1. Introduction

Exhaust gases from turbine jet engines can be divided into three groups. The first are natural products of fuel combustion, i.e. CO2, H2O and NOx. The second group includes products of inefficient combustion: CO, HC and soot. The third group are emissions related to fuel quality, i.e. sulphides and residue particles such as metals. Harmful combustion products result from various causes. Carbon monoxide is produced in the combustion chamber when there is a rich fuel-air mixture. Too little oxygen leads to incomplete oxidation of carbon to carbon dioxide [

1,

2,

3]. In the case of hydrocarbons, the main causes include, among others: poor fuel atomization leading to incomplete combustion, as well as too low combustion speed [

4]. Nitrogen oxide may be formed in several ways, i.e. as a result of the oxidation of atmospheric nitrogen in the combustion chamber behind the flame, in the initial phase of oxidation of the combustion process of rich fuel-air mixtures with a low flame temperature, and also as a result of the oxidation of nitrogen contained in the fuel [

5,

6,

7,

8]

Changes in emission intensity are introduced by new European Union regulations. The RefuelEU initiative has emerged and is a key part of the EU's Fit for 55 package [

9]. These regulations are already partially in force. One of the requirements from 2025 is the use of a 2% admixture of sustainable aviation fuels (SAF). The scope of these fuels includes certified biofuels, renewable fuels of non-biological origin, including renewable hydrogen and aviation fuels with recycled coal [

10]. By 2050, this admixture is expected to constitute 70%.

Hydrogen was used as an alternative fuel for testing in the co-combustion process. Hydrogen fuel is called emission-free, which means that the only combustion products are water and steam, with trace amounts of nitrogen oxides. Compared to commonly used hydrocarbon fuels, it is characterized by, among others, greater reactivity and diffusivity, high flame speeds, and wide flammability limits. Compared to JET A-1 fuel (approx. 43 MJ/kg), it is characterized by a higher specific energy value (120 MJ/kg) [

11]. There are various works on the analysis of hydrogen combustion in engines and its possible commercial application [

12,

13,

14,

15,

16,

17]. It is generally expected that hydrogen can replace kerosene fuel in jet engines of large aircrafts. In the case of smaller machines, due to their lower efficiency in this case, hydrogen fuel cells will be used [

18,

19].

Miniature turbojet engines are a convenient tool for research on the use of various fuels and admixtures. This is due to the fact that their operating costs are much lower than those of normal scale engines. In this type of turbojet engines, combustion chambers in an annular configuration are most often used. There is quasi-reverse flow there. Some of the air behind the compressor moves towards the return channel and is then mixed with fuel in the evaporator. In this way, an air-fuel mixture is created and directed inside the combustion chamber, where it is ignited. The flame tube in this engine model is made of Inconel 600. The safe operating limit of this material is considered to be the range of 870 °C - 1230 °C [

20].

The aim of the study was to check the impact of co-combustion of JET A-1 fuel and hydrogen on the fuel consumption of the GTM400 MOD miniature turbojet engine. An additional goal was to check the temperature distribution in a selected place of the combustion chamber depending on the engine speed. The measuring point was located near the outer flame tube. This made it possible to verify whether it was not overheating due to high gas temperature.

2. Research Method

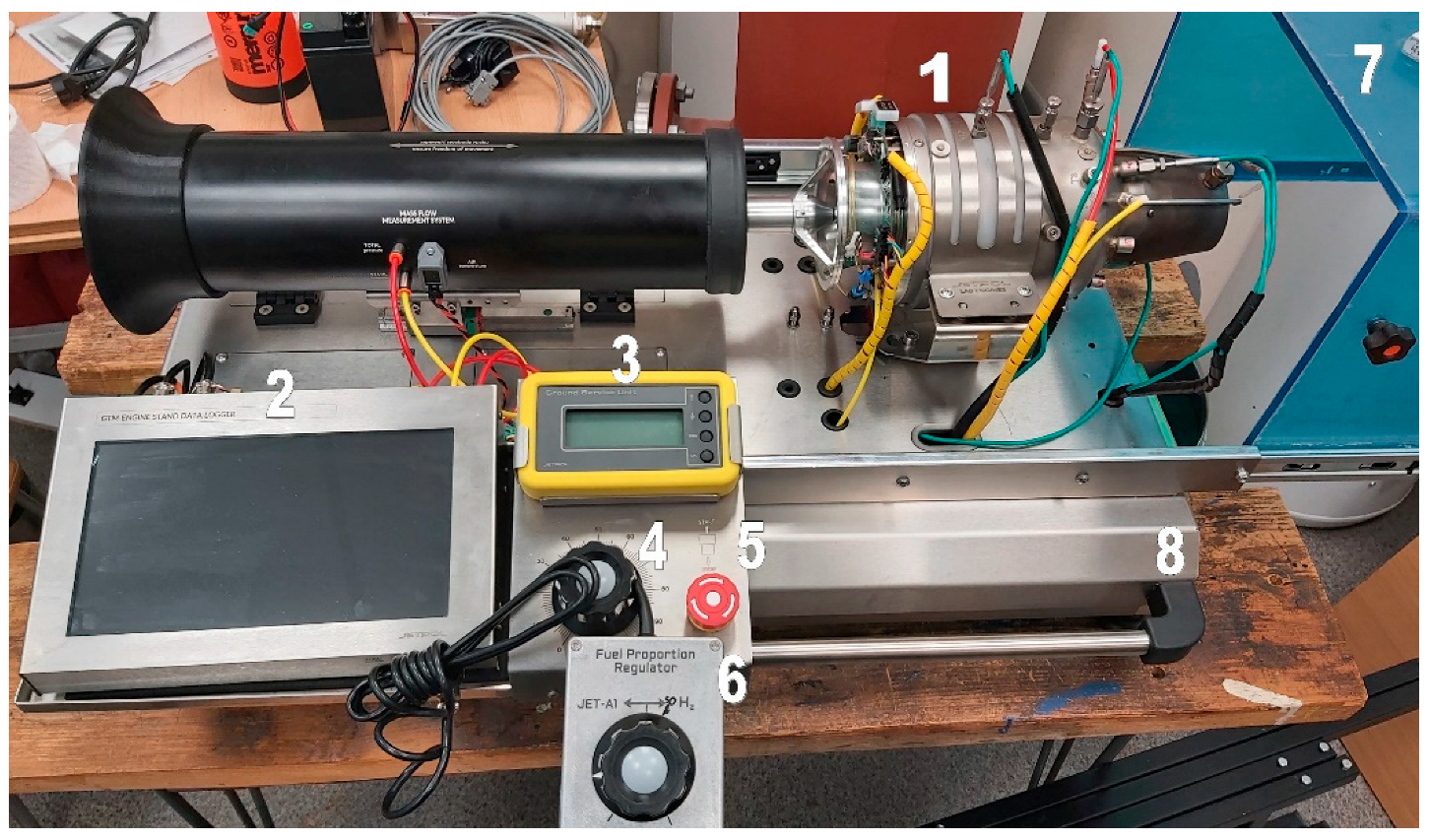

Experimental tests were carried out on the GTM400 MOD turbojet engine from JETPOL. The motor position is shown in

Figure 1.

The engine is characterized by the following technical parameters:

thrust: 15 N - 300 N;

rotational speed: 30000 rpm. – 81000 rpm;

mass air flow: 0,59 kg/s;

fuel consumption: 0,82 kg/min;

engine dimensions: diameter 15 cm, length 39 cm;

total mass: 2,9 kg.

In addition, a hydrogen connection station from Linde Gaz Polska for testing was used for testing. It consists of:

control cabinet;

semi-automatic high pressure reduction panel type READLINE A200;

low pressure reducing panel type W40B;

hydrogen bottles;

tubes, connections and hoses.

Technical hydrogen was used for the tests, the purity of which is 99.955%. It was taken from the cylinder through hoses and directed to pressure reducers. The task of the READLINE A200 reduction panel was to re-educate the pressure from 200 bar to 20 bar. Then the gas reached the second low pressure reducer (W40B), where the pressure was reduced to 8 bar.

Additionally, the stand was equipped with the MCR-2000SLPM flowmeter from Alicat Scientific. This device is designed to work with, among others, hydrogen. It was also placed in the control cabinet. Hydrogen at reduced pressure was sent to the flowmeter, where its flow was regulated. It was then directed to the engine through a flexible hose. There, together with JET A-1 fuel, hydrogen was injected into the evaporator. In the GTM400 MOD engine, the injectors are located at the inlet to the evaporators. JET A-1 fuel and gaseous hydrogen were fed independently through tubes with an internal diameter of 0.6 mm. JET A-1 fuel was injected at a pressure of 4 - 5 bar forced by a gear pump. The location of the experiment and the hydrogen connection point are shown in

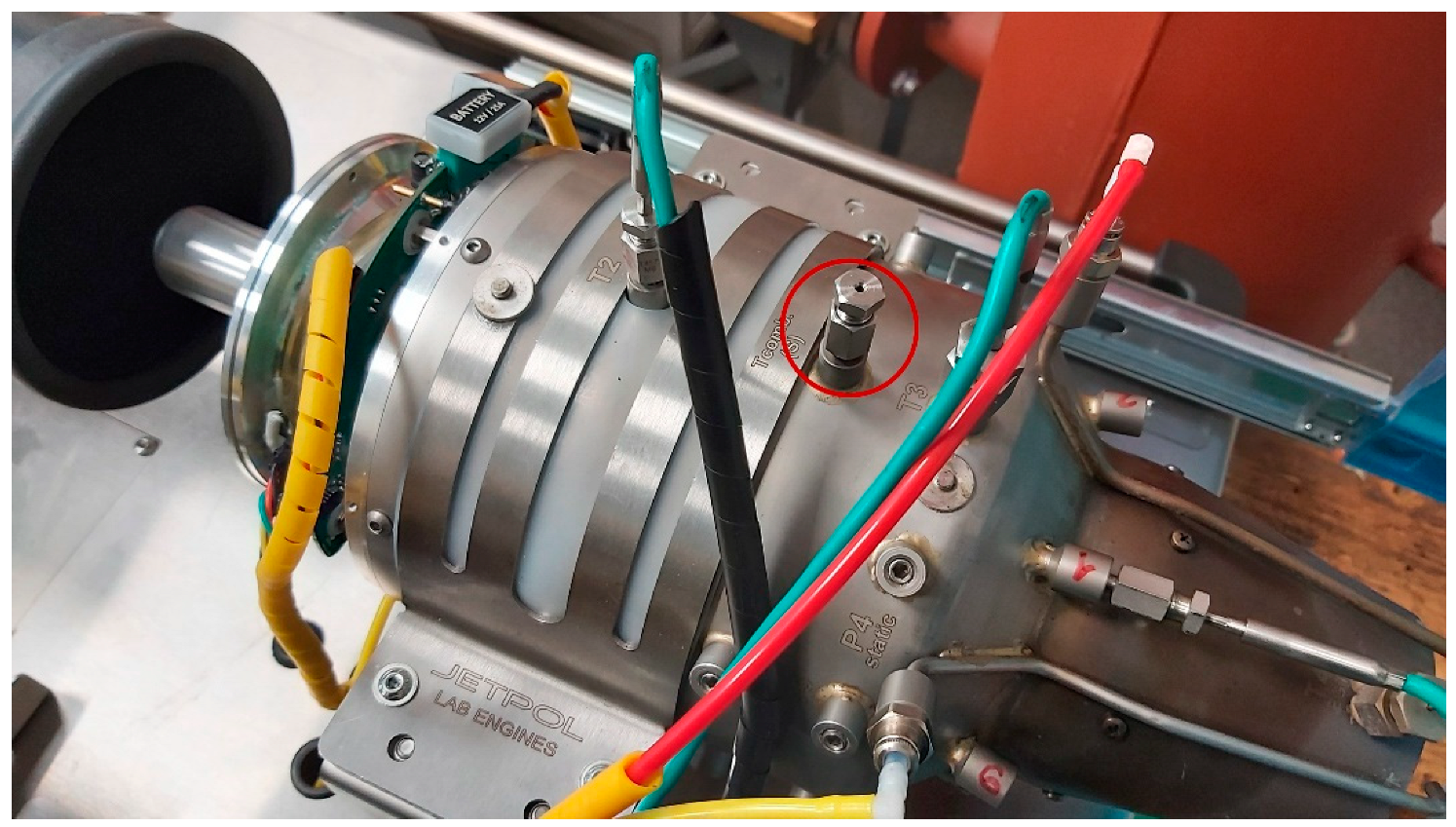

Figure 2.

An S-type thermocouple was used to measure the temperature inside the combustion chamber, the maximum operating temperature of which is 1600 °C. The sensor is 9 cm long. In addition to the distance of the internal areas of the engine, the selection of the sensor length should take into account the distance of its mounting,

Figure 3. It consists of a sleeve, a nut and a screw.

The nut was screwed onto a threaded sleeve permanently located in the engine housing. A screw with a hollow hole for the sensor acted as its lock. The sleeve, nut and screw together form the sensor mount, and their total length was 3.2 cm. The mounting was located 16.8 cm from the inlet. During the tests, the sensor was inserted into the chamber at a distance of 0.28 cm from the inside of the flame tube.

During the tests, the temperature varied in the range of 13.7 °C - 16.2 °C. The turbojet engine was started twice. During the first start-up, the rotation speed was set to 40,000 rpm. During operation, after adjusting the speed, the cylinder valve was opened and hydrogen was supplied to the combustion chamber. The following flow rate values were set on the flowmeter: 25 l/min, 50 l/min. and 93.4 l/min. During the second start-up, the rotation speed was set to 50,000 rpm. In this case, the following hydrogen volume flows were used during operation: 50 l/min. and 93.4 l/min. As a result of the hydrogen flow into the engine, the rotational speed increased. After the recorded increase in rotational speed, it was reduced to the initial value, i.e. 40,000 rpm. (during first start-up) and 50,000 rpm. (during second launch).

3. Results

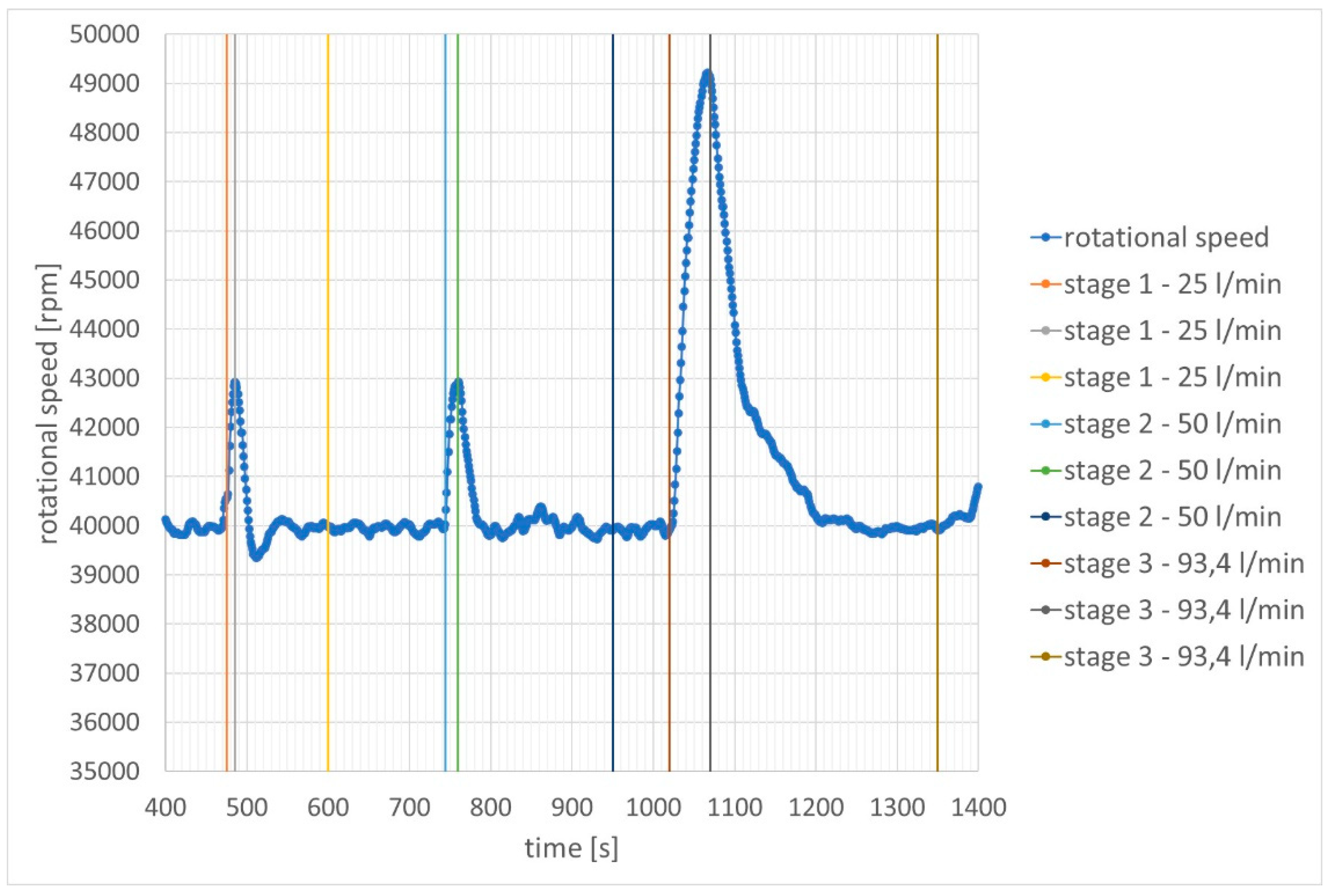

The tests took into account three parameters, i.e. rotational speed, flow rate, and temperature near the inner edge of the flame tube. In the first period after starting the engine, it operated using only aviation kerosene. Three stages are marked in the drawings below: stage 1 - the beginning of hydrogen combustion, stage 2 - the peak of rotational speed (also on the graphs of other parameters), and stage 3 - stabilization of fluctuations of the parameter in question. These are approximate points.

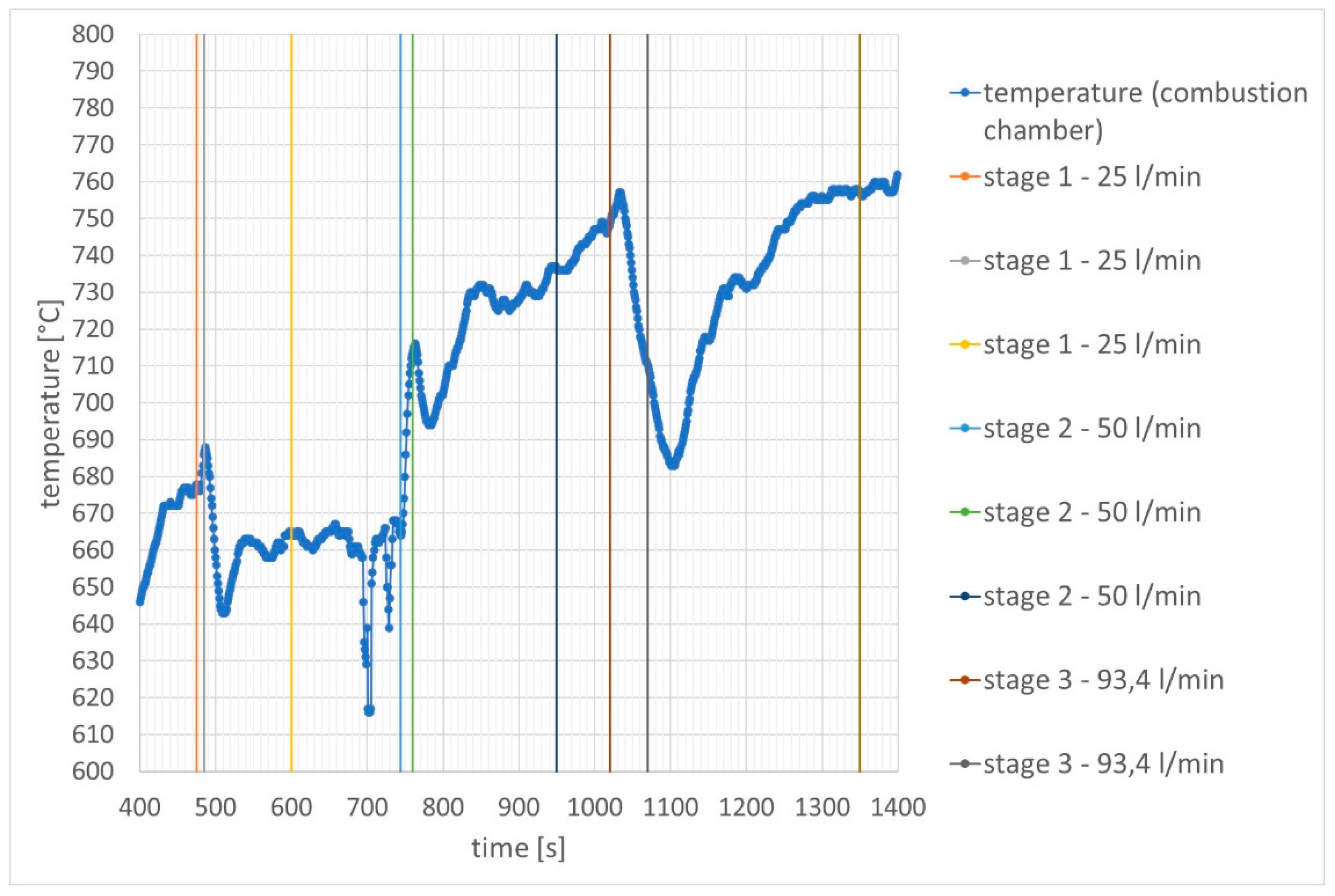

During the first start-up, hydrogen injection began after approximately 475 s, 744 s and 1029 s. The hydrogen flow rate was increased each time. A larger amount of fuel mixture resulted in an increase in rotational speed. The most dynamic increase was recorded for the largest flow, i.e. 93.4 l/min. The dynamics of the speed increase is more important in the analysis, not the speed value. The second value is influenced by the human reaction time (better or worse depending on the moment) and is less reliable. Changes in rotational speed for the first engine start are presented in

Figure 4.

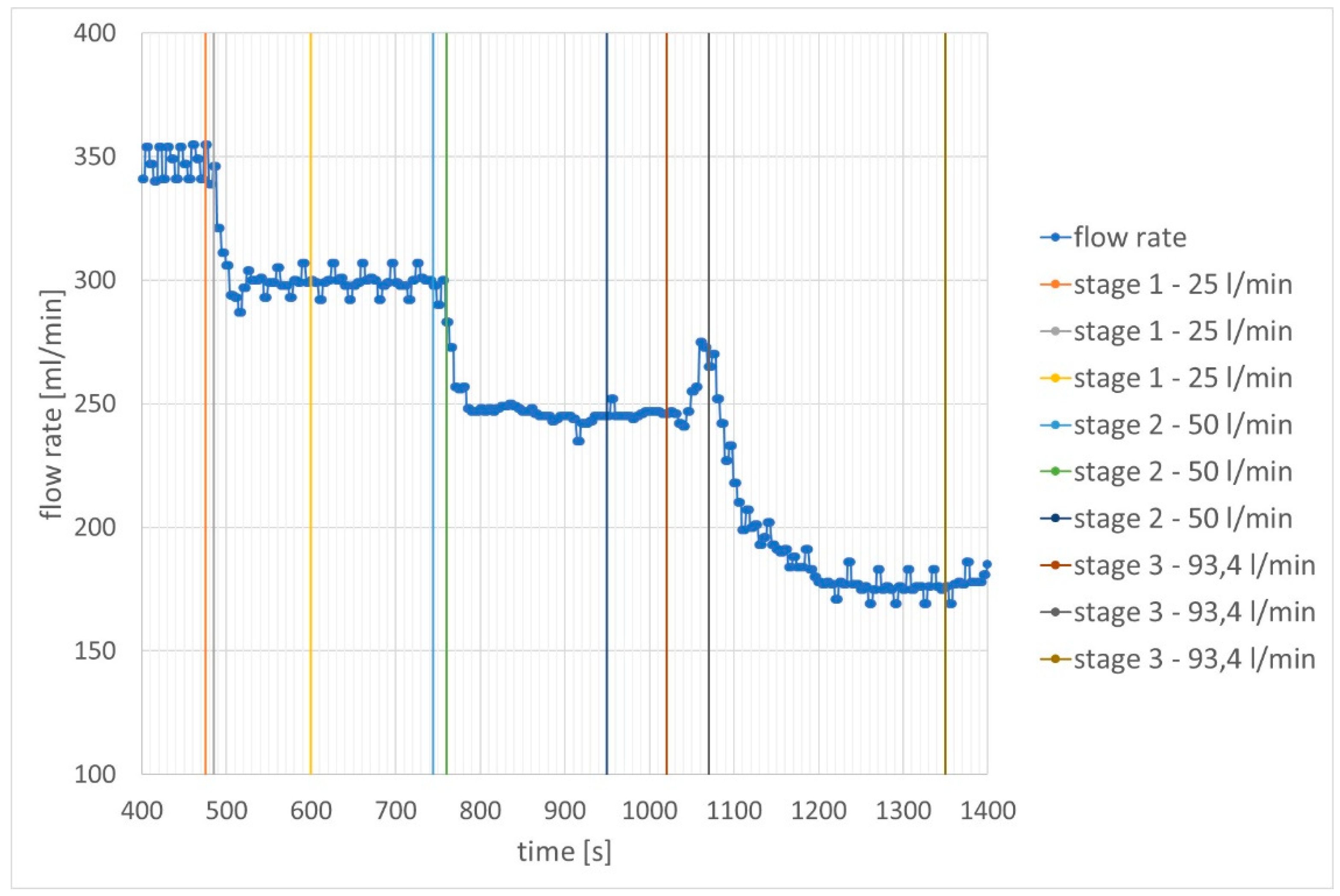

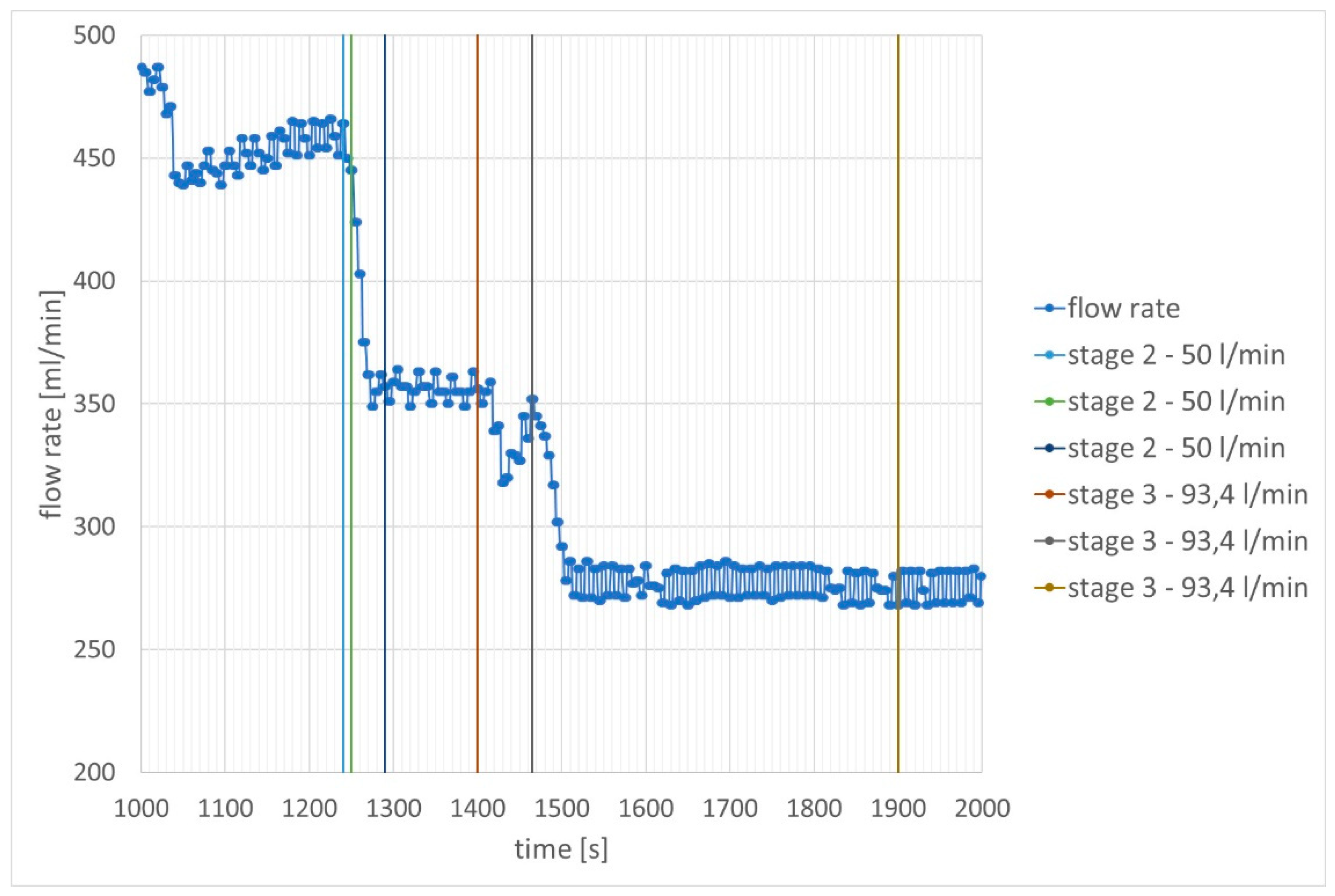

The appearance of hydrogen in the combustion chamber during engine operation is also illustrated by the change in the flow rate of the JET A-1 fuel,

Figure 5. Its values decrease approximately successively by 45 ml/min, 98 ml/min and 167 ml/min. compared to the values where combustion took place without hydrogen.

The share of hydrogen influenced temperature changes at the edge of the glow tube in different ways. The results are presented in

Figure 6. The smallest hydrogen stream causes a slight decrease in the temperature at the measurement point from 677 °C to 663 °C. Increasing the hydrogen stream to 50 l/min increases the temperature to 738 °C. However, after the rotational speed stabilizes, the temperature continues to rise and increases further to 748 °C. The subsequent increase in the hydrogen stream causes the temperature to increase to 758 °C.

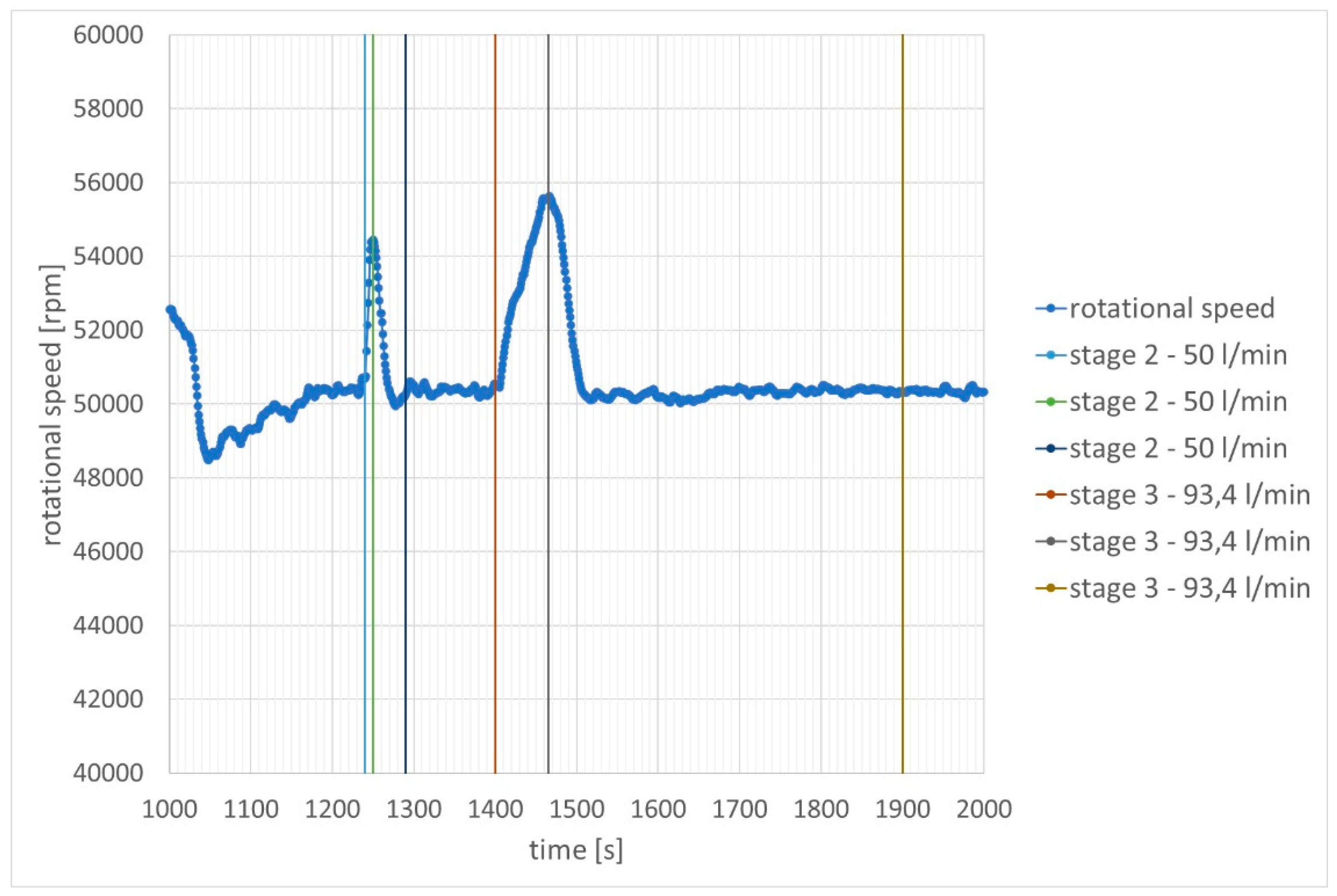

During the second start-up, hydrogen injection began after approximately 1240 s and 1400 s. Similarly to the previous stage of the research, there is a noticeable increase in rotational speed when hydrogen injection into the combustion chamber begins. However, it can be seen that when comparing all mixtures, the values of changes in rotational speeds are smaller,

Figure 7.

During engine operation, hydrogen combustion also affects changes in the flow rate of the JET A-1 fuel,

Figure 8. Its values decrease by approximately 100 ml/min and 185 ml/min in relation to the values where the combustion took place without hydrogen.

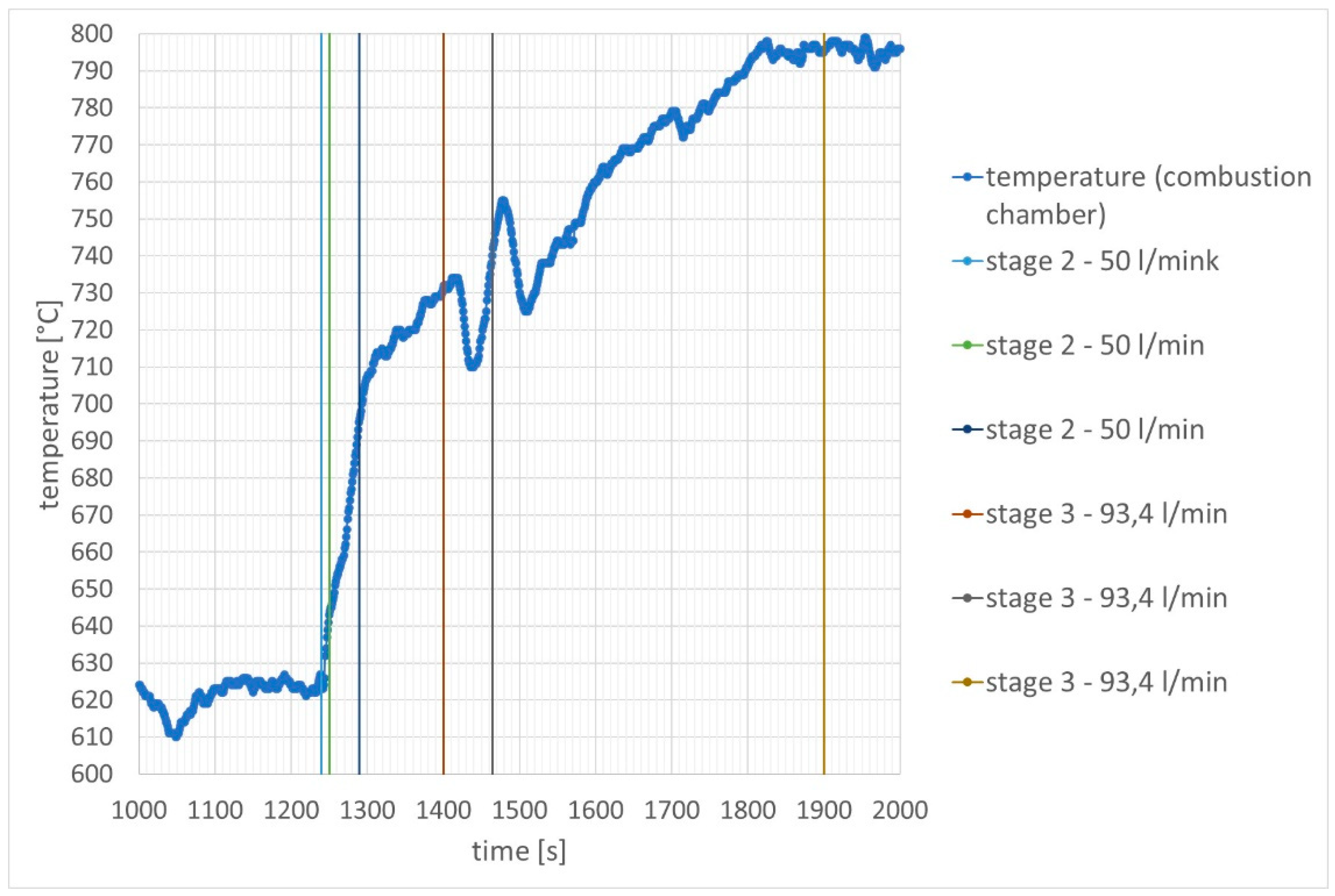

After increasing the rotational speed, hydrogen combustion caused an increase in temperature at the inner edge of the flame tube. In the case of hydrogen dosing with a stream of 50 l/min, the temperature increased from 627 °C to 698 °C. Later it increased further to 732 °C and then decreased to 710 °C. In the case of hydrogen dosing with a stream of 93.4 l/min, an increase in temperature to 796 °C was observed. It can be considered that it was later stabilized and no significant changes were observed. Temperature changes are shown in

Figure 9.

4. Discussion

The analysis showed how the JET A-1 fuel consumption changes when hydrogen is burned in selected amounts at the same time. For the same conditions, a control measurement of a selected place at the edge of the flame tube in the combustion chamber was also carried out.

During the first engine start-up, the test showed that hydrogen injection in the amount of 25 l/min., 50 l/min. and 93.4 l./min resulted in a reduction of the JET A-1 fuel flow to 87.0%, 71.6% and 51.6% in relation to the combustion of clean aviation fuel. It follows that the adopted hydrogen streams cover 13%, 28.4% and 48.4% of the energy demand for the JET A-1 fuel to operate at a speed of 40,000 rpm. During the second engine start, hydrogen injection at a rate of 50 l/min. and 93.4 l./min resulted in a reduction of the JET A-1 fuel flow to 78.3% and 59.8% in relation to the combustion of clean aviation fuel. It follows that the adopted hydrogen streams cover 21.7% and 40.2% of the energy demand for the JET A-1 fuel to operate at a speed of 50,000 rpm.

The measurement analysis also confirmed that mixing both fuels in the combustion process leads to an increase in temperatures in the combustion chamber. For the highest hydrogen share, this increase was approximately 80 °C for 40,000 rpm and almost 180 °C for 50,000 rpm. Considering that this is the area around the edge of the flame tube, the temperature change can be considered significant. However, the temperature does not exceed the permissible values for Inconel 600 material.

It is worth extending the research by taking measurements in other places of the combustion chamber, as well as increasing the probing depth. Additionally, it is worth examining the impact of co-combustion of hydrogen and JET A-1 fuel on the temperatures at the outlet from the combustion chamber. This would allow for a better assessment of the possible higher thermomechanical load on the guide vanes and turbine rotor.

Funding

This research was funded by Ministry of Education and Science.

References

- Kotlarz W., Piaseczny L., Rypulak J., Zadrąg R.: Testy toksyczności spalin turbinowego silnika lotniczego dla warunków startu i lądowania, Combustion Engines, 2006, Vol. 45, No. 4.

- Masiol M., Harrison R.M.: Aircraft Engine Exhaust Emissions and other airport-Related Contributions to Ambient Air Pollution: A Review. Atmospheric Environment, 2014, Vol. 95. [CrossRef]

- Łapucha R.: Komory spalania silników turbinowo-odrzutowych, Biblioteka Naukowa Instytutu Lotnictwa, Warszawa 2004.

- Lefebre A.: Gas Turbine Combustion, 2nd edition, Taylor&Francis Philadelphia, 1998.

- Jeż M.: Airport Environmental Impact – Methodology of Atmosphere Protection. Institute of Aviation Scientific Library, Warsaw 2007.

- Gieras M., Komory spalania silników turbinowych. Organizacja procesu spalania. Oficyna Wydawnicza Politechniki Warszawskiej, Warszawa 2010.

- Dzierżanowski P., Kordziński W., Otyś J., Łyżwiński M., Szczeciński S., Wiatrek R.: Napędy lotnicze. Turbinowe silniki odrzutowe. Wydawnictwo Komunikacji i Łączności, Warszawa 1983.

- Jarosiński J.: Techniki czystego spalania. Wydawnictwo Naukowo-Techniczne, Warszawa 1996.

- Proposal for a Regulation of the European Parliament and of the Council on ensuring a level playing field for sustainable air transport – ‘ReFuelEU Aviation’ – General approach, Council of the European Union, 2021/0205(COD), 9805/22, 2022.

- Regulation of the European Parliament and of the Council on ensuring a level playing field for sustainable air transport (RefuelUE aviation), The European Parliament, the Council, PE-CONS 29/23, 2023.

- Onorati A. et al., The role of hydrogen for future internal combustion engines, International Journal of Engine Research, 2022, Vol. 23, Issue 4. [CrossRef]

- Dahl G., Suttrop F., Engine control and low-NOx combustion for hydrogen fuelled aircraft gas turbines, International Journal of Hydrogen Energy, 1998, Vol. 23, Issue 8.

- Stepien Z., A comprehensive overview of hydrogen-fueled internal combustion engines: achievements and future challenges, Energies, 2021, Vol. 14. [CrossRef]

- Wang B. et al., Current technologies and challenges of applying fuel cell hybrid propulsion systems in unmanned aerial vehicles, Progress in Aerospace Sciences, 2020, Vol., 116.

- Prokopowicz W., Frąckowiak A., A proposal of a hydrogen injection system in to a miniature turbojet engine, Journal of KONBiN, 2023, Vol. 53, Issue 1. [CrossRef]

- Tang X., Kabat D. M., Natkin R. J., Stockhausen W. F., Heffel J.: Ford P2000 Hydrogen Engine Dynamometer Development, SAE 2002-01-0242, 2002.

- Welch A., Mumford D., Munshi S.: Challenges in Developing Hydrogen Direct Injection Technology for Internal Combustion Engines, Westport Innovations Inc., SAE International technical papers, SAE 2008-01-2379, 2008.

- Funke H.H.W. et al., An overview on dry low NOx micromix combustor development for hydrogen-rich gas turbine applications International Journal Hydrogen Energy, 2019, Vol. 44, Issue 13.

- Cecere D. et al., A review on hydrogen industrial aerospace applications, International J Hydrogen Energy, 2014, Vol. 39, Issue 20. [CrossRef]

- Specification Sheet: Alloy 600, Sandmeyer Steel Company, UNS N06600, 2022.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).