso, L.; Durante, M. Optimization of Single-Point Incremental Forming of Polymer Sheets through FEM. Mater. 2023, Vol. 16, Page 451 2023, 16, 451. [Google Scholar] [CrossRef]

- Hou, Z.X.; Wu, J.; Wang, Z.R. A Study of the Bulge-Forming of Polycarbonate (PC) Sheet. J. Mater. Process. Technol. 2004, 151, 312–315. [Google Scholar] [CrossRef]

- Beşliu, I.; Tamaşag, I.; Slătineanu, L. An Experimental Study on Incremental Forming Process of Polycarbonate Sheets. Macromol. Symp. 2021, 395, 2000282. [Google Scholar] [CrossRef]

- Beșliu-Băncescu, I.; Slătineanu, L.; Dodun, O.; Nagîț, G. Influence of Lubrication and Cooling on the Quality of Single-Point Incremental Forming Parts of Polycarbonate Sheets. J. Manuf. Mater. Process. 2021, Vol. 5, Page 75 2021, 5, 75. [Google Scholar] [CrossRef]

- Durante, M.; Formisano, A.; Lambiase, F. Formability of Polycarbonate Sheets in Single-Point Incremental Forming. Int. J. Adv. Manuf. Technol. 2019, 102, 2049–2062. [Google Scholar] [CrossRef]

- Rosca, N.; Trzepieciński, T.; Oleksik, V. Minimizing the Forces in the Single Point Incremental Forming Process of Polymeric Materials Using Taguchi Design of Experiments and Analysis of Variance. Materials 2022, 15, 6453. [Google Scholar] [CrossRef]

- Wei, H.; Zhou, L.; Heidarshenas, B.; Ashraf, I.K.; Han, C. Investigation on the Influence of Springback on Precision of Symmetric-Cone-like Parts in Sheet Metal Incremental Forming Process. Int. J. Light. Mater. Manuf. 2019, 2, 140–145. [Google Scholar] [CrossRef]

- Liu, F.; Li, Y.; Ghafoor, S.; Cheng, Z.; Li, F.; Li, J. Sustainability Assessment of Incremental Sheet Forming: A Review. Int. J. Adv. Manuf. Technol. 2022, 119, 1385–1405. [Google Scholar] [CrossRef]

| Toolpath | Forming time [s] |

|---|---|

| ref_tp | 200.5 |

| hr0.5_tp | 241 |

| hr1.0_tp | 286.5 |

| hr1.5_tp | 337.5 |

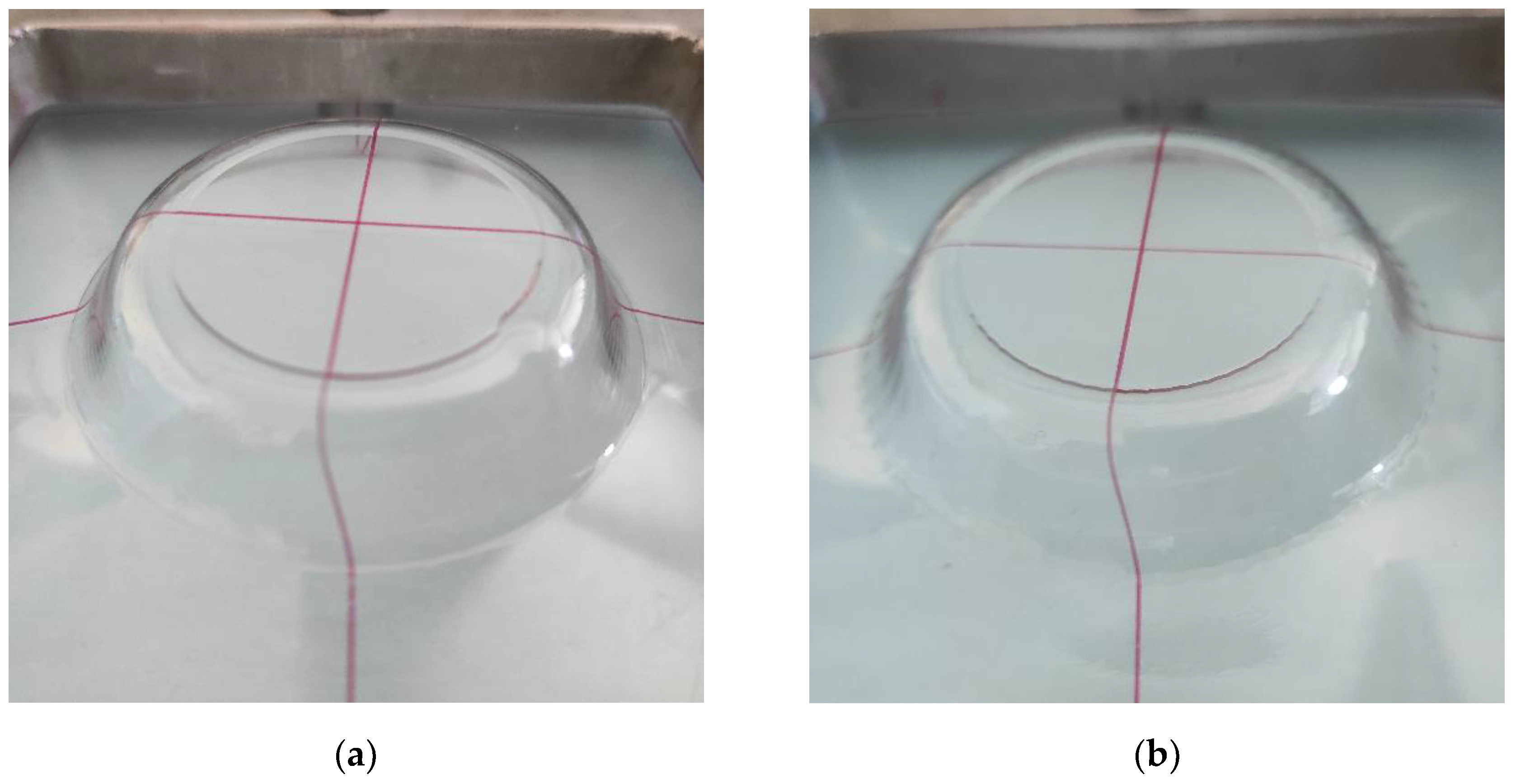

| Toolpath | Twist angle [°] |

|---|---|

| ref_tp | 7.0 |

| hr0.5_tp | 6.9 |

| hr1.0_tp | 6.6 |

| hr1.5_tp | 6.1 |

| hr1.5_tp_dry | 6.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).