Submitted:

04 February 2024

Posted:

05 February 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

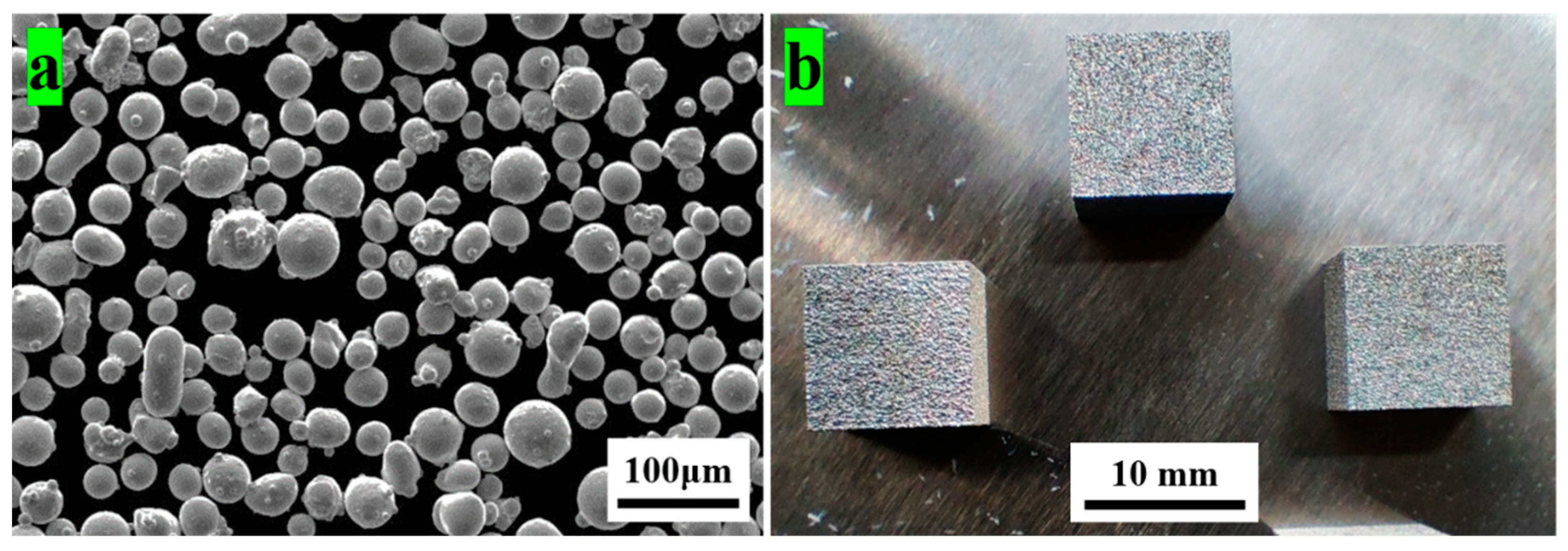

2.1. Fabrication of Particle-Stacking Microporous 316L

2.2. Characterization

3. Results and Discussion

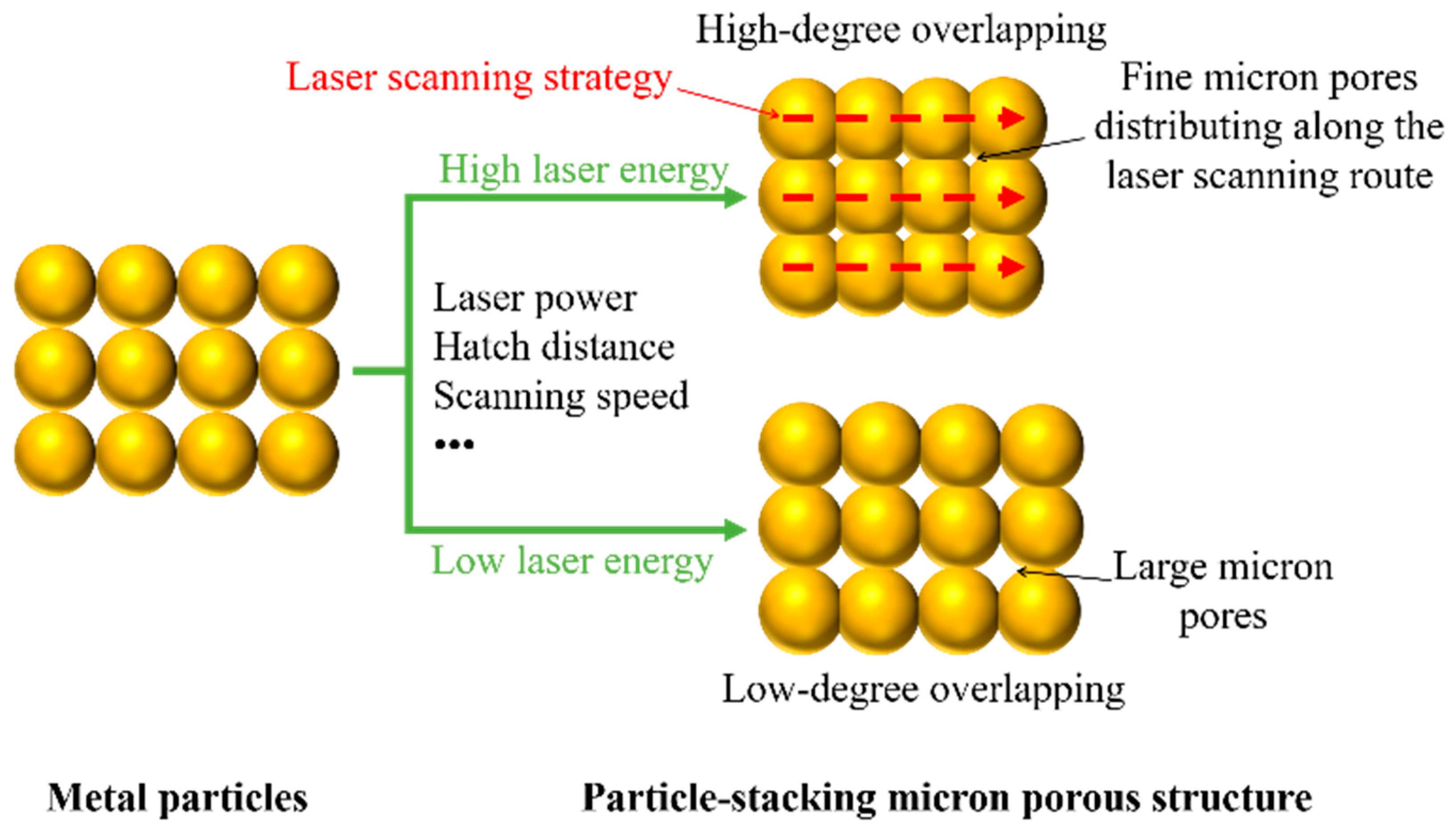

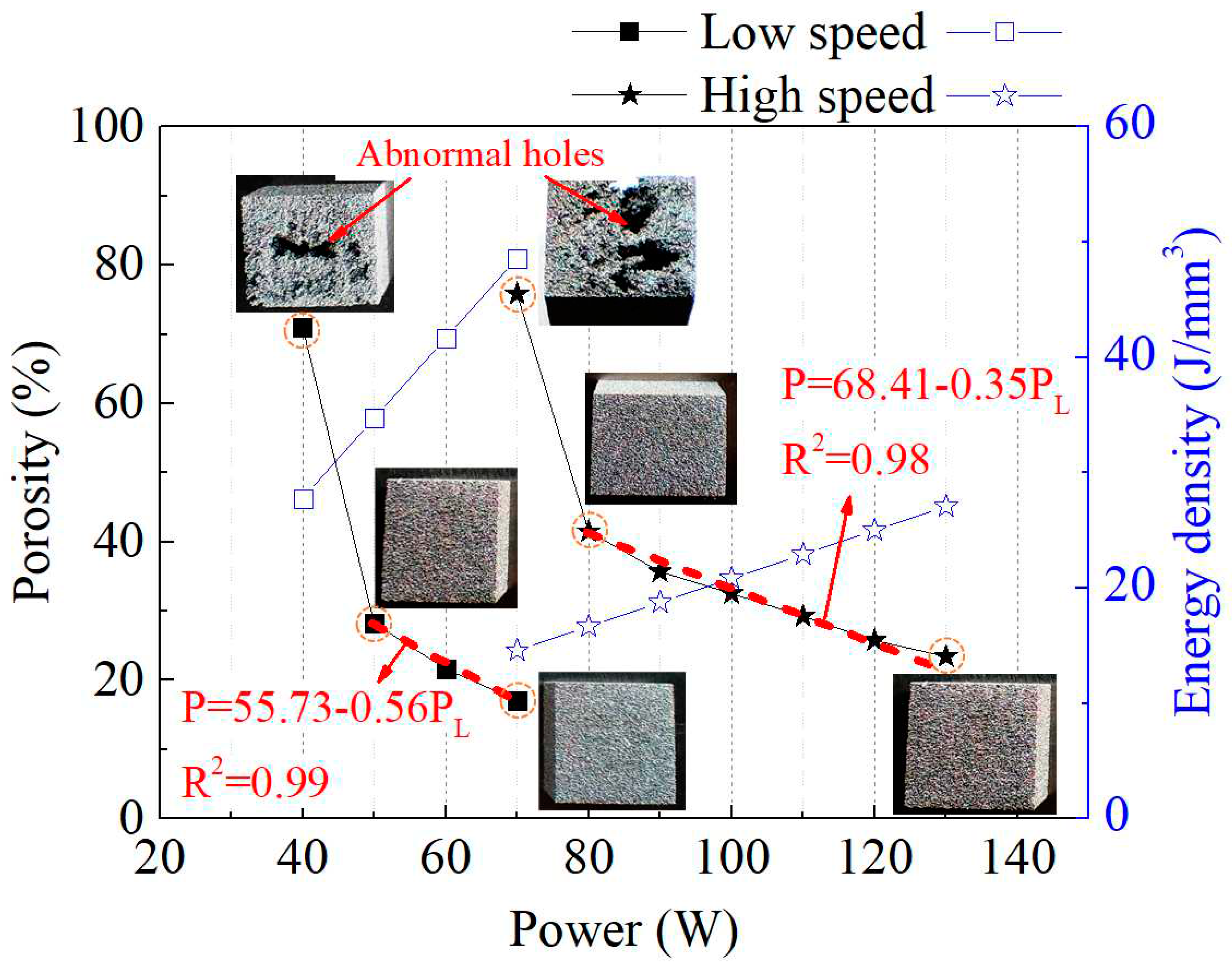

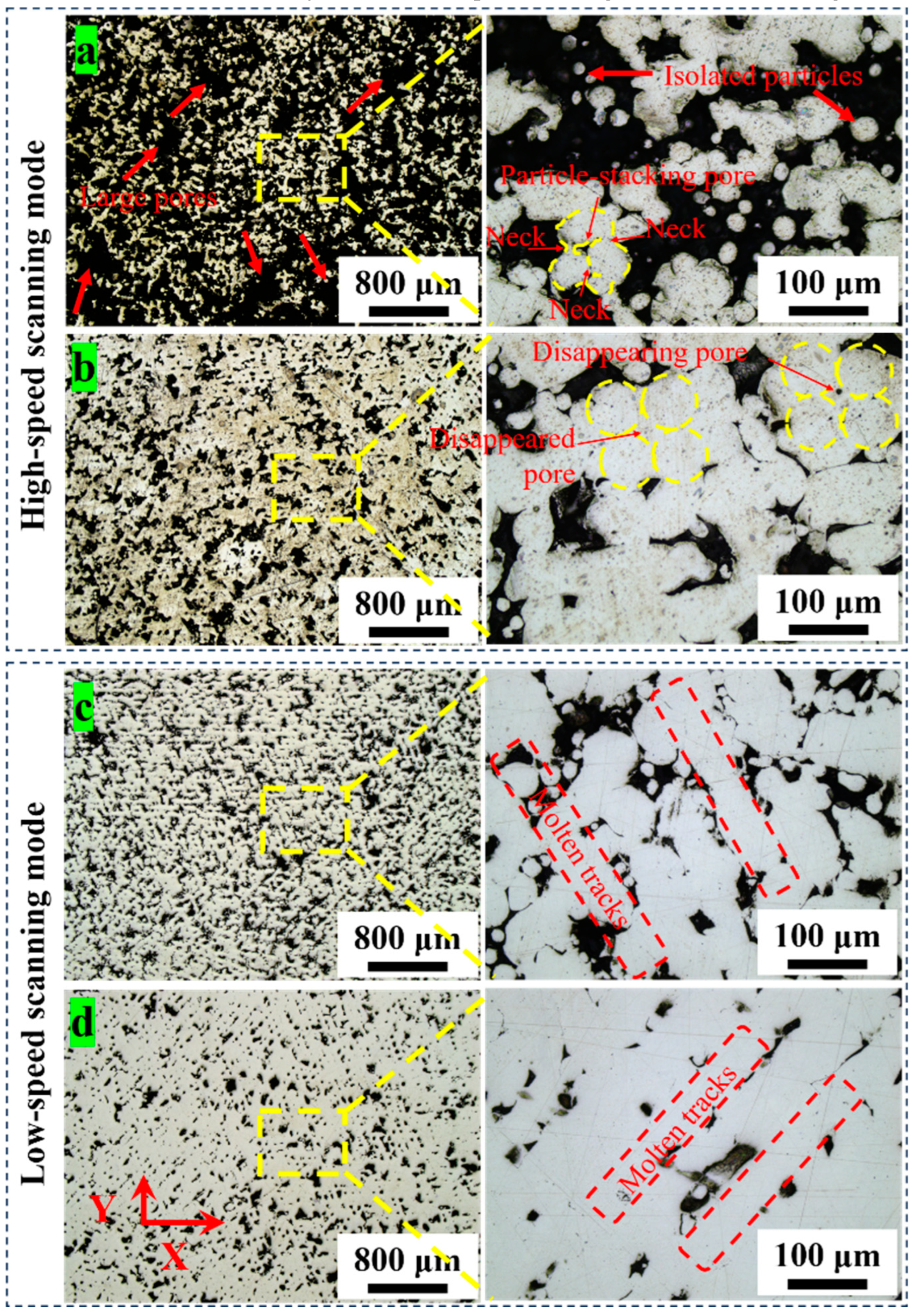

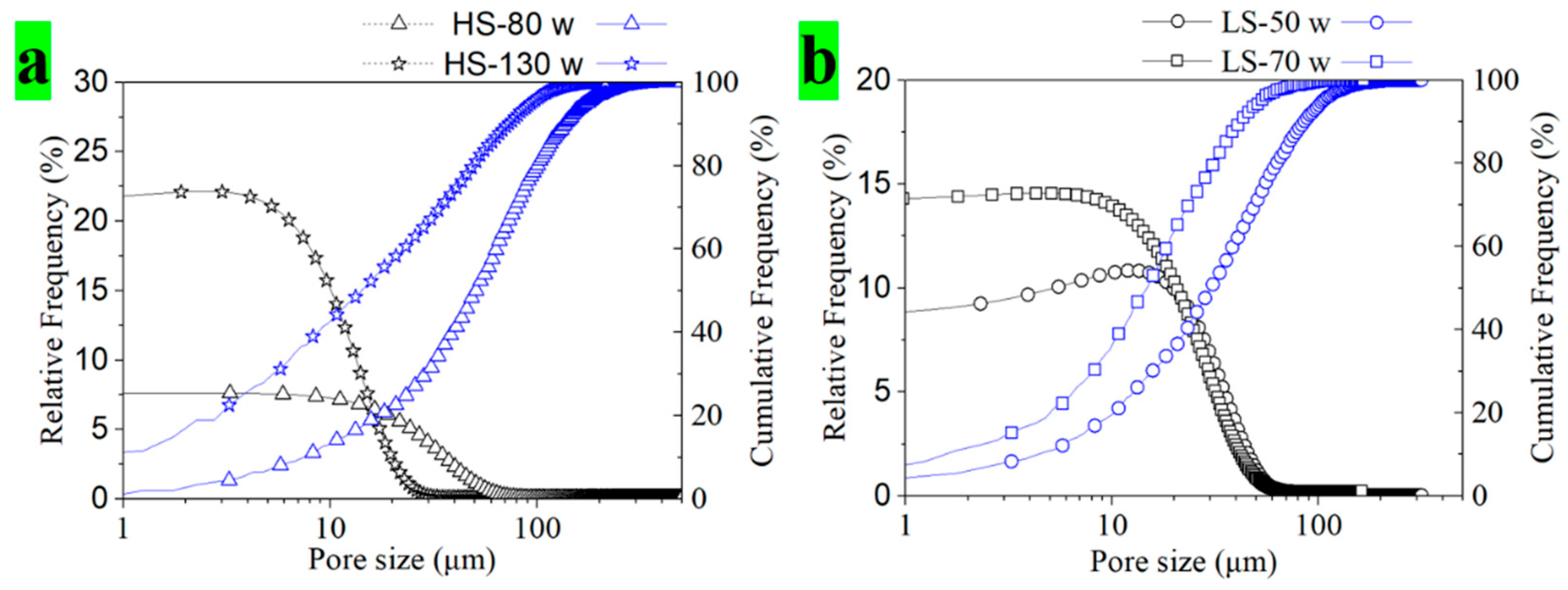

3.1. Effect of Laser Power and Laser Energy Density on Microporous Structure

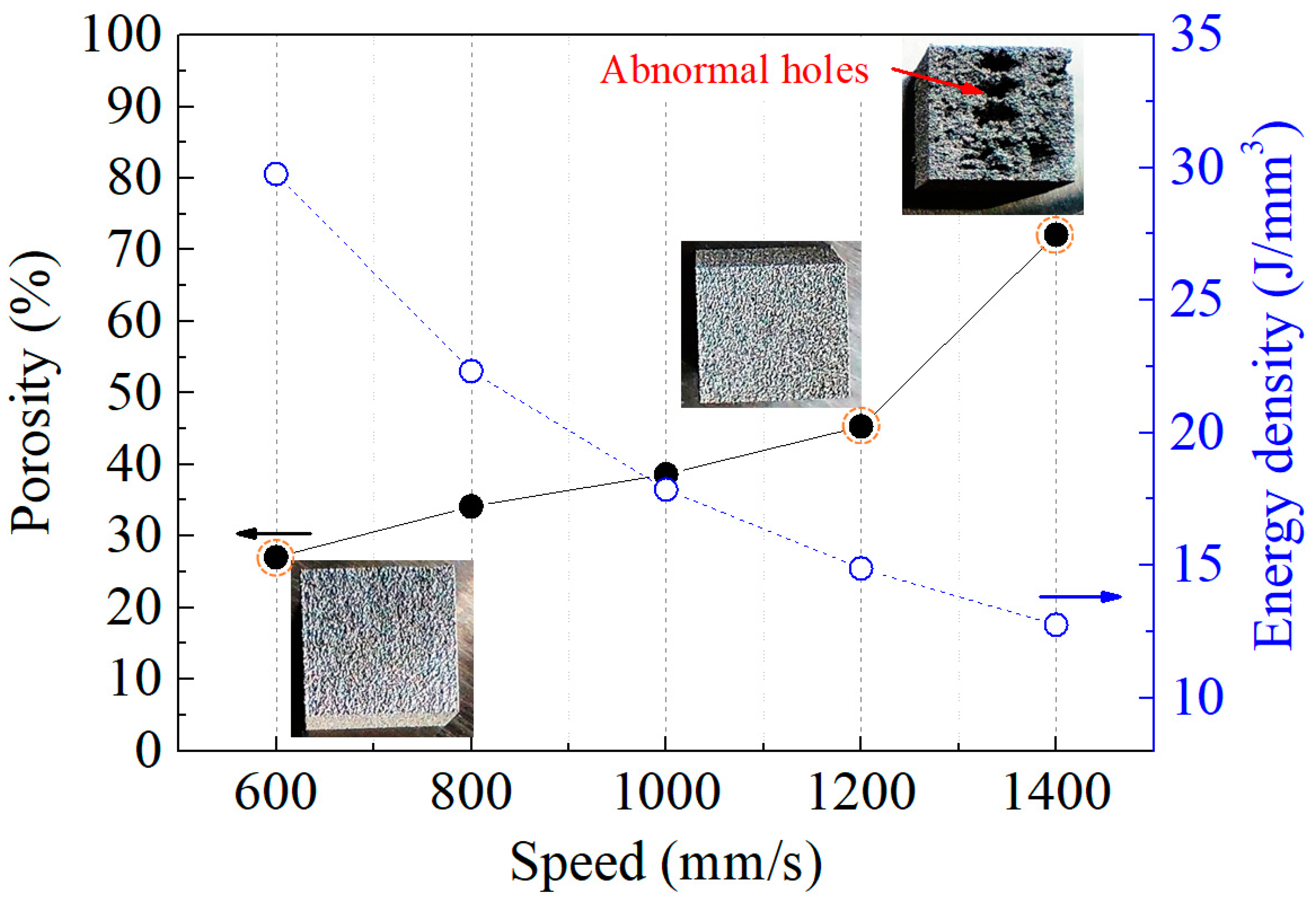

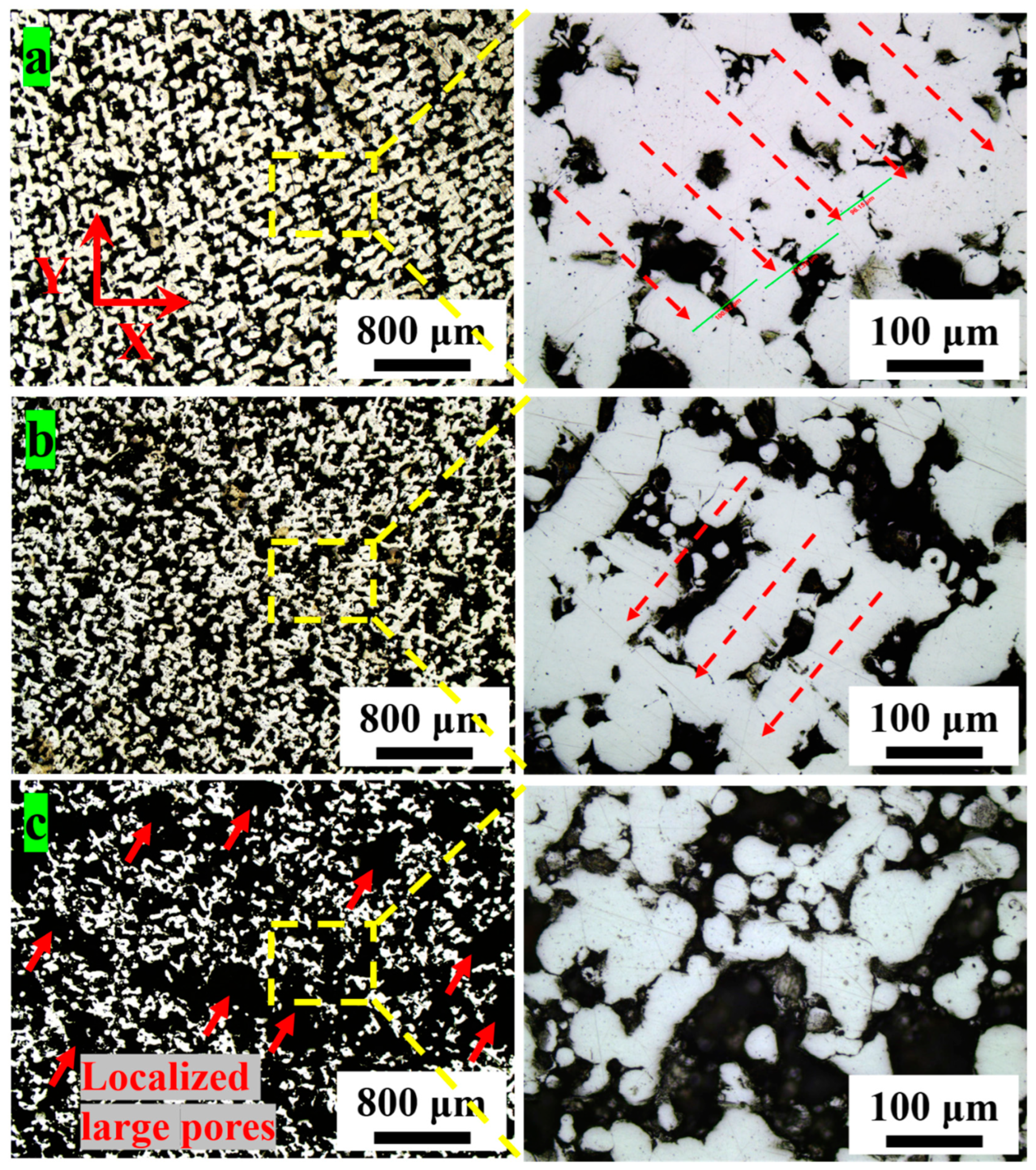

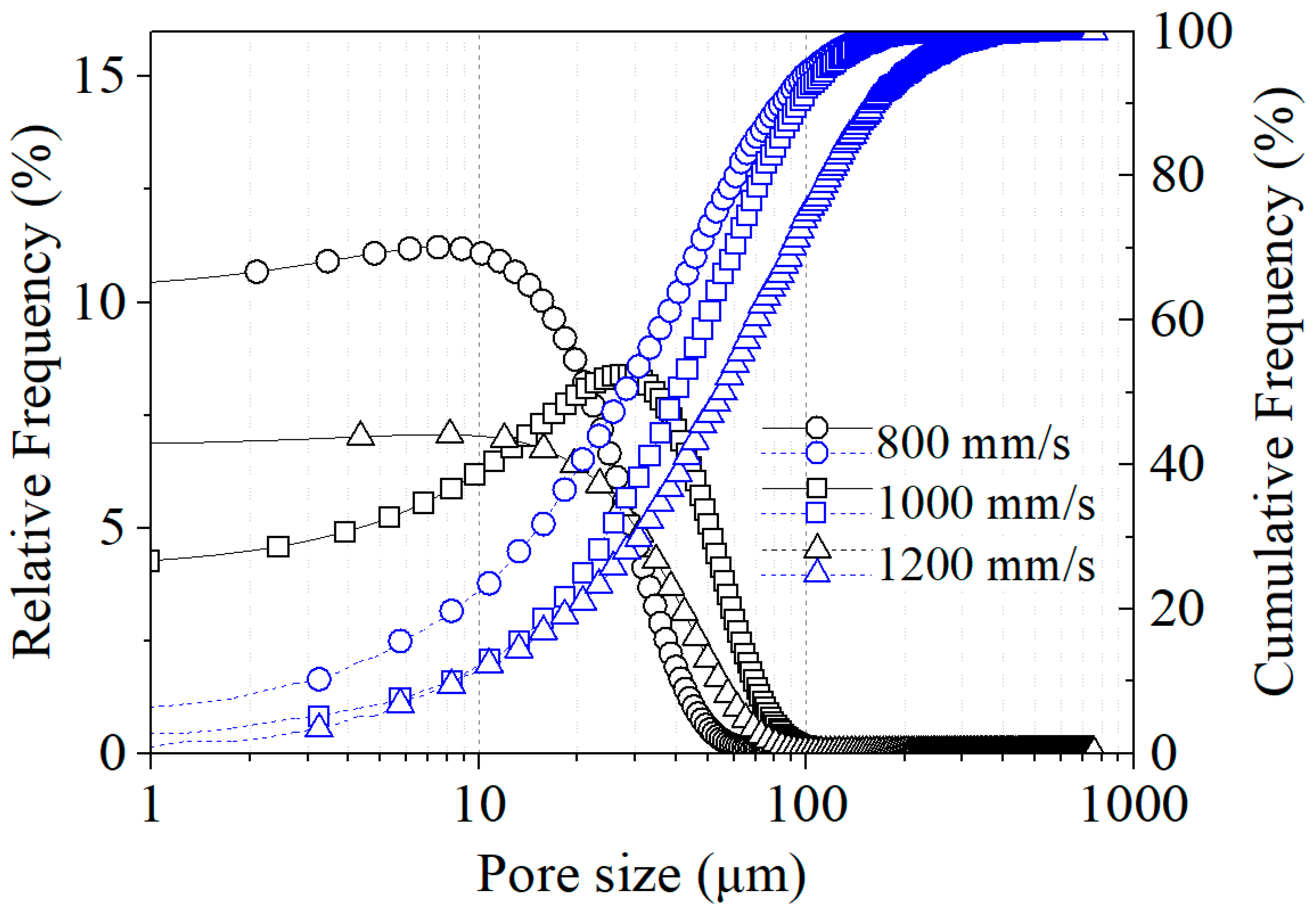

3.2. Effect of Laser Scanning Speed on Microporous Structure

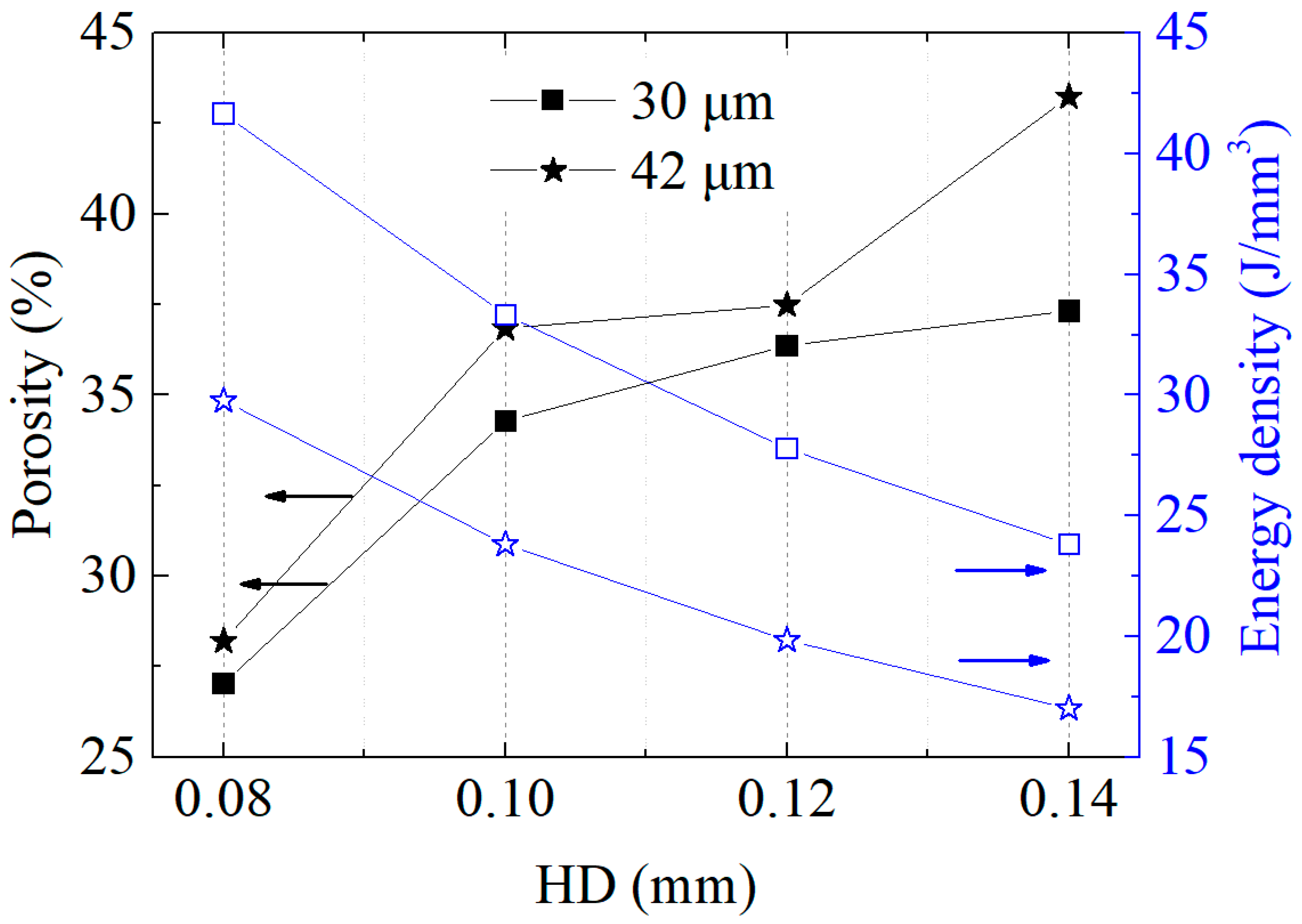

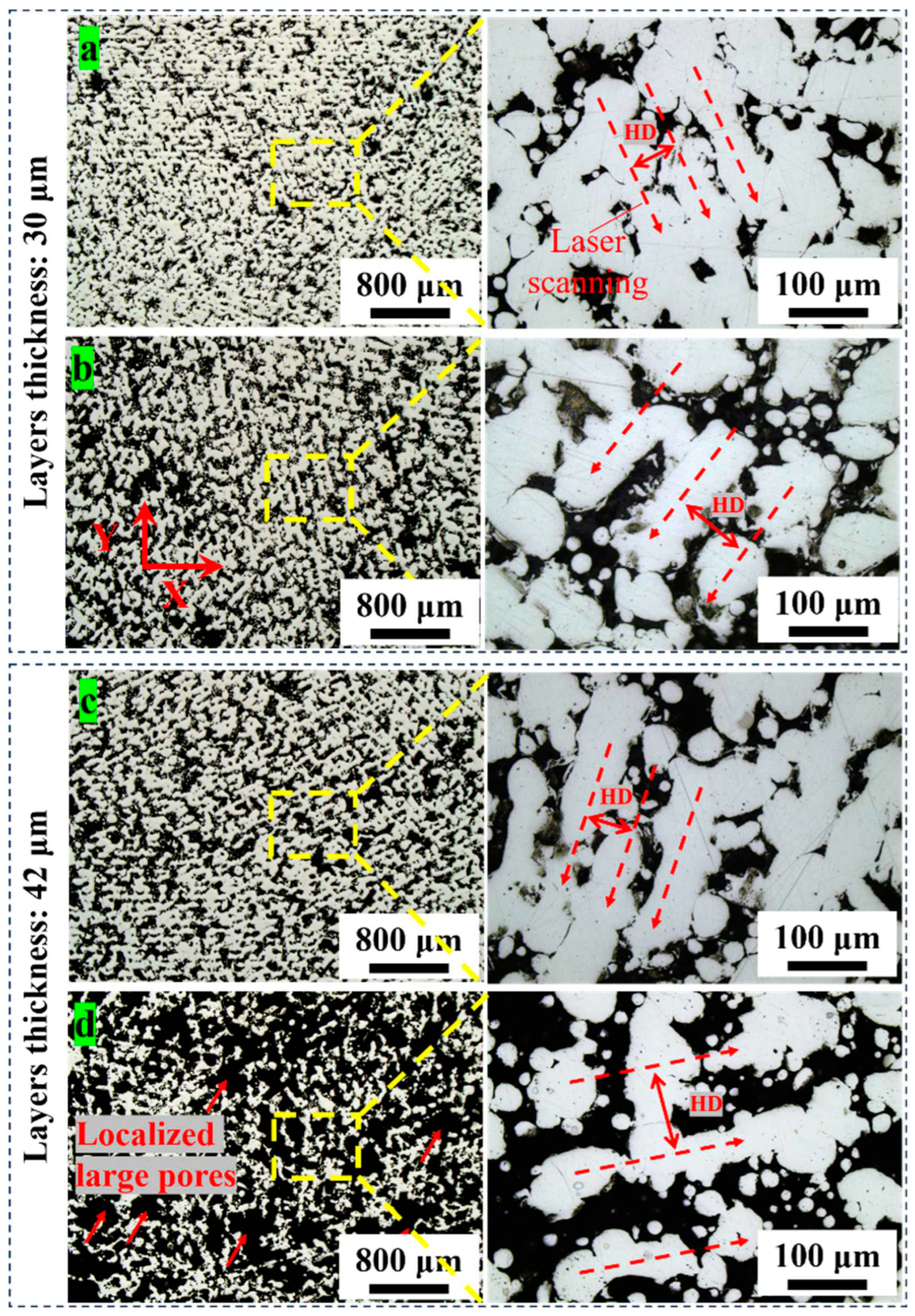

3.3. Effect of Hatch Distance (HD) and Layer Thickness (LT) on Microporous Structure

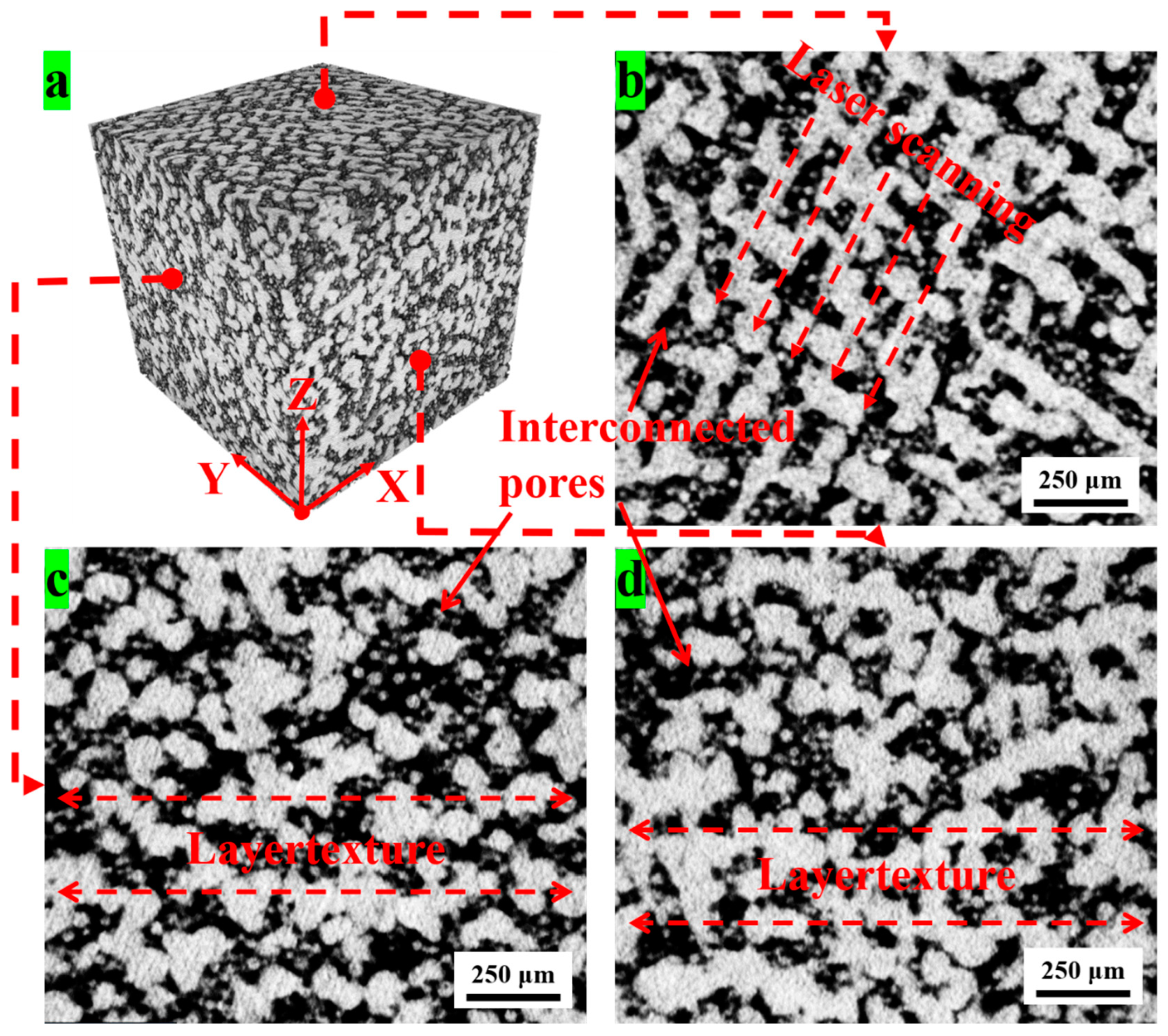

3.4. Three-Dimensional Pore Structure

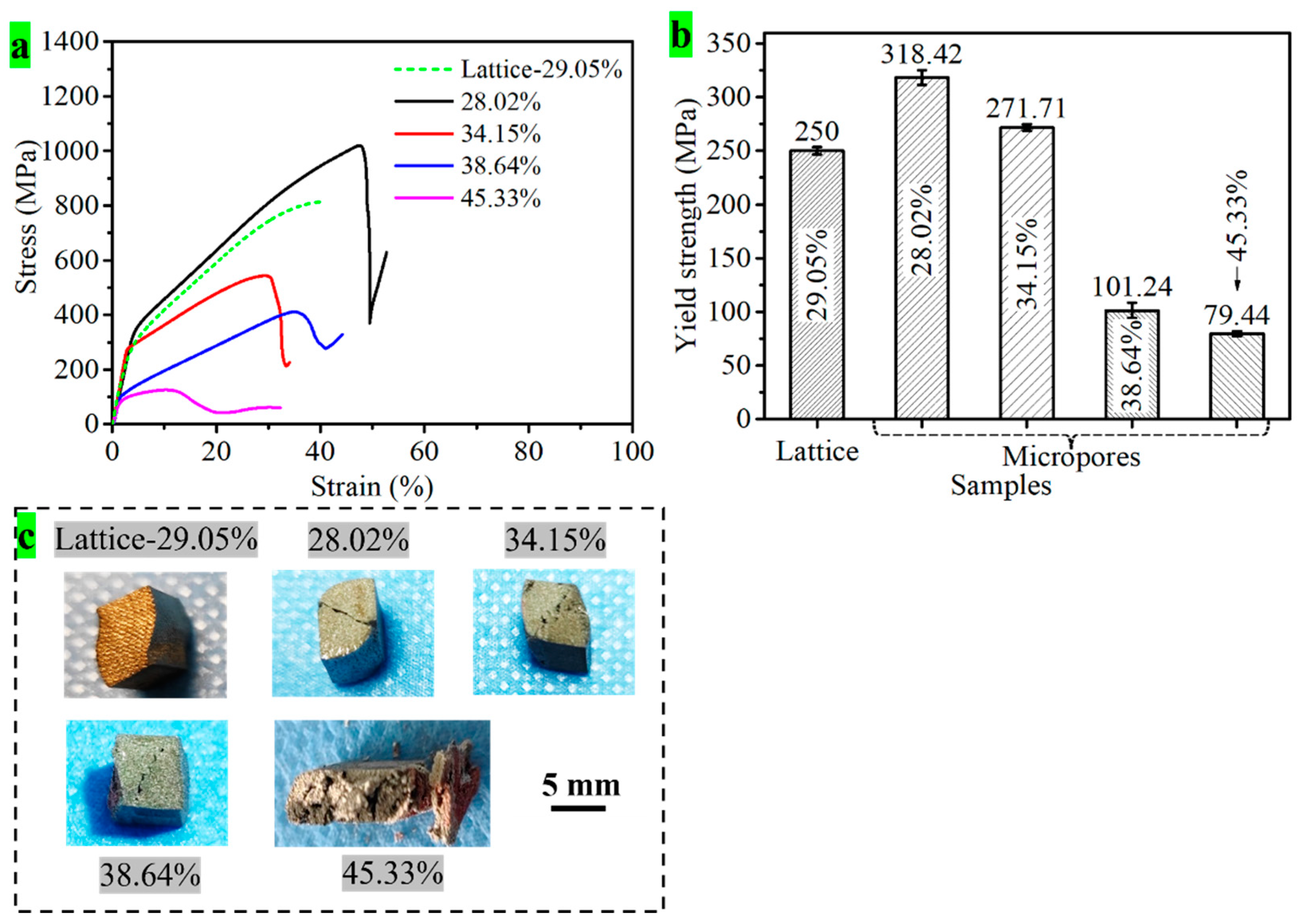

3.5. Compressive Performance of Particle-Stacking Microporous 316L

4. Conclusions

- As a whole, the particle-stacking microporous 316L showed interconnected porous structure with homogenous pore distribution possessed a controllable normal porosity from 17.06% to 45.33%, pore size of D50 less than 50 μm and D90 less than 100 μm, and a high percentage of fine micropores distributed in the pore size of 1-10 μm. The pores in XY plane evenly distributed along the direction of the laser scanning routes and mainly interconnected with each other along the molten tracks, whereas the pore distribution in Z direction showed relatively disordered and mainly linked along the layered direction.

- Laser energy density could not be taken as the determining indicator for the porosity and the formation of microporous structure. High-speed scanning mode showed a general effect on porosity variation, but it required a high laser power for the formation of porous structure, which might disorder the pore structure. Whereas, low-speed scanning would weaken the impact of laser energy pressure and the Marangoni flow on the stacking particles and formed the pores distributed along the laser scanning tracks with an organized pore structure. Narrow hatch distance could be contributed to stack a net porous structure with small pore size while wide hatch distance be beneficial for forming a particle-stacking porous structure with large-sized interconnected pores.

- With the variation of porosity from 28.02% to 45.33%, the yield strength of microporous 316L varied from 318.42 MPa to 79.44 MPa. It showed a stronger compressive yield strength in comparison with the lattice porous 316L with the similar porosity.

Acknowledgements

References

- Balakrishnan Hari Kalathil, Doeven Egan H., Merenda Andrea, Dumée Ludovic F. & Guijt Rosanne M. (2021). 3D printing for the integration of porous materials into miniaturised fluidic devices: A review. Analytica Chimica Acta 338796-338796. [CrossRef]

- Junhua Qin, Qing Chen, Chunyan Yang & Yong Huang. (2016). Research process on property and application of metal porous materials. Journal of Alloys and Compounds 39-44. [CrossRef]

- Wen Lei, Nie Meng, Wang Chongqing, Zhao Yuna, Yin Kuibo & Sun Litao. (2021). Multifunctional, Light-Weight Wearable Sensor Based on 3D Porous Polyurethane Sponge Coated with MXene and Carbon Nanotubes Composites. Advanced Materials Interfaces (5). [CrossRef]

- Fu Chong, Liang Jianwei, Yang Gao, Dagestani Abd alwahed, Liu Wei, Luo Xudong, Zeng Baobao, Wu Haidong, Huang Meipeng, Lin Lifu, Deng Xin. Recycling of waste glass as raw materials for the preparation of self-cleaning, light-weight and high-strength porous ceramics[J]. Journal of Cleaner Production, 2021, 317. [CrossRef]

- ResendeGonçalves Cláudia Inês, Sampaio Nuno, Moreira Joaquim, Carvalho Oscar, Caramês João, ManzanaresCéspedes Maria Cristina.&Souza Júlio. (2022). Porous Zirconia Blocks for Bone Repair: An Integrative Review on Biological and Mechanical Outcomes. Ceramics (1), 161-172. [CrossRef]

- Germaini Marie-Michèle, Belhabib Sofiane, Guessasma Sofiane, Deterre Rémi, Corre Pierre, Weiss Pierre. Additive manufacturing of biomaterials for bone tissue engineering – A critical review of the state of the art and new concepts[J]. Progress in Materials Science, 2022, 130. [CrossRef]

- Kelly Cambre N., Wang Tian, Crowley James, Wills Dan, Pelletier Matthew H., Westrick Edward R., Adams Samuel B., Gall Ken, Walsh William R. High-strength, porous additively manufactured implants with optimized mechanical osseointegration[J]. Biomaterials, 2021, 279 121206-121206. [CrossRef]

- Abdelgawad Khaled Z., Adebayo Abdulrauf R., Isah Abubakar, Muhammed Nasiru S. A literature review of strength and stability of foam and their relationship with the absolute permeability of porous media[J]. Journal of Petroleum Science and Engineering, 2022, 211. [CrossRef]

- Yuksel C. Yabansu, Patrick Altschuh, Johannes Hötzer, Michael Selzer, Britta Nestler, Surya R. Kalidindi. A digital workflow for learning the reduced-order structure-property linkages for permeability of porous membranes[J]. Acta Materialia, 2020, 195 (prepublish): 668-680. [CrossRef]

- Xiaocui Yang, Xinmin Shen, Haiqin Duan, Xiaonan Zhang, Qin Yin. Identification of Acoustic Characteristic Parameters and Improvement of Sound Absorption Performance for Porous Metal[J]. Metals, 2020, 10 (3): 340-340. [CrossRef]

- Sun Wenhao, Pan Baorui, Song Xiang, Xiao Heye, Zhou Jie, Sui Dan. A novel sound absorber design of nanofibrous composite porous material[J]. Materials & Design, 2022, (prepublish): 110418-. [CrossRef]

- X. B. Xu, P. S. Liu, G. F. Chen, C. P. Li. Sound Absorption Performance of Highly Porous Stainless Steel Foam with Reticular Structure[J]. Metals and Materials International, 2020, 27 (9): 1-9. [CrossRef]

- G Trilok, Srinivas Kurma Eshwar Sai, Harikrishnan Devika, N Gnanasekaran, Mobedi Moghtada. Correlations and Numerical Modeling of Stacked Woven Wire-Mesh Porous Media for Heat Exchange Applications[J]. Energies, 2022, 15 (7): 2371-2371. [CrossRef]

- Wyczółkowski Rafał, Bagdasaryan Vazgen, Gała Marek, Król Paweł Artur. The Review of Chosen Methods Used to Investigate Heat Transfer in a Steel Porous Charge[J]. Energies, 2022, 15 (6): 2266-2266. [CrossRef]

- Liang Xiong, Li Yawei, He Zhu, Yan Wen, Tan Fangguan, Wang Qinghu, Zhu Tianbin, Sang Shaobai. The effect of cellular structure on the strength and combustion properties of SiC porous ceramics[J]. Ceramics International, 2022, 48 (2): 2538-2545. [CrossRef]

- Tao Xuefeng, Yang Zhao, Cheng Menghao, Yan Rui, Chen Fan, Cao Sujiao, Li Shuang, Ma Tian, Cheng Chong, Yang Wei. Phosphorus modulated porous CeO2 nanocrystallines for accelerated polysulfide catalysis in advanced Li-S batteries[J]. Journal of Materials Science & Technology, 2022, 131 212-220. [CrossRef]

- Lu Wenjing, Li Tianyu, Yuan Chenguang, Zhang Huamin, Li Xianfeng. Advanced porous composite membrane with ability to regulate zinc deposition enables dendrite-free and high-areal capacity zinc-based flow battery[J]. Energy Storage Materials, 2022, 47 415-423. [CrossRef]

- Federico M,Elisa E,Maxime H, et al. Electrode kinetics of porous Ni-3YSZ cermet operated in fuel cell and electrolysis modes for solid oxide cell application [J]. Electrochimica Acta, 2021, 389. [CrossRef]

- Ibrahim Mohd Hakim, Mustaffar Mohd Idham, Ismail Syarifah Aminah, Ismail Anis Nadhirah. A Review of Porous Glass-Ceramic Production Process, Properties and Applications[J]. Journal of Physics: Conference Series, 2022, 2169 (1). [CrossRef]

- Shweta Singh, Naresh Bhatnagar. A survey of fabrication and application of metallic foams (1925–2017)[J]. Journal of Porous Materials, 2018, 25 (2): 537-554. [CrossRef]

- John Banhart. Manufacture, characterisation and application of cellular metals and metal foams[J]. Progress in Materials Science, 2001, 46 (6): 559-632. [CrossRef]

- Pfeiffer Stefan, Florio Kevin, Puccio Dario, Grasso Marco, Colosimo Bianca Maria, Aneziris Christos G., Wegener Konrad, Graule Thomas. Direct laser additive manufacturing of high performance oxide ceramics: A state-of-the-art review[J]. Journal of the European Ceramic Society, 2021, 41 (13): 6087-6114. [CrossRef]

- J. Gunasekaran, P. Sevvel, I. John Solomon. Metallic materials fabrication by selective laser melting: A review[J]. Materials Today: Proceedings, 2020, (prepublish). [CrossRef]

- Dhiman S,Sidhu S,Bains S P, et al. Mechanobiological assessment of Ti-6Al-4V fabricated via selective laser melting technique: a review [J]. Rapid Prototyping Journal, 2019, 25 (7): 1266-1284. [CrossRef]

- Chunze Yan, Liang Hao, Ahmed Hussein, Philippe Young, David Raymont. Advanced lightweight 316L stainless steel cellular lattice structures fabricated via selective laser melting[J]. Materials & Design, 2014, 55 533-541. [CrossRef]

- Prajapati, Mayur & Kumar, Ajeet & Jeng, Jeng-Ywan. (2022). Multi-material additive manufacturing with lightweight closed-cell foam-filled lattice structures for enhanced mechanical and functional properties. Additive Manufacturing. 54. 102766. [CrossRef]

- Tianlin Zhong, Ketai He, Huaixue Li, Lechang Yang. Mechanical properties of lightweight 316L stainless steel lattice structures fabricated by selective laser melting[J]. Materials & Design, 2019, 181 108076-108076. [CrossRef]

- Jinguo Ge, Jian Huang, Yongping Lei, Peter O’Reilly, Mansur Ahmed, Chao Zhang, Xingchen Yan, Shuo Yin. Microstructural features and compressive properties of SLM Ti6Al4V lattice structures[J]. Surface & Coatings Technology, 2020, 403 126419-. [CrossRef]

- Li Zhenjun, Takano Naoki, Mizutani Masayoshi. Material properties of selective laser melting additive-manufactured Ti6Al4V alloys with different porosities[J]. Precision Engineering, 2023, 83 142-151. [CrossRef]

- Lin Ting-Chiang, Cao Chezheng, Sokoluk Maximilian. & Li Xiaochun. Aluminum with dispersed nanoparticles by laser additive manufacturing. [J]. Nature communications, 2019, 10 (1): 4124. [CrossRef]

- Won Rae Kim, Gyung Bae Bang, Ohyung Kwon, Kyung-Hwan Jung, Hyung-Ki Park, Gun-Hee Kim. & Hyung Giun Kim. (2020). Fabrication of porous pure titanium via selective laser melting under low-energy-density process conditions. Materials & Design (prepublish), 109035-. [CrossRef]

- Bruce Duncan W., O’Hare Dermot, Walton Richard I. Porous Materials[M]. John Wiley & Sons, Ltd: 2010-10-19. [CrossRef]

- E. Sallica-Levaa, A.L.Jardinib, J.B.Fogagnoloa. Microstructure and mechanical behavior of porous Ti–6Al–4V parts obtained by selective laser melting[J]. Journal of the Mechanical Behavior of Biomedical Materials, 2013, 26 98-108. [CrossRef]

- Saad A. Khairallah, Andrew T. Anderson, Alexander Rubenchik, Wayne E. King. Laser powder-bed fusion additive manufacturing: Physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones[J]. Acta Materialia, 2016, 108 36-45. [CrossRef]

- Meier Christoph, Penny Ryan W., Zou Yu, Gibbs Jonathan S. & Hart A. John.(2017). Thermophysical phenomena in metal additive manufacturing through selective laser melting: fundamentals, modeling, simulation, and experimentation [J]. Annual Review of Heat Transfer, 2017, 20 (1): 241-316. [CrossRef]

- Hailong Liao, Junjie Zhu, Shijie Chang, Gang Xue, Haihong Zhu, Baijin Chen. Al2O3 loss prediction model of selective laser melting Al2O3–Al composite[J]. Ceramics International, 2020, 46 (9): 13414-13423. [CrossRef]

- Chen Xu, Wu Yanlong, Liu Huilong, Wang Yaning, Zhao Guangbin, Zhang Qingxian, Wang Fu, Liu Yaxiong. Mechanical performance of PEEK-Ti6Al4V interpenetrating phase composites fabricated by powder bed fusion and vacuum infiltration targeting large and load-bearing implants[J]. Materials & Design, 2022, (prepublish): 110531-. [CrossRef]

- Liu Jiangwei, Guo Kai, Sun Jie, Sun Qidong, Wang Leishuo, Li Hu. Compressive behavior and vibration-damping properties of porous Ti-6Al-4V alloy manufactured by laser powder bed fusion[J]. Journal of Manufacturing Processes, 2021, 66 1-10. [CrossRef]

- Gibson, L.J., Ashby, M.F., 1997. Cellular Solids-Structure and Properties, seconded. Cambridge university, Cambridge.

- Zhou Kai, Chen Wenge, Yang Yana, Li Rong, Dong Longlong, Fu Yong Qing. Microstructure and mechanical behavior of porous tungsten skeletons synthesized by selected laser melting[J]. International Journal of Refractory Metals and Hard Materials, 2021, (prepublish): 105769-. [CrossRef]

- Zhou Kai, Chen Wenge, Yang Yana, Li Rong, Dong Longlong, Fu Yong Qing. Microstructure and mechanical behavior of porous tungsten skeletons synthesized by selected laser melting[J]. International Journal of Refractory Metals and Hard Materials, 2021, (prepublish): 105769-. [CrossRef]

- E. Sallica-Leva, A.L. Jardini, J.B. Fogagnolo. Microstructure and mechanical behavior of porous Ti–6Al–4V parts obtained by selective laser melting[J]. Journal of the Mechanical Behavior of Biomedical Materials, 2013, 26 98-108. [CrossRef]

- Andrey Vyatskikh, Stéphane Delalande, Akira Kudo, Xuan Zhang, Carlos M. Portela1 & Julia R. Greer. Additive manufacturing of 3D nano-architected metals. [J]. Nature communications, 2018, 9 (1): 593. [CrossRef]

| Sample | LS-50 w | LS-70 w | HS-80 w | HS-130 w |

|---|---|---|---|---|

| Mean(μm) | 40.61 | 21.83 | 63.88 | 29.23 |

| D50(μm) | 30.00 | 14.75 | 50.75 | 14.00 |

| D90(μm) | 85.50 | 73.75 | 135.75 | 72.75 |

| Porosity% | 28.20 | 17.06 | 41.50 | 23.42 |

| Sample | Mean(μm) | D50(μm) | D90(μm) | Porosity% |

|---|---|---|---|---|

| 800 mm·s-1 | 40.82 | 28.00 | 84.25 | 34.15 |

| 1000 mm·s-1 | 51.18 | 40.25 | 94.75 | 38.64 |

| 1200 mm·s-1 | 74.65 | 55.75 | 159.25 | 45.33 |

| Sample | Mean(μm) | D50(μm) | D90(μm) | Porosity% | |

|---|---|---|---|---|---|

| 30 μm | 0.08 mm | 31.33 | 22.5 | 64.25 | 27.03 |

| 0.14 mm | 41.29 | 33.00 | 79.25 | 37.33 | |

| 42 μm | 0.08 mm | 34.92 | 26.5 | 66.25 | 28.20 |

| 0.14 mm | 56.62 | 34.75 | 136.25 | 43.24 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).