4.1. NREL-5 MW Wind Turbine

The first step of the validation process involves simulating the simplest configuration of the wind turbine C1 at rated conditions, not taking into account neither the shaft tilt angle

nor blade cone angle

. DUST results are compared to the ones obtained with high-fidelity numerical simulation conducted by Dose et al. [

22] using RANS approach and by Leng et al. [

41].

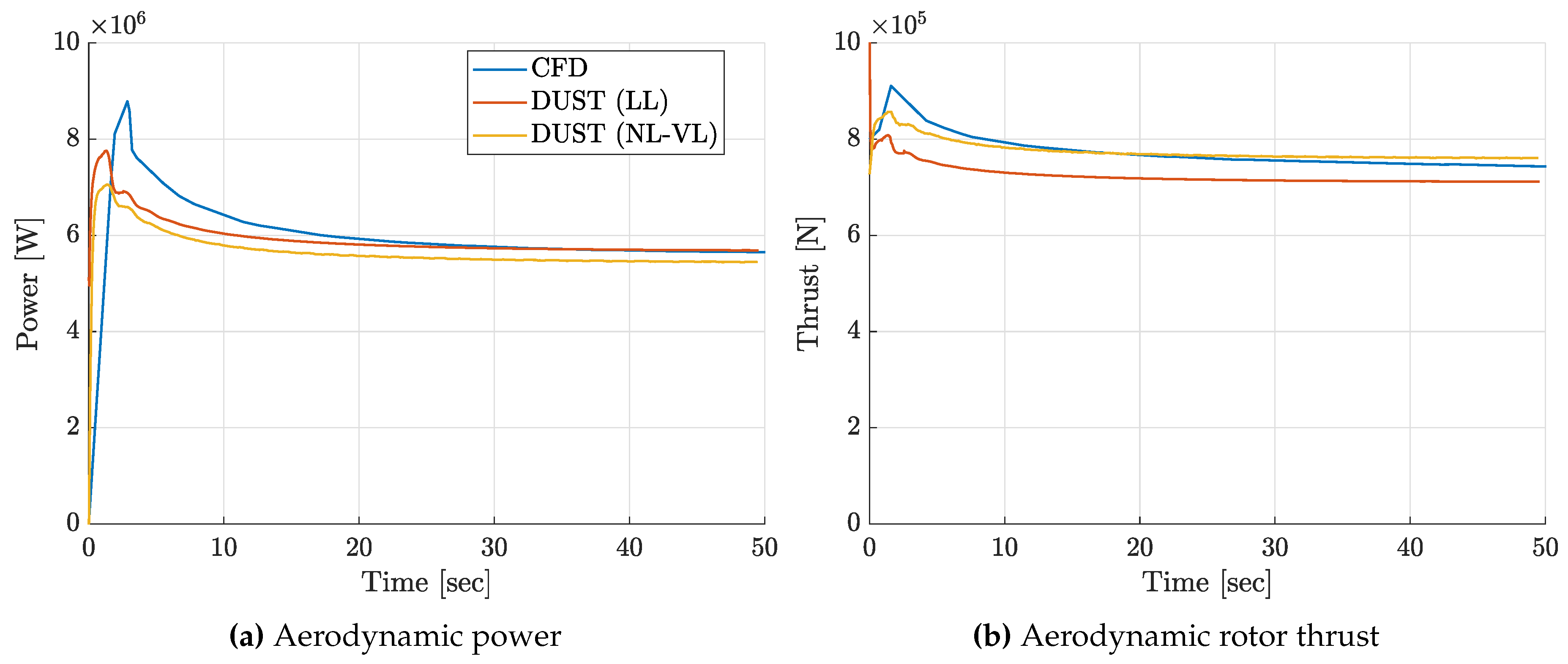

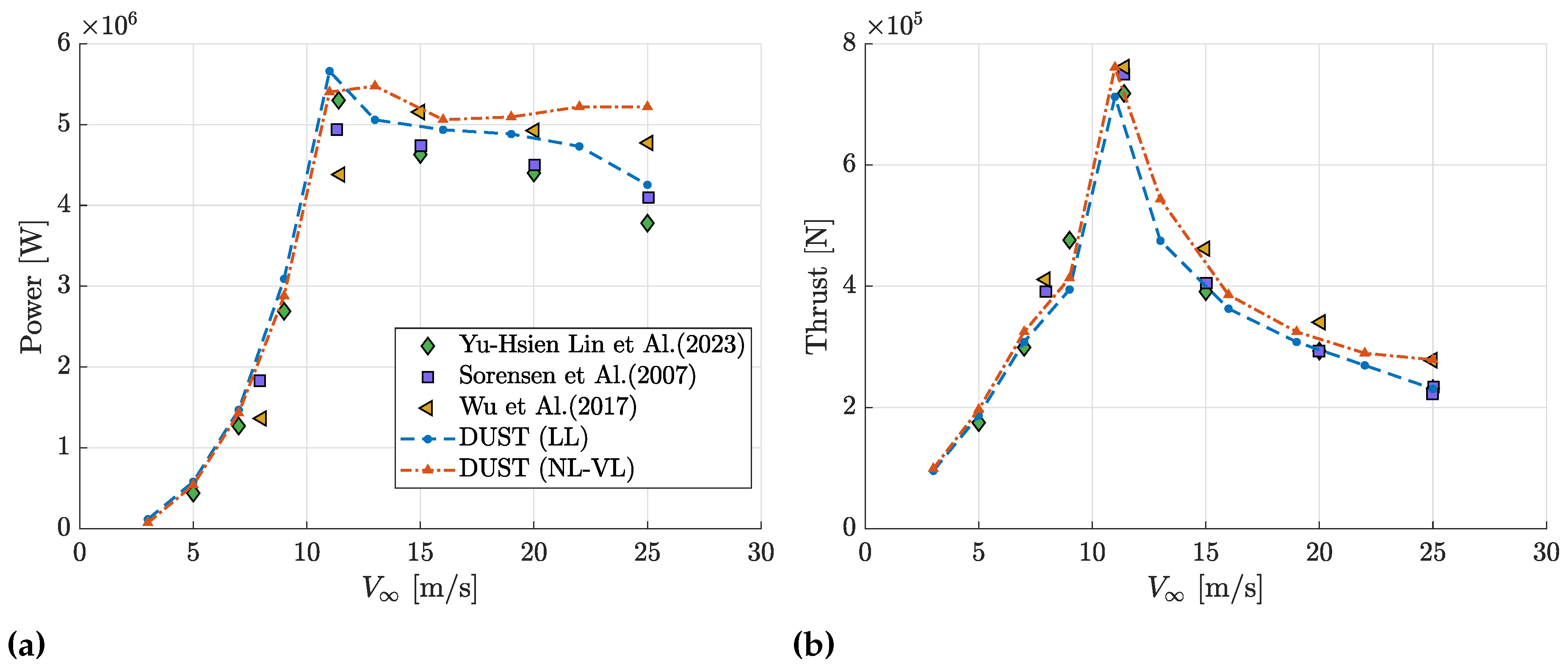

Figure 3 shows the time histories of aerodynamic power and thrust computed by DUST employing both NL-VL and LL elements compared to [

22] CFD results. A convergence of integral loads can be observed for DUST simulations after 30 seconds corresponding almost to 8 revolutions. A good correlation in terms of aerodynamic power between CFD and DUST results, considering both LL and NL-VL elements can be observed. A quite good agreement was found in terms of aerodynamic thrust considering particularly NL-VL elements, while LL elements seems to slightly under-predict the CFD thrust output. Generally, results comparison suggests a quite similar accuracy with respect to CFD that can be obtained from DUST for the calculation of integral loads of a wind turbine at rated inflow condition but with a significant lower computational cost.

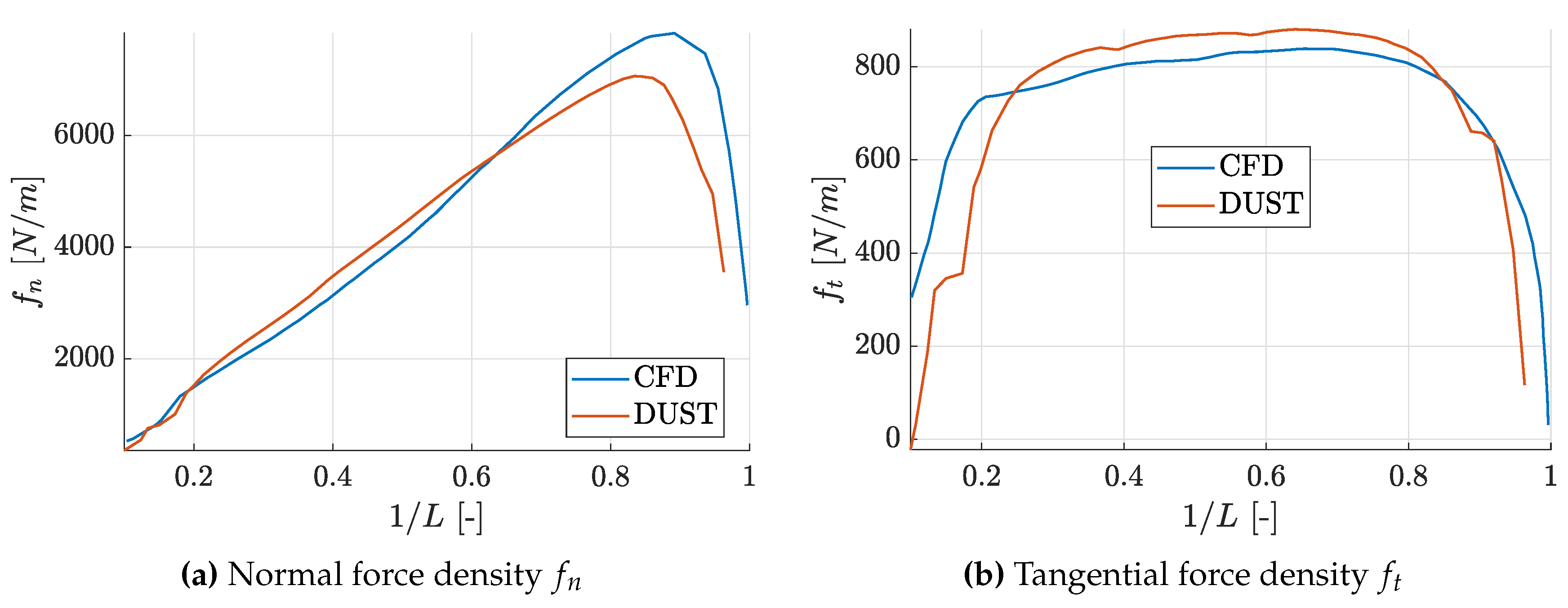

Figure 4 shows the comparison of the normal and tangential sectional forces acting along the normalised spanwise coordinate of the blade computed by DUST NL-VL model and high fidelity CFD simulation by Dose et al. [

22]. The normal force density comparison illustrated in

Figure 4a exhibits a close alignment between DUST and high fidelity CFD data along almost the majority of the blade span. However, near the blade tip DUST slightly underestimate the normal force. This behaviour is expected as wing tip are characterized by a more complex flow regime where three-dimensional phenomena and tip vortices generation typically leads to significant viscous effects and separated flow regions, which can not be accurately captured by DUST mid-fidelity approach. Tangential force density comparison depicted in

Figure 4b shows an underestimation of DUST computation before the first 30% of blade span and a slight overestimation in the central spanwise region. High-fidelity CFD model, however, shows a more pronounced decrease in tangential force towards the blade tip with respect to DUST results, that can be reasonably explained, as said before, by the limits of mid-fidelity approach in this region. Generally speaking, the behaviour of the sectional force comparison confirms the capability of DUST to competently reproduces the general force distribution along the blade span.

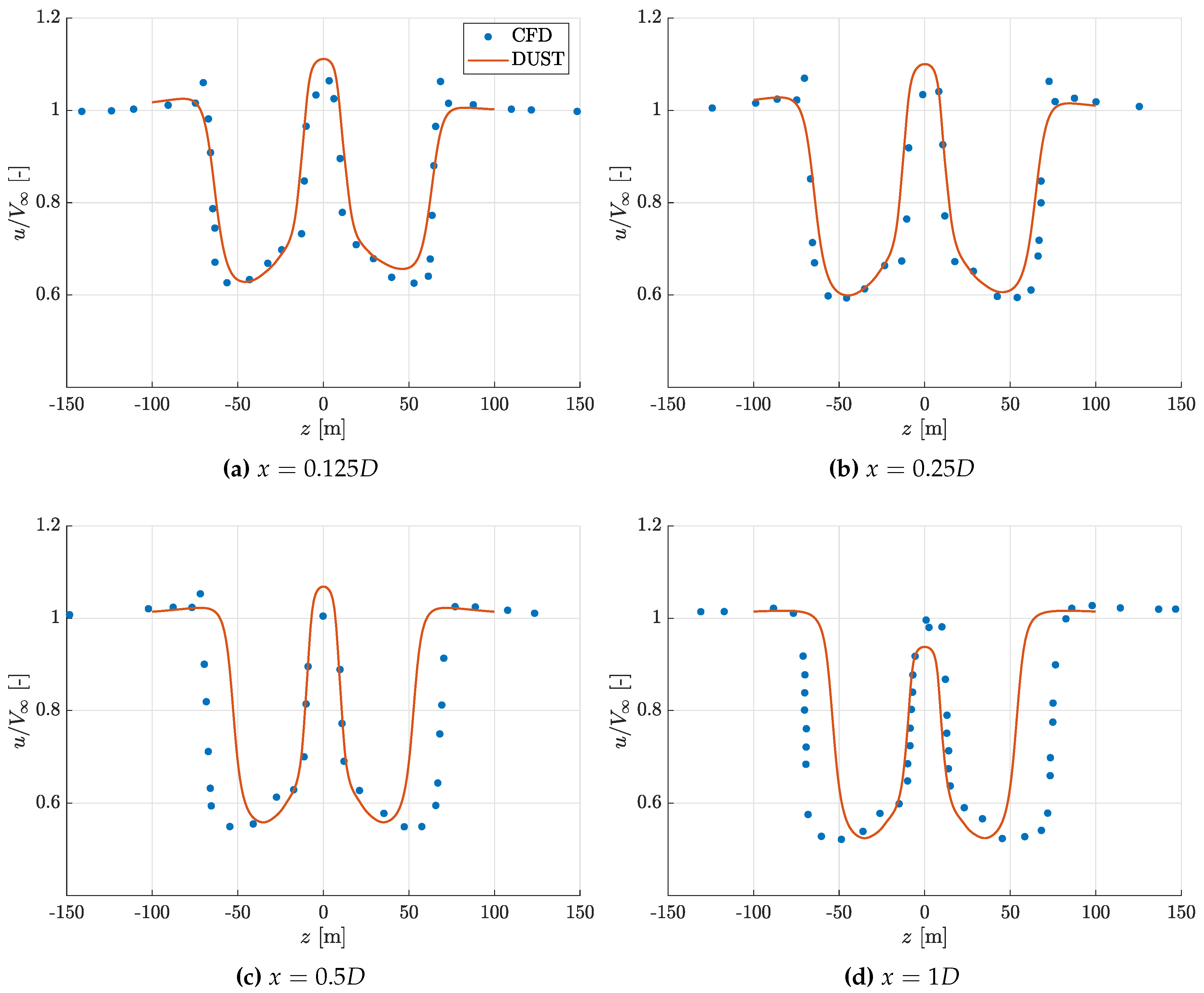

The performance of a wind turbine are significantly affected by the wind turbine wake, then a crucial step for DUST validation is the ability to correctly capture the wake development and its main features in terms of velocity field. Then, the deficit of the axial velocity in the wake calculated by DUST is compared with the high-fidelity simulation by [

42], considering 4 stream wise position located at different distances

x downstream from the rotor plane. Velocity profiles comparison is shown in

Figure 5 as function of

z, representing the distance from the shaft axis parallel to the rotor plane.

A quite good agreement was found between axial velocity profiles in the wake of the wind turbine, particularly near to the rotor disk, i.e.,

and

. Some discrepancies were found at higher distances where CFD results show a slightly larger extension of the wake, probably due to numerical diffusion. Generally,

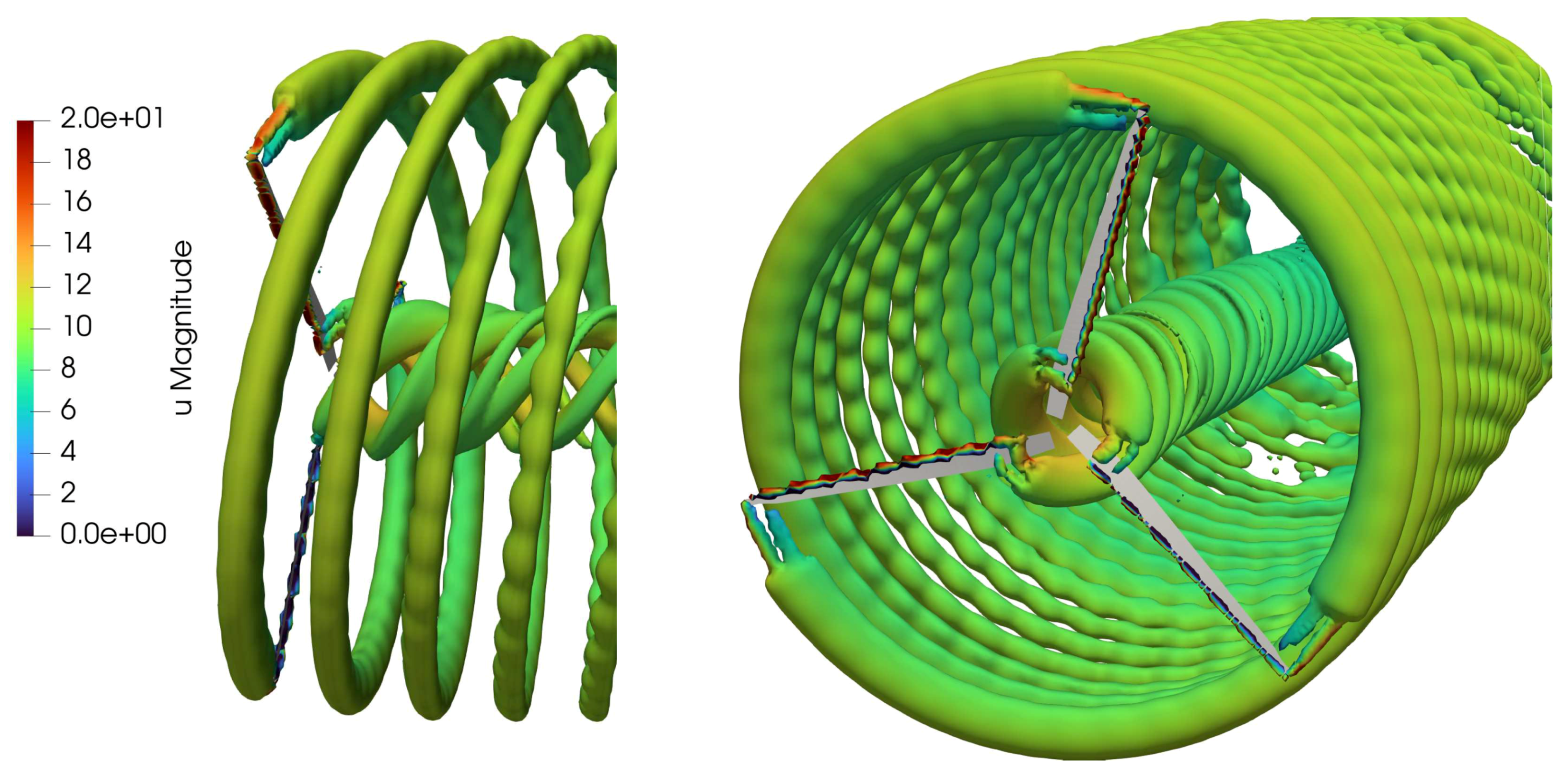

Figure 6 illustrates the wake structure computed by DUST shown as an iso-surface of the vortex Q-criterion. Readers are referred to results reported in [

42] to appreciate DUST capability to capture the behaviour of the wake structure computed by CFD.

The influence of blade cone angle

and shaft tilt angle

on the aerodynamic performance under rated inflow conditions is now explored by comparing results obtained with DUST and high-fidelity CFD by Dose et al. [

22] over C1, C3 and C4 cases. Generally, the sensitivity of integral loads to cone and tilt angles variations is minimal. Indeed, adding a blade cone angle a slight increase of the rotor power is observed. On the other hand, introducing a shaft tilt slightly reduces rotor power and thrust. In particular, the integral power and thrust on the rotor are compared in

Table 7. Both DUST models provide values quite similar to high-fidelity CFD findings. A difference below 2% is found for power evaluation with both LL and NL-VL elements, while thrust evaluation obtained by DUST with NL-VL is in quite good agreement with CFD. An underestimation of rotor thrust of about 8% is found for LL DUST model with respect to CFD.

Case C4 enabled to provide an insight of the effects of varying freestream velocity, thanks to high-fidelity CFD results from Sørensen and Johansen [

16], Lin et al. [

17], Wu and Nguyen [

18].

Figure 7 compares the computed power and thrust as function of wind speeds. Generally, both DUST models capture the behaviour of power and thrust curves evaluated by CFD, thus confirming the capability to model correctly the effects of wind inflow on rotor performance. In particular, LL elements model tends to slightly overestimate power production below the rated wind speed, while NL-VL elements model slightly overestimates rotor power above the rated speed. Now considering thrust evaluation, LL elements model tends to underestimate CFD high-fidelity data along the entire velocity spectrum, while a quite better agreement is obtained with NL-VL elements model.

Different yawed configurations are then investigated. At first, a yaw angle

is considered to assess the integral and the sectional parameters with respect to high fidelity CFD simulation by Dose et al. [

22]. Then, other two yaw angles configurations are considered, respectively

to be compared with the LES study by yaw [

20].

Table 8 compares the integral rotor power and thrust computed for C2 configuration with

. Once again, errors in terms of power and thrust with respect to CFD by Dose et al. [

22] are below 10% for both DUST models. Compared to the axial flow condition case, power and thrust outputs decrease respectively by 27% and the thrust of 12% in accordance to CFD evaluation by Dose et al. [

22].

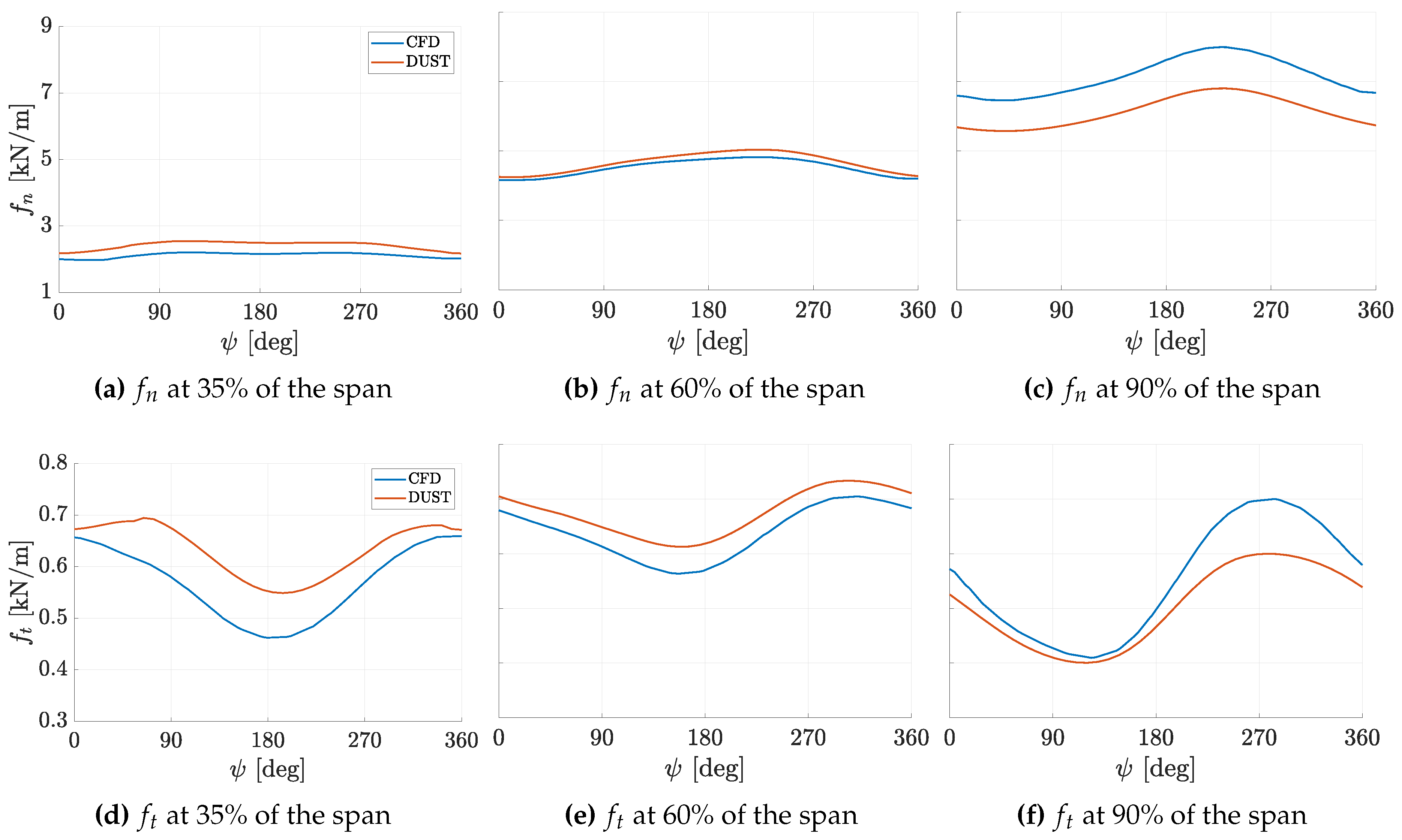

In order to quantify the local effect on blades subjected to yawed inflow, sectional normal and tangential forces are compared at three different spanwise coordinates in

Figure 8 as function of blade azimuthal angle

in the last computed revolution. Generally, DUST tends to calculate higher normal and tangential force densities up to 60% of the span coordinate, while lower force densities are found near the blade tip compared to the high-fidelity CFD results that could be attributed to the complex three-dimensional flow effects occurring in this region. Nevertheless, the local behaviour of the forces acting on blades are captured by DUST representation also in yawed conditions.

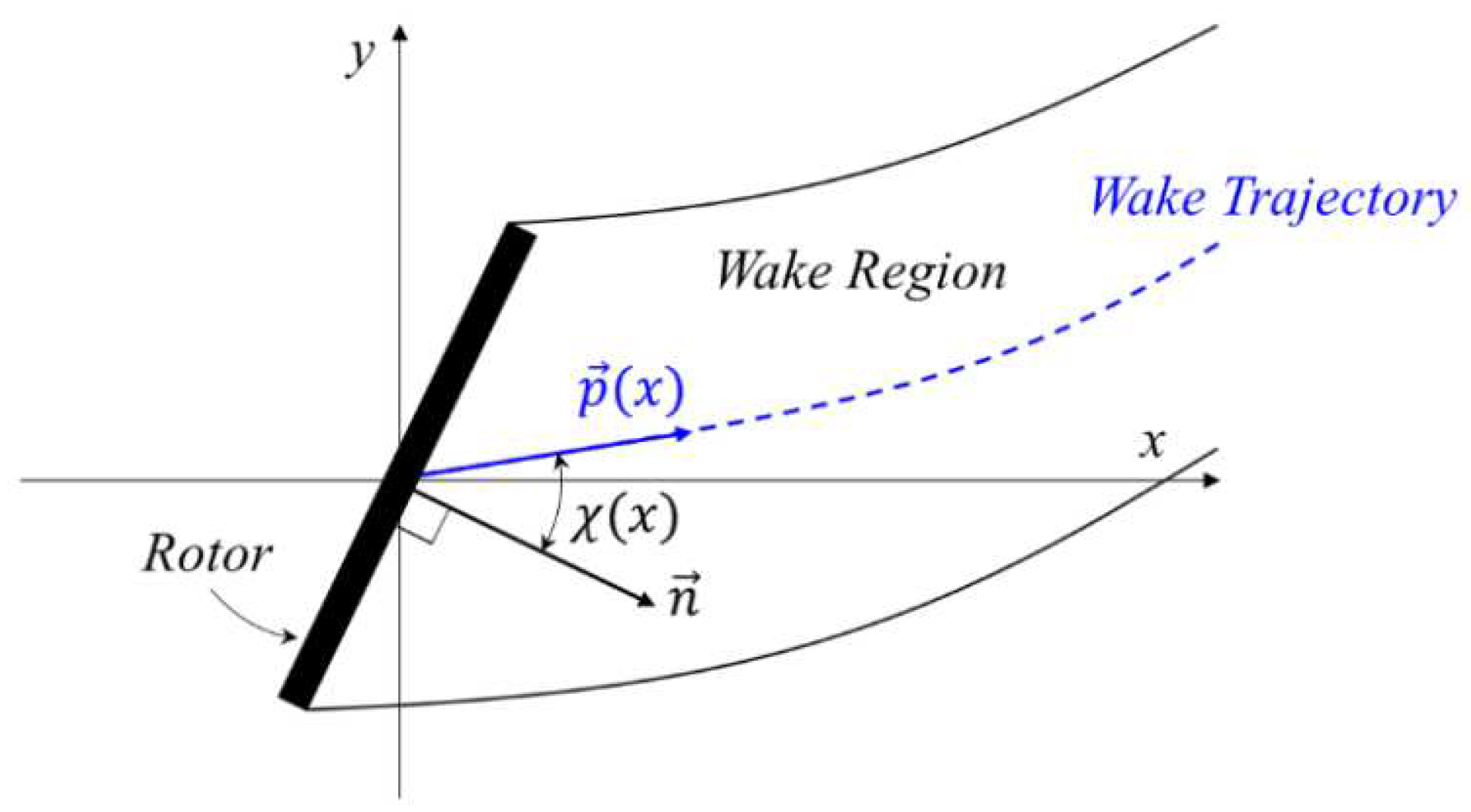

Another important feature to better understand the capability to capture the wind turbine wake behaviour for yawed configuration is the study of the evolution of the wake center-lines and the associated skew angles. The wake center-lines is an imaginary line that runs through the middle of the wake, marking the trajectory of the region with the highest velocity deficit caused by the wind turbine and represents the path that the wake follows downstream the turbine. This line can be calculated as the integral of the velocity deficit on a wake section perpendicular to the flow direction divided by the area of that section [

43]. This method gives an average value that accounts for the different velocities across the entire wake area, providing a singular measure of the wake’s strength. The skew angles, instead, gives a more quantitative analysis of the wake center trajectories. Skew angle

is the angular measure between the position vector

extending from the rotor disk midpoint and the normal vector to the rotor disc, as shown in

Figure 9 and defined in Equation (

1).

Figure 10 shows the skew angles behaviour calculated by DUST compared with LES results by Kim and Lee [

21], for yawed conditions ranging from

to

. The comparison shows how DUST is capable to evaluate correctly the wake center line evolution and the corresponding skew angles that change with respect to yaw angle and show a peak around

.

The final configuration considered deals with the complete case equipped with tower and nacelle for C4 rotor condition.

Figure 6 illustrates a visualisation of wake structure computed by DUST for the complete wind turbine shown as an iso-surface of the vortex Q-criterion.

As done before, DUST simulations results using both LL and NL-VL models are compared with the high fidelity CFD calculation by Yu and Kwon [

26] and Lin et al. [

17]. The results in terms of integral loads comparison are presented in

Table 9 for single rotor and full wind turbine.

The introduction of nacelle and tower provides a reduction of the rotor performance for both power and thrust. This behaviour is captured by DUST simulations, thus showing the capability to reproduce interactional effects between rotor wake and tower, as done by CFD. In particular, NL-VL model shows integral values in quite good agreement with high-fidelity CFD [

17] as evaluated differences are below than 5% for both power and thrust.

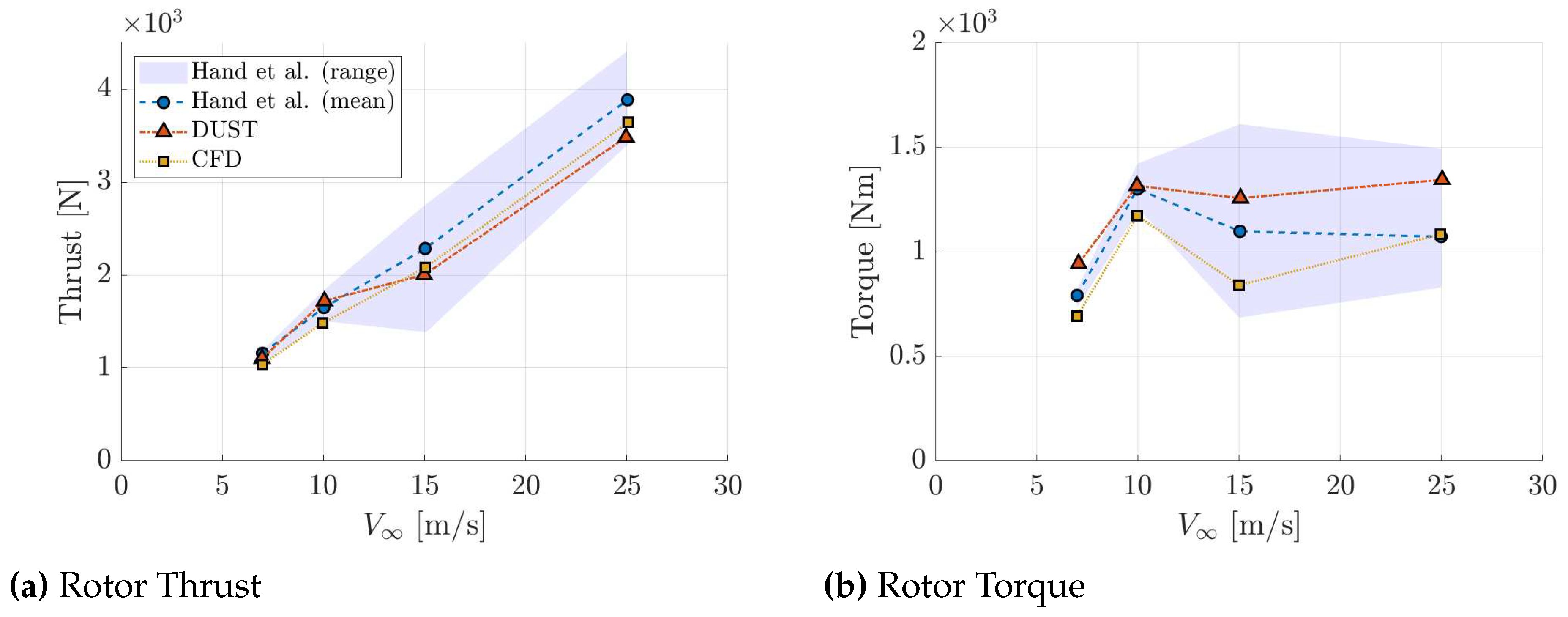

4.2. NREL Phase VI

Firstly, the single rotor performance is considered at four different wind speed. The integral rotor thrust

T and torque

Q computed by DUST using NL-VL model are compared in

Figure 12 with experimental data from Hand et al. [

1] activity and with high-fidelity CFD data by Länger-Möller et al. [

28]. In these figures the standard deviation of the experimental loads is reported as a banded region.

The thrust and torque values computed by DUST show a good agreement with the overall trend of the high fidelity CFD and the experimental data. In particular, DUST computations fall into the confidence band of the experiments almost in the whole range of wind speed considered by the simulations. Indeed, an apparent difference occurs for torque computations at 7 m/s, probably due to the occurrence of massive flow separations in this condition. Generally, the differences of the integral loads values obtained by DUST with respect to the average experimental values are of the same order of the ones obtained by high-fidelity CFD, thus further confirming the promising capability of the mid-fidelity approach for the evaluation of wind turbine aerodynamic performance with respect to methods requiring a quite higher computational effort.

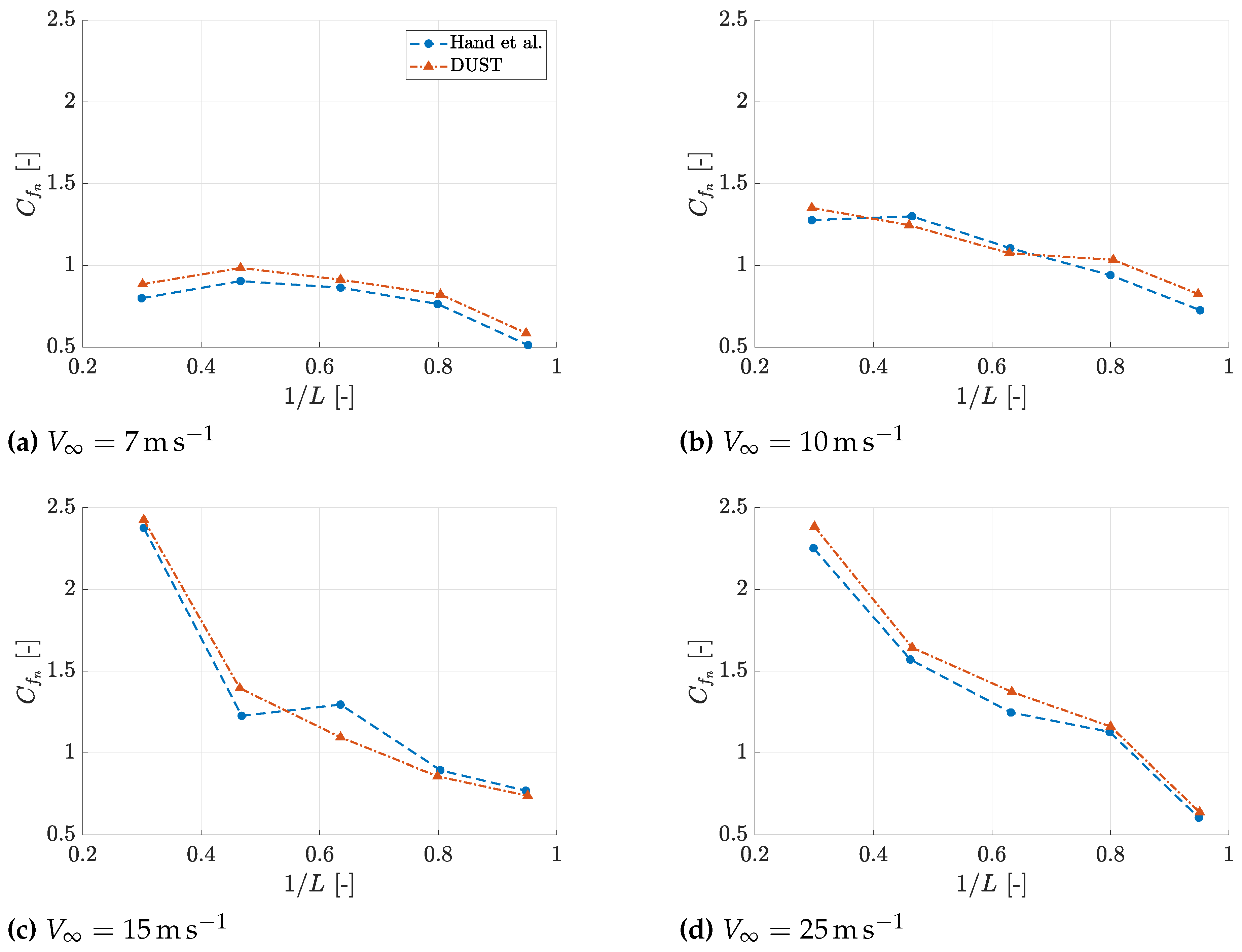

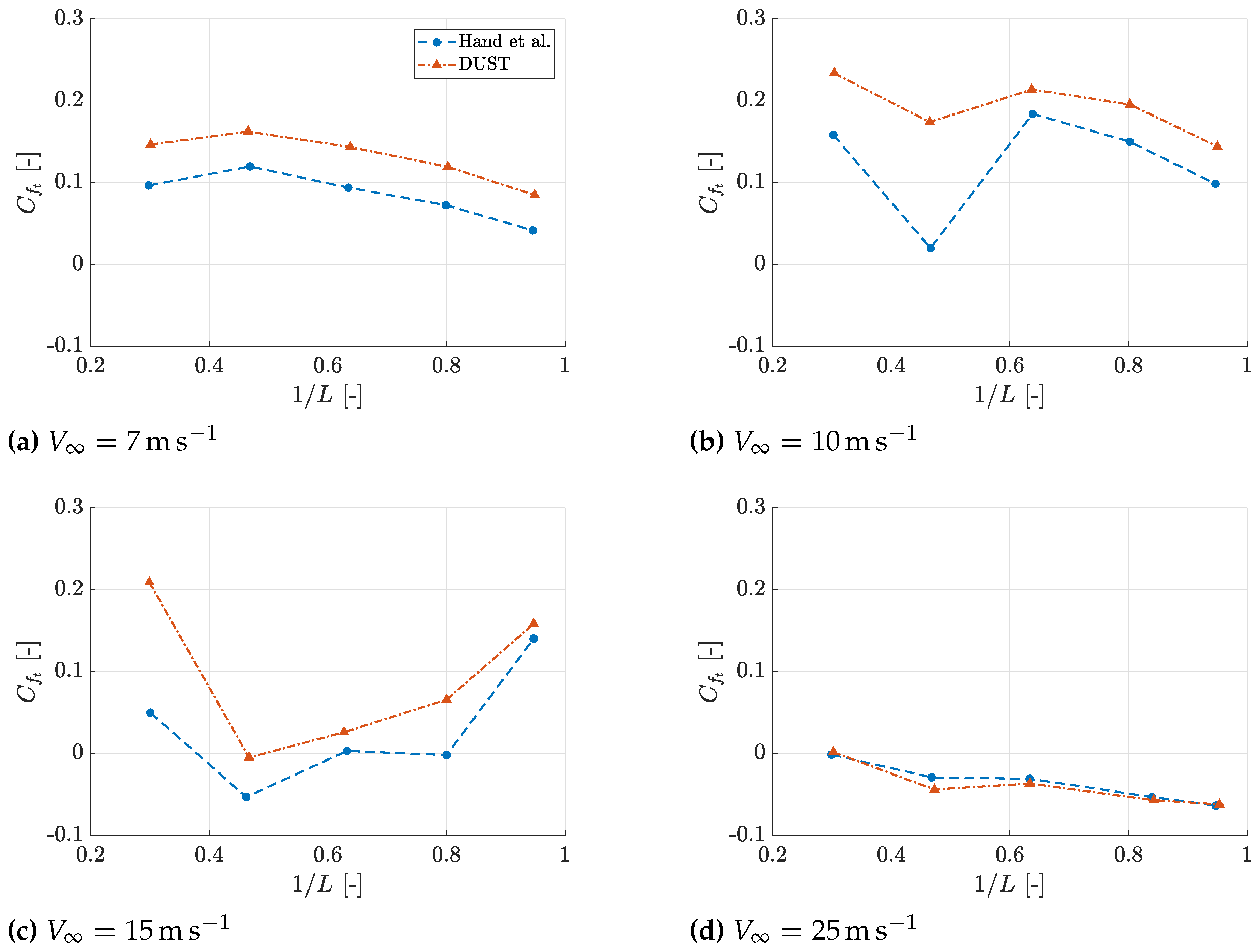

As done before, blade sectional normal and tangential force are compared respectively in

Figure 13 and

Figure 14 for the four wind velocities analysed. Once again, the trends of the sectional forces resembles the experimental data, just showing slight offsets along blade span particularly for normal force while higher discrepancies can be found for tangential component particularly at low speed.

The second part of the validation deals with the analysis of the influence of the blade-tower interaction, thus the complete wind turbine configuration was considered by DUST simulations at two wind speeds. An overview of rotor thrust and torque computed by DUST and compared with experiments and high-fidelity CFD data is given respectively in

Table 10 and

Table 11. Once again, a good agreement of the integral loads values are found for DUST simulations also for the complete wind turbine model, but an exception is found for torque calculation at lower speed analogously to what found before.

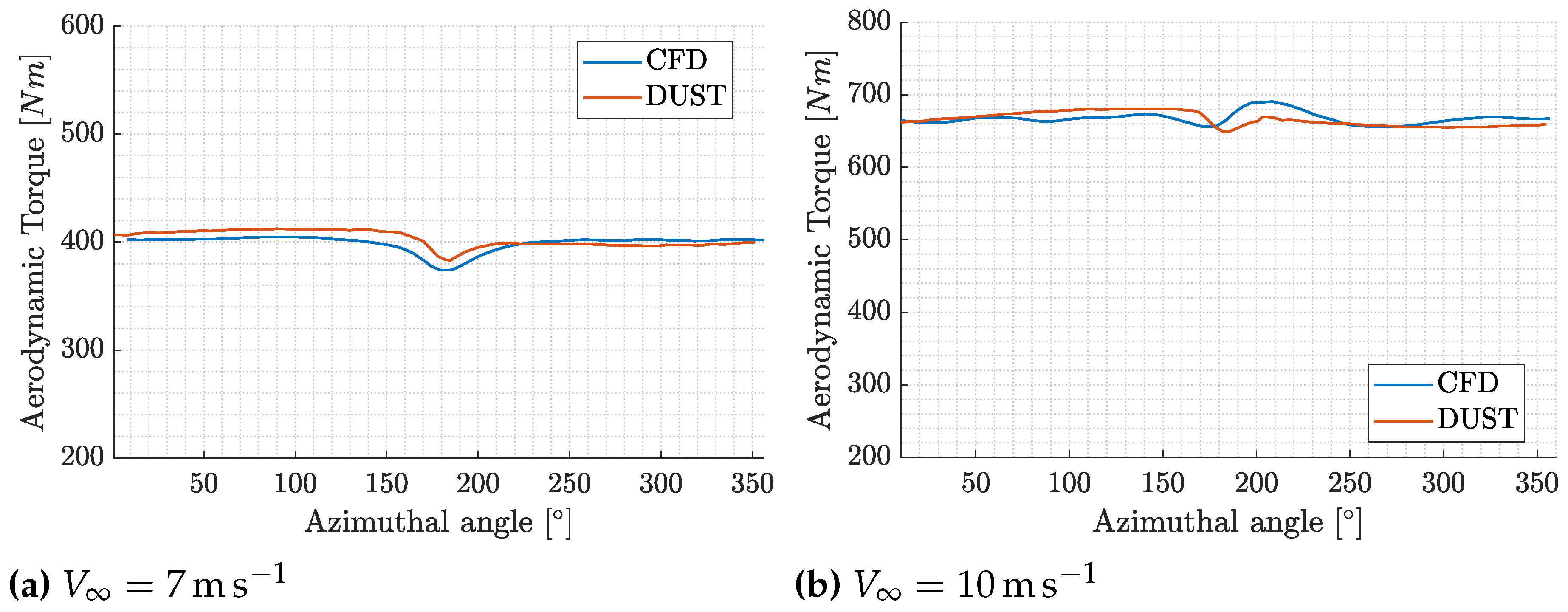

A detailed insight on loads behaviour is provided by the time histories of the rotor torque evaluated on the last computed revolution for the full wind-turbine at different wind speeds. Comparisons with experiments shown in

Figure 15 distinctly illustrates DUST capability to reproduce the reduction in aerodynamic torque as a blade passes in front of the tower around azimuthal angle of

. This reduction, quantified to be approximately 10% relative at 7 m/s with respect to the torque value evaluated when the blade is not influenced by the tower is aligned with experimental observations. At

wind speed, the tower influence is still detectable but is considerably lower but DUST representation remains in good agreement with experimental data.