1. Introduction

Weeds left in sugar beet (beta vulgaris L.) cause problems at harvesting the beet roots for sugar production, decrease yield and increase the weed populations in the future crops due to the mature weed seeds left in the soil. Therefore, an integrated weed management (IWM) strategy is very important and practices needs to be applied in sugar beet cultivation, and in programs of pesticide reducing and environment protection such as the European Green Deal.

Economic, ecological and social factors characterize a modern and sustainable sugar beet production [

1]. Field cropping strategies should consider environmental aims, while ensuring fair profits for farmers and the associated agricultural industry. Nevertheless, after elaboration of management factors such as pesticides, high-yielding and pest-tolerant cultivars, irrigation systems and different synthetic fertilizers, the food quality must also be guaranteed. The interaction of integrated methods of crop protection is mandatory for prospective and sustainable food production [

2]. The European Union directives encourage farmers to meet with stricter standards concerning pest management. That leads to restrictions on herbicide applications, and promotes the reduction of the total amounts of herbicides applied. The European Commission favors a reduced input of pesticides in the agricultural supply chain [

3].

Nevertheless, chemical weed control still plays an important role for the weed management strategy in sugar beet. Therefore, an effective weed management is crucial. Chemical weed control has currently evolved into an unavoidable component of weed management in sugar beet production. The most important herbicide mixtures contain the following active ingredients: metamitron, phenmedipham, desmedipham and ethofumesate [

4]. For sugar beet, the common weed control practice is the implementation of 3–5 post herbicide applications in the cotyledoneous stage of the weeds. Nevertheless, high environmental risks and crop damage may be the consequences of the herbicide application [

5].

A part of IWM is mechanical weed control [

6,

7]. An implementation of mechanical weed control tools in sugar beet production can substitute herbicide treatments and therefore reduce the amount of different herbicides in the environment [

6,

8]. Due to the slow driving speeds and limited working width of the implements, the labor efficiency is relatively low compared to chemical weed control. Even more, hoeing in the intra-row area and operating as closely as possible to the crop area are the requirements for a successful mechanical weed control management strategy [

9]. The use of precision agriculture (PA) is an expedient way of steering the hoe close to the crop row. Gerhards et al., 2020, could show, that 3 m camera-guided hoeing in cereals was possible with only a lateral offset of 19 mm from the crop row. Furthermore, driving speed could be increased up to 8 km/h

−1 with a weed control efficacy of nearly 80% and no crop losses [

10]. The use of PA in agriculture is gaining more and more importance, due to the commercialization of new developments like the Global Positioning System (GPS). The operation with PA can reduce labor costs and is able to increase the speed of the applications [

11]. The use of Global Navigation Satellite System (GNSS) technologies or digital image progression is needed for accurate guidance [

12]. Guidance systems within the field identify the position of the crop rows and a hydraulic side shift system steers the hoe close to the crop area (5 cm on each side) and provides higher driving speeds by reducing the farmers work [

13,

14,

15].

Weed control in sugar beet cultivation is increasingly difficult because the physiological stage of the crop is small and strict and technical rules are imposed with low and precisely fractionated doses. It is interesting to investigate the differences between chemical and mechanical controls on weeds in the mentioned crop, first of all on the products and physiology of the crop plant as well as on the finished product like sugar procent (obtained from the roots) or the animal consumer (packages and leaves) or after industrialization on human in different foods.

Mechanical weed control in agriculture has advanced in terms of precision and working rate over the past years. The real-time communication of implements with sensor systems further increased the potential of mechanical weeding. There is a wide array of available sensors including image analysis by camera, GNSS, laser and ultrasonic systems that can improve weed control efficacy in combination with mechanical systems. Every sensor type has its advantages and disadvantages. Camera-steered hoes with a hydraulic side shifting control for row crops are robust and reliable and they are now widely available from different manufacturers [

16].

The advantages as we anticipate during the experiment is that in the region of study the farmers cultivate sugar beet on 100–200 ha maximum in the culture rotation at a normal farm of 1000 ha arable land, so the hoeing can be done easily in a couple of days because of the high speed advantage from the row guard steering and the recognition of the sugar beet row, and the crop damage is very low.

Therefore, the objectives of this study were to combine chemical (Pre- and Post-emergence herbicides) and sensor-based mechanical treatments (sensor-guided hoeing) to evaluate this combinations to reduce the amount of herbicide use, while maintaining high yield, equal weed control and adequate crop selectivity.

The hypotheses of this study were:

- i)

reduce the chemical treatments (pre-emergence and post-emergence herbicides) and reducing the stress of the plant

- ii)

weed control efficacy up to 98% including the precision technologies and maximizing the yield up to 70 t ha−1, due to mechanical weed control included in the conditions and weed abundance from South Transilvania, Romania.

2. Results

2.1. The Five Most Abundant Weed Species at Each Trial Site

Average weed densities for BBCH 19 at treatment time ranged from 12 plants m

−2 to 49 plants m

−2 in sugar beet. For BBCH 31, the average weed densities at treatment time ranged from 8 plants m

−2 to 24 plants m

−2. The most abundant weed species with their dominance are listed in

Table 1.

Lamb’s quarters (

Chenopodium album L.), the perennial creeping thistle (

Cirsium arvense L.), cocklebur (

Xanthium italicum), green foxtail (

Setaria viridis) chamomile (Matricaria chamomilla) were most abundant in 2021. Cleavers (

Galium aparine L.), birdeye speedwell (

Veronica persica L.), cockspur grass (

Echinochloa crus-galli), common knotgrass (

Polygonum aviculare L.), and shepherd’s purse (

Capsella bursa-pastoris L.) occurred 2022 (

Table 1).

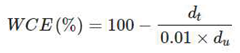

Both of the trial years were different concerning the emergence of the weeds and the precipiation date of arrival in the field after the seeding of the sugar beet but we can see in

Figure 1a composition of the weed species concluding the groups for dictoyledonates and monocotyledonates in the area of the experiment.

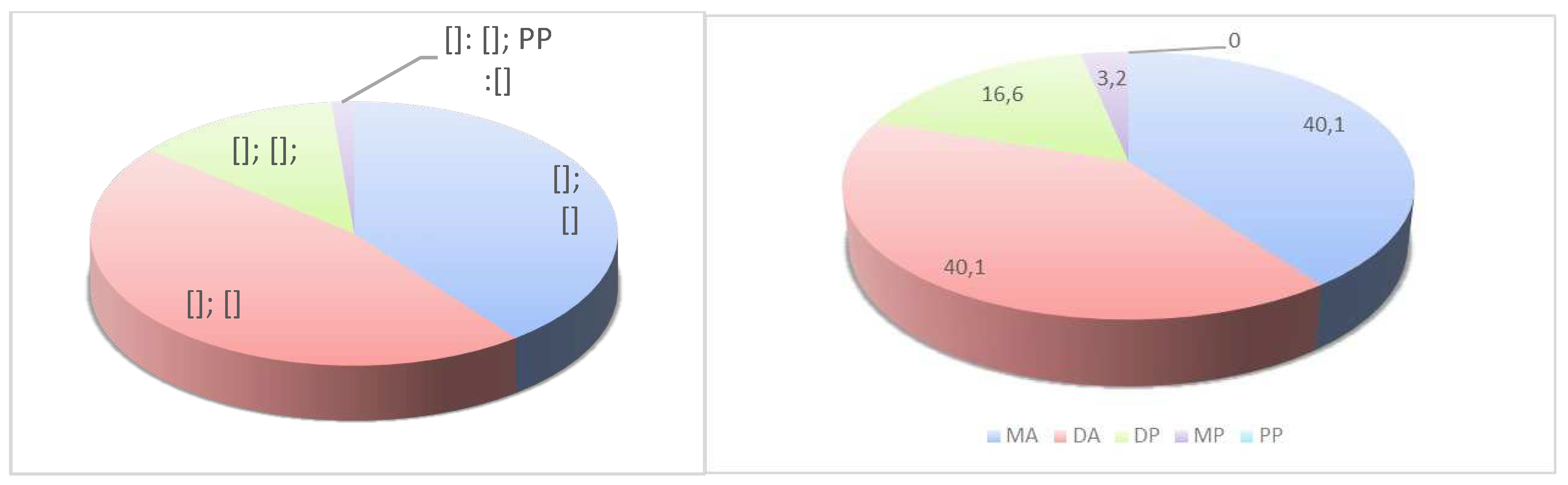

2.2. Weed control efficacy in 2021

In the year 2021, the weed control efficacy was up to 97% until the crop rows were closed (up to 60 days after crop emerge) for the 2021 chemical control as shown in the

Figure 2. The production of sugar beet roots for the year 2021 was up to 64 tones in out farm of study and in the region, of course the yield was much lower in the year 2022 because of the dry months from the summer and in 2021 the precipitations in the summer months were present in the sugar beet crops.

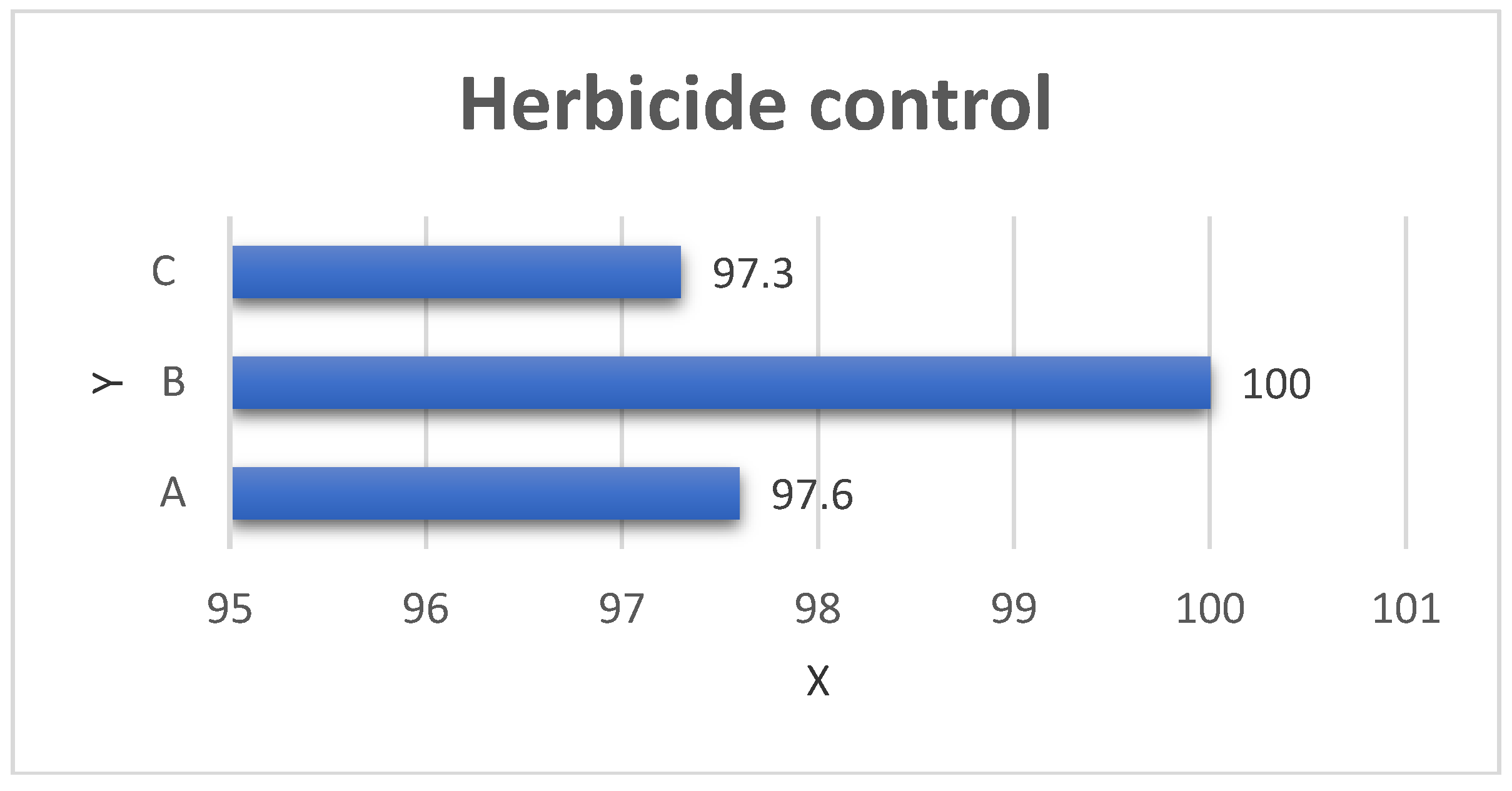

2.3. Weed control efficacy for the first and the second treatment time in 2022

The highest WCE for the first weed control pass could be achieved in the MWC + HWC treatment with 75% followed by the pure herbicide control HWC with 56% WCE, see

Table 2.

Weed control efficacy is done in 2022 with two repetitions on different growth stages of the sugar beet and four experiment plots like control (CRT), mechanical + herbicide weed control (MWC+HWC), herbicide only weed control (HWC) and mechanical only weed control (MWC) as shown in

Table 2 and

Table 3.

The hoeing treatment MWC performed only 37% WCE. The MWC treatment achieved with 36.93% the significantly lowest weed control in total.

For the second application time (

Table 3), MWC + HWC could again achieve the significantly highest WCE with 82% followed by the pure mechanical treatment MWC with 78% WCE. The conventional herbicide application HWC could only achieve 51% WCE but did not differ to the MWC treatment.

2.4. Sugar Beet Yield

In 2021 no crop losses were recorded and in the second year the crop losses were up to 2%, due to the sensor-based mechanical control. The combined treatment of mechanical and herbicide weed control methods (HWC + MWC) showed an significant increase of sugar beet yield of nearly 30 t ha−1 compared to the UC (28.12 t ha−1). Followed by the HWC with 50 t ha−1 and MWC with 42 t ha−1. There was a significantly different between UC and MWC and between MWC and HWC and HWC+MWC.

Sugar beet yield can be increased by introducing the sensor-based mechanical control with hoes in Romania up to + 80 t ha−1 for a performant farm, in the conditions proper to the usage of the hoeing at the period of BBCH 19 and 31 of sugar beet, and with good quantities of water in the soil in the spring and mid summer. At the moment the yield is at the level of +60 t ha−1 done in almost all the farm with the chemical control.

Analyzing the yield results from the experiment comparing with the medium yields at country level from the period 2015–2021 (

Table 5), we can say that excepting the UC trial in all other trials the yields are above average from the country. The yield from HWC and HWC + MWC trials are more than the highest medium yield from Romania.

3. Discussion

Post-emergent hoeing with goosefoot sweeps was very successful and recorded average inter-row weed control efficacies between 94% and 98% [

17].

Mechanical weed control is a complex part of agriculture. It requires considerable experience of the farmer to develop a long-term concept to keep the weed pressure as low as possible [

16].

In our experiment was a high weed density on the intra-row section, especially with the grass weed, and is needed in further research to have a better control also on the intra-row area between the plants, and of course to have a low crop damage because the intra-row practices are very close to the cultivated crop. The inter-row sensor-based hoe it is effective for the large parcels of sugar beets because of the higher speed you can drive the tractor and a very low crop damage, also in the experience farm parcels cultivated with sugar beet have 30–40 ha medium large size and the entire hectars cultivated for sugar beet was among 120–140 ha in each year, that leads to a few days work on the fields with the sensor based hoe with hydraulic steering.

Weed control efficacy (WCE) is better for the herbicides control at the early stages of the sugar beet with spraying herbicides, in most cases is done weekly, and we can loose considerably the yield of sugar beet if it is done after the six leaf stages of the crop (BBCH 19). The mechanical weed control can be done at the late stages of the crop after BBCH 19 and until the sugar beet leafs covers the soil between the rows.

In our experiment WCE is lower at BBCH 19 because of the slower growth of the weeds and it is higher in the BBCH 31 for the MWC control when the weeds are more developed and the hoe ripped them off from the ground, also at the HWC we realise a better control in the early stage of the crop and when the weeds are in the 2–3 leaf stage.

Herbicides should be applied more in the early stages of the crop and mechanical control can be done after the six leaf stage of the sugar beets.

Weed control in sugar beet cultivation is increasingly difficult because the physiological stage of the crop is small and strict and technical rules are imposed with low and precisely fractionated doses of herbicides. It is interesting to investigate the differences between chemical and mechanical controls on weeds in the mentioned crop, first of all on the products and physiology of the crop plant as well as on the finished product like sugar procent (obtained from the roots) or the animal consumer (packages and leaves) or after industrialization on human in different foods.

Concern about herbicides polluting ground and surface water, human health risks from herbicide exposure or residues, effects on the flora and fauna, development of herbicide resistance and the lack of approved and effective herbicides for minor crops such as vegetables, are the major factors driving the present and increasing interest in non-chemical weed control [

18,

19].

Trials have shown that it is possible to control weeds in integrated systems combining mechanical weeding and phytosanitary treatment, even for beet-growing, which is highly demanding in terms of weed competition [

8]. Questions may be legitimately asked about the cost of implementing these practices. The available studies show variable results depending on whether direct costs and/or some indirect impacts are taken into account.

4. Materials and Methods

4.1. Experimental site and design

Four field trials were conducted in sugar beets (beta vulgaris) in 2021 and 2022. The experiments were located at the conventional farm fields “Vintana SA” in the village of Vintu de Jos (45.99°N, 23.48°E), country Alba in Southwest Transylvania. The trials are in the intra Carpathian chain of mountains and at the plateau of the river Mures which has a good environment for agriculture and sugar beet cultivation, at an elevation of 284 m above sea level and an average rainfall of 520–550 mm/anual. The total annual rainfall was 396 mm for the year 2021 and 317 mm for the year 2022 until autumn as it is the time for the sugar beet harvest. The precipitations which are relevant for our climate and included zone of study can be found in the

Table 6 from spring and summer. Tillage before sowing was repeated within all experiments. First, the soil was ploughed in autumn at the 25–30 cm deepth, followed by a seedbed preparation in early March with a Horsch combinator. The soil texture was classified as a loam soil with a pH weak acid around 6,30 and a content of humus around 2% at all locations. Sugar beets were sown in the middle of March at conventional densities of 110.000 seeds ha

−1, at a deep of 4–5 cm and row distance of 45 cm, between the plants on the row it was 18 cm in all experiments.

All experiments were set up as a polyfactorial randomized complete block design with four repetitions and three treatments. The plot size in all trials was 3 m × 24 m, with the longer side of the plots in sowing direction of the crop. The treatments consisted of an untreated control (UC), a conventional herbicide application (HWC) and a mixed of 2× hoeing plus 3× chemical weed control method (HWC+MWC). Treatments description can be found in the

Table 7.

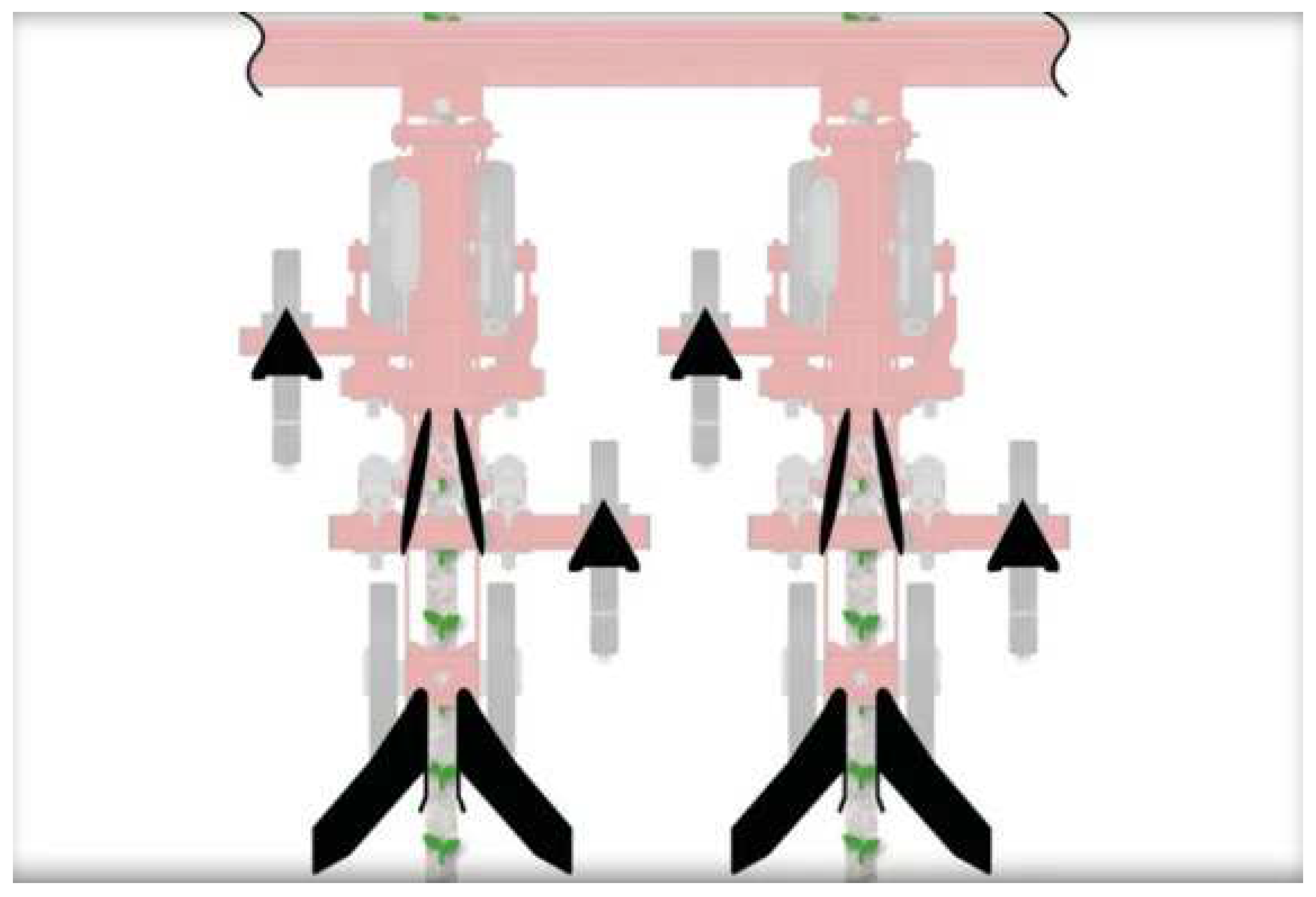

The UC plots were left untreated for the entire growing season. However, it was ensured that the UC also received the same number of passes with the tractor wheels as the mechanical and herbicide treatments. Hoeing was performed with the 3 m wide camera guided hoeing system Chopstar from Einböck. Camera based row detection is implemented in a real-time system for automatic guidance of the goosefeet sweeps in the inter-row with a distance of 50 mm to the crop rows. Therefore, the hoeing system of the experiment had one camera to recognize 3 rows from the experiment field of the sugar beet rows and a hydraulic side shift system (

Figure 4). Hoeing was performed parallel to the crop rows with a driving speed of 8 km h

−1. Hoeing the sugar beet row was performed with two goosefeet sweeps (20 cm), two side-knifes and two protection disks (see

Figure 5). Since each plot comprised six sugar beet rows were required seven implements to control all inter-row spaces of one 3 m plot. The safety distance towards the sugar beet rows was setup to a 5 cm wide range. For intra-row control of the weeds the finger weeders were set up above the ground and the protection shield elements were left on the soil to prevent the crop damage of the sugar beet. The herbicide application in both years was carried out with a mounted sprayer Amazone UF2002, from the company Amazone H. Dreyer GmbH & Co from Hasbergen—Germany, equipped with Lechler IDN 120–025 nozzles from the company Lecher GmbH from Metzingen—Germany at a pressure of 8 bar and a speed up to 8 to 10 km h

−1. Due to the high weed density in Transylvania and the slow emergence of the crop, until row closure, up to 60 days, it has to be minimum three times herbicide mix spraying applied on the whole field post-emergence with the low dosage technique for the broad leaf weeds (see

Table 8). Also it is common that the farmers spray pre-emergence herbicides in sugar beet with a mix of three herbicides. The weed control experiment done in sugar beet in the year 2021 was chemical 6 times spraying the whole field including the substance glyphosate and metamitron pre-emergence, and in 2022 we reduced two chemical pre-emergence herbicides and left only 4 sprayings as post-emergence control only as seen in

Table 8.

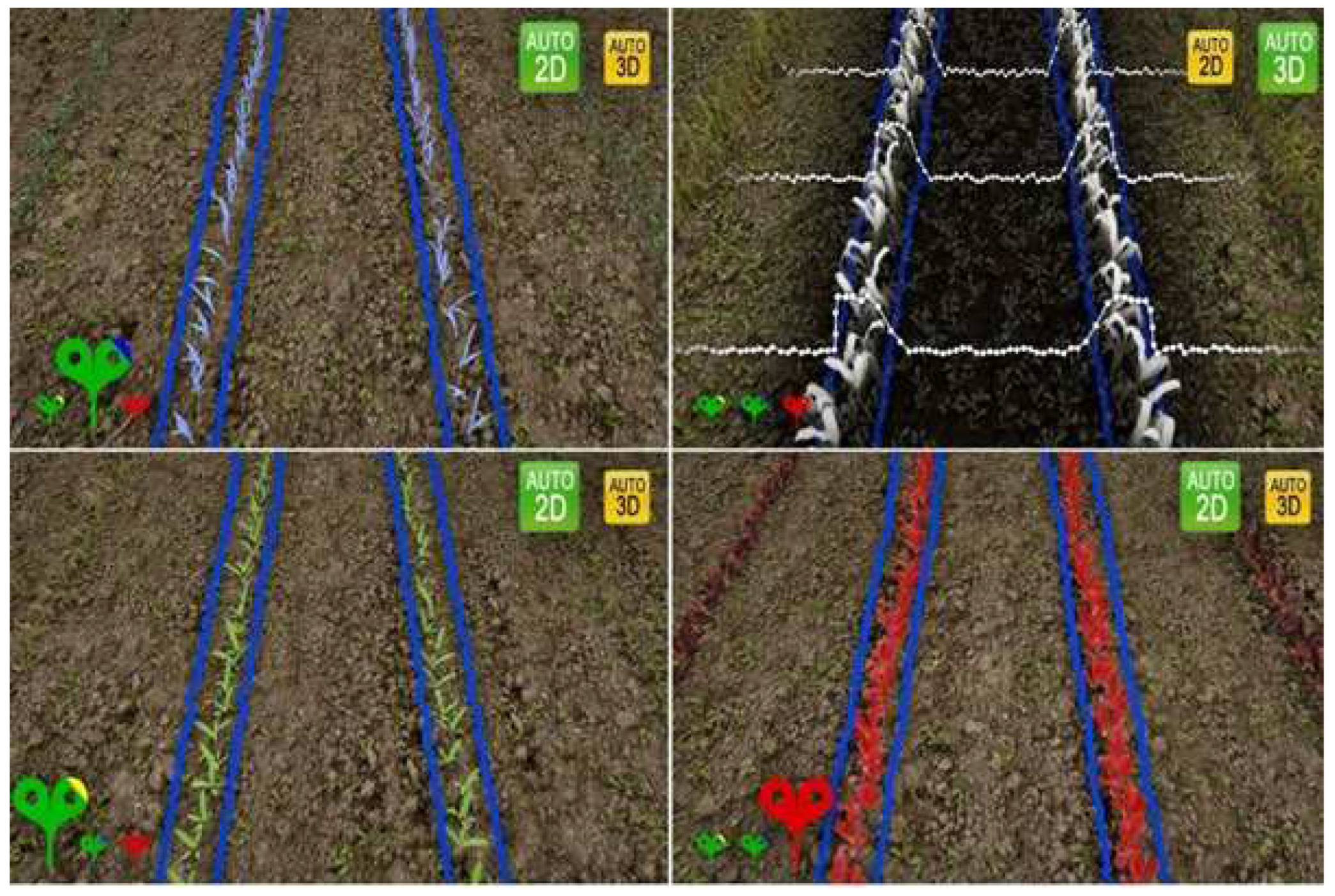

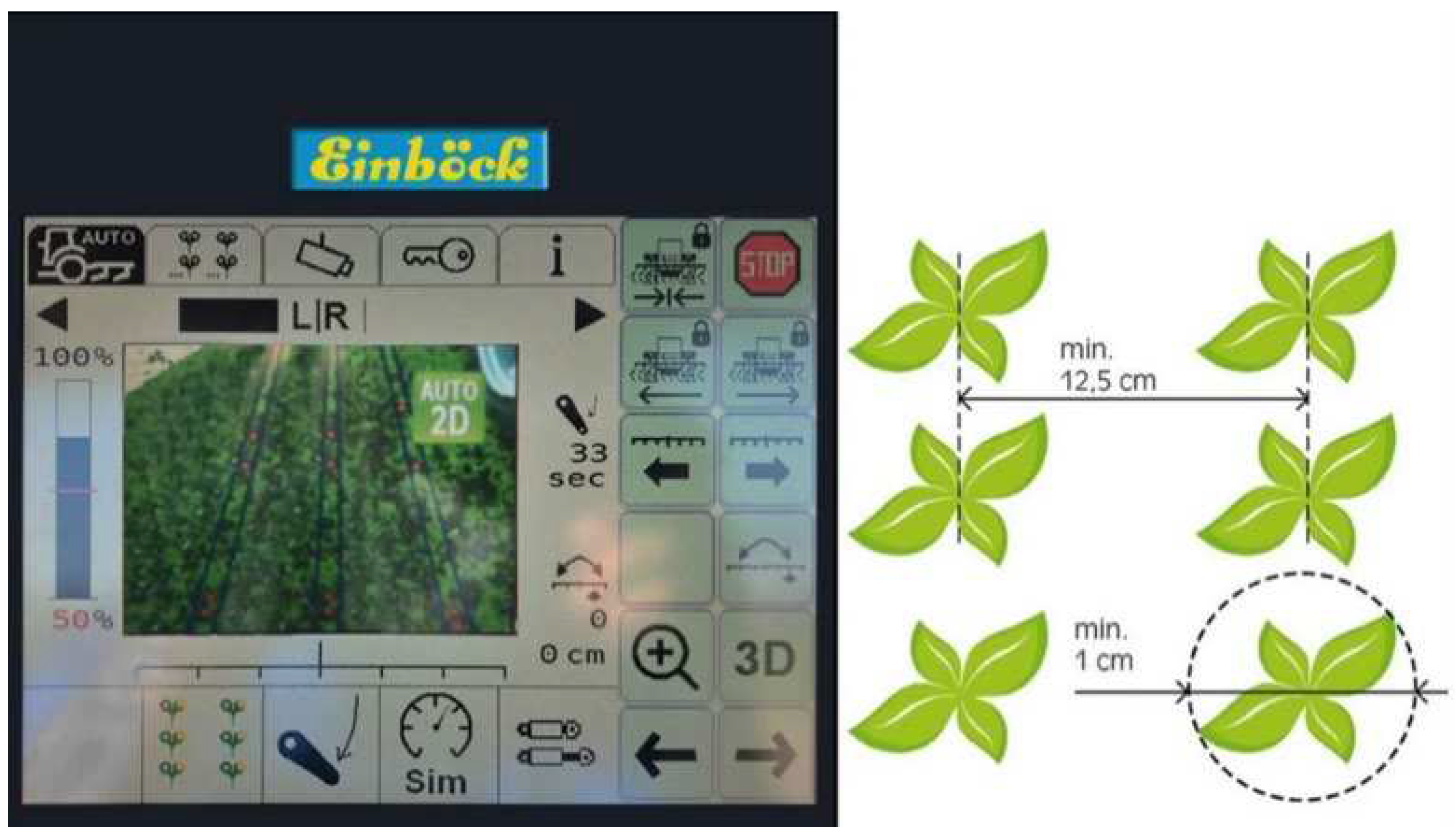

4.2. Description of the camera-based row-detection system used in the Chopstar, Einböck

Images are taken continuously by a 2D RGB-camera, scanning diagonally forward on 4 rows of sugar beets (

Figure 7). The camera is mounted at a separate bracket in a high of 1,8 m on the left side of the hoe. The camera setting can be adjusted to suit the color or height of the crop. You can choose between green/yellow (e.g., corn), green/blue (e.g., soybeans, vegetables) or red (vegetables e.g., beetroot) in 2D mode. The 3D mode can be used for corn, soybeans, sunflowers etc., if the plant rows have a clear growth advance (approx. 10 cm/3.90”) over the weed. Correct adjustment to the crop further increases the accuracy of row guidance (

Figure 6).

If there is a too high weed pressure and crop leaves overlap by weed leaves and the crop line cannot be recognized clearly any more, there is an additional 3D-mode. The camera automatically recognizes the height of the plants and allows to differ between the row structure of the high crops and the small weeds. This guarantees a fast row detection even if the crop leaves partly overlap in the inter-row area. The camera provides robust row detection under most lightning conditions. External artificial light improves the quality of row detection. The automatic camera steering can be conveniently set from the tractor via an operating terminal. With the help of different setting parameters, adapted to the crop (row spacing, number of rows in the camera’s field of view, plant width and height), an appropriate grid is laid over the image. Based on this data, the hoe is centered exactly along the row with the help of the side-shift frame. This ensures a narrow hoeing belt which guarantees maximum weed control.

4.3. Implementation of the Mechanical Treatments

Since only one model of goose feet swipes existed, two passes with the tractor new Holland (

Figure 8) were necessary to treat two sugar beet rows in each plot that had the mechanical weed control with the hoe. So it was performed on the two different plots MWC and HWC + MWC with the goosefoot swipes twice after the chemical treatments, in the two different stages of the sugar beet growth, the six leaf stage and the nine leaf stage that meaning the two different BBCH 19 and 31. The set-up of the mechanical sensor hoe was made in the farm adjusted to the culture of the sugar beet, meaning the width between the rows aligned with the width of the tillage controlling wheels.

4.4. Data acquisition

Weed density and weed species (weeds m

−2) was measured using a 0.5 m × 0.5 m frame (

Figure 9). The frame was placed in a random way three times per plot, three days after the application of the mechanical treatments, chemical treatments after 14 days and also on the uncontrolled plot after three days. Sugar beet harvest (t ha

−1) took place at the middle of September or in the start of October in both trial years depending on the sugar content and the weather conditions, particularly from each other every year in agriculture. The harvest of the sugar beet was done with a plot combine harvester. Washing and weight measurement was done at the farm.

4.5. Data analysis

The data were analyzed with the statistical software Anova Polifact Soft (Cluj Napoca, Romania) Proir to analysis the data were tested for homogeneity of variance and normal distribution. An analysis of variance (ANOVA) was performed. The results of the trials were compared by Duncan test for p 0,05.

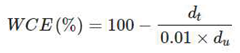

The weed control efficacy (WCE) in % was calculated with the weed density for each plot and for two different growth stages BBCH, according to Rasmussen [

20].

where dt is the weed density (weeds m−2) after application of the treatments, and du is the weed density (weeds m−2) in the untreated control plots.

5. Conclusions

The methods of integrated control management of weeds done in this study includes the post-emergence herbicides and the sensor-based mechanical control replacing the pre-emergence herbicides. Results show that is possible to reduce the pre-emergence herbicides but not replace the post-emergence ones entirely in sugar beet weed control scheme from Romania because of the weed density and abundance of species in most of the farms, and could be achieved a better yield including the integrated strategies of weed management. The number of chemical herbicides in sugar beet is getting smaller and are continuing banned, also the herbicide resistance of weeds is increasing, so the present study can contribute to the reduction of herbicides and a lower weed density testing in what growing stage of the sugar beet can be the most suitable times of sensor-based mechanical control.

The results of the study show that it is possible to obtain increased production of beet roots with a significant reduction of chemical products in the farms from Transylvania. The mechanical shifting precision weed control methods could also achieve less stress for the plants and a better aeration of the soil, and these facts can increase of course the yield aimed. The growing stages experimented in this study: 6-leaf and 9-leaf of sugar beet, BBCH 19 and 31, are suitable for the control of weeds and low crop losses. Results show that in a dry summer as it was for sugar beet in the year 2022, the mechanical and chemical weed control (HWC+MWC) can offer a sustainable and accepted yield controlling significant weed densities. We also have to specify that weed abundance is much higher in Romania that in the West Europe countries that cultivates sugar beet, species of weeds that grow in agricultural lands are up to 5–6 times more than in Germany for example, so for this reason future studies needs to be done for improving the weed control and yield in sugar beet.

Similar latest studies from Germany showed that the sensor-based mechanical control inter-row have less crop losses of sugar beet and the uprooted plants were not significant according to the number of plant per hectare. Kunz, et.al studied that automatic machine guidance systems for inter-row weed hoeing have slightly increased efficacy of weed control compared to conventional mechanical weed control methods. Weeds close to the crop, however, will remain a major constraint of mechanical weeding.

Author Contributions

Conceptualization, S.C.P., T.R. and I.B.; methodology and data analysis, S.C.P., M.S. and I.B.; writing original draft preparation S.C.P. and M.S.; writing review and editing M.S., S.C.P., T.R. and I.B.; funding acquisition, S.C.P. All authors have read and agreed to the published version of the manuscript.

Funding

The experiment is supported from the USAMV Cluj Napoca and the PhD program of Engineered Agricultural Sciences fundings and field trials and work operations were done in the collaboration and with the support of the Association of Agriculture Vintana SA Farm from Vintu de Jos, South of Transilvania, Alba county, which is a representative sugar beet farm. The machines that we worked with are from the Research farm of USAMV Cluj-Napoca and the tractor, adjustment and labor is from Vintana Agriculture farm.

Data Availability Statement

Data supporting reported results can be found in the 21

st International conference Life Sciences for Sustainable Development 2022 from Cluj-Napoca, Romania

https://symposium.usamvcluj.ro.

Acknowledgments

The present study and field trials experiment are done on a local project for several years also including 2023 and 2024. Many thanks to the professors from the University of Agriculture Sciences and Veterinary Medicine from Cluj-Napoca, Romania and the collaboration with the University of Hohenheim, Herbology Institute from Stuttgart, Germany.

Conflicts of Interest

The authors declare no conflict of interests.

References

- Christen, O. (1999). Nachhaltige Landwirtschaft. Von der Ideengeschichte zur praktischen Umsetzung. Bonn: Schriftenreihe des Instituts für Landwirtschaft und Umwelt.

- Geldermann, U.; Kogel, K.-H. Nature’s Concept. The ‘New Agriculture’amidst ecology, economy and the demythologization of the gene. J. Agron. Crop. Sci. 2002, 188, 368–375. [Google Scholar] [CrossRef]

- Hillocks, R. Farming with fewer pesticides: EU pesticide review and resulting challenges for UK agriculture. Crop. Prot. 2012, 31, 85–93. [Google Scholar] [CrossRef]

- Vasel, E. H., Ladewig, E., & Märländer, B. (2012). Weed composition and herbicide use strategies in sugar beet cultivation in Germany. Journal of Cultivated Plants, 64(4).

- Gummert, A.; Laedewig, E.; Märländer, B. (2012): Guidelines for integrated pest management in sugar beet cultivation - weed control. Journal für Kulturpflanzen 64(4), pp. 105–111.

- VAN DER Weide, R.Y.; O Bleeker, P.; Achten, V.T.J.M.; Lotz, L.A.P.; Fogelberg, F.; Melander, B. Innovation in mechanical weed control in crop rows. Weed Res. 2008, 48, 215–224. [Google Scholar] [CrossRef]

- Bowman, G. (1997): Steel in the field: a farmer’s guide to weed management tools. Sustainable Agriculture Network handbook series no. 2, Beltsville, Maryland, USA.

- Kunz, C.; Weber, J.F.; Gerhards, R. Benefits of precision farming technologies for mechanical weed control in soybean and sugar beet—Comparison of precision hoeing with conventional mechanical weed control. Agronomy 2015, 5, 130–142. [Google Scholar] [CrossRef]

- Melander, B., & Rasmussen, G. (2001). Effects of cultural methods and physical weed control on intra-row weed numbers, manual weeding and marketable yield in direct- sown leek and bulb onion. Weed Research, 41(6), 491-508.

- Gerhards, R.; Späth, M.; Sökefeld, M.; Peteinatos, G.G.; Nabout, A.; Ayala, V.R. Automatic adjustment of harrowing intensity in cereals using digital image analysis. Weed Res. 2020, 61, 68–77. [Google Scholar] [CrossRef]

- Plant, R.E. Site-specific management: the application of information technology to crop production. Comput. Electron. Agric. 2001, 30, 9–29. [Google Scholar] [CrossRef]

- Gerhards, R.; Christensen, S. Real-time weed detection, decision making and patch spraying in maize, sugarbeet, winter wheat and winter barley. Weed Res. 2003, 43, 385–392. [Google Scholar] [CrossRef]

- Tillett, N.; Hague, T.; Miles, S. Inter-row vision guidance for mechanical weed control in sugar beet. Comput. Electron. Agric. 2002, 33, 163–177. [Google Scholar] [CrossRef]

- Slaughter, D.; Giles, D.; Downey, D. Autonomous robotic weed control systems: A review. Comput. Electron. Agric. 2008, 61, 63–78. [Google Scholar] [CrossRef]

- Nørremark, M.; Griepentrog, H.W.; Nielsen, J.; Søgaard, H.T. Evaluation of an autonomous GPS-based system for intra-row weed control by assessing the tilled area. Precis. Agric. 2011, 13, 149–162. [Google Scholar] [CrossRef]

- Machleb, J.; Peteinatos, G.G.; Kollenda, B.L.; Andújar, D.; Gerhards, R. Sensor-based mechanical weed control: Present state and prospects. Comput. Electron. Agric. 2020, 176, 105638. [Google Scholar] [CrossRef]

- Machleb, J.; Peteinatos, G.G.; Sökefeld, M.; Gerhards, R. Sensor-Based Intrarow Mechanical Weed Control in Sugar Beets with Motorized Finger Weeders. Agronomy 2021, 11, 1517. [Google Scholar] [CrossRef]

- Lotz, L.; Van Der Weide, R.; Hoereman, G.; Joosten, L. (2002): Weed management and policies: from prevention and precision technology to certifying individual farms. Proceedings 12th EWRS Symposium, Wageningen, pp. 2–3.

- Melander, B.; Rasmussen, I.A.; Bàrberi, P. Integrating physical and cultural methods of weed control— examples from European research. Weed Sci. 2005, 53, 369–381. [Google Scholar] [CrossRef]

- Rasmussen, J. A model for prediction of yield response in weed harrowing. Weed Res. 1991, 31, 401–408. [Google Scholar] [CrossRef]

Figure 1.

Composition groups of the weed species in two different years 2021–2022 where: *MA: Annual monocotyledonates, DA: Annual Dicotyledonates, DP: Perennial dicotyledonates, MP: Perenial Monocotyledonates, PP: Perennial Pteridophytes.

Figure 1.

Composition groups of the weed species in two different years 2021–2022 where: *MA: Annual monocotyledonates, DA: Annual Dicotyledonates, DP: Perennial dicotyledonates, MP: Perenial Monocotyledonates, PP: Perennial Pteridophytes.

Figure 2.

Chemical weed control efficacy in 2021, X axis = efficacy % and Y axis are the three different test plots.

Figure 2.

Chemical weed control efficacy in 2021, X axis = efficacy % and Y axis are the three different test plots.

Figure 3.

Specific curves of WCE for the both stages in 2022.

Figure 3.

Specific curves of WCE for the both stages in 2022.

Figure 4.

Hoeing implement Chopstar with the sensor based camera of row recognition used in the field experiments of Vintana farm from 2021–2022.

Figure 4.

Hoeing implement Chopstar with the sensor based camera of row recognition used in the field experiments of Vintana farm from 2021–2022.

Figure 5.

The set-up for the hoe used in the experiments at Vintana farm in 2021 and 2022. The image shows 2 plots wide (total of six sugar beet rows), picture from the manufacturer Einbock, Austria.

Figure 5.

The set-up for the hoe used in the experiments at Vintana farm in 2021 and 2022. The image shows 2 plots wide (total of six sugar beet rows), picture from the manufacturer Einbock, Austria.

Figure 6.

Addaptation of the camera application to the culture.

Figure 6.

Addaptation of the camera application to the culture.

Figure 7.

The software recognizes the plant rows even in case of heavy weed infestations and/or small plants. The settings can be adjusted on the conditions (Einbock, Austria).

Figure 7.

The software recognizes the plant rows even in case of heavy weed infestations and/or small plants. The settings can be adjusted on the conditions (Einbock, Austria).

Figure 8.

Tractor used New Holland and the sensored-based hoe Einbock Chopstar.

Figure 8.

Tractor used New Holland and the sensored-based hoe Einbock Chopstar.

Figure 9.

The frame (0.5 × 0.5 m) used for the measurement of the weed density.

Figure 9.

The frame (0.5 × 0.5 m) used for the measurement of the weed density.

Table 1.

The five most abundant species of weeds in both trial years 2021–2022 (average of each species participation).

Table 1.

The five most abundant species of weeds in both trial years 2021–2022 (average of each species participation).

| |

2021 |

2022 |

| Names |

Chenopodium album 19% |

Capsella bursa-pastoris 18% |

| |

Cirsium arvense 21% |

Echinochloa crus-galli 16% |

| |

Matricaria chamomilla 29% |

Galium aparine 21% |

| |

Setaria viridis 12% |

Polygonum aviculare 23% |

| |

Xanthium italicum 15% |

Veronica persica 12% |

Table 2.

The results obtained for the mean weed density (plant m−2) at BBCH 19 at 14 days after the first application of each treatment in 2022.

Table 2.

The results obtained for the mean weed density (plant m−2) at BBCH 19 at 14 days after the first application of each treatment in 2022.

| Treatment BBCH 19 |

Weed density (Plants m−2) |

WCE % |

| UC |

49.67 a |

Ct. |

| MWC |

31.33 b |

36.93 b |

| HWC |

21.67 ab |

56.37 ab |

| MWC + HWC |

12.33 c |

75.20 a |

Table 3.

Results obtained for the mean weed density (plants m−2) at BBCH 31 at 14 days after the final application of each treatment in 2022.

Table 3.

Results obtained for the mean weed density (plants m−2) at BBCH 31 at 14 days after the final application of each treatment in 2022.

| Treatment BBCH 31 |

Weed density (Plants M−2)

|

WCE % |

| UC |

108. 33 a

|

Ct. |

| MWC |

10.67 c

|

78.52 b

|

| HWC |

24.0 b

|

51.68 b

|

| MWC + HWC |

8.67 c

|

82.55 a

|

Table 4.

Yield in sugar beet from Vintu de Jos, year 2022.

Table 4.

Yield in sugar beet from Vintu de Jos, year 2022.

| Treatment/Yield |

UC |

MWC |

HWC |

HWC + MWC |

| t ha−1

|

28.12 c

|

42.34 b

|

50.22 a

|

56.48 a

|

Table 5.

Yield in sugar beet crop from Romania.

Table 5.

Yield in sugar beet crop from Romania.

| Year |

UM |

2015 |

2016 |

2017 |

2018 |

2019 |

2020 |

| Surface |

1000 × ha |

26.59 |

24.92 |

28.20 |

25.72 |

22.73 |

22.76 |

| Medium yield |

t/ha−1

|

39.14 |

40.61 |

41.64 |

38.03 |

40.35 |

34.20 |

| Total yield |

1000 × t |

1040.65 |

1012.19 |

1174.50 |

978.27 |

917.16 |

778.30 |

Table 6.

Precipitations in mm for the months March until September in the years 2021 and 2022 for the location Vintu de Jos, south west Transylvania.

Table 6.

Precipitations in mm for the months March until September in the years 2021 and 2022 for the location Vintu de Jos, south west Transylvania.

| Month/Year |

2021 |

2022 |

| March |

50.21 |

17.10 |

| April |

36.12 |

69.42 |

| May |

82.04 |

48.67 |

| June |

28.41 |

8.71 |

| July |

49.32 |

18.63 |

| August |

27.51 |

35.22 |

| September |

8.06 |

70.42 |

| Total |

281.67 |

268.17 |

Table 7.

Detailed description of the treatments at Vintana farm in 2021 and 2022.

Table 7.

Detailed description of the treatments at Vintana farm in 2021 and 2022.

| No. |

Treatment |

Treatment acronyms |

Description |

| 1 |

Untreated control |

UC |

No weed control |

| 2 |

Herbicide 2021 |

HWC 2021 |

Herbicide spraying (Table 3) |

| 3 |

Herbicide 2022 |

HWC 2022 |

Herbicide spraying (Table 3) |

| 4 |

Mechanical weed control BBCH19 + BBCH 31 |

MWC |

Mechanical weed control with goose feet at the stage of 6 leaf and 9 leaf of sugar beet |

| 5 |

Chemical weed control |

HWC |

3× Chemical weed control only, 3 times spraying with a mix of 3 herbicides and 5 different substances |

| 6 |

Chemical and mechanical weed control at BBCH 19 and BBCH 31 |

HWC + MWC |

3× Herbicide spraying + 2× Mechanical weed control |

Table 8.

Application time (BBCH of the sugar beet), active ingredients and herbicide product at both experimental fields in 2021 and 2022.

Table 8.

Application time (BBCH of the sugar beet), active ingredients and herbicide product at both experimental fields in 2021 and 2022.

| BBCH 2021 |

BBCH 2022 |

Active ingredients |

Product name |

FM* |

Concentration |

Application rate |

Supplier |

| 10,14,19 |

10,14,19 |

ethofumesate |

Betanal tandem |

SC |

190 g a.i. L |

285 g ha−1

|

Bayer Crop Science |

| 10,14,19 |

10,14,19 |

phenmedipham |

Betanal Tandem |

SC |

200 g a.i. L |

300 g ha−1 |

Bayer Crop Science |

| 03,10,14 |

10,14,19 |

metamitron |

Goltix |

SC |

700 g a.i. L |

630 g ha−1 |

Adama |

| 03 |

|

glyphopsate |

Clean up |

SL |

360 g a.i. L |

1080 g ha−1 |

Nufarm |

| |

10,14,19 |

lenacil |

Venzar 500 |

SC |

500 g a.i. L |

125 g ha−1 |

FMC Corporation |

| 14,19 |

|

clopyralid |

Lontrel 300 |

SL |

300 g a.i. L |

225 g ha−1 |

Corteva Agriscience |

| 19 |

19 |

quizalofop-p-tefuril |

Pantera 40 |

EC |

40 g a.i. L |

40 g ha−1 |

Arysta Life science |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).