1. Introduction

Sensing technology has constantly accompanied the development of Structural Health Monitoring (SHM). A very recent review [

1] has regarded non-destructive ways to perform SHM, providing a collection of possible technology including ultrasound sensors, mechanical sensors, laser sensors, optical sensors, infrared thermographic sensors, ground penetrating-radar sensors, electrical parameter measuring sensors and micro electromechanical system sensors. Sonbul et al. [

2] conducted a systematic literature review of wireless sensor network (WSN) platforms and energy harvesting techniques in the context of the SHM process for bridges. Deng et al. [

3] tackled the challenge of identifying abnormal data in big monitoring datasets. Abnormal data could result from sensor defects, data acquisition errors, and environmental interference that can introduce noise and bias into the analysis, leading to inaccurate conclusions about the structural condition and performance degradation. They classified abnormal data detection methods into three main classes: statistical probability methods, predictive models, and computer vision, highlighting the pros and cons of each method. Bado et al. [

4] conducted a comprehensive review of the use of distributed sensing technology within the context of Digital Twin (DT) as a maintenance and serviceability strategy based on Structural Health Monitoring.

The scientific community is aggressively pursuing novel sensing technologies and analytical methods that can be used to rapidly identify the structural behavior in an instrumented structural system [

5].

Piezoelectric accelerometers are commonly used in vibration measurements, but the cost can be high, especially if multiple data collection points are needed, [

6]. The recent advances in embedded system technologies such as Micro-Electro-Mechanical Systems (MEMS) sensors hold great promise for the future of smart vibration measurement-based condition monitoring which is a much cheaper alternative. Micro-Electro-Mechanical Systems and Information and Communication Technologies (ICT) have the potential to significantly impact the SHM, [

7]. To assist in dealing with the large amount of data that is generated by a monitoring system, an onboard Analog-to-Digital Converter (ADC) at the sensor and Microprocessor allow simultaneously the sampling and elaboration to be done locally of the vibration data. Such an approach provides for an adaptable, smart sensor, thus reducing the amount of information that needs to be transmitted over the network. Pushing data acquisition forward is fundamental to smart sensing and monitoring systems. Sony et al. [

8] presented a comprehensive review of next-generation smart sensing technology within the context of structural health monitoring, highlighting opportunities and associated challenges. Some of the first efforts in developing smart sensors for application to civil engineering structures were presented by Straser et al. [

9,

10]. They proposed a monitoring platform based on an embedded systems and wireless packet-switching networks for a structural monitoring system based on the hardware to acquire and manage data, and on the software to facilitate damage detection diagnosis. Shamim N. Pakzad et al. [

11], (2009), proposed a spatially dense Wireless Sensor Network (WSN) designed, developed, and installed on a long-span suspension bridge, the Golden Gate Bridge, for a long-term deployment based on MEMS technology, to record ambient acceleration and to assess the accuracy of identified parameters. They designed a sensor board with two MEMS accelerometers with noise spectral density of 32

g/

and 200

g/

and measurement range of ± 0.1 g and ± 2 g, respectively. They used that sensor board in conjunction with commercial WSN motes produced by Crossbow Technology running TinyOS, an open source, BSD-licensed operating system designed for low-power, low-data rate wireless devices. Zanelli et al. [

12] proposed a wireless sensor node relying on an energy harvesting technique to guarantee long-term monitoring capability.

Many of the critical aspects related to structural health monitoring-oriented wireless sensor network design have been reviewed by Federici et al. [

13], allowing the definition of a cost function useful for the assessment of a deterministic criterion to compare different network solutions. However, there is still a lack of studies regarding the practical application and comparison of commercially available low-cost accelerometers under SHM conditions [

14]. The monitoring system is primarily responsible for collecting the measurement output from sensors installed in the structure and storing the measurement data within a central data repository. For example, a low-cost system has been implemented by Girolami et al. [

15] to evaluate the real-time modal properties of a simply supported steel beam in free vibration conditions from synchronized MEMS accelerometer measurements. In developing this work, two critical issues were found concerning the synchronized sampling of the accelerations from distributed nodes and the data rate compared with more expensive piezoelectric sensors. Health monitoring systems for dynamic analysis must be reliable, reconfigurable, and energy-efficient while providing precise measurement synchronization, [

16]. The main features of sensor nodes to be suitably employed for structures’ health monitoring are the measurement performances, (reliable measurements), the easiness of installation, and the long autonomy to grant a permanent installation on the structure. Malik at al. [

17] proposed a framework aiming to develop early warning systems to mitigate any loss of life and property that could affect public civil structures stressed by increasing population and urbanization. They designed an SHM sensor node integrating sensors for vibration, tilt, strain, humidity, and shock measurements. Low-cost sensors were integrated and, to get reliable vibration and tilt values, three MPU-6050 MEMS sensors were integrated averaging the three measured values. Potenza et al. [

18] proposed an inter-disciplinary work focused on the permanent monitoring of a cultural heritage structure, the Basilica S. Maria di Collemaggio, employing a sensor network designed to combine high performance and high-demanding service requirements, as the management costs related to the long-term monitoring. There are several research studies in the literature about the MEMS accelerometer construction and the measurement principle [

19,

20,

21,

22,

23,

24]. Most of the available solutions are based on proprietary platforms, often made with heterogeneous components that need to work together, suffering from interfacing issues.

The proposed solution is based on a hardware platform (SHM-Board) on which there is complete control since it was entirely in-house designed (HW) and programmed (SW). This grants a high level of flexibility and adaptability of the platform to different application needs: the compatibility with several external sensors guarantees the possibility of adapting the platform’s configuration to monitor modern and ancient/historical buildings, bridges, viaducts, trellis, etc. The SHM-Board is a high-performance device for real-time structural health monitoring that integrates a low-noise triaxial MEMS accelerometer to measure vibrations that excite the structure. This system allows for dynamic monitoring for assessing the damages to the structure, which includes a complete solution to measure and analyze the vibrations of civil buildings and infrastructures. In the typical use case, the SHM-Boards are connected over the LAN Ethernet to a local aggregator (gateway). The triaxial accelerometer’s data are 24-bit each and generated at 100 Hz. After an eventual local computation aimed at reducing the amount of the total transmitted bytes, such data are continuously transmitted to a remote server, which handles their storage and allows for event detection and off-line analysis of the historical traces/records to track down the behavior of the structure over long periods. The system allows for the following:

identifying the modal frequencies of the structure and monitoring how they vary over time to detect the presence of damages in the structure as consequences of seismic events or just because of the aging effects

filtering the natural frequencies from the environmental noise due to natural reasons (wind, rain, or daily/seasonal temperature variations) or anthropical ones (human activities, such as vehicular traffic or the possible presence of work constructions in the surroundings)

understanding if the vibrations represent a disturbance or damage factor for the structure and the people living there

vibrational analysis, with which it is possible to detect real-time magnitude of the stress in terms of spectral analysis (amplitude and frequency) to be compared with the thresholds defined by the international limits (UNI, DIN)

The paper is organized as follows. In

Section 2, the wired monitoring system developed for structures’ SHM is described. The focus is on the design of the device equipped with MEMS accelerometer, which is the sensing node to be positioned on the structure. A lab test arranged to evaluate the performances of the developed system in static and dynamic conditions is presented in

Section 3. Some preliminary results of the implementation of the designed long-term monitoring system on a real case study are then shown in

Section 4; contextually, the performance of high-performance MEMS devices is compared with a well-known commercial force-balance accelerometer, previously scheduled for a short-term dynamic test. This comparison allowed for the validation of the proposed solution.

Section 5 provides the FEM model updating using data from the proposed monitoring system and, the conclusions are reported in

Section 6. As well as, actual limitations and future improvements are discussed.

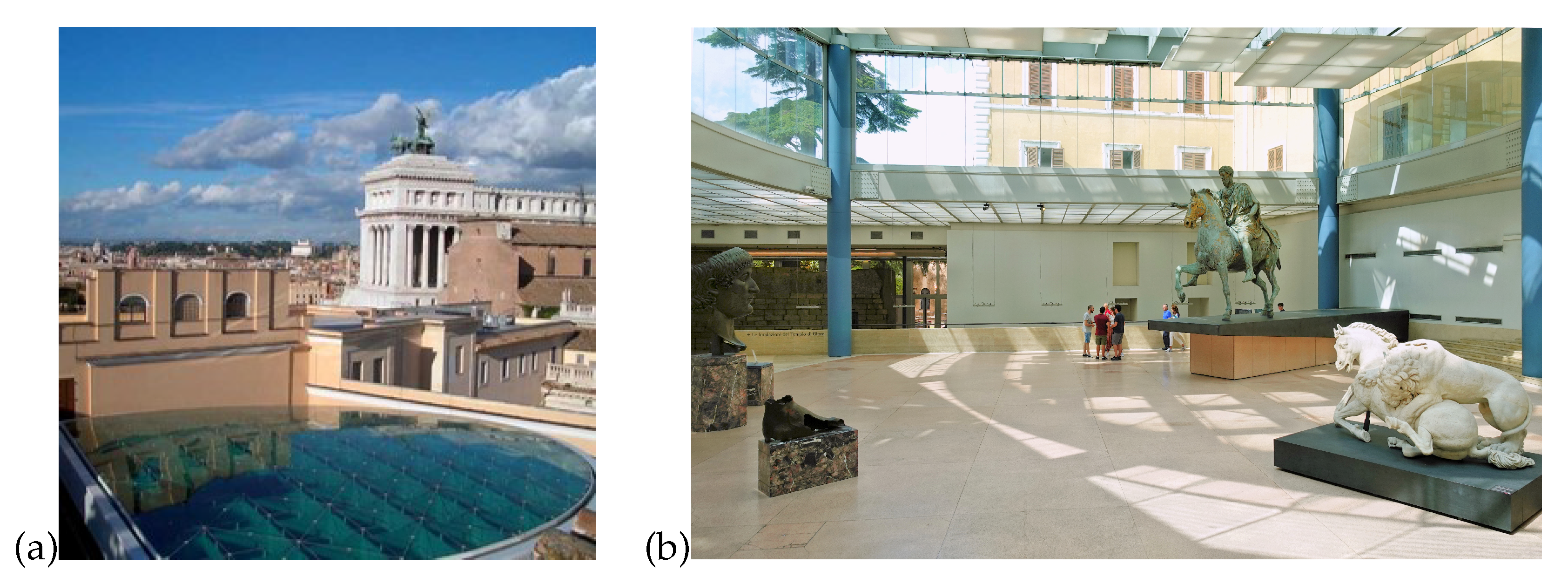

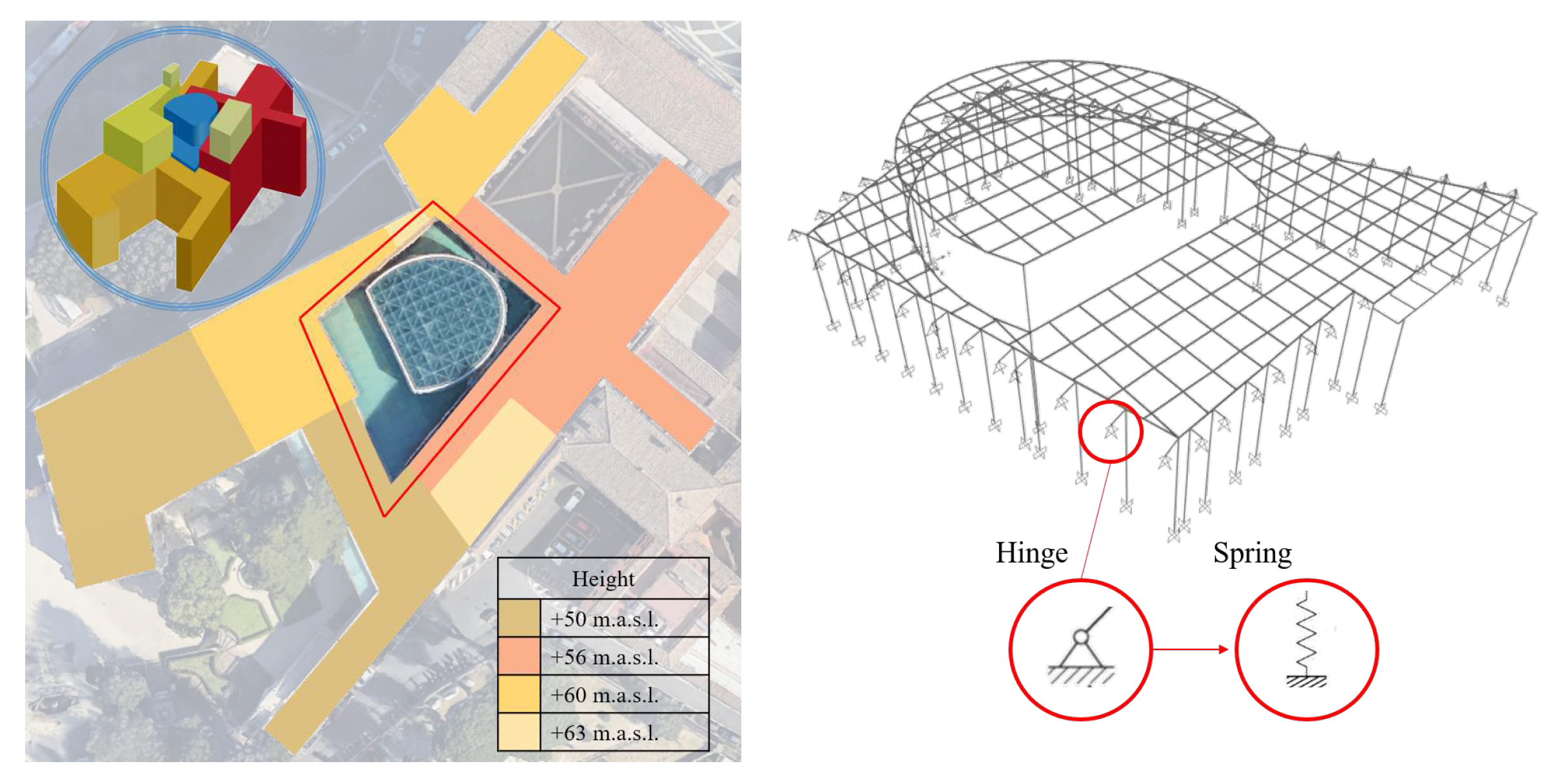

4. Validation on a Real Case Study

The selected case study is the Marcus Aurelius Exedra Hall, located within the Complex of Capitoline Museum in Rome, Italy. The hall is situated in what was known as the

Giardino Romano in the Palazzo dei Conservatori. The hall is a newly constructed grand glass-roofed structure designed by the architect Carlo Aymonino, and it stands as a prestigious piece of modern architecture in the heart of Rome. The hall is home to the famous equestrian statue of Marcus Aurelius and some of the most significant treasures of the museum. Towards the back of the hall, lie the remains of the foundations of the Temple of Jupiter Capitolinus. This Hall also links the historic part of Palazzo dei Conservatori to the newer parts of the museum. The steel and glass structure has a semi-elliptical plan,

Figure 9 (a), supported by six 75 cm-diameter steel pillars, without capitals and bases. The six columns support the massive box section girders at two different altitudes that hold up the perimetrical glass enclosures: the horizontal elliptical roof, and the lateral surfaces, as shown in

Figure 9 (b). Consequently, the glazed roof is divided into two levels connected by a glass “drum”. Rectangular windows are designed to bridge the gap between the two levels and all connections are bolted and welded.

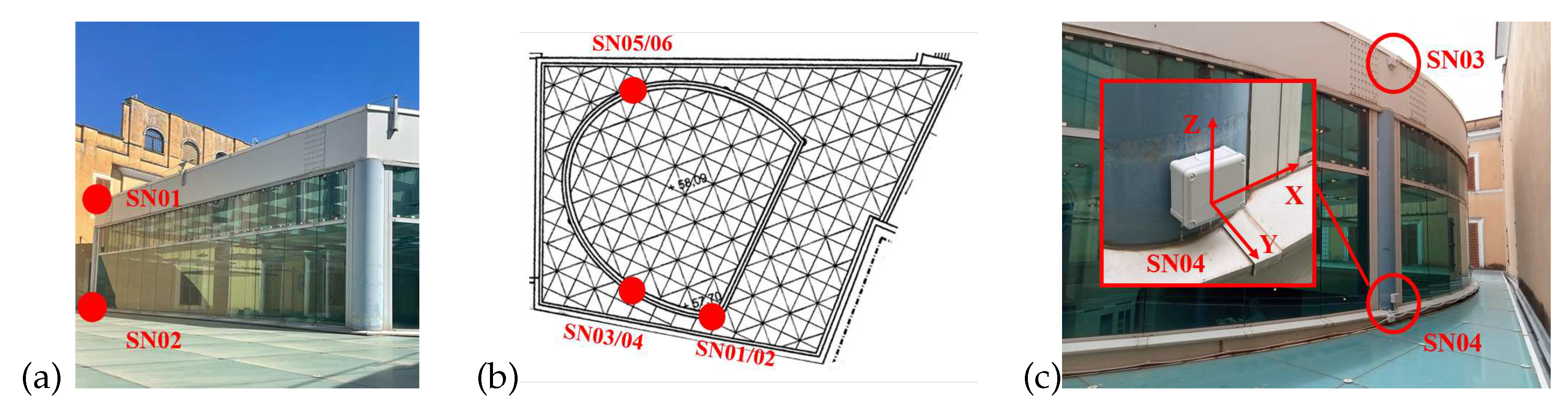

The structure underwent a short-term on-field dynamic test in December 2022 using commercial triaxial accelerometers to analyze its dynamic behavior over a brief period and establish a baseline of identified natural frequencies. Subsequently, the Exedra has been monitored using non-commercial MEMS accelerometers the paper is about, as part of a long-term plan to track natural frequencies over an extended period. Several site surveys have been conducted to identify the optimal locations for sensor placement and to solve the problem of accessibility to the areas of interest. The Exedra monitoring system has been continuously recording since its installation at the beginning of July 2023. The accelerometers were all installed in IP68 watertight sealing containers to ensure their long-term survivability in the field. The containers were made integral with the steel structure via strong and durable magnet attachments suitable for the structure’s material, and have been put in bubble levels to ensure the perfect verticality. The monitoring layout includes six sensor nodes, two for a single column that supports the Hall’s dome, involving the first, the second, and the fourth column. For installation operations, the walkway for maintenance and cleaning has been used.

Figure 10 illustrates the locations of the accelerometers, in a general view (a) and in-plane view (b), outdoors on the main structure, and (c) shows how accelerometers are oriented.

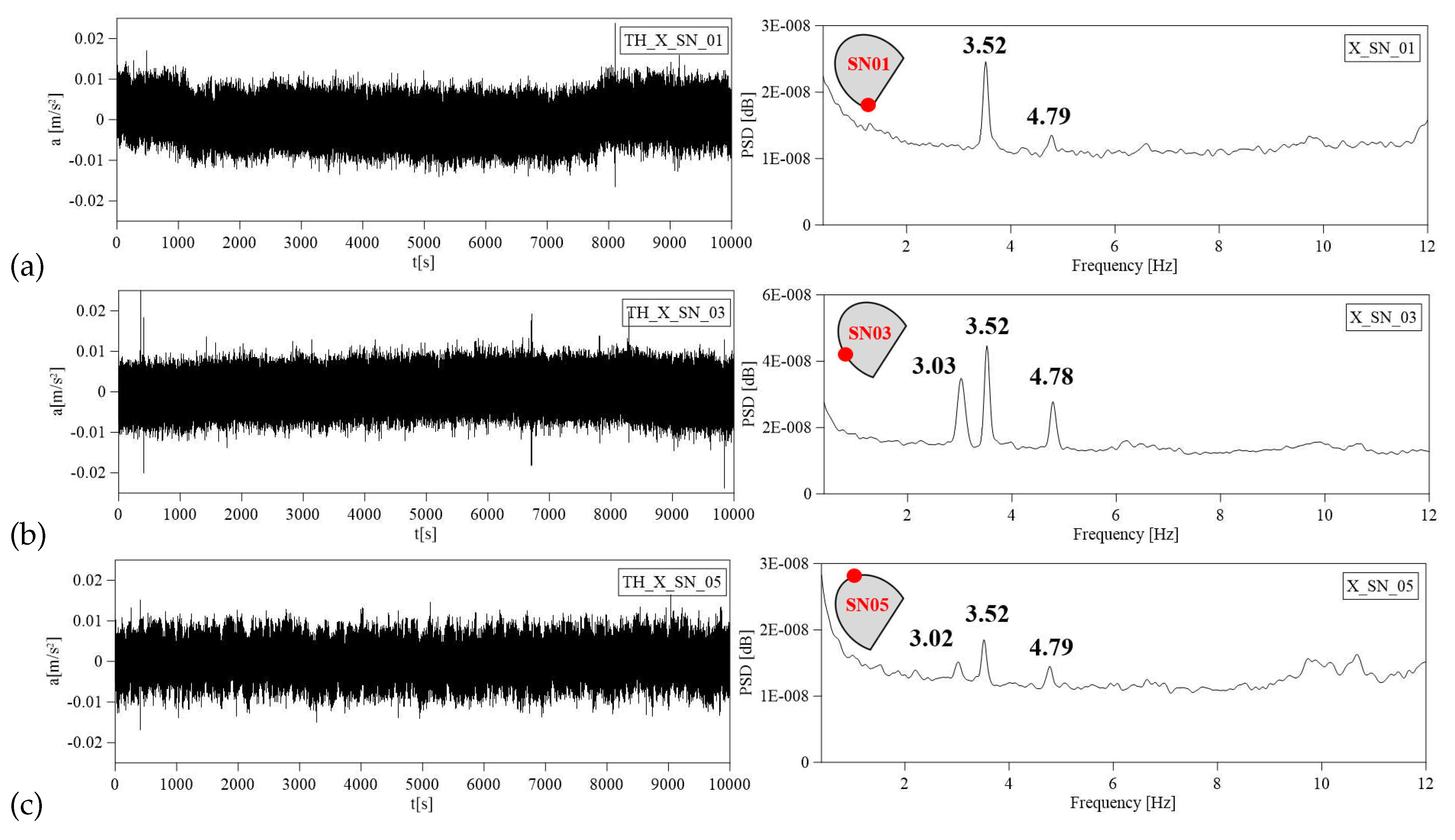

The continuous measurements were recorded and stored from 13

th of July and a preliminary elaboration was made considering the reference period 05:00 - 07:00 a.m. local time, 14

th of July 2023. Data transmission and storage enable efficient retrieval, analysis, and long-term usability. Collected data has been transmitted from sensors to a central data acquisition system, and finally are accessible on the Data Repository where has been stored and organized in a folder structure. The access control is guaranteed through security permission to restrict unauthorized access. The sampling frequency is

and each data point is time-stamped to accurately record when the measurement was taken. Time synchronization ensures proper alignment of data from different sensors. The accelerometer data is organized into folders, each corresponding to a specific accelerometer. Within each folder, there are sub-folders containing one-hour periods of data in .csv files. All the files are named according to the format "sensor ID_starting timestamp_final timestamp", this ensures a clear hierarchy and easy chronological sorting. Power spectrums were computed from the time domain measurements of the accelerometers using Welch’s method with a block size of 2048 points and a 50% overlap. The time history and power spectra from 0 to

from the MEMS accelerometers are shown in

Figure 11, for the 3 sensors lying on the upper level of the drum, respectively (a) SN01, (b) SN03, and (c) SN05. The PSD results provide the dominant frequencies present in the structure’s response derived from the acceleration signals. The acquired acceleration time series have been processed also through a Classical - Data Driven procedure, the Stochastic Subspace Identification (SSI) in the time domain, which allows identifying the stable modes, [

30,

31].

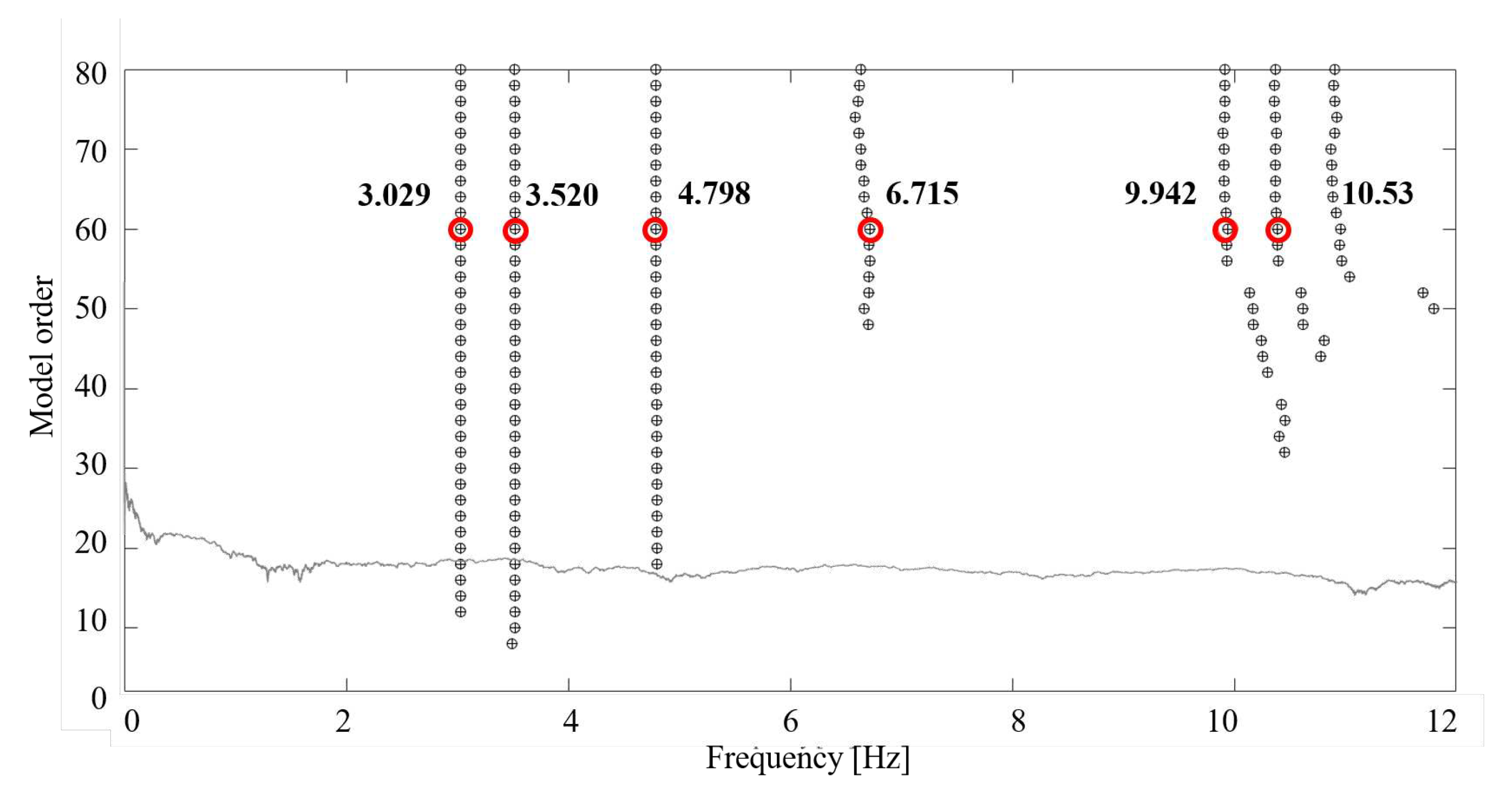

Figure 12 shows the stabilization graphs refer to SSI-reference-based (

is the sensor chosen as reference), obtained using only sensors laying in the upper cover of the structure, [

32,

33]. The frequencies, that could be related to the natural modes of vibration are highlighted with red circles for a model order equal to 60. A total of 16 SSI-reference-based processing of the recorded data have been used selecting different combinations of sensors chosen as reference. According to the frequencies identified in the PSD plots, the first mode of the structure is located at about

, and it shows ua translation in the Y direction. A second mode can be observed at about

, translation in X direction. A third mode can be observed at about

and is a torsional mode. The achieved results are listed in

Table 4, PSD, and

Table 5, reference-based SSI.

4.1. Comparison with Commercial Technology

As mentioned in the previous

Section 4, a short-term dynamic test under ambient vibration has been carried out using Lunitek Triton Accelerograph Force-Balance sensors. Triton-A is an integrated data acquisition system plus sensor conceived with high performance (high signal resolution and very low noise levels at extremely low frequencies), and an available dynamic range of about

. A Force Balance (FB) accelerometer uses a mass suspended by an electrical equivalent mechanical spring, a position detector, an amplifier, and an electromechanical system to convert a mechanical force into a proportional current. The position detector tracks the mass position, which is paired with the force generator, and returns it to its original position if an external force changes it. The FB accelerometer can deliver exceptional performance and accuracy but, typically, these sensors have a large footprint and are very expensive. The experimental setup consists of six FB sensor nodes, two for a single column that supports the hall’s dome, involving the first, the third, and the fourth column. The test duration is one hour of recording, and the sampling frequency is

. To analyze the frequency content of the acceleration signals both the PSD, and the Covariance-Driven Stochastic Subspace Identification, SSI-COV have been computed to detect the stable modes. The results of the short-term dynamic test using commercial accelerometers have been listed in

Table 6 (PSD) and

Table 7 (SSI-COV). This last gives an overview of the different elaborations that were made using several selected sensors as the reference ones. The proposed MEMS must be evaluated in terms of performance, accuracy, and reliability by comparing its frequency response with FB accelerometers.

Table 8 presents a summary of the frequencies obtained from both technologies, MEMS and FB, including their mean value and standard deviation. It is important to note that the frequencies obtained from high-performance MEMS devices match those obtained from force balance accelerometers. Although traditional commercial FB accelerometer has superior frequency response range, precision, and dynamic range, the proposed high-performance MEMS accelerometer provides a reliable and accurate alternative that is compact and cost-effective.

6. Conclusions

The paper illustrated the capabilities and peculiarities of innovative high-performance sensor nodes used for SHM purposes. A low-noise triaxial MEMS accelerometer has been embedded in such a device to record both very low amplitude accelerations (induced for example by ambient noise but also traffic or crowd) and the ones seismic-induced. The authors leveraged their experience from previous research projects to design, deploy, and manage a single sensor and all networks. Improvements have been carried out in the complete communication chain: sensors, hardware, and software architecture. Regarding the sensor, a SHM-Board v3 has been designed, which includes an ultra-low-power microcontroller. This microcontroller is capable of providing numerous high-performance interfaces, as well as onboard data processing to minimize the total amount of data that needs to be transmitted. Another important aspect is the choice of the MEMS accelerometer model (analog device ADXL354). This model can capture the experimental modal features that are useful for interpreting the actual health of the monitored structure. In terms of hardware and software architecture, the most important enhanced features are related to the data coordinator of a local aggregator (gateway), which helps to manage the data acquisition system efficiently by controlling the timing and storage of data. Additionally, a more efficient programming language is required, especially for data collection and processing. After implementing the sensors, the performance of the entire network, consisting of six sensors, was tested and calibrated both in the laboratory and in real-world scenarios. During the lab experiment, the accelerations generated by a shaker with high and low amplitude were compared with the readings from a reference accelerometer, which showed good agreement. Subsequently, the network was utilized for the long-term continuous Structural Health Monitoring of the Marcus Aurelius Exedra Hall. The positions of the sensor nodes have been carefully chosen based on the modal shapes observed by a preliminary Finite Element Method model. The acceleration obtained from ambient noise has been utilized to determine the main modal characteristics of the structures and compare them with the ones identified through commercial technology. In this verification, the comparison shows acceptable results. Finally, a manual model updating of the numerical model has been carried out. This work aims to highlight the steps for setting up an in-house SHM sensors network, with a focus on communication technologies.

The following abbreviations are used in this manuscript:

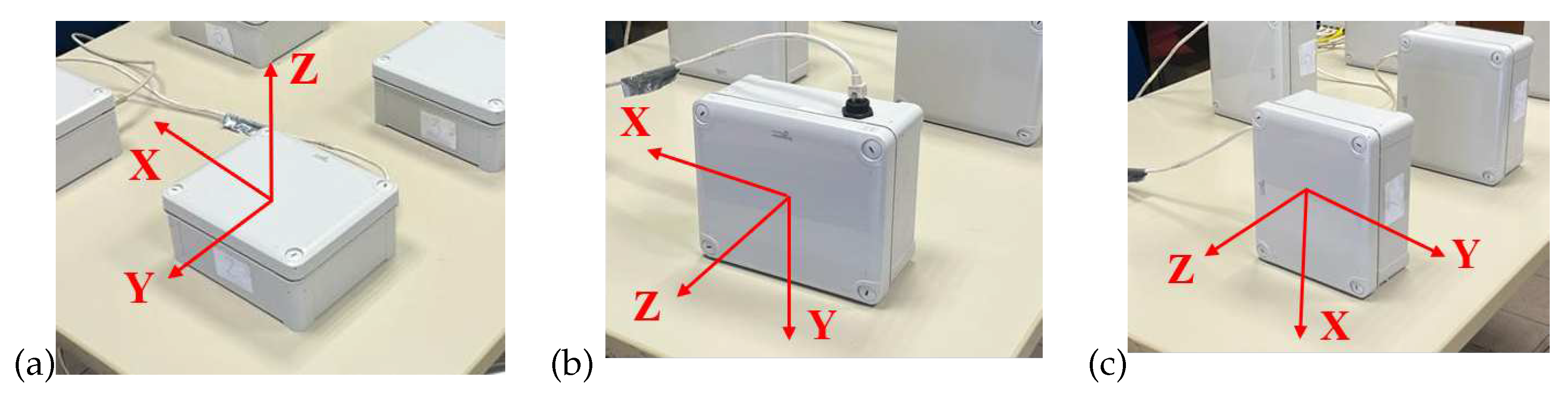

Figure 1.

The sensor node SHM-Board v3: (a) Layout of the SHM-board v3, (b) MEMS’ operating scheme and (a) IP68-watertight sealing.

Figure 1.

The sensor node SHM-Board v3: (a) Layout of the SHM-board v3, (b) MEMS’ operating scheme and (a) IP68-watertight sealing.

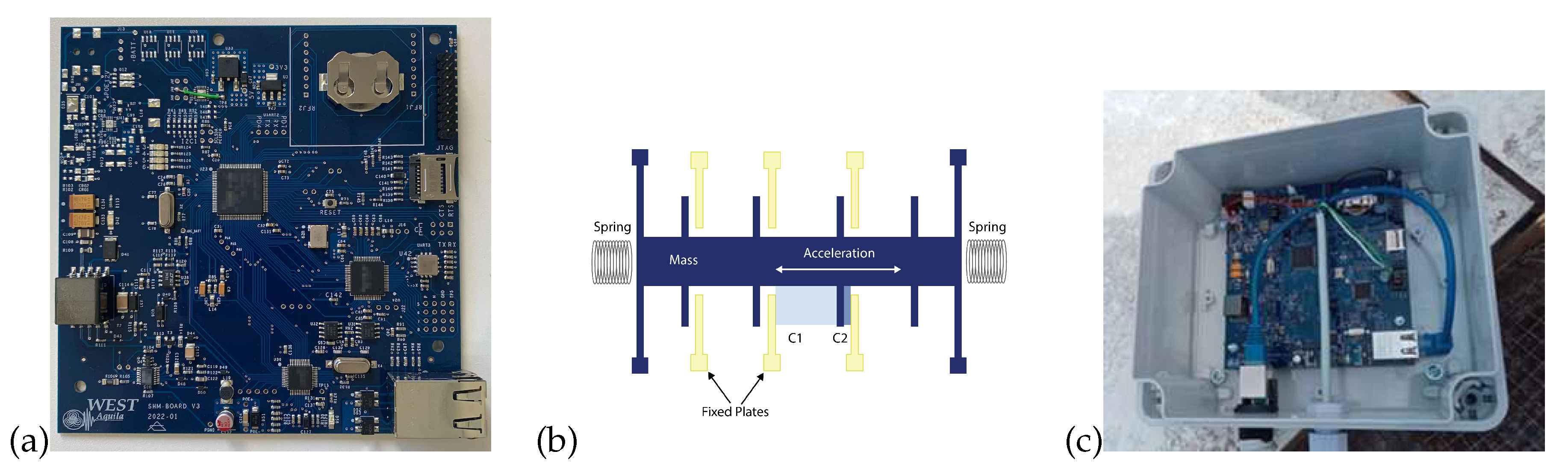

Figure 2.

Gateway node of the sensors’ system.

Figure 2.

Gateway node of the sensors’ system.

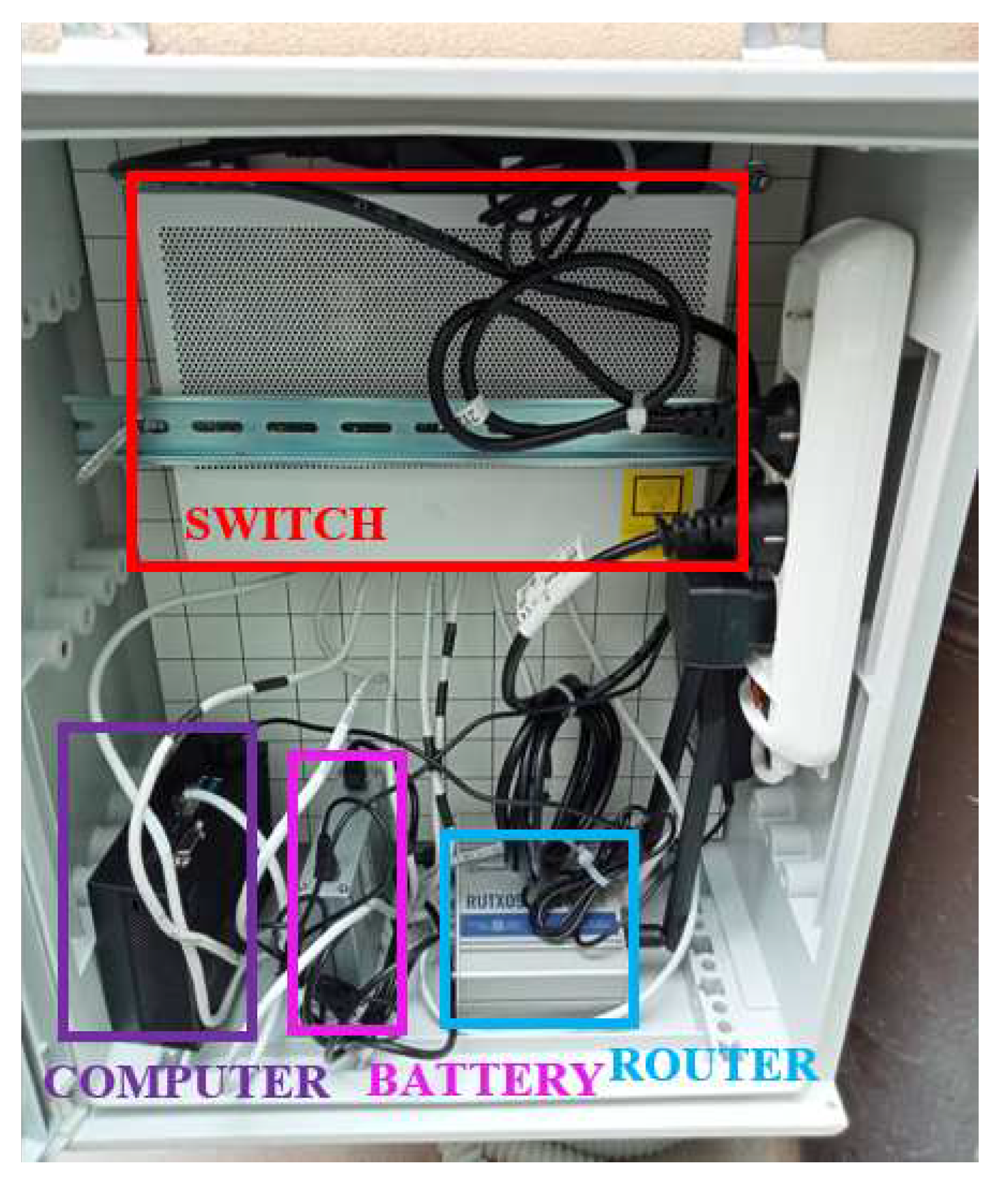

Figure 3.

System architecture

Figure 3.

System architecture

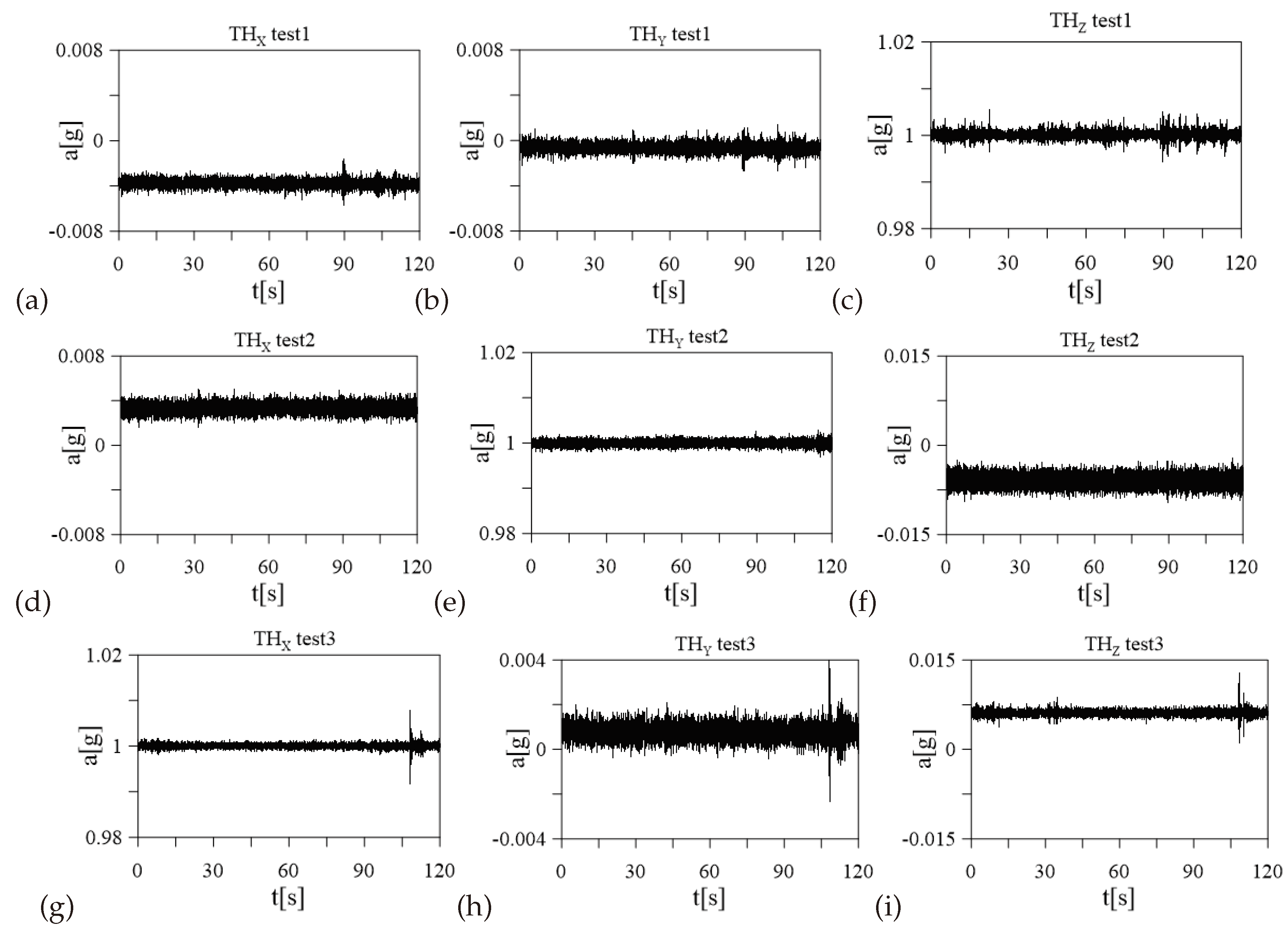

Figure 5.

Time histories of the accelerometers of the SN01: (a) test 1 X-axis, (b) test 1 Y-axis, (c) test 1 Z-axis, (d) test 2 X-axis, (e) test 2 Y-axis, (f) test 2 Z-axis, (g) test 3 X-axis, (h) test 3 Y-axis, and (i) test 3 Z-axis.

Figure 5.

Time histories of the accelerometers of the SN01: (a) test 1 X-axis, (b) test 1 Y-axis, (c) test 1 Z-axis, (d) test 2 X-axis, (e) test 2 Y-axis, (f) test 2 Z-axis, (g) test 3 X-axis, (h) test 3 Y-axis, and (i) test 3 Z-axis.

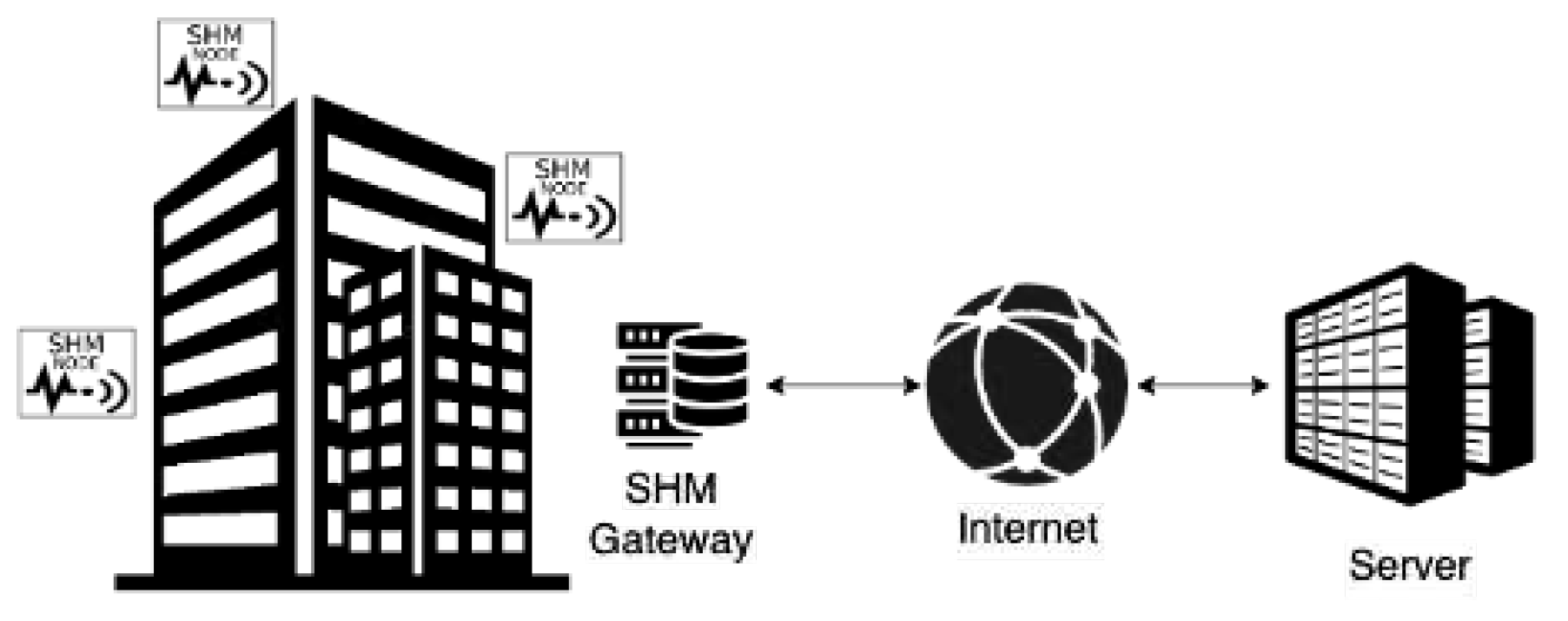

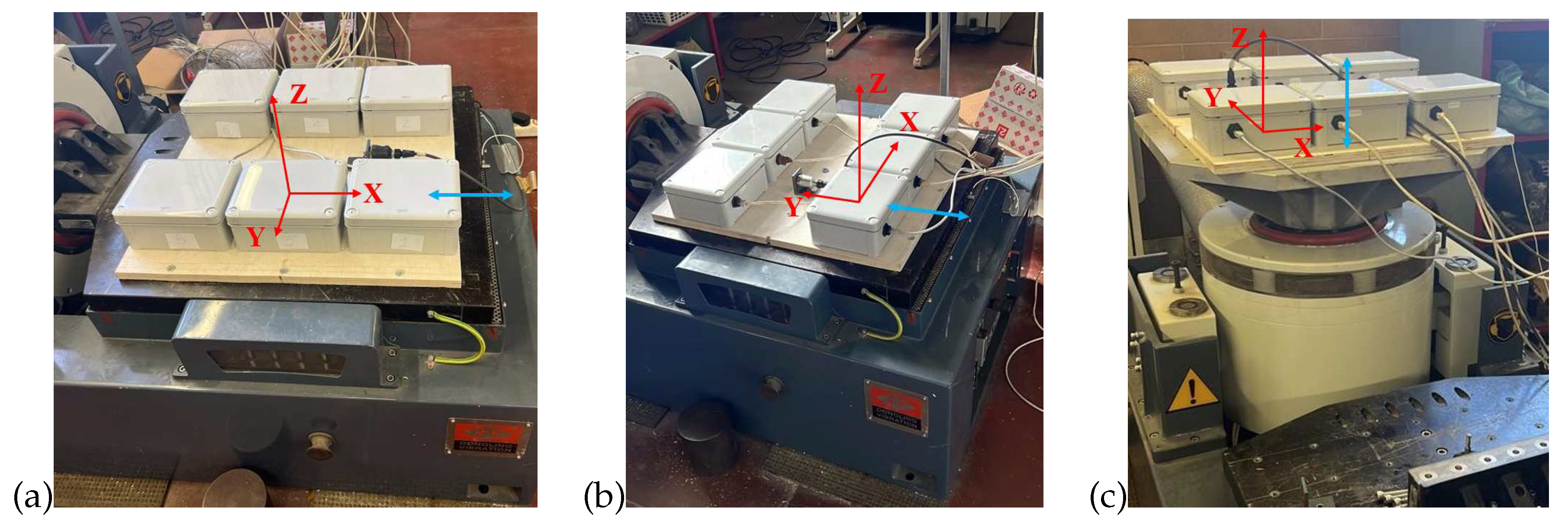

Figure 6.

Dynamic tests’ setup: (a) X-axis, (b) Y-axis, and (c) Z-axis

Figure 6.

Dynamic tests’ setup: (a) X-axis, (b) Y-axis, and (c) Z-axis

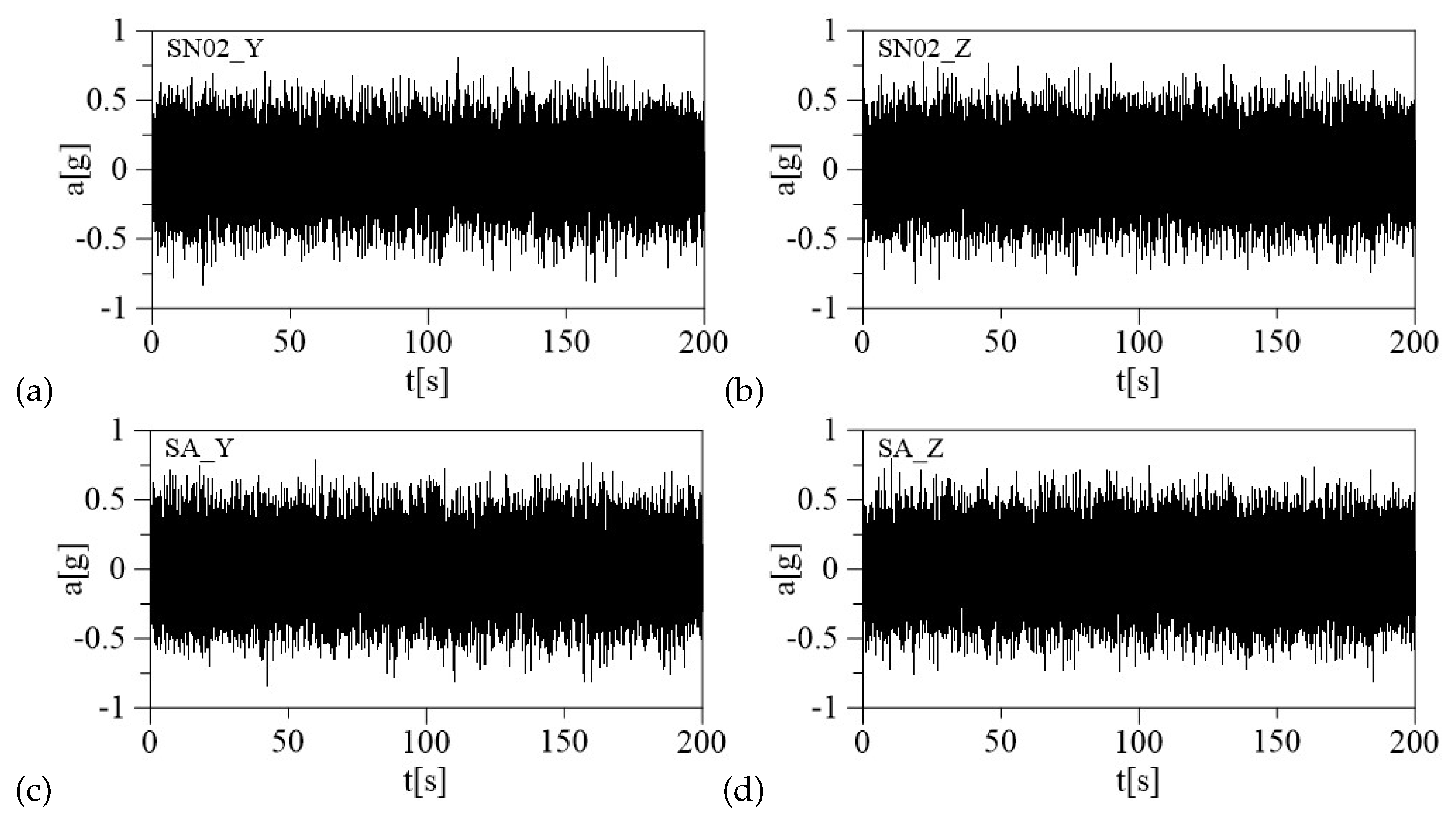

Figure 7.

Comparison between the time histories of the accelerometers in blue and the reference device in orange for the SN01: (a) test 1 X-axis, (b) test 1 Y-axis, (c) test 1 Z-axis, and (d) test 2 X-axis.

Figure 7.

Comparison between the time histories of the accelerometers in blue and the reference device in orange for the SN01: (a) test 1 X-axis, (b) test 1 Y-axis, (c) test 1 Z-axis, and (d) test 2 X-axis.

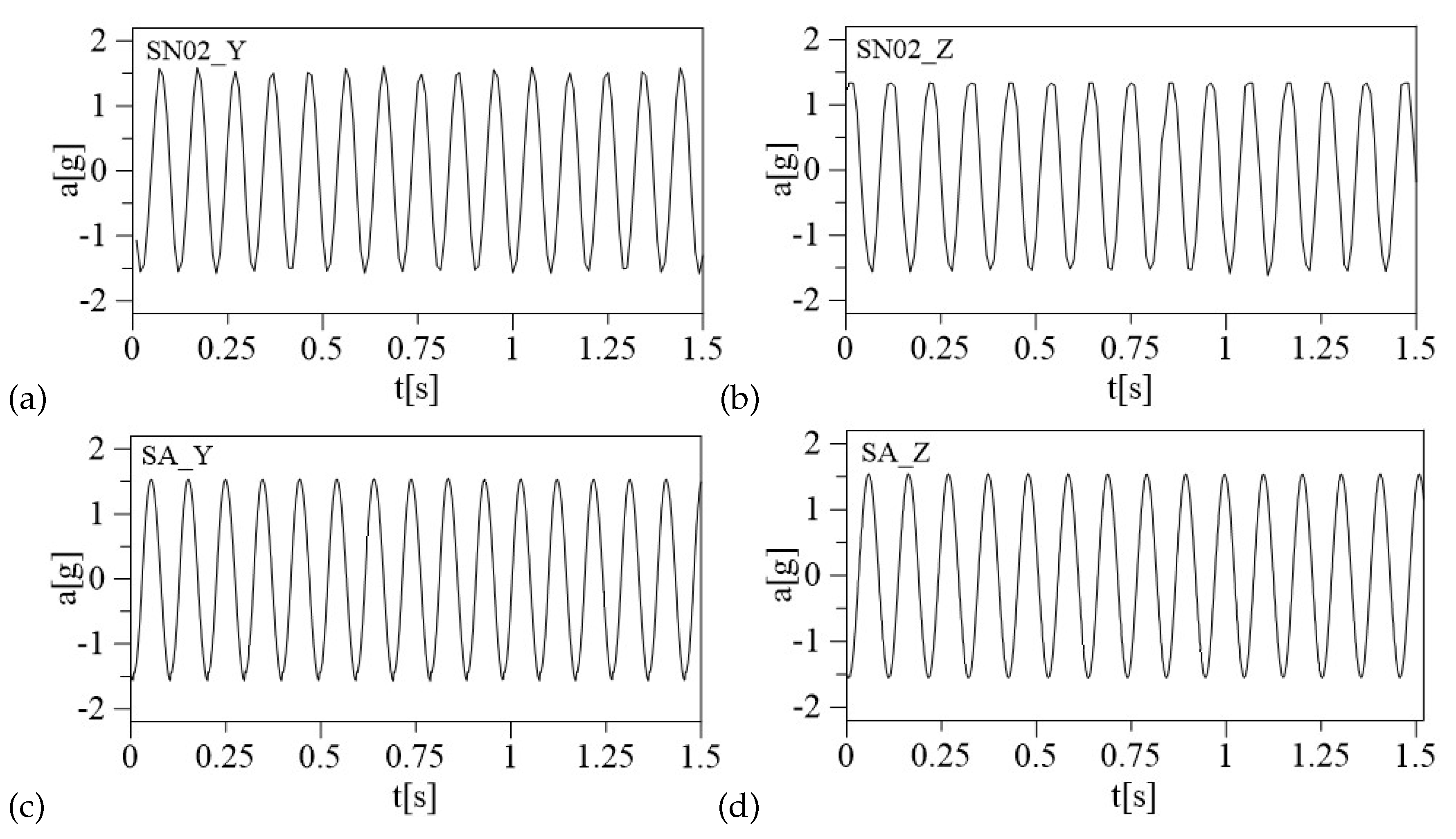

Figure 8.

Comparison between the time histories of the accelerometers in blue and the reference device in orange for the SN01: (a) test 1 X-axis, (b) test 1 Y-axis, (c) test 1 Z-axis, and (d) test 2 X-axis.

Figure 8.

Comparison between the time histories of the accelerometers in blue and the reference device in orange for the SN01: (a) test 1 X-axis, (b) test 1 Y-axis, (c) test 1 Z-axis, and (d) test 2 X-axis.

Figure 9.

Images of the Hall of Marcus Aurelius: (a) top view of the roof, and (b) elliptical structure of the Hall. © Sovrintendenza Capitolina

Figure 9.

Images of the Hall of Marcus Aurelius: (a) top view of the roof, and (b) elliptical structure of the Hall. © Sovrintendenza Capitolina

Figure 10.

Long-term monitoring system setup: (a) general setup view, (b) in-plane view setup, and (c) orientation of the sensors. © Sovrintendenza Capitolina

Figure 10.

Long-term monitoring system setup: (a) general setup view, (b) in-plane view setup, and (c) orientation of the sensors. © Sovrintendenza Capitolina

Figure 11.

Dynamic response TH and PSD: (a) SN01, (b) SN03, and c) SN05

Figure 11.

Dynamic response TH and PSD: (a) SN01, (b) SN03, and c) SN05

Figure 12.

Stabilization diagram from SSI-COV reference-based considering all the available sensors laying in the upper cover.

Figure 12.

Stabilization diagram from SSI-COV reference-based considering all the available sensors laying in the upper cover.

Figure 13.

Calibration of the spring coefficients considering the influence of the buildings surrounding the main Hall.

Figure 13.

Calibration of the spring coefficients considering the influence of the buildings surrounding the main Hall.

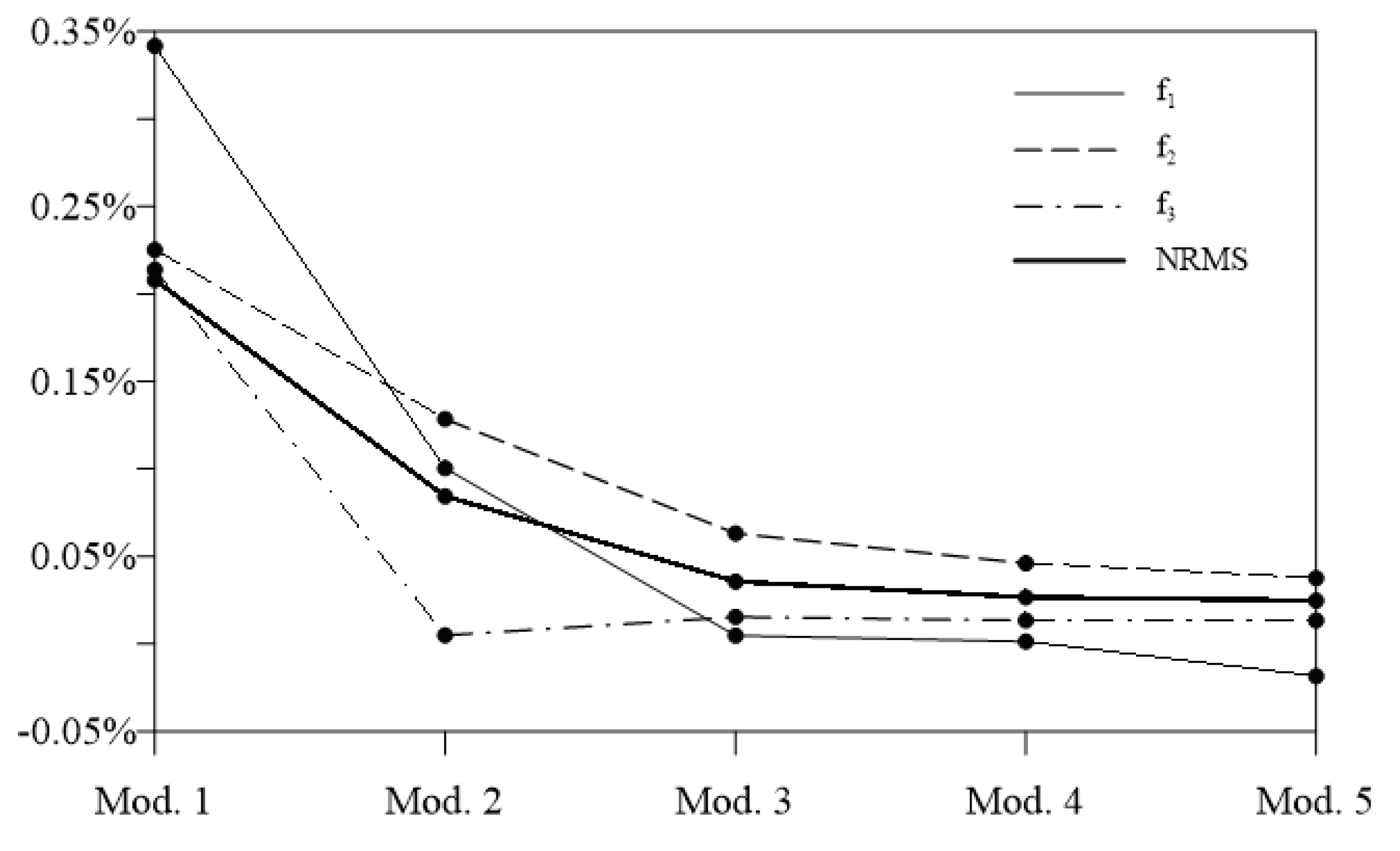

Figure 14.

Finite element (manual) model updating based on the frequencies.

Figure 14.

Finite element (manual) model updating based on the frequencies.

Table 1.

Offset and scale factor (1.0E+06) in X-Y-Z, calculated for each sensor node.

Table 1.

Offset and scale factor (1.0E+06) in X-Y-Z, calculated for each sensor node.

| Sensors’ID |

X-Offset |

X-Scale |

Y-Offset |

Y-Scale |

Z-Offset |

Z-Scale |

| SN01 |

1.8285 |

-0.8119 |

1.8121 |

-0.8036 |

1.8743 |

0.7613 |

| SN02 |

1.8600 |

-0.8515 |

1.8387 |

-0.8411 |

1.8868 |

0.7953 |

| SN03 |

1.8538 |

-0.8431 |

1.8359 |

-0.8286 |

1.8991 |

0.7730 |

| SN04 |

1.8251 |

-0.8200 |

1.8118 |

-0.8150 |

1.8824 |

0.7472 |

| SN05 |

1.8301 |

-0.8227 |

1.8297 |

-0.8095 |

1.8905 |

0.7669 |

| SN06 |

1.8552 |

-0.8445 |

1.8366 |

-0.8322 |

1.9107 |

0.7718 |

Table 2.

Comparison between MEMS accelerometer readings and the shaker reference accelerometer - random excitation test ().

Table 2.

Comparison between MEMS accelerometer readings and the shaker reference accelerometer - random excitation test ().

| Sensors’ID |

Y-StD ref. |

Y-StD MEMS |

Y-StD [%] |

Z-StD ref. |

Z-StD MEMS |

Z-StD [%] |

| SN01 |

0.2097 |

0.2059 |

-1.82 |

0.2106 |

0.2159 |

2.47 |

| SN02 |

0.2095 |

0.2161 |

3.04 |

0.2105 |

0.2238 |

5.92 |

| SN03 |

0.2097 |

0.2114 |

0.79 |

0.2106 |

0.2206 |

4.52 |

| SN04 |

0.2097 |

0.2087 |

-0.46 |

0.2105 |

0.2122 |

0.78 |

| SN05 |

0.2102 |

0.2070 |

-1.53 |

0.2106 |

0.2154 |

2.22 |

| SN06 |

0.2097 |

0.2133 |

1.65 |

0.2105 |

0.2152 |

2.17 |

Table 3.

Comparison between MEMS accelerometer readings and the shaker reference accelerometer - sine excitation test ().

Table 3.

Comparison between MEMS accelerometer readings and the shaker reference accelerometer - sine excitation test ().

| Sensors’ID |

Y-StD ref. |

Y-StD MEMS |

Y-StD [%] |

Z-StD ref. |

Z-StD MEMS |

Z-StD [%] |

| SN01 |

1.0669 |

1.0499 |

-1.62 |

1.0733 |

1.0426 |

-2.94 |

| SN02 |

1.0669 |

1.1032 |

3.29 |

1.0737 |

1.0767 |

0.28 |

| SN03 |

1.0660 |

1.0781 |

1.12 |

1.0737 |

1.0604 |

-1.26 |

| SN04 |

1.0660 |

1.0622 |

-0.35 |

1.0733 |

1.0269 |

-4.52 |

| SN05 |

1.0661 |

1.0506 |

-1.47 |

1.0727 |

1.0362 |

-3.52 |

| SN06 |

1.0660 |

1.0840 |

1.66 |

1.0737 |

1.0089 |

-6.42 |

Table 4.

MEMS Identified frequencies (in Hz) via PSD, using 14/07/2023 05:00 - 07:00 am

Table 4.

MEMS Identified frequencies (in Hz) via PSD, using 14/07/2023 05:00 - 07:00 am

| |

SN01 |

SN02 |

SN03 |

SN04 |

SN05 |

SN06 |

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3.02 |

3.01 |

- |

3.02 |

- |

3.02 |

- |

3.03 |

3.03 |

3.03 |

3.02 |

3.03 |

|

3.51 |

- |

3.51 |

- |

3.52 |

- |

3.53 |

- |

3.52 |

3.51 |

3.53 |

3.50 |

|

4.79 |

4.80 |

4.77 |

- |

4.77 |

- |

- |

- |

4.79 |

4.45 |

4.78 |

- |

|

6.77 |

6.39 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

|

- |

- |

- |

- |

- |

- |

- |

9.65 |

- |

9.57 |

- |

- |

|

- |

- |

- |

10.77 |

- |

10.40 |

- |

- |

- |

10.65 |

- |

10.69 |

Table 5.

MEMS Identified frequencies (in Hz) via reference-based SSI, 14/07/2023 05:00 - 07:00 am.

Table 5.

MEMS Identified frequencies (in Hz) via reference-based SSI, 14/07/2023 05:00 - 07:00 am.

| |

|

|

|

|

|

|

| All 12 |

3.04 |

3.54 |

- |

- |

- |

- |

| Ref. , , |

3.04 |

3.53 |

4.83 |

6.73 |

10.22 |

10.59 |

| Ref. , |

- |

3.49 |

- |

- |

- |

10.43 |

| Ref. , |

3.03 |

3.52 |

4.82 |

6.81 |

10.05 |

10.68 |

| Ref. , |

3.03 |

3.52 |

4.79 |

6.76 |

9.87 |

10.56 |

| Ref. |

3.03 |

3.52 |

4.79 |

6.76 |

9.87 |

10.37 |

| Ref. |

- |

3.52 |

4.76 |

6.74 |

9.97 |

10.51 |

| Ref. |

3.03 |

3.52 |

4.80 |

- |

9.99 |

10.54 |

| All 6 |

3.00 |

3.51 |

- |

- |

- |

10.64 |

| Ref. , , |

3.03 |

3.53 |

4.82 |

6.72 |

- |

10.64 |

| Ref. , |

3.02 |

3.52 |

4.80 |

6.65 |

9.99 |

10.73 |

| Ref. , |

3.03 |

3.520 |

4.81 |

6.73 |

9.95 |

10.41 |

| Ref. , |

3.02 |

3.51 |

4.80 |

6.72 |

9.96 |

10.58 |

| Ref. |

3.03 |

3.52 |

4.80 |

6.71 |

9.94 |

10.53 |

| Ref. |

- |

3.52 |

4.76 |

6.73 |

- |

10.31 |

| Ref. |

3.03 |

3.52 |

4.79 |

- |

10.71 |

- |

Table 6.

FB Identified frequencies (in Hz) via PSD, 19/12/2022 10:30 - 11:00 am

Table 6.

FB Identified frequencies (in Hz) via PSD, 19/12/2022 10:30 - 11:00 am

| |

SN050 |

SN051 |

SN052 |

SN054 |

SN490 |

SN491 |

|

| |

N |

E |

N |

E |

N |

E |

N |

E |

N |

E |

N |

E |

|

|

3.05 |

3.05 |

2.99 |

2.99 |

2.99 |

|

2.8 |

2.92 |

- |

- |

2.99 |

2.99 |

|

|

3.47 |

3.54 |

3.54 |

3.54 |

3.54 |

3.54 |

3.54 |

3.66 |

- |

- |

3.47 |

3.47 |

|

|

4.45 |

- |

- |

- |

4.45 |

4.45 |

- |

- |

- |

- |

- |

- |

|

|

- |

- |

4.51 |

- |

- |

4.51 |

- |

- |

- |

- |

4.51 |

|

|

|

- |

4.76 |

- |

4.76 |

4.76 |

- |

- |

- |

- |

- |

4.76 |

4.76 |

|

|

6.71 |

6.71 |

- |

- |

- |

6.71 |

- |

- |

- |

- |

6.71 |

6.71 |

|

Table 7.

FB Identified frequencies (in Hz) via SSI-COV, 19/12/2022 10:30 - 11:00 am

Table 7.

FB Identified frequencies (in Hz) via SSI-COV, 19/12/2022 10:30 - 11:00 am

| |

Ref SN050 |

Ref SN051 |

Ref SN052 |

Ref All |

|

3.04 |

3.06 |

3.01 |

3.07 |

|

3.51 |

3.51 |

3.50 |

3.43 |

|

- |

- |

- |

- |

|

4.51 |

- |

- |

- |

|

- |

4.82 |

4.81 |

- |

|

- |

- |

6.29 |

- |

Table 8.

Mean value and standard deviation of the frequencies (Hz) identified from short-term dynamic testing using FB and high-performance MEMS accelerometers.

Table 8.

Mean value and standard deviation of the frequencies (Hz) identified from short-term dynamic testing using FB and high-performance MEMS accelerometers.

| |

19/12/2022 - FB acc. |

14/07/202 - MEMS acc. |

| |

SSI |

PSD |

SSI |

PSD |

|

3.043 ± 0.026 |

2.974 ± 0.076 |

3.029 ± 0.011 |

3.023 ± 0.008 |

|

3.486 ± 0.039 |

3.531 ± 0.056 |

3.520 ± 0.009 |

3.516 ± 0.008 |

|

4.821 ± 0.177 |

4.760 ± 0.001 |

4.798 ± 0.021 |

4.737 ± 0.126 |

|

6.733 ± 0.037 |

6.579 ± 0.264 |

6.291 ± 0.001 |

6.712 ± 0.001 |

Table 9.

Optimal FE model.

Table 9.

Optimal FE model.

| |

1st mode [%] |

2nd mode [%] |

3rd mode [%] |

NRMS |

| Mod.1 |

4.06 |

4.31 |

5.75 |

0.2079 |

| Mod.2 |

3.33 |

3.97 |

4.76 |

0.0843 |

| Mod.3 |

3.04 |

3.74 |

4.81 |

0.0355 |

| Mod.4 |

3.03 |

3.68 |

4.80 |

0.0265 |

| Mod.5 |

2.97 |

3.65 |

4.80 |

0.0247 |