1. Introduction

Lattice structures with excellent specific stiffness, specific strength and energy absorption capability, are widely used in aerospace, transportation, and biomedical industries for load-bearing, impact mitigation, and energy absorption [

1,

2,

3,

4,

5,

6]. With the development of additive manufacturing technology, lattice structures with multi-scale and complex cell topology can be fabricated, which facilitates the design for special requirements and expands the design space of property modulation [

7,

8]. Cell topologies of lattice structures in nature are usually irregular and the shape of their single cells is random. Therefore, the performance of these structures in load-bearing and energy absorption is unsatisfactory. To improve the mechanical properties of lattice structures, many efforts have been made to design structures with periodic and regular cell topology [

9,

10,

11,

12].

Recently, researches on improving mechanical properties of BCC lattice structures have kept increasing. Included are structures composed of different density gradient topologies [

13,

14,

15,

16,

17,

18,

19], hybrid lattice structures composed of different cell topologies [

20,

21,

22], structures formed by struts with varying cross-sections [

23,

24,

25,

26,

27,

28], structures with arc-shaped struts [

29,

30], and node-strengthened structures [

28,

31,

32,

33]. Chen et al. [

13] replaced the struts of the BCC structure with shells, which effectively relieved the stress concentration at the nodes and exhibited high specific energy absorption. For structures with relative density of ~ 10%, the relative elastic modulus was increased by 2.4 times, and the relative compressive strength was increased by 5.4 times, compared to the BCC lattice structure. Yang et al. [

25] studied BCC structures with different densities and topologies. The study showed that gradient-type BCC structures had stable connections, high modularity and strength at small strains, and layer-by-layer strengthening characteristics at large strains. Bai et al. [

15] proposed a curved strut structure, which designed the BCC strut as a circular arc or ellipse. This structure changed the stress distribution of the original structure and effectively relieved the stress concentration at nodes. Zhao et al. [

23] designed BCC structures composed of hollow struts and investigated mechanical properties with different internal hollow parameters under periodic boundary conditions. When the internal hollow size increases, the elastic modulus of the hollow strut BCC lattice structure increases significantly, and its deformation modes gradually changes from bending-dominated to stretch-dominated. According to Maxwell’s criterion [

34], struts of the lattice structure are usually divided into bending-dominated and stretch-dominated deformations. The bending dominated structure has a relatively higher specific energy absorption, while the stretch dominated structure exhibits a higher yield strength because they are directly subjected to tension or compression. Therefore, the stretch-dominated lattice structure is mainly used for load-bearing in structural applications. In this study, a new lattice structure is proposed by adding a central cube to the BCC structure.

Because of the limitations of additive manufacture, the 3D printed lattice structures usually include defects such as cracks and micro-porosity in the struts [

35,

36,

37,

38,

39,

40]. Furthermore, printed struts with different tilt angles in the structure can exhibit different mechanical properties [

41]. Both of them could negatively affect the mechanical performance of the structure. To establish finite element (FE) models of lattice structures for studying their mechanical properties, the influence of fabrication defects cannot be neglected. Bill et al. [

40] pointed out that the current computational models for lattice structures based on the FE method often use idealized CAD geometry and neglect defects that commonly occur during the additive manufacturing of lattice structures, which results in an oversimplified model. To overcome this limitation, they incorporated geometric defects (i.e., variation in cross-sectional geometry along the strut length or the ‘waviness’ of the strut.) into the struts, thus improving the model’s predictive accuracy. Sun et al. [

42] tested the tensile mechanical properties of struts printed in 0° and 45° and assigned these different material properties to struts with varied inclination directions in the lattice structure. The FE model with angle-dependent material properties shows significantly improved predictive accuracy compared to the model with uniform material properties. Cao et al. [

43] investigated the mechanical response of lattice structures with random geometric defects (i.e., strut porosity, strut thickness variation, and strut corrugation) induced during the additive manufacturing process. The morphology and distribution of 3D printing-induced defects were captured using X-ray computed tomography (XCT) and introduced into the FE model. Better agreement was observed between the predicted results of the FE model and the experimental results.

Using XCT to study the influence of printed defects on the mechanical properties of lattice structures is currently an efficient and direct method available [

43,

44,

45,

46,

47,

48]. However, it cannot precisely capture the defects in lattice specimens prepared from polymeric materials. In response to the problem of how fabrication defects affect the mechanical properties of polymer lattice structures, this study proposes to incorporate microcracks observed in the printed specimens into the FE model along with a material damage model.

2. Experiments

In this section, a new lattice structure is proposed by adding a cube to BCC structure. Fabrication and geometrical parameters of specimens are given. Meanwhile, the experimental procedures and relevant properties are introduced, including energy absorption, bending strength of struts, and deflection of vertical struts of the central truss.

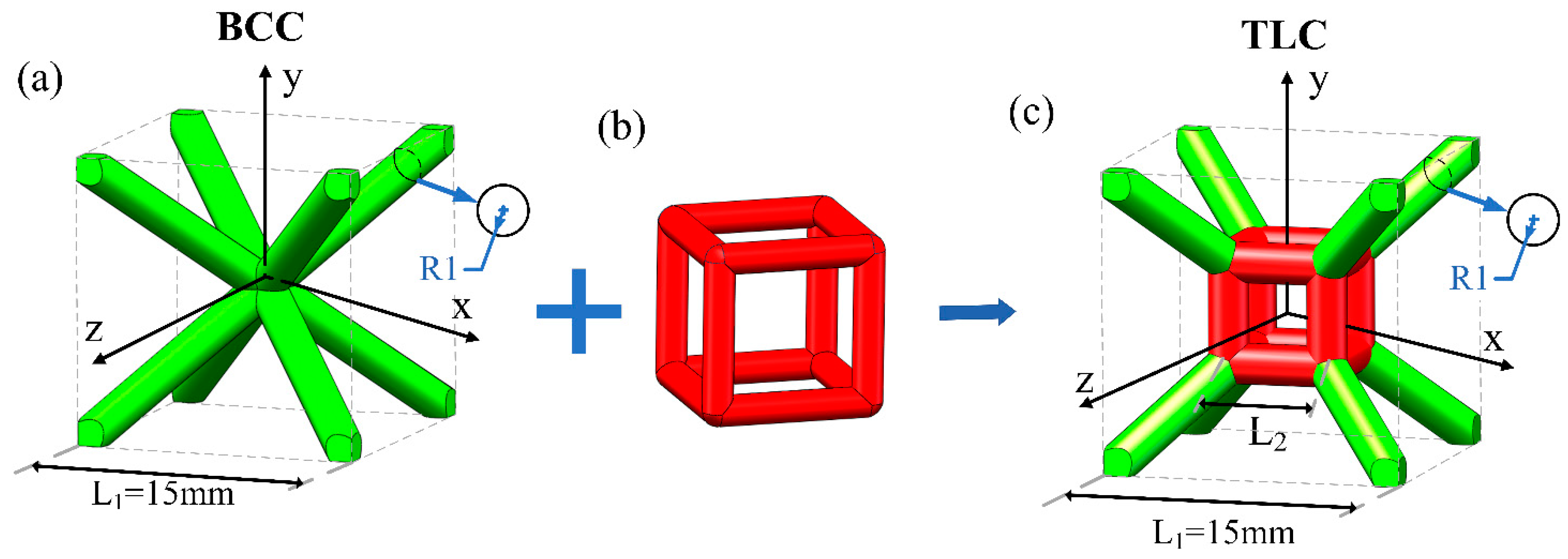

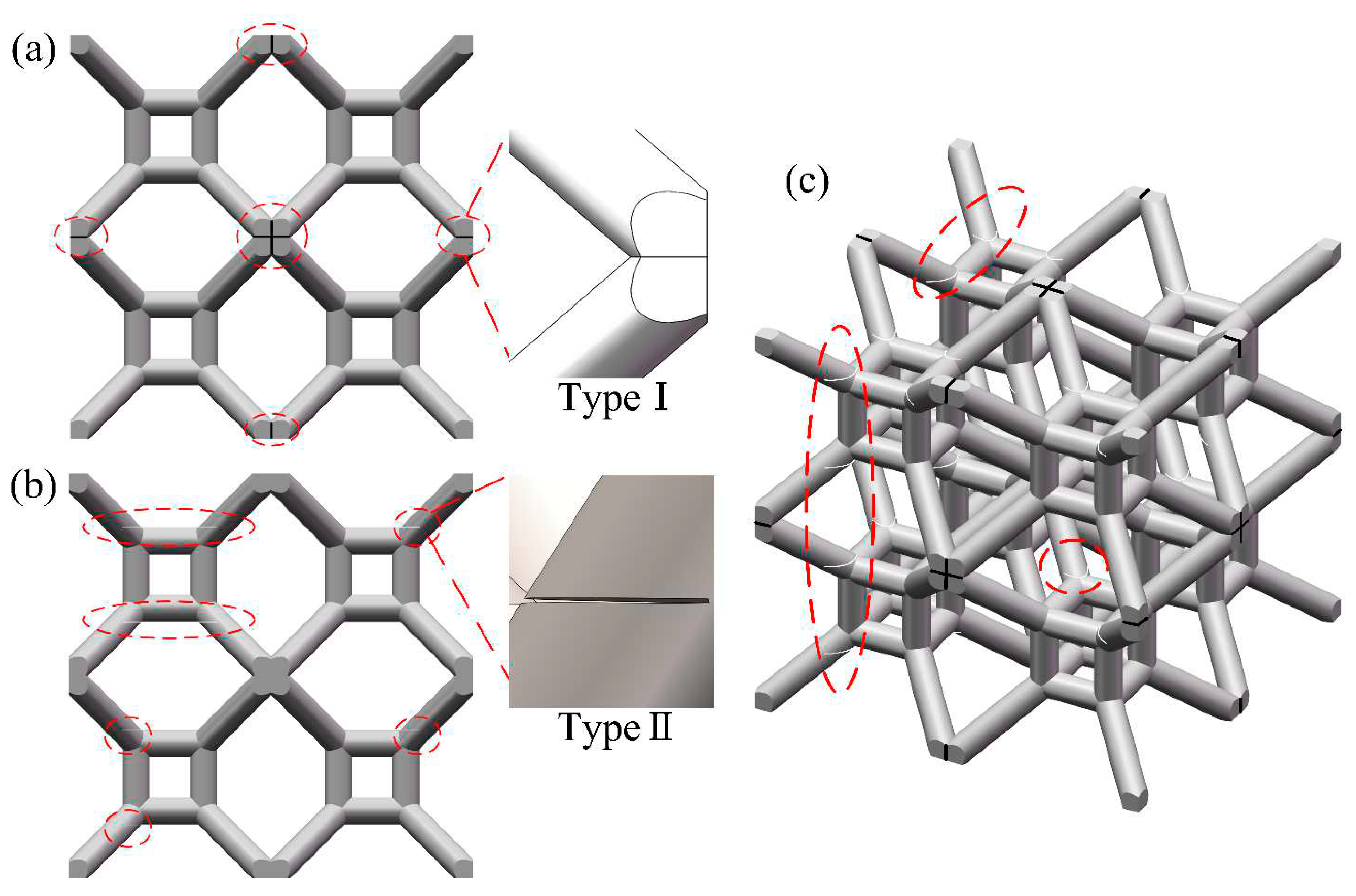

2.1. Design of Lattice Structures

The body-centered cubic (BCC) is a typical lattice structure dominated by bending [

31], as shown in

Figure 1 (a), which consists of eight struts up and down with equal length and diameter. The BCC lattice structure exhibits an excellent post-yield stress plateau under compressive loading, which enables the structure to possess a high energy absorption efficiency. But the low bearing capacity of struts in the BCC structure leads to a low-stress level, which limits its energy absorption capacity and specific strength. In order to design a new lattice structure possessing a stable stress level similar to the BCC lattice structure and a higher energy absorption capacity, the center node of the BCC lattice is replaced by a cubic truss, as shown in

Figure 1 (b). Four vertical struts are added to the new structure for directly resisting the axial compression. It aims to increase the yield strength and flow stress level of the new structure. Meanwhile, the capacity of energy absorption can be improved. The proposed structure is denoted by TLC (Truss-lattice-cube), as shown in

Figure 1 (c). The dimension of a single cell is 15 mm and the diameter of all struts is 2 mm. It is evident that different lengths of the central cubic truss in the TLC lattice structure will exhibit different mechanical properties. The optimal size of the cubic truss is analyzed by experimental tests and numerical simulations. The detail will be discussed in

Section 4.1.

Table 1 shows the key parameters of the BCC and TLC structures. The relative density in

Table 1 is the ratio of the lattice volume (obtained from Solidworks) to the apparent volume of the lattice structure. Here the apparent volume refers to the sum of the solid volume and the closed pore volume of the lattice structure. Apparent density is the ratio of the actual mass (obtained from electronic balance, HZK-JA210S) of the lattice structure to the apparent volume. The theoretical mass of the lattice structures is obtained from Cura software (along with UltimakerS5).

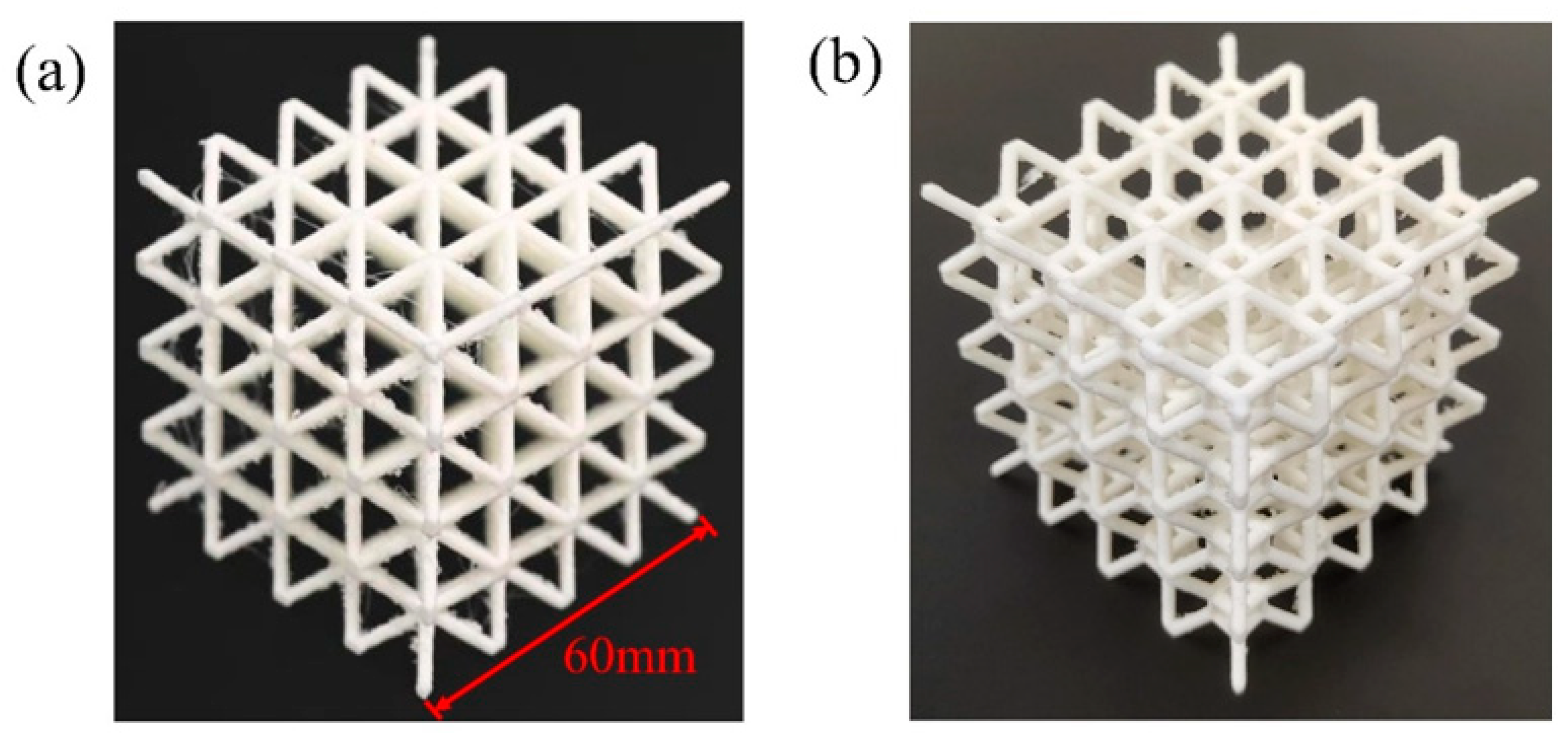

2.2. Additive Manufacturing of Lattice Structures

The 4

4

4 BCC and TLC lattice structures are built using Solidworks (2018). After that, the lattice models are saved in stereolithography (.STL) format and transferred to the Cura software that comes with the UltimakerS5 3D printer for slicing the lattice models. The printed specimens of BCC and TLC structures by UltimakerS5 3D printer are shown in

Figure 2. The printing material for the lattice structures is PolyMax

TM PLA with a diameter of 2.85 mm. UltimakerS5 3D printer has adopts dual printheads, the AA printhead and the BB printhead. In order to print lattice structures with better precision, the BB nozzle is employed to fill the 2.85mm diameter PolyMax polyvinyl alcohol (PVA) water-soluble material. The PVA is used as the substrate in the suspended part of the structure. During printing of lattice specimens, the temperature of the glass plate is set to be 60℃, the printing layer height is set to be 0.1 mm and the printing temperature is 220℃. Considering the fabrication quality of the specimens as well as the fabrication time, the nozzle moving speed is set as 55 mm/s. The external size of all 4

4

4 specimens is 60 mm and the diameter of struts is 2 mm.

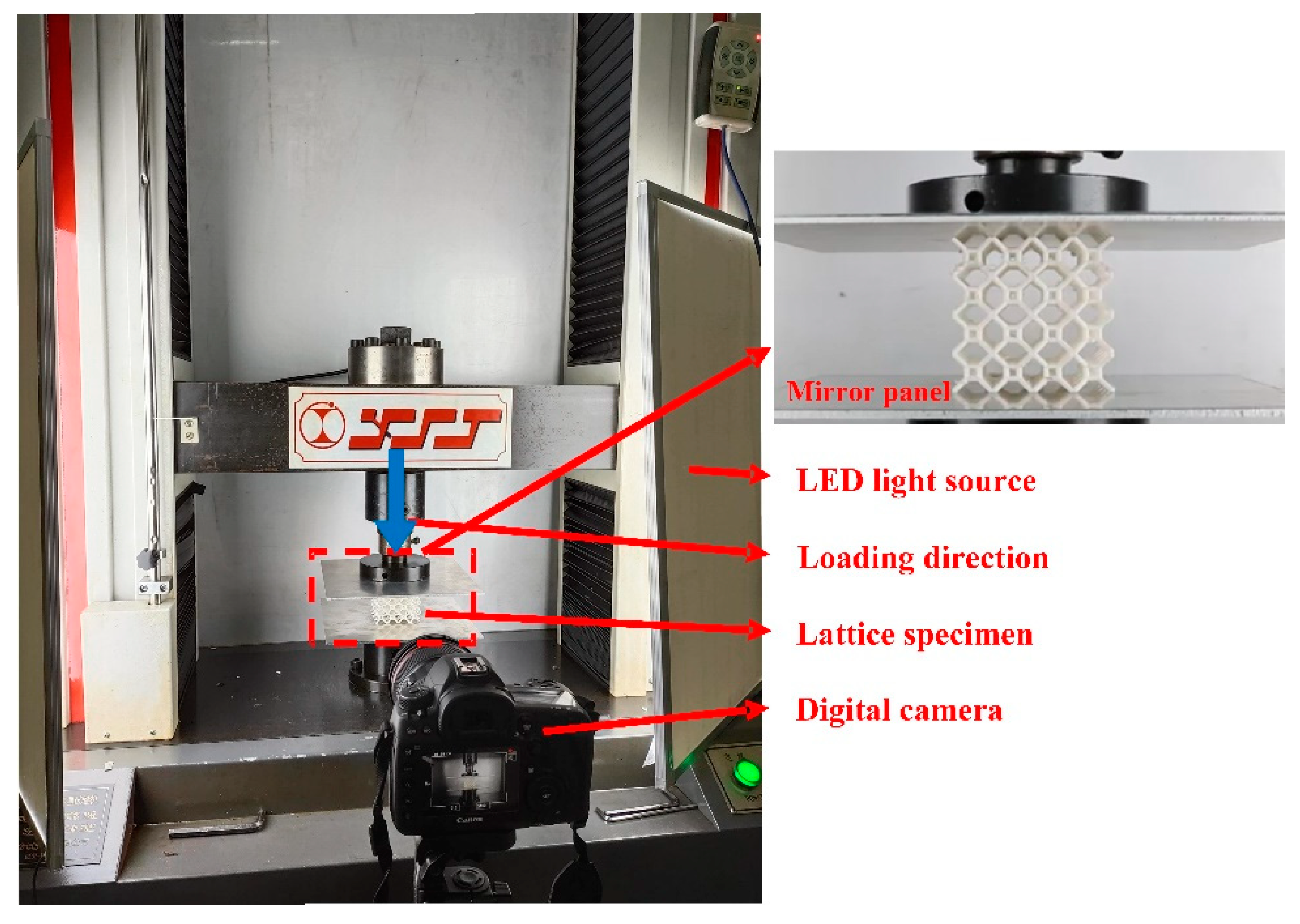

2.3. Mechanical Tests

Quasi-static compression tests of the lattice structures are performed on an electronic universal tensile and compression testing machine (WDS-100). To ensure the accuracy of the lattice structures tests, a mirror aluminum alloy plate, a length

width of 200

200 mm and a thickness of 5 mm, is placed above and below the lattice specimen to reduce the tangential friction. The deformation behavior of each lattice specimen is recorded with a high-resolution digital camera. Backlight plates are placed on the left and right sides of the testing machine to improve the quality of images, as shown in

Figure 3. During the test, the upper platen is moved downward to compress the specimen, while the lower platen is fixed. The experimental test continues until the specimen begins to densify (the strain is about 0.75~0.8). The speed of the upper platen is set at 3.6 mm/min corresponding to a strain rate of 0.001 s

-1.

To study the optimal size of the central cubic truss in the TLC, the single cell and 222 lattice specimens are employed for experimental tests. When specimens are compressed to densification, the loading force does not exceed 4KN. In order to avoid the large error caused by the universal testing machine (WDS-100) with loading force up to 100 KN, a 5 KN universal tensile and compression testing machine (ZQ-990LA) is used to test the single cell and 222 lattice specimens. The compression direction of all specimens in this paper is consistent with the 3D printing direction. Three specimens are tested for each structure.

2.4. Preliminary Analysis

2.4.1. Energy Absorption and Specific Strength

One of the main objectives of present study is to design a new cell topology based on the traditional BCC lattice structure to enhance mechanical properties. The mechanical properties are evaluated based on the energy absorbed (EA) per unit volume, the specific energy absorption (SEA), the energy absorption efficiency (EAE), and the specific strength of the lattice structures.

The EA per unit volume of a lattice structure can be obtained by calculating the area enclosed by the stress-strain curve and its corresponding given strain [

50,

52,

53]:

where

ε represents the engineering strain and

σ(

ε) represents the corresponding engineering stress. Since the BCC and TLC structures have different relative densities, in addition to the EA, the SEA is also considered. SEA refers to the energy absorption per unit mass of the lattice structure [

50,

52,

53]

:

where

ρ represents the density of the lattice structure. The structure with higher SEA has a better energy absorption capacity. The EAE can be calculated as follows [

45]:

This parameter is used to quantify the stability of the post-yield response of the energy absorption. The load-bearing capacity of the lattice structure is evaluated by the specific strength, which refers to the ratio of the corresponding compressive strength under different strains to the apparent density of the lattice structure [

54]

:

where

represents the compressive stress,

represents the apparent density of the lattice structure [

54],

M for the mass and

VA for the apparent volume of the lattice structure, which is the solid volume plus the pore volume. It is obvious that the structures with higher specific strength exhibit better load-bearing capacity.

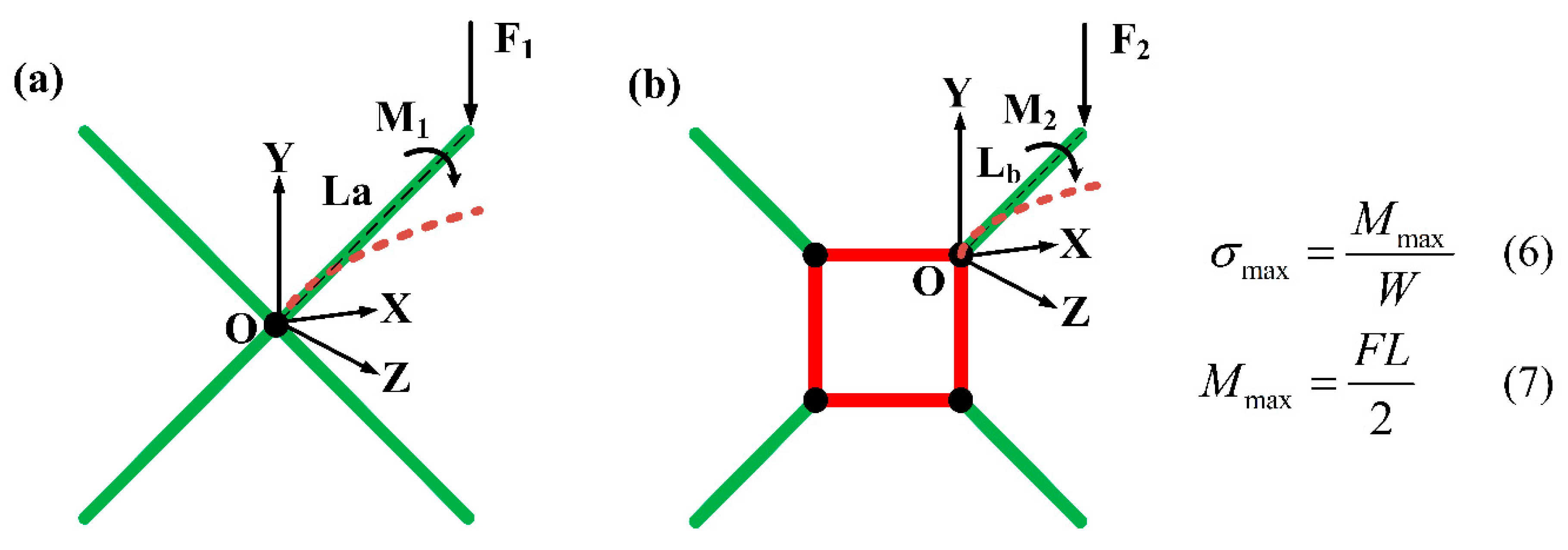

2.3.2. Bending Strength of Struts

The bending strength is the maximum stress that the struts in the lattice structure can withstand when they are under bending loads. It reflects the ability of the material to resist bending and is used to measure the bending performance of the material.

where

represents the maximum bending moment of the strut,

W represents the bending section factor of the strut,

F represents the external force applied, and

L represents the lever arm. As all struts of the lattice structure in this study keep the same diameter, the flexural section factor is fixed, i.e.,

.

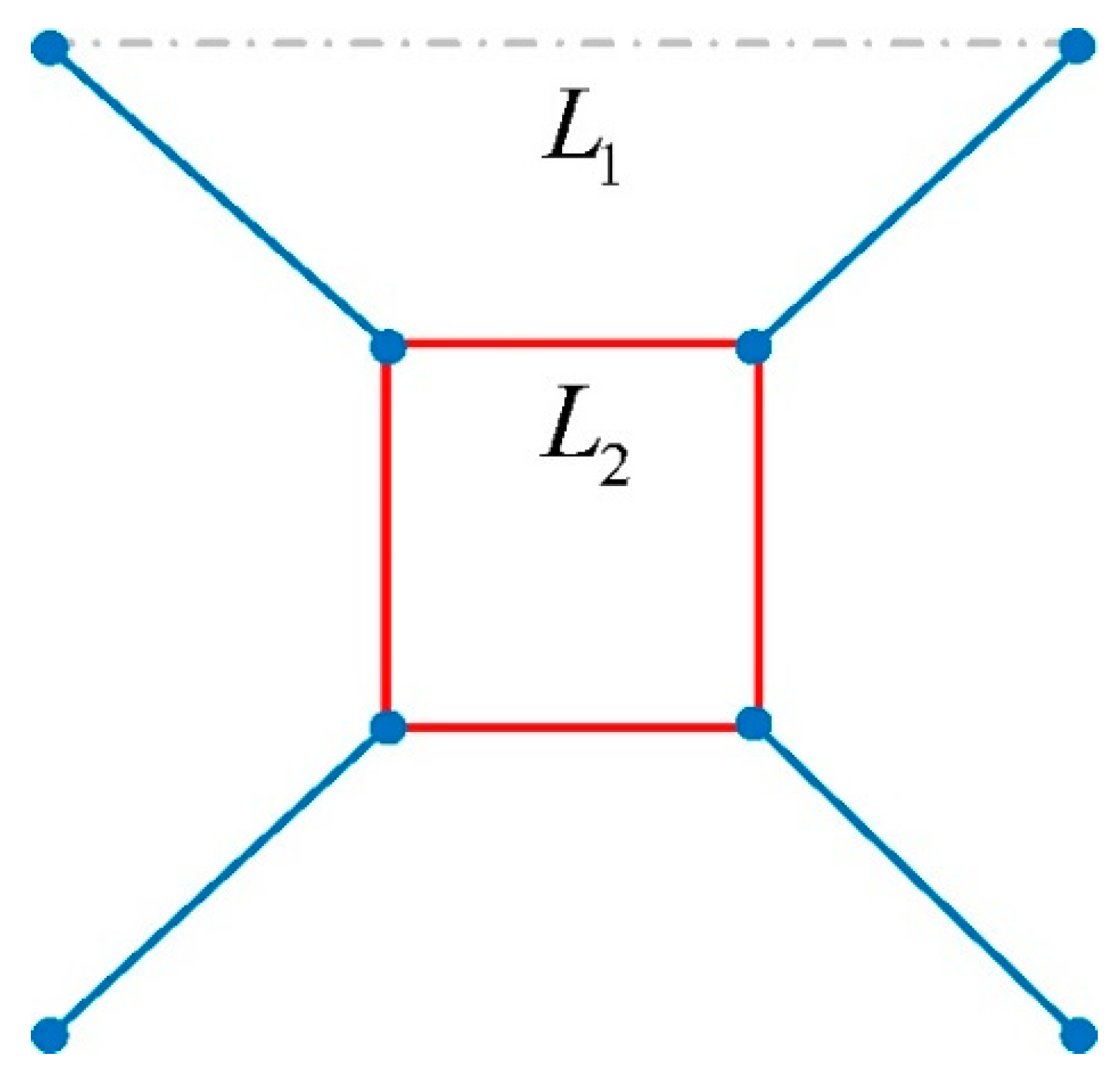

2.3.3. Deflection of Vertical Central Struts

When symmetry of applied force on single cells is broken due to damage or fracture at any location of the lattice structure, lateral deflection of vertical struts would happen and this will reduce the load-carrying capacity of the structure. In this study, the deflection

is used as a variable to evaluate the optimal size of the central cubic truss of the TLC lattice structure. When the lattice structure bears the same load, the larger the deflection, the more likely its vertical struts are to be eccentric, resulting in more frequent damage to the lattice structure. The deflection formula is shown as follows:

Where represents the lateral force applied to the vertical struts, L2 represents the length of the cubic truss at the center of the TLC structure, EI represents the bending rigidity, and I represent the second moment of area. Since the strut diameter and elastic modulus are the same, the factors affecting its deflection are only related to L2. Hence, the selection of the length L2, the size of the central cubic truss, is crucial to its mechanical properties.

3. Finite Element Modeling

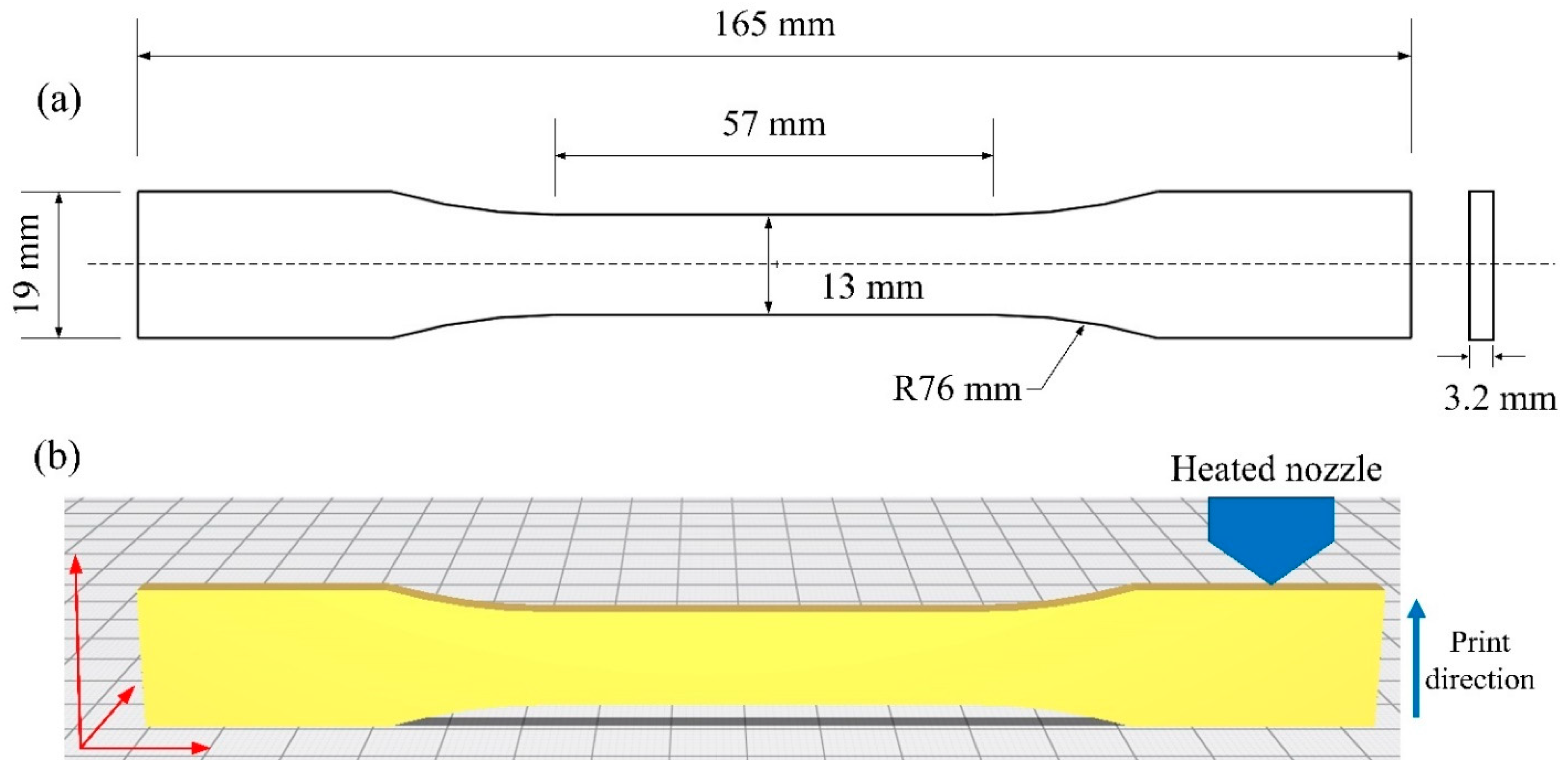

In this section, the printing material properties are obtained by testing dog-bone specimens. A detailed description of the finite element model and numerical simulation, including boundary conditions, element types, loading and meshing, is given.

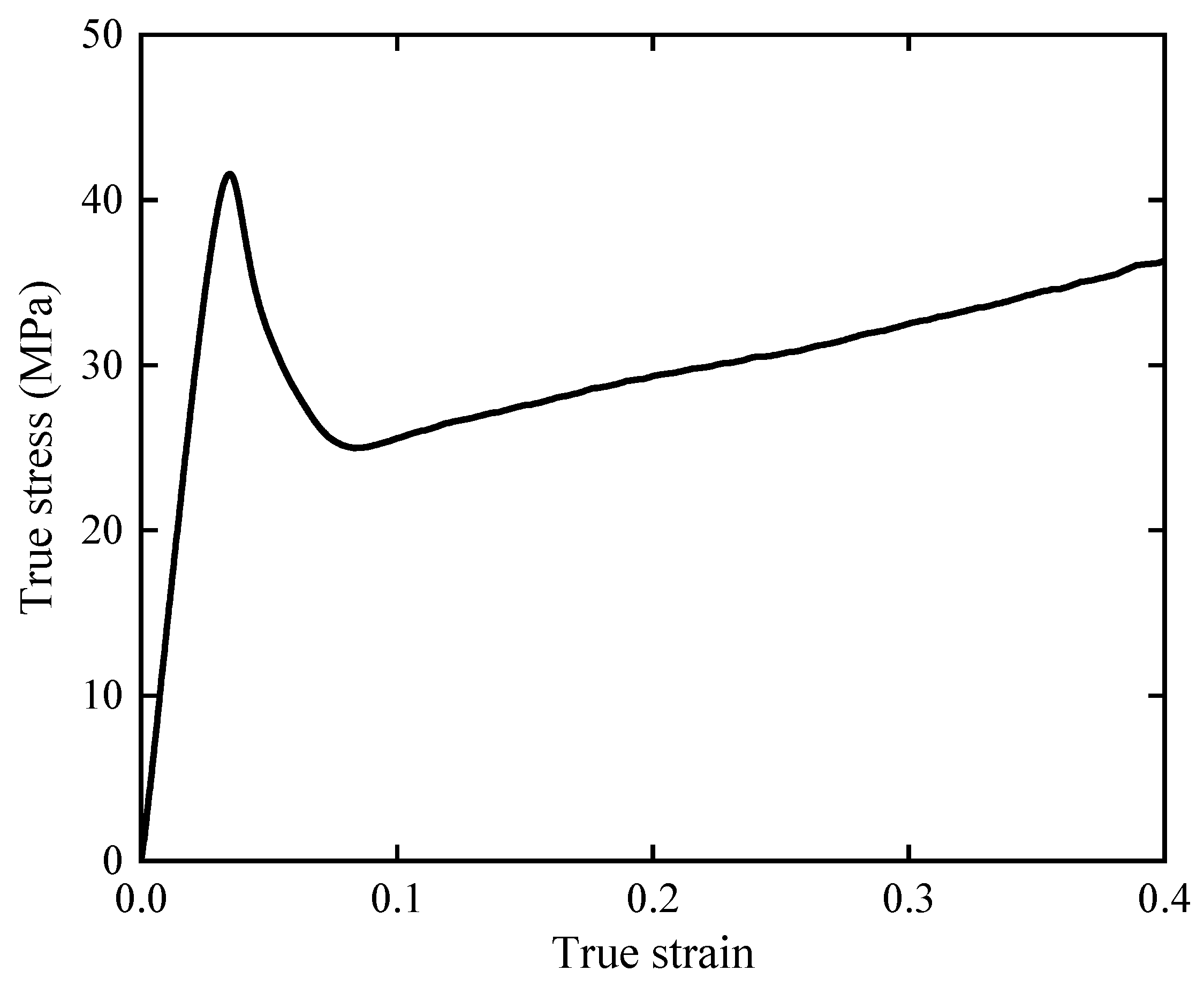

3.1. Material Properties

When the lattice structure is subjected to compression, stresses in different struts are either tensile or compressive. For polymer materials used in this study, the stress resulting in tensile failure is much smaller than the stress resulting in compressive failure. Therefore, as a simplified approach, tensile properties of the printing material are adopted as the material parameters used in FE modeling [

17,

50,

52]

. ASTM D638 Type I dog-bone specimens are fabricated, using the same manufacturing parameters as the lattice structure, to test the mechanical properties of PolyMax

TM PLA materials [

50]. As shown in

Figure 4 (a), dimensions of the ASTM D638 Type I dog-bone specimens are given.

Figure 4 (b) shows the 3D image of the dog-bone specimen for printing. The tensile properties of three dog-bone specimens are tested at 3.41 mm/min using the universal testing machine (ZQ-990LA). The true stress-strain curve is shown in

Figure 5. The elastic and plastic material parameters are given in

Table 2 and

Table 3, respectively.

3.2. Finite Element Model

The FE model of 4

4

4 lattice structure is established for uniaxial compression in ABAQUS 6.14.

Figure 6 shows the FE model of the TLC lattice structure. There are three parts in the numerical model: the loading plate, the lattice structure, and the support plate. The loading and support plates adopt a three-dimensional discrete rigid shell plane. All the lattice models use C3D4 tetrahedral solid elements and the mesh size is set to be 0.65 mm. The support plate sets all degrees of freedom fixed, and the loading plate only retains the degrees of freedom in the “y” direction. The loading plate is set to a downward displacement of 48 mm with a speed of 3.6 mm/min, which is consistent with the experimental strain rate of 0.001 s

-1. In the simulation, the large deformation of lattice structure induces complex self-contact between structural struts. The contact between the loading plate and the lattice structure adopts “general contact”. The friction formula for the tangential behavior is “penalty” and the friction coefficient is set to be 0.2 [

55]. For FE simulation of complex structures, especially for nonlinear compression with large deformations, it is usually calculated using ABAQUS/Explicit [

56,

57]. Compared to ABAQUS/Standard, explicit solvers reduce computational resources and time, and also avoid convergence problems that may be encountered with implicit solvers. To further reduce the computational time of the simulation, the Mass scaling function of ABAQUS is used. Keeping the ratio of kinetic energy to internal energy below 5 % and ensuring that the artificially introduced inertial effects are minimized, the simulation can be considered as quasi-static compression [

56,

57]

. Based on many attempts, the time period is set as 0.01 on the premise of ensuring the accuracy of the simulation results.

4. Results and Discussions

In this section, the optimal size of the central cubic truss of the TLC lattice structure is investigated.

The mechanical properties and deformation modes of the TLC and BCC lattice structure are discussed in detail. The influence of manufacturing defects (i.e., microcracks) on the mechanical properties of the lattice structure is studied in detail.

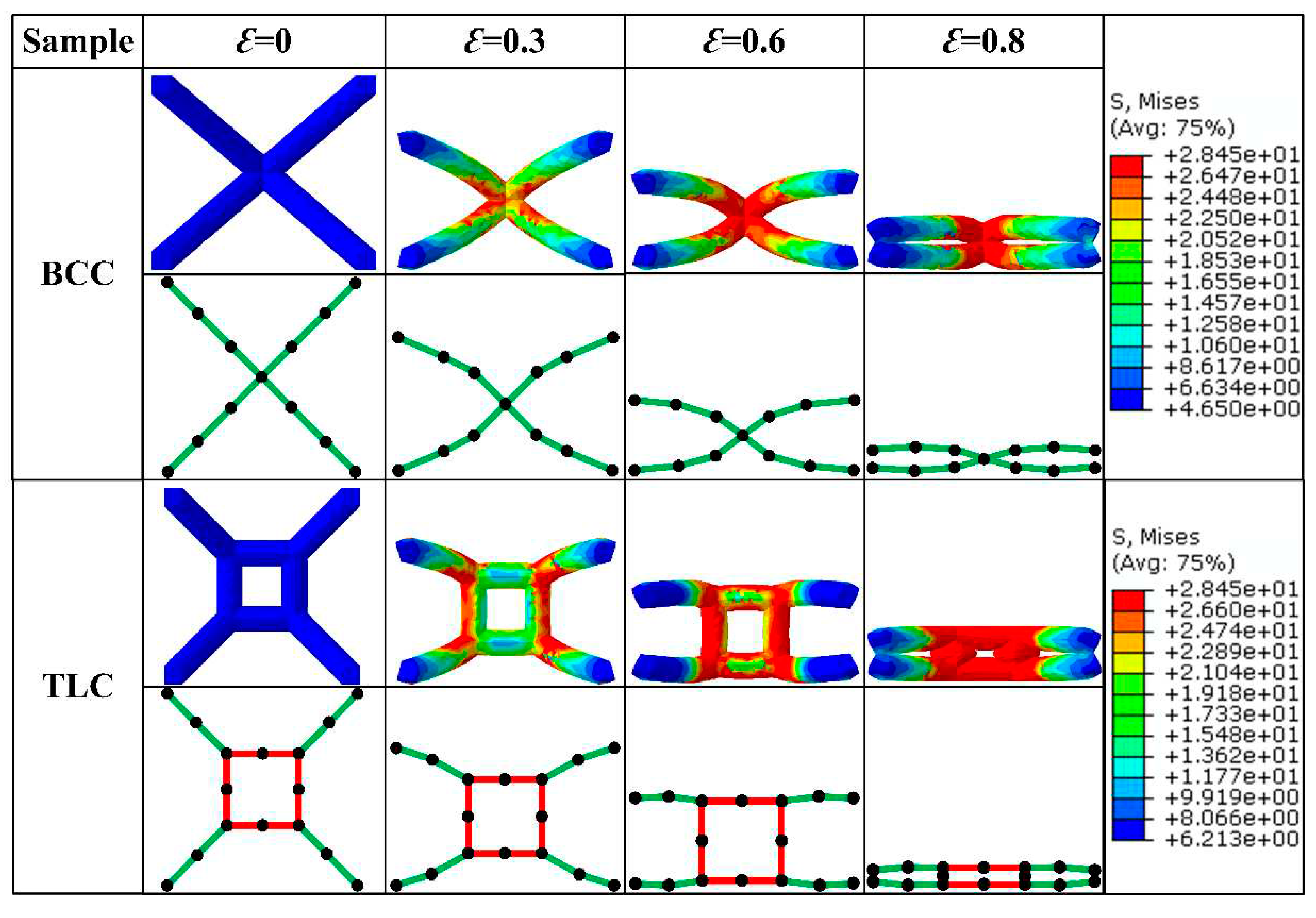

4.1. The Optimal Size of the Central Cubic Truss in the TLC Structure

Figure 7 shows the deformation characteristics of single cells for the BCC and TLC lattice structures at engineering strains of 0, 0.3, 0.6, and 0.8. For the BCC lattice structure, the eight struts are deformed mainly by bending. With the increase in strain, deformation of bending proceeds until the strain reaches 0.8 where the upper strut contacts with the lower strut. Thereafter, the structure starts to densify. In contrast, the deformation of the TLC lattice structure includes two stages: bending for eight inclined struts and compression for vertical struts of the central cube.

When the inclined strut is subjected to a vertical load and the diameter of the strut is fixed, the length (L) of the strut determines its flexural strength, as indicated by Eqs. (6) and (7) in

Figure 8. It is evident that the shorter the strut, the greater the bending strength. For lattice structures in this study, the bending strength of inclined struts affects the yield strength directly. the shorter inclined struts in the TLC structure endows higher yield strength.

Regarding the veritcal struts of the central cube under compression, they belong to short columns and Euler’s formula is not applicable.

Figure 9 is a schematic diagram of the deflection of the central cubic strut due to lateral force. When the TLC structure is under compression, premature damage or fracture would happen in some struts due to printing defects. Therefore, the symmetry of applied force on single cells could be broken and vertical struts of the central truss will be subjected to a resolved lateral force besides the axial loading. Lateral deflection would be unavoidable and the whole structure tends to be unstable. As shown in

Figure 9 with Eqs. (9) and (10), when the diameter of the strut is the same, the longer the length

L2 of the veritical strut the more easily the deflection will occur, which leads to the destruction of the lattice structure at lower strains.

Figure 10 shows the schematic diagram of the cell topology of the TLC lattice structure, where

L2 represents the length of the cubic truss and

L1 for the size of the single cell.

L1 has a fixed value of 15 mm, for all structures. The optimal length of

L2 is investigated in this study.

L2 takes values of 3 mm, 4 mm, 5 mm, 6 mm, 7 mm, and 7.5 mm, respectively, as shown in

Table 4. The TLC structures with six values of central cubic trusses are analyzed by experimental tests and numerical simulations in the following.

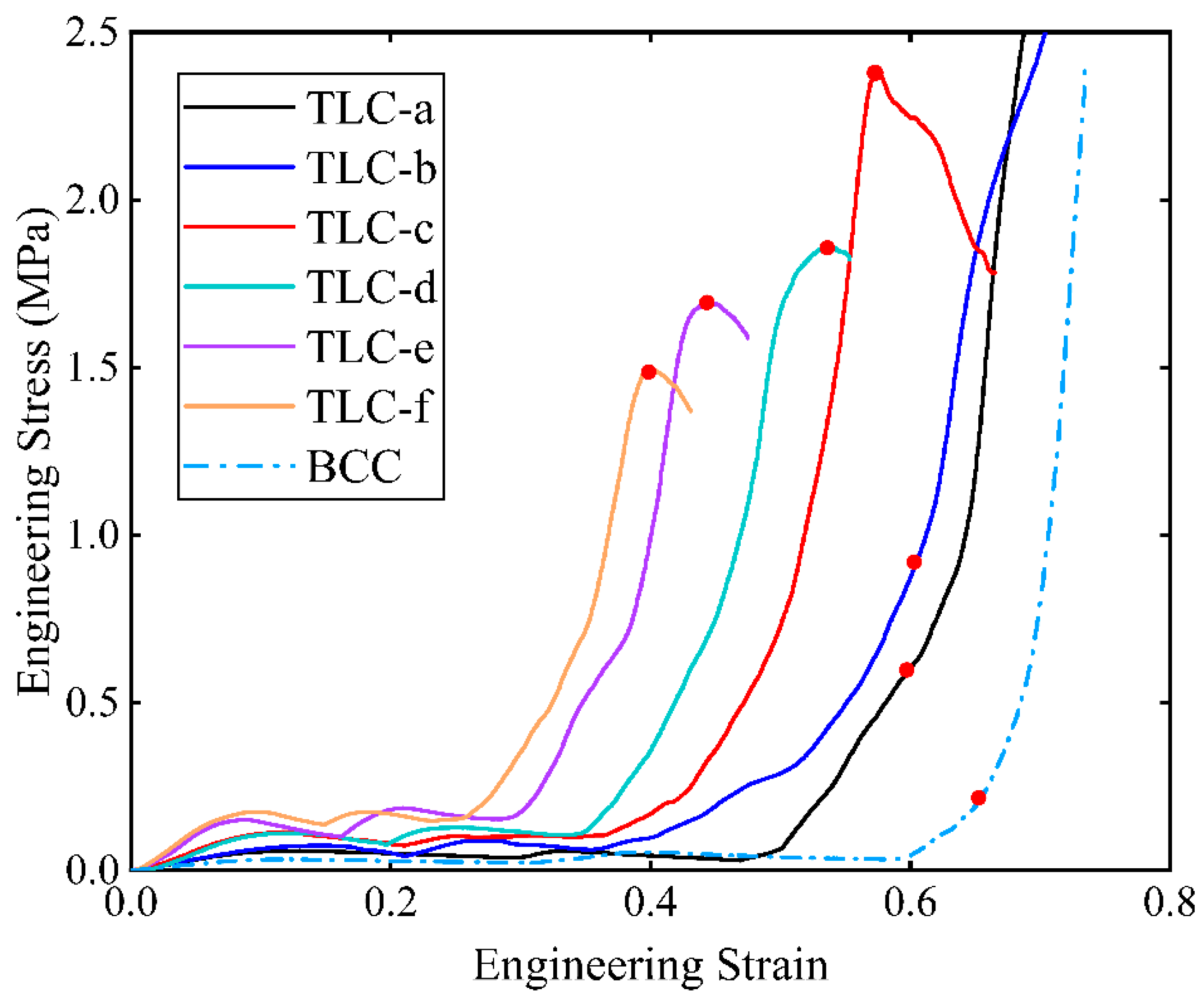

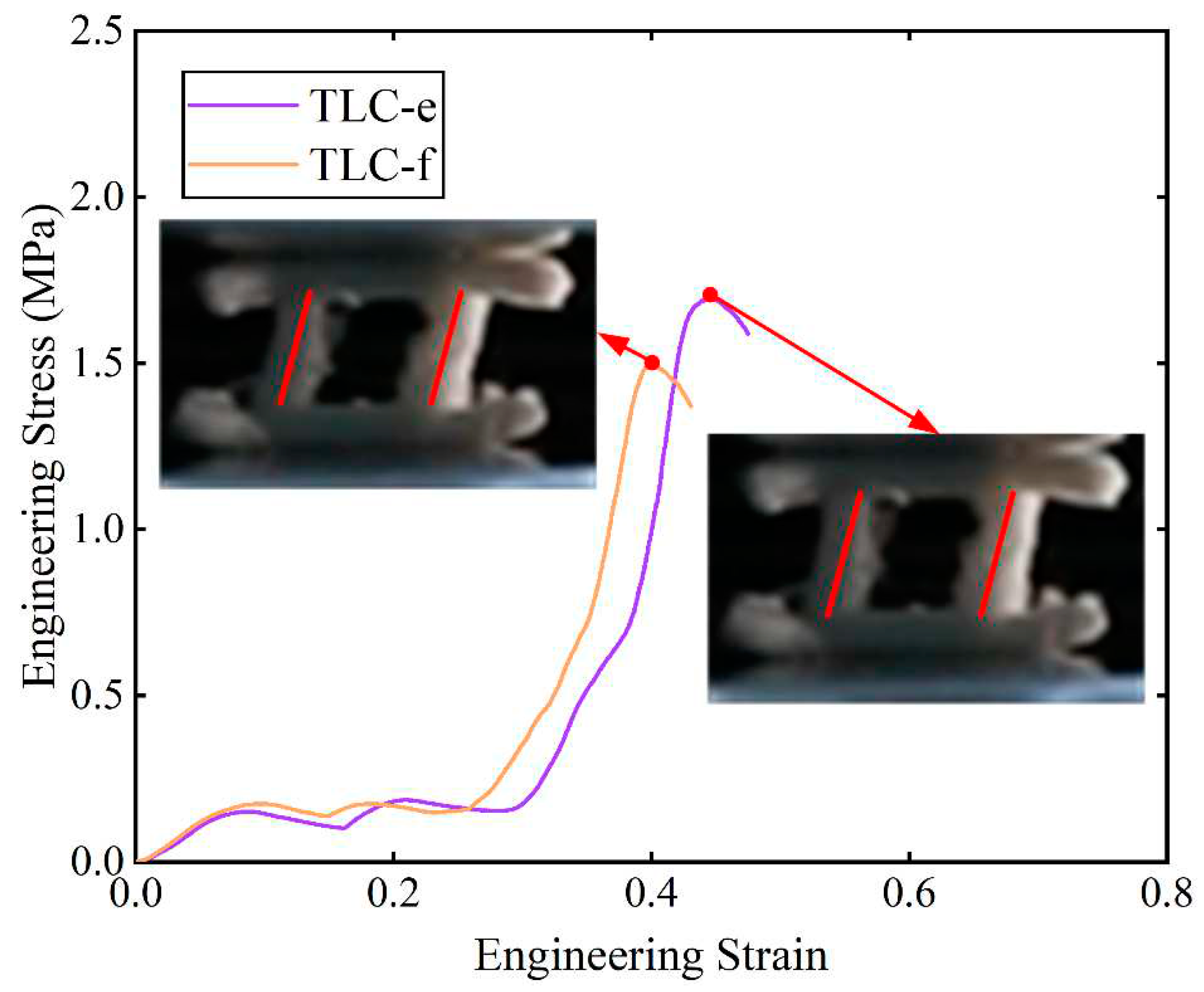

Figure 11 shows the engineering stress-strain curves obtained from compression tests for single cells. The red points marked on the curves indicate the highest stresses of the structure during compression and before densification. Among these curves, stresses of the TLC-e and TLC-f begin to decrease at a strain of ~ 0.4.

Figure 12 shows the deformation characteristics of the TLC-e and TLC-f structures at their highest stresses, respectively. It is consistent with above analysis: the longer the vertical strut (

L2) is, the earlier deflection happens. Furthermore, this deflection results in earlier destruction of the single cell. Therefore, TLC-e and TLC-f are not best choices for the central truss. In contrast,

L2 of TLC-a is the shortest and the deflection of the vertical struts is hard to happen. However, the increased length of the inclined struts will cause decreased yield strength. As shown in

Figure 11, the stress-strain curve of TLC-a almost coincides with that of the BCC structure, and its mechanical properties are not obviously improved compared to the BCC structure. Similarly, the stress level of the TLC-b structure is not significantly elevated compared to the BCC structure. Therefore, both TLC-a and TLC-b should not be regarded as the optimal sizes for the TLC structure.

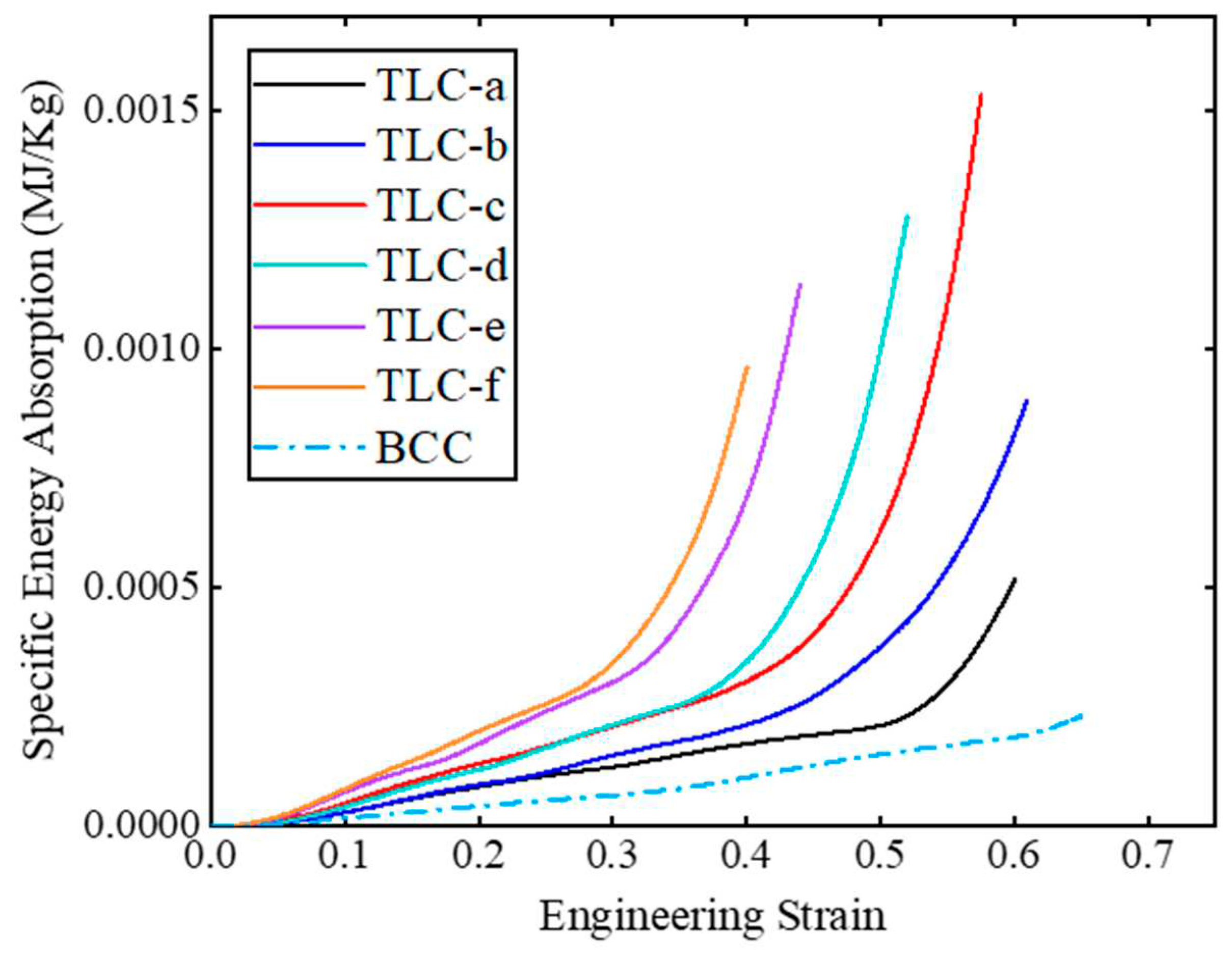

Figure 13 shows the SEA curves of TLC and BCC single cells with respect to strains. Among the six sizes, TLC-c (i.e., the red curve) has the best energy absorption capacity. However, before the strain reaches 0.5, the performance of the TLC-d structure is equal to or even better than that of TLC-c. The simulation results in

Figure 14 illustrate clearly the higher flow stress level of TLC-d, compared to that of TLC-c. Therefore, only by the behavior of single cells, it is difficult to determine which of the two values is the optimal size for the central cubic truss in the TLC structure.

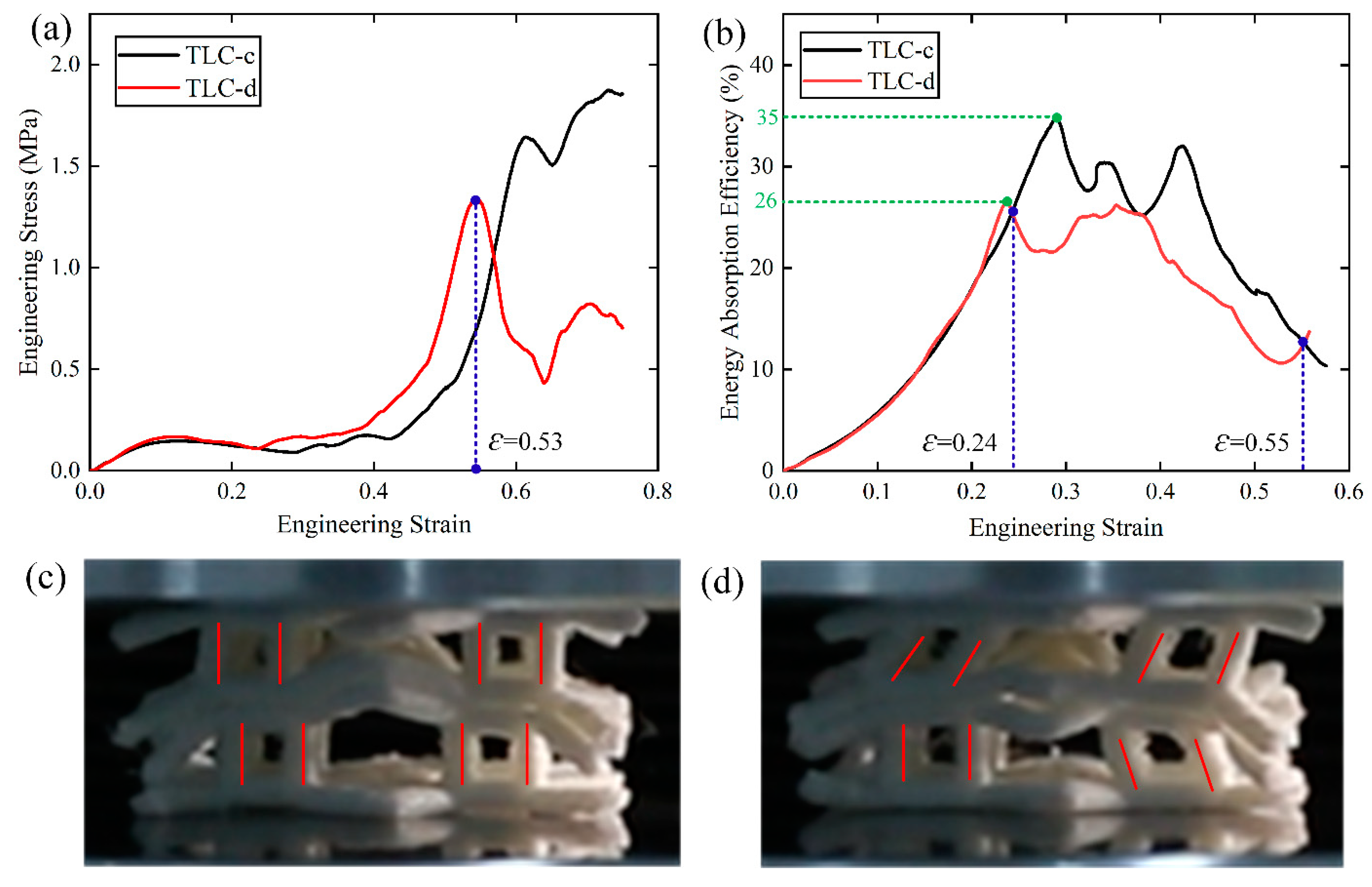

In order to explore the mechanical properties of TLC-c and TLC-d in-depth, 2

2

2 specimens of TLC-c and TLC-d are fabricated for experimental tests, and the results are shown in

Figure 15. The blue dashed line in

Figure 15 (a) indicates the strain corresponding to the highest stress in TLC-d. It shows that before a strain of 0.53, the stress level of TLC-d is a little higher than that of TLC-c.

Figure 15 (b) shows the energy absorption efficiency (EAE) curves of 2

2

2 TLC-c and TLC-d structures. The maximum EAE of TLC-c and TLC-d structures are 35% and 26%, respectively. TLC-c exhibits 1.35 times higher than TLC-d. Between strains from 0.24 to 0.55, the EAE of TLC-c is superior to that of TLC-d obviously.

Figure 15 (c) and (d) show the deformation characteristics of TLC-c and TLC-d at a strain of 0.53, respectively. It is apparent that the vertical struts in TLC-d have been laterally deflected significantly and the whole structure is unstable. In contrast, the vertical struts in TLC-c can still resist the axial load properly. Therefore, to consider three factors together, i.e., the EAE, stability of the structure, and the flow stress level, TLC-c exhibits the best performance. That is to say, the optimal length of the central cubic truss

L2 is determined to be 5 mm. Therefore, the size of the central truss is fixed to be 5 mm in the following study.

22 TLC-c and TLC-d obtained from experimental tests; (b) energy absorption efficiency curves, the green dashed lines represent the highest energy absorption; (c) and (d) are the deformation characteristics of TLC-c and TLC-d at a strain of 0.53, respectively.

4.2. Experimental Results for 44

4 Structures

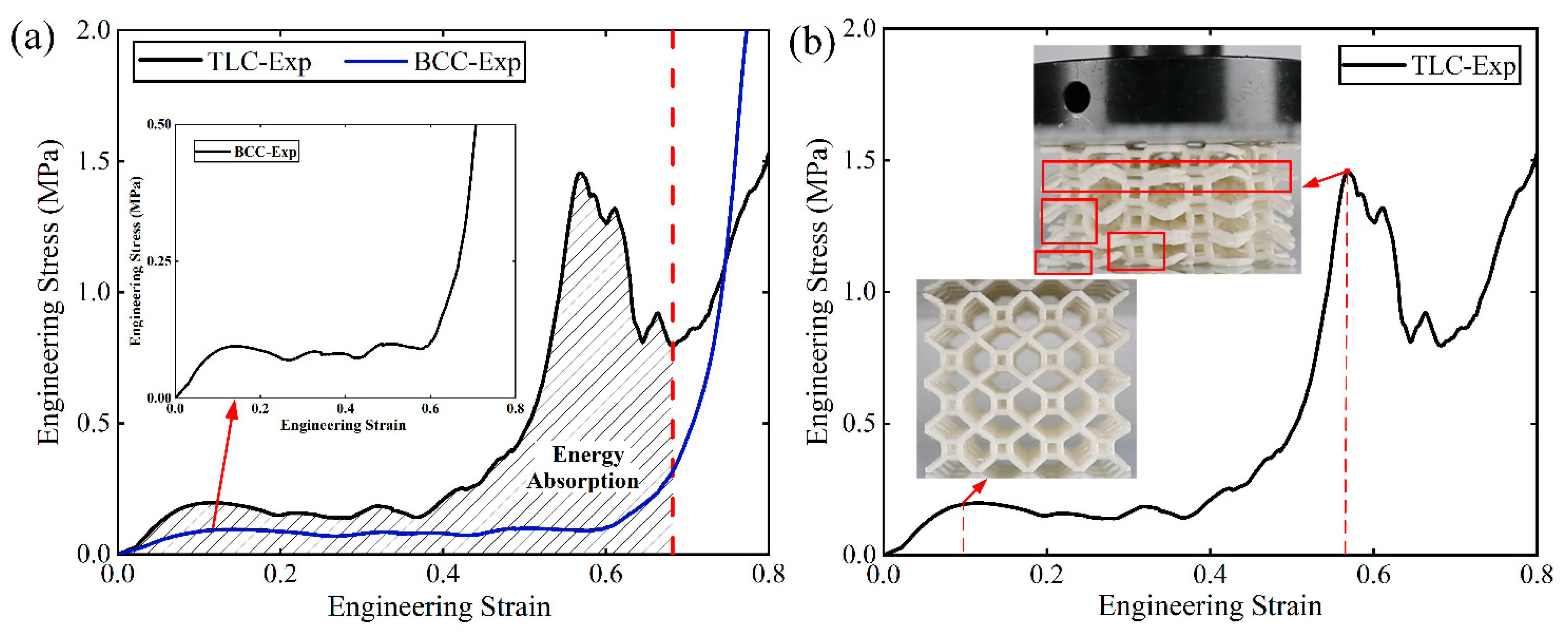

The mechanical properties and energy absorption of lattice structures in this study are discussed based on the results of quasi-static compression tests. The engineering stress-strain curves of 4

4

4 lattice structures are shown in

Figure 16 (a). From the figure, it can be found that the deformation in the BCC and TLC lattice structures are generally composed of three stages. The first stage is elastic deformation: the stress rises elastically with strain until it reaches the yield strength. After this point, the struts undergoing bending start to yield plastically. The curve enters the second stage, and there is a plateau with small stress fluctuation. With the increase in strain, the curves of stress enter the third stage: the flow stress of structures are keeping increasing. For example, when the strain of the TLC lattice structure reaches 0.4, with exhausting bending deformation from eight tilted struts in a cell, axial deformation begins to dominate, which is mainly contributed by vertical struts of the central cube. Thereafter, the stress will increase significantly. However, when the strain reaches about 0.6, the stress of TLC structure decreases abruptly. The reason will be discussed later in this section. The deformation characteristics of TLC structures at strains for initial yielding and the highest stress before densification are shown in

Figure 16 (b). The red squares mark the places where struts break during compression.

As shown in

Figure 16 (a), the flow stresses of the TLC structure are much higher than that of the BCC structure. For instance, the initial flow stress of the TLC structure is increased by 122%, compared to that of BCC structure at a strain of 0.1. The stress of the TLC at a strain of 0.4 is increased by 191%. When the strain increases from 0.5 to ~ 0.6, the stress of the TLC structure rises to a highest point, 1.45 MPa, while the corresponding stress of the BCC is only 0.1 MPa. The vertical struts of the central cube resist the axial loads, and the energy absorption capacity of this structure is improved accordingly. The shaded part under the engineering stress-strain curve is the energy absorbed by the TLC lattice structure. The value is much higher than that of the BCC lattice structure, which indicates that the ability of energy absorption of the TLC lattice structure is significantly improved.

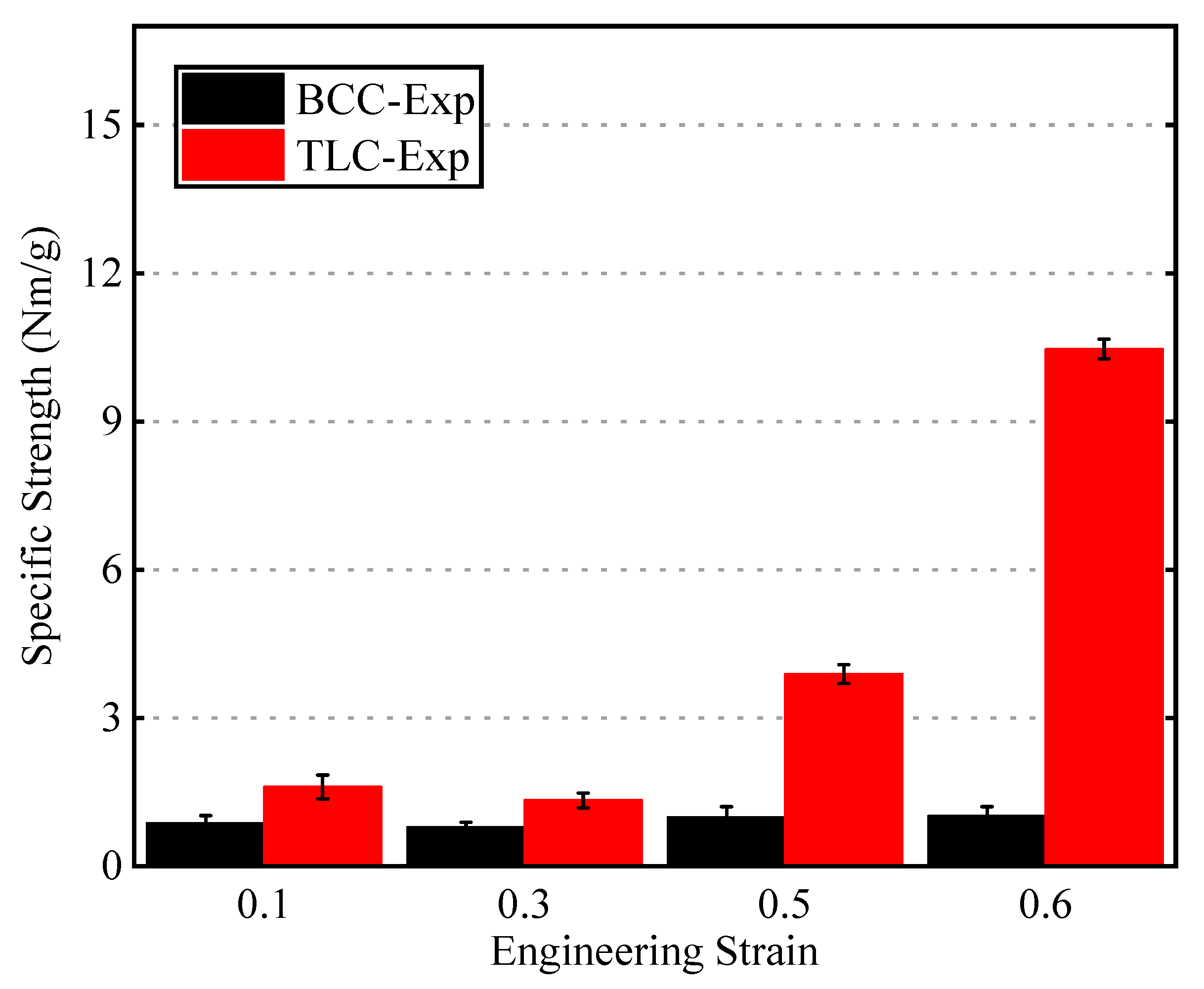

Figure 17 shows the specific strength corresponding to the BCC and TLC at strains of 0.1, 0.3, 0.5, and 0.6, respectively. The BCC structure shows lower specific strength compared to the TLC structure and its values exhibit little changes with strain. The proposed TLC lattice structure shows much better specific strength, indicating an improved load-bearing capacity. For instance, at a strain of 0.5, the specific strength of the TLC is increased by 293% compared to that of the BCC structure.

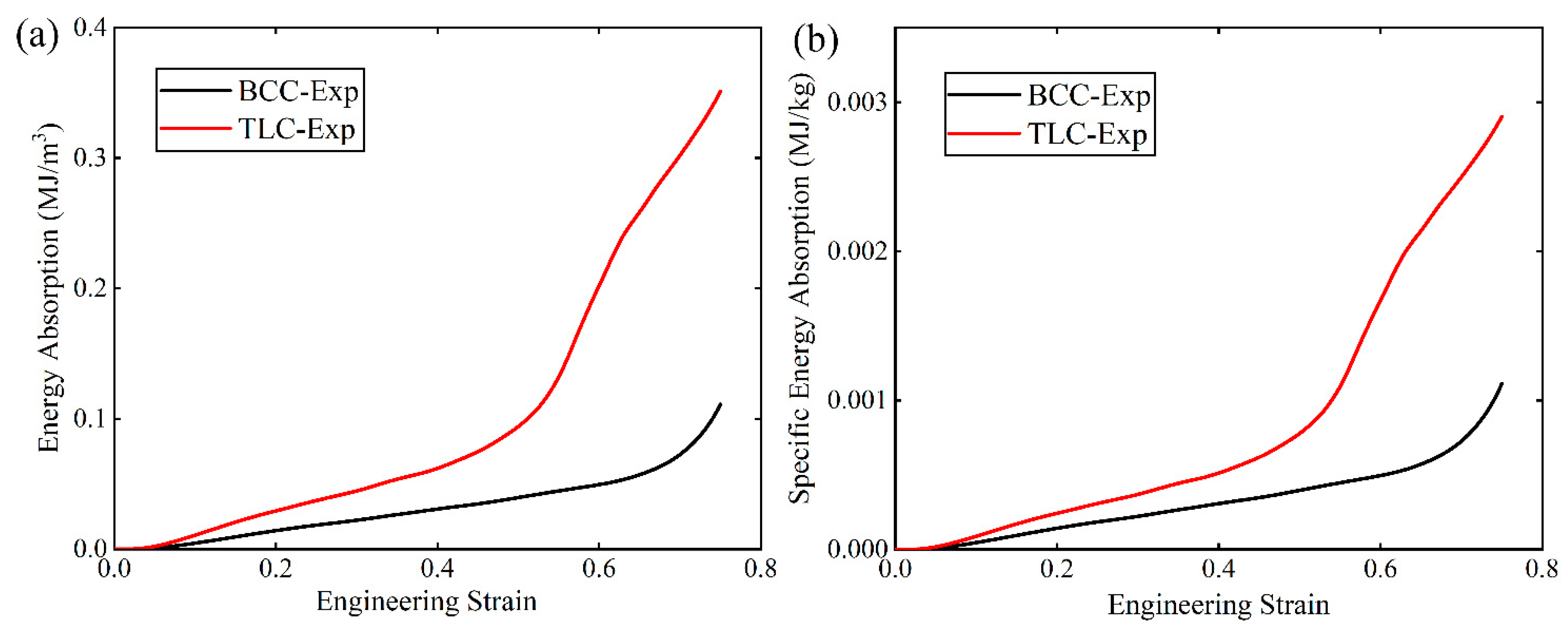

Figure 18 shows EA and SEA of the BCC and TLC lattice structures. The performance of the TLC is much better than the BCC structure. At strains of 0.5 and 0.6, the EA of the TLC is enhanced by 96% and 181% respectively; and the SEA is enhanced by 136% and 312%, respectively, compared to that of the BCC structure.

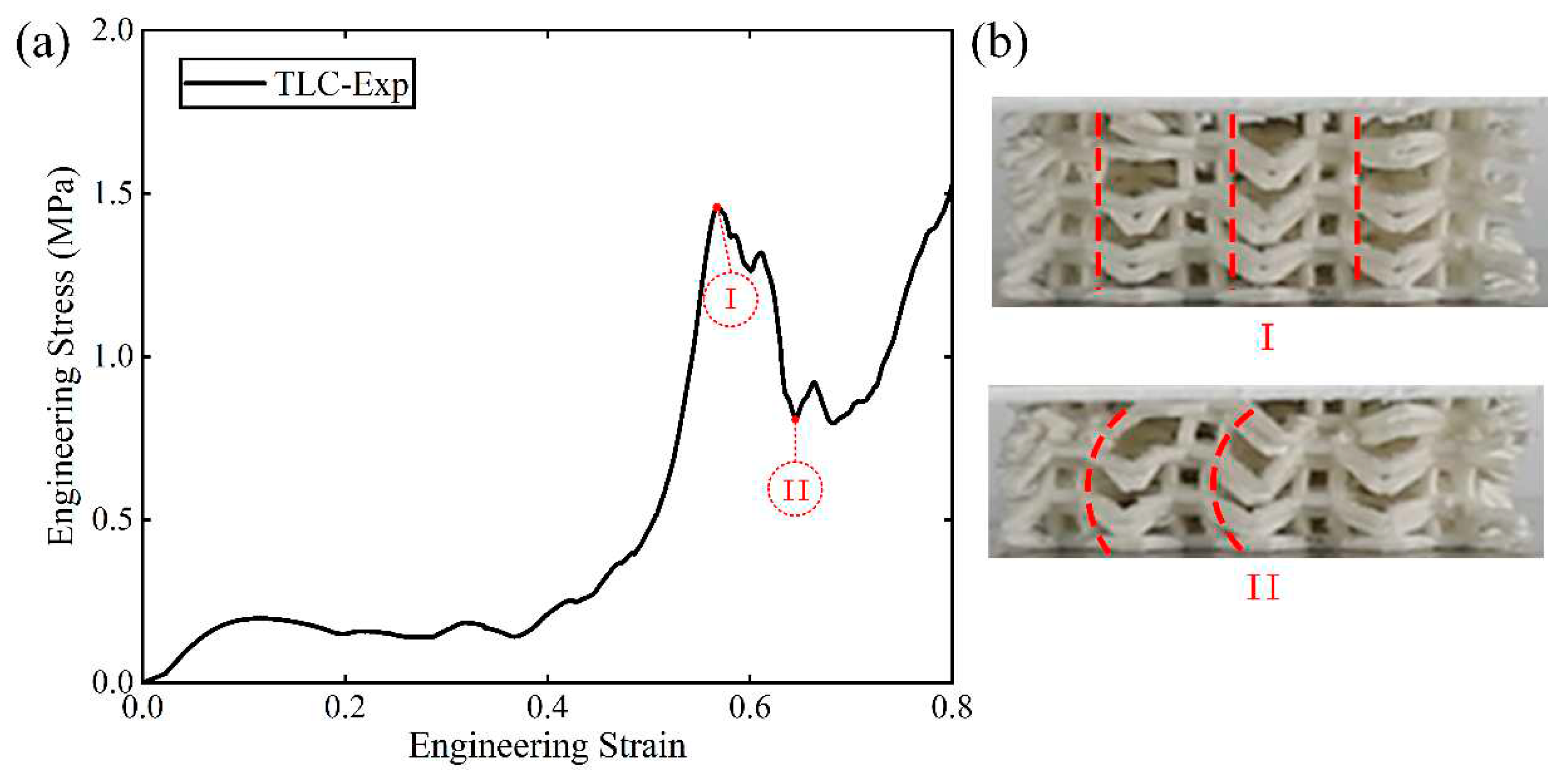

A salient point is worth further discussion: as shown in

Figure 19 (a), the curves for TLC structure exhibit crests at strains just before the final densification of the structure. In contrast, for the BCC structure, such crest in the stress-strain curve cannot be observed.

Figure 19 (b) shows the corresponding images of the TLC specimens at strains near the crest and the trough. Image I denotes the crest and Image II for the trough. It is obvious to find that in the Image I, the vertical struts of the central cube of four layers up and down are almost in a straight line, as indicated by the dashed red lines. They work together like one vertical column to resist compressive loads. When compression proceeds, the vertical struts of four layers cannot keep in a straight line anymore, as shown in Image II by the dashed red lines. Lateral deflection or damage may happen to these vertical struts. Thereafter, destruction of the whole structures continues. Therefore, the crests and the trough near densification in TLC structure is analyzed to be the results from the deformation of vertical struts of the central cubic truss.

4.3. Finite Element Modeling for Lattice Structures with Defects

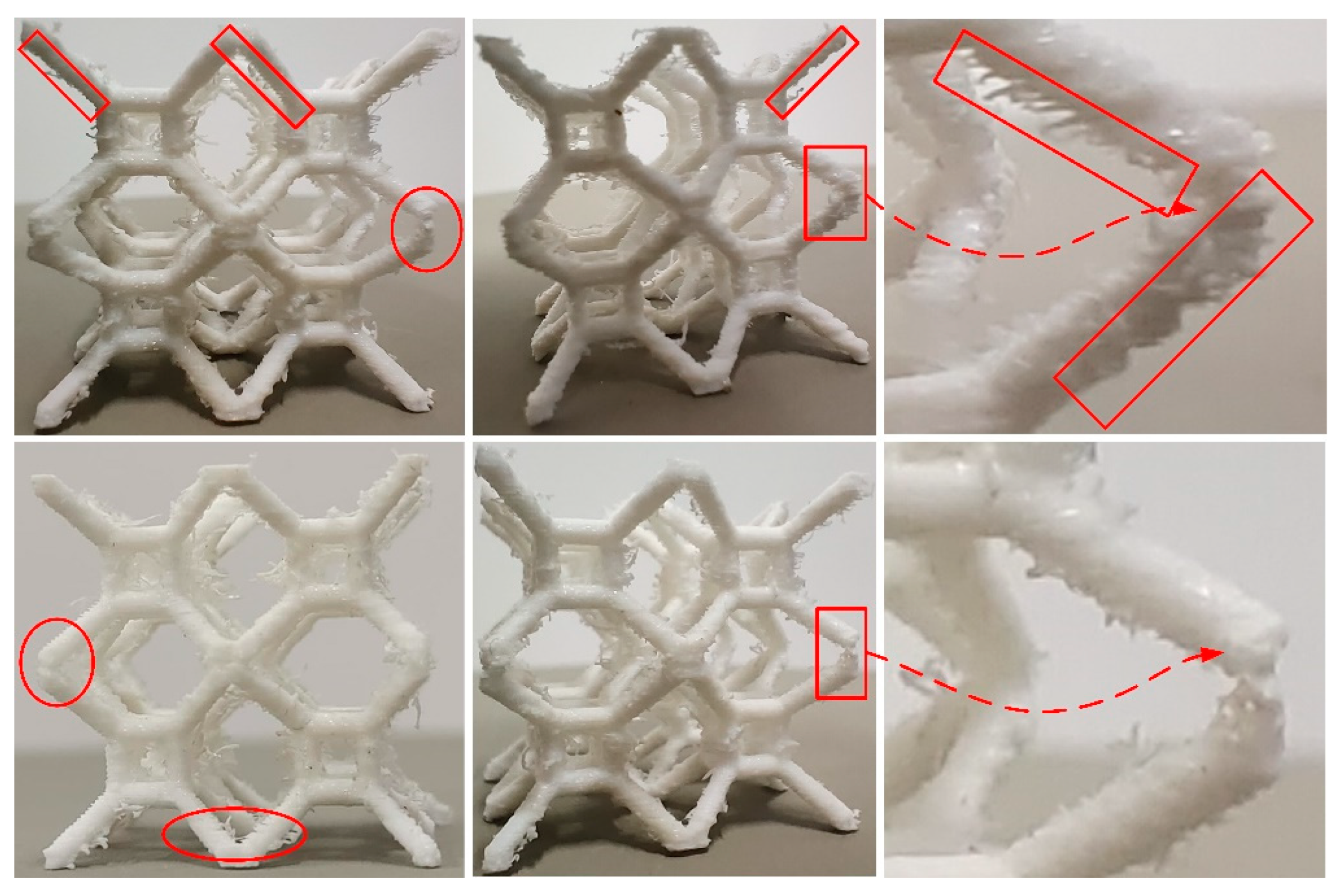

While 3D printing technology makes fabrication of complex structures possible, defects induced by printing are inevitable.

Figure 20 shows 2

2

2 specimens of the TLC lattice structure printed using FDM technology. The red rectangles highlight the places where printing defects are obvious. These images show clearly two typical categories of defects during printing polymer lattice structures: pores and microcracks in the struts or nodes/joints. Although these defects may be small, they can generate a significant negative impact on mechanical properties of lattice structures, and cannot be ignored. Specifically, the pores and microcracks in the inclined struts can be observed clearly in

Figure 20, and the weak connection between two inclined struts can be easily found. These printing defects could result in premature damage or fracture of the struts, and the mechanical performance of the whole structure will deteriorate significantly.

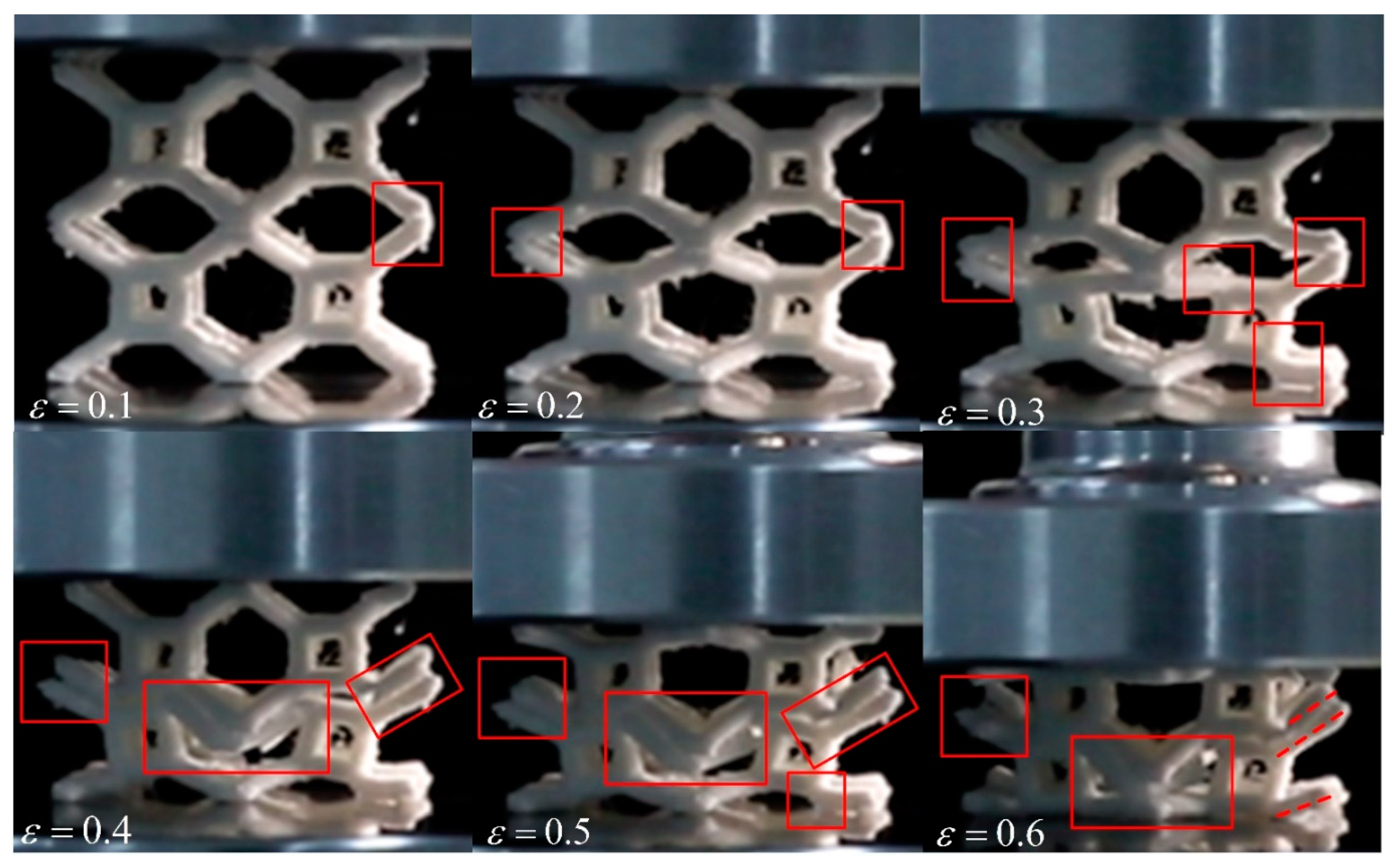

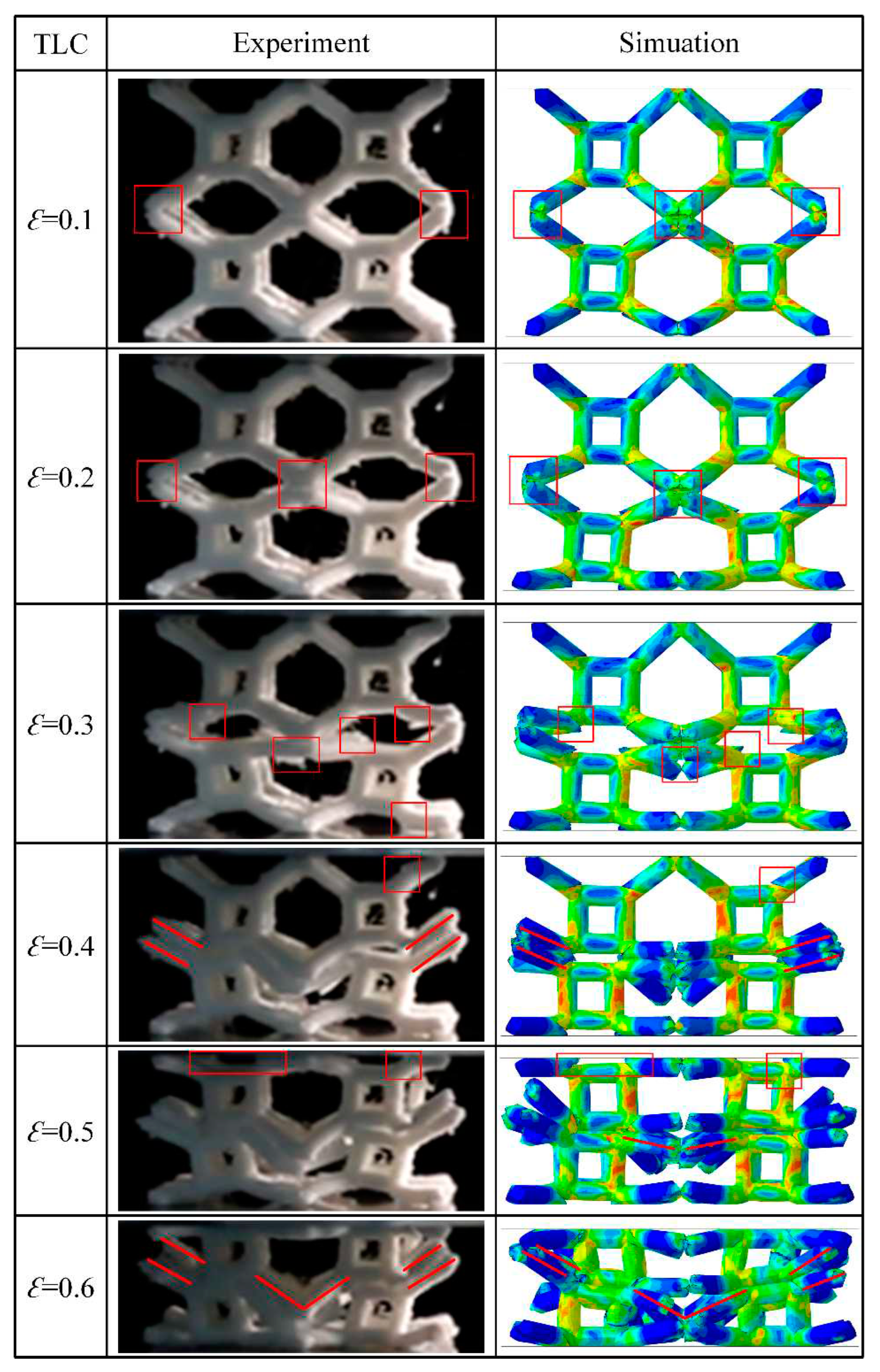

Figure 21 shows the deformation characteristics of 2

2

2 TLC specimens at different strains. At the initial phase of the compressive deformation — i.e., a strain of 0.1, it can be found that the node highlighted by the red rectangle shows an obvious crack. Similar cracks can be found in nodes at a strain of 0.2. When the strain reaches 0.3, serval nodes and struts show clear fracture and the uniform deformation of the lattice structure cannot be maintained anymore. As compression proceeds (i.e., at strains of 0.4, 0.5 and 0.6), collapse of the middle layer supported by inclined struts happens and all inclined struts are breaking and losing their function.

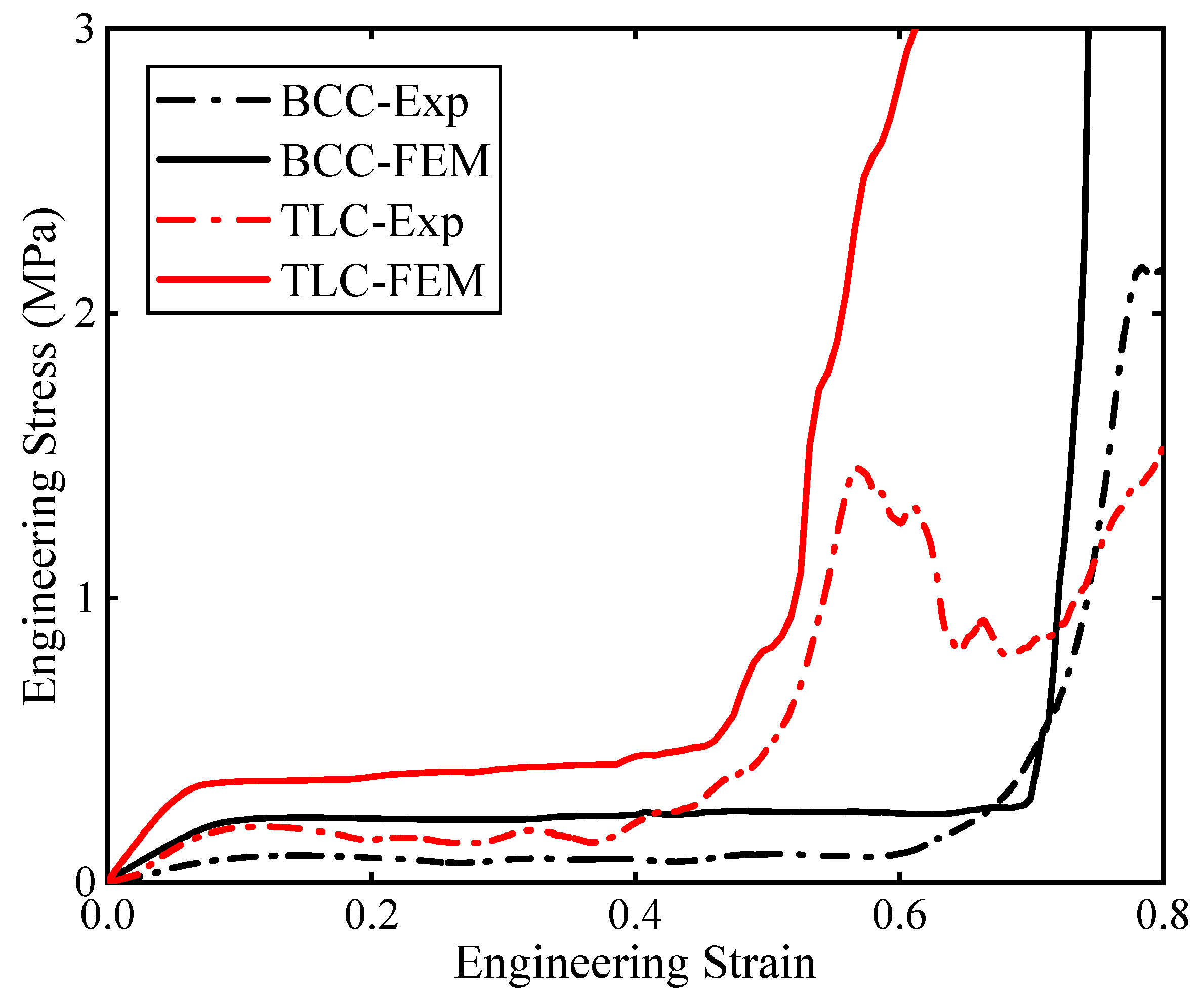

Figure 22 shows the experimental and simulation results for both 4

4

4 BCC and TLC lattice structures. The solid lines are for experiments and the dashed lines for simulations. Although the trend for both results is consistent, the flow stresses exhibit obvious discrepancy between them. The key point is that the FE model adopts an ideal lattice structure while 3D printing defects in experimental structures cannot be avoided. With close observation of the experimental specimens, micro-cracks in printed struts often lead to uneven stress distribution and local damage when the specimens are subjected to compressive loads. Such asymmetric structural stresses could result in unexpected lateral resolved forces, which may further cause the overall collapse and failure of the lattice specimens. However, in the numerical simulation, the model is usually simplified: the struts are designed to ignore printed defects and the nodes of the lattice structure are assumed to be perfectly connected. With the increase of strain, the damage and fracture of the struts in the lattice specimens grow gradually for experiments; in contrast, the ideal structure in the numerical simulation can always maintain a continuous and uniform deformation. Therefore, it is necessary to consider the influence of printed defects during FE modeling for lattice structures to improve the accuracy of the numerical simulation. This work proposes to incorporate microcracks into the FE model for the TLC lattice structure. Due to the high requirement for computational resources after insertion of microcracks in the FE model, only 2

2

2 lattice structures are considered in the following simulations.

4.3.1. Establishment of the Finite Element Model for Lattice Structures with Microcracks

It is worth noting that defects in lattice specimens printed by FDM technology are random. The number and location of defects in each lattice specimen are uncertain, making it challenging to establish a FE model with similar defects for a lattice specimen. Based on experimental observation, two salient points can be concluded that: (i) inclined struts in lattice specimens often have more defects than the vertical struts; (ii) nodes are the locations for stress concentration and defects at or near nodes could generate higher impact on mechanical properties than defects at other places. In consideration of the feasibility of FE modeling, it is proposed in this study that microcracks are explicitly inserted into the lattice structure at or near nodes to capture the influence of printing defects on mechanical performance. In the study, nodes in the TLC lattice structure are categorized into two types: (i) the node between inclined struts (referred to as the Type I node), and (ii) the node between inclined struts and vertical struts (referred to as the Type II node). The two types of nodes have different effects on the mechanical properties and will be discussed later. For Type I nodes, all printing defects on inclined struts and/or on nodes are represented by an equivalent microcrack located at the center of the Type I node (i.e., the struts are disconnected but in full contact) as shown in

Figure 23 (a). For Type II nodes, an equivalent microcrack will be inserted at one end of the strut near the Type II node (i.e., cracks with 50% width of the strut and 0.02 mm thickness) as shown in

Figure 23 (b).

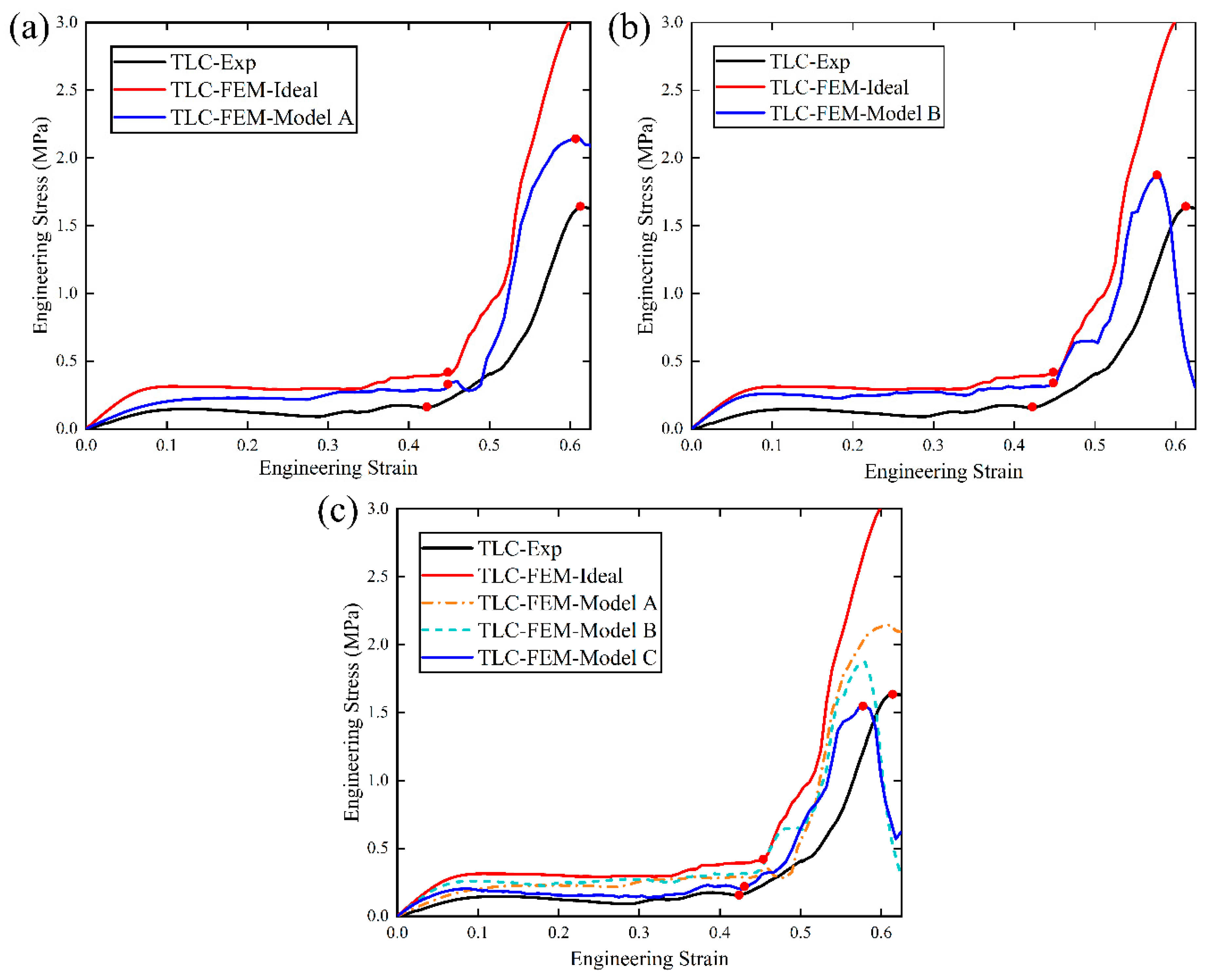

In order to study the influence of defects at different locations on the overall mechanical properties of the structure, three FE models are established for the TLC lattice structures: Model A (the model only with microcracks at the Type I nodes), Model B (the model only with microcracks at the Type II nodes), and Model C (the model with microcracks at both types of nodes).

There are 19 Type I nodes and 64 Type II nodes for a 2

2

2 TLC specimen. Based on experimental observation, Type I nodes usually exhibit weak connection. Therefore, microcracks are inserted into all the Type I nodes, except the one at the center of the lattice structure, as shown in

Figure 23 (a). Since there is a large number of Type II nodes, it is not a real situation that all the Type II nodes are weakened by printing defects. As a primary estimation, 32 nodes (i.e., a half of all the Type II nodes) were randomly selected to add microcracks, as shown in

Figure 23 (b).

Figure 23 (c) shows the lattice structure with inserted microcracks located at both Type I and II nodes, in which the number and location of microcracks are consistent with the previous two structures.

In this study, the built-in ductile damage model in ABAQUS is employed for the three models. The material parameters are determined based on comparison with the experimental results of 2

2

2 lattice specimens. The Fracture Strain in the ductile damage model is set to be 0.12 and the Fracture Energy is set to be 2. Other material parameters are set to be consistent with that given in

Section 3.

4.3.2. Simulation results

Figure 24 (a), (b) and (c) show the compressive simulation results for the three models: Model A, B and C, denoted by blue curves, respectively. The black curve represents the experimental result and the red curve is the simulation result for a 2

2

2 ideal lattice structure. Several interesting points can be noted from the results: (1) It is obvious that the trend of three blue curves in Figs. 24 (a), (b) and (c) from three models are consistent with experimental results (i.e., the black curve). The red dots highlight the transition points and the maximum stress points on the curves. In contrast, the red curve for the ideal lattice structure does not show a maximum stress and its flow stress just keeps increasing as compression proceeds. It is because that the ideal structure does not consider damage of the material; (2) Influences of microcracks at Type I and Type II nodes on the mechanical properties of the structures, are different and can be easily observed from the results for Model A and B in

Figure 24. Compared to the ideal lattice structure,

Figure 24 (a) shows that microcracks inserted at Type I nodes can weaken the initial flow stress significantly. Specifically, at a strain of 0.1, the initial flow stress decease largely with respect to that of ideal structure, and it is only 43% higher than that of the experimental result, while the stress of the ideal structure is 121% larger than that of experiments (see

Table 5). In

Figure 25 (b), microcracks inserted at Type II nodes make the maximum flow stress decease largely with respect to that of Model A, and the maximum flow stress only 14% higher than that of the experimental result. However, its influence on the initial flow stress is not as strong as that of the microcracks at Typer I nodes; (3) The simulation result from Model C in

Figure 24 (c) exhibits excellent agreement with the experimental result, compared to that from Model A and B (see

Table 5). That is to say, the FE model including both types of microcracks can generate a much better prediction.

Figure 25 shows deformation characteristics of a 2

2

2 lattice structure for experiments and FE simulations of Model C. The damage and fracture of struts in experimental specimens can be observed easily with increase of strain. Such evolution of damage and fracture in the lattice structure is captured very well from the simulation of Model C, which includes microcracks at both Type I and Type II nodes. At a strain of ~0.1, damages are usually initiated at Type I nodes, where are the connection points of two inclined struts. When the compressive strain increases to 0.2, cracks at Type I nodes can be easily observed, as highlighted by the red rectangular in the figure, although the structure remains intact as a whole. This indicates that the Type I nodes are the location where premature damage occurs easily, especially with the presence of printing defects. The simulations exhibit inhomogeneous deformations similar to experiments, and the internal structure appears tilted as well. As the load increases, complete fracture at Type I nodes as well as damage at Type II nodes can be clearly observed in both experiments and simulations, as marked by the red box at a strain of 0.3. This will lead to further damage of the whole structure. With continued deformation, the middle layer of the lattice structure appears collapse. The inclined struts related to the middle layer are totally fractured at a strain of 0.4. As the strain increases, other inclined struts are fractured gradually, and vertical struts are also deformed heavily when strain reaches 0.6.

Based on above simulation results, it is evident that presence of the printing defects (i.e., microcracks in this study) affects the mechanical properties of the structure significantly. Incorporation of microcracks at both Type I and II nodes into the lattice structure, proposed in this work, could make the FE simulation capture the deformation characteristics of lattice structures very well and improve the predictive accuracy of simulation significantly.

5. Conclusions

Based on the BCC lattice structure, this study proposes a new structure, TLC, by adding a central cubic truss in the BCC structure. The combination of vertical struts (stretch dominated) and inclined struts (bending dominated) in a single cell is demonstrated to improve the mechanical properties of the TLC significantly in terms of initial flow stress, specific strength and specific energy absorption.

The optimal size of the central cubic truss in the TLC is studied numerically and experimentally. With a fixed unit cell size (15 mm) and strut diameter (2 mm), the optimal size for the central cube is determined to be 5 mm by considering factors of flow stress, specific energy absorption, and stability of the structure. A general finding is that shorter inclined struts will generate a higher yield stress while corresponding longer vertical struts will make the whole structure unstable at a lower strain.

The experimental results show that the mechanical properties can be improved significantly by adding a central cubic truss with optimal size in the BCC lattice structure. For a 444 TLC structure, the initial flow stress of the TLC structure is increased by 122% at a strain of 0.1; the specific strength is enhanced by 293% at a strain of 0.5; and the specific energy absorption is increased by 312% at a strain of 0.6, compared to that of the BCC structure.

This study proposes to incorporate microcracks into FE model of the TLC lattice structure and the simulations capture the influence of printing defects on mechanical properties very well. Microcracks at Type I nodes can decrease the initial flow stress of the TLC notably, while microcracks at Type II nodes can lower the maximum stress of the structure remarkably. The FE model including microcracks at both Type I and Type II nodes makes simulations with good predictive accuracy, compared to the experimental results. The simulation from this model exhibits excellent consistent with the deformation characteristics of the TLC in experiments, including damages and fractures at smalls strains in the structure.

Author Contributions

Shuai Guo: Conceptualization, Investigation, Writing—Original Draft Preparation; Yuwei Ma: Formal analysis, Writing- Review & Editing; Peng Liu: Formal analysis, Writing- Review & Editing; Yang Chen: Funding Acquisition, Supervision, Writing—Review & Editing. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Guangxi Science and Technology Program (No. AD19245155, No. 2020GXNSFAA297029), and National Natural Science Foundation of China (52061008).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ashby, M.; Evans, A.; Fleck, N.; Gibson, L.; Hutchinson, J.; Wadley, H.; Delale, F. Metal Foams: A Design Guide. Appl. Mech. Rev. 2001, 54, B105–B106. [Google Scholar] [CrossRef]

- Wadley, H.N. Multifunctional periodic cellular metals. Philos. Trans. R. Soc. A: Math. Phys. Eng. Sci. 2005, 364, 31–68. [Google Scholar] [CrossRef] [PubMed]

- Gibson, L.J.; Ashby, M.F.; Harley, B.A. Cellular Materials in Nature and Medicine; Cambridge University Press: Cambridge, UK, 2010. [Google Scholar]

- Craster, R.; Guenneau, S. Acoustic Metamaterials: Negative Refraction, Imaging, Lensing and Cloaking 2013. [CrossRef]

- Khelif, A.; Adibi, A.; (Eds), *!!! REPLACE !!!*. Phononic crystals: fundamentals and applications; Springer Verl: New York, NY, USA, 2016. [Google Scholar]

- Babaee, S.; Viard, N.; Wang, P.; Fang, N.X.; Bertoldi, K. Harnessing Deformation to Switch On and Off the Propagation of Sound. Adv. Mater. 2016, 28, 1631–1635. [Google Scholar] [CrossRef] [PubMed]

- Reyes, R.L.; Ghim, M.-S.; Kang, N.-U.; Park, J.-W.; Gwak, S.-J.; Cho, Y.-S. Development and assessment of modified-honeycomb-structure scaffold for bone tissue engineering. Addit. Manuf. 2022, 54, 102740. [Google Scholar] [CrossRef]

- Hajare, D.M.; Gajbhiye, T.S. Additive manufacturing (3D printing): Recent progress on advancement of materials and challenges. Mater. Today: Proc. 2022, 58, 736–743. [Google Scholar] [CrossRef]

- Song, S.; Xiong, C.; Zheng, J.; Yin, J.; Zou, Y.; Zhu, X. Compression, bending, energy absorption properties, and failure modes of composite Kagome honeycomb sandwich structure reinforced by PMI foams. Compos. Struct. 2021, 277, 114611. [Google Scholar] [CrossRef]

- Landi, D.; Zefinetti, F.C.; Spreafico, C.; Regazzoni, D. Comparative life cycle assessment of two different manufacturing technologies: laser additive manufacturing and traditional technique. Procedia CIRP 2022, 105, 700–705. [Google Scholar] [CrossRef]

- Zhong, R.; Ren, X.; Zhang, X.Y.; Luo, C.; Zhang, Y.; Xie, Y.M. Mechanical properties of concrete composites with auxetic single and layered honeycomb structures. Constr. Build. Mater. 2022, 322, 126453. [Google Scholar] [CrossRef]

- Wei, Y.-L.; Yang, Q.-S.; Liu, X.; Tao, R. Multi-bionic mechanical metamaterials: A composite of FCC lattice and bone structures. Int. J. Mech. Sci. 2022, 213, 106857. [Google Scholar] [CrossRef]

- Chen, X.; Ji, Q.; Wei, J.; Tan, H.; Yu, J.; Zhang, P.; Laude, V.; Kadic, M. Light-weight shell-lattice metamaterials for mechanical shock absorption. Int. J. Mech. Sci. 2020, 169, 105288. [Google Scholar] [CrossRef]

- Yang, J.; Chen, X.; Sun, Y.; Zhang, J.; Feng, C.; Wang, Y.; Wang, K.; Bai, L. Compressive properties of bidirectionally graded lattice structures. Mater. Des. 2022, 218, 110683. [Google Scholar] [CrossRef]

- Bai, L.; Xu, Y.; Chen, X.; Xin, L.; Zhang, J.; Li, K.; Sun, Y. Improved mechanical properties and energy absorption of Ti6Al4V laser powder bed fusion lattice structures using curving lattice struts. Mater. Des. 2021, 211, 110140. [Google Scholar] [CrossRef]

- Zhao, M.; Li, X.; Zhang, D.Z.; Zhai, W. Design, mechanical properties and optimization of lattice structures with hollow prismatic struts. Int. J. Mech. Sci. 2023, 238, 107842. [Google Scholar] [CrossRef]

- Feng, G.; Li, S.; Xiao, L.; Song, W. Energy absorption performance of honeycombs with curved cell walls under quasi-static compression. Int. J. Mech. Sci. 2021, 210, 106746. [Google Scholar] [CrossRef]

- Zhao, S.; Zhang, Y.; Fan, S.; Yang, N.; Wu, N. Design and optimization of graded lattice structures with load path-oriented reinforcement. Mater. Des. 2023, 227, 111776. [Google Scholar] [CrossRef]

- Wang, S.; Wang, J.; Xu, Y.; Zhang, W.; Zhu, J. Compressive behavior and energy absorption of polymeric lattice structures made by additive manufacturing. Front. Mech. Eng. 2020, 15, 319–327. [Google Scholar] [CrossRef]

- Zhang, J.; Hong, R.; Wang, H. 3D-printed functionally-graded lattice structure with tunable removal characteristics for precision polishing. Addit. Manuf. 2022, 59, 103152. [Google Scholar] [CrossRef]

- Caiazzo, F.; Alfieri, V.; Campanelli, S.L.; Errico, V. Additive manufacturing and mechanical testing of functionally-graded steel strut-based lattice structures. J. Manuf. Process. 2022, 83, 717–728. [Google Scholar] [CrossRef]

- Plocher, J.; Panesar, A. Effect of density and unit cell size grading on the stiffness and energy absorption of short fibre-reinforced functionally graded lattice structures. Addit. Manuf. 2020, 33, 101171. [Google Scholar] [CrossRef]

- Zhao, M.; Li, X.; Zhang, D.Z.; Zhai, W. TPMS-based interpenetrating lattice structures: Design, mechanical properties and multiscale optimization. Int. J. Mech. Sci. 2023, 244, 108092. [Google Scholar] [CrossRef]

- Dong, L. Mechanical responses of Ti-6Al-4V truss lattices having a combined simple-cubic and body-centered-cubic (SC-BCC) topology. Aerosp. Sci. Technol. 2021, 116, 106852. [Google Scholar] [CrossRef]

- Yang, X.; Gong, Y.; Zhao, L.; Zhang, J.; Hu, N. Compressive mechanical properties of layer hybrid lattice structures fabricated by laser powder bed fusion technique. J. Mater. Res. Technol. 2023, 22, 1800–1811. [Google Scholar] [CrossRef]

- Zhong, H.; Song, T.; Li, C.; Das, R.; Gu, J.; Qian, M. Understanding the superior mechanical properties of hollow-strut metal lattice materials. Scr. Mater. 2023, 228, 115341. [Google Scholar] [CrossRef]

- Xiao, L.; Feng, G.; Li, S.; Mu, K.; Qin, Q.; Song, W. Mechanical characterization of additively-manufactured metallic lattice structures with hollow struts under static and dynamic loadings. Int. J. Impact Eng. 2022, 169, 104333. [Google Scholar] [CrossRef]

- Červinek, O.; Pettermann, H.; Todt, M.; Koutný, D.; Vaverka, O. Non-linear dynamic finite element analysis of micro-strut lattice structures made by laser powder bed fusion. J. Mater. Res. Technol. 2022, 18, 3684–3699. [Google Scholar] [CrossRef]

- Liu, X.; Wada, T.; Suzuki, A.; Takata, N.; Kobashi, M.; Kato, M. Understanding and suppressing shear band formation in strut-based lattice structures manufactured by laser powder bed fusion. Mater. Des. 2021, 199, 109416. [Google Scholar] [CrossRef]

- Zhu, S.; Ma, L.; Wang, B.; Hu, J.; Zhou, Z. Lattice materials composed by curved struts exhibit adjustable macroscopic stress-strain curves. Mater. Today Commun. 2018, 14, 273–281. [Google Scholar] [CrossRef]

- Tancogne-Dejean, T.; Mohr, D. Stiffness and specific energy absorption of additively-manufactured metallic BCC metamaterials composed of tapered beams. Int. J. Mech. Sci. 2018, 141, 101–116. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, J.; Gu, X.; Zhou, Y.; Yin, Y.; Tan, Q.; Li, M.; Zhang, M.-X. Mechanical performance of a node reinforced body-centred cubic lattice structure manufactured via selective laser melting. Scr. Mater. 2020, 189, 95–100. [Google Scholar] [CrossRef]

- Yang, L.; Li, Y.; Chen, Y.; Yan, C.; Liu, B.; Shi, Y. Topologically optimized lattice structures with superior fatigue performance. Int. J. Fatigue 2022, 165, 107188. [Google Scholar] [CrossRef]

- Deshpande, V.S.; Ashby, M.F.; Fleck, N.A. Foam topology: bending versus stretching dominated architectures. Acta Mater. 2001, 49, 1035–1040. [Google Scholar] [CrossRef]

- Ravari, M.R.K.; Kadkhodaei, M.; Badrossamay, M.; Rezaei, R. Numerical investigation on mechanical properties of cellular lattice structures fabricated by fused deposition modeling. Int. J. Mech. Sci. 2014, 88, 154–161. [Google Scholar] [CrossRef]

- Kaur, M.; Yun, T.G.; Han, S.M.; Thomas, E.L.; Kim, W.S. 3D printed stretching-dominated micro-trusses. Mater. Des. 2017, 134, 272–280. [Google Scholar] [CrossRef]

- Carlton, H.D.; Volkoff-Shoemaker, N.A.; Messner, M.C.; Barton, N.R.; Kumar, M. Incorporating defects into model predictions of metal lattice-structured materials. Mater. Sci. Eng. A 2022, 832, 142427. [Google Scholar] [CrossRef]

- Gautam, R.; Idapalapati, S.; Feih, S. Printing and characterisation of Kagome lattice structures by fused deposition modelling. Mater. Des. 2018, 137, 266–275. [Google Scholar] [CrossRef]

- Li, D.; Qin, R.; Chen, B.; Zhou, J. Analysis of mechanical properties of lattice structures with stochastic geometric defects in additive manufacturing. Mater. Sci. Eng. A 2021, 822, 141666. [Google Scholar] [CrossRef]

- Lozanovski, B.; Leary, M.; Tran, P.; Shidid, D.; Qian, M.; Choong, P.; Brandt, M. Computational modelling of strut defects in SLM manufactured lattice structures. Mater. Des. 2019, 171, 107671. [Google Scholar] [CrossRef]

- Günther, F.; Hirsch, F.; Pilz, S.; Wagner, M.; Gebert, A.; Kästner, M.; Zimmermann, M. Structure-property relationships of imperfect additively manufactured lattices based on triply periodic minimal surfaces. Mater. Des. 2022, 222, 111036. [Google Scholar] [CrossRef]

- Sun, Z.; Guo, Y.; Shim, V. Influence of printing direction on the dynamic response of additively-manufactured polymeric materials and lattices. Int. J. Impact Eng. 2022, 167, 104263. [Google Scholar] [CrossRef]

- Cao, X.; Jiang, Y.; Zhao, T.; Wang, P.; Wang, Y.; Chen, Z.; Li, Y.; Xiao, D.; Fang, D. Compression experiment and numerical evaluation on mechanical responses of the lattice structures with stochastic geometric defects originated from additive-manufacturing. Compos. Part B: Eng. 2020, 194, 108030. [Google Scholar] [CrossRef]

- Yang, H.; Wang, W.; Li, C.; Qi, J.; Wang, P.; Lei, H.; Fang, D. Deep learning-based X-ray computed tomography image reconstruction and prediction of compression behavior of 3D printed lattice structures. Addit. Manuf. 2022, 54, 102774. [Google Scholar] [CrossRef]

- Lei, H.; Li, C.; Meng, J.; Zhou, H.; Liu, Y.; Zhang, X.; Wang, P.; Fang, D. Evaluation of compressive properties of SLM-fabricated multi-layer lattice structures by experimental test and μ-CT-based finite element analysis. Mater. Des. 2019, 169, 107685. [Google Scholar] [CrossRef]

- Zanini, F.; Sorgato, M.; Savio, E.; Carmignato, S. Dimensional verification of metal additively manufactured lattice structures by X-ray computed tomography: Use of a newly developed calibrated artefact to achieve metrological traceability. Addit. Manuf. 2021, 47, 102229. [Google Scholar] [CrossRef]

- Geng, L.; Wu, W.; Sun, L.; Fang, D. Damage characterizations and simulation of selective laser melting fabricated 3D re-entrant lattices based on in-situ CT testing and geometric reconstruction. Int. J. Mech. Sci. 2019, 157-158, 231–242. [Google Scholar] [CrossRef]

- Tkac, J.; Toth, T.; Molnar, V.; Dovica, M.; Fedorko, G. Observation of porous Structure’s deformation wear after axial loading with the use of Industrial computed tomography (CT). Measurement 2022, 200, 111631. [Google Scholar] [CrossRef]

- Dallago, M.; Winiarski, B.; Zanini, F.; Carmignato, S.; Benedetti, M. On the effect of geometrical imperfections and defects on the fatigue strength of cellular lattice structures additively manufactured via Selective Laser Melting. Int. J. Fatigue 2019, 124, 348–360. [Google Scholar] [CrossRef]

- Sun, Z.; Guo, Y.; Shim, V. Characterisation and modeling of additively-manufactured polymeric hybrid lattice structures for energy absorption. Int. J. Mech. Sci. 2020, 191, 106101. [Google Scholar] [CrossRef]

- Li, S.; Liu, Z.; Shim, V.; Guo, Y.; Sun, Z.; Li, X.; Wang, Z. In-plane compression of 3D-printed self-similar hierarchical honeycombs – Static and dynamic analysis. Thin-Walled Struct. 2020, 157, 106990. [Google Scholar] [CrossRef]

- Anisotropic compression behaviors of bio-inspired modified body-centered cubic lattices validated by additive manufacturing—ScienceDirect n.d. Available online: https://www.sciencedirect.com/science/article/pii/S1359836822001093 (accessed on 8 October 2022).

- Wang, P.; Yang, F.; Li, P.; Zheng, B.; Fan, H. Design and additive manufacturing of a modified face-centered cubic lattice with enhanced energy absorption capability. Extreme Mech. Lett. 2021, 47, 101358. [Google Scholar] [CrossRef]

- Yang, X.; Ma, W.; Zhang, Z.; Liu, S.; Tang, H. Ultra-high specific strength Ti6Al4V alloy lattice material manufactured via selective laser melting. Mater. Sci. Eng. A 2022, 840, 142956. [Google Scholar] [CrossRef]

- Wang, Z. Recent advances in novel metallic honeycomb structure. Compos. Part B: Eng. 2019, 166, 731–741. [Google Scholar] [CrossRef]

- Gümrük, R.; Mines, R.A.W. Compressive behaviour of stainless steel micro-lattice structures. Int. J. Mech. Sci. 2013, 68, 125–139. [Google Scholar] [CrossRef]

- Chen, Y.; Ye, L.; Zhang, Y.; Fu, K. Compression behaviours of 3D-printed CF/PA metamaterials: Experiment and modelling. Int. J. Mech. Sci. 2021, 206, 106634. [Google Scholar] [CrossRef]

Figure 1.

Schematic diagrams of (a) BCC cell topology, (b) a cubic truss, (c) TLC cell topology. (The length of a single cell is 15 mm and the diameter for all struts is 2mm).

Figure 1.

Schematic diagrams of (a) BCC cell topology, (b) a cubic truss, (c) TLC cell topology. (The length of a single cell is 15 mm and the diameter for all struts is 2mm).

Figure 2.

3D printed specimens of the 444 lattice structures: (a) BCC and (b) TLC.

Figure 2.

3D printed specimens of the 444 lattice structures: (a) BCC and (b) TLC.

Figure 3.

Experimental setup for quasi-static compression tests of lattice structures (downward blue arrows indicates the direction of compression).

Figure 3.

Experimental setup for quasi-static compression tests of lattice structures (downward blue arrows indicates the direction of compression).

Figure 4.

(a) Dimensions of ASTM D638 Type I dog-bone specimens; (b) 3D image of ASTM D638 Type I dog-bone specimen for printing (the blue arrow represents the direction of FDM-based 3D printing).

Figure 4.

(a) Dimensions of ASTM D638 Type I dog-bone specimens; (b) 3D image of ASTM D638 Type I dog-bone specimen for printing (the blue arrow represents the direction of FDM-based 3D printing).

Figure 5.

True stress-true strain curve of PLA.

Figure 5.

True stress-true strain curve of PLA.

Figure 6.

Finite element model with boundary conditions, and the red square defining a single cell of TLC structure meshed with C3D4 tetrahedral elements.

Figure 6.

Finite element model with boundary conditions, and the red square defining a single cell of TLC structure meshed with C3D4 tetrahedral elements.

Figure 7.

Deformation characteristics of BCC and TLC single-cell lattice structures with different strains.

Figure 7.

Deformation characteristics of BCC and TLC single-cell lattice structures with different strains.

Figure 8.

Schematic diagram of force analysis of inclined struts in (a) the BCC lattice structure and (b) the TLC lattice structure.

Figure 8.

Schematic diagram of force analysis of inclined struts in (a) the BCC lattice structure and (b) the TLC lattice structure.

Figure 9.

Deflection of the vertical strut in the center of the TLC lattice structure due to lateral force (assuming that the lower end of the vertical strut is fixed).

Figure 9.

Deflection of the vertical strut in the center of the TLC lattice structure due to lateral force (assuming that the lower end of the vertical strut is fixed).

Figure 10.

Schematic diagram of the cell topology of the TLC lattice structure.

Figure 10.

Schematic diagram of the cell topology of the TLC lattice structure.

Figure 11.

Compressive stress-strain curves of single cells obtained from experiments (a-f denote different lengths of the central cubic truss as given in

Table 4).

Figure 11.

Compressive stress-strain curves of single cells obtained from experiments (a-f denote different lengths of the central cubic truss as given in

Table 4).

Figure 12.

Compressive stress-strain curves for TLC-e and TLC-f, and the insets show the deformed specimens at the highest stress point.

Figure 12.

Compressive stress-strain curves for TLC-e and TLC-f, and the insets show the deformed specimens at the highest stress point.

Figure 13.

Specific energy absorption corresponding to various strains for TLC and BCC single cells.

Figure 13.

Specific energy absorption corresponding to various strains for TLC and BCC single cells.

Figure 14.

Simulated compressive stress-strain curves of single cells of the TLC and BCC structure.

Figure 14.

Simulated compressive stress-strain curves of single cells of the TLC and BCC structure.

Figure 15.

(a) Engineering stress-strain curves of the 2

Figure 15.

(a) Engineering stress-strain curves of the 2

Figure 16.

(a) Engineering stress-strain curves of 444 BCC and TLC; (b) deformation characteristics of TLC specimens at different strains.

Figure 16.

(a) Engineering stress-strain curves of 444 BCC and TLC; (b) deformation characteristics of TLC specimens at different strains.

Figure 17.

Specific strength of the BCC and TLC lattice structures at different strains.

Figure 17.

Specific strength of the BCC and TLC lattice structures at different strains.

Figure 18.

(a) Energy absorption and (b) specific energy absorption of BCC and TLC lattice structures with strain.

Figure 18.

(a) Energy absorption and (b) specific energy absorption of BCC and TLC lattice structures with strain.

Figure 19.

(a) The stress-strain curve of the 4x4x4 TLC structure; (b) images of TLC specimens at points I and II (The red dash lines in the images indicate the status of central vertical struts).

Figure 19.

(a) The stress-strain curve of the 4x4x4 TLC structure; (b) images of TLC specimens at points I and II (The red dash lines in the images indicate the status of central vertical struts).

Figure 20.

3D printing defects in 222 specimens of TLC lattice structure.

Figure 20.

3D printing defects in 222 specimens of TLC lattice structure.

Figure 21.

Deformation characteristics of 222 TLC lattice structures in compressive tests.

Figure 21.

Deformation characteristics of 222 TLC lattice structures in compressive tests.

Figure 22.

Engineering stress-strain curves of experimental and simulation results for BCC and TLC 444 lattice structures.

Figure 22.

Engineering stress-strain curves of experimental and simulation results for BCC and TLC 444 lattice structures.

Figure 23.

TLC lattice structure model with microcracks located at (a) Type I nodes; (b) Type II nodes; (c) both Type I and II nodes.

Figure 23.

TLC lattice structure model with microcracks located at (a) Type I nodes; (b) Type II nodes; (c) both Type I and II nodes.

Figure 24.

(a) Comparison of stress-strain curves between simulations of ideal models, Model A, and experiments; (b) Comparison of stress-strain curves between simulation of ideal model, Model B, and experiments; (c) Comparison of stress-strain curves between simulations of ideal model, Model C and experiments (the dashed lines for Model A and B added in (c) for reference).

Figure 24.

(a) Comparison of stress-strain curves between simulations of ideal models, Model A, and experiments; (b) Comparison of stress-strain curves between simulation of ideal model, Model B, and experiments; (c) Comparison of stress-strain curves between simulations of ideal model, Model C and experiments (the dashed lines for Model A and B added in (c) for reference).

Figure 25.

Comparison of deformation characteristics between experiments and simulations of Model C at various strains.

Figure 25.

Comparison of deformation characteristics between experiments and simulations of Model C at various strains.

Table 1.

Geometrical parameters of the lattice structures.

Table 1.

Geometrical parameters of the lattice structures.

| Structure |

Volume |

Theoretical

mass |

Actual

mass |

Relative

density |

Apparent density |

| BCC |

18.37 cm3

|

21.70g |

21.55g |

0.0850 |

0.0998 |

| TLC |

22.11 cm3

|

26.09g |

26.11g |

0.1024 |

0.1209 |

Table 2.

The elastic material parameters of PolyMaxTM PLA.

Table 2.

The elastic material parameters of PolyMaxTM PLA.

Elastic modulus

(GPa) |

Poisson’s ratio |

Density

(kg/m3) |

Yield strength

(MPa) |

| 1.85 |

0.35 |

1200 |

42 |

Table 3.

The plastic material parameters of PolyMaxTM PLA.

Table 3.

The plastic material parameters of PolyMaxTM PLA.

| Plastic strain |

0 |

0.0045 |

0.012 |

0.021 |

0.034 |

0.132 |

0.2 |

0.3 |

| Plastic stress (MPa) |

40 |

36 |

32 |

29 |

26 |

28 |

30 |

34 |

Table 4.

Length of the central cubic struts.

Table 4.

Length of the central cubic struts.

|

3/15 a |

4/15 b |

5/15 c |

6/15 d |

7/15 e |

7.5/15 f |

|

15mm |

15mm |

15 mm |

15 mm |

15 mm |

15 mm |

|

3mm |

4mm |

5 mm |

6 mm |

7 mm |

7.5 mm |

Table 5.

Comparison of flow stresses between experimental and simulation results (MPa).

Table 5.

Comparison of flow stresses between experimental and simulation results (MPa).

| |

Initial flow stress at a strain of 0.1 |

Maximum stress |

| Experiment |

0.14 |

1.64 |

| Ideal structure |

0.31(121% ↑) |

3.00 (83% ↑) |

| Model A |

0.20 (43% ↑) |

2.15 (31% ↑) |

| Model B |

0.26 (86% ↑) |

1.87 (14% ↑) |

| Model C |

0.19 (36% ↑) |

1.55 (6% ↓) |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).