1. Introduction

In various parts of the world, rural populations face challenges in accessing simple, cost-effective, and locally produced water treatment technologies. Unfortunately, research on water supply options for rural and remote regions is often overshadowed by the issues encountered in urban areas. Advanced and centralised technologies, designed for large-scale operations and skilled personnel, cannot be directly applied to smaller systems due to factors such as energy efficiency, robustness, resilience, and staffing requirements, all of which justify the exploration of alternative solutions [

1]. In this context, passive decentralised water treatment systems emerge as an appealing option. They have been developed to reduce maintenance requirements, diminish the reliance on trained operators, simplify design, and allow for potential off-grid operations [

2].

We recently proposed a passive decentralised treatment option comprising the Biological Ion Exchange (BIEX) process combined with gravity-driven membrane filtration (GDM). This system demonstrated the ability to operate for over 60 days without backwash or regeneration, producing potable water using turbid (5-10 NTU) and coloured (TOC ≈ 7 mg C/L) river water [

3]. The BIEX filtration process involves the operation of an anionic resin with sporadic regeneration to deplete pre-loaded anions (typically chloride). It operates in the secondary Ion Exchange (IEX) region, taking advantage of the self-regeneration induced by naturally occurring anions in the influent water, such as bicarbonate and/or sulphate anions [

4]]. These are displaced by NOM from the influent water. Delaying the regeneration stage reduces secondary pollution from spent brine, transport of regeneration chemicals, maintenance, and costs [

5]. However, the BIEX is not a robust treatment for particulate matter.

GDM filtration, whether utilising ultrafiltration or microfiltration, is considered an efficient removal process. This method necessitates a simple and compact installation, fewer ancillary equipment, lower energy consumption, and operators with lower skill levels [

6]. Based on the aforementioned advantages, BIEX resin pretreatment followed by GDM filtration appears to be a competitive process for eliminating turbidity, colour, and NOM in decentralised surface water treatment applications. For such applications, selecting the right membrane type is essential, maximising productivity and permeate water quality. Comparing the permeability of polymeric and ceramic membranes, it is observed that, for a similar MWCO, polymeric membranes often exhibit higher clean water permeability than ceramic membranes due to the module design (hollow fibre vs. monolithic for ceramics) [

7,

8,

9]. Concerning fouling tendency, some studies have reported similar [

10] or slightly lower [

11] fouling for ceramic membranes. In general, the production cost of ceramic membranes (capital cost) exceeds that of polymeric membranes [

12]. However, the higher cost of ceramic membranes can be offset by their longer lifespan, approximately 20 years, roughly twice that of polymeric membranes [

13,

14].

A crucial advantage of ceramic membranes is their ability to undergo aggressive chemical and physical cleaning without damaging the membrane materials. Given that GDM processes aim to minimise physical and chemical backwashes, the question arises whether the advantages of ceramic membranes are justified in such applications. Alresheedi et al. [

13] demonstrated that backwashes were twice as effective for removing NOM fouling from a ceramic UF (SiC) membrane compared to a polymeric PVDF UF membrane. However, no differences in the removal of irreversible fouling by NaOH and NaOCl were observed between the two membrane types. To date, no equivalent evaluation has been performed to compare the cleaning performances of ceramic and polymeric membranes used in GDM filtration.

A current industry trend involves conducting more frequent yet less aggressive chemical washes to manage fouling [

15]. Such a strategy, often referred to as chemically enhanced backwash, contrasts with GDM operation, where low maintenance is desired, and cake filtration is favoured to stabilise the flux. Consequently, the chemical washing strategy will necessarily differ for GDM filtration systems installed in small decentralised systems. Research is needed to define the optimal chemical conditions and potential benefits of using ceramic membranes to enable aggressive chemical washes of membranes that have been operated for several months without cleaning.

In the present study, the performances of two ceramics (commercial UF and lab-made MF) and two polymeric membranes (commercial UF and MF) were compared during the treatment of turbid, coloured river water with high NOM content using a hybrid BIEX resin + GDM filtration process. After approximately 76 days of operation, physical (air/water backwash with enhanced or decreased air/water flow and pressure) and various chemical cleaning conditions (250 or 500 mg Cl2/L of NaOCl; 20 or 40 mM of NaOH) were tested on the membranes to quantify the removal of different fouling types (reversible/irreversible, physical/chemical). Finally, the effects of the physical cleaning conditions (air/water backwash flow and pressure) and the impact of increasing the chemical agent concentration during chemical cleaning on the flux recovery and fouling removal of each membrane type are discussed.

2. Materials and Methods

2.1. Biological Ion Exchange Resin and Gravity-Driven Filtration Experiments

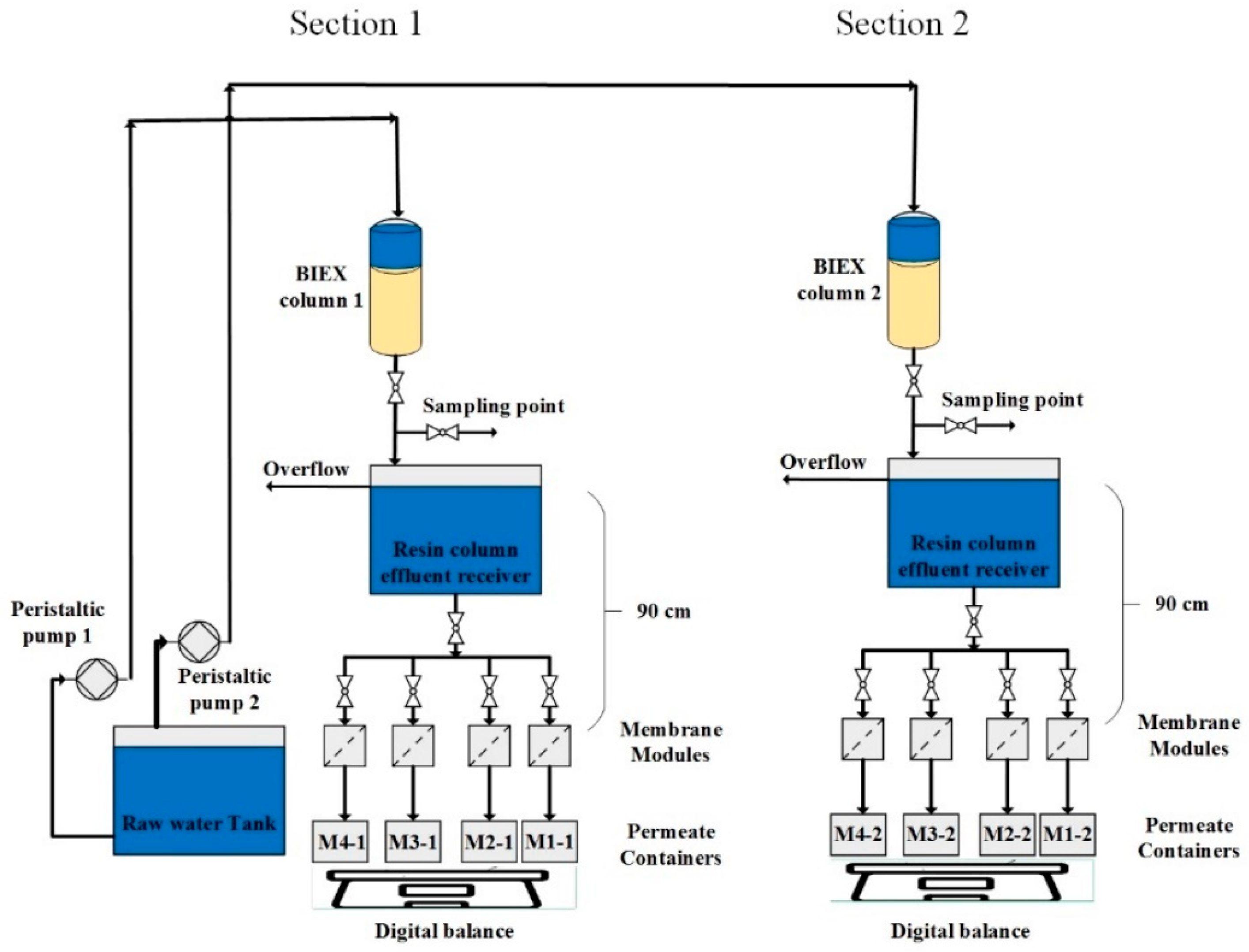

Figure 1 illustrates the experimental setup, consisting of two identical pilots (Sections 1 and 2). Each section comprised a resin column and four parallel membranes. A transparent PVC column (H = 63 cm, ϕ = 1.27 cm) was filled with an approximately 42-cm bed height of resin (resin Bed Volume ≈ 52 mL). The empty bed contact time (EBCT) and filtration rate of the resin column were kept constant at 15 min and 3.47 mL/min (≈ 4 BV/h), respectively, values chosen based on previous studies in our group [

4,

5]. The experiment lasted approximately 76 days (≈ 7,300 BV), sufficient for achieving secondary IEX (NOM exchange with bicarbonate and/or sulphate). In this study, Purolite A860

®, a strong base anion macroporous exchange resin (pre-loaded with chloride), was used. The resin was regenerated after 6,530 BV (day 68) using NaCl (100 g/L, 2 BV/h, and 1.5 h). The anions loading of the resin was calculated using equation (1), where

q (eq/L resin) is the cumulative anion loading on the resin, C

in and C

out are the concentrations of each anion in the inlet and outlet of the resin column (eq/L), V

resin is the total resin volume in the column (52 mL), Q is the flow rate (5 L/d),

is the time between each anion and DOC measurement (d), and i is the number of anions measurements during the experiment. The charge balance was calculated only for chloride, sulphate, bicarbonate, DOC, and nitrate, which were the major negatively charged compounds during the IEX [

16].

Four polymeric/ceramic MF/UF membranes were used for the membrane sections. The membrane compositions are listed in

Table 1. All the membranes used in this study are commercially available, except for M4 (ceramic lab-made MF) which is a flat-sheet disk-shaped ceramic MF membrane made in our laboratory, as described in Section 2.1.1. The equipment in the membrane section was covered with aluminium foil to prevent algal growth. In the receiver of the resin column effluent, an overflow was placed to maintain a transmembrane pressure of 90 cm H

2O (≈ 93 mbar). The temperature was maintained at 21.2 ± 0.7 ˚C by the laboratory air conditioning system. The flux of the membranes (in LMH) was calculated by weighing the daily permeate volume and then normalising it to 20˚C.

M4 Membrane Synthesis

To fabricate M4 (ceramic MF), deionised (DI) water was incrementally introduced into a mixture of kaolin clay (Ward’s Science, Rochester, NY, USA; Al

2O

3.2SiO

2.2H

2O, CAS: 1332-58-7) and boric acid (10 wt%, Ward’s Science, Rochester, NY, USA; H

3BO

3, CAS: 10043-35-3, crystals) to make a suitable dough. Subsequently, the dough was mixed at approximately 100 rpm with a mechanical mixer for 10 minutes. Following this, about 25 g of the mixture was transferred to a disk-shaped mold equipped with a cap. A pressure of 7.3 MPa (Pressure Sensor Product Inc., Madison, NJ, USA) was applied to the cap to compress the mixture and form the disk-shaped membrane, using a clamp (a piece of freezer bag was interposed between the cap and the mold to prevent adhesion during cap removal). After placing the mould on a glass plate, the cap and plastic bag were cautiously removed. Alumina powder (10 wt% of kaolin, Fisher Scientific, Switzerland; Al

2O

3, 40–300 μm, CAS: 1344-28-1, Mw = 101.96 g/mol) was gently poured onto one side of the formed membrane to cover the entire surface. The membrane was then extracted from the mold after drying for a minimum of 24 hours at room temperature. Finally, calcination was carried out at 1100˚C for 2 hours using an electric programmable furnace (Ney Vulcan, 3-550). Seven membranes were synthesised for each experiment. Characterisations, such as DI water flux, porosity, pore size, SEM images, and Energy Dispersive X-ray (EDX) spectra, are provided in the

Supplementary Information (

Figure S1,

Figure S2,

Table S1).

2.2. Characteristics of Influent Water

The experiment was conducted between October and December 2022. A single raw water sample volume of 800 L was collected using 20-L buckets at the entrance of the Pont-Viau water treatment plant (Laval, Canada). The raw water originates from the Des Prairies River. The water was promptly stored at 4°C after collection. Once a week, approximately 80 L of the collected water was extracted from the refrigerator and allowed to attain room temperature (≈ 22 ˚C) for at least 5 h before adding it to the influent water tank. The physical and chemical characteristics of the influent water from the Des Prairies River are detailed in

Table 2, encompassing DOC, turbidity, pH, alkalinity, UVA

254, nitrate, sulphate, and chloride. These low uncertainties indicate relatively constant influent water characteristics during storage.

2.3. Physical and Chemical Cleaning of the Membranes

Physical and chemical cleaning was conducted after 30 days of operation to investigate the dominant fouling type and assess the impact of increasing the chemical cleaning agent concentration (during chemical cleaning) and air/water backwash flow and pressure (during physical cleaning) on membrane flux recovery and the removal of different fouling types. The procedures and steps of the cleaning processes are outlined in

Table 3 and

Figure S3. Physical cleaning involved air and DI water backwashing. After halting the normal filtration process, the fouled membrane surfaces were turned face down (

Figure S3a), followed by air backwashing in section 1 at P = 30 psi, Q = 5 L/h, and t = 2 min; in section 2 at P = 15 psi, Q = 2.5 L/h, and t = 2 min (

Figure S3b,c). Subsequently, a DI water backwash was performed for 4 h under the conditions shown in

Figure S3d, with back pressures of 120 and 90 cm H

2O for sections 1 and 2, respectively. The membranes were then returned to their normal filtration position (

Figure S3e) to measure the DI water flux (

Figure S3f) and calculate the flux recovery using Equation 2.

In equation 2, Jac is the flux after cleaning (physical or chemical), and Jv is the water flux of the virgin membranes, both measured at 90 cm H2O pressure and T= 20 ˚C.

Chemical cleaning procedure commenced by washing membranes with 40 mM of NaOH (pH = 12.40) for t = 6h, T = 21 ˚C, and 90 cm H

2O pressure in section 1. For section 2, 20 mM of NaOH (pH = 12.16) was used for t = 6h, T = 21 ˚C, and 90 cm H

2O pressure (

Figure S3g). After washing with NaOH, the DI water permeability was measured to calculate flux recovery (

Figure S3h). Chemical cleaning was then performed by washing the membranes with NaOCl at concentrations of 500 and 250 mg Cl

2/L in Sections 1 and 2, respectively, both at t = 6h and 90 cm H

2O pressure (

Figure S3i). Finally, the DI water permeability was measured to obtain flux recovery using NaOCl (

Figure S3j).

The total fouling resistance (m

-1, R) during filtration was obtained using Darcy’s law as follows:

where μ

T is the permeate viscosity at temperature T, J

T is the permeate flux measured at temperature T, and ΔP is the hydrostatic pressure.

is the clean membrane resistance calculated using the clean water permeability of the virgin membranes.

Total fouling resistance consists of 1) Hydraulically reversible fouling, fouling caused by cake layer formation on the membrane surface (biofilm) which is removable by backwash (air + water), 2) Hydraulically irreversible fouling, fouling caused by pore blocking which is not removable by backwash (air + water), 3) Chemically reversible fouling, fouling caused by pore blocking which is removable by chemical cleaning (NaOCl and NaOH), 4) Chemically irreversible fouling, fouling which persists after chemical cleaning.

2.4. Analytical Methods for Water Samples

DOC in the water samples was measured after filtration through a prewashed 0.45 µm filter and analysed with a TOC analyser (Sievers M5310C, Trevose, PA, USA). To convert the concentration from mg C/L to eq/L, the charge density of DOC (NOM) was considered to be 10 meq/g C at pH 6.5 [

17] for the anion charge balance. Turbidity was measured using a turbidity meter (TL2300, Hach, Loveland, Col, USA) after calibration with standard samples. The UVA

254 was measured using a UV-visible spectrophotometer (Cary 100 Scan, Varian Inc., USA) on 0.45 µm filtered samples. pH was measured using a pH meter (Accumet AB 15 basic; Fisher Scientific, Waltham, MA, USA) calibrated with standard solutions. Bicarbonate concentration (alkalinity) was determined using the standard titration method with 0.01M H

2SO

4 as the titrant. To measure the anions in the BIEX resin column effluent and influent water, samples were filtered through 0.45 µm syringe filters and analysed using an ion chromatography device (ICS 5000 AS-DP DIONEX, Thermo Scientific, Waltham, MA, USA).

2.5. Measurement of Biofilm Thickness

To study the mean biofilm/cake thickness during filtration (especially before and after membrane cleaning), optical coherence tomography (OCT) imaging was routinely performed on the membranes which were removed from the system for approximately 30 min. For each OCT image, three random locations were selected from the membranes. Raw OCT images were obtained using a Thorlabs SL1310V1 laser (Newton, NJ, USA). The mean biofilm thickness was determined using MATLAB and ImageJ software (NIH, USA). The details and conditions of the OCT imaging have been previously reported [

18].

2.6. Statistical Analysis of Data

Analysis of variance (ANOVA) was used in Microsoft Excel® and GraphPad Prism® (10.0.02) software before membrane cleaning day to investigate the effect of the membrane types on the stabilised flux. Moreover, ANOVA was performed after membrane cleaning to determine the effect of membrane type, chemical agent concentration (in chemical cleaning), and air/water backwash flow (in physical cleaning) on the stabilised flux (as the dependent variable) achieved after the washes. The stabilised flux is defined as a flux data group (from the flux stabilisation day to the end of the operation) in which the slope of the flux – time diagram is not statistically significant than zero.

3. Results and Discussion

3.1. Operation of the BIEX Process

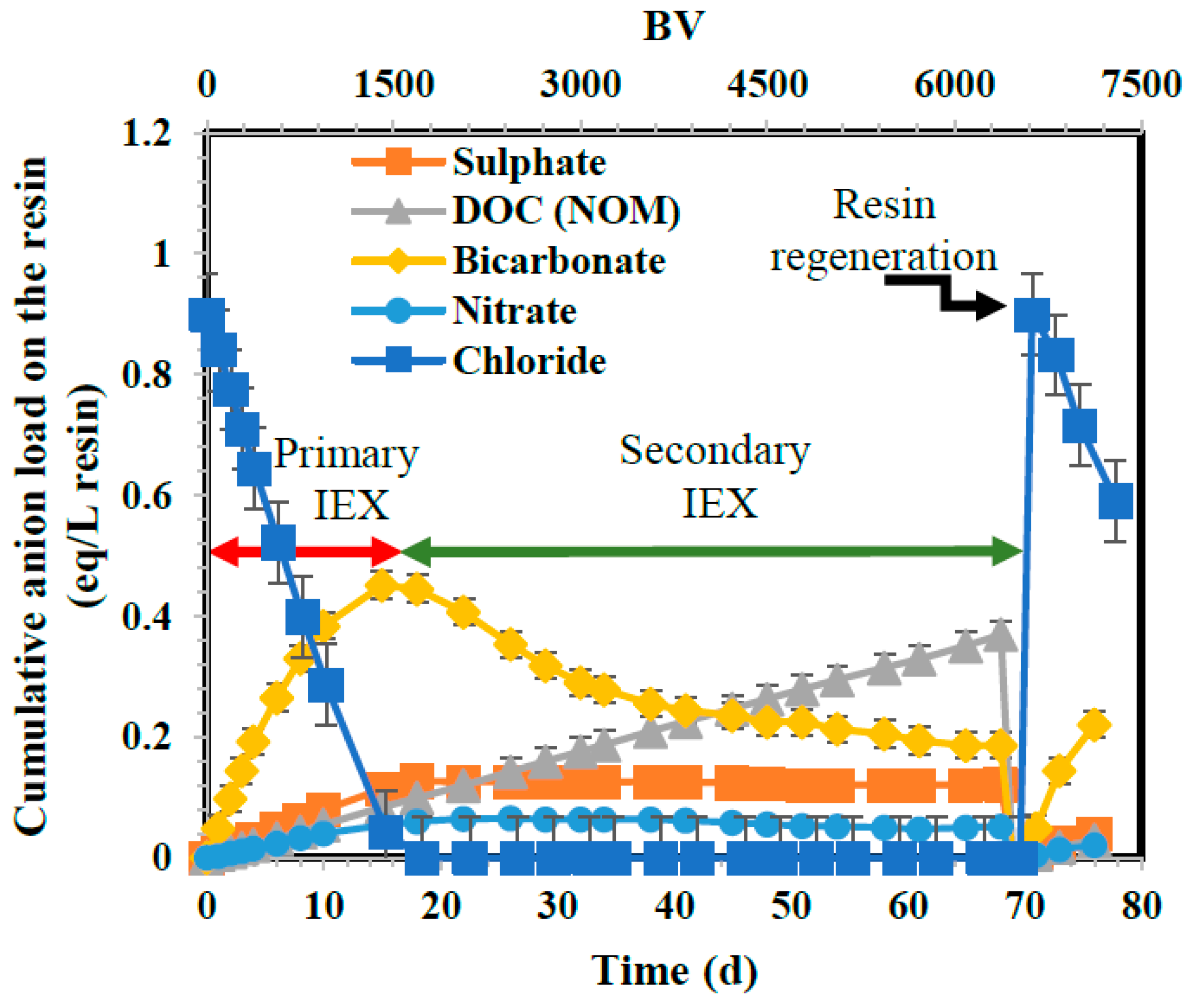

Figure 2 illustrates the calculated anion loading on the resin during the 68-day operation (6,528 BV) in Column 1. Results for Column 2, depicted in

Figure S4, will not be discussed as they exhibited similar behaviour to those in Column 1. The primary IEX capacity of the fresh resin, approximately 0.9 eq/L resin, was depleted after 18 days of operation (1,728 BV). At this juncture, the estimated loadings for DOC, bicarbonate, sulphate, and nitrate were 0.10, 0.45, 0.13, and 0.07 eq/L, respectively. From day 18 to day 68 (1,728 to 6,528 BV), the secondary IEX (BIEX mode) enabled the displacement of bicarbonate, sulphate, and nitrate anions by DOC. Consequently, the loadings for bicarbonate, sulphate, and nitrate decreased to 0.20, 0.10, and 0.04 eq/L, respectively, while NOM increased from 0.10 to 0.37 eq/L at 6,528 BV. After performing regeneration on day 68 (6,528 BV), the resin capacity (0.9 eq/L) was fully recovered using chloride (returning to the primary IEX region).

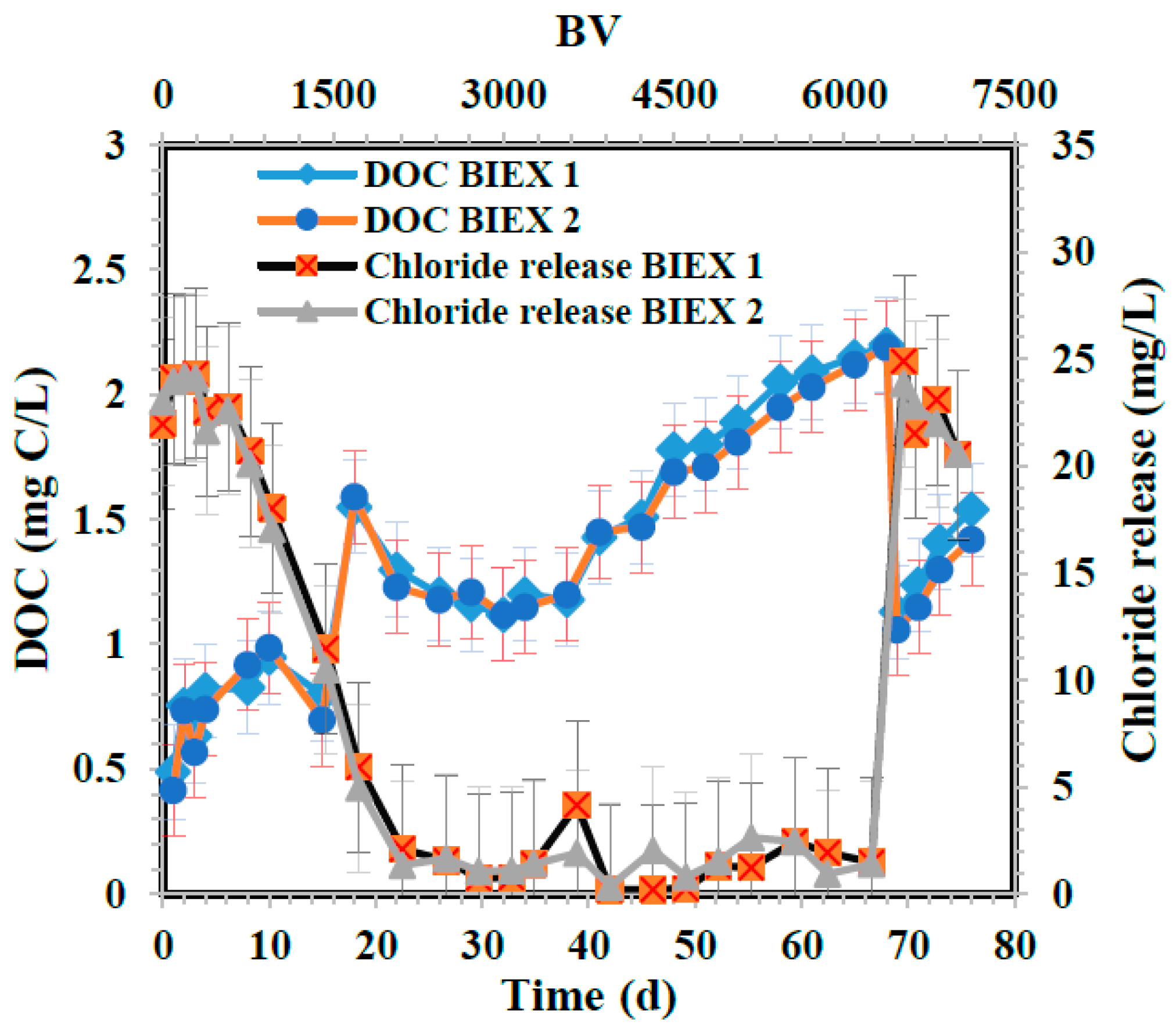

Figure 3a displays variations in effluent DOC and chloride release for BIEX-1 (BIEX column in Section 1) and BIEX-2 (BIEX column in Section 2). Both columns exhibited equivalent performance. Initially, the effluent DOC of the resin columns was 0.4 mg C/L when the chloride release from the columns was 23 mg/L. The chloride release decreased to 1.3 mg/L at approximately 1,728 BV (day 18), while the DOC of the column effluent peaked at 1.55 mg C/L. Considering a constant DOC concentration in the influent water (7.04 mg C/L ± 0.18), DOC removal at the end of the primary IEX was 78%. From 1,728 BV (day 18) to 6,528 BV (day 68), in the secondary IEX region, DOC initially decreased due to the exchange of NOM with bicarbonate and sulphate anions. DOC remained constant from 3,000 to 4,000 BV and then progressively rose to 2.2 mg C/L after 6,528 BV (day 68). DOC removal remained high (68%) after 68 days of operation. At this point, the resin was regenerated, decreasing the DOC of the BIEX column effluent to 1.05 mg C/L and increasing chloride release back to 23 mg/L. A similar behaviour was observed for UVA

254 (

Figure S5a), except for the higher removal rates compared to DOC, given that humic substances have a higher affinity for the resin. The variation in the turbidity of the BIEX column effluent is shown in

Figure S5b.

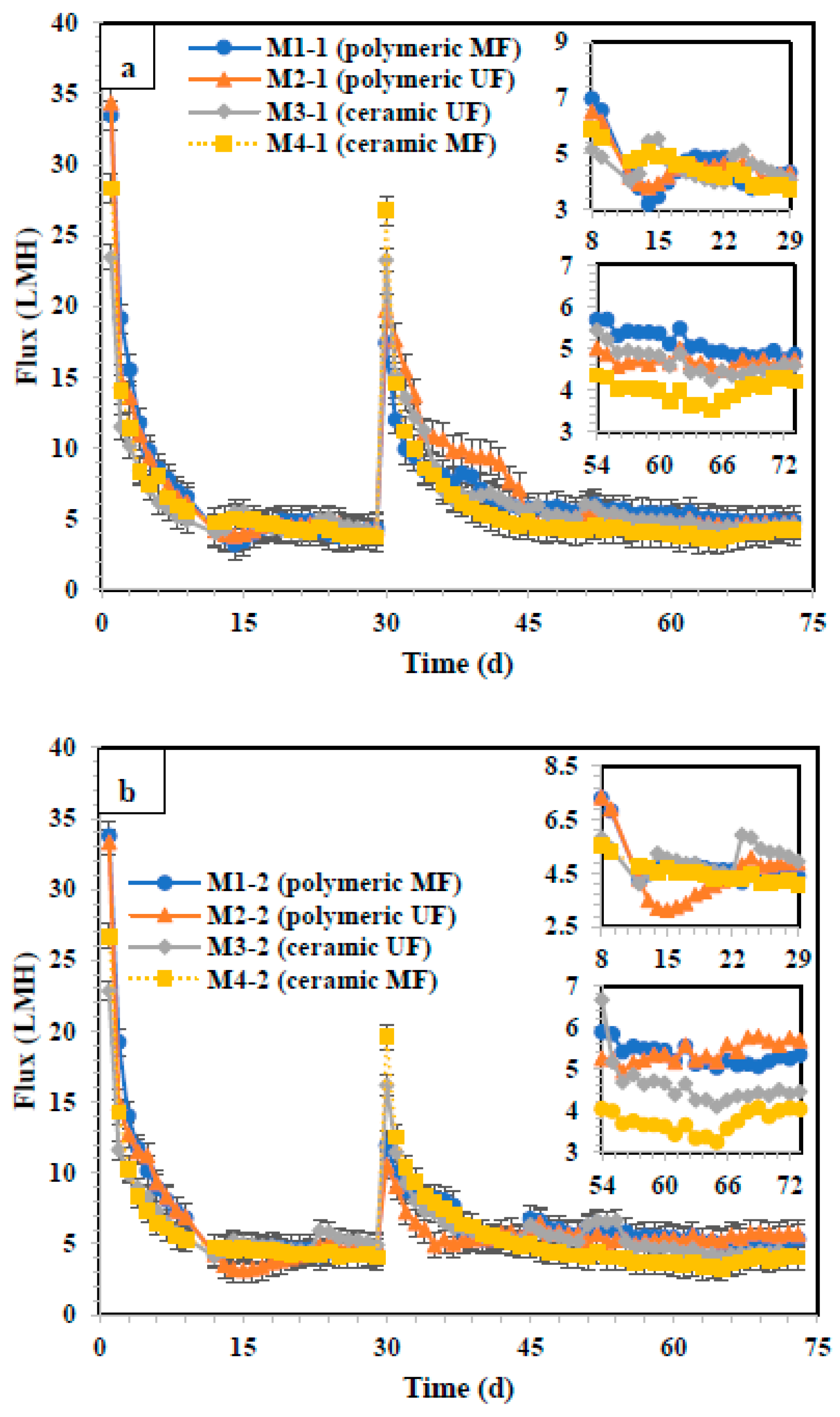

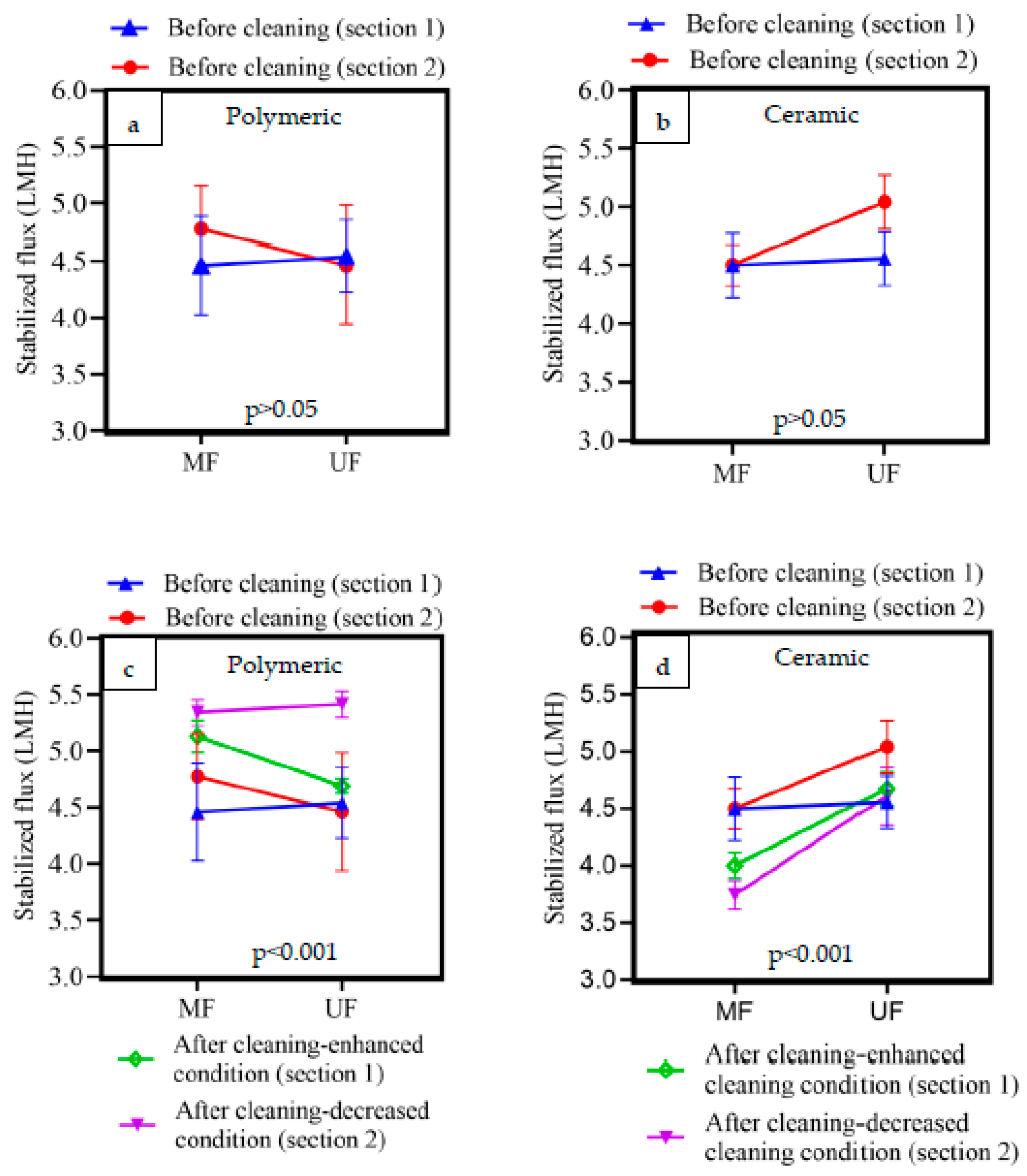

3.2. Effect of Membrane Type and Cleaning Process on the Stabilised Flux and Flux Recovery

The variation in flux over time is shown in

Figure 4. In both pilot sections before the membrane cleaning process (days 1 – 29), the flux stabilised at approximately day 8, after an initial steep flux decline period. To validate the flux stabilisation, the observed flux between days 8 and 29 for each membrane type in both sections was fitted to a linear regression, and the calculated slopes were not statistically higher than zero (p-values of slopes for both sections were > 0.05), indicating a stable operating condition. The mean stabilised fluxes of the membranes from days 8 to 29 in Sections 1 and 2 are shown in

Table 4. Prior to membrane cleaning (days 1 – 29), the stabilised flux was affected by the membrane type (polymeric/ceramic, MF/UF), although the difference was fairly modest. For example, the average stabilised flux from day 8 to 29 for the membranes in sections 1 and 2 were measured as 4.46 – 4.56 LMH and 4.46 – 5.04 LMH, respectively (

Table 4). The differences in the stabilised flux from the membranes in Sections 1 and 2 were not statistically significant (

Figure 5a, b; p > 0.05). This implies that the cleaning conditions described in Section 1 can be compared to those described in Section 2.

After membrane cleaning (days 30 – 73), the flux stabilisation period was reached on approximately day 54 in both sections. Similarly, to confirm flux stabilisation, the flux from days 54 to 73 was fitted to a linear regression, and the obtained slopes were not statistically different from zero (p > 0.05). Average stabilised flux of the membranes during day 54 – 73 varied between 4.00 and 5.15 LMH (in section 1,

Table 4) and 3.75 – 5.34 LMH (in section 2).

After cleaning the polymeric membranes (

Figure 5c), stabilised fluxes increased significantly (p < 0.001) from 4.46 (MF) – 4.54 (UF) LMH to 5.13 (MF) – 4.69 (UF) LMH (after enhanced cleaning condition in section 1) and from 4.77 (MF) – 4.46 (UF) LMH to 5.34 (MF) – 5.41 (UF) LMH (using the less stringent cleaning condition in section 2). Although statistically significant (p < 0.001), increasing the cleaning intensity did not substantially improve stable fluxes from a practical perspective. The membrane type (UF vs. MF) was equally impacted by the cleaning conditions for the ceramic membranes. After cleaning the ceramic membranes (

Figure 5d), the stable MF flux declined for both cleaning conditions (Sections 1 and 2), while the UF was not impacted by cleaning in Section 1 which was subjected to enhanced cleaning conditions. In contrast, the ceramic UF in Section 2, which was subjected to a lower cleaning condition, exhibited a stabilised flux decline of 8.5 %. We suspect that the chemical cleaning led to pore plugging in the ceramic MF membranes, which in turn led to the lower observed stabilised fluxes. During the clean-in-place process, some foulants are solubilised and can penetrate the membrane pores, causing internal clogging when the membranes return to normal operation. In summary, cleaning the membranes generally led to a fairly modest increase in stable flux, except for ceramic MF membranes.

The flux recoveries and foulant reversibilities after physical and chemical washes are shown in

Table 5 and

Table 6, respectively. According to

Table 5, most membrane fouling was hydraulically reversible (57-80%). The additional recoveries provided by cleaning with NaOH or NaOCl were modest, typically less than 10%.

The membranes in Section 1 with enhanced air/water backwash flow and pressure showed higher flux recoveries (i.e. hydraulic reversible fouling removal, 67–79 %) than those in Section 2 (57 – 75%) which were subjected to a less intense air/water backwash flow and pressure (

Table 6). The foulants were more hydraulically reversible on the ceramic membranes (70 – 79%) than on the polymeric membranes (57 – 69%). These findings suggest that it was simpler to remove foulants from ceramic membranes than from polymeric membranes using a basic backwash method involving air and water. The foulants left on the polymeric membranes after physical cleaning were difficult to remove by chemical cleaning. On an average, 26% of the foulants were chemically irreversible. In contrast, the ceramic membranes had the lowest fraction of irreversible fouling (13%), with the UF ceramic (M3) providing the lowest overall irreversible fouling among all the membranes tested (5.1%).

Regarding the impact of chemical wash strength on recovery, increasing the NaOH concentration from 20 to 40 mM led to an increase in recovery from 2–4% to 4 – 6% for the polymeric membranes and from 4 –7% to 7 – 12% for the ceramic membranes. For NaOCl, a lower concentration (250 mg Cl2/L) led to a flux recovery of 4 – 6% for polymeric membranes and 1 – 2% for ceramic membranes, whereas a higher concentration (500 mg Cl2/L) led to equivalent recoveries of 5 – 7% for all membranes. Overall, all the chemical washes provided low flux recoveries. According to these results, optimising physical cleaning appears to be a better strategy than using chemical washes to reduce operating costs, simplify operations, and minimise secondary pollution.

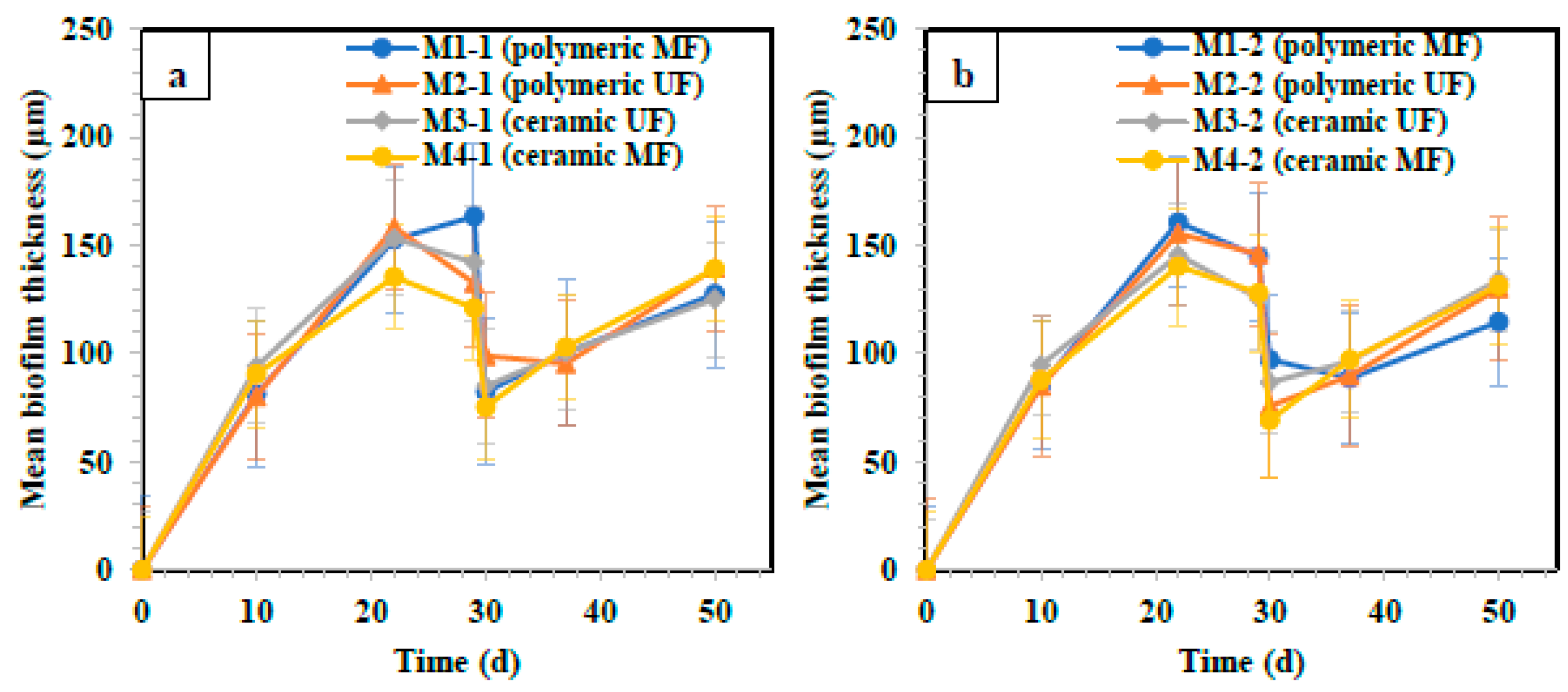

3.3. Mean Biofilm Thickness Formed on the Membrane Surface during Operation

To study the variation in the average thickness of the cake/biofilm accumulated on the membrane during filtration in sections 1 (

Figure 6a) and 2 (

Figure 6b), OCT imaging was performed on days 10, 22, 29, 30, 37, and 50. Raw OCT images of all the membranes before (day 29) and after cleaning (day 30) are shown in

Figure S7. In section 1, mean cake/biofilm thickness of M1 (polymeric MF) and M2 (polymeric UF) was measured as 80 µm on day 10. For ceramic membranes of M3 (ceramic UF) and M4 (ceramic lab-made MF), average thickness was 90 µm on the same day. The cake/biofilm thickness increased by more than 1.5 times for all the membranes until day 22. After that, the thicknesses experienced a slight decrease by approximately 15 – 20 µm for all the membranes except M2 (polymeric UF) which may be due to the detachment of the aged biofilm on the membrane surface [

19,

20]. On day 30, after the cleaning procedure, the mean thickness decreased substantially to 82, 98, 84, and 75 µm for M1 (polymeric MF), M2 (polymeric UF), M3 (ceramic UF), and M4 (ceramic lab-made MF) respectively. Physical cleaning (increased hydraulic reversible fouling removal) explains the marked decrease in biofilm/cake thickness from the membrane surface. Subsequently, the thickness increased almost linearly by day 50 after the filtration. The mean biofilm thickness was not significantly different between sections 1 and 2 (p > 0.05) on day 30. After membrane cleaning event on day 30 in section 2, the thickness was 97, 86, 75, and 69 µm for M1 (polymeric MF), M2 (polymeric UF), M3 (ceramic UF), and M4 (ceramic MF), respectively. In Section 1, which was subjected to the enhanced air/water backwash which resulted in higher flux recoveries (higher hydraulic reversible fouling removal), a lower mean biofilm thickness was expected for all membranes compared to those in Section 2. However, in practice, only two out of four membranes (polymeric MF and ceramic MF) showed lower thicknesses owing to more aggressive cleaning.

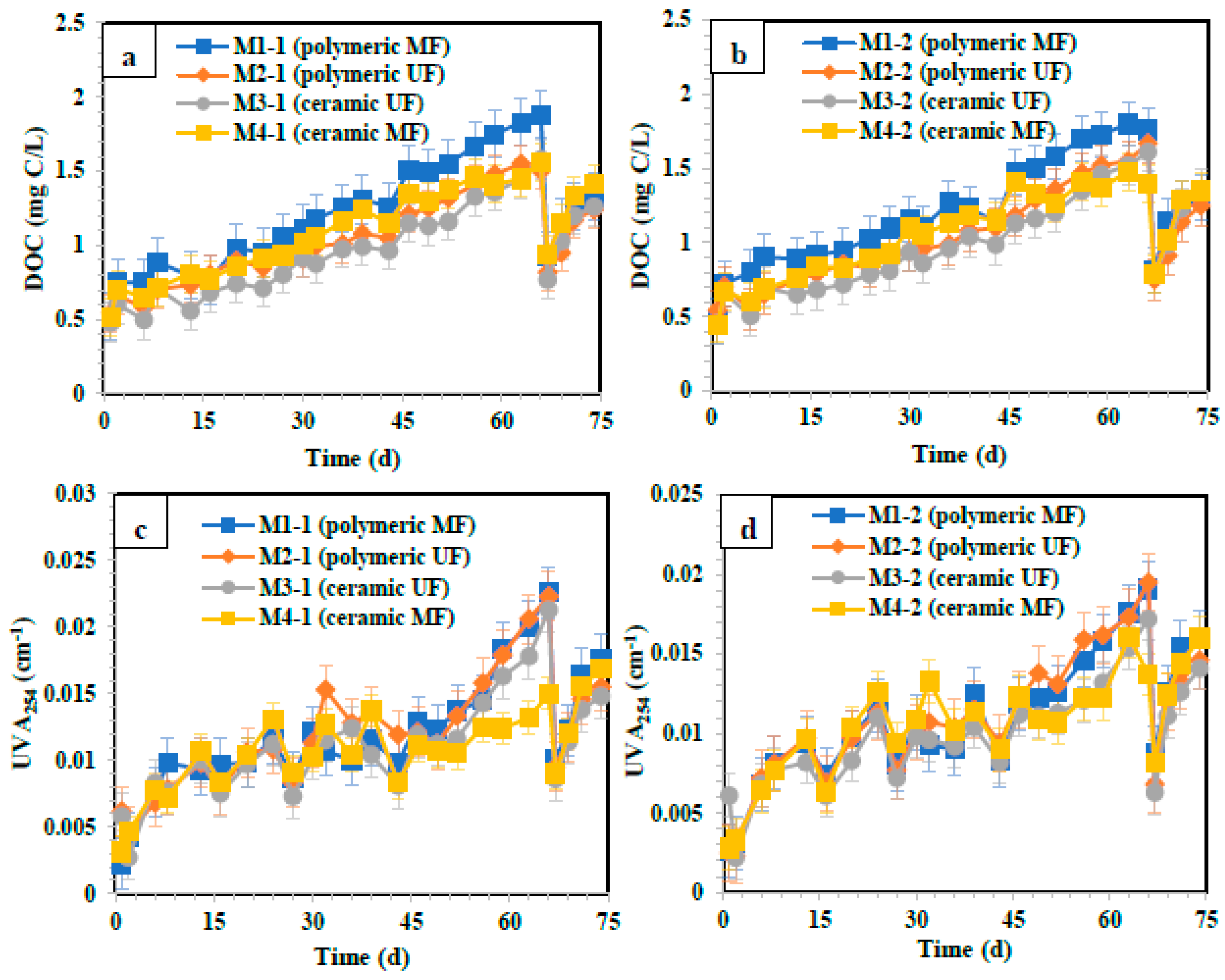

3.4. Permeate Quality of the Polymeric and Ceramic Membranes during the Operation

The evolution of the permeate DOC of the membranes in Sections 1 and 2 is shown in

Figure 7a, b. In section 1, the DOC concentrations of membrane effluents started at approximately 0.5 mg C/L, rose progressively to 1.88, 1.55, 1.58, and 1.56 mg C/L for M1 (polymeric MF), M2 (polymeric UF), M3 (ceramic UF), and M4 (ceramic MF), respectively by day 68. M1 (polymeric MF) removed DOC by approximately 15%, whereas DOC removal using M2 (polymeric UF), M3 (ceramic UF), and M4 (ceramic MF) was approximately 30% on Day 68, compared to the DOC of the BIEX column effluents. Based on

Figure S8a, mean DOC of M3 (ceramic UF) from days 1 – 68 showed the lowest concentration (0.94 mg C/L) among all membranes. After resin regeneration on day 68, the permeate DOC of all the membranes decreased markedly to a value slightly higher than that on the initial day. The performance of the membranes for DOC removal in Section 2 shows a trend similar to that in Section 1. Likewise, according to

Figure S8b, M3 (ceramic UF) showed the best performance of DOC removal (mean DOC during days 1 – 68 = 0.96 mg C/L) in section 2. Therefore, it can be concluded that the increased air/water backwash flow and pressure (during physical cleaning), and chemical agent (NaOCl, NaOH) concentration (during chemical cleaning) in this study had no visible impact on DOC removal by membrane filtration.

UVA

254 exhibited the same trend as DOC in both sections (

Figure 7c,d). UVA

254 in section 1 started at approximately 0.003 cm

-1 for all membranes. This figure then increased by a fluctuating trend to 0.023, 0.022, 0.021, and 0.015 cm

-1 for M1 (polymeric MF), M2 (polymeric UF), M3 (ceramic UF), and M4 (ceramic MF), respectively, by Day 68. UVA

254 removal using M1 (polymeric MF), M2 (polymeric UF), and M3 (ceramic UF) on day 68 was approximately 37%, whereas M4 (ceramic MF) removed approximately 57% of the UVA

254 compared to the effluent of the BIEX column. According to

Figure S8c,d, the mean of UVA

254 from days 1 – 68 was approximately 0.01 cm

-1 for all the tested membranes in both sections, a very high performance. Similarly, no marked influence of variations in air/water backwash flow, pressure, and chemical agent concentration during physical and chemical cleaning on UVA

254 removal was observed. As expected, resin regeneration on day 68 decreased UVA

254 in permeates in both sections to approximately 0.009 cm

-1. In Section 2, the performance of the membranes in terms of UVA

254 removal shows a trend very similar to that in Section 1.

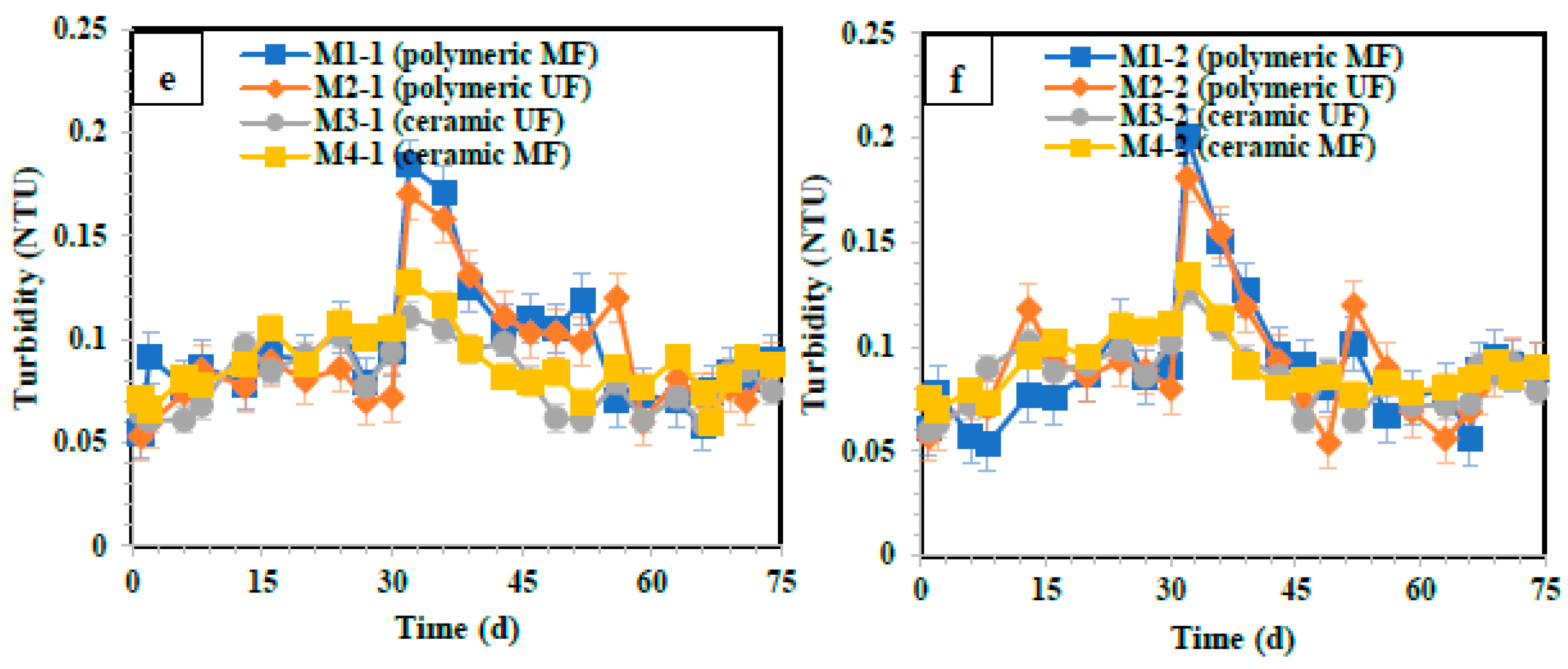

The evolution of turbidity during filtration in Sections 1 and 2 is shown in

Figure 7e and f, respectively. In Section 1, during days 1 – 29 (before membrane cleaning), the polymeric (M1 and M2) and ceramic (M3 and M4) membranes showed similar performances. Turbidity started at approximately 0.05 NTU, followed by a fluctuating upper trend to 0.05 – 0.1 NTU until day 29. Immediately after membrane physical and chemical cleaning on the day 30, turbidity experienced a peak at approximately 0.17 NTU for M1 (polymeric MF) and M2 (polymeric UF), and 0.12 NTU for M3 (ceramic UF) and M4 (ceramic MF). Attributing to the higher mechanical strength of the ceramic membranes during physical cleaning, the turbidity peaked at lower values for these membranes after physical cleaning than for the polymeric membranes. Then, the turbidity of all the membranes decreased and reached a stable value of approximately 0.09 NTU at the end of the filtration time. Based on

Figure S8e,f which is plotted using the turbidity data for the entire study, the membranes showed a turbidity of 0.08 – 0.09 NTU (mean of the turbidity during the whole filtration time). Based on the turbidity results, the physical and chemical cleaning processes of the membrane increased permeate turbidity for only a short period. Finally, the enhanced cleaning conditions (in Section 1) had no marked impact on the turbidity of the membrane permeates compared to those in Section 2.

5. Conclusions

Two commercial polymeric membranes of 0.1-µm MF (M1) and 0.03-µm UF (M2), and two ceramic membranes (300 kDa commercial UF (M3) and lab–made MF (M4)) were used in the BIEX + GDM hybrid process for treating river water. During operation, the IEX mechanism reached a secondary IEX (NOM displacement of bicarbonate and sulphate instead of chloride), and the membrane flux stabilised. The performance of the primary IEX (NOM displacement by chloride) and the secondary IEX was evaluated. Subsequently, the performance of both polymeric and ceramic membranes in terms of flux and permeate quality was studied. Furthermore, physical (air + water backwash) and chemical cleaning (NaOH 20 and 40 mM, NaOCl 250 and 500 mg Cl2/L) were performed to study the dominant fouling type causing the flux decrease in the membranes. Finally, the impacts of increasing the air/water backwash flow and pressure (during physical cleaning) and chemical cleaning agent concentration (during chemical cleaning) on stabilised flux, flux recovery, and permeate quality were investigated. The most important results obtained are as follows:

BIEX resin column successfully reduced DOC from 7.04 mg C/L to below 2 mg C/L over the 68 days of operation.

Before membrane cleaning (days 1 – 29), the fluxes of the membranes stabilised after day 8 at approximately 4.5 – 5 LMH. After membrane cleaning (days 30 – 73), the flux was restabilised after 24 days (i.e. on day 54). The new stabilised flux of the membranes was approximately 3.7 – 5.5 LMH at the end of the filtration, which was statistically significant. However, the difference was not substantial, indicating that the membrane material is not a key factor.

Before cleaning, the ceramic and polymeric membranes showed similar stabilised fluxes. After the cleaning process, the stabilised flux of the ceramic membranes decreased or remained constant, whereas that of the polymeric membranes increased under both enhanced and decreased cleaning conditions compared to that before cleaning.

The majority of membrane fouling (57%–80%) was hydraulically reversible. The membranes in Section 1, with enhanced air/water backwash flow and pressure, showed higher hydraulic reversible fouling removal than those in Section 2. Hydraulically reversible fouling removal was more efficient with ceramic membranes than with polymeric membranes. Chemical cleaning was not effective for removing hydraulically irreversible foulants. Therefore, we recommend performing physical learning and eliminating chemical cleaning steps.

The ceramic UF (M3) membrane showed the best permeate quality, with DOC and UVA254 removals of 30% and 37% on day 68, respectively, as measured against the influent (i.e., the BIEX effluent).

Physical and chemical cleaning had no measurable impact on DOC and UVA254, whereas physical cleaning increased the turbidity of the membranes for a short period. Resin regeneration decreased the DOC and UVA254 of the membrane permeates, whereas it had no significant impact on membrane turbidity.

According to the obtained results, most of the membrane fouling in the hybrid BIEX + GDM process was hydraulically reversible using an air/water backwash. Therefore, future research should focus on optimising physical cleaning to increase flux recovery and stabilise flux.

Supplementary Materials

The following supporting information can be downloaded at the website of this paper posted on

Preprints.org. Figure S1: SEM micrograph of the Lab-made membrane, demonstrating the kaolin support and the top alumina layer. Figure S2: a) SEM micrograph of the Lab-made membrane. Spectrums 1 and 2 show a small area in the kaolin support and alumina top layer. b) The Energy Dispersive X-ray (EDX) spectra of point 1 (in kaolin support), and c) EDX spectra of point 2 (in top alumina layer). Figure S3: Schematic of the steps in physical and chemical cleaning of the membranes. Figure S4: Dynamics of cumulative anion exchange on the resin of BIEX column 2 during the operation. Figure S5: Variations of a) UVA

254 and b) turbidity of BIEX column effluent during the operation. Figure S6: a) Variation of fouling resistance of membranes in section 1 during the filtration, and b) Variation of fouling resistance of membranes in section 2 during the filtration. Figure S7. OCT images of a) M1-1 (polymeric MF in section 1) before cleaning, b) M1-1 (polymeric MF in section 2) after cleaning, c) M2-1 (polymeric UF in section 1) before cleaning, d) M2-1 (polymeric UF in section 1) after cleaning, e) M3-1 (ceramic UF in section 1) before cleaning, f) M3-1 (ceramic UF in section 1) after cleaning, g) M4-1 (ceramic MF in section 1) before cleaning, h) M4-1 (ceramic MF in section 1) after cleaning, i) M1-2 (polymeric MF in section 2) before cleaning, j) M1-2 (polymeric MF in section 2) after cleaning, k) M2-2 (polymeric UF in section 2) before cleaning, l) M2-2 (polymeric UF in section 2) after cleaning, m) M3-2 (ceramic UF in section 2) before cleaning, n) M3-2 (ceramic UF in section 2) after cleaning, o) M4-2 (ceramic MF in section 2) before cleaning, and p) M4-2 (ceramic MF in section 2) after cleaning. Figure S8. a, b) Mean DOC in section 1and section 2 days 1 – 68 c, d) Mean UVA254 in section 1 and section 2 days 1 – 68, e. f) Mean turbidity in section 1 and section 2 during the whole operation period. M1 (polymeric 0.1 µm MF), M2 (polymeric 0.03 µm UF), M3 (ceramic 300 kDa UF), and M4 (Lab-made ceramic MF). The error bars show 95% confidence intervals. Table S1: Porosity, mean pore size and water flux of the lab-made membranes. Mean ± 95% confidence interval.

Author Contributions

conceptualization, Yaser Rasouli, Dominique Claveau-Mallet, Benoit Barbeau; methodology, Yaser Rasouli, Raphaël Maltais-Tariant; software, Yaser Rasouli, Raphaël Maltais-Tariant; formal analysis, Yaser Rasouli, Dominique Claveau-Mallet, Benoit Barbeau; resources, Caroline Boudoux, Dominique Claveau-Mallet, Benoit Barbeau; writing—original draft preparation, Yaser Rasouli; writing—review and editing, Yaser Rasouli, Dominique Claveau-Mallet, Benoit Barbeau, Raphaël Maltais-Tariant, Caroline Boudoux; supervision, Dominique Claveau-Mallet, Benoit Barbeau; funding acquisition, Caroline Boudoux, Dominique Claveau-Mallet, Benoit Barbeau. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Canada Research Chair for Decentralized and Small-Scale Water Treatment (file number 950-232871).

Institutional Review Board Statement

Not applicable.

Data Availability Statement

Data is contained in this article.

Acknowledgments

The authors would like to express their gratitude to the Polytechnique Montreal technicians and research professionals who assisted in setting up the hybrid BIEX + GDM system and provided technical support during the project. The individuals named are Gabriel St-Jean, Julie Philibert, Mélanie Bolduc, Tetiana Elyart, Jacinthe Mailly, and Yves Fontaine.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Omarova, A., et al., Water Supply Challenges in Rural Areas: A Case Study from Central Kazakhstan. Int J Environ Res Public Health 2019, 16. [CrossRef]

- Maniam, G., et al., An assessment of technological development and applications of decentralized water reuse: A critical review and conceptual framework. 2022, 9, e1588. [CrossRef]

- Rasouli, Y., et al., Performance of Biological Ion Exchange Resin and Gravity-Driven Ceramic Membrane Hybrid Process for Surface Water Treatment. Separation and Purification Technology 2023, 125769. [CrossRef]

- Liu, Z., et al., Operating bicarbonate-form versus chloride-form ion exchange resins without regeneration for natural organic matter removal. ACS ES&T Water 2021, 1, 1456-1463. [CrossRef]

- Amini, N., et al., Long-term performance of biological ion exchange for the removal of natural organic matter and ammonia from surface waters. Water research 2018, 146, 1-9. [CrossRef]

- Truttmann, L., et al., Gravity-driven membrane (GDM) filtration of algae-polluted surface water. Journal of Water Process Engineering 2020, 36, 101257. [CrossRef]

- Moulin, C., M.M. Bourbigot, A. Tazi-Pain, and F. Bourdon, Design and performance of membrane filtration installations: Capacity and product quality for drinking water applications. Environmental Technology 1991, 12, 841-858. [CrossRef]

- Bodzek, M. and K. Konieczny, Comparison of various membrane types and module configurations in the treatment of natural water by means of low-pressure membrane methods. Separation and Purification Technology 1998, 14, 69-78. [CrossRef]

- Klomfas, G. and K. Konieczny, Fouling phenomena in unit and hybrid processes for potable water treatment. Desalination 2004, 163, 311-322. [CrossRef]

- Oligny, L., P.R. Bérubé, and B. Barbeau, Impact of PAC Fines in Fouling of Polymeric and Ceramic Low-Pressure Membranes for Drinking Water Treatment. Membranes 2016, 6, 38. [CrossRef]

- Hofs, B., et al., Comparison of ceramic and polymeric membrane permeability and fouling using surface water. Separation and Purification Technology 2011, 79, 365-374. [CrossRef]

- Kurth, C.J., B.L. Wise, and S. Smith, Design considerations for implementing ceramics in new and existing polymeric UF systems. Water Practice and Technology 2018, 13, 725-737. [CrossRef]

- Alresheedi, M.T., B. Barbeau, and O.D. Basu, Comparisons of NOM fouling and cleaning of ceramic and polymeric membranes during water treatment. Separation and Purification Technology 2019, 209, 452-460. [CrossRef]

- Jarvis, P., I. Carra, M. Jafari, and S.J. Judd, Ceramic vs polymeric membrane implementation for potable water treatment. Water Research 2022, 215, 118269. [CrossRef]

- Gul, A., J. Hruza, and F.J.P. Yalcinkaya, Fouling and chemical cleaning of microfiltration membranes: A mini-review. 2021, 13, 846. [CrossRef]

- Liu, Z., et al., Biological ion exchange as an alternative to biological activated carbon for drinking water treatment. Water Research 2020, 168, 115148. [CrossRef]

- Boyer, T.H., P.C. Singer, G.R.J.E.s. Aiken, and technology, Removal of dissolved organic matter by anion exchange: effect of dissolved organic matter properties. Environmental Science & Technology 2008, 42, 7431-7437. [CrossRef]

- Rasouli, Y., et al., Synthesis, characterization, and application of gravity-driven ceramic microfiltration membranes for surface water treatment. Journal of Water Process Engineering 2023, 51, 103430. [CrossRef]

- Akhondi, E., et al., Gravity-driven membrane filtration as pretreatment for seawater reverse osmosis: Linking biofouling layer morphology with flux stabilization. Water Research 2015, 70, 158-173. [CrossRef]

- Wu, B., et al., Optimization of gravity-driven membrane (GDM) filtration process for seawater pretreatment. Water Research 2016, 93, 133-140. [CrossRef]

Figure 1.

Experimental BIEX + GDM filtration pilot setup. BIEX resin operated at 4 BV/h filtration rate and EBCT = 15 min. M1-1 and M1-2: flat sheet disk shaped 0.1-µm (MF) PES, M2-1 and M2-2: flat sheet disk shaped 0.03-µm (UF) PES, M3-1 and M3-2: flat sheet disk shaped 300 kDa (UF) ceramic, M4-1 and M4-2: Lab-made flat sheet disk shaped ceramic MF membranes (Kaolin support + alumina layer).

Figure 1.

Experimental BIEX + GDM filtration pilot setup. BIEX resin operated at 4 BV/h filtration rate and EBCT = 15 min. M1-1 and M1-2: flat sheet disk shaped 0.1-µm (MF) PES, M2-1 and M2-2: flat sheet disk shaped 0.03-µm (UF) PES, M3-1 and M3-2: flat sheet disk shaped 300 kDa (UF) ceramic, M4-1 and M4-2: Lab-made flat sheet disk shaped ceramic MF membranes (Kaolin support + alumina layer).

Figure 2.

Variation of chloride, sulphate, DOC, and bicarbonate loads (as m eq/L of resin) on the BIEX 1 column during the operation. Regeneration was performed on day 68 (6,528 BV). The error bars show 95% confidence intervals.

Figure 2.

Variation of chloride, sulphate, DOC, and bicarbonate loads (as m eq/L of resin) on the BIEX 1 column during the operation. Regeneration was performed on day 68 (6,528 BV). The error bars show 95% confidence intervals.

Figure 3.

DOC concentration and chloride release in the effluent of the BIEX columns during the operation period. Day 68 (6,528 BV) is the resin regeneration day. The error bars show 95% confidence intervals.

Figure 3.

DOC concentration and chloride release in the effluent of the BIEX columns during the operation period. Day 68 (6,528 BV) is the resin regeneration day. The error bars show 95% confidence intervals.

Figure 4.

a) Flux – time diagram of the membranes in a) section 1, and b) section 2. M1 (polymeric 0.1 µm MF), M2 (polymeric 0.03 µm UF), M3 (ceramic 300 kDa UF), and M4 (Lab-made ceramic MF). Day 30 is the physical and chemical cleaning day. The error bars show 95% confidence intervals.

Figure 4.

a) Flux – time diagram of the membranes in a) section 1, and b) section 2. M1 (polymeric 0.1 µm MF), M2 (polymeric 0.03 µm UF), M3 (ceramic 300 kDa UF), and M4 (Lab-made ceramic MF). Day 30 is the physical and chemical cleaning day. The error bars show 95% confidence intervals.

Figure 5.

a) Comparing stabilised flux of the polymeric MF/UF membranes in section 1 with section 2 before cleaning process (day 8 – 29). b) Comparing stabilised flux of the ceramic MF/UF membranes in section 1 with section 2 before cleaning process (day 8 – 29). c, d) The effect of membrane type (polymeric/ceramic, MF/UF) and enhanced (in section 1) or decreased cleaning condition (in section 2) on the mean stabilised flux of the membranes after cleaning process (day 54 – 73). The error bars represent 95% confidence intervals.

Figure 5.

a) Comparing stabilised flux of the polymeric MF/UF membranes in section 1 with section 2 before cleaning process (day 8 – 29). b) Comparing stabilised flux of the ceramic MF/UF membranes in section 1 with section 2 before cleaning process (day 8 – 29). c, d) The effect of membrane type (polymeric/ceramic, MF/UF) and enhanced (in section 1) or decreased cleaning condition (in section 2) on the mean stabilised flux of the membranes after cleaning process (day 54 – 73). The error bars represent 95% confidence intervals.

Figure 6.

Evolution of mean biofilm thickness (µm) of a) the membranes in section 1, and b) the membranes in section 2. M1 (polymeric 0.1 µm MF), M2 (polymeric 0.03 µm UF), M3 (ceramic 300 kDa UF), and M4 (Lab-made ceramic MF). Day 30 is the physical and chemical cleaning day. The error bars show 95% confidence intervals.

Figure 6.

Evolution of mean biofilm thickness (µm) of a) the membranes in section 1, and b) the membranes in section 2. M1 (polymeric 0.1 µm MF), M2 (polymeric 0.03 µm UF), M3 (ceramic 300 kDa UF), and M4 (Lab-made ceramic MF). Day 30 is the physical and chemical cleaning day. The error bars show 95% confidence intervals.

Figure 7.

Variation of a) DOC in section 1, b) DOC in section 2, c) UVA254 in section 1, d) UVA254 in section 2, e) Turbidity in section 1, and f) Turbidity in section 2 during the filtration time. M1 (polymeric 0.1 µm MF), M2 (polymeric 0.03 µm UF), M3 (ceramic 300 kDa UF), and M4 (Lab-made ceramic MF). Days 30 and 68 are the membrane cleaning and resin regeneration days, respectively. The error bars show 95% confidence intervals.

Figure 7.

Variation of a) DOC in section 1, b) DOC in section 2, c) UVA254 in section 1, d) UVA254 in section 2, e) Turbidity in section 1, and f) Turbidity in section 2 during the filtration time. M1 (polymeric 0.1 µm MF), M2 (polymeric 0.03 µm UF), M3 (ceramic 300 kDa UF), and M4 (Lab-made ceramic MF). Days 30 and 68 are the membrane cleaning and resin regeneration days, respectively. The error bars show 95% confidence intervals.

Table 1.

Characteristics of the membranes used in the filtration section.

Table 1.

Characteristics of the membranes used in the filtration section.

| Membrane name |

Membrane type |

Pore size |

Membrane material |

Membrane area (cm2) |

Suppliers |

M1-1*

M1-2

|

Flat-sheet disk-shaped Polymeric |

0.1 µm (MF) |

Polyether Sulfone (PES) |

17 |

Sterlitech, Auburn, WA, USA |

M2-1

M2-2

|

Flat-sheet disk-shaped Polymeric |

0.03 µm (UF) |

PES |

17 |

Sterlitech, Auburn, WA, USA |

M3-1

M3-2

|

Flat-sheet disk-shaped Ceramic |

300 kDa (UF) |

ZrO2/ TiO2

|

17 |

Tami Industries, France |

M4-1

M4-2

|

Flat-sheet disk-shaped Ceramic |

0.62 ± 0.06 µm ** (MF) |

Kaolin support + alumina layer |

15 ± 0.09 **

|

Lab-made |

Table 2.

Characteristics of the influent water from Des Prairies River.

Table 2.

Characteristics of the influent water from Des Prairies River.

| Parameters |

Mean ± 95% confidence interval |

Number of samples |

| DOC (mg C/L) |

7.04 ± 0.18 |

27 |

| Turbidity (NTU) |

5.09 ± 0.27 |

27 |

| pH |

7.17 ± 0.04 |

27 |

| Alkalinity (mg CaCO3/L) |

23.8 ± 0.4 |

27 |

| UVA254 (cm-1) |

0.21 ± 0.005 |

27 |

| Nitrate (mg/L) |

2.71 ± 0.11 |

23 |

| Sulphate (mg/L) |

3.57 ± 0.37 |

23 |

| Chloride (mg/L) |

5.04 ± 0.15 |

23 |

Table 3.

Stepwise description of physical and chemical membrane cleaning.

Table 3.

Stepwise description of physical and chemical membrane cleaning.

| No. |

Step name |

Descriptions |

Figure |

| 1 |

Turning the membranes face down |

Membrane positions were faced down

according to the inlet flow |

Figure S3a |

| 2 |

Backwash with air |

Section 1) P = 30 psi, Q = 5 L/h, t = 2 min Section 2) P = 15 psi, Q = 2.5 L/h, t = 2 min |

Figure S3b,c |

| 3 |

Backwash with DI water |

Section 1) Water head = 120 cm, t = 4h

Section 2) Water head = 90 cm, t = 4h |

Figure S3d |

| 4 |

Returning the membranes face up |

Membrane positions were returned to the normal filtration position. |

Figure S3e |

| 5 |

DI water flux measurement |

Measuring DI water flux at water head of 90 cm for 15 min in both sections |

Figure S3f |

| 6 |

Chemical cleaning by NaOH |

Section 1) NaOH = 40 mM, Water head = 90 cm, t = 6h

Section 2) NaOH = 20 mM, Water head = 90 cm, t = 6h |

Figure S3g |

| 7 |

DI water flux measurement |

Measuring DI water flux at water head of 90 cm for 15 min in both sections |

Figure S3h |

| 8 |

Chemical cleaning by NaOCl |

Section 1) NaOCl = 500 mg Cl2/L, Water head = 90 cm, t = 6h

Section 2) NaOCl = 250 mg Cl2/L, Water head = 90 cm, t = 6h |

Figure S3i |

| 9 |

DI water flux measurement |

Measuring DI water flux at water head of 90 cm for 15 min in both sections |

Figure S3j |

Table 4.

Mean ± 95% confidence interval of membrane stabilised flux in both sections before and after membrane cleaning. Before cleaning from day 8 to 29; after cleaning from day 54 to 73.

Table 4.

Mean ± 95% confidence interval of membrane stabilised flux in both sections before and after membrane cleaning. Before cleaning from day 8 to 29; after cleaning from day 54 to 73.

| Membrane type |

Section 1 (enhanced cleaning) |

Section 2 (decreased cleaning) |

| Polymeric |

Ceramic |

Polymeric |

Ceramic |

| MF (M1-1) |

UF (M2-1) |

UF (M3-1) |

MF (M4-1) |

MF (M1-2) |

UF (M2-2) |

UF (M3-2) |

MF (M4-2) |

| Stabilised flux |

Before cleaning (day 8 – 29) |

4.46 ± 0.42 |

4.54 ± 0.31 |

4.56 ± 0.22 |

4.50 ± 0.27 |

4.77 ± 0.37 |

4.46 ± 0.51 |

5.04 ± 0.23 |

4.50 ± 0.17 |

After cleaning

(day 54 – 73)

|

5.13 ± 0.14 |

4.69 ± 0.06 |

4.67 ± 0.14 |

4.00 ± 0.11 |

5.34 ± 0.11 |

5.41 ± 0.11 |

4.61 ± 0.25 |

3.75 ± 0.12 |

| Change (%) |

+15% |

+3.3% |

+2.8% |

-11% |

+12% |

+21% |

-8.5% |

-16% |

Table 5.

Flux recovery percentages obtained via physical and chemical cleanings (mean ± 95% confidence interval).

Table 5.

Flux recovery percentages obtained via physical and chemical cleanings (mean ± 95% confidence interval).

| Membrane type |

Section 1 (enhanced cleaning) |

Section 2 (decreased cleaning) |

| Polymeric |

Ceramic |

Polymeric |

Ceramic |

| MF (M1-1) |

UF (M2-1) |

UF (M3-1) |

MF (M4-1) |

MF (M1-2) |

UF (M2-2) |

UF (M3-2) |

MF (M4-2) |

Flux

recovery %

|

physical cleaning (air + water) |

67.3

± 8.2 |

69.7

± 3.3 |

79.1

± 6.0 |

79.6

± 4.4 |

57.0

± 2.1 |

61.3

± 5.3 |

75.5

± 10.5 |

70.8

± 8.0 |

| chemical cleaning with NaOH |

4.9

± 4.5 |

6.1

± 4.5 |

12.8

± 3.2 |

7.8

± 4.1 |

2.5

± 2.1 |

3.8

± 2.8 |

6.7

± 6.4 |

4.6

± 3.9 |

| chemical cleaning with NaOCl |

7.5

± 3.9 |

4.9

± 2.7 |

5.3

± 1.6 |

5.1

± 4.0 |

6.2

± 4.2 |

4.4

± 2.7 |

3.0

± 2.0 |

1.1

± 0.5 |

Table 6.

Percentages of different fouling types causing flux decline in the filtration.

Table 6.

Percentages of different fouling types causing flux decline in the filtration.

| Membrane type |

Section 1 (enhanced cleaning) |

Section 2 (decreased cleaning) |

| Polymeric |

Ceramic |

Polymeric |

Ceramic |

| MF (M1-1) |

UF (M2-1) |

UF (M3-1) |

MF (M4-1) |

MF (M1-2) |

UF (M2-2) |

UF (M3-2) |

MF (M4-2) |

| Different fouling types |

Hydraulically

reversible (%)

|

67.3 |

69.7 |

79.1 |

79.6 |

57.0 |

61.3 |

75.5 |

70.8 |

Hydraulically

irreversible (%)

|

32.7 |

30.3 |

20.9 |

20.4 |

43.0 |

38.7 |

24.5 |

29.2 |

Chemically

reversible (%)

|

12.4 |

11.0 |

18.1 |

12.9 |

8.7 |

8.2 |

9.7 |

5.7 |

Chemically

irreversible (%)

|

20.3 |

19.3 |

2.8 |

7.5 |

34.3 |

30.5 |

14.8 |

23.5 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).