Submitted:

24 August 2024

Posted:

26 August 2024

You are already at the latest version

Abstract

Keywords:

Introduction

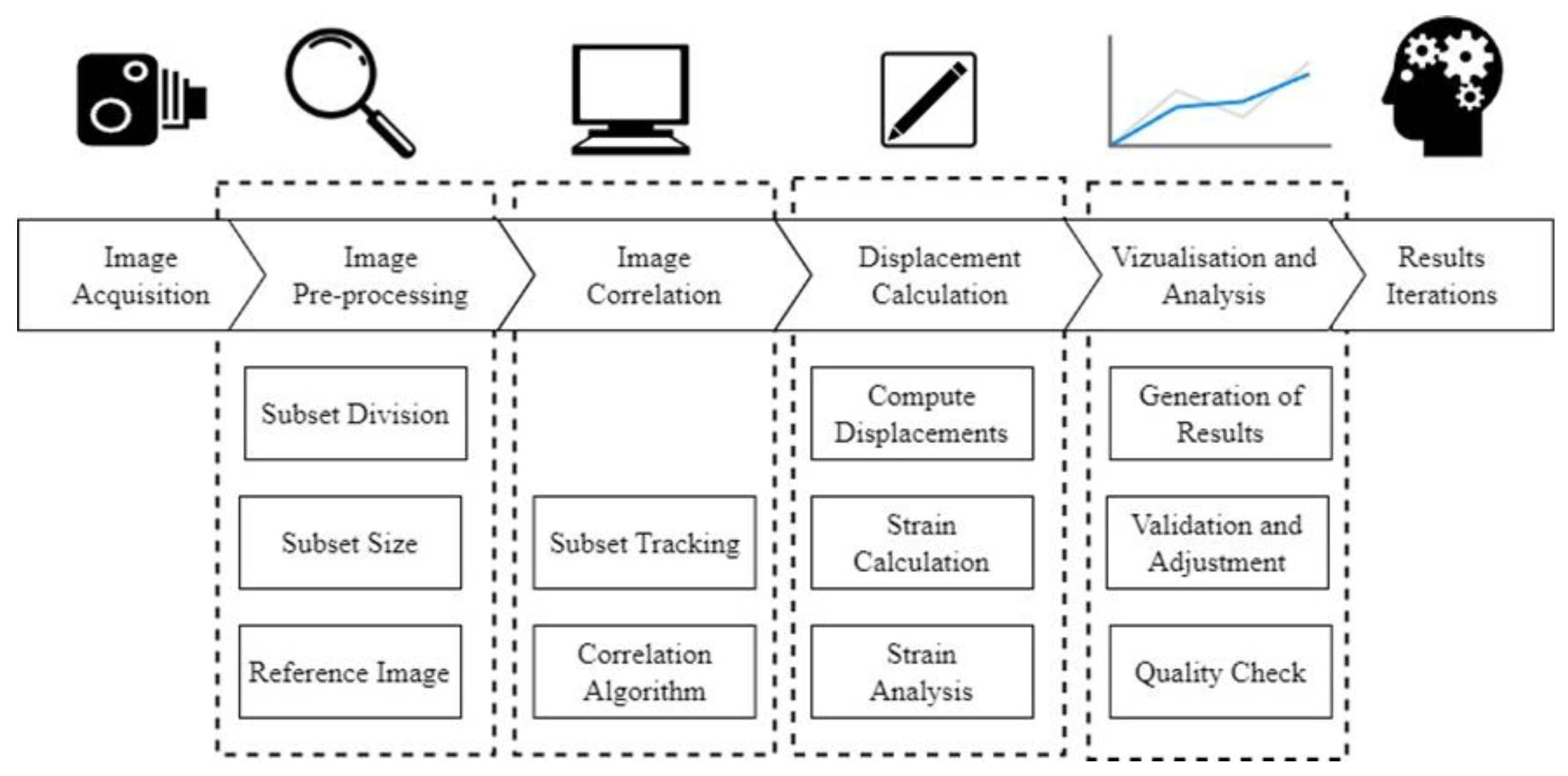

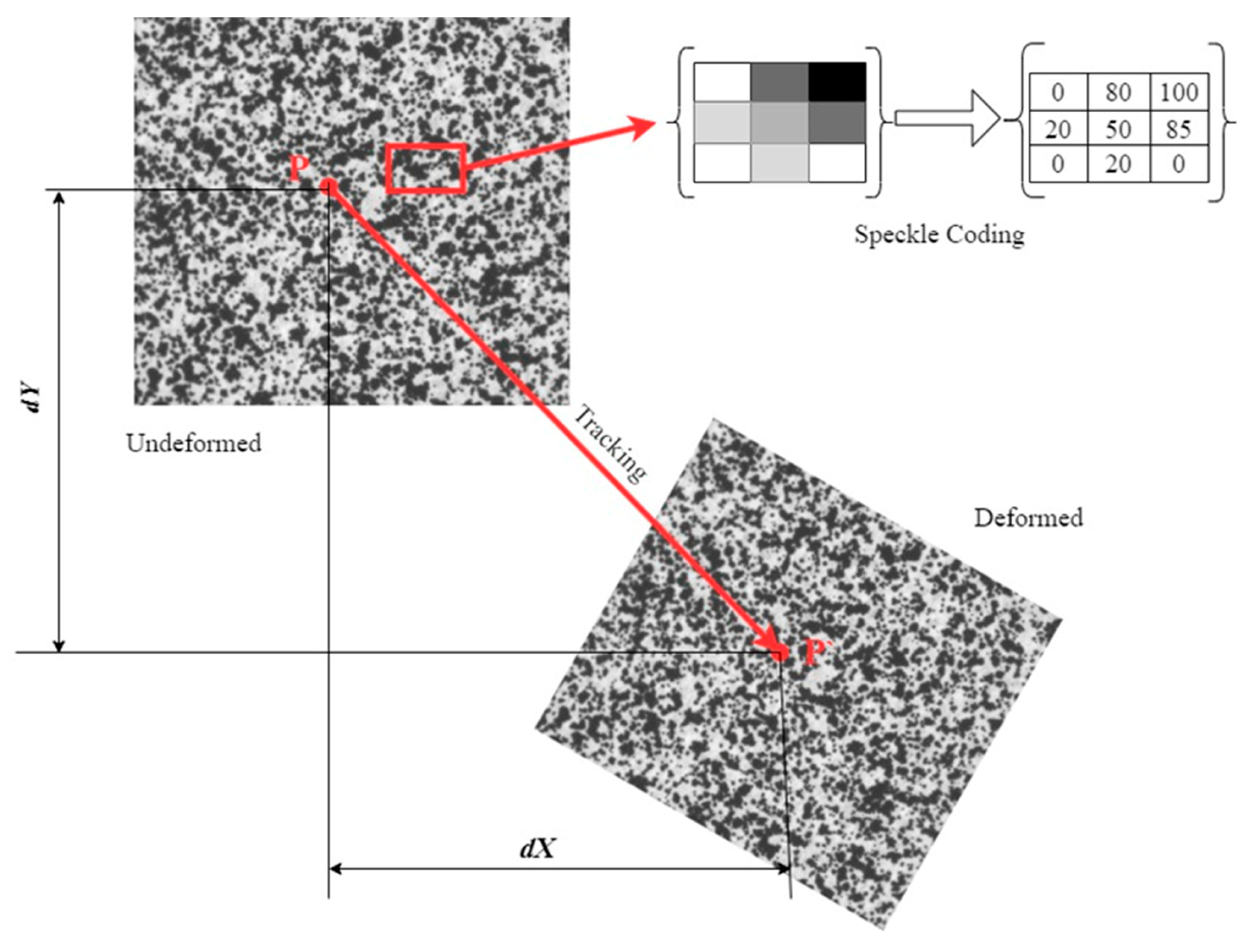

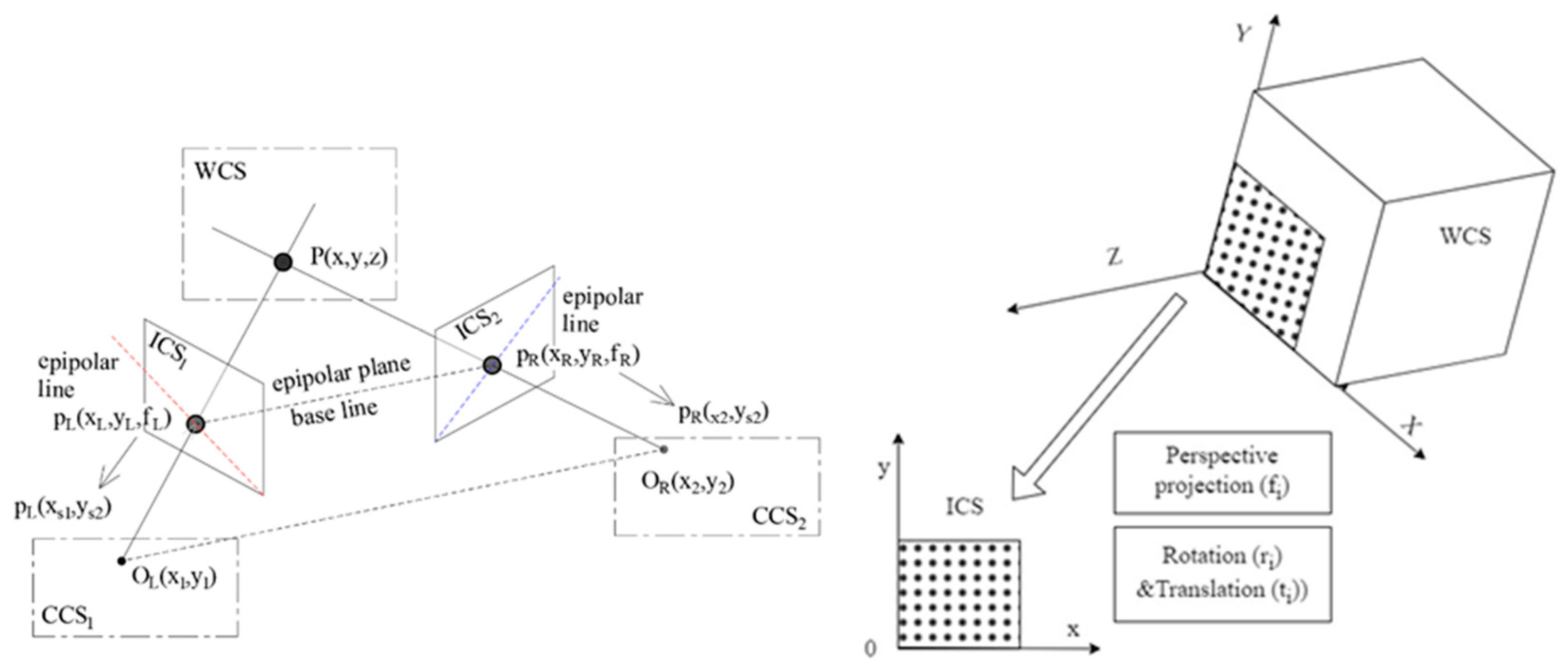

DIC—The Main Principles of the Method

- high contrast;

- 50–70% degree of density;

- isotropy and randomness;

- optimal size of dots;

- consistent speckle size.

The Most Relevant Challenges in On-Site DIC Application

Application of the DIC Method for Bridge Monitoring: Selected Case Studies

| Investigated structure* | Method, pros | Limitations, cons |

Hardware (H), Software (S)** | Source |

| Street bridge over the Flutgraben in Erfurt, Thuringia (non-reinforced concrete bow bridge, L= 27 m, W= 12.5 m. Vehicle (truck) loading test. Camera at distance 32 m | 2D monocular digital photogrammetric technique and an ellipse operator for image coordinates determination | Necessity to close traffic on the bridge. Need of direct access to the asset to mount targets. Impact of the natural illumination changes and overexposure of the targets on the quality of image data processing. Need in reliable methods to detect possible camera orientation changes. | H: machine vision camera (The Imaging Source, 1024 ×768 pixels, 21 fps, standard deviation- 0.017 pixels (EF), rel. accuracy 1: 60.000); grey level machine vision camera (1300×1030 pixels); Still Video camera (Kodak DCS 660, 3040×2008 pixels, 0.1 (max 3) fps, standard deviation-0.01-0.015 pixel (LSM), rel. accuracy 1: 30.000); image rate 1 Hz | [58] |

|

2D-digital image processing for real-time displacement measurement with a target recognition algorithm. | Need of direct access to the asset to mount targets. Limitation for dynamic response monitoring (frequencies below 3 Hz). Impact of vibrations caused by wind (the wind shield equipment should be employed). Impact of low lightning conditions (light source may be needed) | H: digital camcorder (30× optical zooming capability, 720×480 pixels, 30 fps); telescopic lens (8× optical zooming); laptop (Pentium M 1.6 GHz processor 512 MB RAM); S: MATLAB | [51,59] |

| Continuation of Table 2. Optical flow method for post-processing | ||||

| The cable-stayed pedestrian bridge. Vibration testing of cable (Ø=40 mm). Camcorders at distance 2 and 2.5 m. | 2D-digital image processing novel non-target technique based on the use of an optical flow method. | Approach is applicable to vibration assessment of cables without a noticeable sag effect). The amplitude error and image blurriness increase at higher frequencies (about 3 Hz). Long processing time. Not applicable for real-time measurement. Necessity to ensure camera stationarity. Telescopic lens and a large optical zoom capability needed for long-span bridges. | H: digital camcorder (1/3-in. 1.18-megapixel progressive CCDs, 1280×720 pixels, 29.97 fps); lens of F1.8 (52 mm focal length, 10× optical and 200×digital zoom); total station | [77] |

|

2D-DIC with reprojection of video frames by using a linear homography matrix compared with phase-based optical flow method. | Need of direct access to apply targets. Impact of lighting changes. Challenges in aligning the plane of the imaging sensor with the 2D plane of surface to eliminate perspective distortion effects. Need in post-processing for reprojection of out-of-plane motions. | H: 2 Imetrum cameras (6.3 and 13.4mm sensor diagonals); 2 lenses, (12 and 25 mm), Panasonic GH5 camera (12-mm f1.4 lens, 30 fps in B1 and 60 30 fps in B2). S: Imetrum Video Gauge. | [1] |

| Continuation of Table 2. Post-processing approaches for uneven lightning conditions | ||||

| The Wuhan Yangtze River Bridge (L=1670 m, 8 piers, spaced 128 m and 9 apertures). Static and dynamic load testing. Vehicle (truck) and train loading test. Camera at distance 107.3 m, 134.2 m, 164.2 m, 226.1 m. | 2D-DIC. Video deflectometer for active imaging, combining high-brightness monochromatic LED targets with coupled bandpass filter imaging to eliminate against ambient light changes. | Measuring system should be kept stationary during the whole measurement period. Necessity of measurement at night to avoid the interference of daily traffic. | H: camera (Genie HM1024, Teledyne DALSA, ON, Canada, 1024×768 pixels, 8-bit quantization, max 117 fps); fixed-focal optical lens; laser rangefinder (BOSCH GLM 250VFPro, Robert Bosch GmbH, Power, max distance 250 m, ±1 mm), optical theodolite, laptop (Thinkpad T440p, Lenovo, Beijing, China, Intel(R) Core(TM) i7-4700MQ CPU, 2.40 GHz main frequency and 8 GB RAM). | [85] |

| The 1/70 scale model (L=2.15+4.8+2.15=9.1 m) of the GuanHe Bridge (L=32.9+115.4+340+115.4+32.9=636.6 m). Dynamic response experiments. Camera at distance 0.78 m | 2D DIC with dual-channel and the maximum interclass variance for measurement of bridge displacement under uneven illumination | Complicated post-processing, time consuming for structures with high dimensions. Necessity in additional calibration of method in on-site conditions. | H: android phone (HONOR V30) (3840×2160 pixels, 60 Hz) | [82] |

| Highway bridge. Loading by a heavy lorry (32 tonnes). Camera at distance 15 m. | 2D-DIC under the varying lighting conditions between images, eliminated by NPL DIC code. | Impact of imaging at an angle and repositioning of the camera between digital photographs. | H: PhaseOne camera (39 MPixel); 80 mm lens. S: NPL Grid | [83] |

| Continuation of Table 2. Application of filters to eliminate environmental impacts. | ||||

| The Entre-Águas bridge in Caniçal (Madeira, Portugal). Vehicle loading (30-ton trucks). Camera at distance 70 m | 2D DIC measurements without camera calibration with post-filtering to eliminate the measurements noise due to the changing environmental conditions. | Need of direct access to the surface to apply the target speckle pattern. Challenges of large areas monitoring. Possible impacts of wind or road movement (need to ensure stability of tripod and camera). Necessity to ensure camera is parallel to the image frame. Impact of heat wave, causing motion blur (need in short image exposure). | H: digital camera (4-megapixel iDS UI-3370CP, 70 – 300 mm zoom lens, 1.4× teleconverter, eq. to a 420 mm focal distance lens; CMOSIS CMV4000-3E5M sensor, 80 fps). S: INEGI | [69] |

|

2D-DIC measurements, mapped against the wheel positions obtained from laser data sets coupled with noise reduction using the Savitzky-Golay filter. | Need of direct access to the surface to apply the speckle pattern. Necessity to reduce the data noise and oscillations. | H: digital camera (Sony (Tokyo, Japan) IDS, 2.35 megapixels, 1,936×1,216 pixels, 50 fps, 6 ms exposure time, 5.863 mm/pix); high-resolution lens (Kowa, Torrance, California, 35 mm focal length, f1.4 aperture); Infrared (IR) Light Emitting Diode (LED) model, IR filter - 850 nm. S: Istra4D (Nova Instruments) | [70] |

| Continuation of Table 2. Application of filters to eliminate environmental impacts. | ||||

Docklands Light Railway (DLR):

|

2D DIC with optimizing contrast levels and exact positioning of reference points for the virtual strain gauges. DIC calibration by specifying real-world distances. Fatigue management strategy based on measured data. | Necessity to avoid movement in the third dimension compared to the two being measured. Limited time for measurement to avoid traffic closure. |

H: digital camera (20–40 Hz, 1/50th pixel resolution). | [71] |

| The Halton railroad 26.36 bridge (Canada-USA; 43⁰37‟18.7” N, -79⁰55‟54.9” W; steel Deck Plate Girder; 6 spans×30 m; masonry piers). Train loading testing | 2D-DIC with accuracy optimisation by adjusting the scale factor and filtering using a low low-pass filter. | Impact of camera and tripod vibrations (can be reduced by post-processing). Challenges in long-term monitoring. | High speed camera (Allied Vision Technologies (AVT) GX1050 8 8-bit monochrome 1 megapixel (MP)); 85 mm lenses; 100 Hz, | [73] |

| The Delaware River Bridge (4 span; truss, W14×314 sections). Monitoring of structural behaviour during the repair works | 3D-DIC measurements, post-processed with the median filter for area averaging and the binomial filter for time averaging. Rapid application of the DIC pattern with pressure-activated adhesive tape. | Need of direct access to the surface to apply the speckle pattern. Necessity to reduce the environmental noise by area averaging and time averaging. Susceptiveness of results to out-of-plane bending. | H: 2 cameras (2448×2050 pixels); 12 mm lenses. S: GOM Correlate | [91,92] |

| Continuation of Table 2. Other methods to eliminate environmental impacts. | ||||

|

2D-DIC and 3D-DIC for bridge on-site diagnostics and load testing. Methods for mitigation out-of-plane motion, camera movement and ambient errors minimization. | Need of direct access to the surface to apply the speckle pattern. For 2D-DIC-the effect of out-of-plane motion, which may corrupt the data due to fictive planar displacement. For 3D DIC method, - limited region of measurement. Possible impact of lighting condition and environmental factors. Necessity to use additional reflectors to improve natural lightning conditions. |

H: 2 cameras (Basler acA4096-30μm); lens of focal length f = 35 mm, 75 mm, 50 mm (depending on distance). S: Correlated Solutions Inc and ISI-sys GmbH system, VIC-snap, VIC-2D and VIC-3D. | [4] |

| Continuation of Table 2. Other post-processing and correction approaches | ||||

| Ornskoldsvik Bridge, Sweden (2 spans, 12 +12-m frame, L=36.293 m, H=8.2 m). Loading-to failure testing. Camera at distance 3.1 m. | 2D- DIC with MATLAB post-processing with conversion process based on the Mohr–Coulomb strain/stress transformation theory | Need of direct access to the surface to apply the speckle pattern. Need to ensure fixed independent scaffold to prevent accidental displacement of camera. Limitations to the size of the monitored area by performance of the photographic equipment. Need in camera with a shutter speed higher than the velocity of the object movement to avoid blurring. | H: digital camera (Canon EOS 5D); 90-mm lens. S: tailor-made toolkit in MATLAB | [79] |

| Concrete girder bridge. Usual traffic loading | 2D-DIC with camera movement correction method through perspective transformation. | Need of direct access to the surface to apply the speckle pattern. Need in multiply measurements (unloaded and loaded conditions) | H: single-reflex type digital camera (3008×2000 pixels×24 bits) | [87] |

| Continuation of Table 2. DIC measurements for random pattern effect analysis. | ||||

| Girder bridge (L=15.4 m, W=7 m) Loading by a heavy cargo truck (20 t, various positions) | 2D-DIC for random pattern effect analysis: with random-shaped magnet plates attached on the surface to create random pattern and no random pattern attached. | Need of direct access to the asset to attach plates with pattern. The possibility of incompatibility of deformations of plates and studied surface (e.g. sliding, delamination). Need in additional illumination by high-intensity light sources. | H: 2 single-lens reflex cameras for 2 girders (3072×2048 pixels and 3504×2336 pixels resolution) | [60] |

|

2D-DIC for random pattern effect analysis: with target panel and on an existing surface. Approaches to mitigate ambient light conditions at night: illuminated by a flashlight, using the surface-attached LED lights. | Need of direct access to the surface to attach targets. Need in additional illumination by high-intensity light sources. Impacts of wind induced vibration and lightning changes. Increased errors at long measurement distances. Long-term preparation to install additional lightning sources. | H: monochrome camera (Point Grey/FL3-U3-13Y3M-C, 1280×1024 pixels, 150fps, CMOS sensor, 4.8 μm pixel size, C-mount lens); Kowa/LMVZ990 IR lens (9 to 90 mm focal length, maximum aperture F1.8); Sony /PCG-41216L laptop (Intel(R) Core(TM) i7-2620M CPU, 2.70 GHz, 8192 RAM, 250 HDD, 14.1" Screen), Tripod, USB3.0 type-A to micro-B cable. S: FlyCapture Software Development Kit (SDK) by Point Grey Research | [46] |

| Continuation of Table 2. DIC measurements with natural texture of the surface. | ||||

| Masonry arch railway bridge (4 spans). Train loading testing (weight ca. 45 tonnes per bogie, maximum speed 200 km/h). Camera at distance 10 m. | 2D DIC with the random grey intensity distribution of natural texture of the specimen’s surface. | Need to use shutter remote control to avoid errors due to camera movement and lighting. Impact of vibration, correlation function errors in the region of rough edges, i.e. intersection of the specimen with the background. Difficulties in detecting the correct position of the subset. Demonstration of method, rather than numerical values in the test. | H: digital camera (Nikon D3100 DSLR, 14 MPixel); Nikon AF-S DX Micro NIKKOR 40 mm f/2.8G lens; Photo Video Studio focusable Redhead spotlight. S: MatchID-2D (Mechanical Engineering department of the Catholic University College Ghent) | [72] |

| Pedestrian bridge (campus of the Faculty of Engineering of the University of Porto). Static loading. 3D-Cameras at distance 30 m, separated at 4 m. 2D-Camera at distance 13 m. |

Parallel 3D and 2D-DIC measurements with irregular contrasting pattern of the natural surface. Distortion computing by camera calibration using the Zhang calibration algorithm (2nd and 4th orders) | Necessity in post-processing to compute distortions due to perspective. Substantial level of noise over the whole region of interest for 3D-DIC. No visible gradient on the 2D displacement field due to small field of view. |

H (3D-DIC): 2 cameras (Bosch DINION IP Ultra 8000 MP, 75 mm lens, 4000× 3000 pixels). H (2D-DIC): 1 USB camera (iDS uEye UI-3370CP model, 150 mm lens, 2048×2048 pixels). S: MATLAB. |

[67] |

| Continuation of Table 2. Calibration from the simple pinhole camera model. | ||||

| Shuohuang railway bridge (3 spans, L=60 m). Deflection measurement under freight train travelling with speed of 80 km/h. Camera at distance 22.5-22.8 m. | 2D-DIC. Video deflectometer for off-axis targetless imaging with calibration from the simple pinhole camera model. | Necessity to ensure the system stationarity. Necessity to ensure aperture of the lens, sufficient contrast without overexposure. Possible impact of texture information contained in the subset, ambient vibration, ambient temperature, wind, and light variations. | H: high-speed area scan monochrome camera (Genie HM1024, Teledyne DALSA, Ontario, Canada, max capture rate of 117 fps, 1024×768 pixels, 8-bit quantization); fixed-focal optical lens; laptop (Thinkpad T440, Lengend, Intel(R) Core(TM) i7-4700 MQ CPU,2.40 GHz main frequency and 8GRAM); laser rangefinder (BOSCH, GLM 250VFPro, max distance 200 m, ±1 mm); optical theodolite. | [84] |

|

Target-tracking 3D-DIC for monitoring the vibration frequencies. Camera calibration with pinhole camera model. | Need of direct access to the asset to attach targets. Possible impact of arbitrary excitations like ambient vibrations of bridges due to wind loads. | H: 2 high-speed cameras (IL5QM4, Fastec Imaging, USA, 2560 × 2048 pixels, 8-bit grayscale); FasMotion software. S: TRITOP; GOM photogrammetric. | [10,66] |

| Continuation of Table 2: Other calibration methods. | ||||

| High-speed railway bridge (MS=16 m). Camera at distance 30 m. | 2D-DIC off-axis scheme and a full-field scale factor determination method assisted by a laser rangefinder. | The trade-off between resolution and speed. Challenges due to non-suitable natural texture patterns (need in artificial speckle patterns or LED-illuminated speckle targets). Need in post-processing, mean and median filtering to reduce the measurement noise. Dependency on image resolution, intensity variations, field of view, measurement distance, frame rate, environmental constraints. | H: high-speed video camera (Daheng Imaging, Mer-131-210u3m, 1280 ×1024 pixels, 8-bit grayscale, 210 fps), fixed focal length/ fixed focus lens (F-number according to the actual imaging needs), laser distance measurer/rangefinder (Bosch GLM200, max distance: 200 m, measurement accuracy ± 1 mm); electronic theodolite; tripod; laptop. | [86] |

| Suspension bridge (MS=50 m). Vibration analysis under pedestrian loading. Cameras at distance 54.6 m, separated at 0.644 m. | 3D DIC measurement with new calibration method for large structures (using inertial measurement units (IMU) and laser sensors along with a virtual stereovision tool). | Need of direct access to the surface to apply targets. Need in calibration process prior to measurement. Impact of lighting condition and environmental factors (temperature, humidity, and wind). | H: 2 cameras (Sony, recording period 563s, frequency 0.002Hz.); Nikon total station; IMU-laser sensors | [68] |

| Continuation of Table 2: Dynamic displacement measurements. | ||||

| Marsh Lane Viaduct (brick masonry viaduct; up to 25-ton axles, up to 55 km/h speed; investigated arch with span of 7.7 m, a rise of 2.1 m, W= 8 m). Train loading testing | 2D-DIC and 3D-DIC: multipoint dynamic displacement measurement using vanishing points and a single distance in the image. | Potential errors due to lighting changes, image texture, and camera movements. Need in specific calibration to minimize pixel-metric scaling errors. Possible influence of radial distortions and out of-plane movements on relative displacement (can be eliminated with division and pinhole camera models). | H: 2 video cameras (industrial-grade Allied Vision GigE, 2048×1088 pixels, 11.26 × 5.98-mm-size sensor, 50 Hz). S: Imetrum Video Gauge software; MATLAB | [3] |

| The truss bridge model (28 spans: 0.35×0.35×0.35 m, L=9.8 m; 353 rods connected by 112 bolted balls (Ø50 mm); Q235 steel; simply supported at both ends). Modal Analysis | 2D-DIC for tracking of the dynamic displacement and identification of the natural frequencies and mode shapes of bridges. | Small displacement amplitudes and long shooting distance may result in the low quality of the measured data (can be eliminated by filtering). Impacts of environmental disturbance of the camera and image distortion. | H: digital video camera (D5300, Nikon Corporation, Japan); MA: 2 acquisition systems: JM3840 (Jing-Ming Technology Inc., Yangzhou, China), acceleration sensors with nominal sensitivity of 100 mV/g. S: kit software. | [80] |

| Continuation of Table 2. Cable-force measurements. | ||||

| The 2-pylon concrete cable-stayed Godeok bridge under construction (L=1000 m; MS=540m; H= 165 m). Tension-testing in cables. (Target cable -CRS05R). Camera at distance 300 m. | 2D-digital image processing for the sag-based cable tension force evaluation based on the parabolic cable theory. Post-processing with the perspective transformation approach. | Need of direct access to the surface to apply B/W markers for reference points. Need in post-processing to correct distortion due to the internal factors of the camera, geometric changes and to remove the effect of perspective projection. The method narrowly focused on cable-stayed bridges. | H: digital camera (Canon’s EOS R5; 8192× 5464 pixels); 70–200 mm F2.8 telephoto lens; total station. S: camera calibrator toolbox in MATLAB. | [41] |

| The 1/70 scale model (L=2.15+4.8+2.15=9.1 m) of GuanHe Bridge (L=32.9+115.4+340+115.4+32.9=636.6 m). Dynamic response experiments. Camera at distance 0.78 m. | Combination of 2D-DIC and DIP (digital image processing) for cable force measurement with the vibration frequency method. | Measuring errors due to more complex background changes such as bad weather, changes in light and the emergence of other dynamic backgrounds. Could be eliminated by targets such as LED lights and narrowed region of interest. The method narrowly focused on cable-stayed bridges. | H: digital camera (DSLR Canon 70D, 1280×720 pixels r, 50 frs); Canon STM lens (Focal length: 18–55 mm, manual zoom); acceleration sensor (TST120A500, 100 Hz) | [81] |

| Continuation of Table 2. The use of UAV | ||||

| Bridges in Lowell, Massachusetts (concrete cast-in-place). Assessment of displacements due to the thermal expansion and contraction of the concrete abutments and expansion joint. Cameras at distance 1.75 m, separated at 0.707 m, 25°separation angle. | Unmanned aerial vehicle (UAV) and 3D-DIC full-field displacement monitoring with 3D measurement stitching, and 3D point-tracking techniques. | Need of direct access to the surface to apply the speckle pattern. Challenge of positioning and localization in GPS restricted environments. Problems with stitching the point cloud data sets for large areas monitoring. Impacts of lighting and UAV oscillations. | H: 2 cameras (Basler acA1600-20 series, 2 2-Megapixels employing a (7.16 ×5.44)·10-3m); Sony ICX274 charge coupled device monochrome image sensors (1626×1236 pixels, pixel size of 4.4×4.4 μm); 8.5 mm focal length lenses (Edmund Optics Ltd), Minnowboard MAX dual-core single board computer. UAV: InstantEye®Gen 4 Quadcopter (Physical Science, Inc.);. S: GOM’s TRITOP; ARAMIS. | [88,89,90] |

| Nansha Bridge, Guangdong province, China (twin-tower 1 span suspension bridge, MS= 1200 m, side span =360 m, span ratio= 1:9.5, the center spacing of 2 main cables = 42.1 m, the standard spacing of cables is 12.8 m. H=193.1 m, W= 49.7 m). Cable forces testing | Unmanned aerial vehicle (UAV) and 2D-DIC for noncontact cable force estimation. Post-processing with line segments detector (LSD) and matching algorithm for calculating dynamic displacements of bridge cables without need to adjust predefined parameters. | Challenge of positioning and localization in GPS restricted environments. Impacts of lighting and UAV oscillations. Applicability of method only for large vibrations and under the condition of non-windy region. | H: Digital camera (DJI Zenmuse X4S, 4096×2160 pixels resolution, 60 Hz); UAV: Model Jingwei M200 (DJI). | [78] |

| Continuation of Table 2. Full-field monitoring for structural health assessment. | ||||

| Three bridges near Lowell, Massachusetts. Crack and spalling evaluation. | 3D DIC for measuring full-field displacement, strain, and locating cracks from images recorded at different dates and operating conditions. | Need of direct access to the surface to apply the speckle pattern and (or) targets. Dimensional distortions due to subpar camera calibration, shallow camera angle, lens distortion errors, camera shift. Need in imagining from multiply points. |

H: DIC cameras; high power projector. S: GOMTM’s ARAMIS. |

[63] |

|

2D DIC for monitoring stop criteria in in situ proof-loadings for a systematic reclassification of concrete bridges based on crack detection and monitoring. | Need of direct access to the surface to apply the speckle pattern. Challenges in identification of optimal parameters of the speckle pattern. Possible pseudo deformation from out-of-plane movement and rotation of the surface. Environmental impacts circumstances (humidity, temperature, wind, variation of lighting, contrast pattern detection, reflections). |

H: 2 cameras: Canon 6D with 20 Megapixel (Mpx) with a wide-angle lens (Canon EF 16-35 mm f/2.8L II USM); Canon 550D with 18.7 Mpx with a regular lens (Canon EF-S 18–55 mm f/3.5–5.6 IS). Images were captured every 3 min (on site) and 10 s (lab). S: GOM Correlate. |

[74] |

Recommendations and Future Perspective Directions of Research

Conclusions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- M. Ghyabi, L.C. Timber, G. Jahangiri, D. Lattanzi, H. W. Shenton III, M. J. Chajes, M. H. Head. “Vision-Based Measurements to Quantify Bridge Deformations”. Journal of Bridge Engineering, vol. 28, no 1, 05022010, 2023. [CrossRef]

- Y. Blikharskyy, N. Kopiika, R. Khmil, J. Selejdak, Z. Blikharskyy (2022). “Review of development and application of digital image correlation method for study of stress–strain state of RC Structures”. Applied Sciences, vol 12, no 19, 10157, 2022. [CrossRef]

- S. Acikgoz, M. J. DeJong, K. Soga. “Sensing dynamic displacements in masonry rail bridges using 2D digital image correlation”. Structural Control and Health Monitoring, vol 25, no 8, e2187, 2018. [CrossRef]

- V. Stančík, P. Ryjáček. “The application of modern methods for bridge diagnostics and load testing”. ce/papers, vol 6, no 5, pp. 949-958, 2023. [CrossRef]

- Maksymenko, O.M. Sakharuk, Y. L. Ivanytskyi, P.S. Kun. “Multilaser spot tracking technology for bridge structure displacement measuring” Struct. Control Health Monit, vol 28, no 3, e2675, 2021. [CrossRef]

- M. A. Mousa, M. M. Yussof, T. S. Hussein, L. N. Assi, S. Ghahari. “A Digital Image Correlation Technique for Laboratory Structural Tests and Applications: A Systematic Literature Review”. Sensors, vol 23, no 23, 9362, 2023. [CrossRef]

- M. A. Mousa, M. M. Yussof, U. J. Udi, F. M. Nazri, M. K. Kamarudin, G. A. Parke, L. N. Assi, S. A. Ghahari. “Application of digital image correlation in structural health monitoring of bridge infrastructures: A review”. Infrastructures, vol 6, no 12, pp 176-194, 2021. [CrossRef]

- N. Kopiika, J. Selejdak, Y. Blikharskyy. “Specifics of physico-mechanical characteristics of thermally-hardened rebar”. Production Engineering Archives, vol 28, no 1, pp. 73-81, 2022. [CrossRef]

- C. Niezrecki, J. Baqersad, A. Sabato. “Digital Image Correlation Techniques for Non-Destructive Evaluation and Structural Health”. Monitoring. Handb. Adv. Non-Destr. Eval, pp. 1-46, 2018.

- L. Ngeljaratan, M. A. Moustafa. “Structural health monitoring and seismic response assessment of bridge structures using target-tracking digital image correlation”. Engineering Structures, vol 213, 110551, 2020. [CrossRef]

- Y. Blikharskyy, N. Kopiika, R. Khmil, Z. Blikharskyy. “Digital Image Correlation Pattern for Concrete Characteristics—Optimal Speckle”. In International Conference Current Issues of Civil and Environmental Engineering Lviv-Košice–Rzeszów, Cham: Springer Nature Switzerland, pp.22-31, 2023. [CrossRef]

- B. Pan, K. Qian, H. Xie, A. Asundi, “Two-dimensional digital image correlation for in-plane displacement and strain measurement: a review”. Measurement science and technology, vol 20, no 6, 062001, 2009. [CrossRef]

- VIC-2D. Reference Manual. Correlated Solutions, Inc. Knowledgebase-Manuals and Guides. 26p. Available online: https://correlated.kayako.com/article/87-vic-volume-manual (accessed on 30 January 2024).

- StrainMaster. Digital Image Correlation Systems for Full Field Shape, Displacement and Strain. Manual. LaVision. 20 p. Available online: https://www.lavision.de/de/products/strainmaster/index.php (accessed on 13 January 2024).

- GOM Correlate Pro. Electronic Manual. GOM. Available online: https://www.globus.co.il/wp-content/uploads/2022/01/Operating-Instructions-gom-correlate-prof-basic-v8.pdf (accessed on 13 January 2024).

- Solid Mechanics DIC. Dantec Dynamics. Available online: https://www.dantecdynamics.com/solutions/stress-strain-espi-dic/solid-mechanics-dic/measurement-principles-of-dic/#:~:text=Digital%20Image%20Correlation%20(DIC)%20is,mechanic%20applications%20in%20materials%20testing. (accessed on 13 January 2024).

- The MatchID. Compose the software stack that best fits your needs https://www.matchid.eu/en/solutions-overview/software (accessed on 13 April 2024).

- Image Systems https://imagesystems.se/ (accessed on 13 April 2024).

- Imetrum. Measuring the industrial world. https://www.imetrum.com/ (accessed on 13 April 2024).

- Ncorr: 2D Digital Image Correlation Matlab Software. Available online: https://www.ncorr.com/index.php (accessed on 13 April 2024).

- J. Blaber, B. Adair, A. Antoniou. “Ncorr: Open-Source 2D Digital Image Correlation Matlab Software”. Exp Mech, vol 55, pp. 1105–1122, 2015. [CrossRef]

- R. Harilal, M. Ramji. “Adaptation of Open Source 2D DIC Software Ncorr for Solid Mechanics Applications”. 9th International Symposium on Advanced Science and Technology in Experimental Mechanics, New Delhi, India, November 2014. [CrossRef]

- Digital Image Correlation Engine (DICe). Center for Computing Research (CCR). Sandia National Laboratories. https://www.sandia.gov/ccr/software/digital-image-correlation-engine-dice/ (accessed on 13 April 2024).

- D.Z. Turner. “Digital Image Correlation Engine (DICe) Reference Manual”. Sandia Report, SAND2015-10606 O, 2015. https://dicengine.github.io/dice/ (accessed on 10 May 2024).

- YaDICs. https://yadics.univ-lille1.fr/wordpress/index.html (accessed on 13 April 2024).

- R. Seghir, J.F. Witz, S. Coudert. YaDICs - Digital Image Correlation 2/3D software. https://www.yadics.univ-lille1.fr , 2014. (accessed on 10 May 2024).

- Py2DIC: https://github.com/Geod-Geom/py2DIC (accessed on 13 April 2024).

- V. Belloni, R. Ravanelli, A. Nascetti, M. Di Rita, D. Mattei, M. Crespi. “py2dic: A new free and open source software for displacement and strain measurements in the field of experimental mechanics”. Sensors, vol 19, no 18, 3832, 2019. [CrossRef]

- V. Belloni, R. Ravanelli, A. Nascetti, M. Di Rita, D. Mattei, M. Crespi. “Digital Image Correlation from commercial to FOS software: a mature technique for full-field displacement measurements”. The International Archives of the Photogrammetry, Remote Sensing and Spatial Information Sciences, vol XLII-2, pp. 91-95, 2018. [CrossRef]

- R. Ravanelli, A. Nascetti, M. Di Rita, V. Belloni, D. Mattei, N. Nisticò, M.Crespi. “A new Digital Image Correlation software for displacements field measurement in structural applications”. The International Archives of the Photogrammetry, Remote Sensing and Spatial Information Sciences, vol XLII-4/W2, pp. 139-145, 2017. [CrossRef]

- µDIC: A toolkit for digital image correlation. https://mudic.readthedocs.io/en/latest/ (accessed on 13 April 2024).

- S. N. Olufsen, M. E. Andersen, E. Fagerholt, E. “μDIC: An open-source toolkit for digital image correlation”. SoftwareX, vol 11, 100391, 2020. [CrossRef]

- Augmented Lagrangian Digital Image Correlation and Tracking https://www.mathworks.com/matlabcentral/fileexchange/70499-augmented-lagrangian-digital-image-correlation-and-tracking (accessed on 13 April 2024).

- J. Yang, K. Bhattacharya. “Augmented Lagrangian Digital Image Correlation”. Exp.Mech., vol 59, no 187, 2018. [CrossRef]

- MultiDIC: a MATLAB Toolbox for Multi-View 3D Digital Image Correlation https://github.com/MultiDIC/MultiDIC (accessed on 13 April 2024).

- D. Solav, K. M. Moerman, A. M. Jaeger, K. Genovese, H. M. Herr. (2018). “MultiDIC: An open-source toolbox for multi-view 3D digital image correlation”. Ieee Access, vol 6, pp. 30520-30535, 2018. https://ieeexplore.ieee.org/document/8371235/.

- M. Sutton, J. Yan, V. Tiwari, H. Schreier, J. Orteu. “The effect of out-of-plane motion on 2D and 3D digital image correlation measurements”. Optics and Lasers in engineering, vol 46, pp. 746–757, 2008. [CrossRef]

- V. Stančík, P. Ryjáček. “The application of modern methods for bridge diagnostics and load testing”. ce/papers, vol 6, no 5, pp 949-958, 2023. [CrossRef]

- H. Schreier, J-J. Orteu, M.A. Sutton. “Image Correlation for Shape, Motion and Deformation Measurements”. New York: Springer US, 322 p, 2009. [CrossRef]

- J. Zhao, Y. Sang, F. Duan, F. “The state of the art of two-dimensional digital image correlation computational method”. Engineering reports, vol 1, no 2, e12038, 2019. [CrossRef]

- H.C. Jo, S. H. Kim, J. Lee, H. G. Sohn, Y.M. Lim. “Sag-based cable tension force evaluation of cable-stayed bridges using multiple digital images”. Measurement, vol 186, 110053, 2021. [CrossRef]

- B. Pan, D. Wu, Y. Xia. “An active imaging digital image correlation method for deformation measurement insensitive to ambient light”. Opt. Laser Technol. 2012, vol 44, no 1, pp 204-209, 2012. [CrossRef]

- B. Pan, L. Yu, D. Wu, L. Tang. “Systematic errors in two-dimensional digital image correlation due to lens distortion”. Opt. Lasers Eng, vol 51, no 2, pp 140-147, 2013. [CrossRef]

- Y. Xu, J. M. W. Brownjohn, J. “Review of machine-vision based methodologies for displacement measurement in civil structures”. Civil Struct. Health Monit, vol 8, pp 91-110, 2018. [CrossRef]

- T. Khuc, N. Catbas, “Completely contactless structural health monitoring of real-life structures using cameras and computer vision”. Struct. Control Health Monit, vol 24, no 1, e1852, 2017. [CrossRef]

- M. Q. Feng, Y. Fukuda, D. Feng, M. J. Mizuta. “Nontarget Vision Sensor for Remote Measurement of Bridge Dynamic Response”. Bridge Eng, vol 20, no 12, pp 1-12, 2015. [CrossRef]

- J. G. Chen, N. Wadhwa, Y. J. Cha, F. Durand, W. T. Freeman, O. Buyukozturk. “Modal identification of simple structures with high-speed video using motion magnification”. J. Sound Vib., vol 345, pp 58-71, 2015. [CrossRef]

- H. Yoon, H. Elanwar, H. Choi, M. Golparvar-Fard, B. F. Spencer. “Target-free approach for vision-based structural system identification using consumer-grade cameras”. Struct. Control Health Monit., vol 23, no 12, pp 1405-1416, 2016. [CrossRef]

- P. Podbreznik, B. Potočnik. “Influence of temperature variations on calibrates cameras”. International Journal of Computer and Information Engineering, vol 2, no 4, pp. 261-267, 2008.

- C. A. Murray, W. A. Take, N. A. Hoult. “Dynamic measurements using digital image correlation”. International Journal of Physical Modelling in Geotechnics, vol 17, no 1, pp 41-52, 2017. [CrossRef]

- J. J. Lee, M. Shinozuka. “A vision-based system for remote sensing of bridge displacement.” Ndt & E International, vol 39, no 5, pp 425-431, 2006. [CrossRef]

- C. Niezrecki, P. Avitabile, C. Warren, P. Pingle, M. Helfrick. "A review of digital image correlation applied to structural dynamics." In AIP Conference Proceedings, vol. 1253, no. 1, pp. 219-232. American Institute of Physics, 2010.

- R. Jiang, D. V. Jauregui, K. R. White. “Close range photogrammetry applications in bridge measurement: literature review.” Measurement, vol 41, no 8, pp 823–834, 2008. [CrossRef]

- D. V. Jauregui, K. R. White, P. E. Woodward, K. R. Leitch. “Non contact photogrammetric measurement of vertical bridge deflection.” J. Bridge Eng., vol 8, no 4, pp 212–222. 2003. [CrossRef]

- F. B. Bales. “Close-range photogrammetry for bridge measurement.” Transportation Research Record, Washington, DC, vol 950: pp 39–44, 1985.

- J. C. Li, B. Z. Yuan. “Using vision technique for bridge deformation detection.” Proceedings of International Conference on Acoustic, Speech and Signal Processing, New York, pp 912–915, 1988.

- G. W. Johnson. “Digital close-range photogrammetry – a portable measurement tool for public works.” Proceedings of 2001 Coordinate Measurement Systems Committee Conference, Coordinate Measurement Systems Committee, Albuquerque, USA. 2001.

- J. Albert, H. G. Maas, A. Schade, W. Schwarz, W. “Pilot studies on photogrammetric bridge deformation measurement.” In Proceedings of the 2nd IAG Commission IV Symposium on Geodesy for Geotechnical and Structural Engineering, vol. 21, pp 24-31, 2002.

- J. J. Lee, M. Shinozuka. “Real-time displacement measurement of a flexible bridge using digital image processing techniques.” Experimental mechanics, vol 46, pp 105-114. 2006. [CrossRef]

- S. Yoneyama, A. Kitagawa, S. Iwata, K. Tani, H. Kikuta. “Bridge deflection measurement using digital image correlation.” Experimental techniques, vol 31, pp 34-40, 2007. [CrossRef]

- C-H. Chiang, M-H. Shih, W. Chen, C-P. Yu. “Displacement measurements of highway bridges using digital image correlation methods”. In: Seventh international symposium on precision engineering measurements and instrumentation. International Society for Optics and Photonics, vol 8372, 2011. [CrossRef]

- J. Peddle, A. Goudreau, E. Carlson, E. Santini-Bell. “Bridge displacement measurement through digital image correlation”. Bridge Struct, vol 7, no 4, pp 165-173, 2011. [CrossRef]

- C. Nonis, C. Niezrecki, T-Y. Yu, S. Ahmed, C-F. Su, T. Schmidt. “Structural health monitoring of bridges using digital image correlation.” In: Health monitoring of structural and biological systems. International Society for Optics and Photonics, vol 869507, 2013. [CrossRef]

- C. Murray, A. Hoag, N. A. Hoult, W. A. Take. “Field monitoring of a bridge using digital image correlation.” In: Proceedings of the institution of civil engineers-bridge engineering. Thomas Telford Ltd, vol 168, no 1, pp. 3-12, 2015. [CrossRef]

- C. Murray. “Dynamic monitoring of rail and bridge displacements using digital image correlation.” Queen's University (Canada); 2013, 107 p.

- L. Ngeljaratan, M. A. Moustafa. “System identification of large-scale bridge models using target-tracking digital image correlation.” Front Built Environ, vol 5, no 85, 2019. [CrossRef]

- F. Barros, S. Aguiar, P. J. Sousa, A. Cachaço, P. J. Tavares, P.M. Moreira, D. Ranzal, N. Cardoso, N. Fernandes, R. Fernandes, R. Henriques, P.M. Cruz, A. Cannizzaro. “Displacement monitoring of a pedestrian bridge using 3D digital image correlation.” Procedia Structural Integrity, vol 37, pp 880-887, 2022. [CrossRef]

- Y. C. Lin, C. H. Tseng, C. H. Chiang, W. H. Hung. “Vibration Analysis and Digital Image Correlation Techniques for a Suspension Bridge.” NDT-CE 2022 - The International Symposium on Nondestructive Testing in Civil Engineering Zurich, Switzerland, August 16-18, 2022. [CrossRef]

- P. J. Sousa, F. Barros, P. Lobo, P. J. Tavares, P. M. Moreira, P. M. “Experimental measurement of bridge deflection using Digital Image Correlation.” Procedia Structural Integrity, vol 17, pp 806-811, 2019. [CrossRef]

- M. Dhanasekar, P. Prasad, J. Dorji, T. Zahra. “Serviceability assessment of masonry arch bridges using digital image correlation.” Journal of Bridge Engineering, vol 24, no 2, 04018120, 2019. [CrossRef]

- J. Winkler C. Hendy. “Improved Structural Health Monitoring of London’s Docklands Light Railway Bridges Using Digital Image Correlation”. Structural Engineering International, vol 27, no 3, pp 435-440, 2017. [CrossRef]

- I. Koltsida, A. Tomor, C. Booth. “The use of digital image correlation technique for monitoring masonry arch bridges.” In 7th International Conference on Arch Bridges, pp. 681-690, 2013.

- A. Hoag, N. A. Hoult, W. A. Take, F. Moreu, H. Le, V. Tolikonda. V. “Measuring displacements of a railroad bridge using DIC and accelerometers.” Smart Structures and Systems, vol 19, no 2, pp 225-236. 2017. [CrossRef]

- C. O. Christensen, J. W. Schmidt, P. S. Halding, M. Kapoor, P. Goltermann, P. “Digital image correlation for evaluation of cracks in reinforced concrete bridge slabs” Infrastructures, vol 6(7), no 99, 2021. [CrossRef]

- H. Al-Salih, M. Juno, W. Collins, C. Bennett, J. Li, E. J. Sutley. “Evaluation of a digital image correlation bridge inspection methodology on complex distortion-induced fatigue cracking.” Procedia Structural Integrity, vol 17, pp 682-689, 2019. [CrossRef]

- L. Dellenbaugh, X. Kong, H. Al-Salih, W. Collins, C. Bennett, J. Li, E. J. Sutley. “Development of a distortion-induced fatigue crack characterization methodology using digital image correlation.” Journal of Bridge Engineering, vol 25, no 9, 04020063. 2020. [CrossRef]

- Y. F. Ji, C. C. Chang. (2008). “Nontarget image-based technique for small cable vibration measurement.” Journal of Bridge Engineering, vol 13, no 1, pp 34-42, 2008. [CrossRef]

- Y. Tian, C. Zhang, S. Jiang, J. Zhang, W. Duan. “Noncontact cable force estimation with unmanned aerial vehicle and computer vision.” Computer-Aided Civil and Infrastructure Engineering, vol 36, no 1, pp 73-88, 2021. [CrossRef]

- G. Sas, T. Blanksvärd, O. Enochsson, B. Täljsten, L. Elfgren. “Photographic strain monitoring during full-scale failure testing of Örnsköldsvik bridge.” Structural Health Monitoring, vol 11, no 4, pp 489-498, 2012. [CrossRef]

- G. Chen, Z. Wu, C. Gong, J. Zhang, X. Sun. “DIC-based operational modal analysis of bridges.” Advances in Civil Engineering, vol 2021, 6694790, pp 1-13, 2021. [CrossRef]

- W. Du, D. Lei, P. Bai, F. Zhu, Z. Huang. “Dynamic measurement of stay-cable force using digital image techniques.” Measurement, vol 151, 107211, 2020. [CrossRef]

- K. Xie, D. Lei, W. Du, P. Bai, F. Zhu, F. Liu. “The monitoring of bridge under complex illumination based on digital image technology.” Measurement, vol 206, 112219, 2023. [CrossRef]

- N. J. McCormick, J. D. Lord “Practical in situ applications of DIC for large structures”. Applied mechanics and materials, vol 24, pp 161-166, 2010. [CrossRef]

- B. Pan, L. Tian, X. Song. “Real-time, non-contact and targetless measurement of vertical deflection of bridges using off-axis digital image correlation”. Ndt & E International, vol 79, pp 73-80, 2016. [CrossRef]

- L. Tian, B. Pan. “Remote bridge deflection measurement using an advanced video deflectometer and actively illuminated LED targets”. Sensors, vol 16, no 9, 1344, 2016. [CrossRef]

- L. Tian, J. Zhao, B. Pan, Z. Wang. “Full-Field Bridge Deflection Monitoring with Off-Axis Digital Image Correlation”. Sensors, vol 21, no 15, 5058, 2021. [CrossRef]

- S. Yoneyama, H. Ueda. “Bridge deflection measurement using digital image correlation with camera movement correction”. Materials transactions, vol 53, no 2, pp 285-290, 2012. [CrossRef]

- D. Reagan, A. Sabato, C. Niezrecki, T. Yu, R. Wilson. “An autonomous unmanned aerial vehicle sensing system for structural health monitoring of bridges”. In Nondestructive Characterization and Monitoring of Advanced Materials, Aerospace, and Civil Infrastructure, vol 9804, pp. 244-252, 2016. [CrossRef]

- D. Reagan, A. Sabato, C. Niezrecki. “Unmanned aerial vehicle acquisition of three-dimensional digital image correlation measurements for structural health monitoring of bridges”. In Nondestructive Characterization and Monitoring of Advanced Materials, Aerospace, and Civil Infrastructure, vol 10169, pp. 68-77, 2017. [CrossRef]

- D. Reagan, A. Sabato, C. Niezrecki. “Feasibility of using digital image correlation for unmanned aerial vehicle structural health monitoring of bridges”. Structural Health Monitoring, vol 17(5), 1056-1072, 2018. [CrossRef]

- Y. Wang, A. P. Thrall, T. P. Zoli “Delaware river bridge fracture: Repair strategy and monitoring by digital image correlation”. ProcWorld Steel Bridge Symp, vol 2018, pp 1-6, 2018.

- Y Wang, M. D. Tumbeva, A. P. Thrall, T. P. Zoli. “Pressure-activated adhesive tape pattern for monitoring the structural condition of steel bridges via digital image correlation”. Struct Control Health Monit, vol 26, no 8, e2382, 2019. [CrossRef]

- Z. Liang, J. Zhang, L. Qiu, G. Lin, F. Yin. “Studies on deformation measurement with non-fixed camera using digital image correlation method”. Measurement, vol 167, 108139, 2021. [CrossRef]

- M. Juno, H. Al-Salih, W. Collins, C. Bennett, J. Li, E. J. Sutley. Investigating lighting and focus limitations of digital image correlation as a bridge inspection tool. In Structures Congress, 2020, pp. 341-348.

- V. Belloni, A. Sjölander, R. Ravanelli, M. Crespi, A. Nascetti. “Crack Monitoring from Motion (CMfM): Crack detection and measurement using cameras with non-fixed positions”, Automation in Construction, vol 156, 10507, 2023. [CrossRef]

- H.-G. Sohn, Y.-M. Lim, K.-H. Yun, Gi-H. Kim. “Monitoring Crack Changes in Concrete Structures”, Computer-Aided Civil and Infrastructure Engineering, vol 20 pp. 52–61, 2005. [CrossRef]

- S. Nishiyama, N. Minakata, T. Kikuchi, T. Yano. “Improved digital photogrammetry technique for crack monitoring”, Advanced Engineering Informatics, vol 29, pp. 851-858, 2015. [CrossRef]

- M. Brøns, T.A. Kasper, G. Chauda, S.W.B. Klaassen, C.W. Schwingshackl, M.R.W. Brake. “Experimental investigation of local dynamics in a bolted lap joint using digital image correlation” Journal of Vibration and Acoustics, vol 142, no 5, 051114, 2020. [CrossRef]

- W. Chen, D. Jana, A. Singh, M. Jin, M. Cenedese, G. Kosova, M. R.W. Brake, C. W. Schwingshackl, S. Nagarajaiah, K. J. Moore, J.-P. Noël. “Measurement and identification of the nonlinear dynamics of a jointed structure using full-field data, Part I: Measurement of nonlinear dynamics”, Mechanical Systems and Signal Processing, vol 166, 108401, 2022. [CrossRef]

- M. Jin, G. Kosova, M. Cenedese, W. Chen, A. Singh, D. Jana, M. R.W. Brake, C. W. Schwingshackl, S. Nagarajaiah, K. J. Moore, J.-P. Noël. “Measurement and identification of the nonlinear dynamics of a jointed structure using full-field data; Part II-Nonlinear system identification”, Mechanical Systems and Signal Processing, vol 166, 108402, 2022. [CrossRef]

- D. Roettgeni, E. Jones, A. Brinle, P. Reu, D. Rohe, J. Wagner. “Nonlinear System Identification using Digital Image Correlation”. No. SAND2018-5857C. Sandia National Lab.(SNL-NM), Albuquerque, NM (United States), 2018.

- Kopiika, N.; Blikharskyy, Y. Digital Image Correlation for Assessment of Bridges’ Technical State and Remaining Resource. Preprints 2024, 2024021251. [CrossRef]

| Error sources of DIC in on-field measurements | Resolution | Repeatability | Accuracy | Mitigation approaches |

| Preparation of experimental set-up (before measurement) | ||||

| Target/speckle pattern | 3 | 3 | 3 | Implementation of artificial targets; Optimal size and location of targets. Optimal speckle dots` size, contrast level, subpixel precision, intensity gradients, etc |

| Low quality of images | 3 | 1 | 3 | Use of cameras and lenses with appropriate resolution |

| Metric calibration | 1 | 1 | 3 | Detailed geometric survey during the set-up. Assessment of camera extrinsic parameters and reconstructed features. |

| Continuation of Table 1. | ||||

| Image recording | ||||

| Movement of camera | 1 | 3 | 3 | Ensuring the stable position of a camera. Correction during post-processing through comparison with stationary targets. Filtering during postprocessing. |

| Environmental impacts | 1 | 3 | 3 | Autoexposure. Monitoring in shade with artificial lightning control during short periods. Protective barriers. Temperature-displacement models |

| Elastic deformations and rigid body rotations | 1 | 1 | 1 | The use of high-order shape functions in DIC processing. |

| Out-of-plane movement | 1 | 1 | 3 | Alternative parallel measurements. The use of 3D-DIC method. |

| Image processing | ||||

| Correlation algorithms | 1 | 1 | 1 | Iterative choice of the most optimal algorithm |

| Subset selection | 2 | 1 | 1 | Smaller subsets in critical areas. Advanced algorithms to handle discontinuities. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).