1. Introduction

Artificial intelligence (AI) has gained widespread application in industries such as metallurgy, petrochemicals, and energy, emerging as the central driving force behind intelligent manufacturing [i,ii,iii]. The transition from the third industrial revolution, characterized by automation, is evolving into the fourth industrial revolution with the integration of AI, commonly known as Industry 4.0 [iv,v]. In response to the demands of industrialization and automation, mass sensors are deployed on industrial sites to collect diverse process data [vi]. Simultaneously, the progress in the Internet of Things (IoT), cloud computing, and big data analytics enhances the capability and likelihood of AI integration within industrial processes [vii,viii].

Currently, the global annual growth rate of municipal solid waste (MSW) has reached 8% to 10% [ix,x]. MSW incineration (MSWI) technology is one of the waste-to-energy (WTE) methods, providing an effective approach to address challenges in terms of environmental sustainability [xi]. As a typical industrial process [xii,xiii], MSWI achieves WTE through fermentation, combustion, heat exchange, and gas cleaning [i,[xiv]. Among these stages, fermentation involves numerous uncertain biological reactions. The combustion stage is characterized by high-temperature chemical reactions within the interaction of solid, gas, and liquid phases, and heat flow forces. The heat exchange stage facilitates the conversion of heat energy to mechanical energy and subsequently to electric energy. The flue gas cleaning stage utilizes physical and chemical principles to eliminate toxic and harmful substances from the flue gas. In addition to fulfilling its energy requirements, the MSWI process also supplies various forms of energy, including electricity and heat, to external entities [xv]. Furthermore, it ensures a reduced risk of environmental pollution emissions. Studies indicate that the mass reduction rate, volume reduction rate, and energy recovery rate of the MSWI process can reach 70%, 90%, and 19% [xvi,xvii], respectively. The recognized potential value in the economy and environmental protection has been acknowledged by developing countries [xviii,xix].

After half a century of development, the MSWI control system has evolved towards a large-scale, integrated, and intelligent direction. This transformation is attributed to the integration of automation technology, computer technology, and advancements in incineration equipment and processes [ii]. Presently, operational, under-construction, and proposed MSWI plants predominantly employ grate furnace incinerators, high-parameter boiler power generation equipment, and progressive cumulative flue gas cleaning processes. The objective is to facilitate the low-carbon transformation of enterprises, thereby enhancing economic efficiency and competitiveness [xx,xxi]. However, the composition and generation of MSW are influenced by numerous uncertainties and regional factors, including societal, economic, and environmental aspects. The use of large-scale operational equipment further complicates the achievement of efficient and stable control of the MSWI process, particularly under critical conditions [xxii,xxiii]. Therefore, the development of smart optimal control for the MSWI process, based on AI assistance, is already underway.

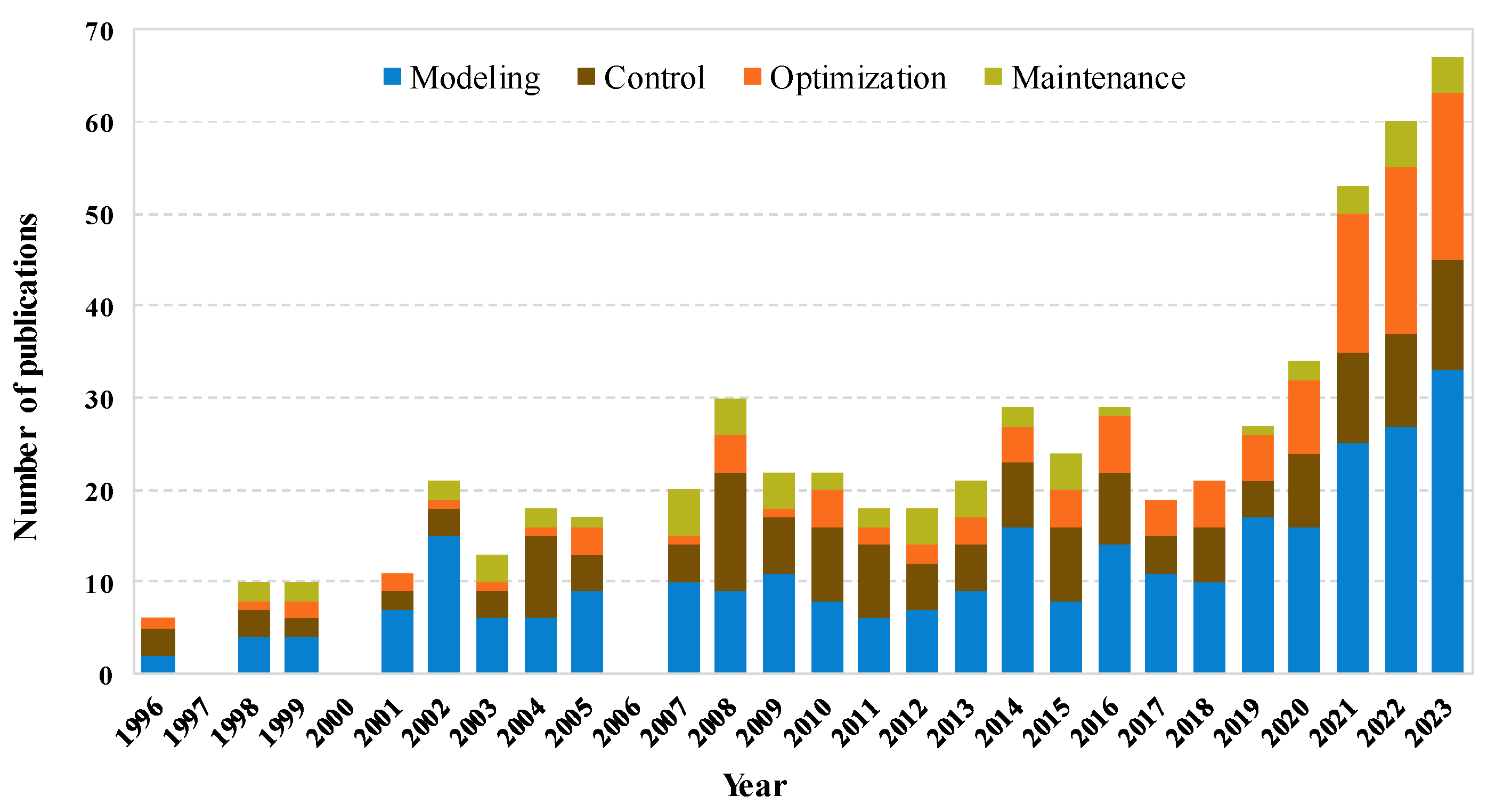

Figure 1 illustrates the annual number of studies related to the AI application for the MSWI process in the Web of Science (WoS). The data encompasses the period from 1996 to 2023, and the keywords include “modeling,” “control,” “optimization,” and “maintenance”.

Figure 1 indicates a rapid increase in studies focused on the application of AI in MSWI in recent years. Within this trend, modeling emerges as the most prominent research direction, with a consistently increasing number. The studies on optimization have experienced significant growth, particularly after 2021. Meanwhile, research on control and maintenance has maintained a stable level, with maintenance studies constituting a smaller portion. Hence, the investigation into smart optimal control of the MSWI process, driven by AI applications, is progressively evolving into a research hotspot.

Based on the summary of existing studies, there appears to be a gap in the literature, as a comprehensive review of AI applications for smart optimal control of the MSWI process is currently lacking. This study aims to systematically review existing research in MSWI that incorporates AI techniques, to address this gap in the literature. The contributions of this study are outlined as follows. 1) The review is conducted from four perspectives, namely, modeling, control, optimization, and maintenance, focusing on the smart operational tasks of the MSWI process. The detailed summary of AI applications in these four aspects is intended to assist researchers and practitioners effectively. 2) A timeline map is included to illustrate the evolution of various AI algorithms in the MSWI process, providing a visual representation of the application trends of AI methods over time. 3) The review is closely integrated with the practical aspects of the MSWI process, and the applied AI algorithms are thoroughly discussed. Furthermore, the review identifies current challenges and suggests future directions, thereby contributing to the advancement of AI applications in the field of MSWI.

2. AI in Optimal Control of the MSWI Process

2.1. Description of Different Phases in Terms of Optimal Control

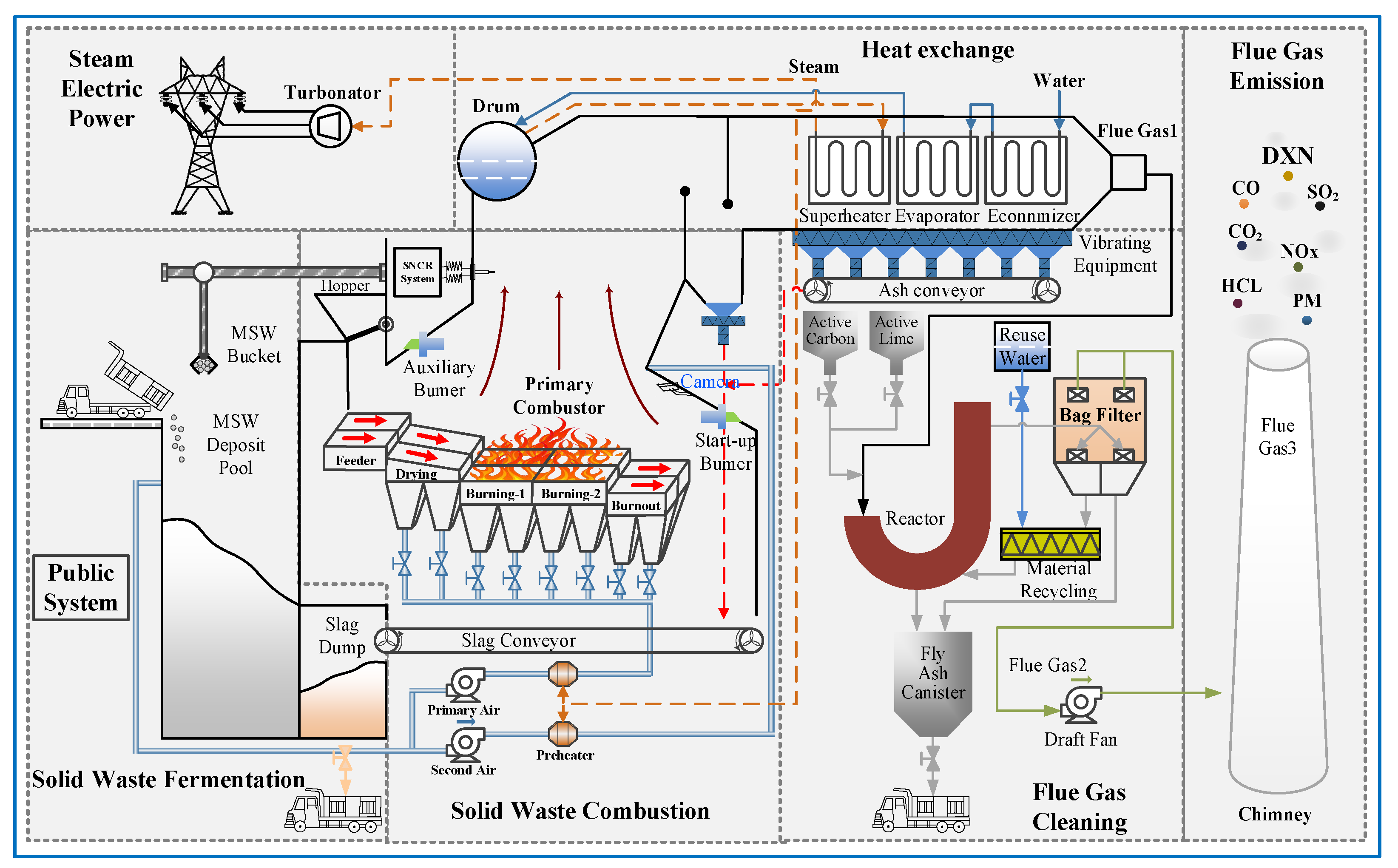

Figure 2 depicts the process flow of the grate-type MSWI process in Beijing.

Figure 2 illustrates that the MSWI process comprises six stages: solid waste fermentation, solid waste combustion, heat exchange, steam electric power, flue gas cleaning, and flue gas emission. The primary functions of these stages are outlined as follows.

1) Solid waste fermentation stage: The original MSW contains a significant amount of water, which hinders combustion. To address this, it undergoes 3-7 days of biological fermentation in the MSW deposit pool. After the initial dehydration, the MSW reaches the incineration condition and is then transferred into the hopper using a bucket. Subsequently, it is pushed into the incinerator by the feeder, entering the solid waste combustion stage. The primary optimal control variable for this stage is the calorific value of the MSW.

2) Solid waste combustion stage: The MSW transforms into high-temperature flue gas and solid residues through the coupled interaction of multiphases such as solid-gas-liquid, and multiple fields such as heat- flow-force. This stage is divided into three sub-stages: drying, burning, and burnout.

a) Drying sub-stage: The total moisture content, including both surface and internal moisture, of MSW on the dry grate significantly influences its ignition. The surface moisture gradually evaporates as the furnace temperature increases and is completely evaporated when the temperature reaches 100°C. The internal moisture precipitates and absorbs mass heat energy with the further increase in furnace temperature. Consequently, the total moisture content of MSW is closely related to the calorific value of the furnace, impacting the combustion status and overall operating conditions of the entire process.

b) Burning sub-stage: From the ignition of MSW to intense luminescent heating and ultimately to the conclusion of the oxidation reaction, the process involves strong oxidation, pyrolysis, and atomic group collision reactions. The strong oxidation reaction signifies the complete reaction of the combustible components with oxygen. The pyrolysis reaction occurs under anaerobic or near anaerobic conditions, where thermal radiation energy disrupts or reorganizes the chemical bonds between the elements of carbon-containing polymer compounds. This process results in the precipitation of volatiles, which are subsequently oxidized. The atomic group collision reaction signifies that the electronic energy transition of the atomic group, along with the rotation and vibration of the molecule, generates infrared thermal radiation, visible light, and ultraviolet light. This process ultimately forms the flame shape. Hence, the reactions involved in the combustion process are intricate and variable, featuring strong coupling between each other and the characteristics of multi-reaction synchronous operation. The combustion air volume and grate speed emerge as key manipulated variables for maintaining a stable combustion process.

c) Burnout sub-stage: Following combustion, the remaining combustible components in MSW primarily consist of coke. Subsequently, due to the high temperature and the presence of primary air, the oxidation reaction of coke with O2 takes place, as well as the gasification reaction of coke with CO2, water vapor, and other substances. Inert substances, including gaseous CO, H2O, and ash, gradually accumulate until all MSW on the grate transforms into ash. The combustion weakens until it is completely stopped [xxiv]. Therefore, the process is characterized by low flammability, increased inert substances, a relatively high oxidant content, and a low reaction zone temperature. Typically, extending the burnout process can effectively enhance the thermal ignition reduction rate of MSW and improve the reduction level.

To ensure the decomposition and combustion of harmful substances in the flue gas, the principle of ‘3T+E’ is often employed [xxv], where the furnace temperature exceeds 850°C, the flue gas residence time is longer than 2 s, and the flue gas turbulence intensity and excess air coefficient are maintained at appropriate values. The primary manipulated variables in this stage include the MSW feed rate, grate speed, and furnace inlet air volume. The main controlled variables encompass furnace temperature, flue gas oxygen content, steam flow, and combustion line.

3) Heat exchange stage: Firstly, the high-temperature flue gas undergoes initial cooling through the water wall. Secondly, heat energy is transferred to the boiler through radiation and convection involving the superheater, evaporator, and economizer. Thirdly, the water in the boiler transforms into high-pressure superheated steam, entering the steam power generation stage. Finally, the flue gas temperature at the boiler outlet is reduced to 200°C. It is essential to rigorously control the cooling rate at this stage. The primary manipulated variable is the boiler feed water volume, and the main controlled variable is the boiler steam flow.

4) Flue gas cleaning stage: Firstly, the Selective Non-Catalytic Reduction (SNCR) system removes NOx at temperatures ranging from 850°C to 1100°C. Secondly, the semi-dry deacidification process neutralizes acidic gases (HCl, HF, SO2, heavy metals) by injecting lime and water. Thirdly, activated carbon adsorbs DXN and heavy metals in the flue gas. Finally, the particulate matter, neutralizing reactants, and activated carbon adsorbates in the flue gas are removed by the bag filter, completing the flue gas purification. The primary manipulated variables in this stage include the consumption of urea, activated carbon, lime, and other materials.

5) Flue gas emission stage: The flue gas, complying with the national emission standard of different countries, is released into the atmosphere through the chimney using the induced draft fan. Currently, environmental indicators of concern include pollutants such as particulate matter, NOx, SO2, HCl, and CO.

2.2. AI in Model, Control, Optimization, and Maintenance of MSWI Process

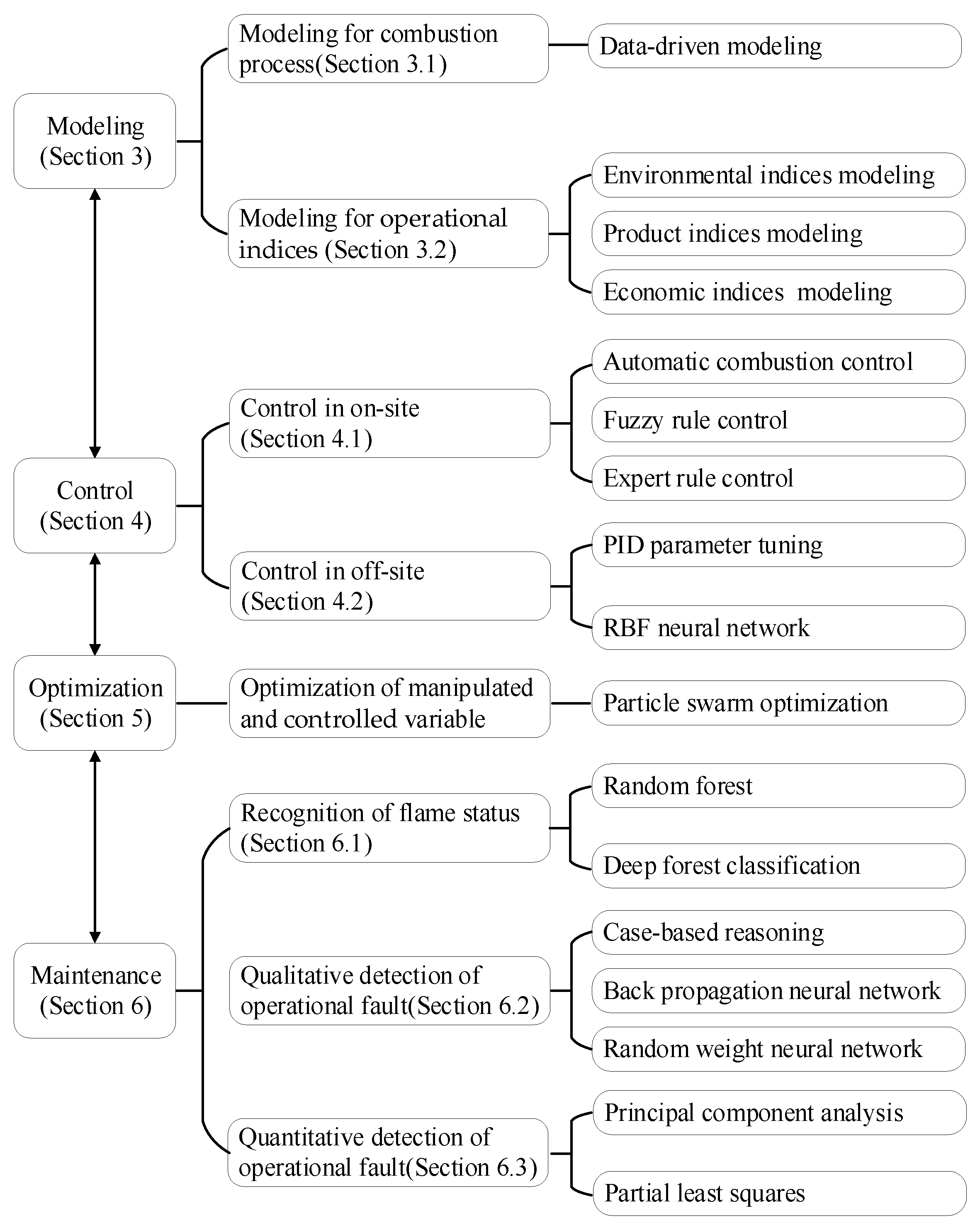

Figure 3 illustrates the task function description of the MSWI process and AI applications, encompassing modeling, control, optimization, and maintenance.

In this study, the AI application concerning the task functions of the MSWI process is classified into modeling, control, optimization, and maintenance. The structure of the review is outlined as follows.

- 1)

Modeling: The AI application in the modeling of the MSWI process is subdivided into combustion process modeling and operational index modeling. The former is elaborated in

Section 3.1, focusing on data-driven modeling. The latter is detailed in

Section 3.2, covering environmental, product, and economic indices modeling.

- 2)

Control: The AI application in the control of the MSWI process is categorized into on-site control and off-site control. The review of existing research on on-site control is presented in

Section 4.1 and encompasses topics such as automatic combustion control, fuzzy rule control, expert rule control, etc. The research on off-site control is discussed in

Section 4.2, covering PID parameter tuning and RBF neural network.

- 3)

Optimization: The AI application in the optimization of the MSWI process, focusing on manipulated and controlled variables, is predominantly discussed in

Section 5. Particle swarm optimization (PSO) is highlighted as a significant algorithm in this field.

- 4)

Maintenance: The AI application in the maintenance of the MSWI process is categorized into three parts: recognition of flame status, qualitative detection of operational faults, and quantitative detection of operational faults. Recognition of flame status, utilizing random forest and deep forest classification, is introduced in

Section 6.1. Qualitative detection of operational faults is discussed in

Section 6.2, covering applications such as case-based reasoning, backpropagation neural network, and random weight neural network. Quantitative detection of operational faults is presented in

Section 6.3, including the application of principal component analysis (PCA) and partial least squares (PLS).

2.3. Development of AI Applications Research in the MSWI Process

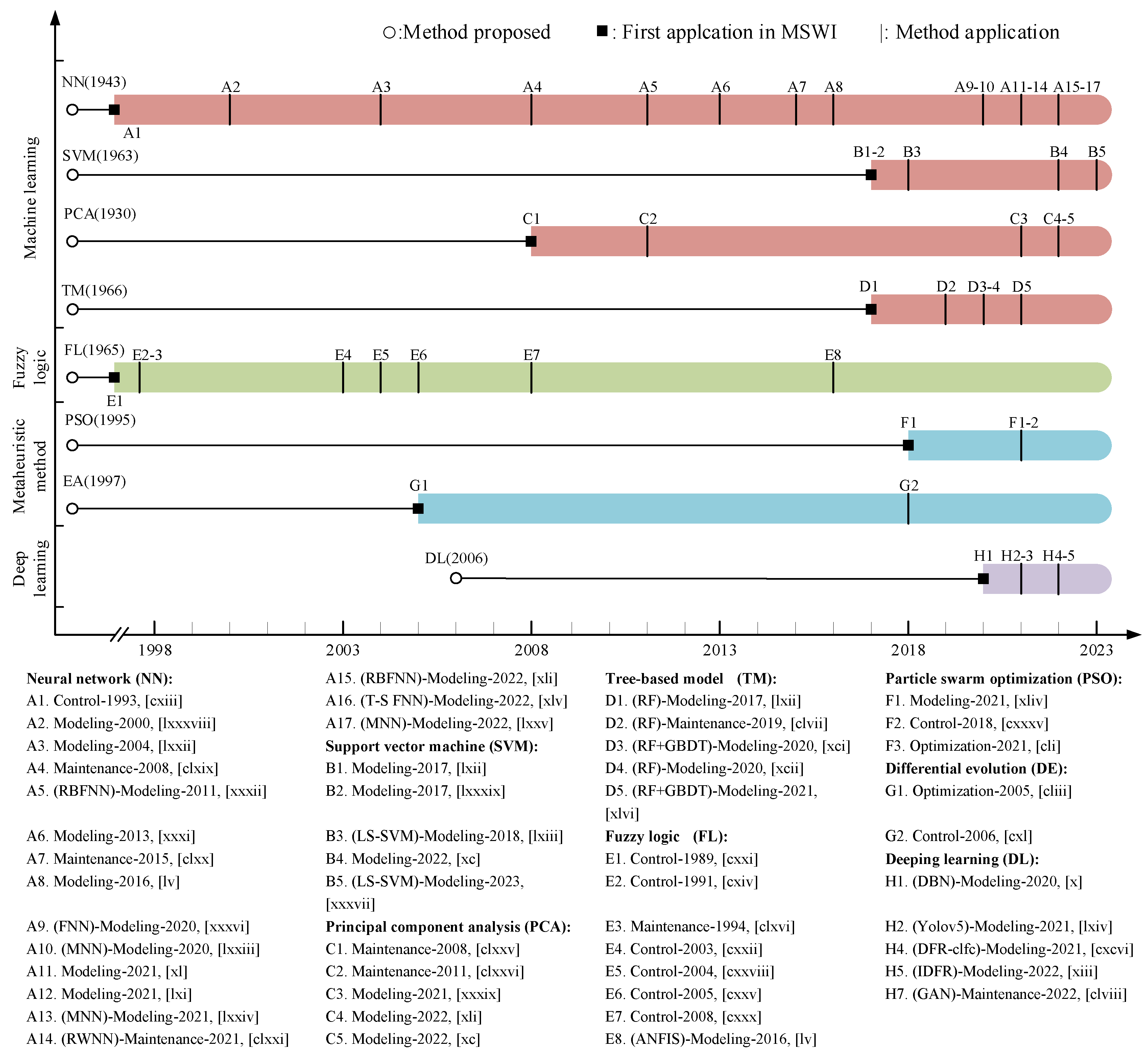

To visually illustrate the relationship among development, method, and application,

Figure 4 s provides a timeline summarizing the development of AI algorithms and their applications in the MSWI field. It presents the proposed years of the methods, the first application in the MSWI field, and method applications. AI algorithms are classified into four categories: machine learning, fuzzy logic, metaheuristic methods, and deep learning. It is important to note that only classic methods are provided in each category.

- 1)

Machine learning is a prominent AI method in the application of the MSWI process.

Figure 6 provides a summary of machine learning applications, including NN, SVM, PCA, and TM. In this domain, NN methods represent the most active direction. Firstly, NN exhibits robust learning capabilities, enabling its application in various tasks such as control, modeling, and maintenance. Secondly, the flexible structure of NN allows for improvements based on specific operational requirements and conditions. Despite the earlier proposals of TM and SVM methods, their application in the MSWI process did not occur until 2017. Additionally, PCA is employed for feature extraction in modeling and monitoring, but its practical applications are relatively limited.

- 2)

Fuzzy Logic (FL) is a well-established method known for controlling complex process systems. Consequently, FL has been applied in the MSWI process since 1989. FL became one of the most popular control methods between 2003 and 2005, and it was also considered for maintenance and modeling in the MSWI process. However, research on FL has gradually decreased in recent years, likely influenced by the emergence of NN and other methods. In response to this trend, researchers have proposed the fuzzy neural network (FNN) method by combining FL and NN.

- 3)

Particle Swarm Optimization (PSO) is one type of the evolutionary algorithms in terms of the metaheuristic method. They are capable of searching for optimal parameters for models and controllers of the MSWI process. However, the application area of metaheuristic methods is limited due to factors such as randomness and time cost.

- 4)

Deep Learning (DL) was developed in 2006, making it more novel compared to other methods. The applications of the DL method in the MSWI process concentrated in 2021 and 2022. It is anticipated to undergo rapid development in future studies.

3. AI Application Research in Modelling of MSWI Process

As a typical process industry, the MSWI process exhibits strong nonlinearity and coupling, encompassing numerous stages and variables. To accurately depict the AI application in the modeling of the MSWI process, this study categorizes it into two main areas: modeling for the combustion process and operational indices.

3.1. Modeling for Combustion Process

Typically, complex industrial processes utilize historical data to construct controlled object models, validating intelligent control algorithms [xxvi,xxvii,xxviii,xxix]. This subsection is further divided into two parts, namely key controlled variables and auxiliary variables.

3.1.1. Key Controlled Variables

Key controlled variables in the combustion process encompass furnace temperature (FT), flue gas oxygen content (FGOC), steam flow (SF), and combustion line position, et al.

1) Multi-input single-output (MISO) modeling

FT is usually measured using a thermocouple, serving as a vital parameter to characterize the stability of the combustion status and directly influencing pollutant emissions [xxx,xxxi]. The establishment of a controlled FT model is a crucial prerequisite for achieving stable control and validating algorithms [xxxii,xxxiii]. The existing studies on data-driven models include multi-model intelligent combination [xxxiv], T-S fuzzy neural network [xxxv,xxxvi], and least squares-support vector regression (LS-SVR) [xxxvii], among other approaches. However, these studies mostly focused on a single operating condition within a narrow range, and there is a need for improvement in their adaptability.

FGOC refers to the coefficient of excess air, which can characterize the combustion status to a certain extent [xxxviii]. Measuring points for flue gas oxygen content (FGOC) are typically installed at the outlet of the waste heat boiler (flue gas G1) and the chimney (flue gas G3). Sun et al. [xxxix] proposed a weighted principal component analysis (PCA) and an improved long short-term memory network (LSTM) strategy for constructing a prediction model at the G3 location, but further improvement is needed in modeling accuracy.

SF determines the recovery efficiency of the waste heat boiler and the power generation of the steam turbine [xl]. Studies on predicting model for SF include: Giantomassi et al. [xxxii] adopted a radial basis function (RBF) neural network based on adaptive Kalman filter parameter updating. Sun et al. [xli] used RBF based on the average influence value algorithm for feature selection. Yang et al. [xlii] employed the LSTM algorithm, among others.

Unfortunately, the aforementioned studies all employed data-driven methods to construct MISO soft sensing or prediction models, which are not control-oriented models for controlled objects. Consequently, it is challenging to support the research of optimal control algorithms.

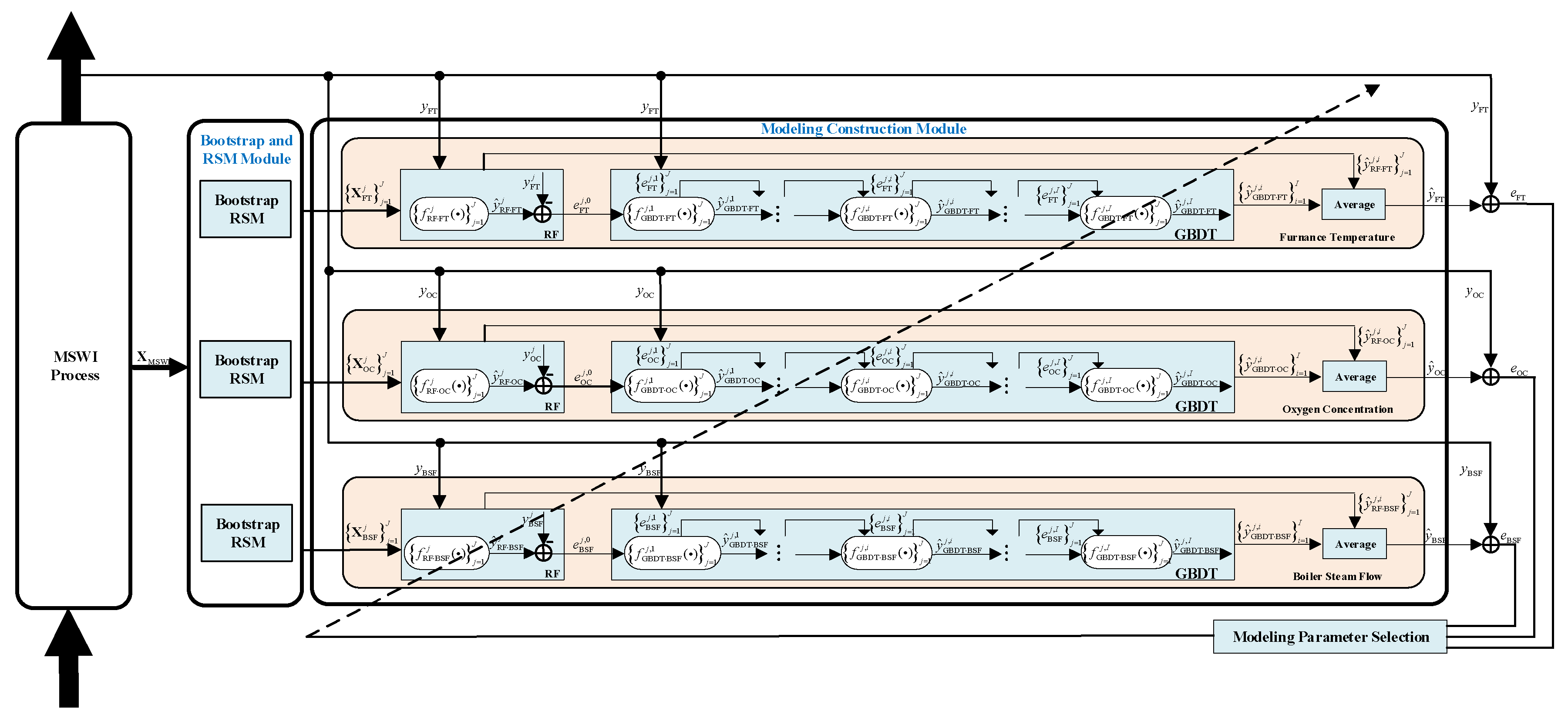

2) Multi-input multi-output (MIMO) modeling

As a typical MIMO system, the coupling between manipulated and controlled variables in the combustion process is significant. In this regard, Leskens et al. [xliii] constructed an ARX model for FGOC and SF. Furthermore, for FT, FGOC, and SF, Chen et al. [xliv] constructed a cascade transfer function model based on adaptive weight particle swarm optimization (PSO); Ding et al. [xlv] built a T-S fuzzy neural network model; and Wang et al. [xlvi] built a hybrid ensemble model of RF and GBDT, which strategy diagram is shown in

Figure 5.

The studies mentioned above support research in optimal control; however, they encounter challenges such as poor modeling accuracy and an unresolved issue regarding the model’s adaptability under various operating conditions.

For combustion line position, Miyamoto et al. [xlvii] proposed a quantitative method based on process data and flame images. However, research on constructing the mapping model between manipulated variables and combustion line position has not been reported.

In summary, the combustion process exhibits nonlinear and strong coupling characteristics. Building upon existing studies of other industrial processes [xlviii,xlix], there is a need for in-depth research on the MIMO controlled object model of the MSWI process, particularly focusing on its adaptability to complex operating conditions.

3.1.2. Auxiliary Variables

The stability of the combustion process is influenced by numerous auxiliary variables. This study, however, only focuses on the calorific value of MSW and the thickness of the MSW layer.

1) Calorific value of MSW

The calorific value of MSW is a crucial factor in the combustion process. It directly influences the selection of manipulated strategies, including decisions on whether to add auxiliary fuel and in what quantity. Additionally, it impacts the operation, maintenance, management, and economic benefits of enterprises [l,li]. In addressing the challenge of direct detection difficulty, Chen [lii] and Zeng et al. [liii] employed the heat balance mechanism for estimation. Kessel et al. [liv] initially constructed a soft sensing model based on process data. Subsequently, various data-driven models based on BPNN [lv,lvi,lvii,lviii,lix], L-M backpropagation neural network [lx], RBF [lv], adaptive network based fuzzy inference system (ANFIS) [lv], fuzzy neural network [lxi], and others have been successively introduced. Non-neural network soft sensing models encompass SVM [lxii], LS-SVM [lxiii], and RF [lxii], among others. Additionally, You et al. [lxii] conducted a comparison of ANN, ANFIS, SVM, and RF, with the results indicating that ANFIS exhibited the best performance, followed by RF, while ANN performed less effectively. Recently, Xie et al. [lxiv] introduced a real-time soft sensing model for calorific value based on deep learning and image recognition. Unfortunately, the truth samples used to construct a soft sensing model for the calorific value of MSW present challenges, including high acquisition costs, sparse samples, and a limited range of operating conditions. Combining the characteristics of modeling data is necessary to enhance generalization performance.

2) Thickness of the MSW layer

The thickness of the MSW layer undergoes dynamic changes throughout the combustion process and is closely related to the calorific value of MSW and SF. Therefore, it can also be considered as a controlled variable. Nuclear instruments are employed for direct detection, but they pose challenges such as high costs, complicated maintenance, and limited practicality. Given the aforementioned challenges in obtaining truth samples, acquiring soft sensing models mainly relies on indirect calculations using data such as air pressure, air volume, negative pressure, and grate area, considering the perspective of physical properties [liii,[lxv,lxvi]. Hence, achieving more accurate and economical real-time detection methods needs further study.

3.2. Modeling for Operational Indices

3.2.1. Environmental Indices Modeling

The indices related to environmental protection encompass numerous variables, among which particulate matter and emission concentrations of NOx, SO2, HCl, HF, and CO2 can be detected online through the CEMS. The emission concentration of toxic heavy metals and organic pollutants, such as dioxin (DXN) and volatile organic compounds (VOCs), is primarily determined through offline testing conducted in the laboratory. [lxvii]. The sub-section is divided into two categories, namely, the prediction model for easily detectable indices and the soft sensing model for difficulty-to-detect indices.

1) Prediction model for easily detectable indices

Considering the reliability of the CEMS system and the requirement for smart optimal control, it is essential to construct a prediction model for easily detectable indices.

For NOx, Matsumura et al. [lxviii,lxix] initially employed system identification to construct a NOx emission model and utilized its output as a feedback signal to control the amount of NH3 injected. Additionally, Huselstein et al. [lxx] utilized continuous-time system identification [lxxi] to establish a multi-transfer model of NOx emissions with FGOC and secondary air volume as inputs. They analyzed the effects of manipulated variables, such as air volume and feed volume, on NOx emissions. Subsequently, many researchers utilized machine learning algorithms to build NOx emission prediction models, including BPNN [lxxii], RBF [lxxiii,lxxiv], and LSTM [lxxv]. Nevertheless, practical verification of the aforementioned models on actual MSWI plants remains to be conducted.

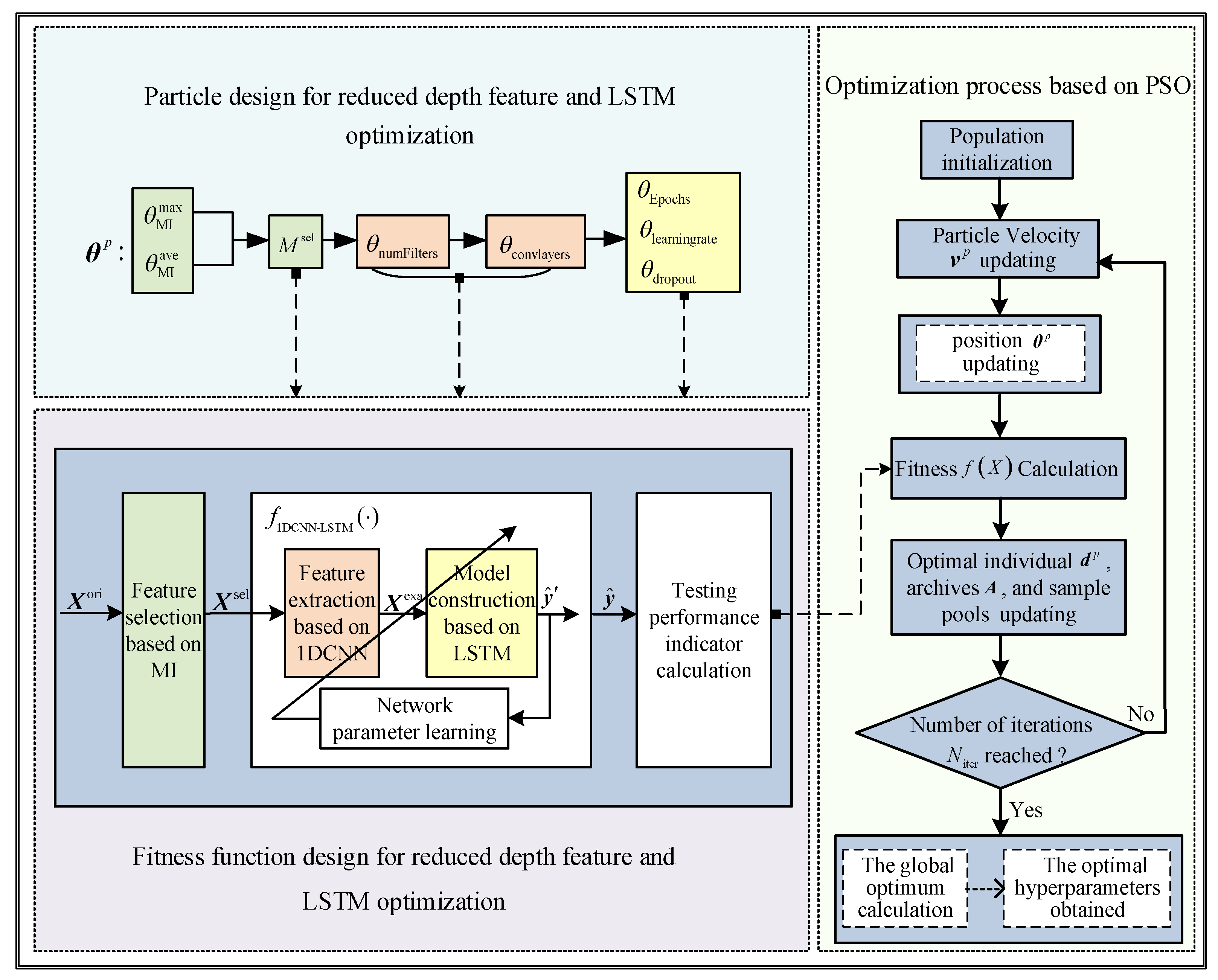

As one of the toxic gases produced by MSWI process, carbon monoxide (CO) must be strictly controlled [lxxvi]. Additionally, CO is directly related to DXN [x]. The standard of a half-hour average is generally adopted due to the noticeable spike phenomenon in CO emission concentration. [lxxvii]. Zhang et al. [lxxviii] proposed a CO emission prediction method based on reduced-depth features and a long short-term memory (LSTM) optimization strategy. This method comprises three parts: a particle design for reduced-depth feature and LSTM optimization, a fitness function design for reduced-depth feature and LSTM optimization, and optimization based on PSO. The strategy diagram is shown in

Figure 6.

Figure 1.

Strategy diagram of Ref. [lxxviii]

Figure 1.

Strategy diagram of Ref. [lxxviii]

The results demonstrate that the machine learning-based prediction models mentioned above can effectively predict environmental indices in specific scenarios. Unfortunately, prediction models for particulate matter and acidic gases such as HCl and HF have not been reported yet [lxxix]. Most of the existing studies have utilized software, such as computational fluid dynamics, for numerical simulation [lxxx,lxxxi], and subsequently provided support for optimizing process design and analyzing mechanisms. Notably, studies on carbon emissions for the MSWI process have not been reported.

2) Soft sensing model for difficulty-to-detect indices

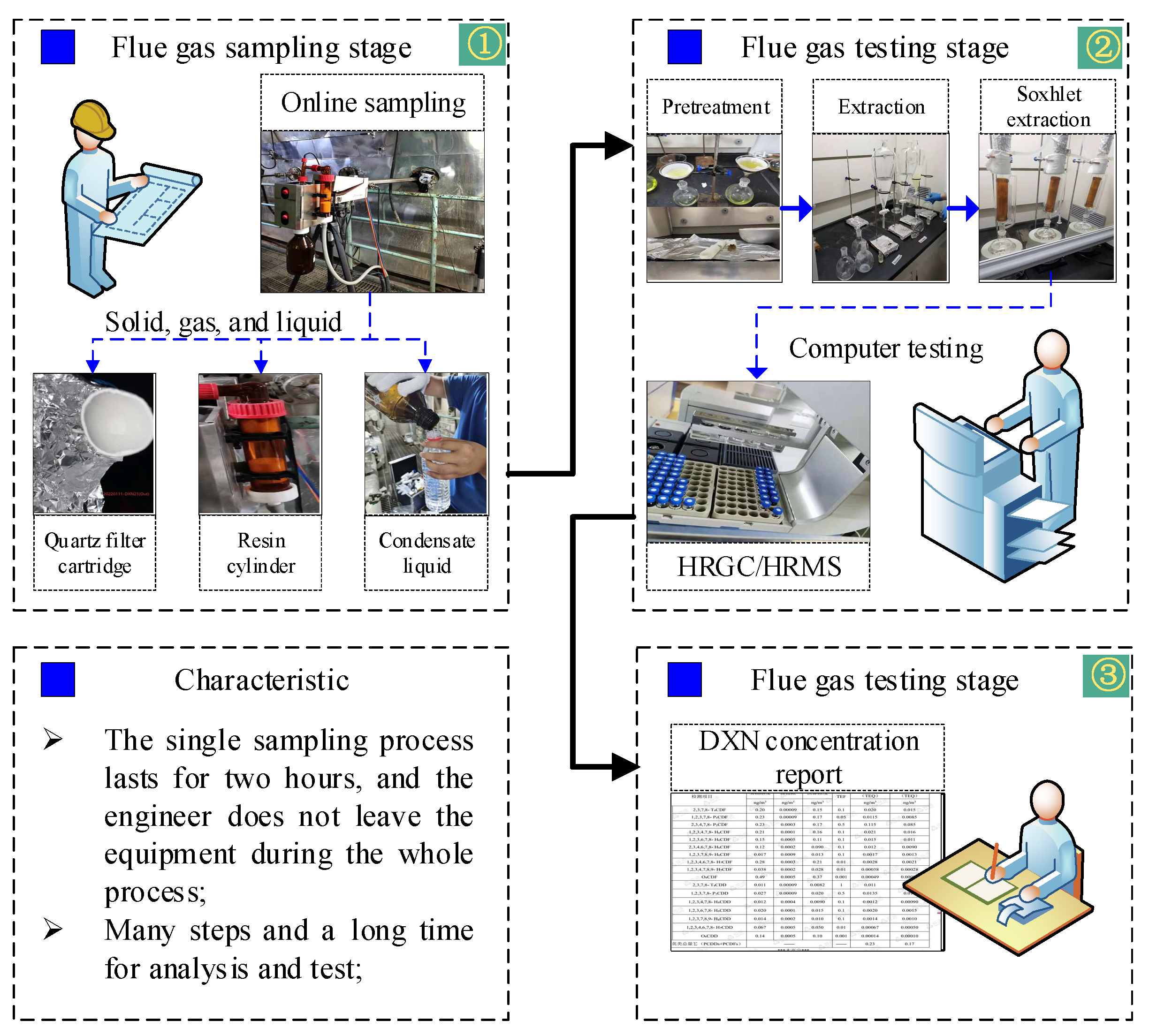

In consideration of environmental indices that cannot be detected online, this study focuses solely on reviewing DXN, which contributes to the “NIMBY effect” of MSWI plants [lxxxii]. From the perspective of the generation mechanism, DXN reactions, including formation, decomposition, resynthesis, and adsorption, are distributed throughout the entire process. These related physical and chemical reactions occur within a short timeframe. There is a “memory effect” that has not been adequately explained [lxxxiii]. Obtaining complete modeling samples is challenging due to the time, labor, and economic costs associated with on-site sampling and laboratory testing.

DXN concentration is primarily determined through laboratory tests. After collecting samples at the site to be detected over an extended period, inspectors transport the samples to the laboratory for testing, ultimately obtaining the DXN concentration at the sampling time. The detection process is illustrated in

Figure 7.

Clearly, the aforementioned detection process of DXN concentration lacks real-time capabilities, making it challenging to support the smart optimal control of the MSWI process with dynamic changes in operating conditions. Therefore, establishing a soft sensing model for DXN becomes a crucial approach to guide the research on smart optimal control.

Hasberg et al. [lxxxiv] established the mapping relationship between flue gas temperature, CO, and DXN concentration. Chang et al. [lxxxv] developed a multiple linear regression analysis model, indicating a linear mapping relationship between DXN concentration, combustion chamber temperature, and CO concentration when FGOC was 7%. Building upon this, a linear mapping model between DXN concentration and flue gas flow, furnace temperature, and manipulated variables was established. Additionally, Ishikawa et al. [lxxxvi] constructed a linear model for DXN concentration with FGOC, proportion of primary air volume, and total air volume as inputs through regression analysis of actual data. DXN is a product of nonlinear MSWI process, and the aforementioned models face challenges in accurately describing the nonlinear relationship between their inputs and outputs.

Studies utilizing neural network algorithms include BPNN based on genetic programming for parameter identification [lxxxvii], BPNN based on genetic algorithm to optimize parameters [lxxxviii], and BPNN based on selection features by correlation analysis and PCA [xli]. The studies utilizing the SVR algorithm include SVR based on mechanism for feature selection [lxxxix], selective ensemble SVR based on PCA in terms of sub-region extraction and selection of latent features [xc], et al. The studies based on decision tree algorithm include a hybrid ensemble based on RF and GBDT [xci], and RF based on sample transfer learning [xcii]. The feature learning ability of the aforementioned classical machine learning model needs further enhancement.

Currently, existing studies primarily concentrate on the DXN concentration model of the G3 flue gas position, and they exhibit the following common problems: 1) Limited performance improvement of the model due to sparse samples; 2) Insufficient studies that integrate MSWI process and DXN mechanism characteristics; 3) Difficulty in fully supporting DXN emission reduction control based on the generation mechanism with the existing models.

In summary, it is essential to conduct in-depth exploration and research on the environmental indices for the MSWI process.

3.2.2. Product Indices Modeling

The product indices of the MSWI process are significantly different from those of industrial processes such as mineral processing and petrochemical. The reason is that the MSWI process lacks commodity attributes [xciii]. In this study, the product indices of the MSWI process are determined as fly ash yield, heat reduction rate of slag, and combustion efficiency.

1) Fly ash yield

The fly ash produced by the MSWI process originates from the combustion of MSW, particles generated during desulfurization and deacidification, and activated carbon after adsorption of DXN and heavy metals [xciv,xcv], among other sources. Such fly ash has the potential to cause significant harm to the sustainable development of human beings and the ecological environment [xcvi]. Considering the limitations of Air Pollution Control Devices (APCDs) technology and the increasingly stringent environmental protection emission policies, coupled with the challenges in effectively controlling fly ash yield, the primary research focus of industry and academia is mainly on the harmless treatment [xcvii,xcviii] and resource utilization [xcix,c], and other aspects [ci]. Therefore, research on modeling, prediction, and smart optimal control remains a challenging problem to be addressed.

2) Heat reduction rate of slag

The heat reduction rate of slag refers to the percentage of the reduced quality of the slag after burning compared to the original. It is an important index for evaluating the incineration effect and the reduction rate of MSW capacity. [cii]. Relevant national standards stipulate that the upper limit for the heat reduction rate of slag is 5%. Currently, it is measured using an off-line testing mode, which involves on-site sampling, transportation, sample delivery, as well as weighing, drying, burning, cooling, and analysis in the laboratory [ciii]. In this regard, Luo et al. [civ] developed on-line detection equipment, but the harsh working environment made it challenging to operate stably for a long period. Sun et al. [cv] associated the appearance characteristics of slag with its heat reduction rate, but the corresponding mapping model was not constructed. Undoubtedly, the above studies provide a preliminary exploration idea for on-line reliable detection.

Up to now, the actual industrial practice relies on expert experience to control the heat reduction rate of slag. Strategies include increasing the combustion time on the grate and adopting oxygen-enriched combustion [cvi,cvii].

3) Combustion efficiency

Combustion efficiency refers to the ratio of the heat of heating combustion products during fuel combustion to the low calorific value released by the complete combustion of the fuel under adiabatic conditions. Unfortunately, there is no report on it. The standard for pollutant control on hazardous waste incineration (GB 18484-2020) in China defined it as the percentage of CO2 concentration in the flue exhaust gas to the sum of CO2 and CO concentration. Studies on coal combustion and co-combustion of other fuels [cviii,cix] have shown that combustion efficiency can quantitatively evaluate the combustion status. Usually, higher combustion efficiency is considered better. However, it may be contradictory to CO concentration and carbon reduction, indicating the need for multi-objective optimization research.

In conclusion, there are currently no pertinent reports on product indices for conducting smart optimal control research in the field of the MSWI process. Theoretically, optimizing the control of product indices has the potential to decrease the operating costs of MSWI plants.

3.2.3. Economic Indices Modeling

The economic benefits of an MSWI plant primarily stem from MSW processing fees and on-site power generation. Due to the inherent environmental properties of the MSWI process, its rated capacity and turbine power generation are relatively fixed. Therefore, it is imperative to maintain the upper limits to ensure optimal returns. The power generation of a typical MSWI plant is approximately 0.3-0.7 MWh/t [cx]. Under normal operating conditions, strategies to ensure that power generation is close to the upper limit include: 1) When the calorific value of MSW is high, the processing capacity decreases; 2) When the calorific value of MSW is moderate, the processing capacity increases; 3) When the calorific value of MSW is low, the processing capacity of MSW increases significantly. Due to the limitations of the process, power generation efficiency needs to be decreased as the MSW processing capacity increases. Currently, both heat exchange efficiency and combustion efficiency increase. To maximize the utilization of energy, additional heat energy needs to be employed for heating primary and secondary air and other stages that require heat energy. Therefore, the aforementioned economic indices need to be redefined in the research on smart optimal control for the MSWI process. Currently, there are no reported studies on modeling and prediction in economic indices.

4. AI Application Research in Control of MSWI Process

Studies indicates that the cornerstone for achieving the stable operation of the entire MSWI process lies in the incinerator [cxi]. Effectively controlling the combustion process, characterized by numerous variables, strong coupling, and nonlinearity, has consistently been a central challenge in both industry and academia. The subsequent review is approached from the dual perspectives of on-site and off-site control. The aim is to delineate the boundary between industrial application and academic research more distinctly and bridge existing gaps [cxii].

4.1. Control in On-Site

In general, the Automatic combustion control (ACC) system can achieve the automatic control of the combustion process under the condition of stable calorific value of MSW and normal operating conditions [cxiii]. Nevertheless, substantial manual intervention is necessary during abnormal conditions, such as fluctuations in composition and calorific value due to insufficient mixed fermentation of MSW, steam flow less than the rated value leading to furnace temperature decreases, steam flow exceeding the rated value causing furnace temperature increases, and maintenance cycles of incineration equipment, among other factors. In light of these challenges, the industry has made improvement research.

4.1.1. Research of ACC System

Onishi et al. [cxiv] incorporated a fuzzy controller for air volume and air temperature into the ACC system, demonstrating improved robustness and effectiveness. Schuler et al. [cxv] utilized an infrared thermal imager to detect furnace temperature and its fluctuation information, leading to an enhanced rapid response in the fine-tuning process. Miyamoto et al. [xlvii,[cxvi] employed a neural network to construct a combustion status recognition model, utilizing its output as feedback information for the ACC system. The results showed effective reduction in CO concentration. Subsequently, Zipser et al. [cxvii] detected temperature information of MSW, flue gas, and flame through infrared image analysis to aid combustion control. To address fluctuations in furnace negative pressure caused by grate turnover, Zeng et al. [cxviii] implemented a control scheme based on a filtering algorithm to ensure the stability of furnace temperature. For optimal combustion, Xu et al. [cxix] designed a closed-loop control strategy for steam flow to adapt to changes in MSW calorific value, achieving prolonged stable operation. Wang et al. [cxx] introduced denitrification, lime slurry, emission factor, and other elements to the ACC system, achieving preliminary localization improvement.

4.1.2. Research of Non-ACC System

Regarding furnace temperature in actual industrial sites, Ono et al. [cxxi] applied fuzzy rule control to an MSWI plant in Japan. Shen et al. [cxxii] summarized expert experience as fuzzy control rules and implemented them in an MSWI plant in Shenzhen. Carrasco et al. [cxxiii] developed a combustion control system based on expert rules for an MSWI plant in Spain. However, rule-based control systems face challenges in maintaining stable operation in the presence of frequent fluctuations in operating conditions.

Despite the extended use of the introduced ACC system in China over many years, MSWI plants still operate at a fundamental control level. Particularly in instances of damage to detection instruments and equipment, there is a greater reliance on manual control modes. Clearly, this impedes the achievement of long-term stable and optimal operation.

4.2. Control in Off-Site

The academic community has conducted numerous studies on key controlled variables from both single-input and single-output (SISO) and multi-input and multi-output (MIMO) viewpoints.

4.2.1. SISO Control

1) Furnace temperature

Krause et al. [cxxiv] proposed a neural network fuzzy controller after analyzing the limitations of fuzzy rule controller in the application of a MSWI plant in Germany, but the effect was not simulated and tested. Given the challenges faced by the introduced ACC system in China, researchers have undertaken extensive studies to address these issues. In the domain of fuzzy control, Qian et al. [cxiii] compensated feeder control based on fuzzy rules using the MSW water content estimation model. Shen et al. [cxxv,cxxvi] introduced a fuzzy rule controller with a self-tuning factor, demonstrating its capability to control furnace temperature stably. Based on Ref. [cxxii], Chang et al. [cxxvii] designed a fuzzy rule controller with an adaptive weighted factor, highlighting its effective control. Taking into account practical issues such as real-time requirements and computational memory consumption, Wang et al. [cxxviii] proposed a hierarchical fuzzy rule control strategy with an optimized quantization factor and self-tuning scaling factor. A notable feature is that the correction factor can be selected based on the operating condition. Based on Ref. [cxxiv], Hu et al. [cxxix] introduced a T-S fuzzy neural network controller, showcasing faster response speed and higher control accuracy. Employing traditional PID control, Dai et al. [cxxx] introduced a fuzzy adaptive PID controller to enhance the system’s anti-interference ability, flexibility, and adaptability. He et al. [cxxxi] proposed an RBF-based PID parameter dynamic adjustment strategy to suppress disturbances. Additionally, Ni [cxxxii], Xiao [cxxxiii] and Wu [cxxxiv] et al. introduced a Human simulated intelligent controller (HSIC), simulating the cognitive mechanism and operational behavior of domain experts. Building on this, Wu et al. [cxxxv] proposed a PSO-based HSIC temperature controller.

The aforementioned studies have yielded satisfactory results, but the quantity of controlled variables in these studies is typically singular. This poses challenges in addressing the strong coupling characteristics inherent in the MSWI process.

2) Flue gas oxygen content

In addressing the challenge of stable control of flue gas oxygen content, Sun et al. [cxxxvi] introduced an RBF-based model predictive controller. Following an analysis of the stability of the control system, its effectiveness was verified through simulation.

3) Steam flow

In the context of stability control for steam flow, Chen et al. [cxxxvii] and Yang et al. [cxxxviii] employed a fuzzy rule controller with grate speed as the manipulated variable, demonstrating a significant reduction in fluctuations caused by abnormal operating conditions. Watanae et al. [cxxxix] adopted a feedback control strategy with a fixed time window to achieve stability control. Additionally, Annunziato et al. [cxl] proposed a control strategy that combines fuzzy logic, neural network, and evolutionary computation. Verification results indicate not only its effectiveness but also its contribution to reducing pollutant emissions. Furthermore, Falconi et al. [cxli] introduced a stable closed-loop control system based on a linear quadratic regulator, verifying its effectiveness through simulation experiments.

4.2.2. MIMO Control

1) Double input and double output

For the simultaneous control of steam flow and flue gas oxygen content, Leskens et al. [cxlii] introduced a linear model predictive control (LMPC) strategy, demonstrating that the errors in both the manipulated and controlled variables were superior to those in traditional combustion control systems. However, the LMPC strategy faces challenges in dealing with strong nonlinear problems. Furthermore, Leskens et al. [cxliii,cxliv] proposed a nonlinear model predictive control (NMPC) strategy to estimate the optimal air and material distribution through the rolling time domain. Additionally, Leskens et al. [cxlv] introduced a PID control strategy that couples parts of the two loops, showing effective improvement in tracking characteristics and a significant enhancement in the economic benefits of the MSWI plants. For the simultaneous control of furnace temperature and flue gas oxygen content, Ding et al. [cxlvi] proposed a self-organizing fuzzy neural network controller based on multi-task learning. However, its application is limited to single operational condition.

2) Triple input and triple output

For the simultaneous control of furnace temperature, steam flow, and flue gas oxygen content, Ding et al. [cxlvii] introduced a multi-loop PID controller based on a quasi-diagonal recurrent neural network. This controller can adaptively adjust its parameters according to the error signals. Additionally, Wang et al. [cxlviii] proposed a multiple input multiple output control method based on a single neuron adaptive PID. The accuracy and effectiveness of the proposed method were verified using actual industrial data. The diagram of the control strategy is shown in

Figure 8.

Nevertheless, the applicability of the aforementioned studies is limited to specific operational conditions, and there is a need to enhance their universality.

The above studies highlight differences in the research focus between industrial applications and academic research. To address these issues, it is necessary to make research with a team-based perspective, leveraging expertise in both industrial practices and control theory and algorithms [cxii]. Clearly, the challenge lies in conducting more in-depth academic research in terms of application to enhance its universality and applicability to the industry, posing a complex problem that requires further exploration.

5. AI Application Research in Optimization of MSWI Process

The optimization of key controlled variables (furnace temperature, flue gas oxygen content, steam flow, combustion line, etc.) in the MSWI process has not been extensively reported. Most existing studies primarily concentrate on the setpoints of manipulated variables related to “air distribution” and “material distribution” [cxlix]. To achieve smart optimal control of the MSWI process, the objective from these two viewpoints is to minimize exhaust emissions, minimize material consumption, maximize combustion efficiency, and optimize other relevant product indices while satisfying various equality and inequality constraints. Therefore, the optimization of the MSWI process requires the use of intelligent optimization algorithms to address multi-objective conflicts.

In the context of air distribution, Xia et al. [cxlix] employed case-based reasoning (CBR) to intelligently set it based on domain expert knowledge. Additionally, Ding et al. [cl] intelligently compensated the secondary air volume, achieving optimal settings. However, the core idea of CBR-based intelligent setting involves the reuse of expert experience. The advantage lies in conforming to empirical cognition, while the disadvantage is that the range is limited, and finding the true optimal setpoints is challenging. In recent efforts to optimize the setpoints of primary/secondary air volume, Cui et al. proposed a multi-objective PSO algorithm [cli] and a multi-condition operational optimization with adaptive knowledge transfer algorithm [clii]. The algorithm was verified using industrial field data, and the results demonstrated strong global optimization ability and robustness.

In addressing material distribution, Anderson et al. [cliii] utilized a multi-objective evolutionary algorithm to determine optimal setpoints for the feed rate. The results demonstrated effective achievement of the goals of maximizing the feed rate and minimizing the ash carbon content.

The aforementioned studies have demonstrated positive outcomes in optimizing the setpoints of manipulated variables under single operating conditions. However, several challenges persist, including a lack of consideration for adaptability to multiple operating conditions, the presence of multiple objectives, and the integration of multi-modal data.

There are limited studies on the optimization of controlled variables. Huang et al. [cliv] employed the multi-objective competitive swarm optimization algorithm to optimize furnace temperature and flue gas oxygen content, achieving multi-objective conflict optimization for NOx and combustion efficiency. However, this study focused solely on providing setpoints for the key controlled variables without considering the controller. Clearly, further exploration is required in this area of research.

The optimal research of the MSWI process presents numerous challenging problems, including determining optimal setpoints for multi-conflicting objectives, managing multiple controlled variables, and optimizing whole process operational indices using multi-modal data-driven approaches.

6. AI Application Research in Maintenance of MSWI Process

Relying on DCS monitoring process data, industrial camera monitoring furnace flame, and on-site information obtained through regular manual inspection, domain experts utilize their experience to diagnose on-site faults in MSWI plants. However, the following problems persist:

1) The information within the DCS system undergoes frequent changes. The alarm function for abnormal operating conditions is triggered solely based on whether the collected data exceeds a limit value, leading to false alarms and making it challenging to trace issues.

2) The high temperature and intense light during the combustion process, along with the molten material it produces, hinder the industrial camera’s ability to capture a clear combustion picture. Consequently, operating engineers face challenges in making informed decisions, potentially resulting in fluctuations in operating conditions.

3) In high-temperature and noisy environments, inspection engineers can only assess the normality of equipment by listening, making it challenging to ensure optimal operation.

The fault diagnosis mode conducted by domain experts faces issues such as sub-optimality, delay, and subjectivity. Ensuring the safety, stability, and optimal operation of the MSWI process becomes challenging under these circumstances.

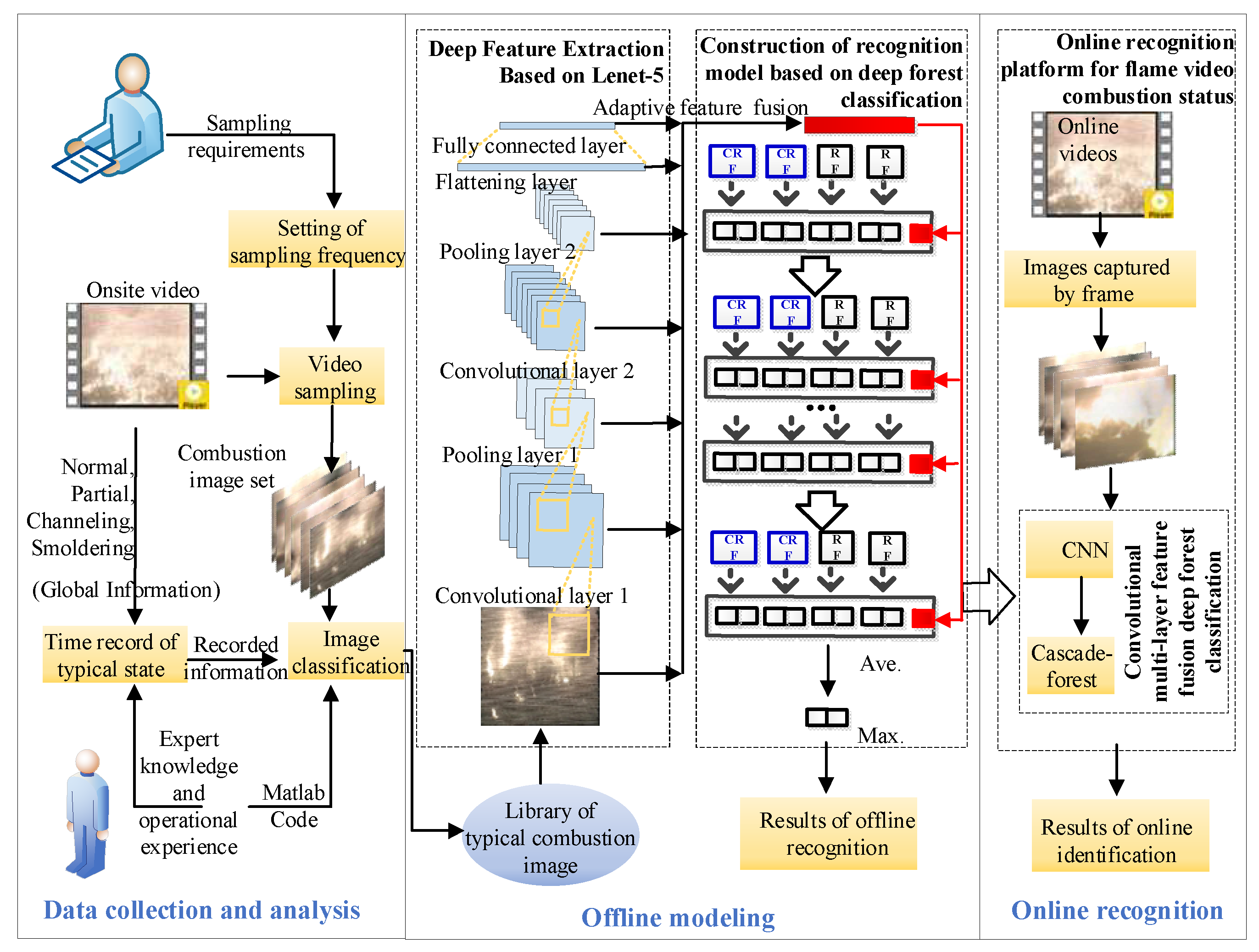

6.1. Recognition of Flame Status

The flame features, comprising the combustion line position and essential physical meaning features such as area, height, and brightness, play a crucial role in assessing the flame status within the combustion process [clv]. These features directly impact the understanding of phenomena like partial burning, local burning through, coking, ash deposition, and corrosion occurring in the furnace [clvi]. Researchers have developed various approaches for recognizing the combustion status based on the combustion line position and other flame characteristics. Duan et al. [clvii] utilized a combustion status recognition model, incorporating multi-scale color moment features and Random Forest (RF) algorithm. Guo et al. [clviii] presented a strategy for combustion status recognition that relies on the hybrid enhancement of generative adversarial networks (GANs). Pan et al. [clix] introduced a novel online recognition method using deep forest classification (DFC) based on convolutional multi-layer feature fusion. The strategy diagram for Pan et al.’s method is depicted in

Figure 9.

Han et al. [clx] proposed a recognition model for unknown flame combustion status using a semi-supervised approach. Sun et al. [clxi] aimed to reveal the relationship between combustion flame images and temperature, reconstructing the temperature field in each region of the flame using the acoustic emission temperature detection method. Zheng et al. [clxii] combined the Newton iteration method and Hottel emissivity model to establish a relationship model between multi-spectral flame images and temperature. Yan [clxiii], and He [clxiv] et al. used spectrometers to detect the flame and built mapping models between its characteristics and the concentration of alkaline metals emitted. Zhou et al. [clxv] conducted three-dimensional visualization modeling of flame temperature based on Monte Carlo and multi-imaging angles. Notably, most of these studies relied on additional physical equipment and did not consider the recognition of combustion status based on multi-modal data.

In summary, there is a need for further research on detecting combustion status based on multi-modal data and performing fusion verification.

6.2. Qualitative Detection of Operational Fault

Since the 1990s, researchers have been exploring the application of computer and AI technology in the fault diagnosis of the MSWI process to assist domain experts in decision-making. Ono et al. [clxvi] developed a fuzzy expert fault reasoning system for the incineration and boiler system. This system can carry out symptom analysis, early warning, fault alarm, analysis, and recognition within and outside the limits of the DCS system. Subsequently, Chen et al. [clxvii] conducted online diagnosis of abnormal exhaust emission and steam flow based on cluster analysis, neural networks, and Monte Carlo statistics. Aiming at the problems of MSW partial burning through, poor slag discharge, and coking in the furnace, Tao et al. [clxviii] constructed a fault tree based on process analysis and historical experience. They then used a rule reasoning expert system to detect it, achieving an accuracy rate of 90% in experiments. At the same time, Tao et al. [clxix] used a BPNN modeling strategy for diagnosis. For the recognition of combustion status, Zhou et al. [clxx] constructed a BPNN-based diagnostic model with a high accuracy rate of 99%. However, there were issues such as overfitting and high requirements for training samples. Additionally, Ding et al. [clxxi] constructed a CBR model based on RWNN similarity retrieval for superheater and economizer leakage, ash deposition, and slagging in horizontal flues, as well as coking and poor slag discharge in the furnace. The experiments showed good performance. However, these studies mainly focus on constructing classifier models that can determine whether a fault occurs, without providing quantification or localization of the fault.

6.3. Quantitative Detection of Operational Fault

Multivariate statistical process monitoring (MSPM) technology based on industrial data for quantitative fault detection has garnered extensive attention from both industry and academia [clxxii,clxxiii,clxxiv]. The basic strategy is as follows: Firstly, the latent structure model is established using normal operating condition data. Then, the collected high-dimensional variables are projected into a low-dimensional space. Further, statistical indices such as squared prediction and Hotelling’s T2 are compared to determine whether a fault occurs. Finally, fault location is performed through data reconstruction. Zhao et al. [clxxv] initially employed PCA and rule reasoning for the quantitative detection of incinerator faults. The findings demonstrated a notable reduction in the false positive rate associated with faults. In a similar vein, Tavares et al. [clxxvi] conducted a comparative analysis between PCA-based and PLS-based fault diagnosis approaches. The results not only indicated superior overall performance but also highlighted the effectiveness of various statistical indices in precisely locating faults. Notably, the existing literature on fault quantitative detection in MSWI processes is limited, predominantly relying on the linear PCA/PLS method. It is evident that the dynamic, nonlinear, multiscale, and multimodal characteristics inherent in the MSWI process present novel challenges to both theoretical and applied research in MSPM.

7. Outlook on AI Application for MSWI Process

The amalgamation of AI with specific industrial domain is denoted as industrial AI technology. At its core, this technology aims to facilitate innovative applications such as high-performance controllers, intelligent operational decision-making, and intelligent algorithm updating [ii]. Its primary objective is to seamlessly adapt to the intricate and dynamic industrial environment to accomplish diverse operational goals and tasks [clxxvii]. Evidently, achieving sustainable development in the MSWI process necessitates a profound integration with industrial AI technology, thereby diminishing reliance on domain experts. Urgent attention is required for research in AI technology pertaining to modeling operational indices, intelligent control of the combustion process, collaborative optimization of the whole process, and intelligent maintenance of the overall system.

7.1. Operational Indices Modeling

The effective operation of an integrated system facilitating intelligent optimization, decision-making, and control for complex industrial processes hinges on the ability to conduct real-time monitoring of key operational indices [clxxviii]. Clearly, the online detection of environmental, product, and economic indices plays a pivotal role in ensuring the safe, stable, and optimal operation of the MSWI process. The modeling and prediction of various industrial processes [clxxix] can be accomplished by constructing intelligent models based on easily collectible multi-modal data, such as process variables and flame videos. The distinctive characteristics of the MSWI process, including its multi-process, multi-stage nature, complexity, and unclear mechanisms, result in different time scales, variations, and uncertainties in modeling samples. It is imperative to analyze the delay characteristics between process variables and operational indices based on the mechanisms of thermal power transmission and chemical substance conversion, as well as the correlation between multi-temporal and spatial scale samples and operational indices. The process variables within the MSWI process are numerous and intricately coupled. The correlation between operational indices and various process stages varies, with an unclear underlying mechanism. Utilizing numerical simulation becomes imperative to elucidate these mechanisms, drawing upon the expertise of domain professionals and extracting knowledge embedded in data to minimize model input. In addressing high-dimensional sparse modeling samples, techniques like virtual sample generation are employed to expand sample numbers, mitigating issues related to imbalanced sample distribution and unknown expected distribution. A study on AI algorithms with strong interpretability is essential for modeling and predicting operational indices. The actual MSWI process exhibits numerous interference factors and frequent fluctuations in operating conditions, necessitating an operational index model capable of adaptive adjustments to dynamic process changes for accurate predictions. Employing methods based on mathematical models [clxxx,clxxxi], multivariate statistics [clxxxii,clxxxiii], and AI [clxxxiv,clxxxv] aids in predicting drift time, drift degree, and drift position under new operating conditions specific to MSWI operational indices. Incorporating adaptive update algorithms, continuous learning mechanisms, knowledge transfer, and incremental learning strategies becomes important to enhance the robustness and generalization performance of online modeling.

In recent years, researchers have conducted numerous studies on operational indices modeling in complex industrial processes, such as blast furnace ironmaking, fused magnesium, and petrochemical processes. Addressing the challenge of sparse labeled samples for modeling, various methods have been proposed, including virtual sample generation [clxxxvi,clxxxvii], semi-supervised [clxxxviii], weakly supervised [clxxxix], and unsupervised [cxc]. These strategies offer robust support for investigating the sample completion mechanism in the modeling of the MSWI process. To enhance multi-source information representation and model interpretability, diverse methods have been introduced, including multi-feature information fusion [cxci], multi-modal deep learning [cxcii], visual data depth modeling [cxciii], Bayesian data-driven T-S fuzzy [cxciv], and deep forest regression [cxcv,cxcvi]. These serve as the theoretical foundation for exploring intelligent reduction of multi-source features and constructing interpretable models in the MSWI process. Confronting the challenge of online dynamic prediction, studies on broad learning systems [cxcvii,cxcviii], concept drift learning [cxcix], and dynamic self-organization model [cc] indirectly demonstrate the promising feasibility of developing intelligent prediction systems for operational indices.

7.2. Intelligent Control of Combustion Process

In comparison to power generation processes utilizing coal and gas as input materials, achieving precise control in the combustion process of the MSWI process is notably more challenging due to numerous interference factors and frequent fluctuations in operating conditions [lxvii,cxlvii]. Despite the abundance of process data, its distribution is unbalanced. Furthermore, the integration of unstructured data, such as images and videos, with process data is hindered by time delays and information asymmetry, presenting difficulties in fusion. Additionally, obtaining, quantifying, and utilizing knowledge related to the incineration mechanism poses challenges. The MSWI process exhibits significant nonstationary characteristics, including frequent transitions between steady-state conditions and transition conditions, as well as substantial sensor drift in high-temperature and high-pressure environments, among other factors. These factors underscore the importance of effective operating condition perception and fault diagnosis for each process stage as crucial guarantees to ensure the stable operation of the controller. Additionally, the development of models for operating condition perception and fault diagnosis encounters challenges such as a lack of samples, unknown types, difficulty in explanation, uncertain changes/occurrences, and unidentified potential faults. Given the regional and seasonal variations in MSW composition and calorific value, coupled with the diverse experiences of operators and varying levels of operation and maintenance, the MSWI process exhibits a multitude of operating conditions. Traditional PID controllers prove inadequate in adapting to these deferent situations. Clearly, effective perception of operating conditions necessitates the adoption of diverse intelligent control algorithms tailored to different operating conditions. Research indicates that intermittent operation in the MSWI process results in severe pollution, a significant increase in operating costs, and challenges in processing capacity [cci]. Consequently, a controller operating under dynamic disturbance must possess the capability for fault tolerance, robustness, and adaptability.

The rapid advancement of AI technology has given rise to numerous studies on intelligent control in various industrial processes. For instance, adaptive sliding mode control [ccii], fuzzy neural control [cciii], and reinforcement-learning-based tracking control [cciv] have been explored for wastewater treatment processes. Event-triggered control [ccv], adaptive tracking control [ccvi], and model predictive control [ccvii] have been investigated for continuous stirred-tank reactor systems. Similarly, model-free adaptive predictive control [ccviii], model predictive control [ccix], and fuzzy control [ccx] have been applied to blast furnace ironmaking processes. These studies not only establish a theoretical foundation but also provide technical support for the controlled object model and basic loop intelligent controller in the MSWI process. Furthermore, research on data-driven operating condition monitoring in coal-fired power generation processes [ccxi] and self-organizing control in wastewater treatment processes [ccii] and blast furnace ironmaking process [ccxii] contributes to the exploration of intelligent condition perception, fault diagnosis, and the self-organizing mechanism of intelligent controllers under dynamic conditions.

7.3. Collaborative Optimization of Whole Process

In the realm of collaborative industrial processes, addressing a category of challenges arises, involving mixed, multi-objective, multi-constraint, and multi-scale dynamic conflict optimization problems [ccxiii,ccxiv]. The intelligent optimal decision-making in human-machine collaboration encompasses tasks such as feed selection, operation and maintenance, and on-site decisions. The collaborative optimization of the entire process assumes that each process stage’s control system in the MSWI process acts as an independent agent, and setpoints are collaboratively determined with the aim of optimizing multiple conflicting and multi-scale operational indices. The selection and configuration of process parameters, as well as the optimal operation of the whole process, primarily depend on domain experts in the actual industrial setting. Nevertheless, the qualitative expression of operational status and decision-making information encounters challenges related to inaccuracy, uncertainty, fuzziness, and even non-uniqueness. Optimal operation stands as the core of intelligent control [ccxv,ccxvi], involving the resolution of real operational statuses or process planning problems through optimization. Addressing the actual needs of a MSWI plant, achieving the optimal solution for multi-conflict objectives holds great significance in realizing smart optimal control [cliii]. The environmental, product, and economic indices in MSWI processes exhibit characteristics of multi-conflict, multi-constraint, dynamic time-varying, and multi-spatial scales, given the limitations of processes and technologies. Consequently, the optimization problem in the MSWI process can be conceptualized as a multi-objective function extremum problem under multi-constraint conditions, representing a notably challenging issue. The diverse sources and complex components of MSW, coupled with the variability and fluctuations in operating conditions, further intensify the complexity of real-time optimal operation. In the context of intelligent optimization in the process industry, Chai et al. [ccxvii,ccxviii] highlighted that human-machine collaboration and interactive learning between domain experts and intelligent optimal decision-making systems are pivotal directions for future development. The MSWI process aspires to achieve minimal energy and material consumption, zero emission of pollutants, and environmental greening. This necessitates the capabilities of perception, cognition, decision-making, and execution possessed by domain experts. In nature, achieving intelligent decision-making in complex industrial processes relies on the enhanced interactive evolution of domain experts and industrial AI technology.

Collaborative optimization decision-making, integrating new AI technology, emerges as a feasible approach to achieve intelligent operation and reduce reliance on domain experts in industrial processes [ccxix]. Numerous studies in this domain have yielded outstanding cases that serve as valuable references. Noteworthy achievements in collaborative optimization include distributed optimization subject to inseparable coupled constraints in the ethylene process [ccxx], multi-objective optimization under the dynamic environment of the iron removal process [ccxxi], carbon emission optimization under different time scales in the sintering process [ccxxii], blast furnace charge surface optimization with feedback compensation [ccxxiii], and intelligent optimization of the ironmaking process supported by a mixed model [ccxxiv,ccxxv]. These accomplishments provide valuable guidance and support for the collaborative optimization of the entire process in the MSWI process. In the realm of intelligent optimization decision-making, studies on the intelligent decision-making of the entire process operation in mineral processing [ccxxvi], scheduling optimization of the ethylene cracking furnace system [ccxxvii], multi-furnace optimal scheduling of silicon single crystal and fused magnesium production processes [ccxxviii,ccxxix], and others have been successfully conducted. These achievements underscore that research on multi-objective real-time optimization algorithms and human-machine collaborative enhanced interactive evolution for intelligent decision-making in the MSWI process has a solid theoretical foundation and practical feasibility.

7.4. Intelligent Maintenance of Whole Process

The enhanced automation of the MSWI process brings about a considerable increase in both complexity and uncertainty, subsequently raising the likelihood and severity of faults [lxvii]. Failure to detect and address faults promptly may result in substantial losses. However, manual monitoring faces challenges, particularly in identifying minor faults that are difficult to detect. Hence, intelligent maintenance for the MSWI process becomes imperative.

In practice, the MSWI process undergoes transitions between diverse operating conditions based on factors such as waste components, feeding amounts, combustion temperature, and changes in setpoint values, aligning with the requirements of production indicators and safety standards. Consequently, addressing the quantification and evaluation of MSWI process operating conditions is a prominent challenge. Distinct operating conditions exert varying influences on system stability, efficiency, and pollutant emissions. Given the extended duration, multistage structure, and multifaceted nature of the MSWI process, the requirements at each operational stage lack consistency. The characteristics of process data undergo rapid and frequent changes with the shifting operational stages, posing tracking difficulties. Furthermore, the protracted operation cycle of the MSWI process results in extended device runtimes, impacting the current condition due to the influence of previous operational conditions. Therefore, swift and accurate recognition of multi-stage operational conditions stands as a key aspect of MSWI process monitoring, necessitating consideration of time continuity. In comparison to normal conditions, abnormal occurrences are less frequent and may be singular. Consequently, there exists a substantial gap in the number of process data instances between normal and abnormal operating conditions, giving rise to a class imbalance problem [ccxxx,ccxxxi]. Constructing an accurate and robust fault diagnosis model based on class imbalance data proves challenging, leading to considerable instances of false positives and false negatives.

Process monitoring and fault diagnosis, driven by AI technologies, have found widespread application in complex industrial processes, including petrochemicals, metallurgy, and energy. Notably, to address condition-switching challenges in multimode process monitoring, various techniques have been proposed. Examples include the hybrid cluster variational autoencoder designed for blast furnace ironmaking [ccxxxii], similarity-preserving dictionary learning applied to the roasting process [ccxxxiii], and dynamic locality-preserving PCA tailored for power generation processes [ccxxxiv]. These approaches aim to solve diverse condition-switching problems encountered in process monitoring. Existing research on complex industrial processes demonstrates the feasibility of multimode MSWI process monitoring. To address class imbalance problems in fault diagnosis of mechanical equipment, widely practiced techniques include virtual sample generation (VSG) and transfer learning. Illustrative instances encompass the features selection oversampling technique for bearing fault diagnosis [ccxxxv], SMOTEBoost for rotor-bearing systems [ccxxxvi], and adversarial transfer learning applied to planetary gearboxes [ccxxxvii]. These approaches provide valuable references and support for tackling class imbalance challenges in MSWI fault diagnosis.

8. Conclusions

In conclusion, significant researches have been made in the application of AI technology to the MSWI process. This study systematically examines AI research pertaining to modeling, control, optimization, and maintenance, addressing the foundational challenges associated with smart optimal control. AI technology plays an important role in fostering the ongoing development of the MSWI process. However, there is a discernible widening gap between academic research and industrial practical implementation. To effectively bridge this divide, future research endeavors focusing on AI applications should prioritize attention to the following aspects:

- 1)

From a modeling perspective, the primary challenges involve establishing dynamic and robust soft measuring and prediction models for operational indices. Additionally, developing an intelligent software system that integrates intelligent perception, prediction, and traceability of operational indices based on AI poses significant challenges.

- 2)

In terms of control, the key objectives for future AI application research include building an intelligent controlled object model based on multi-modal data and mechanistic knowledge. Constructing a steady-state intelligent loop controller tailored for diverse operational conditions, along with its self-organizing mechanism under strong dynamic interference, stands out as key issue.

- 3)

Regarding optimization, future AI application research should address issues such as the intelligent perception mechanism integrating data and knowledge for the whole process, the analysis of multi-level intelligent optimization mechanisms, and the development of intelligent decision-making algorithms for human-machine collaborative enhanced interactive evolution.

- 4)

In terms of maintenance, essential directions for future AI application research encompass conducting qualitative and quantitative evaluations of multi-conditions for the MSWI process. Swift and accurate identification of multi-stage operating conditions with time continuity, coupled with fault detection based on imbalances between normal and abnormal operating conditions, represents significant research avenues.

Author Contributions

Methodology, Jian Tang; Writing—original draft, TianZheng Wang; Resources, Data curation, Heng Xia; Writing-review & editing, Canlin Cui. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

There are not data in this study.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this article.

References

- Cioffi, R.; Travaglioni, M.; Piscitelli, G.; Petrillo, A.; De Felice, F. Artificial Intelligence and Machine Learning Applications in Smart Production: Progress, Trends, and Directions. Sustainability 2020, 12, 492. [CrossRef]

- Yang, T.; Yi, X.; Lu, S.; Johansson, K.H.; Chai, T. Intelligent Manufacturing for the Process Industry Driven by Industrial Artificial Intelligence. Engineering 2021, 7, 1224–1230. [CrossRef]

- Zhao, C. Perspectives on nonstationary process monitoring in the era of industrial artificial intelligence. J. Process. Control. 2022, 116, 255–272. [CrossRef]

- Lee, J.; Davari, H.; Singh, J.; Pandhare, V. Industrial Artificial Intelligence for industry 4.0-based manufacturing systems. Manuf. Lett. 2018, 18, 20–23. [CrossRef]

- Ahmed, I.; Jeon, G.; Piccialli, F. From Artificial Intelligence to Explainable Artificial Intelligence in Industry 4.0: A Survey on What, How, and Where. IEEE Trans. Ind. Informatics 2022, 18, 5031–5042. [CrossRef]

- Yang, Z.; Ge, Z. On Paradigm of Industrial Big Data Analytics: From Evolution to Revolution. IEEE Trans. Ind. Informatics 2022, 18, 8373–8388. [CrossRef]

- Gill, S.S.; Tuli, S.; Xu, M.; Singh, I.; Singh, K.V.; Lindsay, D.; Tuli, S.; Smirnova, D.; Singh, M.; Jain, U.; et al. Transformative effects of IoT, Blockchain and Artificial Intelligence on cloud computing: Evolution, vision, trends and open challenges. Internet Things 2019, 8, 100118. [CrossRef]

- Misra, N.N.; Dixit, Y.; Al-Mallahi, A.; Bhullar, M.S.; Upadhyay, R.; Martynenko, A. IoT, Big Data, and Artificial Intelligence in Agriculture and Food Industry. IEEE Internet Things J. 2020, 9, 6305–6324. [CrossRef]

- Gómez-Sanabria, A.; Kiesewetter, G.; Klimont, Z.; Schoepp, W.; Haberl, H. Potential for future reductions of global GHG and air pollutants from circular waste management systems. Nat. Commun. 2022, 13, 1–12. [CrossRef]

- Qiao, J.; Guo, Z.; Tang, J. Dioxin Emission Concentration Measurement Approaches for Municipal Solid Wastes Incineration Process: A Survey. Acta Automatica Sinica 2020, 46 (6), 1063–1089. [CrossRef]

- Naveenkumar, R.; Iyyappan, J.; Pravin, R.; Kadry, S.; Han, J.; Sindhu, R.; Awasthi, M.K.; Rokhum, S.L.; Baskar, G. A strategic review on sustainable approaches in municipal solid waste management and energy recovery: Role of artificial intelligence, economic stability and life cycle assessment. Bioresour. Technol. 2023, 379, 129044. [CrossRef]

- Walser, T.; Limbach, L.K.; Brogioli, R.; Erismann, E.; Flamigni, L.; Hattendorf, B.; Juchli, M.; Krumeich, F.; Ludwig, C.; Prikopsky, K.; et al. Persistence of engineered nanoparticles in a municipal solid-waste incineration plant. Nat. Nanotechnol. 2012, 7, 520–524. [CrossRef]

- Xia, H.; Tang, J.; Aljerf, L. Dioxin emission prediction based on improved deep forest regression for municipal solid waste incineration process. Chemosphere 2022, 294, 133716. [CrossRef]

- Vilardi, G.; Verdone, N. Exergy analysis of municipal solid waste incineration processes: The use of O2-enriched air and the oxy-combustion process. Energy 2021, 239, 122147. [CrossRef]

- He, W.; Zheng, Y.; Liu, B.; Zhang, B. Effects of Garbage Classification on Air Pollutant Emissions from Garbage Incineration. China Environmental Science 2022, 42 (5), 2433–2441.

- Kumar, A.; Samadder, S.R. A review on technological options of waste to energy for effective management of municipal solid waste. Waste Manag. 2017, 69, 407–422. [CrossRef]

- Liu, Y.; Sun, W.; Liu, J. Greenhouse gas emissions from different municipal solid waste management scenarios in China: Based on carbon and energy flow analysis. Waste Manag. 2017, 68, 653–661. [CrossRef]

- Bajić, B. Ž.; Dodić, S. N.; Vučurović, D. G.; Dodić, J. M.; Grahovac, J. A. Waste-to-Energy Status in Serbia. Renewable and Sustainable Energy Reviews 2015, 50, 1437–1444.

- Kalyani, K.A.; Pandey, K.K. Waste to energy status in India: A short review. Renew. Sustain. Energy Rev. 2014, 31, 113–120. [CrossRef]

- Ministry of Ecology and Environment. Automatic Monitoring Data Disclosure Platform for Domestic Waste Incineration Power Plants: Available online: https://ljgk.envsc.cn/, (accessed on December 30, 2022).

- Long, J.; Du, H.; Zou, X.; Huang, J. Systematic Study on Carbon Emission Reduction of Municipal Solid Waste Treatment. Bulletin of Chinese Academy of Sciences 2022, 37 (8), 1143–1153.

- Khandelwal, H.; Dhar, H.; Thalla, A.K.; Kumar, S. Application of life cycle assessment in municipal solid waste management: A worldwide critical review. J. Clean. Prod. 2018, 209, 630–654. [CrossRef]

- Kolekar, K.; Hazra, T.; Chakrabarty, S. A Review on Prediction of Municipal Solid Waste Generation Models. Procedia Environ. Sci. 2016, 35, 238–244. [CrossRef]

- Yang, Y.; Goh, Y.; Zakaria, R.; Nasserzadeh, V.; Swithenbank, J. Mathematical modelling of MSW incineration on a travelling bed. Waste Manag. 2002, 22, 369–380. [CrossRef]

- Hunsinger, H.; Jay, K.; Vehlow, J. Formation and destruction of PCDD/F inside a grate furnace. Chemosphere 2001, 46, 1263–1272. [CrossRef]

- Bardi, S.; Astolfi, A. Modeling and Control of a Waste-to-Energy Plant [Applications of Control]. IEEE Control. Syst. 2010, 30, 27–37. [CrossRef]