Submitted:

28 February 2024

Posted:

28 February 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Literature Review of Low-Tech POU Water Treatment Options

2.1. Some of the Basic Issues of Failure of Available Low-tech Water Treatment Options

- (i)

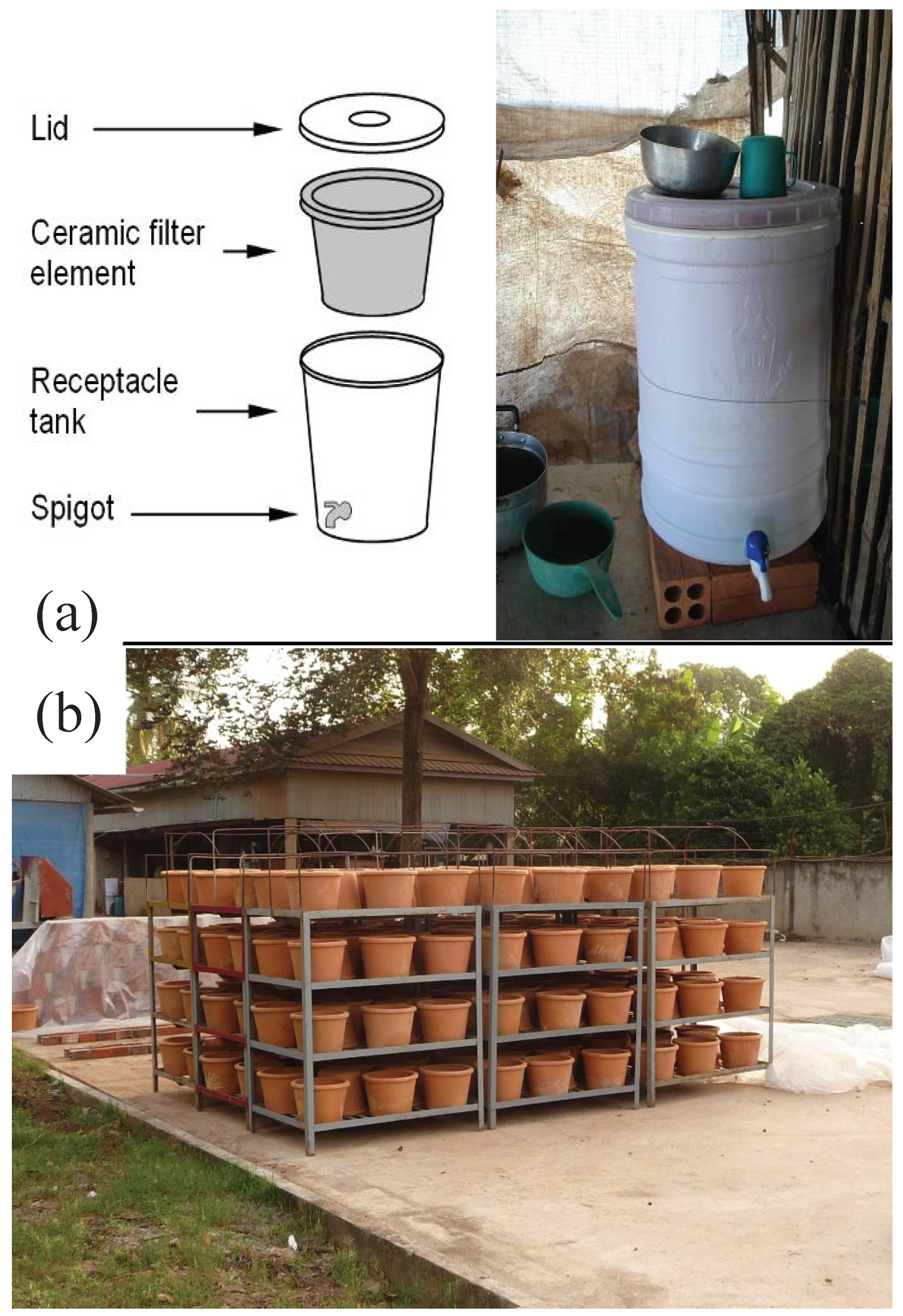

- Making Ceramic Filters in the Form of a CPF -The CPF structure can be a major deterrent for use since there exists an ongoing concern about allowing the outside of the CPF becoming contaminated by an individual touching the outside portion of the pot during the cleaning process to remove sediments; this contaminates the treated water.

- (ii)

- Lifespan of the Ceramic Filter - Ceramic filter systems generally are reported to have a lifespan varying from 6 months to 3 years, although raw water quality, water usage, and maintenance issues all impact the lifespan of the CPF. More specifically, examples include that during a 27-month monitoring study by Venis& Basu (2021) on ceramic water filters, 14% of the filters broke by the 3-month interviews, escalating to 18% at the 6-month mark, 22% at 12 months, and 24% at 15 months.

- (iii)

- Lifespans of Alternative Low Tech Water Treatment Technologies Vary - Many alternative water treatment technologies have short lifespans in the developing world even when they are relatively expensive. As an example, the costs of an Arsenic Iron Removal Plants (AIRP) are ~60$US/unit), an example of which is shown in Figure 3. Although pertinent to a different water treatment technology, McBean (2012) and Sorenson and McBean (2014, 2015) reported fewer than 40 of 135 originally installed Arsenic Iron Removal Plants (AIRPs) in Bangladesh were still in use in 2012 after three years of operation. Hence, this finding is important because many social considerations stopped continuing use of the AIRP technology. These considerations include (a) functional issues including the presence of insects entering the tanks, and broken parts; (b) the difficulties of cleaning the technology because parts of the technology are particularly heavy) (Sorensen & McBean, 2014 & 2015); and (c) the most important dimension which ends up causing dis-continued use of AIRPs is because while arsenic contamination causes cancer, the illness is not evident for a number of years. Hence, users tend to reach the conclusion ‘why bother to maintain the technology’ as they forget the long-term objective (Brennan and McBean, 2011a, b).

- (iv)

- Repair Options for Many CPFs Don’t Exist - Generally, CPFs have been made in sizable factories such as at RDI in Cambodia (as per Figure 2(b)). It is noted that there is now increasing manufacturing being done in villages (see ‘youtube making clay pots for water treatment e.g. see https://www.youtube.com/watch?v=VB1Sg6JjFos)). Regardless, non-functional CPFs must be replaced, not repaired.

- (v)

- Removal of the Sediments -The flow rates of ceramic filters decrease over time, particularly when surface water is used (e.g. Brown and Sobsey, 2009; Farrow et al., 2018). Consequently, periodic cleaning of the CPF’s internal surface is essential to restore the flow throughput. Further, CPF factories recommend employing a stiff laundry brush for scraping the filter surface, and this is sometimes advised to be done once every 4 weeks (Brown and Sobsey, 2010). By others, with a primary focus on restoring water flow, McBean et al. (2019) and Farrow et al. (2018) suggest that ceramic filters should be brushed regularly every 2-3 days using a soft brush, to maintain optimal flow rates and extend the filter's lifespan. It is noted that brushing a CPF is challenging for both old and young individuals due to the weight (about 7 kg) so heavy to remove the CPF from the receptacle tank while also avoid touching the outside of the CPF to avoid contaminating the treated water, underscores both the importance of, and need for, careful maintenance to ensure performance of CPFs.

2.2. Summary Dimensions of Features concerning CPFs as a Low-Tech Water Treatment Option

- (i)

- Cost of a CPF – Cost is a key factor since many rural poor have incomes of just a few dollars/day. The cost of the RDI CPF has historically been ~8$US for CPF plus the remaining parts (receptacle tank, spigot etc.) represent additional costs. Farrow et al. (2018) used the RDI CPF in southern China and it was very enthusiastically acclaimed by the residents (e.g. when the field trials were completed, the residents asked to keep the technology rather than return it and hence, was not a deterrent).

- (ii)

- Failure to Maintain the Necessary Minimum Flow Rate – For a family, the need is typically characterized to have flows of 1-3 L/hr which provides sufficient water supply for drinking water and for basic food preparations to a household. If the CPF flow is low, many users abandon the technology. Without proper maintenance, the flow rate of ceramic disk filters will decline significantly. Slow rates of water throughput are a common cause for abandonment of use of the filter were mainly caused by flowthrough rate being too slow (e.g. 31% reported by Clasen et al. (2006)).

- (iii)

- Need for Frequent Re-filling of the CPF for All Days – The CPF has a maximum volume of ~9 L which means that someone (which typically falls upon a young child) must carry out frequent refilling during the day, thus preventing the child from attending school.

- (iv)

- Failure of the Design to Provide Safe Water – Failure of the ceramic filter apparatus to provide safe water has been widely identified (e.g. in Ethiopia where they didn’t reach the desired 3Log removal of E. coli. (Bulta & Michael, 2019)). Many of the CPFs described in the literature have not been properly evaluated to determine whether delivery of safe water is provided although Bulta and Micheal (2019) claim elimination of approximately 99.88% of waterborne disease agents for rural point-of-use water.

- (v)

- Breakage of the CPF Frequently Occurs Since the Technology is Heavy – Breakage of the CPF is a continuing issue. The pot is heavy and requires the CPF to be removed from the holding apparatus, to allow removal of the accumulated sediments within the CPF. The removal of the sediments is only attained if the CPF is scraped/brushed, to enable removal of the sediments. Either of two options put the quality of the treated water in jeopardy: (a) if the CPF is cradled in the arms, the outside of the CPF is touched by the individual and/or the CPF is placed on the ground why doing the cleaning, resulting in the exterior of the CPF being contaminated, and/or (b) the CPF is heavy and dropped, breaking the CPF. As examples of these concerns, in Bolivia, after 9 months, 67% of the households regularly continued to use the filter, 13% in occasional use and 21% not using the filter or the filter broke (25%) (Clasen et al. 2006). Further, Brown et al. (2009) reported that in Cambodia reported breakage at 42% of the households. Since the CPF is heavy, users of the CFU drop the device; there is no repair option available which would refurbish the CPF.

- (vi)

- Additives to Enhance Effectiveness of a CPF ‐ An option which is available to many types of CPFs is to add ‘silver’ using a brush after firing. Venis and Basu (2021) reviewed a series of options for potentially improving the CPF using silver (dipping/painting or co‐firing). Silver nitrate is indicated to have the effect of killing and disabling the reproduction of the smallest bacteria able to pass through the pores as well as help to prevent mold from growing on the filter surface over time and continued use the pores of the filter diminish in size due to clogging. Silver has also been utilized where the silver nanoparticles interact and disrupt the cell wall of bacteria thus acting as an effective micro‐biocide to prevent mold from growing on the filter. Application of silver nitrate involves a cost of ~3$/application (Venis and Basu, 2021).

- (vii)

- Removal of Metals in CPFs -Some research has been done to consider the removal of water-borne toxic metals, organics and pathogens in the CPF, aimed primarily at chemical pollutants (e.g. Chaukura et al., 2020b) and such as the average removal efficiencies for Hg, Pb, and As are 91.5, 92.1 and 50.2 percent respectively (Pérez-Vidal et al., 2021). While important, trying to remove chemicals is an expanded purview of concerns and is beyond microbial issues, so not dealt with herein.

- (viii)

- Evaluation of Effectiveness of CPF on Removal of Viruses – Removal of viruses has seen only limited attempts to assess the removal of viruses in CPFs or some equivalent thereof. It is acknowledged that lab testing for viruses generally requires access to a Tier 3 lab which is not generally available. To some extent, viruses tend to infect larger microorganisms (bacteria and protozoa) and hence, a virus is removed when the larger microorganisms are removed, and/or by the biofilm that develops on the interior of the ceramic filter (Farrow and McBean, 2014; Brunsting & McBean, 2011).

3. Safe Water and Full Schools

4. Performance of Technology Opportunities Obtained by the Guelph Water Filter (GWF) as a Low-Tech Water Filter

4.1. Background to Features of GWF

- (i)

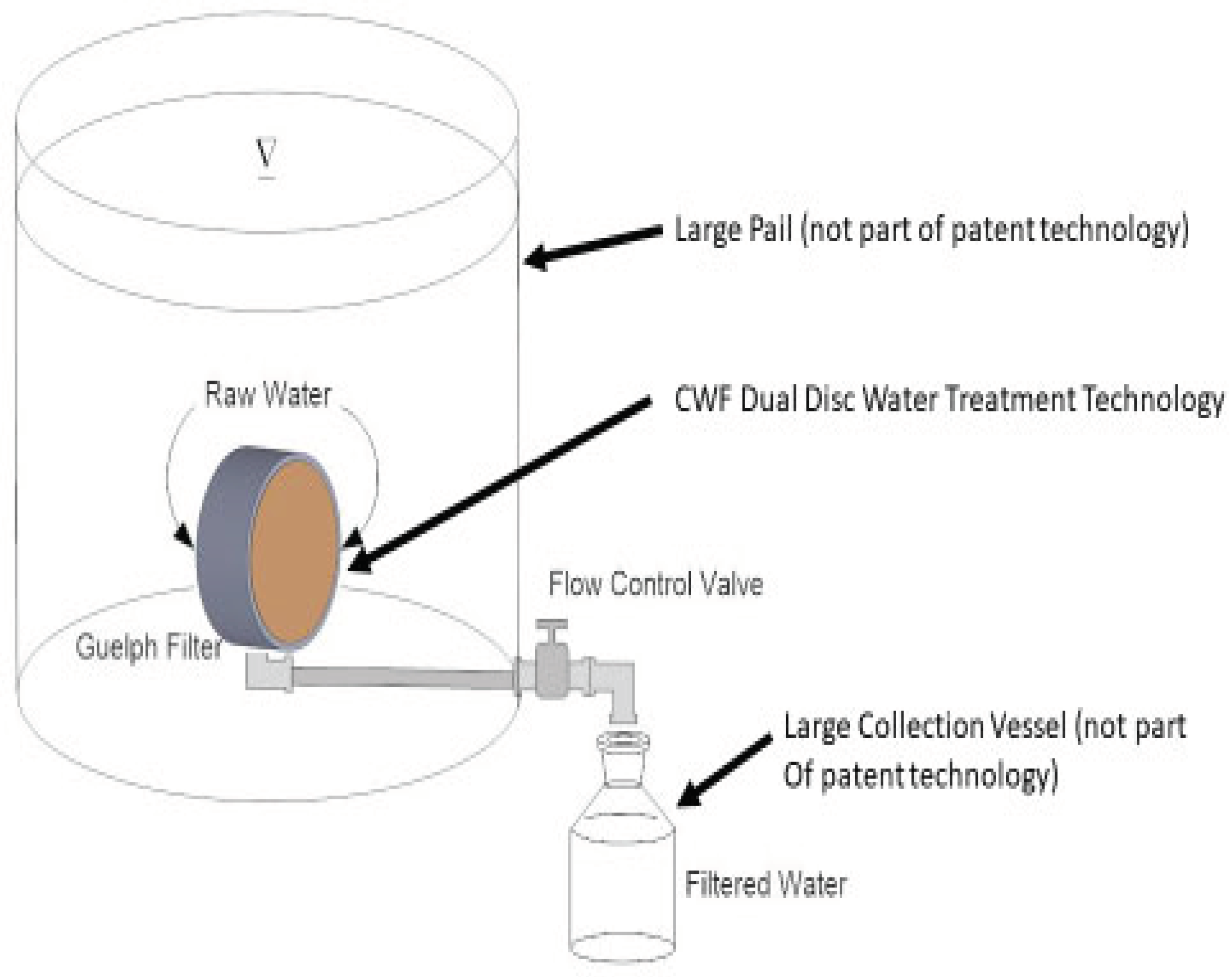

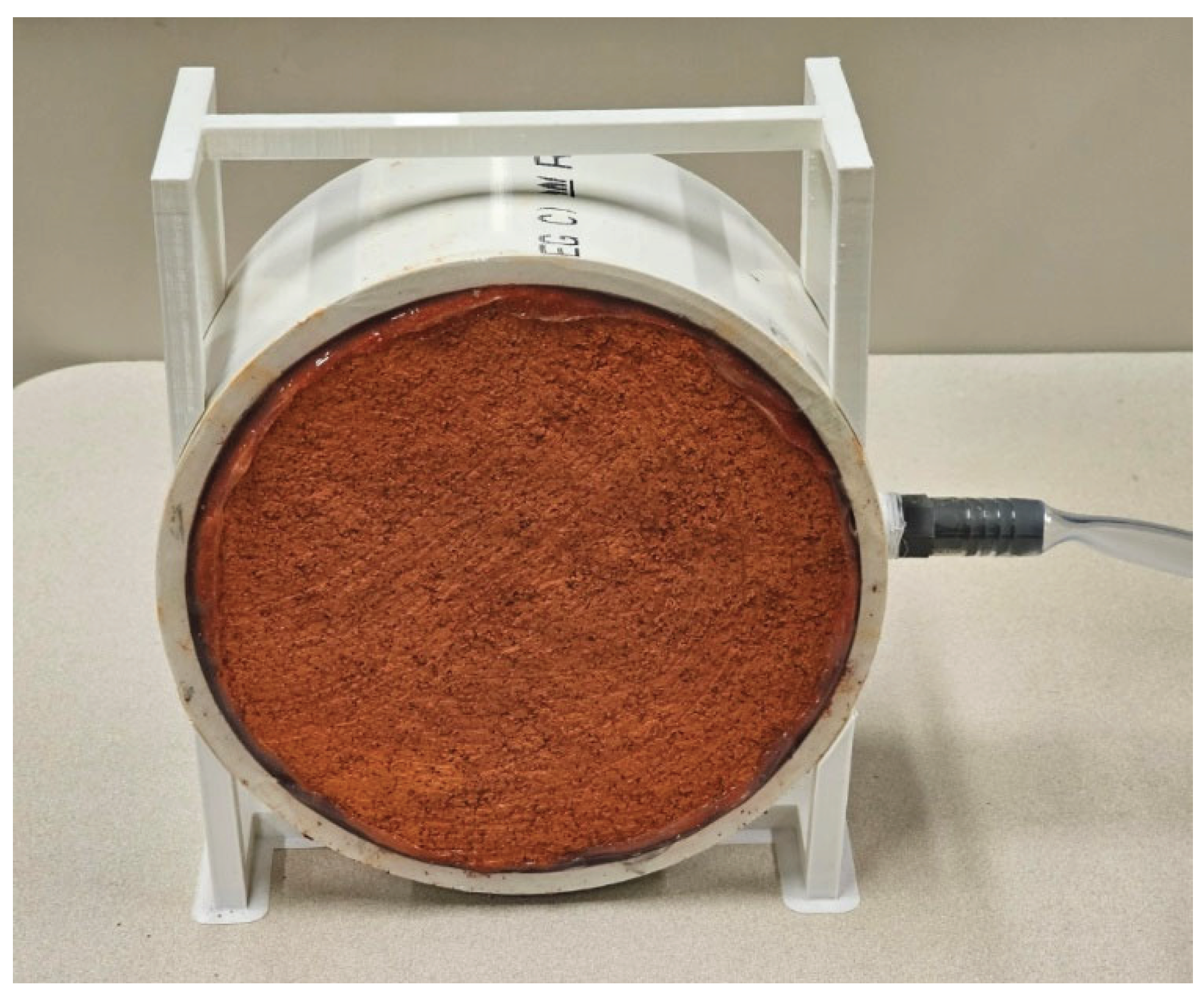

- The two-sided ceramic disc filter technology is as depicted in Figure 4 and Figure 5 where the depth of raw water in the large reservoir provides the hydraulic energy to move water through the ceramic disk filter and housing, into the interior of the technology, followed by capture between the two disks and exiting via a flexible tube to an exterior drinking water vessel.

- (ii)

- With the GWF there are two ceramic disc filters, each with a 20cm diameter disc. The housing of the disc has been utilized within the short PVC length, sealed around the perimeter of the disc using silicone, and an outlet to deliver the water to an exterior vessel.

4.2. Specific Attributes of the GWF

- (i)

- Large raw water reservoir – The large tank can be filled when convenient. Clearly, the proximity of the raw water to the GWF will influence the time required to fill the raw water tank, allowing the filling tasks not interfering with the children being able to attend school. The effort of refilling is necessary to be completed only every two days, to enable treated water to be available, and thus sufficient to meet the needs of the family.

- (ii)

- Accessibility to Safe Water -Access to the treated water is immediately available from the exterior, filtered water vessel.

- (iii)

- Cost of the GWF - The major costs of the GWF are related to the 20 cm diameter segment of PVC pipe, and 8.8 cm long. It is noted that recycled PVC pipe may be available and, if thoroughly cleaned, could enable use that would greatly reduce the price for manufacture of the GWF.

- (iv)

- Ease of Repair of the GWF -If there is failure of one or perhaps both ceramic filters, local (village level) replacement of the ceramic filter(s) could be easily accomplished, requiring no need to send the GWF to a distant location. The PVC pipe serves as protection against breakage, making the GWF robust.

- (v)

- Vertical Orientation of the Ceramic Filters in GWF - The GWF is best utilized vertically so that entrained sediments from the raw water are less prone to become entrained in the ceramic filters. Hence, the sediments that would otherwise tend to clog the ceramic filter(s) will fall harmlessly to the bottom of the raw water tank. The sediments on the bottom of the large reservoir can be washed out via a small drain at the bottom of the raw water tank. Gentle brushing of the surface of the ceramic filters dislodges the sediments and particulates that break off within the filter (something which happens in all ceramic filters), restoring the flowthrough rate of the filters.

- (vi)

- Placement of GWF Vertically, as opposed to Horizontally - By placing the ceramic filter technology vertically, there are two filters providing a total area of 626 cm2 x 1 cm thickness and hence, greater filter availability, thereby doubling the filtering surface.

- (vii)

- Implication of Placement of GWF at Bottom of Large Raw Water Vessel - By placement of the GWF at the bottom of the raw water tank, the GWF stays in position at the bottom, not having to be removed, preventing the dropping/breaking of the technology. A handle is provided (see Figure 6) so that the GWF can be lifted (if required, although not necessary for most purposes required such as needed for clay pots, for example).

- (viii)

- GWF is easily maintained and managed at the local level - The simplicity means that even school children can maintain them. Thus, this filter reduces the workload, freeing up the child’s time to pursue other activities, including getting an education. Facilitating the education of young women has important societal benefits. According to the World Bank, educated women are more informed about nutrition and healthcare, have fewer and healthier children, marry later, have higher economic security, and are more likely to participate in the labor market (Caruso, 2021).

- (ix)

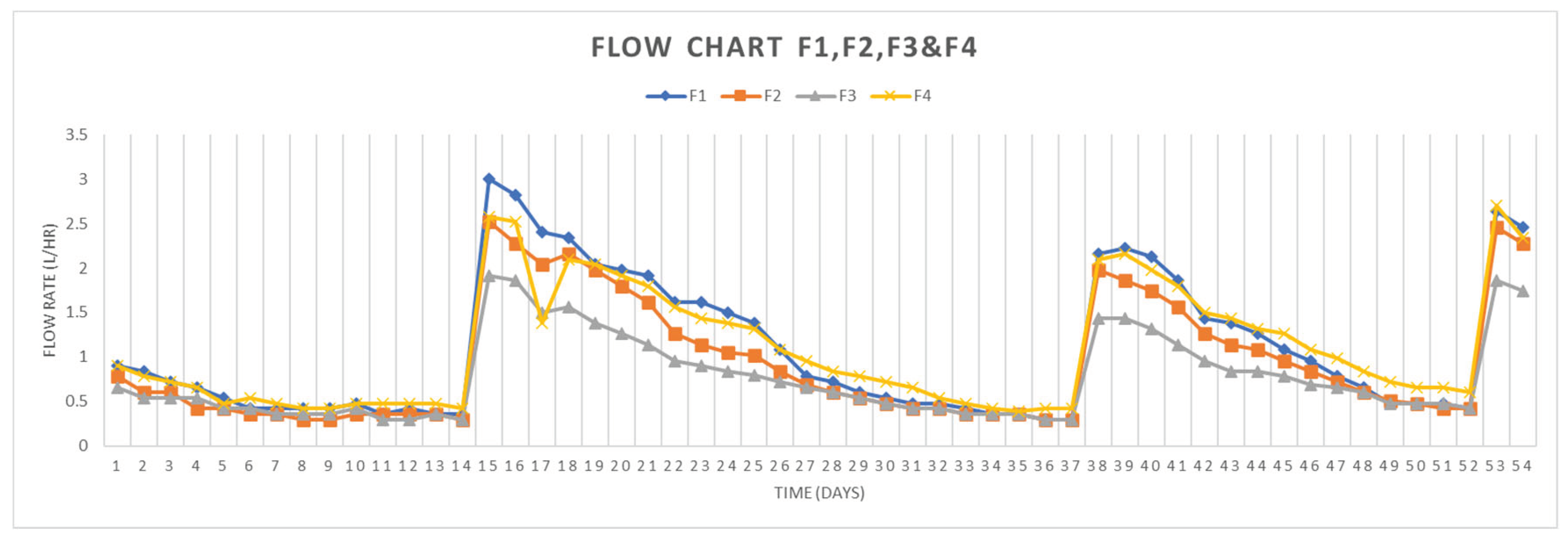

- Hydraulic Throughput the GWF -The hydraulic transmissivity through the ceramic filters is evident in Figure 7. Of most importance, when functioning as intended, the filters provide substantial quantities of water varying from 0.5 to 3 L/hr/ceramic disk (and even more, if desired since there are two disks).

- (x)

- Protection Against Breakage of the Ceramic Filters - The PVC housing helps to protect the integrity of the ceramic filters. Since there is minimal need to remove the ceramic filter technology, the PVC protects the integrity of the filters from cracking/breakage.

- (xi)

- Cleaning out the Sediments from the Filters -Advantages compared to the other low-tech water treatment technologies. including ease of maintenance (simple brushing to remove sediments and particulates from the filter, all the while with the filter providing no access to the ‘clean’ side of the filter being touched, reducing the needed frequency of refilling the raw water reservoir, with no possibility of contamination of the treated water by users.

- (xii)

- Longevity of Life of GWF - Since ceramic filters raw water effectively for up to (at least) two years (no situation trialed at present beyond several months) and has not deteriorated sufficiently that it had to be replaced.

- (xiii)

- Raw Material Sourcing - This approach is cost-effective, environmentally friendly, and the ceramic filters can be manufactured using locally sourced materials and labor in the village.

- (xiv)

- Retains Healthy Minerals: Ceramic filters may be able to remove some minerals while not removing healthy minerals such as calcium and magnesium.

- (xv)

- Removal of Various Harmful Contaminants: Ceramic water filters are highly effective at removing contaminants from water, namely turbidity, sediments, and micro-organisms. Coupled with other filters such as activated carbon filters, the list could be expanded to include other treatment options. Hence, removal of harmful contaminants can be accomplished by combining the GWF with an additional, external filter. However, this doesn’t preclude use of additional dimensions being added to the GWF to enable reliable removal of chemicals through sorption, for example.

- (xvi)

- Use of Natural Materials in the Filter Ceramic water filters are natural and don’t contain any chemicals, metals, or plastics.

- (xvii)

- Testing in the Lab Prior to Dispersal - Hydraulic testing of the GWF must be completed using submerged water to ensure there are no leaks around the edges of the filters and then put in oven at 50 oC for 1 day. This procedure will avoid biological growth within the ceramic disk, returning to the useful hydraulic throughput.

- (xviii)

- The youtube video guiding the procedure to make the GWF is shown in https://youtu.be/_fAGcGGLM60 for the GWF).

4.3. Hydraulic Performance of the GWF

4.3.1. Performance of GWF over Time

4.3.2. Hydraulic Performance of GWF Components

- (i)

- Flow throughput for single ceramic disks over time shows brushing effects at ~13 days between successive brushings. Characterized in Table 1 are the E. coli removals (all tested by themselves as single filters, not in combination with other filters). Since there are two filters, deteriorated performance of one of the filters may occur but still have a combined production rate from the two filters to deliver 1 L/hr.

- (ii)

- The influent E. coli concentration during the removal percentages of E. coli : 3.8 x 106 CFU/100 mL. The removal percentages for each of the four ceramic filters are listed in Table 1.

4.4. Social Implications of the GWF

5. Conclusions

Acknowledgments

References

- Akosile, S., Ajibade, F., Lasisi, K.H., Ajibbade, T., Adewumie, J., and Babatola, J., 2020. Scientifici African, Vol. 7, Mar.

- Annan, E., Agyei-Tuffour, B., Bensah, Y., et al., 2018. “Application of Clay Ceramics and Nanotechnology in Water Treatment: A Review”, Cogent Engineering, Volume 5, Issue 1. [CrossRef]

- Bielefeldt, A.R., Kowalski, K., Schilling, C., Schreier, S., Kohler, A., Scott Summers, R., 2010. Removal of virus to protozoan sized particles in point-of-use ceramic water filters. Water Research. 44, 1482–1488. [CrossRef]

- Bloem, M. W., Semba, R. D., Kraemer, K. et al. 2009. An Introduction to the Impact of Climate Change, the Economic Crisis, and the Increase in the Food Prices on Malnutrition. The Journal of Nutrition, 140, 132-135. [CrossRef]

- Brennan, R., and McBean, E., 2011. "A Performance Assessment of Arsenic-Iron Removal Plants in the Manikganj District of Bangladesh", Journal of Water and Health, 09.2, pp. 317-329. [CrossRef]

- Brennan, R., and McBean, E., 2011. "The Role of Orthophosphate and Dissolved Oxygen in the Performance of Arsenic-Iron Removal Plants Installed by SPACE in the Manikganj District of Bangladesh", Journal of Environmental Science and Health, Part A, 46, pp. 1-10. [CrossRef]

- Brown, J., Proun, S., Sobsey, M., 2009. Sustained use of a household-scale water filtration device in rural Cambodia, Journal of Water and Health, 7(3):404-12. [CrossRef]

- Brown, J., Sobsey, M.D., 2010. Microbiological effectiveness of locally produced ceramic filters for drinking water treatment in Cambodia. 2009. J. Water Health 8, 1–10. [CrossRef]

- Brown, J., Proun, S., Sobsey, M., 2009. Sustained use of a household-scale water filtration device in rural Cambodia. Journal of Water and Health, 2009 7(3):404-12. [CrossRef]

- Brunsting, J., and McBean, E, 2011. "Virus Removal Efficiency of Cambodian Ceramic Pot Water Purifiers", Journal of Water and Health, 09.2, pp. 306-311. IF 1.660. [CrossRef]

- Bulta, A.L., and Micheal, G.A. W., 2019. “Evaluation of the Efficiency of Ceramic Filters for Water Treatment in Kambata Tabaro zone, southern Ethiopia”, Environmental Systems Research. [CrossRef]

- Caruso, B., “Women still carry most of the world’s water” where Caruso refers to a report by UNICEF, accessed Jan 21, 2021, https://theconversation.com/women-still-carry-most-of-the-worlds-water-81054.

- Casanova, LM., Walters A., Naghawatte, A., Sobsey, MD. 2012. A post-implementation evaluation of ceramic water filters distributed to tsunami-affected communities in Sri Lanka. Journal of Water and Health, 2012:10(2):209-20,. [CrossRef]

- Chaukura, N., Katengeza, G., Chiedza I. M., Thabo TI. Nkambule, M. M., Kuvarega, A. 2020b. Development and evaluation of a low-cost ceramic filter for the removal of methyl orange, hexavalent chromium, and Escherichia coli from water. Materials Chemistry and Physics, 249. [CrossRef]

- Chaukura, N., Chiworeso, R., Gwenzi, W., Motsa, M., Munzeiwa, W., et al. 2020. “A new generation low-cost biochar-clay composite ‘biscuit’ ceramic filter for point-of-use water treatment”, Applied Clay Science, 185 (105409a). [CrossRef]

- Clasen, T., Brown,J., Collin S., Preventing diarrhoea with household ceramic water filters: Assessment of a pilot project in Bolivia. International Journal of Environmental Health Research, 2006: 16(3):231-9. [CrossRef]

- Dinka, M., 2018. Safe Drinking Water: Concepts, Benefits, Principles and Standards: in Glavan M., Water Challenges of an Urbanizing World, IntechOpen London, 163-181. [CrossRef]

- Dung, T.T.N., Thi, L.P., Nam, V.N., Nhan, T.T., Quang, D.V., 2019. “Preparation of silver nanoparticle-containing ceramic filter by in-situ reduction and application for water disinfection”. J. Environ. Chem Eng. 7, 103176. [CrossRef]

- Ensink, JHJ, Bastable A., Cairncross S. Assessment of a membrane drinking water filter in an emergency setting”. Journal of Water and Health 2008;79(5):696-701. [CrossRef]

- Farrow, C., McBean, E., Huang, G., Yang, A., Wu, Y.C., Liu, Z., Dai, Z, Cawte, T., 2018. “Ceramic Water Filters: A Point-of-Use Water Treatment Technology to Remove Bacteria from Drinking Water in Longhai City, Fujian Province, China”, Journal of Environmental Informatics, 32(2), pp 63-68. [CrossRef]

- Farrow, C., and McBean, E., 2014. “Virus Removal Efficiency of Ceramic Water Filters: Effects of Bentonite Turbidity”, Water Science and Technology, Water Supply, 14.2, pp. 304-311. [CrossRef]

- Huang, G., personal communication, 2023.

- Kallman, E. N., Oyanedel-Craver, V. A., & Smith, J. A..2013. Ceramic filters impregnated with silver nanoparticles for point-of-use water treatment in rural Guatemala. Journal of Environmental Engineering, 139(September), 1152–1161. [CrossRef]

- McBean, E., 2010. "Risk Management of Arsenic in Drinking Water for the Rural Poor in a Climate Changing World", Plenary presentation at the International Conference on Environmental Health and Technology, Kanpur, India, March 15-17.

- McBean, E., Zhu, Z., and Zeng, W., 2008. "Systems Analysis Models for Disinfection By-Product Formation in Chlorinated Drinking Water in Ontario ", Journal of Civil Engineering and Environmental Systems, 25:2, pp. 127-138. [CrossRef]

- McBean, E., Farrow, C., Preston, T., Yang, A., Huiyan, C., Yichen, U., Zhen, L., Zhineng, D., Fu, H, Beauchamp, J., Beutel, R., Huang, G., 2019. “Investigation of Maintenance Impacts on Flow Rates in Ceramic Disc Water Filters”, Journal of Environmental Informatics Letters, 1(2), pp 81-86. [CrossRef]

- McBean, E., 2022. “Novel but Simple: A Low-Tech Water Treatment Technology for Producing Safe Water”, presented at Canadian Society of Civil Engineers 2022 Annual Conference, Whistler, B.C., May 25-28.

- McBean, E., and Farrow, C., 2021. “Design and Performance for a Novel Low-Tech Water Filter System”, Journal of Environmental Informatics, ISSN: 2663-6859 print/2663-6867. [CrossRef]

- McBean, E.,” Improved Human Health Risk Characterization for Regions with Arsenic-Contaminated Groundwater”, Keynote Presentation, Fifth International Groundwater Conference, Maharashtra, India, Dec 18-21, 2012.

- Pérez-Vidal, A., Silva-Leal, J., et al. 2021. Performance Evaluation of Ceramic Pot Filters Combined with Adsorption Processes for the Removal of Heavy Metals and Phenolic Compounds”, Journal of Water Health 19(5): 750-761. [CrossRef]

- Pooi, C.K., & Ng, H.Y., 2018. Review of Low-Cost Point-of-use Water Treatment Systems for Developing Countries”, www.nature.com/npjcleanwater.

- Rayner, J., 2013 Rayner. J., Skinner, B., Lantagne, D., 2013. Current practices in manufacturing locally made ceramic pot filters for water treatment in developing countries. J. Water Sanitation Hyg. Dev. 3 (2013) pp252-261. [CrossRef]

- Rivera-Sanchez, S.P., Ocampo-Ibanez, et al. 2020. “A Novel Filtration System Based on Ceramic Silver-Impregnated Pot Filter Combined with Adsorption Processes to Remove Waterborne Bacteria”, Scientific Reports, 10, Article Number 11198. [CrossRef]

- Seghal web page (https://www.smsfoundation.org/). Accessed 6/10/2023.

- Shepard Z J, Zhang Y, Anaya N M, Cardac.e D and Oyanedel-Craver V. 2020. Development of ceramic water filter clay selection criteria. Water, 12(6): 1657. [CrossRef]

- Sorensen, I., and McBean, E., 2015. “Beyond Appropriate Technology: Social Considerations for the Sustainable Use of Arsenic-Iron Removal Plants in Rural Bangladesh”, Technology in Society, 41, pp. 1-9. [CrossRef]

- Sorensen, I., and McBean, E., and Rahman, M., 2014. “Retrofitting Arsenic-Iron Removal Plants for Performance Change in Rural Bangladesh”, Journal of Water, Sanitation and Hygiene for Development, 0.4/3, pp 401-409. [CrossRef]

- Tashnimal, H., Farrow, C., and McBean, E., 2012. “Performance of a Novel, Low-Tech Water Treatment System for Surface Water”, presented at One Health- One World Conference, University of Guelph, May 11.

- UN, 2002, General Comment No. 15. “The right to water. UN Committee on Economic, Social and Cultural Rights”, November 2002.

- UN, 2010, Resolution adopted by the General Assembly on 28 July 2010, 64/292. The human right to water and sanitation, General Assembly, United Nations A/RES/64/292, 3 August 2010.

- van Halem, D., van der Laan, H., Soppe, A. I. A., & Heijman, S., G. J. (2017). High flow ceramic pot filters. Water Research, 124, 398–406. [CrossRef]

- van der Lann, H., van Halem, D. Smeets, P., Soppe, A., Kroesbergen, J., Wubbels, G., Nederstigt, J., Genrburger, I, and Heijman, S., 2014. Bacteria and virus removal effectiveness of ceramic pot filters with different silver applications in a long term experiment”, Water Research, 51, 47-54, Vol. [CrossRef]

- Venis, R., and Basu, O.D., “Mechanisms and Efficacy of Disinfection in Ceramic Water Filters: A Critical Review”, Critical Reviews in Environmental Science and Technology, 2021, Vol. 51, No. 24, pp 2934-2974. [CrossRef]

- Wafy, K., El-Aswer, E., Salah,W., El-Sabbagh, S., 2023. Water DisinfectionUsing Durable Ceramic Filter Coated with Silver Nanoparticles Synthesized using Actinomycetes, Applied Water Science 13(6):140. [CrossRef]

- WHO, 2017, Diarrhoeal disease, Key facts¸ May 2017 https://www.who.int/news-room/fact-sheets/detail/diarrhoeal-disease#:~:text=Infection%3A%20Diarrhoea%20is%20a%20symptom,for%20drinking%2C%20cooking%20and%20cleaning.

- WHO, 2023. Schistosomiasis, Key facts, 1 February 2023, https://www.who.int/news-room/fact-sheets/detail/schistosomiasis#:~:text=Schistosomiasis%20is%20an%20acute%20and%20chronic%20parasitic%20disease%20caused%20by,will%20reduce%20and%20prevent%20morbidity.

- WHO/UNICEF, 2022 Progress on drinking water, sanitation and hygiene in schools: 2000-2021 data update. New York: United Nations Children’s Fund (UNICEF) and World Health Organization (WHO), 2022.

- WHO/UNICEF, 2023a. “Lack of sanitation for 2.4 billion people is undermining health improvements”, Final MDG progress report on water and sanitation released. Geneva/New York, USA.

- WHO/UNICEF, 2023b. Progress on household drinking water, sanitation and hygiene 2000–2022: special focus on gender. New York: United Nations Children’s Fund (UNICEF) and World Health Organization (WHO), 2023.

- World Health Organization (WHO) and UNICEF, 2017., Water and Sanitation for Health Facility Improvement Tool (WASH EIT), World Health Organization.

- World Health Organization (WHO). Burden of Disease from Inadequate Water in Low- and Middle-income Countries. http://apps.who.int/gho/data/view.main.INADEQUATEWATERv?lang=en (2018).

- WHO. (2017a). 21 billion people lack safe drinking water at home, more than twice as many lack safe sanitation. Geneva: World Health Organization.

- World Health Organization (WHO). The top 10 causes of death. http://www.who.int/news-room/fact-sheets/detail/the-top-10-causes-of-death (2020).

- World Health Organization (WHO) and UNICEF (2917), 2022., Water and Sanitation for Health Facility Improvement Tool (WASH EIT), World Health Organization., 25 April 2022.

- Zhu, Z., McBean, E. and B. Harper, 2014. “Assessment of Mitigation Strategies for Disinfection By-Product Formation through Bayesian Network Modeling”, Journal of Water Management Modeling, USSB 2292.6062, pages 1-8. [CrossRef]

| Filter Number | Log removal of E. coli | E. coli Removal (%) |

|---|---|---|

| F1 | 4.52 | >99.99% reduction |

| F2 | 4.63 | >99.99% reduction |

| F3 | 3.78 | >99.9% reduction |

| F4 | 4.49 | >99.99% reduction |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).