1. Introduction

Microfluidic devices are increasingly common in many scientific fields. The typical manufacturing process for microfluidic devices is soft lithography[

1,

2,

3] where the silicone polymer polydimethylsiloxane (PDMS) is cast onto a silicon wafer with surface relief created by photolithography.[

4] In this process cured photoresist creates surface relief which is the inverse of the final device and for that reason is called a “negative master” using photographic terminology. However, in some situations it is preferable to create a “positive master” with surface relief which matches the final device via wet etching,[

5] plasma etching,[

6] or micromilling[

7] to reduce fabrication time, cost, or create channels with shapes or curvature which may be impractical to create in a negative master.

In these cases a two stage casting method is required to first invert the original positive master into an intermediate negative master which can then be used to cast the final PDMS device. Common methods of creating an intermediate master include thermal imprinting polymethylmethacrylate (PMMA) sheets[

8] for mass production and using epoxy resin[

9] or polyurethane resin[

10] for rapid prototyping. Another method is PDMS “double casting” where the intermediate master is also PDMS, but this method requires careful separation of the PDMS layers.[

11] The separation is typically facilitated by the application of a release agent to the intermediate or the chemical passivation of the intermediate to prevent bonding between the PDMS layers.[

12] Early release agents used for PDMS double casting include silanization using tetraethylorthosilicate[

13] and hydroxypropylmethylcellulose (HPMC).[

14] Later work passivated the intermediate using thermal aging[

15] or plasma/alcohol treatment.[

16]

The aims of this paper are to present and compare two methods for creating microfluidic devices using the silicone polymer polydimethylsiloxane (PDMS) from an original physical positive master with the same surface relief as the finished device. The methodology for both two stage resin/PDMS casting and PDMS double casting will be described in detail, the timing of both methods will be compared directly, and the benefits and limitations of each method will be discussed.

2. Materials and Methods

Both methods being compared follow the same general four stage process of preparing the master using CAD (Fusion 360) and a CNC mill (Snapmaker A350) to mill a positive master directly into a plastic petri dish, preparing the intermediate cast using casting resin (Crystal Clear 204 urethane or Art’N Glow epoxy) or PDMS (Sylcap 284-S or Qsil 216) and a planetary centrifuge (Thinky ARE-310), preparing the final PDMS cast, and finishing the device using a plasma cleaner (Diener Zepto), sampling punch (WellTech Rapid-Core 0.75), and glass microscope slides.

2.1. Master Preparation

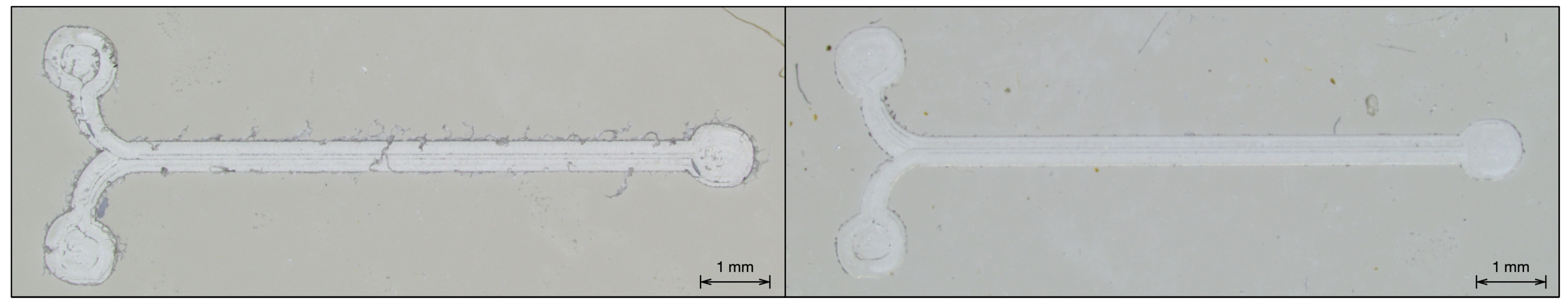

The first step for any microfluidic device is to design the model in 3-D modeling software. The software used for the work presented here is Fusion 360, but most CAD 3-D modeling applications have the same tools and operate similarly. Using the sketch tool (or similar analog), make a rectangular outline of a suitable size for the glass slides being used, then extrude (apply height/z-axis dimension) to a height greater than the maximum drill depth to allow for material to remain under the milled channels. Next, sketch the outline of the desired channel (a curved Y-channel for the work presented here, see

Figure 1) on top of the extruded rectangular base. Ensure that the injection sites and output site have a diameter of 1 mm to accommodate external tubing connections and that the channel depth and width are within the specifications of the mill-end being used. The range used in this paper were between 0.2 mm and 0.4 mm for the depth and width of the device channels and the length of the longer channel being between 0.8 mm and 1.0 mm. Once you have your finished model with the desired dimensions switch from design to manufacture mode. In manufacture mode, the g-code for the CNC machine is created for the milling of the device. This code should have negative values for the z position to mill into the dish.

Milling is a subtractive process, so material will be removed regardless of whether it was designed to mill a positive or negative master. The milling time differs substantially between milling a positive or negative master but there are advantages to both. Milling a positive master takes about an hour depending on length of device, but then an intermediate casting step is required during device fabrication. Milling a negative master can take about 24 hours to complete, has a higher failure rate due to breaking mill ends, and can lead to lower quality masters due to mill end degradation during milling, but an intermediate cast is not required during fabrication. For these reasons it is typically preferable to mill a positive master. In the procedures that follow, a milled positive master is assumed. The following procedures may need to be modified slightly as appropriate for the CNC mill being used. First a plastic petri dish is clamped onto the substrate in the milling machine, but not too tightly as the dish may warp or crack. Then the g-code file is loaded onto the flash drive plugged into the milling machine to start the mill. After the milling is done the tray and mill will need to be cleared of plastic milling debris. In an inspection microscope take measurements of the channel width and length and the radii of the input ports and output ports to confirm the milled master matches the design specifications. After measuring the dimensions, the channel will need to be cleaned as there will be milling residue left in the channels and ports as seen in

Figure 1.

2.2. Initial PDMS Casting

To clean the master a thin PDMS cast is used to physically remove all residue. The cleaning round of PDMS needs to coat the milling area and the work here used 22 g of PDMS using a scale to weigh out 20 g of PDMS and 2 g of hardener in the usual 10:1 ratio which is then mixed and defoamed in a planetary centrifuge. After mixing pour the PDMS into the milled dish and degas the dish in a vacuum chamber for 30 minutes so that the air bubbles rise to the top. After removal from the vacuum chamber use a heat gun to remove the air bubbles at the top of the dish and then cure the PDMS in the oven for 90 minutes at 70 °C. Finally, cut out a circle in the cured PDMS that is around 80% of the dish diameter, leaving an outer ring for the intermediate casting step, and remove the inner circle to pull the residue out of the milled channel. The milled master before and after the initial PDMS casting is shown in

Figure 1. The initial PDMS casting process takes about 2.5 hours total.

2.3. Resin Intermediate Casting

Creating the intermediate cast from resin is the same procedure as the initial PDMS cleaning cast other than the material and mixture ratio. For the epoxy resin used here 8 g of resin and 6.4 g of hardener were mixed and degassed. The mixing and degassing takes the same amount of time as with PDMS but the cure time is 24 hours.

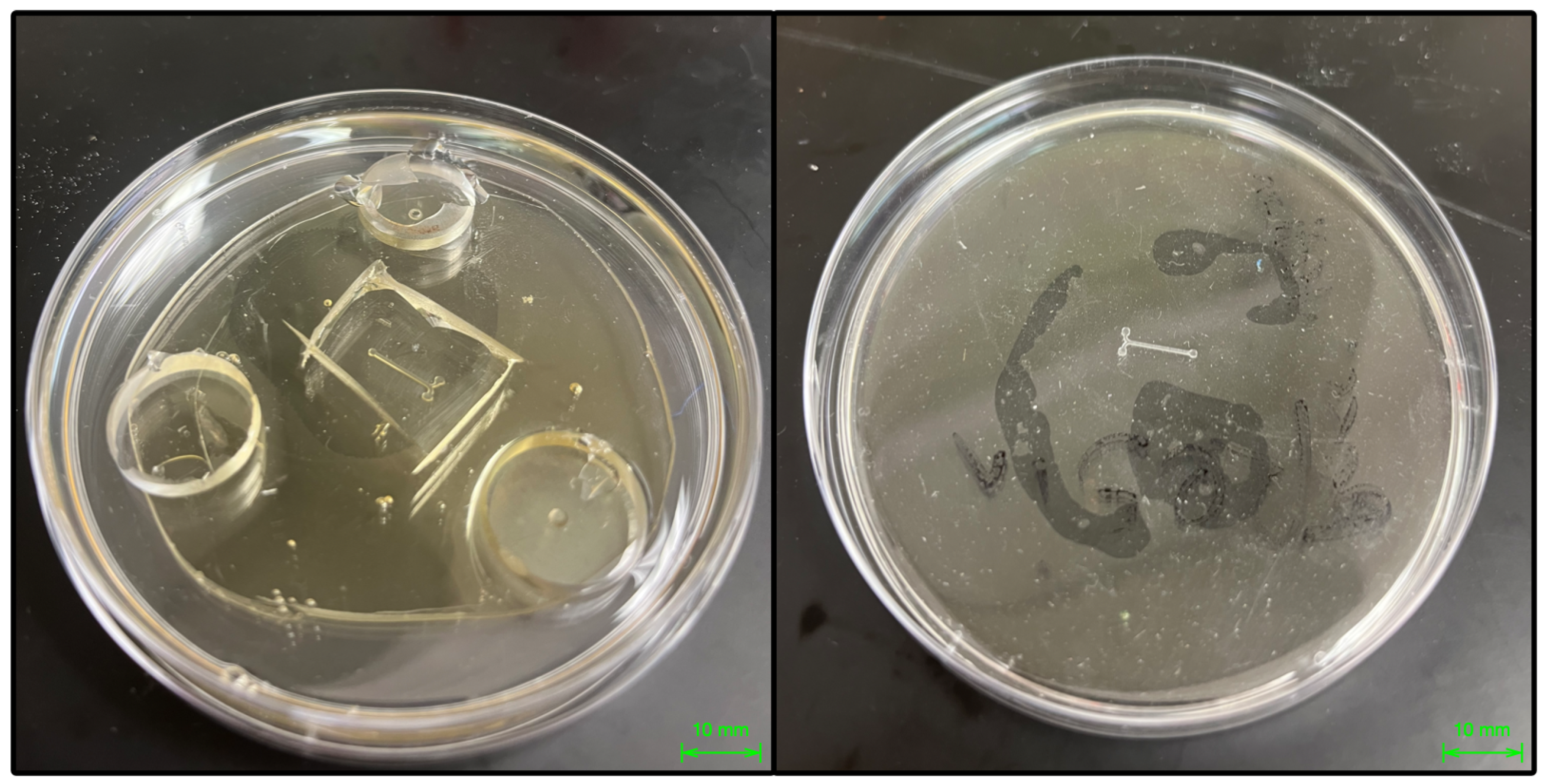

After the resin is cured the next step is to remove the intermediate resin mold from the original positive master. To facilitate this, first remove the remaining PDMS ring from around the resin intermediate. Carefully peal the resin cast from the plastic master. When using epoxy resin the dish is usually broken during the process of separating the cast from the dish. When using urethane resin the dish is less likely to break, but breaks are still common. After the intermediate resin cast is removed from the original master the edge of the resin cast will need to be trimmed due to meniscus curvature at the boundary. After the resin cast is ready place it into a new dish with the device features facing up for subsequent PDMS casting. Here three magnets are used to hold the resin cast down to the dish to prevent it from floating in the PDMS. The resin intermediate after final PDMS casting and device removal is shown in

Figure 2. The resin intermediate casting process takes about 24 hours total.

2.4. PDMS Double Casting

The PDMS double casting method described here is adapted from Kim et al. [

16] with slight modifications. We found that increasing the duration of plasma cleaning to 60 s and using exclusively methanol resulted in a significantly lower failure rate.

Creating the intermediate cast from passivated PDMS begins with creating a PDMS cast, the method for which is identical to that of the initial PDMS cast. Namely, 20 g of PDMS to 2 g of hardener are mixed and defoamed in the planetary centrifuge, degassed in a vacuum chamber for 30 minutes, remaining air pockets are ruptured with a heat gun, and the PDMS is cured at 70 °C for 90 minutes. Next, the PDMS intermediate can be put through the passivation process. Start by cutting out a circular ring around the features, resulting in an interior disk including the features and an outer ring approximately 1 cm in width. Remove the resulting PDMS ring and circular cutout, discard the outer ring, and flip over the cutout to ensure that the features are facing up. Then, plasma clean the PDMS disk for 60 seconds and place it in a new petri dish. Pour methanol into the container until the disk is fully submerged and degas the PDMS mold in the vacuum chamber for 30 minutes. After removing the PDMS mold from the vacuum chamber, discard the excess methanol, and place the PDMS mold into the oven at 70 °C for at least 5 minutes to evaporate any remaining alcohol. The end of this round of baking marks the end of the passivation process and at this point the PDMS intermediate is capable of acting as a negative master for final PDMS casting. A passivated PDMS intermediate is shown in

Figure 2. The passivated PDMS intermediate casting process takes a little over 3 hours, about 2.5 hours for casting the PDMS intermediate itself and about 45 minutes for the passivation process itself.

2.5. Final PDMS Casting

After the intermediate master has been cast by either method the final PDMS casting is nearly identical to the initial PDMS casting. The key difference in this iteration is the amount of PDMS is increased to 33-44 g (the 10:1 component ratio increased to 30-40 g of PDMS and 3-4 g of hardener) as it needs to both submerge the intermediate master, filling in around the edges, and create a device of functional thickness. After this casting has been completed, the PDMS device is ready to be extracted. The freshly cured PDMS device should come free from the passivated material when flexed at the transition plane between the layers. It should be noted that some uncured PDMS may have gone underneath the passivated disk and need to be removed as well. After the PDMS device has been extracted the intermediate master (from either method) can be immediately reused for additional castings. The final PDMS casting process takes about 2.5 hours total.

2.6. Device Finishing

After the PDMS casting is finished from either method, cut out a square of the PDMS cast including all of the device features. To create the input and output connections place a sampling punch on the connection locations, features side up, and punch the holes through the device. The final step is to plasma bond a glass slide to the features side of the PDMS device. Place the separated glass slide and PDMS device features up in the plasma oven on a flat support and plasma treat for one minute. Remove the glass slide and the PDMS device and combine the glass slide and the PDMS device with the features side touching the glass slide. Next wrap the device in a paper cloth and clamp it between two glass slides with a binder clip to apply pressure and put the clamped device in the oven at 70 °C for 15 minutes to allow to fully bond. The microfluidic device is now finished. This final step takes roughly 30 minutes.

3. Results and Discussion

The two different methods described above both have their own strengths and weaknesses. Using a resin intermediate requires nearly 30 hours to go from initial master to final device while PDMS double casting requires only about 9 hours. The timing of each method is compared in

Table 1. Using a resin intermediate will more than likely cause the initial master dish to break while the intermediate is being removed. Thus, even when the intermediate cast is successful only one intermediate master can be created from each initial master. However, the intermediate resin mold is highly reusable with the failure rate for final PDMS casting extremely low. The PDMS double casting method poses little risk to the initial master but is heavily reliant on the successful passivation of the intermediate. Failure of the PDMS intermediate to become distinct from the final PDMS device will result in the loss of both the device and the intermediate. However, even in this situation the initial master is unaffected and is reusable. Additionally, PDMS double casting avoids the lengthy 24 hour curing duration required by the resin. From initial master to final device using a passivated PDMS intermediate requires only 30% of the time compared to using a resin intermediate. This provides the potential for a one day process from design to a finished device, a significant boon for rapid prototyping.

4. Conclusions

From the comparative study here we come to the conclusion that both resin intermediate casting and PDMS double casting have utility but PDMS double casting is preferable in most situations. With PDMS double casting the process time is shorter, the risks to the initial master are far lower, and multiple intermediates can be created from the same initial master. The possibility for failure of the passivation step is higher than the possibility of failure for any step using a resin intermediate, but the failure is not catastrophic as the initial master remains intact. The possibility of failure is lower using a resin intermediate, near zero after the successful creation of the intermediate, but the production of multiple intermediates from one initial master is nearly impossible and the process time is significantly longer. From this we conclude that PDMS double casting is the preferable method both for rapid prototyping due to the shorter process time and for scalable production due to the ability to create multiple intermediates from one initial master. The resin intermediate method could remain a preference for research groups with scarce resources where the loss of material due to failure is a larger concern than the increased processing time.

Author Contributions

Conceptualization, N.T.; methodology, B.C., A.O., and N.T.; investigation, B.C. and A.O.; writing, B.C., A.O., and N.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Xia, Y.; Whitesides, G.M. Soft lithography. Annual Review of Materials Science 1998, 28, 153–184. [Google Scholar] [CrossRef]

- Duffy, D.C.; McDonald, J.C.; Schueller, O.J.; Whitesides, G.M. Rapid prototyping of microfluidic systems in poly (dimethylsiloxane). Analytical Chemistry 1998, 70, 4974–4984. [Google Scholar] [CrossRef] [PubMed]

- Whitesides, G.M. The origins and the future of microfluidics. Nature 2006, 442, 368–373. [Google Scholar] [CrossRef] [PubMed]

- Thompson, L.F. An introduction to lithography; ACS Publications, 1983.

- Lee, D.K.; Kwon, J.Y.; Cho, Y.H. Fabrication of microfluidic channels with various cross-sectional shapes using anisotropic etching of Si and self-alignment. Applied Physics A 2019, 125, 1–7. [Google Scholar] [CrossRef]

- Richter, K.; Orfert, M.; Howitz, S.; Thierbach, S. Deep plasma silicon etch for microfluidic applications. Surface and Coatings Technology 1999, 116, 461–467. [Google Scholar] [CrossRef]

- Wilson, M.E.; Kota, N.; Kim, Y.; Wang, Y.; Stolz, D.B.; LeDuc, P.R.; Ozdoganlar, O.B. Fabrication of circular microfluidic channels by combining mechanical micromilling and soft lithography. Lab on a Chip 2011, 11, 1550–1555. [Google Scholar] [CrossRef] [PubMed]

- Li, H.F.; Lin, J.M.; Su, R.G.; Cai, Z.W.; Uchiyama, K. A polymeric master replication technology for mass fabrication of poly (dimethylsiloxane) microfluidic devices. Electrophoresis 2005, 26, 1825–1833. [Google Scholar] [CrossRef] [PubMed]

- Carugo, D.; Lee, J.Y.; Pora, A.; Browning, R.J.; Capretto, L.; Nastruzzi, C.; Stride, E. Facile and cost-effective production of microscale PDMS architectures using a combined micromilling-replica moulding (μ Mi-REM) technique. Biomedical microdevices 2016, 18, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Tompkins, N.; Cambria, M.C.; Wang, A.L.; Heymann, M.; Fraden, S. Creation and perturbation of planar networks of chemical oscillators. Chaos: An Interdisciplinary Journal of Nonlinear Science 2015, 25. [Google Scholar] [CrossRef]

- Koerner, T.; Brown, L.; Xie, R.; Oleschuk, R.D. Epoxy resins as stamps for hot embossing of microstructures and microfluidic channels. Sensors and Actuators B: Chemical 2005, 107, 632–639. [Google Scholar] [CrossRef]

- Yang, L.; Hao, X.; Wang, C.; Zhang, B.; Wang, W. Rapid and low cost replication of complex microfluidic structures with PDMS double casting technology. Microsystem technologies 2014, 20, 1933–1940. [Google Scholar] [CrossRef]

- Briones, M.P.P.; Honda, T.; Yamaguchi, Y.; Miyazaki, M.; Nakamura, H.; Maeda, H. A practical method for rapid microchannel fabrication in polydimethylsiloxane by replica molding without using silicon photoresist. Journal of chemical engineering of Japan 2006, 39, 1108–1114. [Google Scholar] [CrossRef]

- Gitlin, L.; Schulze, P.; Belder, D. Rapid replication of master structures by double casting with PDMS. Lab on a Chip 2009, 9, 3000–3002. [Google Scholar] [CrossRef]

- Kwapiszewska, K.; Żukowski, K.; Kwapiszewski, R.; Brzózka, Z. Double casting prototyping with a thermal aging step for fabrication of 3D microstructures in poly (dimethylsiloxane). AIMS Biophys 2016, 3, 553–562. [Google Scholar] [CrossRef]

- Kim, S.H.; Lee, S.; Ahn, D.; Park, J.Y. PDMS double casting method enabled by plasma treatment and alcohol passivation. Sensors and Actuators B: Chemical 2019, 293, 115–121. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).