1. Introduction

Low-background experiments in the field of particle physics are an actively developing area of modern experimental physics. The goal of these experiments is to answers a number of fundamental questions about the modern structure of the Universe - the nature of Dark Matter particles [

1,

2], the fundamental properties of neutrinos [

3]. Low-background experiments are carried out in underground low-background laboratories [

4,

5]. Due to the fact that most of these experiments need a target operating at cryogenic temperatures, the main structural element of corresponding detectors is a low-background cryostat. The main trend in the development of modern low-background detectors is an increase in their sensitive volumes due to an increase in the mass of the detector’s construction elements. This leads to the fact that the size of cryostats increases significantly and the amount of required low-background structural materials increases to tens of tons. The previously used approach of selecting material with the required low radioactivity from a warehouse does not work for such masses of structural materials. It is necessary to develop industrial methods for the production of low-background materials.

Promising low-background materials are titanium alloys. Titanium-sponge is the primary product for all titanium-alloys. It is produced from simple chemical compounds – metal magnesium and titanium tetrachloride (TiCl

4) using the method of magnesium-thermal reduction [

6]. It is obvious that if the initial products have ultra-low-background properties, then the products obtained from them must also have ultra-low-background properties, if the ingress of radioactive impurities is avoided during the manufacturing process. Our previous studies have shown that TiCl

4, obtained directly and locally within the production cycle of titanium-sponge by deep distillation of chlorides of ore concentrates, has the necessary low-background properties [

7], whereas metal magnesium requires special preparation. Commercial metal magnesium is a proven source of radioactive impurities in titanium-sponge [

6]. However, it has been shown that titanium-sponge can be produced with ultra-low levels of radioactive impurities, below 1 mBq/kg.

In order to prove the possibility of manufacturing structural titanium-alloys, it is necessary to analyze the stages of titanium-sponge transformation into a titanium-alloy and study the migration of radioactive impurities in industrial processes accompanying these stages. For this purpose, samples of materials were selected from various stages of titanium-alloy production. Quantitative analysis has been carried out using the ICP-MS method for the total content of uranium and thorium isotopes. Massive samples of titanium-sponge and metallic titanium have been additionally analyzed by gamma-spectroscopy with high-purity germanium detectors located in the underground laboratory.

2. Materials and Methods

2.1. Methods for Studying Samples Using ICP-MS

Inductively coupled plasma mass spectrometry was used to analyze the chemical purity of all samples. The samples were transferred from the solid sample to the liquid phase. Alloy samples were dissolved in hydrochloric acid (7N) purified by surface distillation systems (BSB-929-IR, BERGHOFF GmbH&Co., Wenden, Germany) in polytetrafluoroethylene autoclaves (DAP-100, PTFE, BERGHOFF GmbH&Co., Wenden, Germany) using SPEEDWAVEFOUR installation for microwave decomposition (BERGHOFF GmbH&Co., Wenden, Germany). The dissolution product was transferred into a polypropylene (PP) tube. Deionized water was obtained using an Aqua-MAX-Ultra 370 Series unit (Young Lin Instruments Co. Ltd., Seoul, South Korea) and had an electrical resistance of 18.2 MΩ cm. Then the resulting solution was transferred to a polypropylene test tube, and then the solution was diluted with water. The solution thus prepared was analyzed using inductively coupled plasma mass spectrometry (ICP-MS). Analytical measurements were carried out on an inductively coupled plasma mass spectrometer NexION300D (PerkinElmer Inc., Waltham, MA, USA). Quantitative analysis of Th and U was carried out using the “additive” method, taking into account the concentration of the main (matrix Ti) elements in the analyzed solution. Standard solutions (PerkinElmer Inc.) were used for calibration.

2.2. Methodology for Analyzing Radioactive Impurities in Titanium Metal Samples at Various Stages of Production Using the HP-Ge Method

2.2.1. Description of the Installation and Measurement Technique

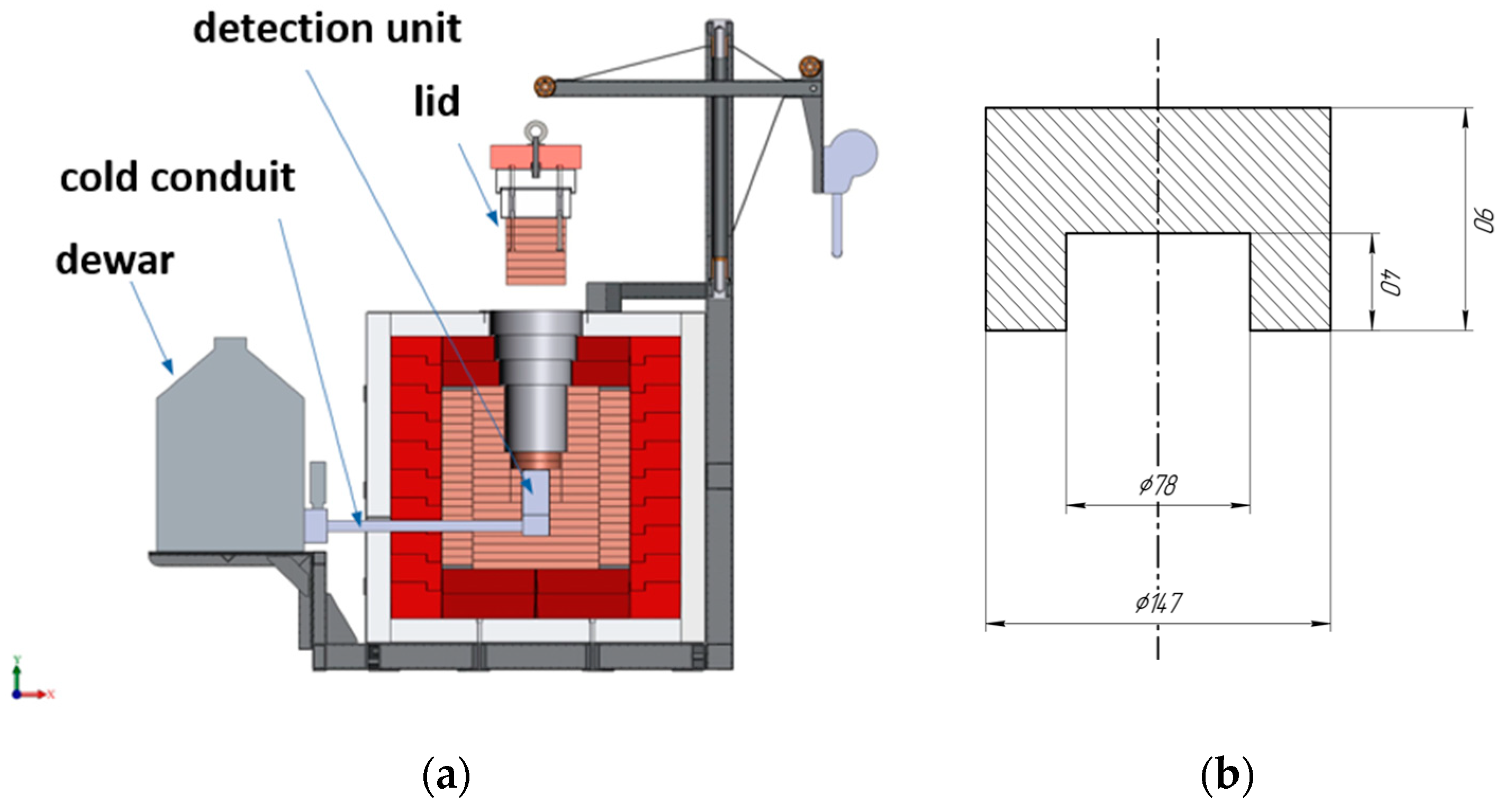

The measurements have been carried out on low-background gamma spectrometers made of ultra-pure germanium, located inside a passive shield consisting of ~20 cm copper, ~15 cm lead and ~8 cm borated polyethylene. The installation is located in the underground laboratory of the Baksan Neutrino Observatory (BNO INR RAS). The detector’s sensitive element has a diameter of 60.6 mm and a height of 34.2 mm and is packaged in a thin-walled aluminum housing made of ultra-low background aluminum with a wall thickness of 1.5 mm (

Figure 1a).

Bulk products (titanium-sponge) were placed in low-background plastic conical containers made of polyethylene (90 mm upper diameter, 80 mm lower diameter, height 45 mm at the top of the lid, height inside 40 mm) with a volume of 180 ml and a weight of 13 g). The samples were washed with alcohol to remove dust before placing into containers. The container with the sample was placed on the upper edge of the detection unit casing.

Round bars in a U-shaped section were machined from titanium ingots, which were “put on” the detection unit (

Figure 1b).

Disks and rings were machined from titanium-sheets to form the U-shape structure the same shape as the U-shaped bars made of titanium ingots. The same sample shape for sheets and ingots simplifies the process of comparing spectrometric measurement results.

The samples of titanium ingots and sheets were etched with a solution of 20% nitric and 1% hydrofluoric acids, followed by washing in high-purity, low-radioactive deionized water.

2.2.2. Calculation Technique

The aim of measuring gamma radiation spectra of the samples by HP-Ge method is to determine its specific residual radioactivity, which allows restoring volumetric concentration of radioactive isotopes at the levels of mBq units and below. This mathematical task belongs to the class of inverse problems and its solution is possible only with a sufficient amount of a priori data about the object of study. The correct reconstruction of radiation sources from measured spectra is possible only if the propagation of gamma radiation in the detector and the sample itself is correctly taken into account. To do this, it is necessary to simulate the propagation of the detector’s own gamma background together with the expected background from the sample.

Calculations of the efficiency of registration of γ-quanta from radionuclide decays in the samples under study were made using the MCC-MT (Monte Carlo Calculation Multi Thread) software package [

8] included with low-background gamma spectrometers. This program allows building a 3D model of the installation including the detector, detector’s structural elements and a sample as well as simulating a predefined set of radionuclide decays in the sample. The output of the simulation is the spectrum of energy release in the detector. The number of events at the peak of total absorption of gamma rays was determined from the model spectra. The results of the calculation based on the simulation are presented in the

Table 1.

The specific activity of radionuclides was determined by the formula:

where

A is the specific activity of the radionuclide [Bq/kg],

k is the estimated number of recorded gamma rays per 10

6 decays,

S is the number of events in the total absorption peak minus the contribution of the detector background,

t is the time [s],

m is the mass of the sample [kg]. The

S value was determined as the difference between the number of events in the peaks in the spectrum with the sample and in the background spectrum normalized to the time of measurements with the sample, taking into account the absorption of gamma rays in the sample.

To calculate the activity of Th-232, U-235 and U-238, peaks from the gamma lines 238.6 keV (Pb-212), 143.8 keV (U-235) and 351.9 keV (Pb-214), respectively, were used. It is assumed that the secular equilibrium in the decay chain is not disturbed.

2.2.3. Data Processing Technique and Preliminary Measurement Results

Measurements of the sum of the sample activity and the detector’s background were carried out for about 500 hours for each sample. The measured spectra were compared with the detector background spectrum without samples. The contribution due to the sample was determined from the difference in the spectra. The sum-spectra show peaks at energies of 1460.8 keV, 1173.5/1332.5 keV and 351.9 keV corresponding to the following isotopes K-40, Co-60 and Pb-214/U-238 respectively. In addition, two lines at 889.3 and 1120.6 keV have been observed, which indicate the presence in titanium of a short-lived isotope Sc-46, with a half-life of 83.8 days. The presence of this isotope in a titanium sample is due to its production in titanium under the influence of cosmic ray neutrons [

9].

3. Results and Discussion

3.1. Analysis of Radioactive Impurities in Master Alloys Used in the Production of Titanium Alloys Using ICP-MS

The introduction of master alloys into titanium-alloys to correct its physical and mechanical properties is a standard procedure in the production of titanium-alloys. Master alloys are introduced into the titanium-sponge mixture before pressing into consumable electrodes for the VAR process. In order to study whether master alloys were a source of contamination with uranium and thorium, a selection and analysis of residual concentrations of uranium and thorium for master alloys used in titanium production at PJSC VSMPO-AVISMA Corporation (Verkhnya Salda, Russia) was carried out: chopped aluminum wire rod (Al-01), vanadium-aluminum alloy (VnAl-70V30Al), aluminum-tin alloy (Al-Sn - 50Al50Sn). These master alloys have been introduced into the charge of titanium-ingots in an amount averaging 4-5%, assuming that there are no secondary charge materials in the charge.

In addition to the studied master alloys, there are complex ones, consisting of 4-5 elements. Their amount in the charge of titanium-ingots can reach 15-18%.

The analysis of the chemical purity and content of residual U and Th in samples of master alloys used in the production of titanium-alloys (

Table 2) showed that the most chemically pure material is the Al-Sn alloy produced by VSMPO-AVISMA, obtained by liquid rolling. The lowest content of residual uranium and thorium has been determined in the VnAl alloy, obtained by aluminothermy (reduction of vanadium oxide with aluminum powder) at Uralredmet JSC (Verkhnyaya Pyshma, Russia).

However, the level of U and Th in the master alloys reaches such a level that if they are added to the electrode for the VAR and evenly distributed throughout the volume of the ingot, the requirements for radioactive purity will not be met. It is possible to conclude that it is necessary to refrain from introducing any master-alloys into the consumable electrode when producing ultra-low-background titanium-alloys. The only alloy for the manufacture of structural ultra-low background titanium alloy is VT1-00.

3.2. Analysis of Radioactive Impurities in Titanium Metal Samples at Various Stages of Production Using ICP-MS

Samples of materials from various stages of VT1-00 titanium-alloy production were selected to prove the possibility of producing structural titanium-alloys with activity levels below 1 mBq/kg required for low-background experiments. The samples of titanium-sponge were selected of grade TG-90 with the index “EK-3”, fraction +12-70 mm.

Titanium ingots of the VT1-00 alloy with a diameter of 180 mm and a weight of 15 kg were manufactured from the prepared samples of titanium-sponge weighing 17 kg. The ingots were produced using the three continuous stage of VAR. After the first and second remelting of the ingot the ingot’s surface is washed. The ingot surface is machined after the third remelting. The top and bottom parts are removed from the final remelting ingots.

The production of the titanium sheet samples with dimensions of 350×500×2 mm was carried out by cold rolling from the ingots.

The analysis of the residual U and Th in the samples taken from various stages of titanium metal production (

Table 3) showed that in a number of cases it is possible to obtain titanium-sponge with a U equal to 1.30±0.01 ppb and Th equal to 0.49±0.10 ppb. Analyzes of the titanium ingot and sheet showed that little change of the uranium and thorium. The main part of uranium and thorium was introduced during the production of ingots from titanium sponge TG-90EK-3.

Thus, it can be argued that if the primary material has ultra-low background properties, contamination can be avoided during the subsequent technological stages of the production of structural titanium-alloy. However, the identification of a general pattern and its quantitative assessment have not been identified due to the insufficient number of samples subjected to measurements. This work is planned to continue, because the establishment of such a pattern will ensure the preservation of the original ultra-low-background properties from the state of sponge titanium to rolled titanium.

3.3. Analysis of Radioactive Impurities in Titanium Metal Samples at Various Stages of Production Using the HP-Ge Method

To subtract the background of the detector from the measured data, the number of gamma quanta in the total absorption peaks were normalized for 500 hours of measurements. The normalized data are shown in the

Table 4.

The activities of radionuclides in titanium samples were obtained based on the sizes of the total absorption peaks of gamma rays in the measured spectra (

Table 5). The measured numbers were corrected according to previously measured detector efficiency, simulated self-absorption in the sample, and gamma ray scattering associated with the geometry and physical properties of the detector sample.

4. Conclusions

The results of impurity analysis of master alloys showed that their use greatly pollutes future titanium in terms of background radiation. An alternative is to avoid an application of the master alloys and use an ultra-low background titanium-sponge. Analysis of the results for uranium and thorium by ICP-MS and HPGe turned out that the values obtained by the germanium detector are slightly lower, which can be explained by the homogeneity and larger mass of the samples. This may also be an indication of a violation of the secular balance, which requires additional research.

Thus, the experiments carried out confirmed that it is possible to obtain ultra-low-background titanium of the VT1-00 grade in a standard technological process, provided that the titanium sponge is initially ultra-low-background.

Author Contributions

Conceptualization, I.A. and A.C. (Alexander Chub); methodology, A.C. and A.C. (Alexander Chub); software, M.Z.; validation, S.V. and A.T., M.K; formal analysis, I.A.; investigation, M.Z., A.G. (Albert Gangapshev) and A.G. (Ali Gezhaev); resources, A.C.; data curation, M.Z.; writing—original draft preparation, A.C. and S.V.; writing—review and editing, I.A. and D.R.; visualization, E.V. and D.T.; supervision, M.Z.; project administration, A.C.; funding acquisition, A.C. All authors have read and agreed to the published version of the manuscript.

Funding

This study was financially supported by the Ministry of Science and Higher Education of the Russian Federation, Grant No. 13.2251.21.0113 (in SIIS «Electronic budget» agreement No. 075-15-2021-1392).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors are grateful to the Mendeleev Center for the Collective Use of Scientific Equipment for the optical measurements.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ginzburg, V. L. On Superconductivity and Superfluidity (What I Have and Have Not Managed to Do), as Well as on the “physical Minimum” at the Beginning of the XXI Century (December 8, 2003). Physics-Uspekhi 2004, 47, 1155–1170. [Google Scholar] [CrossRef]

- Bertone, G.; Tait, T. M. P. A New Era in the Search for Dark Matter. Nature 2018, 562, 51–56. [Google Scholar] [CrossRef] [PubMed]

- Empl, A.; Jasim, R.; Hungerford, E.; Mosteiro, P. Study of Cosmogenic Neutron Backgrounds at LNGS. 2012. [Google Scholar] [CrossRef]

- Gavriljuk, J. M.; Gangapshev, A. M.; Gezhaev, A. M.; Kazalov, V. V.; Kuzminov, V. V.; Panasenko, S. I.; Ratkevich, S. S.; Smolnikov, A. A.; Yakimenko, S. P. Working Characteristics of the New Low-Background Laboratory (DULB-4900). Nucl. Instruments Methods Phys. Res. Sect. A Accel. Spectrometers, Detect. Assoc. Equip. 2013, 729, 576–580. [Google Scholar] [CrossRef]

- Westerdale, S.; Meyers, P. D. Radiogenic Neutron Yield Calculations for Low-Background Experiments. Nucl. Instruments Methods Phys. Res. Sect. A Accel. Spectrometers, Detect. Assoc. Equip. 2017, 875, 57–64. [Google Scholar] [CrossRef]

- Kroll, W. The Production of Ductile Titanium. Trans. Electrochem. Soc. 1940, 78, 35. [Google Scholar] [CrossRef]

- Zykova, M.; Voronina, E.; Chepurnov, A.; Rymkevich, D.; Tankeev, A.; Vlasov, S.; Chub, A.; Avetissov, I. Role of Magnesium in Ultra-Low-Radioactive Titanium Production for Future Direct Dark Matter Search Detectors. Materials (Basel). 2022, 15, 8872. [Google Scholar] [CrossRef] [PubMed]

- Software package MCC-MT (Monte Carlo Calculation Multi Thread) - https://www.tals.eu/mcc-mt.

- Zhang, C.; Mei, D.-M.; Mei, D.; Kudryavtsev, V.A.; Fiorucci, S. Cosmogenic Activation of Materials Used in Rare Event Search Experiments. Astropart. Phys. 2016, 84, 62–69. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).