1. Introduction

The automobile industry is going through an exciting transformation all over the world, driven by the demand for new ways of thinking that promote economic growth. Among the pillars of this advancement are the employment of good software configuration management, the adherence to high-quality standards, and the effective use of current software tools. The automotive sector is vulnerable in the face of an economic crisis and geopolitical upheaval, as the Russia-Ukraine War and related events resulted in a quick spike in crude oil prices. As a result of this occurrence, the price of WTI crude oil futures reached 133.460 US dollars per barrel on March 7, 2022, while Brent crude oil futures reached 139.130 US dollars per barrel, the highest price since July 2008 [

1,

2].

As an outcome, in circumstances where there is certain turbulence and influence from the scarcity of particular materials on the market, we must realize the benefits of a collaborative industrial approach based on knowledge and innovation. Germany, for example, is commonly considered the leading supplier of traditional and cutting-edge technical applications with opportunities for collaboration because geographic location influences business dynamics and logistics settings in manufacturing processes [

3,

4]. Therefore, those making decisions can develop reliable and constructed solutions for manufacturing infrastructure in the automotive sector and can offer results as a single or integrated decision-support tool. Despite changes in the global market, the European Union, tucked within the centuries-old continent, has significant power due to its intrinsic potential [

5]. Within this context, industries, particularly mechanical and automotive engineering, demonstrate enormous potential, with Italian design and German innovation at the center of the stage. Strong small- and medium-sized businesses, as well as several original equipment manufacturers (OEMs), actively participate in creating greenfield projects beyond their typical limits. As a result, the process of putting charging outlets in electric vehicles is complex, including various aspects and parties, and has a significant impact on the overall effectiveness and usefulness of the electromobility system.

Fostering creative ideas is a critical aspect of influencing the future trajectory of the global automobile industry with software configuration management, high-quality standards, and software compliance through the skilled use of software tools. The needs of application developers are inextricably linked to the utilization of various automobile components. Most of them can define a basic set of metrics and reliability measurements [

6,

7]. Manufacturers aim to meet consumer expectations, ensure product safety, and shorten product development timelines, particularly for software and the finished vehicle.

Choosing the right configuration components to estimate and forecast future demand is crucial when considering the entire logistical process, from procurement to manufacturing engineering [

8]. Significant benchmarks in specific business segments are inextricably tied to the presence of critical sectors in a variety of industries, which can have an impact on the development and use of existing solutions. Most industries use roughly similar natural resources (aluminum, copper, gold, etc.) for the production of raw materials, and integration spans a wide range of industries, including aviation, shipbuilding, medicine, electronics, and automotive, resulting in a comprehensive landscape for innovation and collaboration [

9,

10].

Given the need for more closely regulated legal regulation and standardization, the starting point for standards in Europe differs substantially from that of Asia and the Middle East. With a constant increase in the number of electric vehicles projected in the current infrastructure and future development, the European Union, which has witnessed substantial growth in electric passenger vehicles over the last decade, is important for the sustained market expansion of this technology. Regardless of whether the European market is experiencing an increase in industrial production, certain global developments are predicted to occur in the coming months. This is mainly related to the scope of AI-related security concerns and the availability of specific security flaws [

11,

12].

This article aims to present a synopsis of a scientific inquiry into the effects of global market changes on automotive production over a certain period from 1995 to 2023, focusing on associated manufacturers and market segmentation in automobile brands. We are attempting to cover a variety of data sources from which we might estimate potential future changes in the automotive industry’s sales. Selected sources will focus on the United States of America and Washington State. This is one of the countries with the most developed markets for the use of different types of vehicles and their combinations of drivetrains.

When writing our article, we followed the structure that defines the analysis of individual research sections and related forms of investigation that cover different aspects, so that the key components of the research structure are as follows: literature review, materials and methods, automotive business engineering, embedded software for modern vehicles, global challenges and made in China 2025, new logistic approach to issues in the automotive sector with an outline of the processes involved in supplying final products to the market, results, discussion, and conclusions.

1.1. Literature Review

Because there are different approaches to reviewing the literature, addressing the problem of complexity in the automotive industry would be the best option. In this way, combining a specific study of trends and contributions would be the ideal way to view the field’s current position. This part of the research will focus on a specific review of the literature, as described later in the article.

As a result, the literature review is divided into the following sections:

Complex automotive systems using domain languages

Aspects of security inside modern vehicles

Business models and upgrading Function-on-Demand

Industrial organizations and safety issues

1.1.1. Complex Automotive Systems Using Domain Languages

Software engineers [

13], when developing software, use specialist domain languages to efficiently present a visual representation of the components of a complex automotive system using appropriate tools. The primary goal of combining the quality model and software analytics is to create clear and valuable information on the prototype, the interaction approach, and the possibilities for the user of the system [

14]. The reasons why organizations choose to adopt domain languages and modeling approaches are manifested in the customers and all members of the teams working on the creation of visual knowledge of specific software or hardware products.

The Unified Modeling Language and the Systems Modeling Language are modeling languages that are widely used in the automotive industry. The authors [

15] present the model-driven method for specifying domain-specific languages and domain-specific tools in this paper. Others [

13] are working on an optical-based technique to obtain operating deflection forms of devices with complex geometries that are linked to domain languages.

A multiview 3D DIC technique is also applied and proven to forecast the vibrational properties of an automotive muffler with a complex structure. The resulting deflection forms are stitched together in the frequency domain to extract the operating deflection shapes and resonance frequencies of the complex structure of the car body panel. For dealing with nested inquiries, the system employs unique algorithms that integrate linguistic analysis with deep-domain reasoning.

The authors [

16] to show the possibilities, submit a new benchmark dataset containing genuine business intelligence queries based on an ontology derived from the FIBO and FRO finance ontologies. AUTOSAR, the de facto standard for expressing automotive system architecture, is a massively comprehensive standard that gives designers complete control over everything from abstract system description to bare metal-level deployment.

1.1.2. Aspects of Security Inside Modern Vehicles

In terms of security, the authors [

17] looked at practical security techniques that employ machine learning. Their objective in conducting this research is to have a better grasp of the machine learning and engineering safety requirements that software in modern automobiles must meet. Security cannot be verified without proper testing of variations of all factors that may change after the system is distributed.

To address this issue, the authors [

18] conducted an analysis that looked at the consequences of changing risk parameters, with the ultimate goal of displaying the events discovered. The significance of this study lies in the ability to retest after the update has been implemented without interfering with critical functions. Software and its capabilities and expected speeds when operating various vehicles are strongly related to innovations in the automotive industry.

1.1.3. Business Models and Upgrading Function-on-Demand

The authors of the study [

19] consider business approaches that promote cellular use and upgrade after the sale of Function-on-Demand (FoD). Security aspects must be very precisely regulated in this situation through the support of the necessary visible security certificates for software components. The discussion of progress in the technological aspect [

9] demonstrated that certain changes have occurred in terms of development methods and their relationship to industrial requirements. The processes of assembling vehicle prototypes have changed as systems are increasingly connected electronically. Information and communication technology approaches in vehicles have enabled functionality and a greater degree of convenience for end users.

The research of the authors [

20] demonstrates their efforts in the development of the domain metamodel and the application of object-oriented programming. Successful verification is achieved through the successful connection of network blocks and the realization of the possibility of vehicle communication. One of the relevant EU projects for the automotive industry called DRIVES [

21] deals with finding skills and ways to develop future cars.

1.1.4. Industrial Organizations and Safety Issues

Through the insight and analysis of relevant sources, we had the opportunity to become familiar with the research of many industrial organizations [

22] who are not satisfied with the approaches presented in various scientific journals and professional literature.

The safety issues considered by the author [

23] refer to the importance of road infrastructure, the availability of adaptive management systems, and adequate lighting and signaling within the vehicle. In the paper [

23], the standards in the automotive industry were also reviewed from the point of view of road user safety.

1.2. Contributions and Novelty

This study adds to the current knowledge in automotive engineering by focusing on modern automobiles, production methods, and sales trends over a specific time frame. To be profitable, any company in the automotive sector must achieve specific standards that will eventually be reflected in the sale of the finished product of the car. The initial idea of contributing during the investigation represents the goal of highlighting the potential of merging standards with integrated software systems contained within the vehicle. The success of the sale is also reflected in the happiness of the end user and client, who require a specific degree of equipment or capabilities inside the vehicle related to the software and the operational mode of starting the car.

What we consider to be a certain new contribution and novelty within this are the following:

Recognizing software developers’ needs, especially in the usage of automotive components that recognize specific metrics, represents a contribution to streamlining application development. Data analysis is critical for understanding these indicators, providing useful insights into component performance, and allowing continuous application modification. Therefore, developers must have a particular level of expertise and comprehension of requirements, as well as their complexity during use, which we have tried to cover within this research.

Future data-enabled purchasing approaches that emphasize the importance of configured components in logistics and procurement processes are complementary to data-driven procurement strategies. Among our contributions was the development of a new logistic method for the organization. This covers component selection for efficiency and quality through the use of novel logistic approaches for automotive challenges that explain the processes involved in the supply of finished products to the market.

Data-driven insights denote the potential contribution of data analysis to the automobile sector. The focus on metrics and reliability indicators demonstrates a dependence on data-driven insights. Contributions include developing the industry’s ability to make future decisions, predictive maintenance processes, and continuous product development with performance improvement.

Incorporating data analysis into the automobile sector structure improves not only operational efficiency but also strategic decision-making, ensuring that advances are anchored on practical insights derived from massive data sets. This highlights the industry’s dedication to using data as a critical asset to drive innovation and quality.

2. Materials and Methods

The foundation for the research approach will be the application of the research questions and the processing of the obtained data, which are public and accessible for research purposes under applicable licenses.

Some potential criteria will include the following (schematic representation in

Figure 1):

The research approach we have chosen is the application of hypothesis verification to data from a selected dataset, which is available under the Open Database License (ODbL). According to this license policy, the data is released for free sharing by users. The authors of the study declare that they have taken, analyzed, and evaluated the data from the source according to the standard scientific procedures described in this experimental study and the attached source programs. The data used will not be used elsewhere nor disseminated for the purpose of obtaining monetary or other benefits.

The procedure for verifying established hypotheses consisted of establishing concepts, defining hypotheses, obtaining resources, defining fitting models on which we applied regression of the appropriate type, and verifying the regression model.

2.1. Selection Criteria

The selection criteria were based on a collection of distinct keywords that were used to search and discover relevant scientific publications. In this study, the qualitative research technique was used. In this type of research, we have used a critical analytical method to better understand the various meanings and experiences.

The literature and data were gathered from several scientific databases and search engines. The initial literature search was performed using relevant terms from the most well-known databases, such as Google Scholar, JSTOR, Scopus, and Web of Science.

The investigation methods will be within these research types:

-

In the automotive industry, research should include examining technological transitions, responses to previous disruptions, geopolitical influences, and the historical context of cross-industry collaborations, as well as providing valuable insights into the industry’s adaptive strategies and long-term trends based on collected numerical and non-numerical data.

This technique would provide a thorough grasp of the real world’s issues and triumphs. A qualitative and context-specific understanding of the challenges and triumphs in implementing software configuration management and quality standards. Using qualitative and quantitative lenses, we can explore the links between logistical environments and corporate processes.

We will use data analysis approaches to study market data and performance indicators as a research type for qualitative research and data analysis. Using qualitative and quantitative lenses, we can explore the links between logistic environments and corporate processes. This could involve analyzing industry reports, market data, and performance indicators to derive quantitative insights into the impact of software configuration and quality standards on the automotive sector.

We will combine research methodologies to create a more thorough and nuanced view of the numerous topics mentioned in the research by adopting a mixed-methods research strategy. We will evaluate the relationships between the adoption of various technologies and improvements in product development time, customer satisfaction, or other key performance measures that may affect future output using statistical methodologies.

2.2. Keywords

During our investigation, we have used some of the following keyword combinations:

Future trends in global innovations and the automotive industry in china by 2025;

Manufacturer strategies to reach customer satisfaction with safety protocols by following efficient product development;

Global industry impact and procurement dynamics for manufacturing process;

2.3. Questions

There are numerous approaches that can be utilized to obtain specialized information on the research issue. In this sense, we intend to use research questions to clearly guide the course of this study. As a result, we have identified specific questions as a distinct research direction. In light of this, we would want to have answers to the following questions:

What effects would the shift have on worldwide market developments in contemporary vehicle automobile manufacturing?

How are global market changes and losses in modern automobile production determined in the numerous data sources acquired from today’s datasets?

What are the current and historical car companies with changes in vehicle propulsion energy sources?

3. Automotive Business Engineering

To improve the automotive sector, it is vital to progress toward sustainability of the living environment, the economic model, and the integration of novel technical solutions. This involves the integration of technical processes such as electronics, mechanical systems, and materials science, which are critical components of finished goods. Environmentally friendly cars require the use of novel materials that can decompose in the environment. This requires cooperation with chemists and researchers in the field of manufacturing certain materials that may be used during the engineering process to develop conceptual solutions [

24].

Cooperation between engineering companies and leadership is required to examine the difficulties and suggest specific strategies and tools from many disciplines. It is feasible to perform an analysis based on existing data and make recommendations for the next steps by integrating engineering expertise into the economic and financial aspects of the profitability of a specific vehicle type. Automotive engineering can be divided into various areas and focuses that address certain complex processes [

7,

24]:

The first relates to the creation and design of items that are intended to meet market demands while also adapting to consumer tastes and preferences. This pertains specifically to new and current automobile components, as well as their subsequent applications.

The second focus is on cost reduction and quality assurance (QA), which can ensure a smooth business cycle with the prospect of self-sufficiency in the defined production cycle.

The third category comprises logistics management and the procurement of critical raw materials to ensure vehicle delivery to end customers.

The fourth element is involved with the positioning of the product and the marketing strategy. This refers especially to the sale of vehicle cleaning and maintenance equipment. Promoting and selling linked products ensures the sale of automobile interior and exterior products.

The fifth category deals with management in terms of monitoring financial data and improving methods that optimize financial outcomes and offer impetus to long-term production growth.

Management of production procedures and infrastructure is feasible with automotive business engineering, which is required for success when building a new product such as autonomous vehicles. The automobile industry is one of the fastest-growing industries in the world, incorporating various scientific topics and disciplines such as mathematics, physics, chemistry, mechanical engineering, and software engineering. Connects and advances research by providing business prospects and innovative ideas that may be subsequently copyrighted and capitalized on by the automobile industry.

Situations in which people drive vehicles using different systems, such as adaptive cruise control, automatic parking [

24,

25,

26], and various vehicle signaling, represent the basis for the following legal frameworks and standardization at all levels of local and international character. Improving traffic safety requires a review and a more detailed analysis of legal regulations and driver liability issues, and insurance in the event of traffic accidents [

27,

28,

29].

In relation to the outlined agenda for sustainable living spaces, prototypes of hybrid and electric vehicles are being perfected. Successful research in automotive engineering is focused on creating greater efficiency and performance (lower fuel consumption, easier vehicle control, safer accompanying instruments). Recognition of certain objects on the roads during driving requires the use of certain machine learning techniques and automated detection, changes, and application systems during driving [

30,

31].

Their main task is to verify, based on the theoretical framework, the experimental methods and beliefs that have arisen in the field of automotive-business engineering. In addition, it is important to achieve digital transformations in the ecological development of production. It is already possible to recognize the need for resources in human knowledge and skills, which include the possibilities of developing artificial intelligence models and programming industrial robots [

32].

4. Embedded Software for Modern Vehicles

Today’s vehicles have installed software that controls the various systems and functions they perform. Control of stability, powertrain, transmission, and advanced driver assistance systems (ADAS) are elements of the vehicle system [

24]. Today’s age of the vehicle industry takes into account all elements of both infrastructure and safety for road users. Due to the aforementioned, the main challenges relate to the fulfillment of the strict requirements of the regulatory bodies in matters of reliability and safety. In order to respond, it is necessary to bring all systems to a perfect functional state that will not endanger all road users. In addition to adequate road infrastructure, this refers mainly to improving embedded software using a cumbersome design and testing process. The accompanying implementation of key safety standards ISO 26262 is also necessary.

Innovative vehicles are accompanied by another challenge related to the adequate integration and connection of advanced functions based on the increasing demands of consumers. More and more are expected from the demands of the complex market, where various possibilities are integrated, such as the installation of smartphones and other devices that will enable practicality in driving. Based on further development, it is possible to install sophisticated software in vehicles that can process complex algorithms and large amounts of information. This enables the setting of advanced functions such as autonomous driving, which represents an assistant to drivers making driving more practical [

24,

28,

33].

To enable a vehicle with reliability and safety features, it is necessary to install high-quality software that will correspond to the characteristics of a modern vehicle. In the automotive industry, manufacturers use tools and techniques to improve software. Model-based testing, real-time operating systems (RTOS), and automatic code generation are applied.

The future improvement of the automotive industry is seen in the possibilities of more active research on installed software that will develop more complete systems and functions to provide greater security, connectivity, and more advanced features [

24].

4.1. Safety Standards

IEC 61508 and ISO 26262 are two software security standards. The examination of the software development process’s possibilities is in compliance with the ISO 26262 standard. The use of an appropriate workflow, which stems from the desire to improve the program, is related to the security of its use.

Analysis of the success of business processes in electronics and software development is an interstate regulation to enable the expansion of the ISO/IEC 15504 standard (Automotive SPICE 3.0, or Spice). The ISO 26262 (Road Vehicle Functional Safety) standard, which is used for the development of software and hardware, is necessary to meet the expansion requirements. The main task of enabling the support of isolated virtual electronic control units in the environment of the current time interval refers to the concept based on ISO 26262 automotive safety standards. They focus on the safety of vehicles and their assumptions [

34].

The sensitivity of electronic requirements for vehicles relies on more complex assessments and an approximation of the ISO 26262 standard with machine learning. By using the software ’DELMIA-V5’, the robot is simulated outside of real-life conditions. Specifically, this refers to the simulation of certain actions, such as carrying loads and the possibility of catching, moving, and improving interactions between the four robots. The most important simulation for the automotive industry is the process of welding in spots at two or more points when joining different vehicle elements [

10].

The key standards used in the autonomous vehicle industry are [

7]:

ISO 26262 is an international standard that refers to the development of safety systems for vehicles. This standard defines a group of techniques and process procedures that are implemented with the aim of preserving the stability, safety, and reliability of these systems.

SAE J3016 is a standard perfected by the Society of Automotive Engineers (SAE) and represents a set of technical and process procedures used for the development of autonomous vehicles. Within the framework of the standard, a certain number of automation levels is defined, which ranges from 0 to 5, where later detailed instructions are provided for testing and validating the system that should emerge from a previously designed conceptual concept.

ISO 21448 refers to autonomous driving systems and the standardization of the development process of advanced driver assistance systems (ADAS). For the security and reliability of these systems, the implementation of process elements and techniques of this standardization is necessary.

UNECE Regulation No. 151 is a defined set of regulations that was perfected by the United Nations Economic Commission for Europe (UNECE) and applies to the development of autonomous vehicles. It deals with issues governing the development and design of complex autonomous vehicle systems, covering aspects of testing and validation of information transmission to drivers and passengers.

The necessity of implementing the listed standards refers to the reliability and safety of autonomous vehicles, which clearly dictates the design process and the success of the development of the aforementioned systems.

4.2. Automotive Applications

The integration of automated driving implies the applicationinvolvesengineering approach in the conceptual visualization of ideas and design solutions related to hardware and software [

24]. During the design of the engineering process and work on automotive communication systems, the Internet of Things (IoT) is included. The technological financial challenges that must be solved in the coming period are considered. Today’s possibilities of interconnection through different instances of Internet-of-Everything (IoE) create possibilities of combining automated and semiautomated systems with minimal human interaction. Communication is realized through the use of communication and cognitive links processed by artificial intelligence (AI) and created machine models. Machine models contain the ability to process different voice commands [

35].

Awareness of the interconnected environment and the persistence of a direct network of communication between people are realized through the use of IoE. General intelligence and interactivity through digital assistants provide a better understanding of the relevant information that is necessary when making decisions and moving in traffic. The presence of this type of assistance should help the driver quickly identify crisis situations and prevent incidents in the form of collisions. As such, IoE in its framework provides an appropriate environment for creating semantic solutions that are stored at a specific location within a vehicle. Specifically, this further enables the exchange of previously collected information from other vehicles and ensures the launch of the best IoE instance.

4.3. The Production of Integrated Software

Based on the above, we can say that there is a need to connect teneedperts with the aim of creating integrated software for autonomous vehicles and IoT is the basis for successful cooperation and business in the automotive industry. These systems work purposefully using advanced software development engineering techniques that involve linking different development methods and tools. Verification of reliability, stability, and high performance is achieved through defined processes that include the application of SPL and CI/CD.

The basis of autonomous vehicles and connected IoT devices is based on specificities that imply the use of operating systems and accompanying application software. The software can be located directly on the chip in the form of an integrated system that has the possibility of programming only by the factory, on the basis of which a high level of security can be ensured.

After creating the integrated software on the chip, it is necessary to carry out accompanying tests with the aim of ensuring compatibility and optimal performance. The verification process is very complex due to the necessity of involving several different teams dealing with solving different problems. As part of the process itself, it is necessary to solve hardware and software problems, as well as conflicts and confrontations between teams that may arise during work.

The methodological approach to successful integration is the application of a systemic and structural approach. This implies the involvement of various technical solutions that basically use design solutions based on the prototype model, automatic code generation, and software distribution through infrastructure as code (IaC). Adequate system testing involves testing the entire software together with the analysis of the interactions between the various components of the system.

4.4. Software Product Lines (SPL)

Certain approaches when creating software enable the inclusion of a number of different software products and technologies. Implementing the software product line (SPL) enables a more efficient and cost-effective development process through the reuse of already existing components. Applying SPL reduces the need for lengthy customization and software engineering startup processes. The main aspect that is considered in every development process when it comes to software is security and the possibility of repeating security checks with minimal error. It is usual that repeating the use of standard elements in certain cases can lead to certain omissions and impacts on the distributed software.

For its main role, SPL lays the foundations of security standardized checks and uses the latest security components without containing specific weaknesses. Research teams recognize multiple possibilities for solving security problems. Some of the techniques used are penetration and fuzz testing and the use of security patterns that enable the refinement of common components. Large systems that are integrated with a large number of components are complicated for security control by SPLs. Complexity can be an aggravating circumstance in recognizing and fixing security risks. For this reason, experts have implemented more effective techniques such as security modeling, analysis, and the use of automated tools that help manage complex security operations. We see that based on current and future challenges, various software engineering techniques have been identified that must be continuously improved. A critical review of SPL refinement is key to overcoming future security issues and weaknesses [

36].

A high level of quality can be achieved by effectively understanding the market and defining certain sets of systems through SPL engineering that has the ability to create artifacts. The product obtained by applying SPL implies the persistence of configurational characteristics that can be joined together without violating previously defined specifications.

The processes of checking the compatibility of the set engineering ideas can be techniques for starting a business such as a startup business in which specialized development is carried out. The reasons for starting a separate business are reflected in the possibility of reducing technical debt and employing a smaller team that will respond to the goals and challenges set by the automotive company that supports innovative ideas.

Previous analyzes of SPL have progressed by seeing the problems that occur during practical implementation. The achieved results have opened a discussion within academic and practical research, regarding the creation of a new legal organizational unit that is capable of achieving better business results without endangering the reputation of investors.

In view of the collected research considerations, SPL as the main basis requires the use of interactive features with the help of which the verification of usual business practices and the relevance of current trends is carried out [

37,

38]. A set of different services provides the possibility of follow-up development and guaranteed delivery of functional/non-functional requirements set by the orders of organizations for standards, countries, and various legislative bodies. All this together should set certain mechanisms and propose their construction method through the possibilities of future expansion and analysis [

39].

4.5. Field-Programmable Gate Array (FPGA)

Field-programmable gate arrays (FPGAs) are key hardware used for many applications of digital functions within a number of industries. FPGAs enable reprogramming as needed, which is most often used in cases of repair or solving a certain problem that occurred during operation. The aforementioned hardware is widely used in the automotive industry due to its convenience related to flexibility and high performance [

40]. The implementation of FPGA in the automotive industry is largely related to the improvement of complex interconnected components that are in different stages of development. The most important part of the vehicle refers to the improvement of the driver assistance system called advanced driver assistance systems (ADAS) [

24].

This further complicates the synchronized and continuous operation of the entire system. FPGA hardware uses as data sources several different arrays or groups of devices consisting of cameras, different types of sensors, and intelligent and smart systems. The activation of certain elements of the system can directly affect the ability to drive vehicles. Another reason for the use and application of FPGA within the automotive industry is reflected in the possibilities of controlling the powertrains of electric and hybrid vehicles. Within the framework of its capacities and safety assurance, the following monitoring of battery condition in the case of hybrid vehicles, the efficiency of the car aggregate, and monitoring of the management of all drive systems are carried out.

Real-time decision-making processes involve the use of FPGAs. Their characteristics are reflected in high-performance systems within which it is possible to realize the transfer of large amounts of data and the direct application of algorithms in real-time. FPGA circuits have their own architecture with certain variations depending on the application of appropriate standards that may relate to security and physical security aspects [

40]. In order to modernize user functionalities and meet the complex safety requirements of engineering systems during design, it is necessary to review and harmonize the relevant regulations and standards.

The ways to estimate the rate of inadequate design are based on a methodological approach that is directly incorporated into the FPGA SoC. It represents a type of integrated chip installed by different brands. SoC presented a direct implementation of a system on a chip that can achieve a higher degree of speed compared to classic architectures, where the system is located on external memory [

41].

4.6. Modern Integrated Circuits (ICs)

Complex use cases and applications within today’s system design and automotive engineering require the use of modern integrated circuits (ICs). During the historical period, the IC was expanded with an increasing degree of functionality and other built-in components that became an integral part of this chip. The comprehensive functioning of the system is unstable due to the complexity and impossibility of testing the constituent components at a deep level [

42].

ICs are widely distributed and used in various industries and devices as an integral part of microelectronic devices with various dedicated functions. Its application can be found inside smartphones, car systems, computers, and radio transistors. The constituent components of ICs are diodes, resistors, transistors, and components with very low physical pressure in the form of a single chip made of silicon and other bonding materials.

The main reasons for the application are reflected in certain disadvantages and advantages of modern ICs [

42]:

The advantages include the following characteristics:

The first characteristic and the main reason is the small size of the chip itself and the possibility of use in limited spaces with support for a wide range of electronic devices that rely on the characteristics of a modern IC.

Another form and decisive factor in the automotive industry are the high performance and data-transfer capabilities of IC in fractions of a second. The necessity of instant reaction requires more dynamic processing of information in order to obtain an ideal use value.

The third advantage and the reason for the decision to use a modern IC is reflected in the relatively low price due to the reason for serial production. From the perspective of economies of scale, this significantly reduces production costs and the time required to obtain the final product. Today’s IC features high design, safety, and durability.

Deficiency: The main disadvantage is the complex architecture of the modern IC, and it can be said that due to this characteristic, it is impossible to repair, which leads to delayed design and production in cases when certain faults are detected during serial production. Another problem related to modern ICs is sensitivity to physical damage, which includes heat, physical shocks, the influence of external factors, and high dependence on rare minerals. Some of the most frequently used materials that are in very limited supply on the global market refer to neodymium, indium, and gallium.

The production of IC requires the presence and use of the aforementioned materials due to their specific characteristics that cannot be found in other minerals and are therefore not suitable for the production process. The list of rare materials that are necessary due to their characteristics is as follows:

Indium - its characteristic is that it possesses the characteristics of the flexibility of the metal structure. The reasons for using this metal lie in its ability to be a good conductor inside the transistor which is a very thin film along with other components. The mentioned material is relatively rare at the world level of reserves. It can be estimated that it is only available in a few thousand metric tons worldwide.

Gallium - belongs to metals and is a basic material for power electronics in the form of gallium nitride (GaN). This metallic element is used in IC manufacturing as a substrate material.

Europium - is a rare material with semiconductor properties and is used as a dopant with the purpose of targeted bonding to obtain electrical conductivity. It is added in cases of intentional chemical reactions for the purpose of changing the properties of the material and in order to create certain properties.

Neodymium - is rare and, like the previously mentioned material, is used as a dopant in the production of ICs and the creation of semiconductor materials.

Logistical challenges in providing all the mentioned materials can significantly complicate the necessary time in the procurement and production of Ic, which may lead to a permanent stoppage of the production process of all vehicle devices since they are closely dependent on this component. Understanding the challenges in the creation and production of practical tools within the industry requires connecting the research of software and hardware aspects. It is necessary to test for different challenges and loads, which can be carried out using a specific hardware tool such as FPGA [

42,

43,

44].

4.7. Time-Sensitive Networking (TSN)

More dynamic development of software applications is enabled using programming languages such as Python and C#. These languages have the ability to automatically remove the program code from memory, increasing the productivity, stability, and reliability of the software. The application of higher-level language is used for the needs of various applications within mobile desktop and server devices in cases of the necessity of obtaining answers in real-time.

One of the reasons for the necessity of using this type of programming language is reflected in the requirements during network communication, which is of a sensitive nature and uses Time-Sensitive Networking (TSN). TSN initiates road debates for the adoption of safety requirements within certain standards that are relevant for automotive embedded systems. The main reasons for consideration and frequent discussions are the reliance on TSN, which is the basis of communication with other systems. When proposing integration solutions that include TSN, direct implementations with Integrated Hardware Garbage Collector (IHGC) are suggested. IHGC is well suited for processes and actions that are in a continuous state of execution and that need to be directly accessible during use [

45,

46].

TSN is designed as a set of network technologies that support real-time communication using Ethernet networks. This set of communication technology approaches is necessary for the processes of connecting communications within the automotive industry and connecting software lines for several reasons that we will state:

The most important real-time communication is the creation of interactivity by the user with control capabilities inside the vehicle. After this, a critical set of data is exchanged using the TSN. The initiated process of sending and receiving data requires high reliability and a very low delay when the communication channel is established. The mentioned communication channel is of essential importance for the automotive industry, because the components and all connected systems must have the possibility of coordination in the present time. In cases of delays and slow data processing, security may be violated and commands may not be executed in real-time.

Interoperability has the ability together with TSN to communicate independently with different hardware/software platforms. The importance of interoperability is in the smooth functioning of systems and components used within the automotive industry regardless of the use of components created by different manufacturers.

Scalability, in conjunction with TSN, allows networks used for diverse devices and systems to be expanded without compromising their features, capabilities, and dependability. This is critical for the building of car prototypes since the networks must support all systems and components. These include adaptive cruise control and advanced driving assistance systems (ADAS).

Together with TSN, the security function comprises authentication and encryption to protect against potential cyber threats. The dependability and safety of installed components is critical in the automotive sector.

TSNs and software product lines (SPLs) capable of real-time communication, scalability, interoperability, and reliability over network protocols are examples of technology advances in the automotive sector. The built-in car systems’ restrictions are driven by rigorous time constraints and required reaction intervals from the system to the end user.Proving the given time frames necessitates suitable design thinking and logic. The purpose is to effectively examine and demonstrate compliance with the required requirements. Time intervals are being employed to prevent cyber attacks on communication components. They ensure that the attacker does not have enough time to carry out the attack, estimate the algorithm, or communicate effectively [

46,

47].

4.8. Original Equipment Manufacturer (OEM)

In the industrial markets of goods and services, the question arises as to the relationship between producers and customers. If there are no alternative options for purchasing goods and services, consumers are directed to the Original Equipment Manufacturer (OEM). They represent the founders of production processes and the cycle of the creation of final products. Therefore, it is necessary to analyze the production system on a global level, which includes logistics, suppliers, contract manufacturers, and OEMs. For the automotive industry, the functioning of the OEM’s work is an important factor and an irreplaceable screw. Its irreplaceability is made by the following facts [

48,

49]:

OEM manufacturers help achieve savings, i.e. lower total vehicle production costs. They produce more efficient automotive components at lower prices than other manufacturers.

The requirements for obtaining high product quality refer to the tougher application of control on all OEM manufacturers’ components. On the basis of this, a continuous level of quality is ensured, as is the possibility of duplicating previously attained outcomes while improving quality, procedures, and engineering methodologies.

OEM manufacturers must adjust their existing solutions in response to fluctuating needs and a highly competitive market in the implementation of emerging technology. The objectives pertain to the achievement of optimal results in the competition. The alignment of features and design of original equipment in response to market needs occurs effectively to preserve worldwide dominance or share.

Specialization in vehicle components and parts is correlated with global industrial growth in vehicle production. This refers to the use of innovative ideas, intelligent design, renewable materials, and efficiency in the optimal use of energy sources.

The most essential aspect of the automobile industry is related to the existing foundation of OEMs, which represents the certainty of profitability and efficient production through the application of high-quality standards. The presence of OEMs on the worldwide market influences the creation and evaluation of criteria for optimal vehicle characteristics in the design and guaranteed prices of new goods.

On the basis of the collected research results from the accompanying scientific material, we saw that there are certain difficulties when accepting certain methodological approaches and design proposals. The main reason is found in the verification process, including a survey analytical approach in which a certain focus group is asked a series of questions through a series of interviews. In certain cases, this process is implemented in focus groups composed of inspection and quality assurance institutions, service providers, and OEMs [

48,

49].

The collected information enables examination and segmentation of the current market structure resulting from previously collected works. By looking at the economic perspective, it is possible to accurately identify the desired characteristics and problems that can be solved by producers and directly achieve financial profit [

50].

4.9. Additive Manufacturing (AM)

Adaptable production using 3D techniques and the ability to print (3DP) multiple casts from various materials is becoming increasingly important. Because it dramatically alters the method of thinking while designing a concept product, Additive Manufacturing (AM) presents a one-of-a-kind production possibility. On the basis of the developed physical model, the 3D model contained within the software can be verified. Direct quality assurance is performed within the software during vehicle production by employing physical materials in the end products.

AM investigates the compatibility of industrial needs and is a significant part of the verification process when discovering and using new types of materials. It eliminates some challenges and obstacles encountered during the implementation of 3D printing by performing double verification via 3D scanning, allowing for the subsequent direct adjustment of the 3d model in real time.

AM is utilized to manufacture spare parts and has tremendous potential to improve the actions of their delivery to end customers. Because of the intricacy of the parts and the required precision in terms of deviations stated in micrometers, the technology is typically employed in the automotive and aerospace sectors. Their goal is evident in the early detection of machine industry barriers, where parts must match exactly in terms of deviations. Deviations from the required measures for spare and original parts may result in high financial expenditures and the inability to install on cars [

51].

Business engineering within the automotive industry and previous sections explain some of the required techniques, where a close connection to AM can be seen when producing complex physical geometric shapes. The main part of the connection is reflected in the areas of engineering that deal with business and the durability of materials that are created using the 3DP printing technique. After the realization of castings created in sand using regular methods and 3D printing, scanning and 3D data collection is performed, based on which certain decisions can be made. The resulting castings are tested for various aspects such as durability, load capacity, breaking point, thermal changes, and the possibility of returning to the original state due to bending [

52].

4.10. Modern Vehicles

The main aspects of looking at modern vehicles refer to previously realized research in this area and published works that are the starting point for continuing further study of the complexity of automotive engineering. The focus of the work is on understanding the connection between software and hardware. The industrial development aspect of innovation achieves a significant shift in the field of communication systems that are integrated and distributed over several different segments in today’s modern vehicles. Specifically, this refers to being equipped with various wireless communication technologies that provide uninterrupted interactivity without cables, as well as interaction in communication with other vehicles and IoT devices located on the road infrastructure. Technologies used for communication purposes are Bluetooth, Wireless, LoRa, and others [

28].

By opening communication channels, the range of cyber attacks on vehicles increases, because there is a greater number of protocols that now need to be protected appropriately. For these reasons, the distribution of a certain version of software and the possibilities provided by the application of innovative techniques that have not been sufficiently tested and verified by researchers are abandoned [

1,

53,

54,

55]. Realized research efforts have contributed to simpler management using the electronic control unit (ECU). A modern vehicle has the possibility of direct communication with software functions and realizes a specific connection through a network with special hardware such as sensors, actuators, and various radar systems.

One of the main ways to collect data inside modern vehicles is the use of cameras that detect and recognize types of objects, after which the computer inside the vehicle has the ability to make real-time decisions.

5. Global Challenges and Made in China 2025

The Republic of China represents the largest economy in the world market that is currently growing. It plans to implement the strategic plan MIC 2025 (Made in China 2025) by the end of 2025 with the aim of canceling the presence of foreign technology on its own market and integrating the growing technological potential at the global level [

56].

Considering that there is competition in the field of highly sophisticated technologies and innovations in the world, it has implemented several important national strategies such as “Made in China 2025” [

57]. The strategic direction of MIC 2025 refers to the transformation of manufacturers from low- to high-quality products. The administrative body exerts pressure on the realization of these processes through a comprehensive program and directives related to the improvement of technologies based on analyzes and initiatives.

The state is making efforts to realize constant growth of economic activities in order to ensure competitiveness with other leading industries of the world. This refers to the consolidation of production capacities, the increase in the production of digital technologies, and the creation of competition in areas such as high-speed lines in the railway infrastructure, while simultaneously achieving high quality of the final products. By setting high goals, China creates growth in technological capacity and reduces dependence on foreign advanced technologies. The state administration is aware of its own huge market with over a billion consumers, which represents great potential not only for the world but also within its own borders.

The agenda of the “Made in China 2025” strategy reflects the German plan "Industry 4.0". Analyzing the approach of other leading industrial countries such as Japan, the USA, and Germany, using MIC 2025 constantly raises the bar of standards, becoming the most dominant manufacturing industry in the world [

56]. The state plans to support this initiative by involving financial support for research conducted by the Ministry of State Science and Technology. Industrial technological research and training are carried out in the fields of intelligent and additive manufacturing, innovative resources, biomedicine, and in the new generation of information technologies. The main task is to perfect industrial transformation such as industrial robots, equipment for additional production, artificial intelligence, the Internet of things, cloud systems, machines that learn, cyber security, and automation.

Industrial transformation represents a clear agenda of China’s “Belt and Road” or “New Silk Road” initiative. Serious intentions are reflected in the substitution of component assemblers, i.e. copying brands for the Western market and their placement in Europe and North America, to the export of high-quality products. to the rest of the world by the Chinese giants. The MIC 2025 development strategy and the realization of goals refer to changing the clear role of the Republic of China, pushing it to the pedestal of a leading industrial producer in the world. The result of this fact will lead multinational corporations (MNCs) and foreign companies to face a series of challenges that may disrupt free trade in the future.

6. Logistic Problems

The automotive industry and the supply of final products to the market are spread all over the world because there is a great demand for them. For the success of small businesses that control supply chains globally, it is necessary to implement business modes that include telecommunications technologies, software platforms, and commercial transactions that operate outside of border frameworks. Effective control and management of vehicle supply chains is possible thanks to technological solutions, such as modern information systems that are available to companies with the help of cloud computing [

58].

Profitability and efficiency are necessary for the vehicle placement market. The key provision of these preconditions is made by business management, whose role is to create an environment for the reduction of supply chain links, which will shorten the delivery time of final products. For a good approach in the processes of business coordination and the success of the step of supplying raw materials, a strategy that refers to each of the stages of the production of goods and the provision of services is necessary. In this way, producers will minimize barriers in business and achieve higher profits.

The basis of the existence of automotive engineering is reflected in the creation of transportation forms of vehicles on the basis of which internal and external logistics processes could be realized. By considering the economic aspect and logistics, a more efficient alignment with existing market requirements is created. Logistical problems and marketing of final products can represent success/failure for certain producers due to inadequate planning of necessary materials in production cycles.

The logistics of product supply are becoming more complex due to the needs of companies on a global level and the presence of various new market requirements [

59].

6.1. New Logistic Approach for Issues in the Automotive Sector with an Outline of the Processes Involved in Supplying Final Products to the Market

The automotive industry and the supply of final products to the market are spread all over the world because there is a great demand for them. For the success of small businesses that control supply chains globally, it is necessary to implement business modes that include telecommunications technologies, software platforms, and commercial transactions that operate outside of border frameworks. Effective control and management of vehicle supply chains are possible thanks to technological solutions, such as modern information systems that are available to companies with the help of cloud computing [

58].

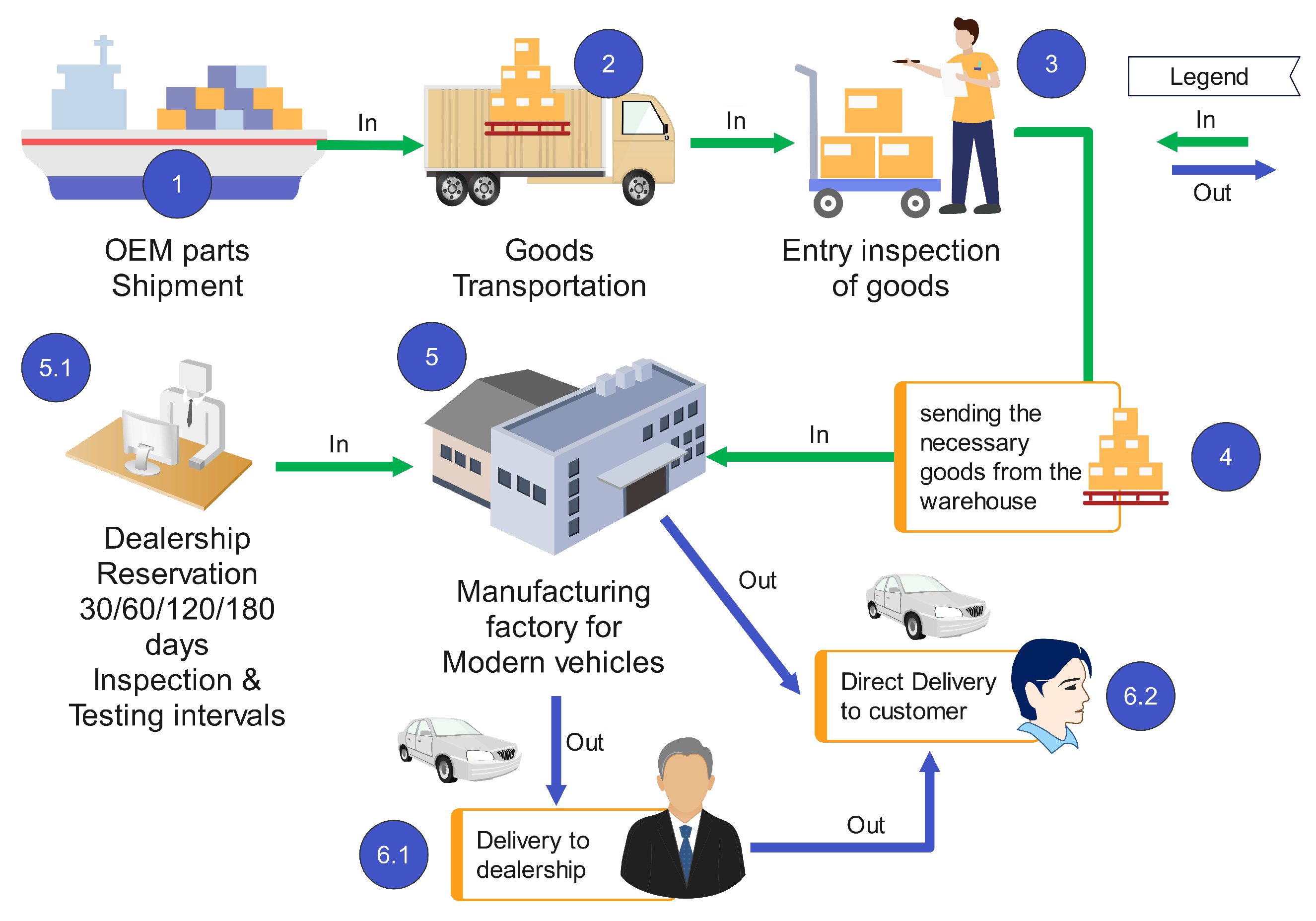

The whole process can be explained through the steps (1-6) presented in

Figure 2 where the displayed legend shows the entry and exit process of the movement of goods, starting from the original producer to the end customer (6.2).

The vehicle placement market requires profitability and efficiency. The primary provision of these preconditions is made by business management, whose responsibility is to establish an atmosphere conducive to the reduction of supply chain links, hence shortening final product delivery time. For a good approach to business coordination processes [

60] and the success of the raw material supply step, a strategy is necessary that refers to each of the stages of goods production and services provision. In this way, producers will minimize barriers to business and achieve higher profits.

The basis of the existence of automotive engineering is reflected in the creation of transportation forms of vehicles on the basis of which internal and external logistics processes could be realized. By considering the economic aspect and logistics, a more efficient alignment with existing market requirements is created. Logistical problems and marketing of final products can represent success/failure for certain producers due to inadequate planning of necessary materials in production cycles. The logistics of product supply are becoming more complex due to the needs of companies on a global level and the presence of various new market requirements [

59].

7. Results

As a display of the connection within the data, the findings of this study should highlight the data processing process to discover many unanticipated changes that resulted in increased purchases or a significant decline.

As a result of the result and the ability to apply without delay, we need appropriate hardware resources, which are at the core of computer systems. We must prioritize adequate hardware resources to complete extraction, transformation, and load (ETL), data model training, and data analysis successfully. For these operations, we require a powerful CPU that allows for efficient execution, as well as adequate RAM to handle many operations at once. When GPU resources become available, we may improve our performance for GPU-accelerated jobs in AI training and standards compliance. Multi-core computers and efficient cooling should improve processing efficiency even further.

To deliver a highly resilient and high-performance development and deployment environment, we must align these resources with the deployment scale. We evaluated the created new dataset from the mentioned sources [

61,

62] and performed the associated analyzes using an i5-5250U processor with 8.00 GB RAM and a 64-bit Windows 10 Pro version 22H2 operating system.

7.1. Dataset Collection and Analysis

To test our hypothesis, we used data [

61,

62] to check the following changes of a battery electric vehicle (BEV), a plug-in hybrid electric vehicle (PHEV), and a hydrogen-powered vehicle on public roads in Washington. Together, after cleaning, we had approximately 855,916 (rows) individual vehicles available with the following representation of drive sources, which is contained in

Table 2.

Table 1.

Statistical distribution of the number of vehicle drive types in the data obtained from [

61,

62].

Table 1.

Statistical distribution of the number of vehicle drive types in the data obtained from [

61,

62].

| |

Battery Electric |

Plug-in Hybrid Electric |

Hydrogen Powered |

| Data |

74% |

26% |

<1% |

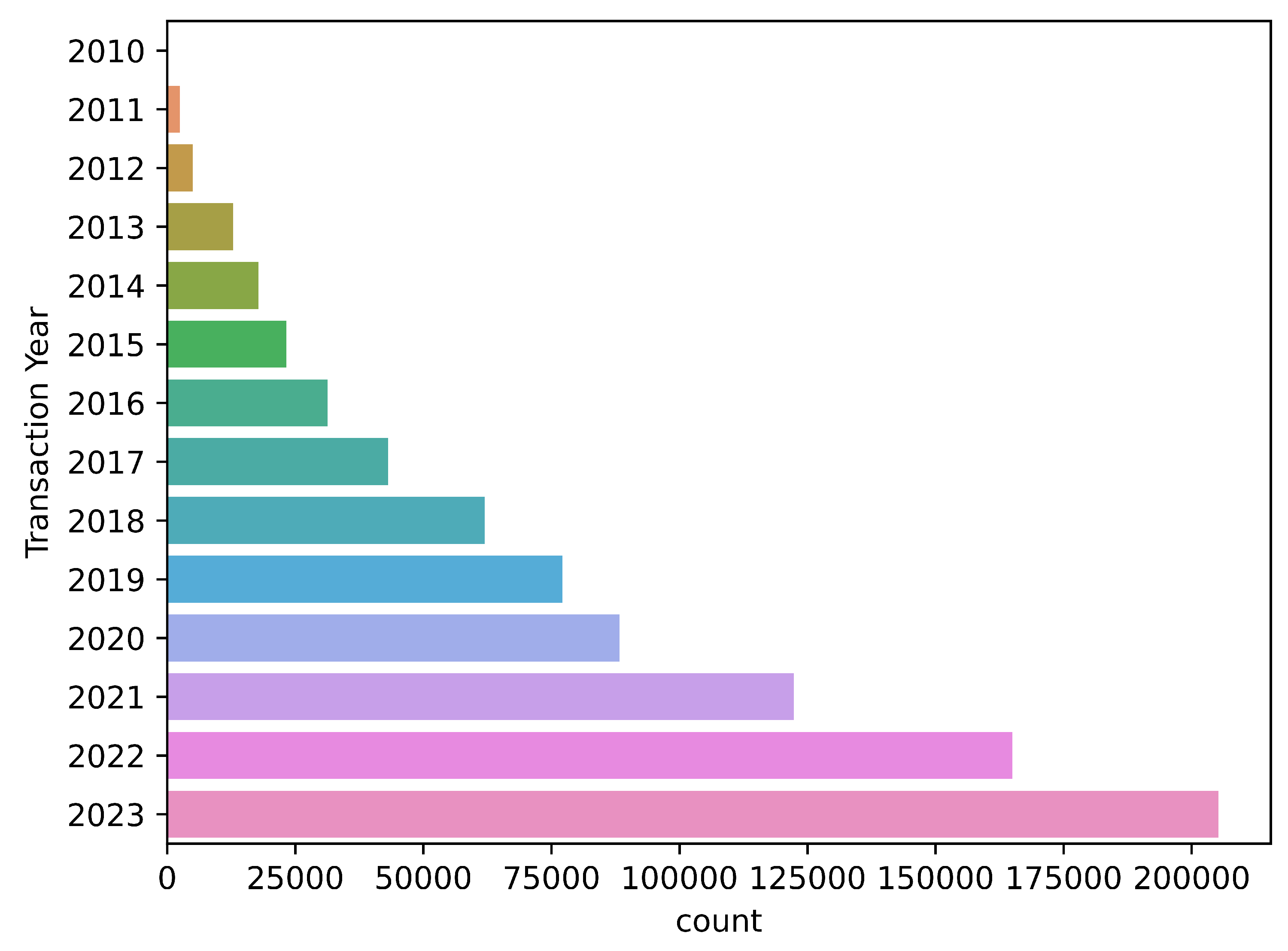

The recorded sales transactions of the investigated vehicles fall into the 2010-2023 period with a clear increase in sales (

Figure 2). If we look at the year of manufacture of individual vehicles, we also see a certain volume of vehicles manufactured since 1992. However, they make up a smaller part that cannot be neglected.

Figure 3.

Number of recorded vehicle transactions in data from the source: [

61,

62].

Figure 3.

Number of recorded vehicle transactions in data from the source: [

61,

62].

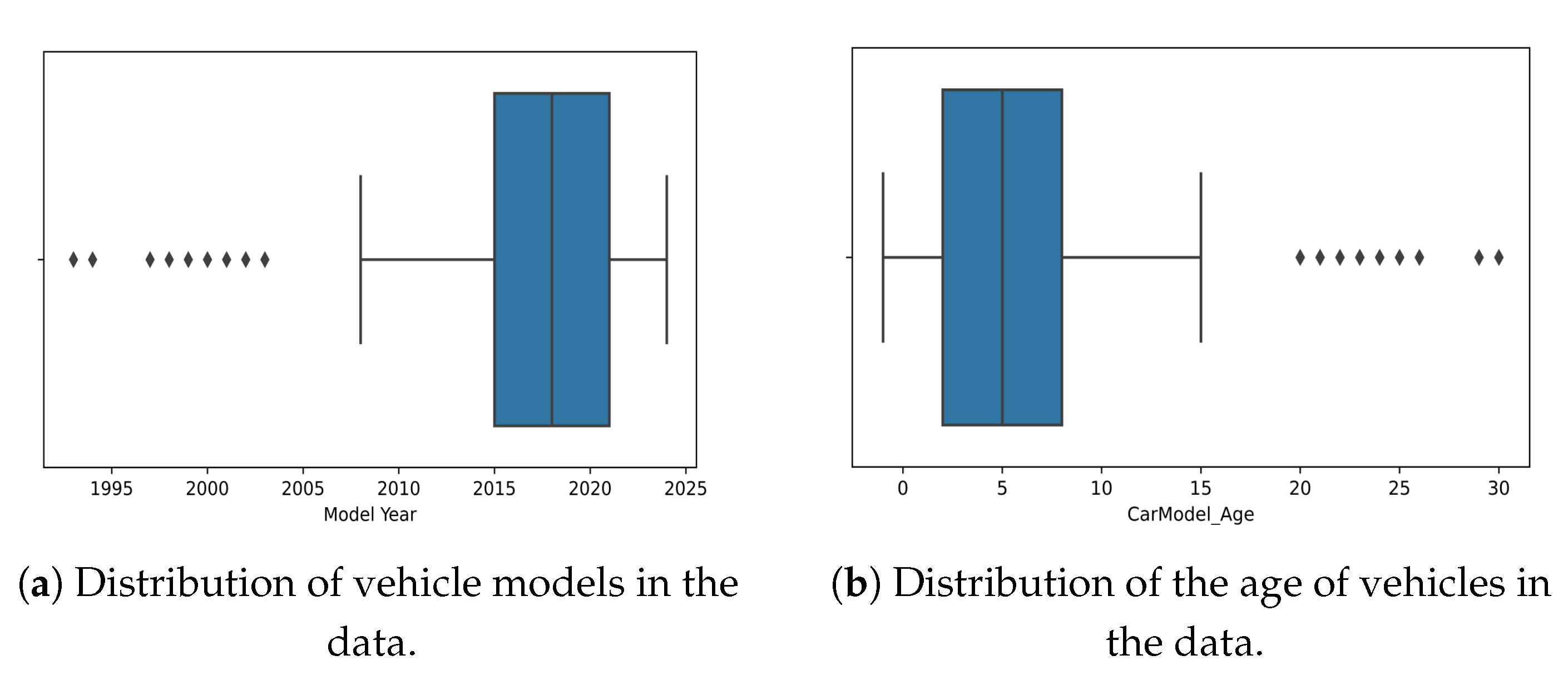

If we look closer at the box plot (

Figure 4a), we can see that half of all vehicles sold were vehicles with a model from 2015 to 2021 with a median of 2018. We attribute such results to two basic possibilities. First, the best models with ideal parameters were created in these years. Second, our data mainly capture this period, when there was a boom in electric mobility all over the world, and thus the total number of vehicles is larger in this period.

From the boxplot diagram of model years, it is possible to get the impression that individual vehicles change hands practically immediately after production. However, this is not the case, as we saw in the box plot (

Figure 4b), where we plot the distribution of the data in the data set according to the age of the vehicle at the time of sale. This shows us that these were partially older vehicles with a median age of 5 years.

Figure 4.

Boxplot diagram of the distribution in data. Where (a) shows the distribution of vehicle models (Model Year) with values. While (b) shows the distribution of the age of vehicles (Car Model Age) in the data from the source: [

61,

62].

Figure 4.

Boxplot diagram of the distribution in data. Where (a) shows the distribution of vehicle models (Model Year) with values. While (b) shows the distribution of the age of vehicles (Car Model Age) in the data from the source: [

61,

62].

7.2. Data Preprocessing

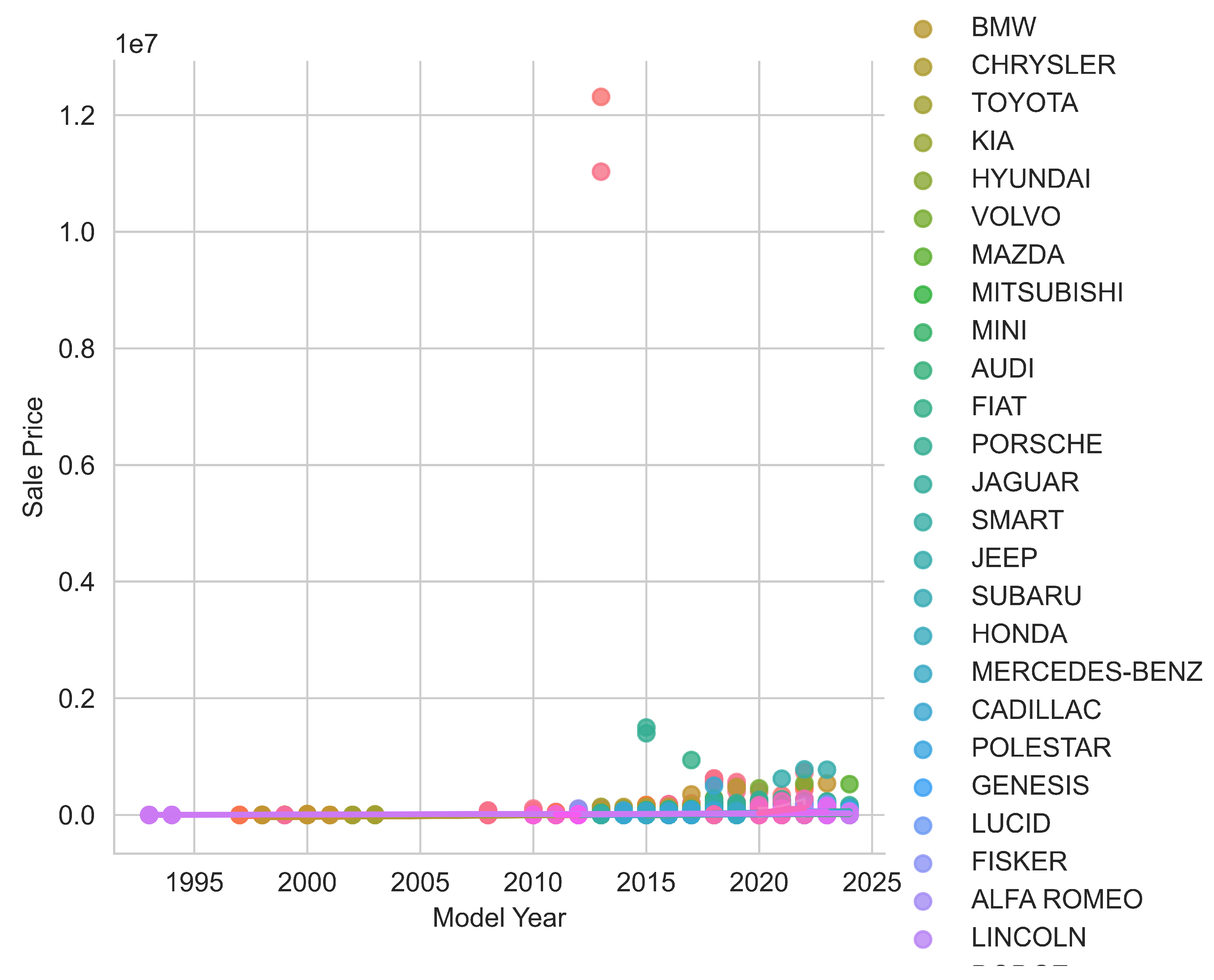

Using the regression model through the popular Python library Seaborn in version 0.12.2, we created a model (

Figure 5) to predict the prices of vehicles with alternative types of fuel, among which we also include vehicles with electric drive.

For the data obtained, we used a linear regression model, which we found to be the most suitable after basic visualization. The basic linear regression relationship is shown in Equation 7.2.

Subsequently, we show the resulting regression model in

Figure 5 and the specific values of the variables can be seen in the following equation 7.2 with the standard error for the constant 1.81e + 04 and for the coefficient b with the value 8.957.

When using linear regression, we did not take into account individual types of vehicles, which differ in price within the group.

Table 2.

Prediction of the average price of vehicles with the researched drive in the state of Washington, USA by 2025 with a probability of 95%. Source: author’s contribution.

Table 2.

Prediction of the average price of vehicles with the researched drive in the state of Washington, USA by 2025 with a probability of 95%. Source: author’s contribution.

| |

2023 |

2024 |

2025 |

| Prediction from data in USD |

22967.261 |

25362.203 |

27757.145 |

7.3. Classification of Individual Brands

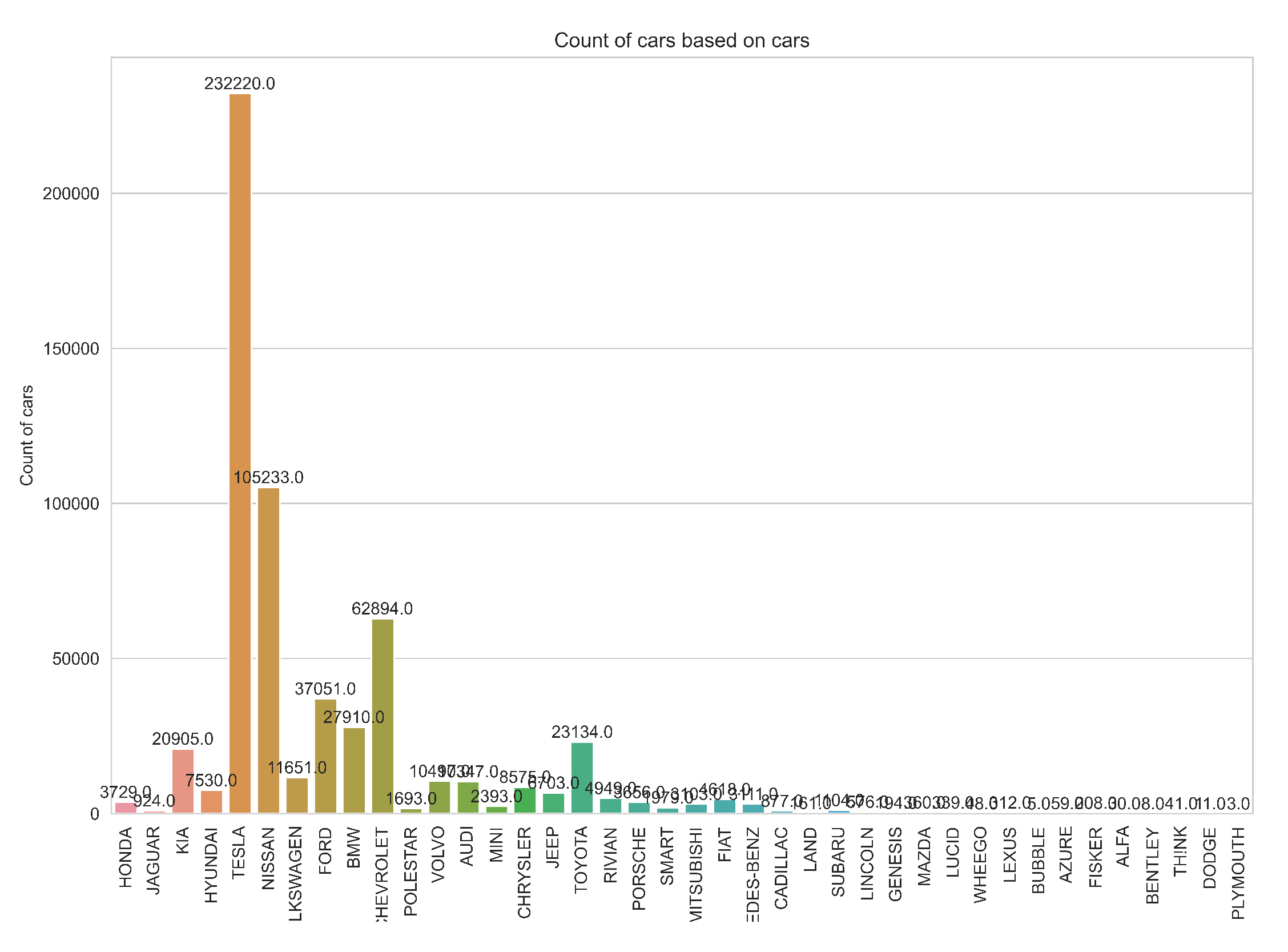

In

Figure 6 we see the proportional representation of vehicle models of individual brands in our data. It is clear from the data that the most represented type of vehicle is TESLA, with a significant numerical advantage over vehicles from NISSAN.

7.4. Identifing Interest Events and Analysis Windows

In the context of automotive manufacturing, identifying events of interest and constructing analysis windows requires picking relevant occurrences and time intervals for careful examination. We can focus more on assessing significant achievements by providing a comprehensive view of the historical background and patterns in automotive production by identifying certain study windows and pinpointing events of interest.

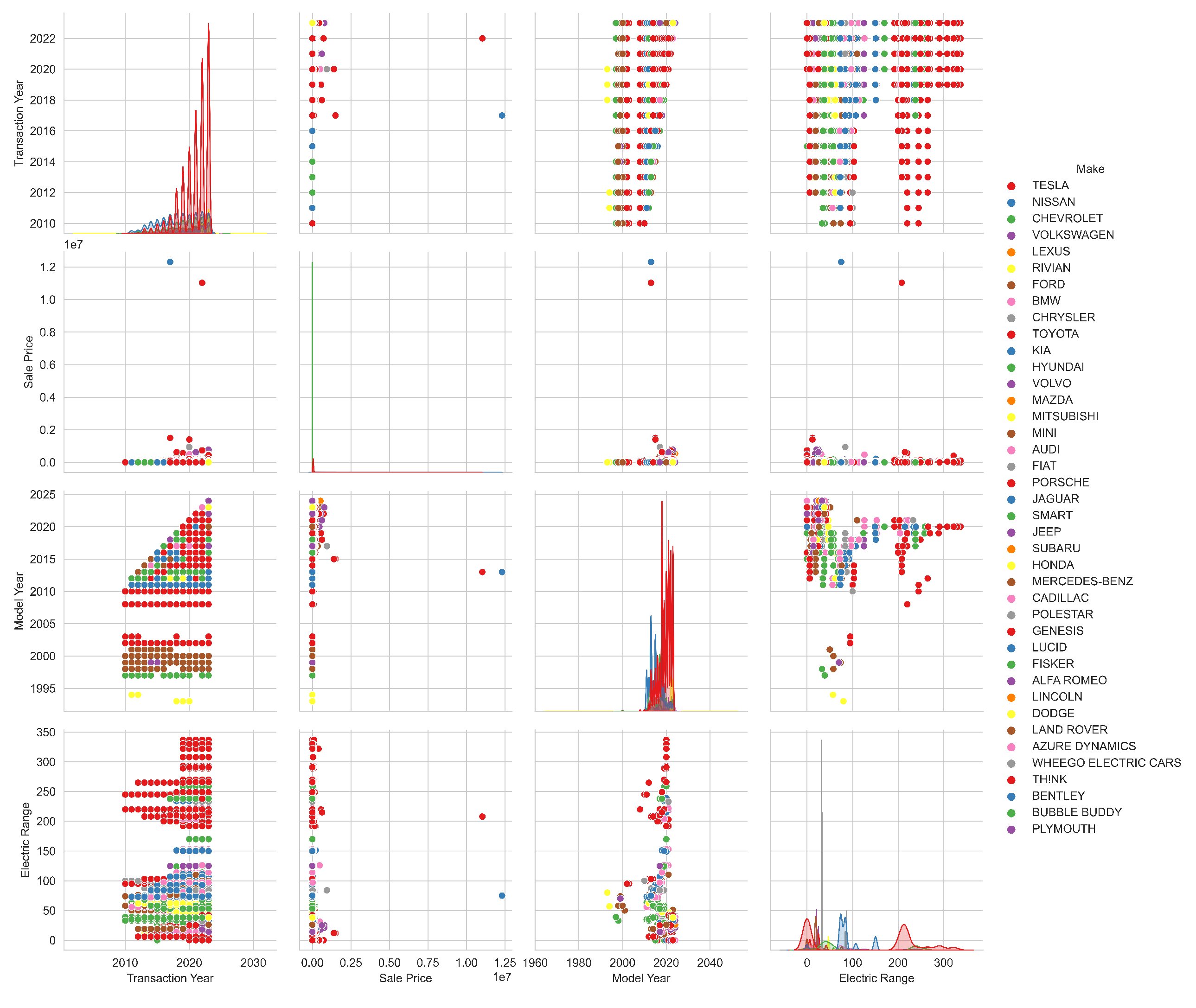

Figure 7.

Summary view the relationships of individual selected quantities with each other which covers different brands of cars, years of transactions, etc. Source: author’s contribution.

Figure 7.

Summary view the relationships of individual selected quantities with each other which covers different brands of cars, years of transactions, etc. Source: author’s contribution.

8. Limitations of the Study

Because limitations are fundamentally just one aspect of the research in our research investigation, we were able to summarize the following limitations:

The scope of the investigation provides an overall picture of the evolution, innovation, and integration of the automobile industry with other sectors through the use of new technology. However, because the focus was on the accessible data inside the dataset itself, it does not go further into individual case studies of companies, detailed ratings, or locations.

One of the limitations is the limited data analysis investigation because the research does not cover other regions of the world; therefore, a more complete examination of the EU and other parts of the world would be beneficial. A comparative analysis could be useful to investigate how geographic location impacts logistical setups and commercial operations in the automotive industry. This technique will eventually provide insight into regional disparities in industry dynamics. This would create a clearer picture of the differences in how data analysis is integrated into decision-making processes, as well as its specialized contributions to the automotive sector.

Geographical specificity refers broadly to the global automotive industry, but does not specify geographical nuances or variations. A more nuanced analysis, considering regional differences, regulations, and market dynamics, would offer a more comprehensive understanding of the challenges and opportunities facing different parts of the industry.

By addressing these limits, future research can provide a more nuanced, detailed and contextually rich understanding of the developments, challenges, and contributions within the global automotive industry.

9. Discussion

Based on the data, several analytical inferences and discussion points can be drawn about the intricacies of the automobile business. Looking at the results of the material collected during the investigation, we noticed several different technological changes that will lead to a higher level of production of electric and hybrid vehicles in the coming period. A discussion is opened about the use of certain new materials and the negative effects they can produce during mining or their emissions.

There is a continuous trend of discourse on the use of new energy sources that could meet the needs of vehicle electrification and increased consumption of electricity. It is necessary to analyze the real facts regarding the justification of complete electrification or the application of hybrid methods in vehicle starting.

Based on the defined questions, we obtained the following results:

9.1. RQ 1:

We managed to see the historical evolution of global market changes in automotive manufacturing from 1995 to today, which has been transformative. Key milestones include the introduction of the Tesla assembly line in 2012, with the first Model S rolled off the assembly line at our factory in Fremont, California, and the integration of digital technologies.

We managed to see and learn that the 21st century witnessed a paradigm shift with the rise of electric vehicles, reshaping industry dynamics and emphasizing sustainability. Predispositions to solving modern production problems will involve leveraging historical insights, embracing emerging technologies, and navigating the accelerating transition to electric or hybrid vehicles in the ever-evolving global automotive landscape.

9.2. RQ 2:

We were able to see a diverse network of data sources incorporated into the current data sets that are used to calculate global market changes and losses in modern car manufacturing. Sales and market reports provide quantitative insights into consumer preferences and market dynamics, as well as a snapshot of sales volumes and trends.

9.3. RQ 3:

After examining the concerns, we were able to examine the benefits and drawbacks of using specific materials during the development of a prototype modern automobile. There is a steady trend in debates about the use of new energy sources that could meet the needs of vehicle electrification, and electricity use is increasing. To justify complete electrification or the use of hybrid technologies to start the vehicle, the facts must be examined.

Future research difficulties will necessitate the development of a discourse on the complexities of designing automotive systems. Increased consumer preferences result in the development of more inventive solutions. When it comes to new technology, technical skills and examples of good practice in transferring knowledge can lead to success and problem solving.

9.4. Open Questions

These open questions highlight areas where additional historical research could contribute valuable insights, shedding light on trends, patterns, and factors that have influenced the development of the automotive industry over time. Previous studies on cross-industry integration have consistently highlighted the potential effectiveness of collaborations between diverse sectors.

These studies show that effective collaborations in the past have significantly helped advance industrial advancements and create an environment of creativity and adaptation, with an emphasis on the benefits of knowledge transfer, resource sharing, and innovation for future perspectives. The capacity to harness complementary skills, technology, and views from multiple domains appears to be the basis of cross-industry integration efficacy and the production of synergistic results.

How can we shape the long-term future of the automotive industry based on past technological revolutions and historical events?

What are the effectiveness and historical success aspects of cross-industry integration?

How do geopolitical and economic factors affect the automotive industry, and how have these factors affected industry dynamics?

The working hypothesis, in line with these points of view, suggests that the historical success of cross-industry collaborations has had a long-term impact on the automotive industry. This means that the industry’s present integration strategies will likely be affected by previous successful models and long-term relationships characterized by innovation and durability.

10. Conclusions

The global automotive industry is undergoing a revolutionary shift as a result of the demand for efficient innovation and development. They include robust software configuration management, adherence to high-quality standards, and smart use of current software tools, as they are the primary components of evolution. Manufacturers emphasize safety and strive for better efficiency in product development timelines. The importance of carefully chosen and configured components cannot be emphasized as they serve as the foundation of the entire procurement and production process. These components, which are capable of recognizing a basic set of metrics and dependability measurements, adapt to the changing needs of application developers in a fast-paced business.

This cross-industry collaboration not only amplifies the impact of solutions, but also fosters a complete landscape of innovation. As the automotive sector faces global market problems, its adaptability, resilience, and technological developments place it at the forefront of transformative change. Within the realm of automotive engineering, we distill the essential strategies demanded by the contemporary industry. Advancement in manufacturing is dependent on meticulous tracking of metric measurements and standardization of processes. Our research emphasizes that the synergy between practical application and market dynamics profoundly shapes the development of modern vehicles. In particular, software products emerge as critical, acting as cornerstones for integrating the creative prowess and knowledge of top-tier engineers into intelligent interconnected vehicle systems.

The results provided are crucial decision-support tools for stakeholders who define the dynamic automotive scene on regional and global scales. These findings, which apply to both private and public transportation, including electric vehicles, benefit decision-makers in developing reliable services and manufacturing infrastructure. In addition, insights explore the obstacles given by rugged terrains, as well as an early assessment of investment requirements for nations considering partnerships and new industrial techniques.

In our initial investigation, we found that it is possible to use linear regression to predict vehicle prices based on the current trend while maintaining increasing production volume and inflation-driven price increases in an uncertain global market. The forecast is that by 2025 they will be bought at 120.86 % of the current average price valid for 2023.

In future research, we can recommend a check of the achieved prediction and its correction due to the level of inflation, the limitations of individual manufacturers’ production capacity, and the scarcity of production resources due to current events in the world. One of the conclusions and verifications is reflected in the constant uncertainty and refinement of the prediction due to the rapidly changing conditions in the national and world economy. The second option for changing the predicted price is the possibility of intervention or support for changes in ownership, tax, and other factors by the national government. We assume that young people, who are more likely to have ecological sensibilities, will also get involved.

Author Contributions

Conceptualization, Data Curation, Formal and Data analysis, Investigation, Methodology, Project administration, Validation, Visualization, and Writing—Original draft and editing: P.D.; Visualization, Data Curation, Formal and Data analysis, Review—Writing and Project Administration: I.S; Methodology, Conceptualization, Visualization, Data Curation, Review—Writing, Editing, Proofreading, Project Administration, and Supervision: V.T; All authors have read and agreed to the published version of the manuscript.

Funding