1. Introduction

Carbon Fiber Reinforced Polymers (CFRPs) find extensive applications in the aerospace, aviation, automotive, and energy sectors [

1,

2]. CFRPs are preferred due to their remarkable specific strength, high modulus, and oxidation resistance, often outperforming traditional, heavier metals. This material choice is associated with expected weight savings, reducing fuel consumption, and environmental benefits. However, CFRPs currently suffer from resource inefficiency, involving high energy demands during manufacturing and limited recycling options, resulting in a significant portion of composites ending up in landfills [

3,

4]. The continuous rise in regulations, increasing landfill expenses, and the growing desire for lightweight structures have intensified the need to find methods to recycle composites, and particularly thermosets CFRPs [

5,

6]. Current recycling methods for CFRPs can be broadly classified into three main categories: mechanical, chemical, and thermal methods. Mechanical recycling involves grinding the CFRP to convert them into particles that can be used again in the manufacturing section. Thermal methods rely on elevated temperatures required for the polymer matrix to undergo vaporization, leaving behind recoverable fibers. Chemical processes use solvents to chemically break down the polymers, preserving the fibers for future use [

7]. Mechanical and pyrolysis processes were the primary methods identified for treating composite waste. However, these methods have limitations when it comes to recovering carbon fibers with mechanical properties comparable to those of virgin carbon fibers [

8]. Modern recycling methods mainly use pyrolysis, a process that, while recovering carbon fibers as a valuable resource, has disadvantages such as significant energy consumption and the production of brittle fibers that are not suitable for textile applications [

9].

In recent years, chemical degradation has emerged as the most promising method for recycling CFRPs, offering the potential to recover residual value from both fibers and chemicals [

10]. It is imperative to enhance chemical recycling technology to make it applicable to a wide range of uses in order to become an asset for resource recovery and reduction of environmental impact. Promising solvents for chemical treatment include water, acetone, and alcohols. In particular, water and alcohols stand out due to their environmental friendliness, wide availability, cost-effectiveness, and low toxicity [

11]. For instance, water can be classified as an environmentally friendly reaction medium due to its ready availability, cost-effectiveness, and low potential for toxicity. As a primary solvent, water effectively breaks down the epoxy resin, releasing the virgin fibers under varying decomposition conditions [

12]. Also, supercritical acetone offers several advantages, notably its proximity to the Hansen solubility parameter of epoxy resin and its effective solvent capability for epoxy resin degradation [

13]. Chemical recycling and in particular solubilization using water and acetone as solvents has been investigated in recent years. Kim et al. [

14] investigated solvolysis using water as a solvent (hydrolysis) in supercritical conditions specifically at temperature 405 ± 2 °C, pressure 280 ± 10 bar, and reaction times of 10, 30, 60, and 120 minutes. They observed that the elimination efficiency of resin was over 99% when the reaction time was 120 minutes. Yuyan et al. [

12] achieved a complete decomposition using water in subcritical conditions. Furthermore, the tensile measurements of single fibers showed that the reclaimed fibers exhibited only a 1.8% reduction in tensile strength compared to the virgin fibers. Okajima and Sako [

13] investigated the removal of epoxy resin using acetone under superheated and supercritical conditions at 350°C, with the decomposition efficiency increasing with reaction time up to 60 min to a maximum of 95.6%. Sokoli et al. [

15] investigated the degradation of hybrid fiber composites using near-critical water or supercritical acetone. Notably, under specific conditions, supercritical acetone demonstrated the ability to achieve almost complete resin degradation more specifically at a temperature of 280°C, pressure of 70 bar, and reaction time of 30 minutes. Furthermore, carbon fibers were effectively retrieved with no significant loss in tensile strength when either water or acetone was used. Okajima et al. [

16] explored the chemical recycling of CFRP using supercritical alcohols or ketones as solvents, with optimal degradation achieved through supercritical acetone at a temperature 320°C and reaction time of 20 minutes, and the recovered carbon fibers maintained their original shape and exhibited minimal tensile strength reduction.

The growth of CFRP production has increased the challenge of efficient recycling, requiring sustainable methods to address environmental problems. Current recycling practices, such as mechanical grinding and pyrolysis, have limitations in recovering carbon fibers with mechanical properties comparable to virgin fibers. Recognizing this gap in achieving integrated recycling, our research focuses on solvolysis as a promising route. In the present work, CFRP samples were subjected to solvolysis using supercritical and subcritical water and supercritical acetone. The main objective of the work was to examine the different solvolysis conditions, including the temperature, the pressure, and the reaction duration, which were applied without the use of catalysts. Maintaining a constant loading rate, defined as the volume of solvent relative to the reactor volume, a controlled and reproducible methodology was established. In addition, the effectiveness of the chemical recycling process was assessed by measuring the efficiency of the epoxy resin removal and characterizing the morphology and the mechanical behaviour of the recovered fibers by novel single-fiber tension tests. These developments significantly enhance the field of CFRP recycling, thus providing a deeper insight into the solvolysis process and its influence on material recovery.

2. Experimental

2.1. Materials

The CFRPs were supplied by KVE Composites Group ([0]8) and the unidirectional carbon prepregs (Sigrapreg C U600-0/SD-E501-33%) were manufactured by SGL Carbon. The resin matrix (E501) is an epoxy, and the resin mass content was found to be 33%. The carbon fibers (SIGRAFIL C T50-4.0/240-E100) had a filament diameter of 7.0 μm. To conduct the solvolysis experiments, the specimens were cut into the dimensions of 30 mm x 50 mm using a milling cutter. The thickness of the specimens was 4 mm.

2.2. Solvolysis Tests

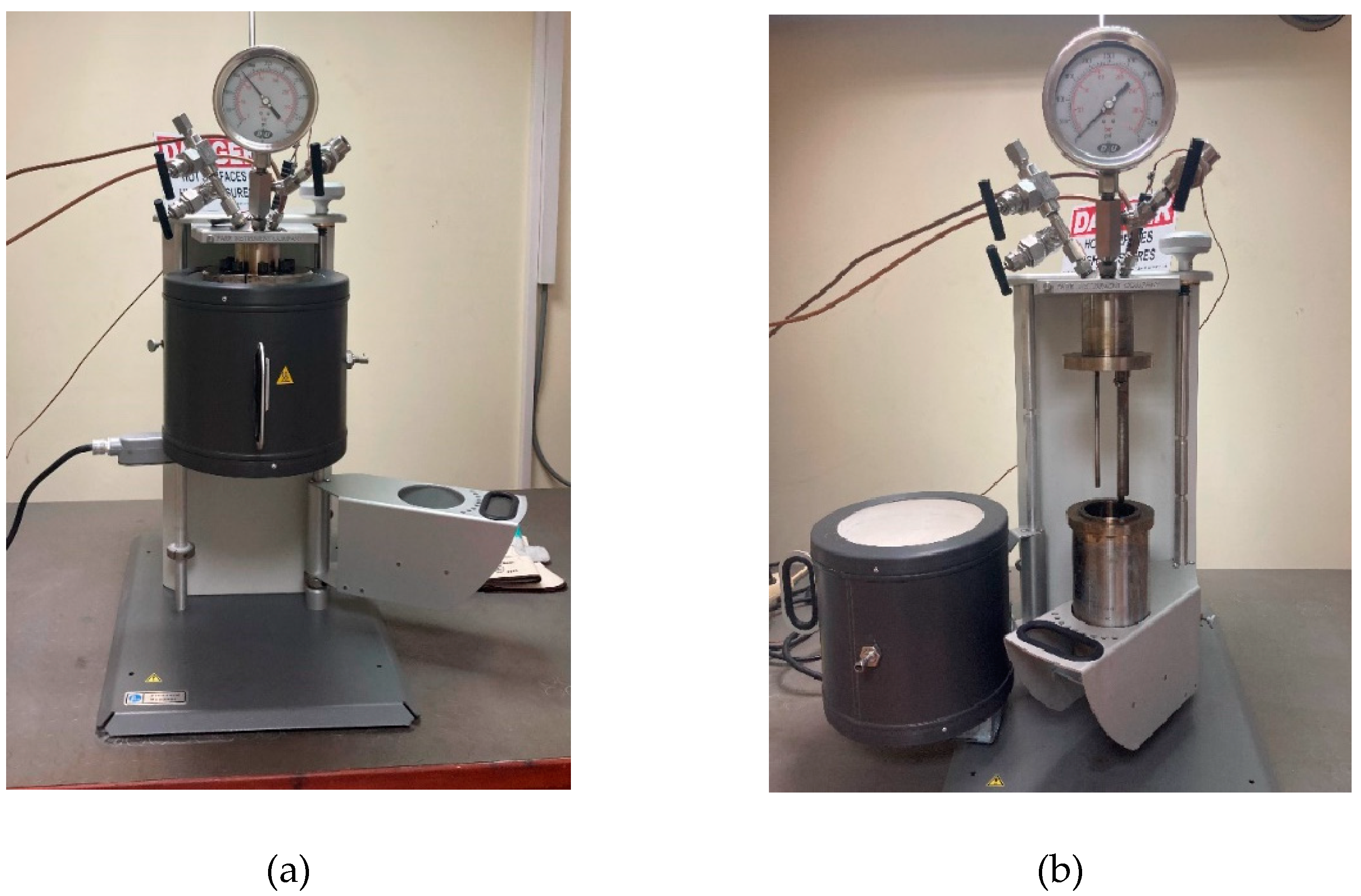

The epoxy resin in the CFRPs was decomposed using a non-stirred batch reactor (Parr Instrument Company) shown in

Figure 1. The reactor’s vessel is a high-pressure/high-temperature vessel with a 500 mL total volume capacity. The sample was put into the vessel at a loading rate (volume of solvent/reactor volume) of 0.6. The solvolysis tests were conducted using CFRP samples subjected to supercritical and subcritical water and supercritical acetone. The selection of water and acetone as solvents was based on their environmental friendliness, wide availability, cost-effectiveness, and low toxicity, as discussed in the introduction. Five experiments were conducted with a 300 ml solvent. Initially, the system was slowly heated to reach the target temperature. Subsequently, after the predetermined duration (reaction time) of each experiment, the system was cooled down to room temperature through a cooling system (with the use of tap water). In the first series of experiments (#01-03), de-ionized water was used as a solvent under various conditions, and in the last two experiments (#04-05) acetone was used in supercritical conditions. The testing conditions are listed in

Table 1. After the cooling, the reactor was unsealed, and the fibers, along with the liquid fraction containing the dissolved organic products resulting from the degraded resin, were collected, and retrieved. Stringent safety precautions, including the use of personal protective equipment (such as gloves and safety glasses) and adequate ventilation, were implemented throughout the experimental procedures. A fume hood cupboard was used for ventilation to actively protect the operator from inhalation of toxic vapors due to resin decomposition. Also, safety and emergency equipment, such as fire extinguishers and first aid kit, is available in the laboratory.

2.3 Characterization of the Recovered Fibers

The resin decomposition efficiency (RDF) was measured in terms of mass. The RDF is defined as the ratio of the resin mass separated from the fibers to the total mass of the resin before recycling. The RDF is calculated using the resin content of the sample, the mass of each sample before the solvolysis experiment, and the mass of the solid residue after recycling [

12,

17] by:

where

is the mass of the composite,

is the mass of the solid residue and

is the mass of the resin in the composite.

The recycled fiber samples underwent thorough analysis using a Scanning Electron Microscope (SEM) analysis. The SEM examination was performed using a Zeiss SUPRA 35VP model, employing a high vacuum mode with a 1.7 nm resolution at a 10 kV accelerating voltage. This analysis aimed to evaluate aspects such as fiber morphology, diameter, and the visual identification of any resin residues.

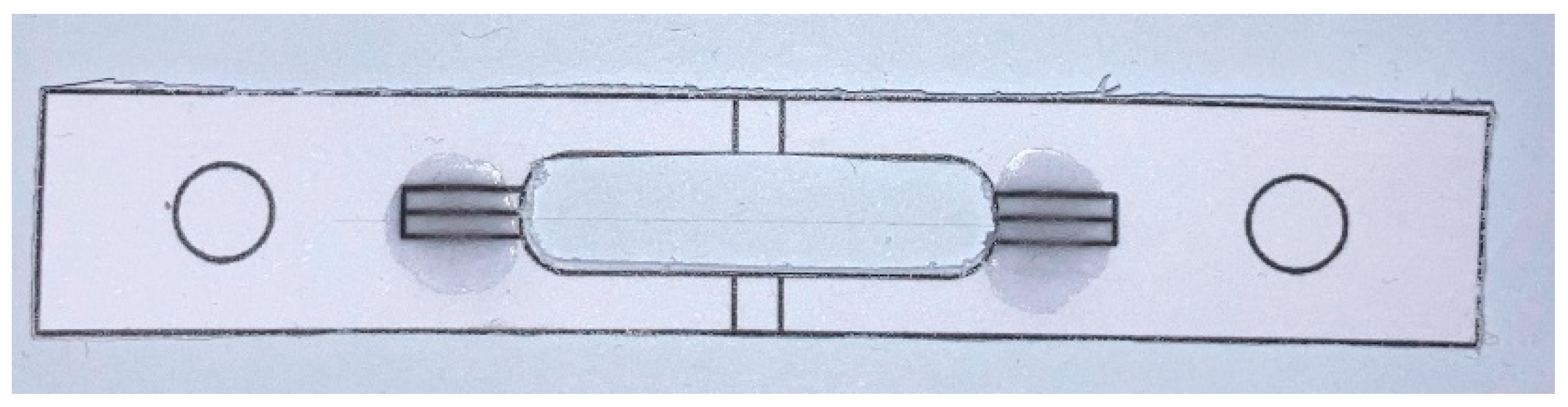

Finally, the efficiency of the recycling processes has been evaluated using single-fiber tension tests on the recovered fibers, which were conducted according to the ASTM C 1557-14 standard [

18]. From the tests, Young’s modulus and the tensile strength of the recycled fibers were measured. The single carbon fiber filaments underwent a meticulous separation process and were temporarily attached to a thick paper mounting tab with a 25 mm gauge length (

Figure 2). Once properly positioned and aligned, they were securely bonded using epoxy adhesive. The tests were conducted using a Miniature Materials Tester named Minimat 2000 fitted with a 200 N cell as shown in

Figure 3, using a crosshead speed of 2 mm/min. For each sample, a minimum of 25 filaments were tested.

3. Results and Discussion

Following the solvolysis experiments, the recovered fibers were subjected to a treatment process. Specifically, they were immersed in an acetone bath for 20 min to facilitate the removal of any resin residues. After the bath treatment, the humidity was removed by placing the fibers in an oven for 24 h at 40°C. After the solvolysis process, the samples were visually inspected, and the results are depicted in

Figure 3. The visual examination reveals a significant removal of epoxy resin, leaving the fibers in a clean (almost) condition. The length of the fibers appears to be continuous, with negligible changes from their initial length. Additionally, following the solvolysis, the fibers exhibit a non-aligned and fluffy morphology. The recycled carbon fibers typically exhibit this fluffy appearance attributed to the elimination of sizing agents and epoxy resin.

3.1. Resin Decomposition Efficiency

The results from the application of Eq. (1) are listed in

Table 2. In detail, in Experiment #01, a resin removal efficiency of 91.58% was achieved, demonstrating the effectiveness of the method under specific conditions. Moving on to Experiments #02 and #03, an important Resin Decomposition Factor (RDF) was exhibited in both, signifying almost complete elimination of resin, particularly noteworthy under supercritical conditions. Experiment #04, however, showed a slightly lower RDF of 65.76%, likely due to the lower applied pressure conditions. However, Experiment #05 stood out between the two acetone experiments with an RDF of 97.01%, highlighting the consistent performance of the method under high pressure and temperature conditions. In conclusion, in the first three experiments that were conducted using water, the removal efficiency increased with increasing the temperature and pressure. The higher rates of resin elimination were achieved under supercritical operating conditions. In experiment #03, it was observed the highest resin removal rate, reached almost 100%. However, in experiment #04, the rate was lower compared to the others.

3.2. SEM Images

The surface microstructures of recovered fibers were observed by SEM.

Figure 4 displays the SEM images of them. The recovered fibers showed negligible traces of resin residues on their surfaces, and there were no detectable signs of physical damage such as cracks, or any changes in morphology with regard to diameter. In experiment #04 (

Figure 4(d)), there is visible resin residue, which confirms the lower rate of resin removal.

Utilizing SEM, several diameter measurements, 15 measurements for each experiment, were also conducted and displayed in

Figure 5. The measured average diameters are listed in

Table 3. The values revealed that the mean diameter in every experiment exhibited a negligible change. These negligible changes in diameter could be explained by the removal of the sizing agents during the solvolysis process. Sizing agents are substances applied to fibers during manufacturing to improve adhesion to the matrix. The sizing process, particularly under supercritical conditions where resin removal is greater, can effectively remove sizing agents without causing significant changes in fiber diameter. Therefore, the observation of the diameter in fibers after solvolysis suggests that the method is successful in maintaining the structural integrity of them.

3.3. Mechanical Properties and Statistical Analysis

From the single-fiber tension tests on the recovered fibers, the Young’s modulus and the tensile strength were determined and used to assess the recycling process. For the mechanical properties of the virgin fibers, an average value was used, derived from data available in the literature and, more specifically, from [

10,

17,

18,

19,

20,

21,

22].

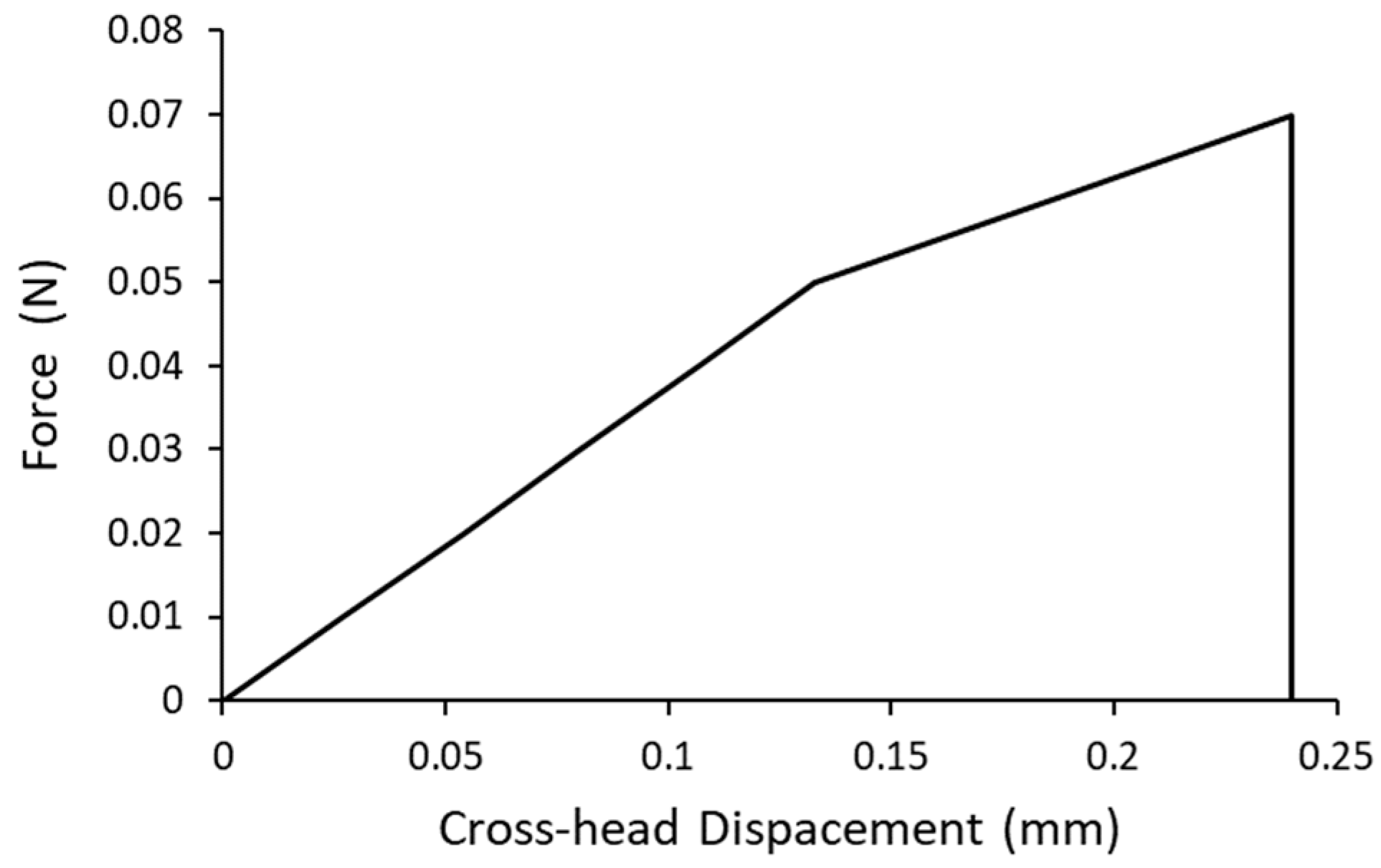

The constant cross-head displacement rate of the single fiber tensile test was 2mm/min and the maximum possible strength at fracture was obtained within 30 seconds. A typical load-displacement curve of a single-fiber tension test conducted on a recovered carbon fiber is illustrated in

Figure 6. As shown, the fiber exhibited an almost bilinear tensile behavior.

The maximum load that the fibers could withstand before failure and the displacement were recorded for each test and their average for each experiment was calculated and presented in

Table 4. The maximum values of the force obtained ranged from 0.065 to 0.075 Newton, while the range of the displacement was 0.34 to 0.4 mm. The displacement provided a quantitative measurement of the ability of the fibers to undergo elongation during the tensile test and will subsequently be used to calculate Young’s modulus.

The Young’s Modulus was calculated based on ASTM C 1557-14 standard using the following formula:

where

is the fiber Young’s modulus (Pa),

is the gage length (m),

is the recorded crosshead displacement (m), and

is the system compliance (m/N) which has been measured according to the standard.

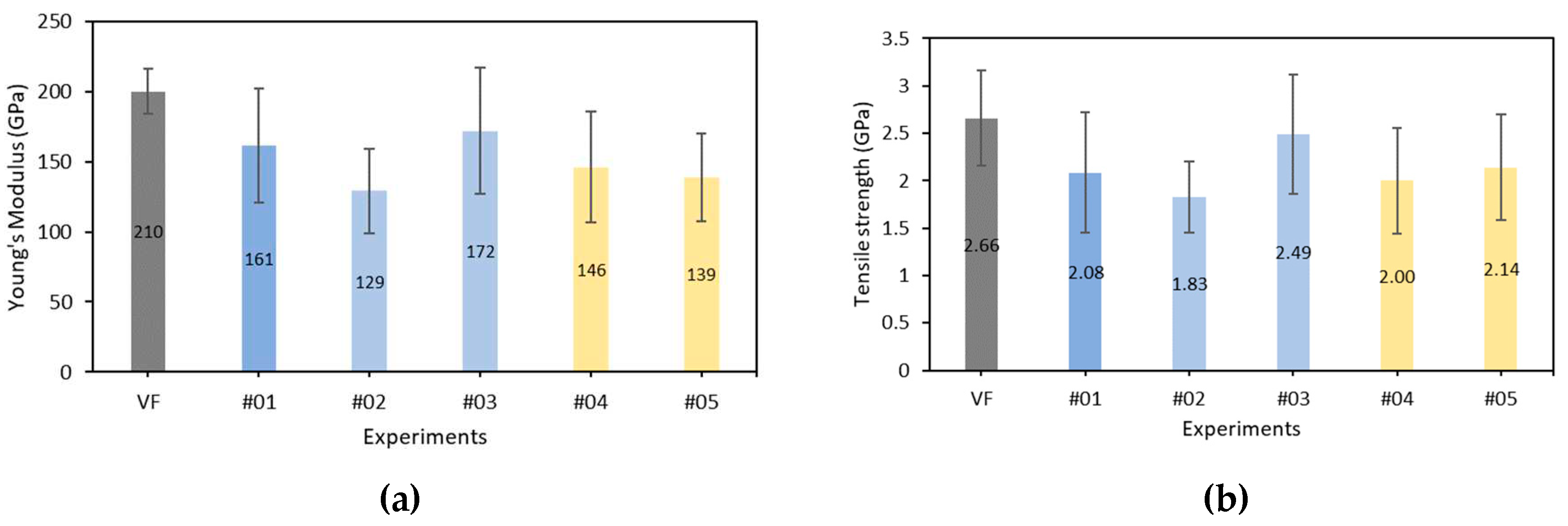

The derived Young’s modulus values of the different recovered CFs are presented in

Figure 7(a) and

Table 5 along with the standard deviation. The literature value for the virgin fibers is 210 GPa. A significant reduction in Young’s modulus of the CFs due to solvolysis varying from 18% for experiment #03 to 38.6% for experiment #02 is observed. The reduction varies with the solvolysis conditions.

As in all experiments, a significant deviation was observed, to examine the significance of the differences in the Young’s modulus between the recovered and virgin fibers, t-tests were conducted. The derived p-values from the t-tests are 0.151, 0.014, 0.234, 0.081 and 0.012 for Experiments #01 to #05, respectively. Based on α p-value of 0.05, Experiments #02 and #05 showed a statistically significant difference, while Experiments #01, #03 and #04 did not. For the latter, this finding suggests that the observed differences may not be statistically significant, indicating a negligible decrease in Young’s modulus.

The tensile strength (σ) was derived from the maximum force in the force-displacement curve. The literature value for the virgin fibers is 2.66 GPa. The derived values of tensile strength are presented in

Figure 7(b) and

Table 5 along with the standard deviation. Similar to Young’s modulus, a significant reduction of strength is observed ranging from 6.4% to 31%. The extended reaction times during the supercritical solvolysis experiments had a remarkable effect on the mechanical characteristics of the recovered fibers. Again, due to the large standard deviation, t-tests were conducted. The resulting p-values are 0.054, 0.01, 0.165, 0.026, and 0.045 for Experiments #01 to #05, respectively. Based on a p-value of 0.05, it becomes that Experiments #02 and #04 yielded statistically significant differences, whereas Experiments #01 and #03 did not. The variation of the tensile strength values of the recovered fibers follows the same trend with Young’s modulus except for the interchange between Experiments #04 and #05.

4. Conclusions

In this paper, a pre-screening of the solvolysis recycling process for CFRPs based on the mechanical properties of the recovered fibers is reported. Solvolysis tests were conducted on unidirectional CFRP samples under supercritical and subcritical conditions using acetone and water. The SEM results reveal that in the majority of experiments, the recycled fibers exhibit a clean (almost), smooth, and continuous morphology, with negligible changes in fiber diameters. Furthermore, the solvolysis process demonstrates excellent decomposition efficiency, ranging between 90% and 100% in four out of five experiments, utilizing only water or acetone as solvents, without the need for any catalyst. Particularly, experiments conducted under supercritical conditions with water showed a direct correlation between increased temperature/pressure and superior resin removal efficiency. Experiment #03, with a shorter reaction time, emerged as excellent, achieving nearly 100% resin removal under water-based solvolysis. Further analysis indicates the importance of optimizing the reaction time, particularly evident in Experiment #03. The mechanical tests reveal that the recovered fibers retain over 70% of their initial tensile strength and over 64% of their initial Young’s modulus. The observed variations in tensile strength and Young’s modulus in all experiments underscore the important balance between resin removal and fiber integrity. Supercritical solvolysis experiments have shown that longer reaction times have a remarkable impact on the mechanical properties of the recovered fibers. In Experiment #02 and Experiment #05, extended reaction times led to a significant decrease in tensile strength. However, the important standard deviation observed in the mechanical properties requires careful consideration and indicates the need for further investigation. Statistical tests were initiated to further investigate the variations, revealing significant differences in tensile strength and Young’s modulus between recycled and virgin fibers in specific experiments. These findings not only support the validity of solvolysis as a recycling method but also underline the importance of continuing the research to further improve and optimize CFRP recycling processes.

Author Contributions

Conceptualization, C.V. and K.T.; methodology, C.V and K.T..; investigation, C.V and K.T.; resources, C.V.; data curation, C.V.; writing—original draft preparation, K.T.; writing—review and editing, C.V. and K.T.; visualization, C.V.; supervision, K.T.; project administration, K.T.; funding acquisition, K.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data are presented in the manuscript.

Acknowledgments

The authors would like to thank KVE Composites for the materials used for the experiments, Lykourgos Kontaxis and the Laboratory of Biomechanics and Biomedical Engineering of the University of Patras for helping and providing access to the Miniature Materials Tester Minimat 2000.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- E. Witten, M. Sauer, M. Kühnel Market Developments, Trends, Outlook and Challenges Available online:. Available online: https://composites-united.com/media/3988/eng_ccev_market-report_2019_short-version.pdf (accessed on 13 September 2023).

- Revolutionizing Aircraft Materials and Processes; Pantelakis, S. , Tserpes, K., Eds.; Springer International Publishing: Cham, 2020; ISBN 978-3-030-35345-2. [Google Scholar]

- Borjan, D.; Knez, Ž.; Knez, M. Recycling of Carbon Fiber-Reinforced Composites—Difficulties and Future Perspectives. Materials 2021, 14, 4191. [Google Scholar] [CrossRef] [PubMed]

- Vogiantzi, C.; Tserpes, K. On the Definition, Assessment, and Enhancement of Circular Economy across Various Industrial Sectors: A Literature Review and Recent Findings. Sustainability 2023, 15, 16532. [Google Scholar] [CrossRef]

- Kao, C.C.; Ghita, O.R.; Hallam, K.R.; Heard, P.J.; Evans, K.E. Mechanical Studies of Single Glass Fibres Recycled from Hydrolysis Process Using Sub-Critical Water. Composites Part A: Applied Science and Manufacturing 2012, 43, 398–406. [Google Scholar] [CrossRef]

- Butenegro, J.A.; Bahrami, M.; Abenojar, J.; Martínez, M.Á. Recent Progress in Carbon Fiber Reinforced Polymers Recycling: A Review of Recycling Methods and Reuse of Carbon Fibers. Materials 2021, 14, 6401. [Google Scholar] [CrossRef] [PubMed]

- Pietroluongo, M.; Padovano, E.; Frache, A.; Badini, C. Mechanical Recycling of an End-of-Life Automotive Composite Component. Sustainable Materials and Technologies 2020, 23, e00143. [Google Scholar] [CrossRef]

- Nunes, A.O. Composites renforcés à fibres de carbone : récupération des fibres par vapo-thermolyse, optimisation du procédé. phdthesis, Ecole des Mines d’Albi-Carmaux, 2015.

- Rabe, D.; Häntzsche, E.; Cherif, C. Recycling of Carbon Fibres and Subsequent Upcycling for the Production of 3D-CFRP Parts. Materials 2022, 15, 5052. [Google Scholar] [CrossRef] [PubMed]

- Das, M.; Varughese, S. A Novel Sonochemical Approach for Enhanced Recovery of Carbon Fiber from CFRP Waste Using Mild Acid–Peroxide Mixture. ACS Sustainable Chem. Eng. 2016, 4, 2080–2087. [Google Scholar] [CrossRef]

- Knight, C.C.; Zeng, C.; Zhang, C.; Wang, B. Recycling of Woven Carbon-Fibre-Reinforced Polymer Composites Using Supercritical Water. Environmental Technology 2012, 33, 639–644. [Google Scholar] [CrossRef] [PubMed]

- Yuyan, L.; Guohua, S.; Linghui, M. Recycling of Carbon Fibre Reinforced Composites Using Water in Subcritical Conditions. Materials Science and Engineering: A 2009, 520, 179–183. [Google Scholar] [CrossRef]

- Okajima, I.; Sako, T. Recycling Fiber-Reinforced Plastic Using Supercritical Acetone. Polymer Degradation and Stability 2019, 163, 1–6. [Google Scholar] [CrossRef]

- Kim, Y.N.; Kim, Y.-O.; Kim, S.Y.; Park, M.; Yang, B.; Kim, J.; Jung, Y.C. Application of Supercritical Water for Green Recycling of Epoxy-Based Carbon Fiber Reinforced Plastic. Composites Science and Technology 2019, 173, 66–72. [Google Scholar] [CrossRef]

- Sokoli, H.U.; Beauson, J.; Simonsen, M.E.; Fraisse, A.; Brøndsted, P.; Søgaard, E.G. Optimized Process for Recovery of Glass- and Carbon Fibers with Retained Mechanical Properties by Means of near- and Supercritical Fluids. The Journal of Supercritical Fluids 2017, 124, 80–89. [Google Scholar] [CrossRef]

- Okajima, I.; Watanabe, K.; Haramiishi, S.; Nakamura, M.; Shimamura, Y.; Sako, T. Recycling of Carbon Fiber Reinforced Plastic Containing Amine-Cured Epoxy Resin Using Supercritical and Subcritical Fluids. The Journal of Supercritical Fluids 2017, 119, 44–51. [Google Scholar] [CrossRef]

- Yildirir, E.; Onwudili, J.A.; Williams, P.T. Recovery of Carbon Fibres and Production of High Quality Fuel Gas from the Chemical Recycling of Carbon Fibre Reinforced Plastic Wastes. The Journal of Supercritical Fluids 2014, 92, 107–114. [Google Scholar] [CrossRef]

- C28 Committee Test Method for Tensile Strength and Youngs Modulus of Fibers; ASTM International.

- Yang, P.; Zhou, Q.; Li, X.-Y.; Yang, K.-K.; Wang, Y.-Z. Chemical Recycling of Fiber-Reinforced Epoxy Resin Using a Polyethylene Glycol/NaOH System. Journal of Reinforced Plastics and Composites 2014, 33, 2106–2114. [Google Scholar] [CrossRef]

- Xu, P.; Li, J.; Ding, J. Chemical Recycling of Carbon Fibre/Epoxy Composites in a Mixed Solution of Peroxide Hydrogen and N,N-Dimethylformamide. Composites Science and Technology 2013, 82, 54–59. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, J.; Jiang, Z.; Tang, T. Chemical Recycling of Carbon Fibre Reinforced Epoxy Resin Composites in Subcritical Water: Synergistic Effect of Phenol and KOH on the Decomposition Efficiency. Polymer Degradation and Stability 2012, 97, 214–220. [Google Scholar] [CrossRef]

- Tian, Z.; Wang, Y.; Hou, X. Review of Chemical Recycling and Reuse of Carbon Fiber Reinforced Epoxy Resin Composites. New Carbon Materials 2022, 37, 1021–1041. [Google Scholar] [CrossRef]

- Cai, G.; Yin, G.; Wada, M.; Kitaoka, S.; Wei, H.; Ohsawa, I.; Takahashi, J. INFLUENCE OF RECYCLING PROCESS ON THE TENSILE PROPERTY OF CARBON FIBER. 2017.

- Jiang, G.; Pickering, S.; Lester, E.; Turner, T.; Wong, K.; Warrior, N. Characterisation of Carbon Fibres Recycled from Carbon Fibre/Epoxy Resin Composites Using Supercritical n-Propanol. Composites Science and Technology 2009, 69, 192–198. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).