1. Introduction

High quality asset design provides value to organizations, owners, and end users in the construction sector. Design creation involves managed interactions between project stakeholders and takes participants from an initial vague-unknown position to a subsequent known-and-desired solution [

1,

2]. This process results in a set of collated information, involving drawings, specifications, schedules, and digital models, from which the tangible assets can be constructed. Design management (DM) therefore involves the management of project-related design activities, processes, people, and other resources to enable the effective flow, and production of design information [

3,

4,

5]. However current project delivery approaches regarding the management of design, remains problematic. One persistent concern regards the separate perspectives held by project actors around what successful construction project delivery is, because of various project time, cost, and quality targets [

6,

7,

8]. Hence, without effective decision support systems, design management approaches may not always be focused on realizing desired project outcomes [

9]. An additional issue revolves around how achieving such collaborative and integrated working across a temporary project organization (TPO) has usually been a messy, and ‘analogue’ coordination process involving process waste. Bolpagni at al [

10] discuss how in Industry 4.0, because of an increasing adoption of digital design through the likes of Building Information Modelling (BIM), such information-rich content could be much better managed through more digital means. In brief, BIM involves creating a digital version of what is to be built, and then using it as the basis for construction. Using specialist computer software, designers create a three-dimensional (3D) model, that is an exact, rather than approximate representation of the asset. Succar [

11] initially suggested that BIM would provide “

…technological and procedural shift" within construction, and Gledson [

12] later identified its impact as “

the most prominent radical, transformative and disruptive innovation to hit the construction industry”.

Again, because of the increasing adoption of digital design through the likes of BIM, information-rich content can now be much better managed using more digital means. The aim of this work therefore is to report on project that employed design science research methodology (DSRM), resulting in the development of a bespoke digital web-based dashboard prototype intended to enhance the efficiency, productivity, and ultimately the effectiveness of the construction design management (CDM) function. Design Science Research (DSRM) focuses on developing innovate solutions to address practical problems. In this project the output of the DSRM intends for better realization of construction projects, through digitally supported design management (DsDM) functions, by way of a standalone dashboard, that uses data processing to better manage information, facilitate good evidence-based decision-making and drive project performance. Before discussing design science research methodology (DSRM), and the discrete design management functions targeted by the prototype dashboard, some inherent problems in the conventional design process, the value of the design management role, and how it could be enhanced through use of project data analytics, are now discussed.

2. Literature Review

Gledson [

13] summarizes various inefficiencies in design processes that, ultimately lead to inherent problems in the existing design management process. At project inception, lead designers first establish the nature of the design problem at hand be it ‘well-defined’, ‘ill-defined’ or ‘wicked’[

14,

15]. To do this, they extract early non-formalised requirements through guided client interactions, to try to ensure their needs will be met. Tizani [

16] describes the information flows that occur within current design processes and identifies inefficiencies including: poor capture of formalised building requirements; rigidity of design process flow; compartmentalised decision making; lack of fidelity; minimal opportunities for design experimentation; lack of accommodation for late design changes and lack of design automation. Dictated by selected project procurement strategy, a set order of the design activities to be carried out, before the information can be transferred down to other project participants is undertaken. This fragmented approach to managing design flow is often criticised [

17] albeit perhaps most notably by Anumba et al [

18] who framed this as the 'over the wall' approach. Once each area of design has been produced, the recipient of design information has to interpret the information in order to be able to make judgements. Because of the quality of design available to them, they may also have to make several assumptions which may lead to misinterpretations. The recipients of information will also need all of the multiple project views available and correct to the latest versions to fully understand the design. Checking is done to ensure the design is ‘clear’, ‘correct’, ‘consistent’, ‘coordinated’ with the associated design information (which may have been created by another producer) and is ‘complete’: “

To carry out these checks effectively and consistently takes time and requires extraordinarily high, but generally unacknowledged, levels of skill, discipline and judgement. Such talents are rare and often unavailable on fast moving projects, which means that fundamental mistakes are often made" [

19]. More effective digital project decision-support systems could therefore benefit the process of checking and coordinating design information.

Cidik and Boyd [

20] recently warned against the narrow, but commonly held view of design coordination involving only the integration of separate design outputs by fragmented design actors, and instead emphasise the “

shared sense of purposefulness” that the design team members should have. Regardless, because several design disciplines provide input into even the most basic of design activities, their co-ordination requires much time and skilled resource. Without a dedicated design manager to ensure fit-for-purpose design quality achieved, design coordination can be inefficient and ineffective. Current means of generating and managing construction project design – even when using the likes of BIM – can therefore be inefficient and ineffective without such a dedicated role providing the necessary oversight. Whilst the focused use of BIM can facilitate improvements in conventional design processes, concerns persist around how use of such design tools enhance design quality. Therefore, greater focus on the DM role, and how it can support design quality by better use of digital project information is welcomed.

Savolainen et al [

21] acknowledged the role in value creation that design management plays. Depending on the procurement route used, and with reference to the RIBA Plan of Work 2020, Design Managers can be substantively involved across Stage 1 ‘Preparation and Briefing’ through to Stage 6 ‘Handover’ of projects. Again, depending upon procurement mechanisms, they can be involved in activities as diverse as: preparing and monitoring design programmes, undertaking design reviews, coordinating the development of technical designs, and resolving technical and site-based queries. Recently, various researchers [

22,

23] have reviewed design processes interactions and identified concerns around quality of information flow and information exchanges in DM processes. Similarly, Uusitalo et al [

24,

25], investigated the roles between design and design management actors in construction project contexts, specifically regarding information flow and solving design quality problems. These researchers ultimately found that project teams should look to better enhance ways of communicating and collaborating when managing design. Ultimately, much of knowledge base has hinted at how better use of project information could be enacted digitally to enhance construction practice. To that end, this specific project makes use of Project Data Analytics to better support design management actors in their role.

2.1. Project Data Analytics

Project Data Analytics (PDA) involves leveraging advanced data analytics techniques to extract valuable insights from structured data. In construction, Project Data Analytics (PDA) can enhance decision-making across the project lifecycle in areas such as: risk management; cost estimation; schedule optimization; resource allocation, and performance monitoring [

26]. Various forms of project data analytics exist. These include use of low autonomous/intelligence Robotic Process Automation (RPA) tools such as transactional ‘bots’ through to much vaunted, high autonomous/intelligence narrow/general Artificial Intelligence (AI) solutions [

27]. Application Programming Interface(s) (API), also enable data analytics to occur via connections between computers and software applications. Given the range of design management processes and growing use of project data analytics, it was identified that a range of DM functions could be digitally supported through project data analytics by creating a DM solution. Specifically, this project made use of API analytics via a web-based project dashboard interface to digitally support a range of design management (DsDM) functions. In this work, we describe only a selection of these below, including opportunities to:

Allow better coordination and management of design process interactions, as captured through Technical Queries (TQs) and Requests for Information (RFI) mechanisms.

Ensure that the design team are aware of and maintaining their design delivery programme and focusing on their critical design priorities, through better monitoring of planned design release against actual design production.

Overview of design management issues at project- or portfolio- levels.

Provide additional design management process assurance at project-level.

3. Design Science Research Methodology (DSRM)

Descriptive research is to accurately portray the likes of events or situations [

28]. This descriptive research reports on the results of a collaborative industry-academia Knowledge Transfer Project (KTP) that employed a design science research methodology (DSRM) to produce a web-based Design Management prototype dashboard. Design Science Research (DSR) is a research paradigm that concentrates on developing and validating prescriptive knowledge. It enables the development of innovative artefacts (systems, models, processes etc.) as solutions to address practical, real-world problems [

29]. DSR typically employs design, development, evaluation, and implementation stages, albeit solutions are iteratively refined and improved upon, based on feedback and empirical testing of the artefacts throughout [

30]. The DSR paradigm is applied within various scientific disciplines that emphasize the need to solve complex problems through the creation and validation of innovative artefacts. Examples of the diverse disciplinary contexts that apply DSR include Health Informatics: Education Technology; Library and Information Science; Environmental Science; and Architecture and Urban Planning. However, fields closer to this present work include:

Information Systems (IS): In which information systems and technologies to address organizational and societal challenges are designed and evaluated.

Computer Science: Where DSR is applied to create novel software systems, algorithms, and computational models to address specific problems.

Engineering: Various engineering disciplines, e.g., systems engineering, software engineering, industrial engineering etc, use DSR to address engineering challenges through the design and evaluation of engineering solutions.

Management Science: Organizational processes, decision support systems, and new management practices designed and tested by way of DSR.

Operations Research: Where DSR can be applied to design and optimize decision-making processes, algorithms, and systems for efficient resource allocation and management.

Within DSR, Design Science Research Methodology (DSRM) occurs using the principles or guidelines associated with this paradigm [

31]. There have been various attempts to formalize methodology [

32,

33] though it differs across disciplines [

34,

35,

36]. For example, within Information Systems Research, Peffers et al. (2007) defined the Design Science Research Methodology (DSRM) as a six-activity process summarized thus [

37]:

Problem Identification and Motivation: Define the real-world problem or opportunity that requires a design-oriented solution for the context and stakeholders involved.

Define the objectives for the solution: Clear articulation of research goals or objective(s). Define project boundaries.

Design and development: Create the initial design of the artifact. Follow an iterative process, to refine and improve design based on feedback and insights. Create the artifact.

Demonstration: Apply the solution to address all or part of the research problem.

Evaluation: Assess how well the artifact addresses the identified problem.

Communication: Document the research and share findings.

Table 1 shows how the alignment between the DSRM activities and the 4 Project Stages in this collaborative industry-academia Knowledge Transfer Project (KTP) that resulted in the production of a web-based Design Management prototype dashboard.

In line with the project stages 1-3 and the associated DSRM activities listed in

Table 1, the remainder of this work now reports on the identification of problems, and then the development of the prototype dashboard. For purposes of problem identification qualitative survey research, specifically semi-structured interviews with 9 purposively identified design managers were held, to uncover first-hand, real world DM concerns and validate these against challenges identified from the knowledge base. Data from these interviews were analysed using Nvivo Software (See

Table 1 for Themes). Then, by way of DSRM, the web-based design management prototype dashboard was designed, iteratively developed and evaluated. This tackled some of the identified challenges of the design management role by digitalizing selected design management processes to better manage data and information, facilitate good decision-making, and improve the efficiency, and productivity of this role. Results from across these project stages are now reported on below.

4. Results

At the outset of the collaboration and to obtain funding, various supporting statements were obtained from design management or DM adjacent practitioners to justify the project. One important statement advised: “

Design management plays an increasingly important role in projects as it uniquely crosses the boundaries between the quantitative/process related issues dealt with by project management colleagues, and qualitative design related issued being delivered by the design team. The benefits to the user that a central dashboard where project decisions can be made and presented to the client provide [include those of]

challenging the delivery programme by utilizing data, and [of] digitizing analogue processes”. This reveals that better project data analytics can assist the design management function. After project award and following the initial ‘Situational Awareness’ phase (Project Stage #1), ‘Problem Definition and User Requirement gathering’ (Project Stage #2) activities occurred. This involved a further review of the knowledge base, followed by online interviews with design managers. A mass of qualitative data were obtained from these interviews, which were then thematically analysed. As evidenced in

Table 2, several interrelated DM challenges were revealed, though the present work focuses only on some of these, as ultimately addressed by specific functions within the web-based design management prototype dashboard. These being the creation of: digital TQ/RFI systems (to support challenges of communication, coordination, information flow and decision making); the digital tracking of designer performance in the production of their project deliverables (similarly, to support challenges of coordination, information flow, efficiency and value); the ability to provide more accurate views of design management issues at project- or portfolio- levels, and ; by way of an associated stand-alone application to further digitally support the Design Management function, the provision of additional process assurance at project-level.

4.1. The Challenges of Design Coordination and Information Management

Participants revealed how better coordination and improvements in the management of design process interactions as captured via conventional ‘Requests for Information’ are needed: Participant 9 discussed one specific element of works on one of their projects was affected by this: “I’ve had 250 RFIs on site that I’ve had to deal with. Had, 20 days of site delay, and we’ve had to make 25 changes on site, to er, cable and drainage, and such”. The impact of such, seemingly difficult to manage: “…you are sitting there, dealing daily with a million RFIs that are coming in from your site managers … I don’t know how many days on site have been wasted, and I don’t know how many RFIs have been generated from it…” (Participant 9). Participant 4 also revealed the need for better digital management of project RFIs: “As an example, if I asked for a schedule of RFIs from a project, ‘tell me how many there are’, it will probably take them two weeks to extract those RFIs into an Excel sheet, [that] won’t give you very much, whereas if I could get and use that data to influence and understand it, I can then link it to things like programme or whatever we need to do with it.” Participant (#4) also understood how project data analytics could further aid the production process: “[Regarding] outstanding RFIs, TQs, from subcontractors, clients or whatever it is, if we can see those outstanding issues on a dashboard and their dates … if we can get everybody to think about the priorities in relation to time, and they can see those clearly through a dashboard … we can build it properly”.

Across the interviews, challenges of communication, coordination, information flow and decision-making concerned DM practitioners. These were ultimately addressed through the creation of a digital RFI system, as discussed in a below section.

4.2. The Challenges of Ensuring Design Team Maintain Their Design Delivery Programme

Regarding the production of design programmes, existing situations were outlined: “I would ask the consultants to produce a list of deliverables, whether drawings, specs, whatever they are for each construction package and when they need to be released”. (Participant 2). These are incorporated into an agreed design programme, or an Information Release Schedule (IRS) which is set out with activities and timings, “…then that would be monitored by the architects and myself. I would speak with the architect every 2 weeks [for a] progress update” (Participant 1). This is then monitored: “If it’s as the plan, everything’s fine. If they’re slightly behind we need to monitor the impact of that on the design coordination, making it all fit, which then goes on to procurement … we then must monitor that and make sure procurement is linked into build.” (Participant 1). Once design information released: “…it would be a simple case of just going through the [common] data repository that they would upload it to, and it would be a simple matter of just going through and checking that those drawings and those schedules or specs have been received” (Participant 2). As to any problems with existing process, designer performance in terms of design release against agreed design programmes was a frustration: “… and the day comes and the deadline comes and next Friday turns into Monday, turns into sort of Wednesday and by the next Friday … erm, if they’re late, that’s recorded.” (Participant 1). Using current existing process, the design manager is often in a reactive state, whereas participants would prefer they were able to be more proactive: “The biggest challenge we’ve had consistently for the past two years has been design managers not being process managers, not really [being able to] actively influence procurement or design programme progress.” (Participant 4). Ultimately, what participants wanted was to be able to better track and manage designer performance: “I want to see [visibility from] the design manager, the key challenges they’re having on the project. I would like to see how the design and procurement programme and the project programme is working, against the [designers] own actions, what they’re doing, and I’d like to see [from designers], erm an element of compliance” (Participant 4). Again, across the interviews, challenges of coordination, information flow, efficiency and value creation concerned DM practitioners. These were ultimately addressed as discussed in a below section, through the creation of a digital system, for better tracking of designer performance in the production of their project deliverables.

5. Prototype Dashboard Development

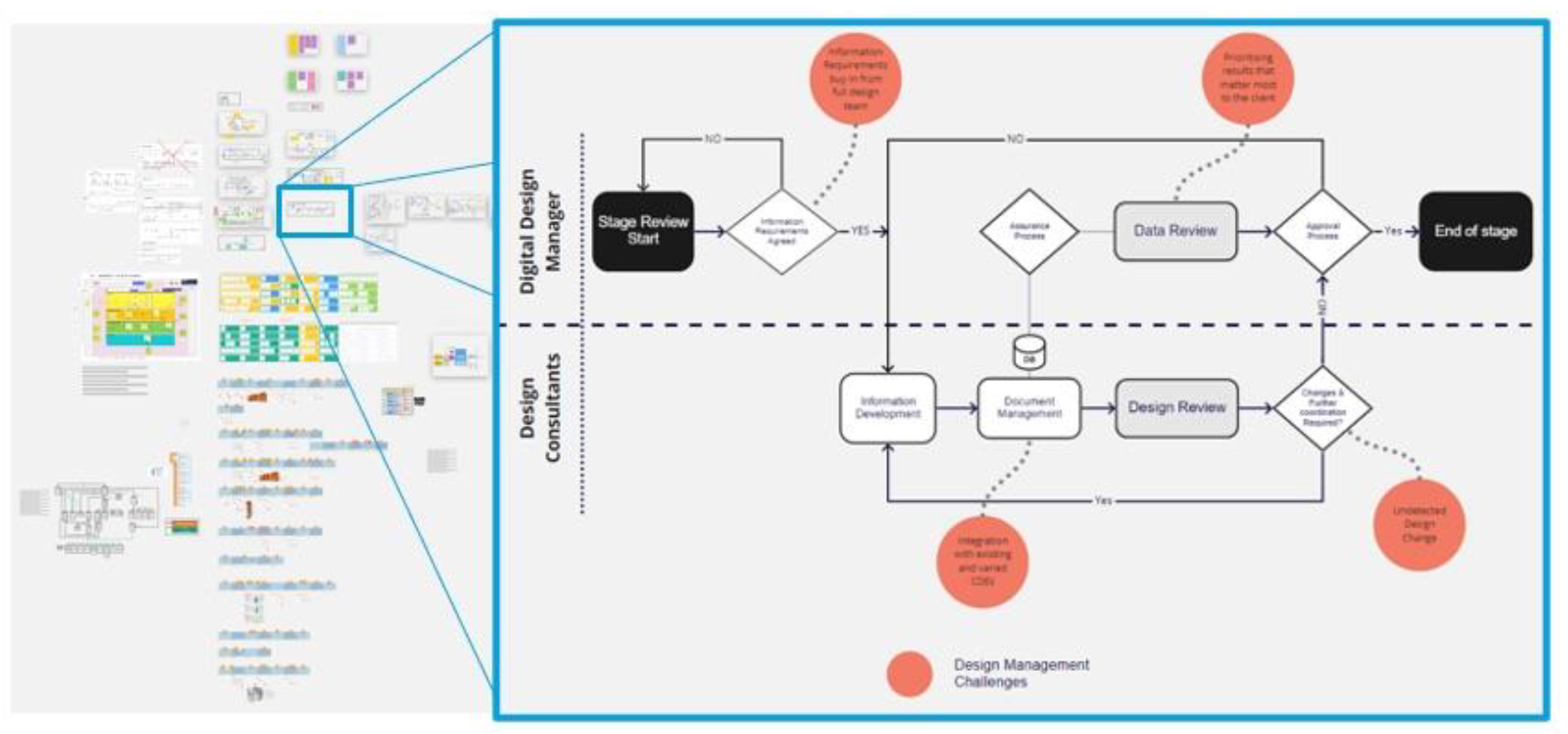

Following the prior ‘Problem Definition and User Requirements’ stage (#2), the ‘Problem Solving, System Design and Development stage (#3) occurred. The main activities in this stage involve the design of the DsDM process itself, and the iterative and agile design, development, and evaluation of the bespoke DsDM prototype dashboard, its functionalities and user interface occurred. Summary details are here provided. Regarding process review, and design of the DsDM, over the duration of the project these aspects were continually storyboarded and refined using online collaborative tools such as the Miro service.

Figure 1 evidence this, which ultimately identified ‘what’ needed to be done in the design and development tasks.

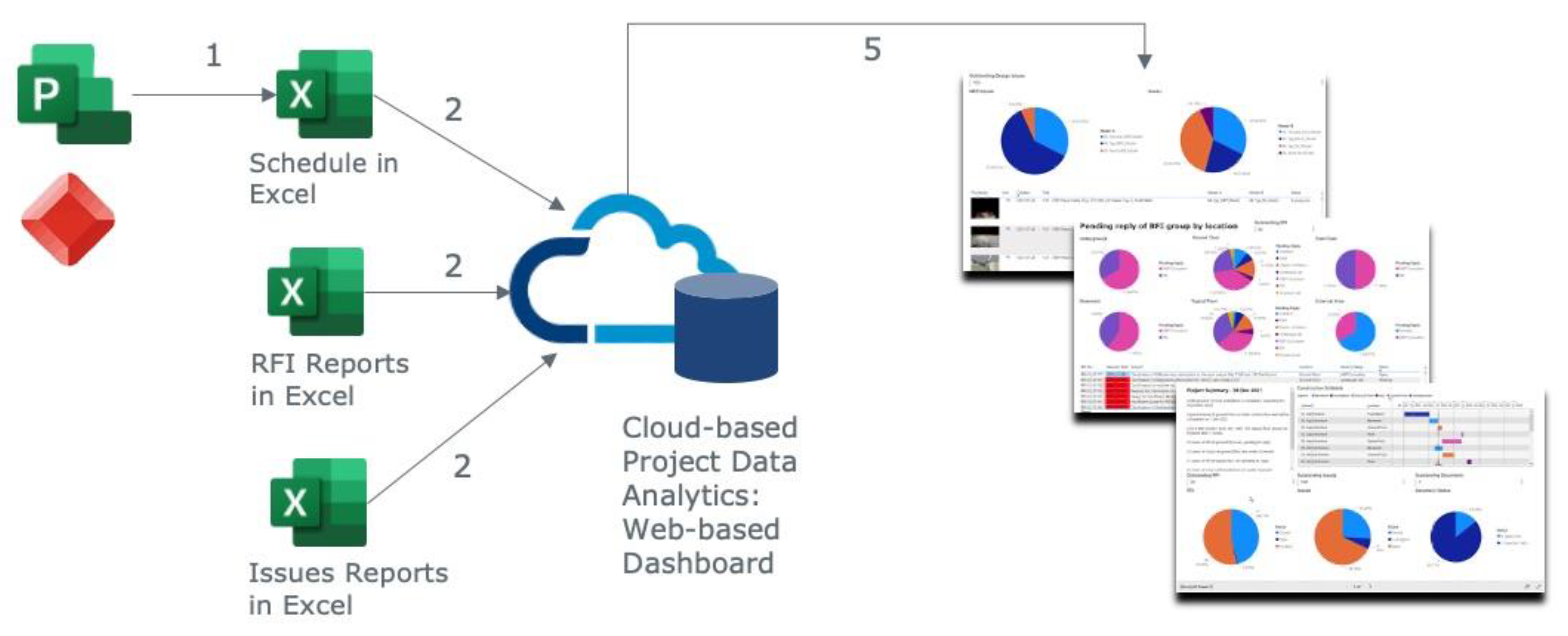

Thereafter, ‘how’ the DsDM dashboard would be iteratively designed and developed was determined. Indicative system architecture for this is evidenced in

Figure 2.

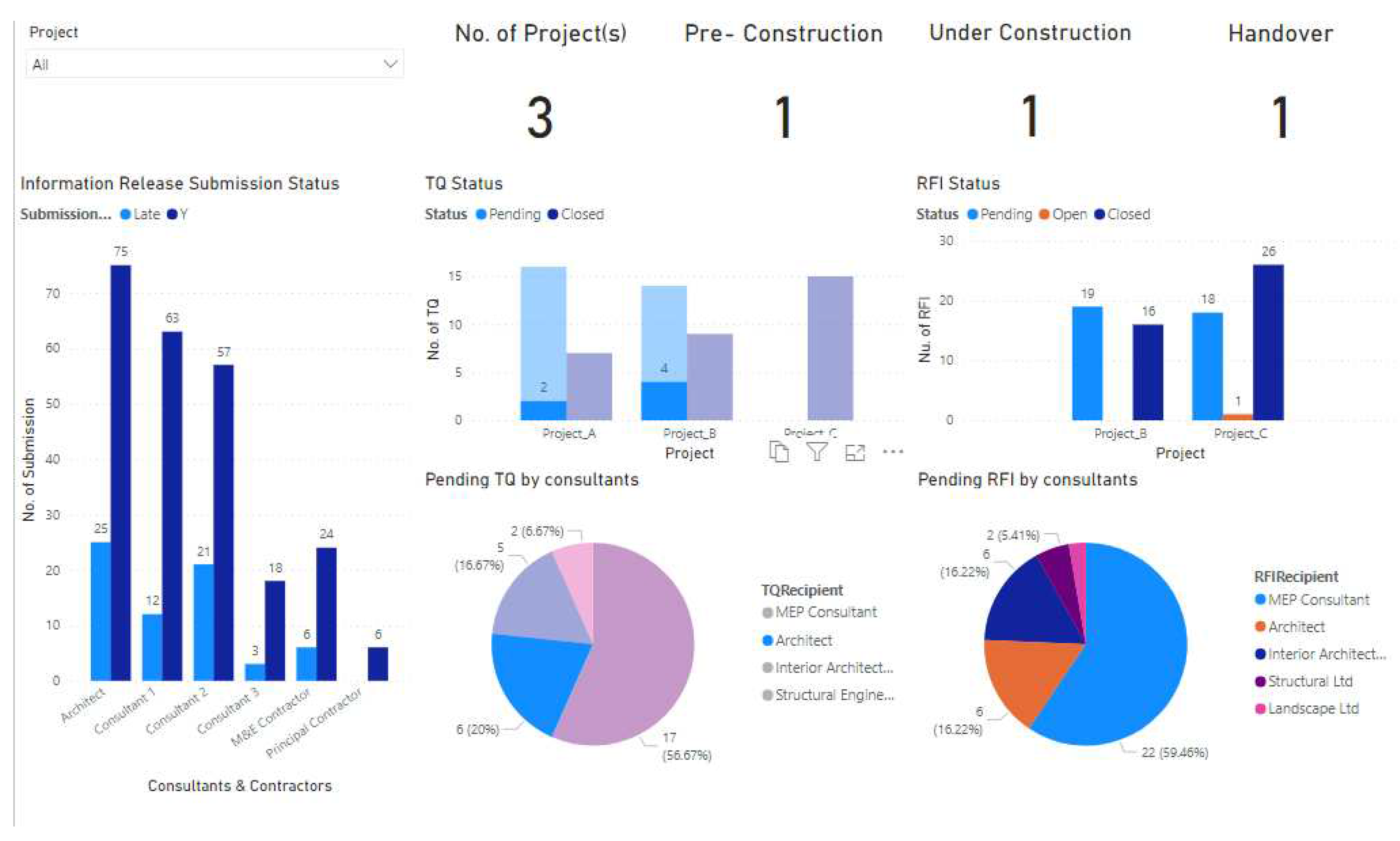

The developed DsDM prototype dashboard draws upon relevant project data to aid design coordination activity and facilitate DM task prioritization and reporting functionality. It enables useful visual reporting capability that, in turn: allows focus to be retained on priority Technical Queries (TQs) / Requests for information (RFI), and; enables design production to be monitored, and trends in designer performance to be assessed.

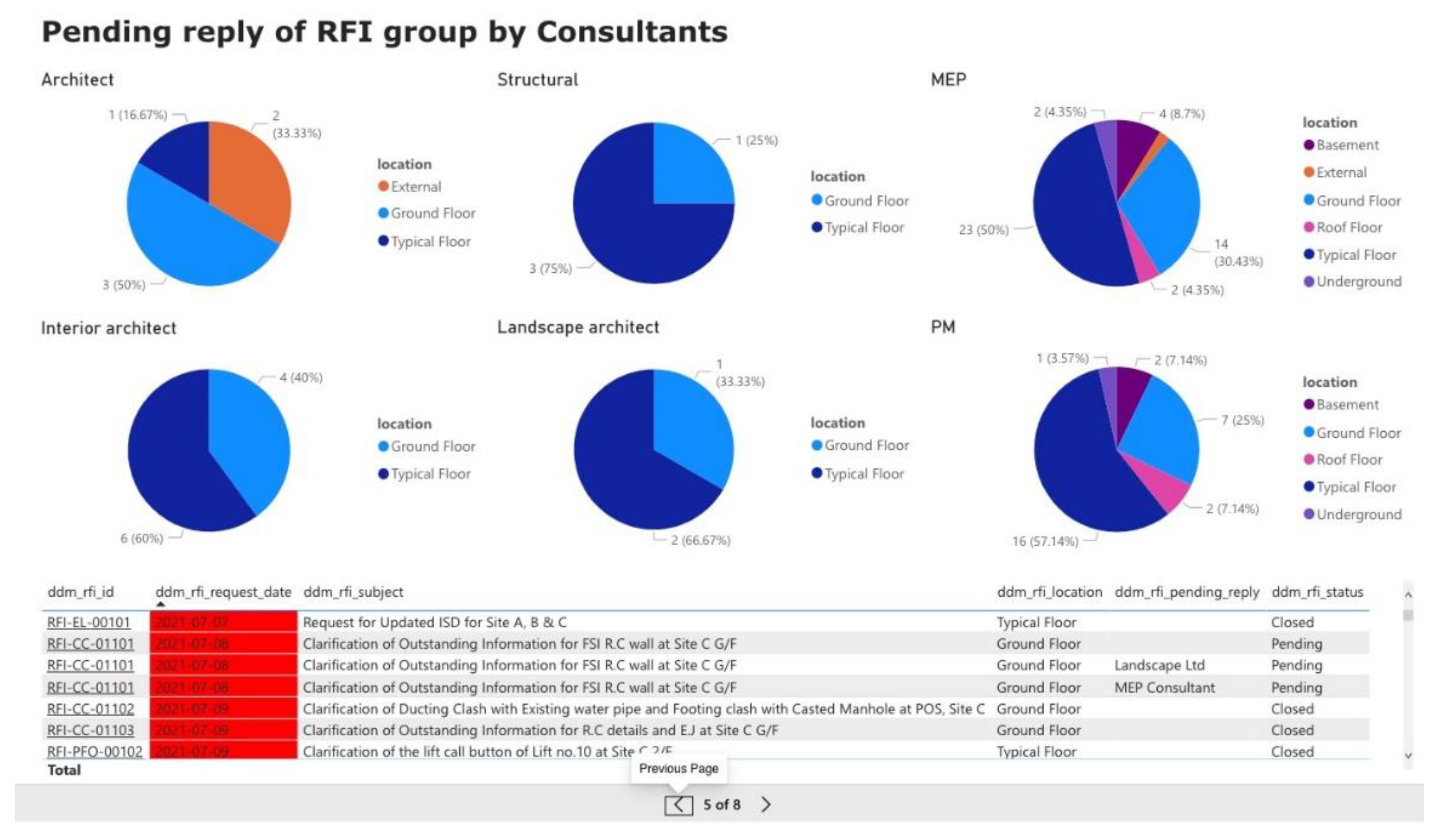

5.1. Addressing Challenges of Design Coordination and Information Management through Managed RFIs

Typically, Technical Queries (TQs) at pre-construction stages (e.g., RIBA Stages 0-4) or site queries, in the format of Requests for Information (RFIs) during associated construction stages (e.g., RIBA Stage 4-5+) are generated by design consultants/others and can be issued in many different formats (e.g., by emails, typed word docs, or handwritten memos etc). The key contents of these are then typically captured and aggregated via excel-based registers by DM personnel. The DsDM web-based dashboard allows for the capture and collation of these TQs/RFIs. Summary reports appear in a projects Common Data Environment (CDE), that hosts and visually presents key information from these queries for review, prioritising, possibly onward routing, but ultimately addressing. However, the web-based dashboard does not just host conventionally created TQs/RFIs. On this project the team also developed a new web-based form and associated cross-platform mobile app that allowed for electronic queries to be created ‘on the go’ (e.g., whilst on the jobsite), and uploaded to respective TQ / RFI schedules via ubiquitous computing tools such as a laptop computer or mobile cell phone device. Post issue, an autogenerated email is sent to advise the Design Manager of new queries, who in turn can route these on to the best placed project actor(s) to address the particulars. Using a programmed workflow to automate the task, total TQ/RFI data ultimately gets synthesized within respective schedules schedule overall so that better management and control of all project TQs and RFIs occur.

Figure 3 gives an indication of this, showing how via analytics, whereby RFI data is presented visually, and therefore more meaningfully in the web-based dashboard so to add value to the design management process.

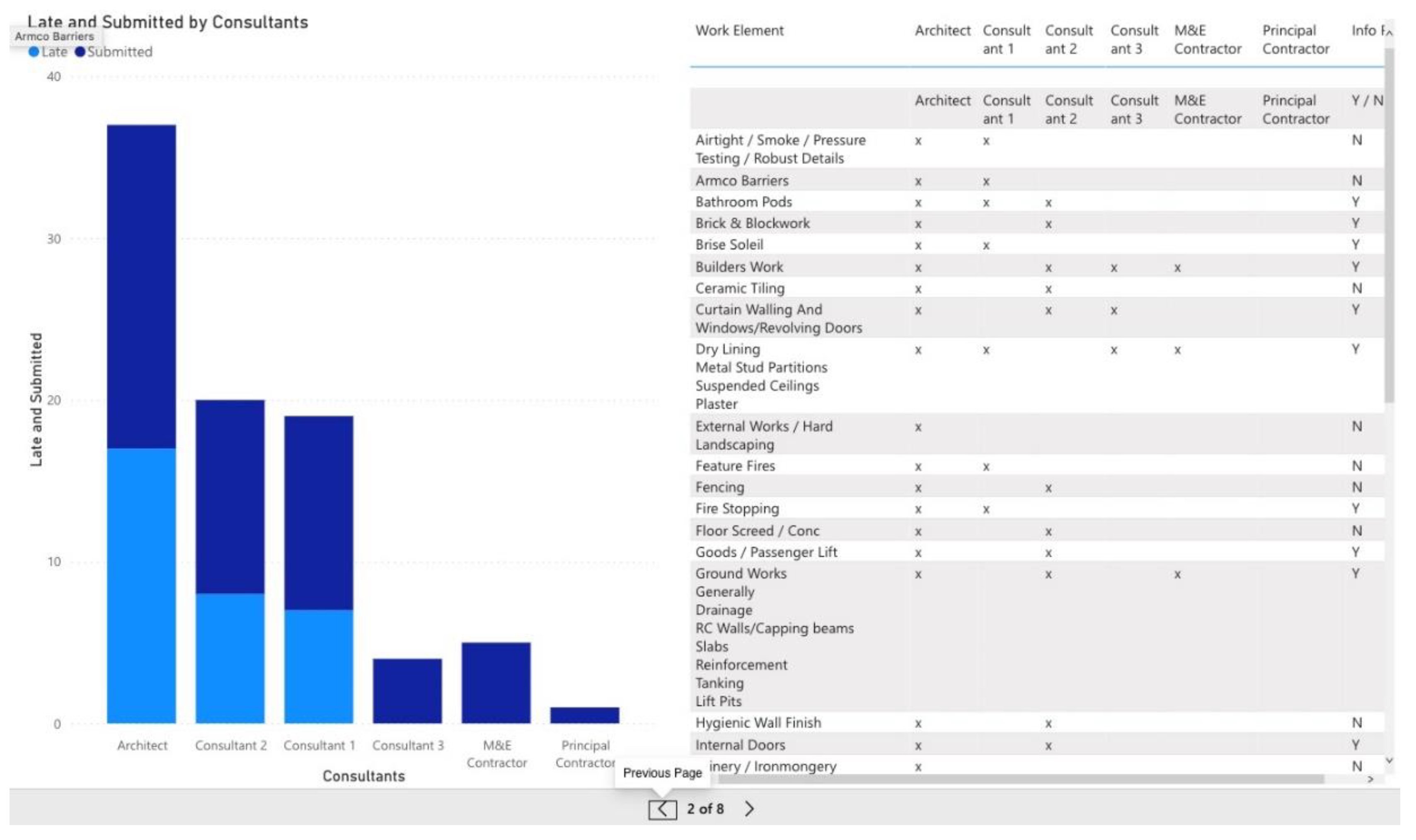

5.2. Addressing Challenges of Design Delivery Programme

Presently, although design programmes are routinely prepared on projects, the accurate monitoring of designer performance in terms of if/how targeted design release dates are met by designers is unsatisfactory. Similarly, because of a long subsequent chain of activities following design release, project-decision makers are too often unaware of the impact upon the project of poor performance by designers in terms of the planned vs actual design release dates. This is because, after design release is achieved there follows various: design approval(s); subcontract package procurement; subcontract award; and subcontractor lead-times; before trade contractors start their work packages on site. Therefore, without being explicitly aware of these logical relationships it can be difficult to see how dates that are missed by designers, can impact upon planned start on site dates several months later. Current approaches to tracking performance against Design Programme do not clearly reveal this impact, or indeed longer-term highlight trends of continually missing dates. These often involve tracking via excel based ‘Information Release Schedule’ (IRS) forms. The DsDM web-based dashboard corrects this by using such excel based data to better visually presenting such information for trend analysis and uses programmed workflow to semi-automate this activity.

Figure 4 gives an indication of how via analytics, such data is presented visually, and therefore more meaningfully in the web-based dashboard so to add further value to the design management process.

Plans to enhance these functions via the web-based prototype dashboard were shared back with various participants (amongst other targeted users),, who acknowledged the value these would add to the DM role: “A monitoring system like that is really good […] that’s really powerful, because that’s the sort of thing that as a design manager I would have loved to have had.” (Participant 9), and: “I think, having something like that is a huge benefit. You just get a better view, and the design team manage it a lot better, and they’re being overseen. From a [project] control perspective, that’s quite important.” (Participant 8).

5.3. Additional Challenges Addressed

In addition to the better coordinating and managing project-level design process interactions, and the better tracking of the work in progress of project-level design teams, other challenges addressed by the web-based prototype dashboard included:

The DsDM prototype dashboard allows project-level design management analysis to be undertaken by Design Managers. Above project-level, and at the higher portfolio-level, CSO directors can also monitor and review a range of concerns across a range of projects that use the DDM dashboard as indicated in

Figure 5 below.

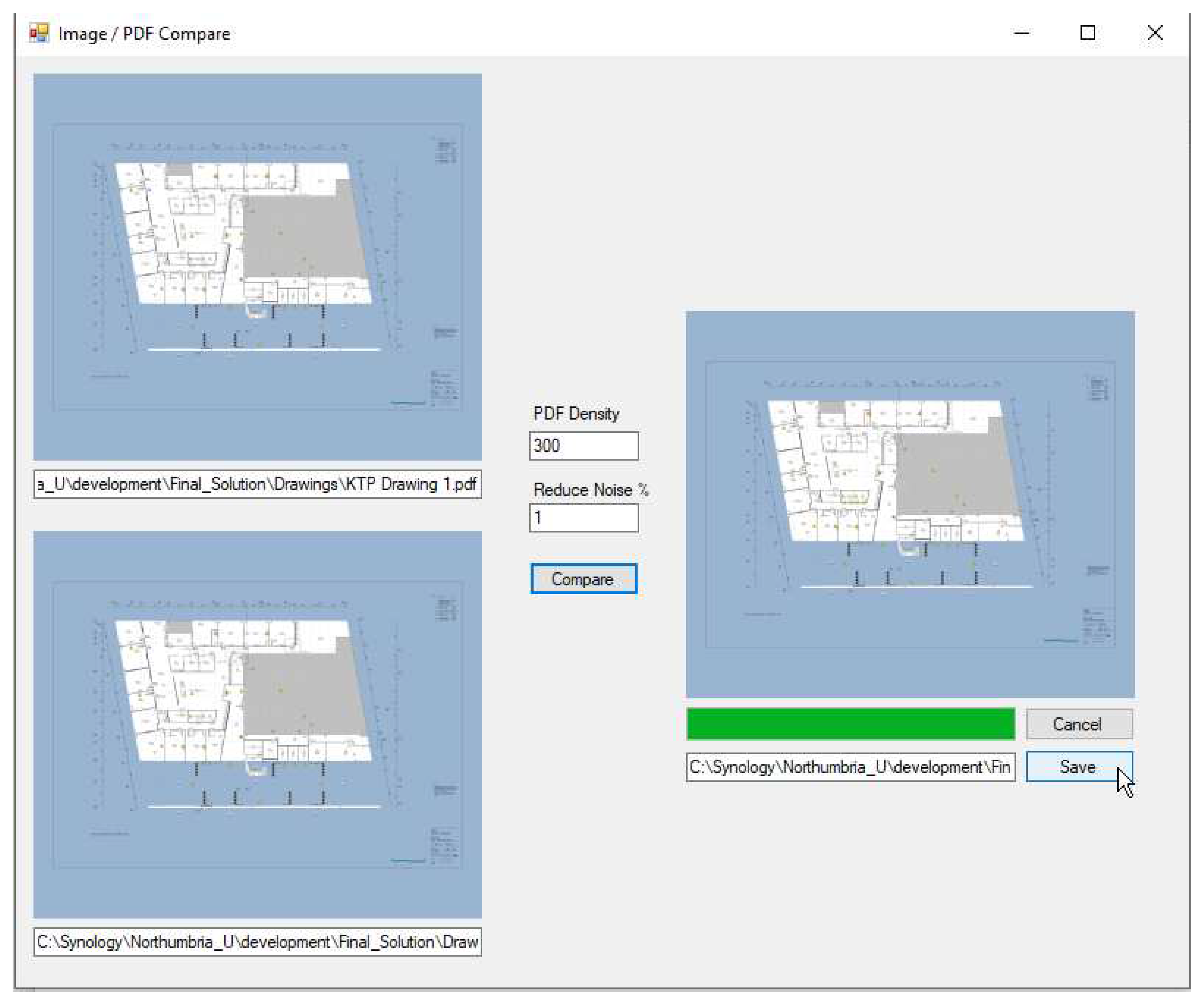

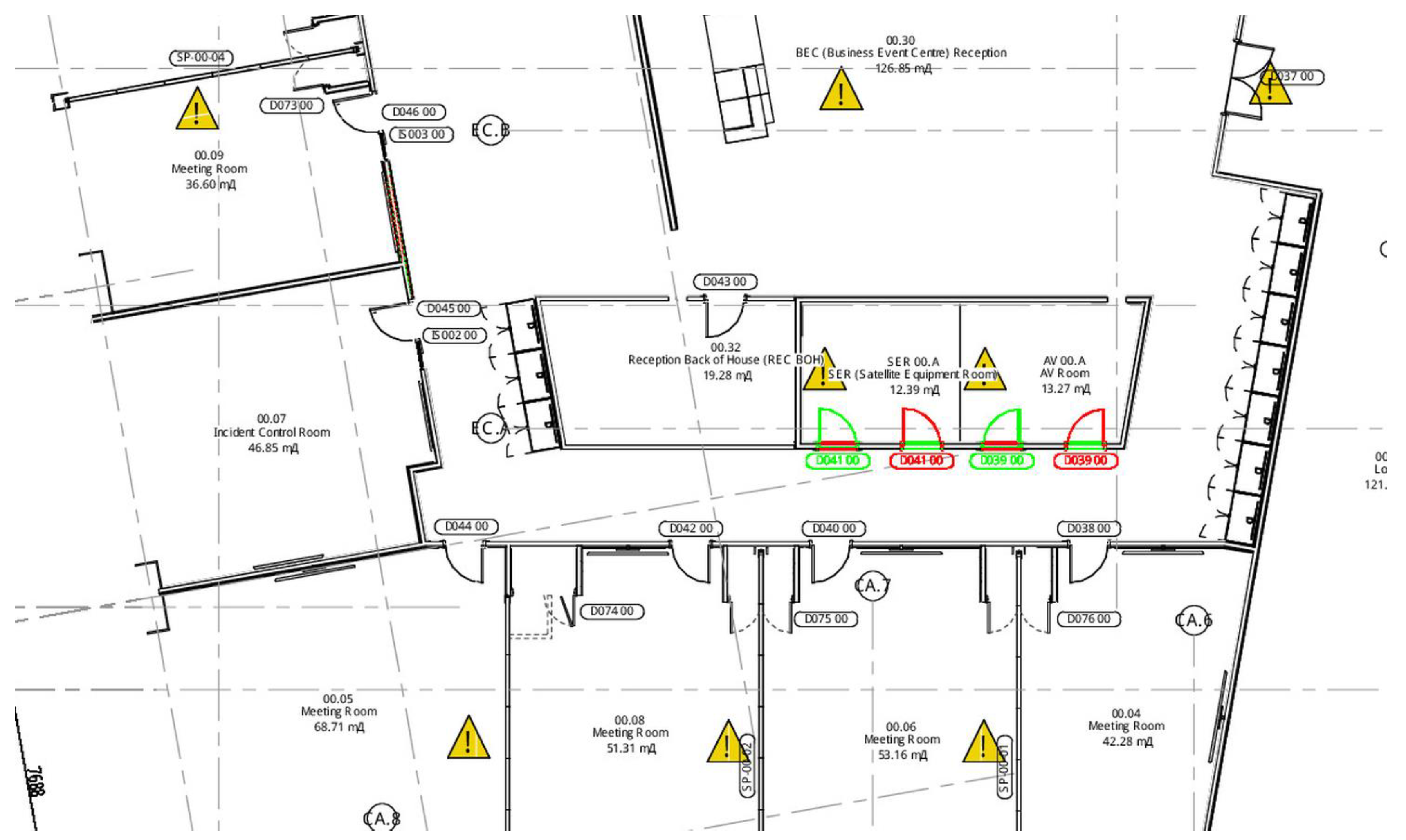

Similarly, via a stand-alone associated application also developed for this project, design managers can compare-and-contrast published design information in PDF formats, to identify any differences between revisions that have not been explicitly flagged by their publishers. Therefore, this helps spot any hidden changes that have not been identified by conventional clouding/bubbling on PDF drawings, as indicated in

Figure 6 and

Figure 7 below

6. Discussion and Conclusions

Digital dashboards can provide businesses with near real-time updates using data visualization, that allows for easier and efficient display of complex data [

38]. This makes it easier for managers to understand key metrics and make informed decisions [

39]. Web based dashboards can be accessed from any locations with an internet connection, allowing the relevant stakeholders to stay informed and make decisions on-the-go. They can be shared among team members, allowing for improved collaboration, and transparency. Various researchers have discussed how digital dashboards, using project data analytics can help manage construction projects [

40,

41,

42] and areas in which digital dashboards are deemed useful here include:

Real-time monitoring of design and/or construction activities to show which activities are on track and which are behind schedule, thus enabling informed decisions and corrective actions to be undertaken.

Collaboration, as allowing stakeholders to view the same information, so that everyone is works from the same data set, can improve team communication and coordination.

Performance tracking, as providing visual representations of project performance, can make it easier to track progress and identify areas where improvements are needed.

Against the context of the increasing adoption of digitally enabled design, Construction Design Managers face specific challenges that the use of a digital web-based dashboard could now better help alleviate. These include challenges around the management of project-related design activities, processes, people, and other resources to enable the effective flow, and production of design information to occur. To date, no other digital dashboard is known of that addresses these specific concerns. This research addresses this gap. This descriptive research reports on the development of a web-based prototype dashboard, produced as part of the current progress of a collaborative industry-academia Knowledge Transfer Project (KTP) designed to tackle some of the challenges of the Construction Design Management role. A design science research methodology (DSRM) was employed to deliver the necessary KTP project stages. Addressing Project Stages #1 and #2, purposively selected design managers were first interviewed to further uncover real world DM concerns against those found in the knowledge base. These interviews revealed how problems of design coordination, and designer performance monitoring remain key challenges worth addressing. Then, to address these concerns a web-based DsDM prototype dashboard was developed during Project Stage #3 which uses project data to aid design coordination activity and facilitate DM task prioritization and reporting functionality. By digitalizing selected design management processes to improve efficiency, and productivity, the visual reporting capability of the dashboard enables design production to be monitored at project and portfolio levels; trends in designer performance to be assessed and focus to be retained on technical queries (TQs) and requests for information (RFIs). In addressing Project Stage #4 by reporting on the development of this web-based Design Management prototype dashboard and illustrating how it can enhance design management productivity in construction firms, this work also provides further evidence of how employing a design science research methodology in construction can produce practical solutions that address real world construction concerns.

Author Contributions

Conceptualization, B.G., A.T., and K.R.; Funding acquisition, B.G., A.T., and K.R.; Project administration, B.G., and A.T.; Supervision, B.G., and K.R.; Methodology, B.G., and K.R.; Formal analysis, B.G.; Resources, B.G., and K.R; Software, K.R., Visualization, B.G., and K.R., Writing—original draft preparation, B.G. Writing – reviewing and editing, B.G., K.R., and H.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Innovate UK, as part of Knowledge Transfer Partnership number KTP011700.

Data Availability Statement

The data utilized in this project is proprietary and subject to commercial confidentiality. Due to contractual and commercial obligations, we are unable to share the raw data or specific datasets associated with this study. However, we are committed to providing transparency and are available for inquiries regarding the methodology, analysis procedures, and any non-proprietary details related to the research. For further information or requests, please contact Barry Gledson.

Acknowledgments

The authors wish to recognize the project work of KTP Associates Emma Tallet and Mo Koon Hung Luk, the project supervision of Drew Wigget and Michael Landy, the governance support of John Clayton of Innovate UK, and George Mokhtar of Turner and Townsend, as well as the administrative support of Hazel Juggins, Marie Foalle and Tracey Mellor from Northumbria University.

Conflicts of Interest

The authors declare no conflict of interest.

References

- E. Pikas, L. Koskela, and O. Seppänen, “Improving building design processes and design management practices: A case study,” Sustainability (Switzerland), vol. 12, no. 3, 2020. [CrossRef]

- P. Mujumdar and J. U. Maheswari, “Design iteration in construction projects – Review and directions,” Alexandria Engineering Journal, vol. 57, no. 1, 2018. [CrossRef]

- H. Ponton, A. Osborne, N. Thompson, and D. Greenwood, “The power of humour to unite and divide: a case study of design coordination meetings in construction,” Construction Management and Economics, vol. 0, no. 0, pp. 1–23, 2019. [CrossRef]

- M. S. Cidik and D. Boyd, “‘Shared sense of purposefulness’: a new concept to understand the practice of coordinating design in construction,” CONSTRUCTION MANAGEMENT AND ECONOMICS, vol. 38, no. 1, pp. 18–31, 2020. [CrossRef]

- R. F. Herrera, C. Mourgues, L. F. Alarcón, and E. Pellicer, “Comparing team interactions in traditional and bim-lean design management,” Buildings, vol. 11, no. 10, 2021. [CrossRef]

- P. Serrador and R. Turner, “The relationship between project success and project efficiency,” Project Management Journal, vol. 46, no. 1, pp. 30–39, Feb. 2015. [CrossRef]

- Q. He, Z. Tian, and T. Wang, “Performance measurement methods in megaprojects: An analytical review,” International Journal of Project Management, vol. 40, no. 6, pp. 634–645, 2022. [CrossRef]

- D. Bwalya Chiponde, B. Gledson, and D. Greenwood, “Contrasting Perceptions of Construction Managers and Project Managers Around Failure in Light of Morris and Geraldi’s Institutional Context,” Engineering Project Organization Journal, vol. 2022, no. 0, p. 0, 2022, Accessed: Oct. 26, 2023. Available online: https://epojournal.net/v11-danstan.

- J. Eynon, The design manager’s handbook. Oxford: Wiley-Blackwell, 2013.

- M. Bolpagni, R. Gavina, D. Ribeiro, and I. P. Arnal, “Shaping the Future of Construction Professionals,” in Industry 4.0 for the Built Environment, Springer, 2022, pp. 1–26.

- B. Succar, “Building information modelling framework: A research and delivery foundation for industry stakeholders,” Autom Constr, vol. 18, no. 3, pp. 357–375, May 2009. [CrossRef]

- B. Gledson, “Hybrid project delivery processes observed in constructor BIM innovation adoption,” Construction Innovation: Information, Process, Management, vol. 16, no. 2, pp. 229–246, Apr. 2016. [CrossRef]

- B. Gledson, “Innovation Diffusion within the UK Construction Sector: a study of the adoption of 4D BIM,” PhD, Northumbria University, 2017. Available online: http://nrl.northumbria.ac.uk/32529/.

- C. W. Churchman, “Guest editorial: Wicked problems,” Manage Sci, vol. 14, no. 4, pp. 141–142, 1967. [CrossRef]

- S. Emmitt and K. Ruikar, Collaborative design management. Abingdon, Oxon; New York: Routledge, 2013.

- W. Tizani, “Engineering Design,” in Constructing the future: nD modelling, G. Aound, A. Lee, and S. Wu, Eds., New York: Taylor & Francis, 2007, pp. 14–39.

- V. Laovisutthichai and W. Lu, “Design for manufacture and assembly (DfMA) in architectural design meetings: from a case study to knowledge-to-action framework,” Smart and Sustainable Built Environment, vol. 12, no. 5, pp. 1117–1134, 2023. [CrossRef]

- C. J. Anumba, C. Baugh, and M. M. a. Khalfan, “Organisational structures to support concurrent engineering in construction,” Industrial Management & Data Systems, vol. 102, no. 5, pp. 260–270, 2002. [CrossRef]

- R. Crotty, The Impact of Building Information Modelling: Transforming Construction. Oxon: SPON Press, 2012.

- M. S. Çıdık and D. Boyd, “‘Shared sense of purposefulness’: a new concept to understand the practice of coordinating design in construction,” Construction Management and Economics, vol. 38, no. 1, pp. 18–31, 2020. [CrossRef]

- J. M. Savolainen, A. Saari, A. Mannisto, and K. Kahkonen, “Indicators of collaborative design management in construction projects,” Journal of Engineering, Design and Technology, vol. 16, no. 4, pp. 674–691, 2018. [CrossRef]

- J. Jacob and K. Varghese, “A framework for ad hoc information management for the building design process,” Engineering Construction and Architectural Management, vol. 25, no. 8, pp. 1034–1052, 2018. [CrossRef]

- M. Sutrisna and J. Goulding, “Managing information flow and design processes to reduce design risks in offsite construction projects,” Engineering Construction and Architectural Management, vol. 26, no. 2, pp. 267–284, 2019. [CrossRef]

- P. Uusitalo, O. Seppanen, A. Peltokorpi, and H. Olivieri, “Solving design management problems using lean design management: the role of trust,” Engineering Construction and Architectural Management, vol. 26, no. 7, pp. 1387–1405, 2019. [CrossRef]

- P. Uusitalo et al., “To trust or not to trust: is trust a prerequisite for solving design quality problems?,” Construction Management and Economics, vol. 39, no. 4, pp. 279–297, 2021. [CrossRef]

- G. Parkes, “How greater data access will make civil engineering and construction more productive,” Proceedings of the Institution of Civil Engineers: Civil Engineering, vol. 175, no. 4, pp. 168–174, Jul. 2022. [CrossRef]

- APM, “Getting started in Project Data,” Buckinghamshire, UK, 2022. Available online: https://www.apm.org.uk/media/50992/getting-started-in-project-data-web-final.pdf?utm_source=knowledge_campaign&utm_medium=Email_launch&utm_campaign=DataGuide22.

- M. Saunders, P. Lewis, and A. Thornhill, Research methods for business students, 5th ed. Essex: Pearson Education Limited, 2009. Accessed: Jul. 14, 2014. [Online]. Available: http://scholar.google.com/scholar?hl=en&btnG=Search&q=intitle:Research+methods+for+business+students#0.

- J. van Aken, A. Chandrasekaran, and J. Halman, “Conducting and publishing design science research,” Journal of Operations Management, vol. 47–48, no. 1, 2016. [CrossRef]

- A. Hevner and S. Gregor, “Envisioning entrepreneurship and digital innovation through a design science research lens: A matrix approach,” Information and Management, vol. 59, no. 3, 2022. [CrossRef]

- A. Benfell, “Modeling functional requirements using tacit knowledge: a design science research methodology informed approach,” Requir Eng, vol. 26, no. 1, 2021. [CrossRef]

- A. R. Hevner, S. T. March, J. Park, and S. Ram, “Design science in information systems research,” MIS Q, vol. 28, no. 1, 2004. [CrossRef]

- K. Peffers, T. Tuunanen, M. A. Rothenberger, and S. Chatterjee, “A design science research methodology for information systems research,” Journal of Management Information Systems, vol. 24, no. 3, 2007. [CrossRef]

- G. L. Geerts, “A design science research methodology and its application to accounting information systems research,” International Journal of Accounting Information Systems, vol. 12, no. 2, 2011. [CrossRef]

- T. Haryanti, N. A. Rakhmawati, and A. P. Subriadi, “Measuring the digital transformation maturity level independently with the design science research methodology,” Systems Engineering, 2023. [CrossRef]

- S. Kanjanabootra, “Design Science method and theory in a construction and engineering context: ‘a phronetic tale of research,’” Engineering Project Organization Journal, vol. 6, no. 2–4, pp. 64–77, Oct. 2016. [CrossRef]

- D. Douglas, “A Framework for the Development of Digital Twin in Road and Rail Infrastructure Asset Management (Unpublished),” Northumbria University, Newcastle Upon Tyne, UK, 2023.

- J. Reinking, V. Arnold, and S. G. Sutton, “Synthesizing enterprise data through digital dashboards to strategically align performance: Why do operational managers use dashboards?,” International Journal of Accounting Information Systems, vol. 37, 2020. [CrossRef]

- S. Shirowzhan, S. M. E. Sepasgozar, and J. Trinder, “Developing Metrics for Quantifying Buildings’ 3D Compactness and Visualizing Point Cloud Data on a Web-Based App and Dashboard,” J Constr Eng Manag, vol. 147, no. 3, 2021. [CrossRef]

- V. Weerapura, R. Sugathadasa, M. M. De Silva, I. Nielsen, and A. Thibbotuwawa, “Feasibility of Digital Twins to Manage the Operational Risks in the Production of a Ready-Mix Concrete Plant,” Buildings, vol. 13, no. 2, 2023. [CrossRef]

- A. Arsiwala, F. Elghaish, and M. Zoher, “Digital twin with Machine learning for predictive monitoring of CO2 equivalent from existing buildings,” Energy Build, vol. 284, 2023. [CrossRef]

- B. P. Y. Loo and R. W. M. Wong, “Towards a Conceptual Framework of Using Technology to Support Smart Construction: The Case of Modular Integrated Construction (MiC),” BUILDINGS, vol. 13, no. 2, 2023. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).