1. Introduction

Saudi Arabia produces more than 14% of the world's

total production of dates, viewing the date palm as the most important fruit

tree in country. Barhi dates fruits are tasty, physiologically mature, crisp

and firm during the Khalal stage (yellow in color) of maturation [1]. They are also perishable and have a high

moisture content of 66% to 75% (wet bases) and water activity 0.95 to 0.97. In

this region, Barhi fruits during the Khalal maturation (Bisr) was mainly chosen

because of their desirable texture, sweetness, and great flavors [2]. Researchers, food innovators and producers, consumers,

and health experts are emphasizing the need for food quality for fruits to be

more palatable, healthy, natural, and wholesome.

Fruit losses in farms reached 25% due to the huge

production of Barhi dates over a short season and the lack of commercial means

to maintain fresh Barhi at its Khalal maturation stage that caused drop of

fruit prices during peak season. Towards approaching the end of the season,

Barhi prices gradually rise reaching ten times that of average season [3].

Cooling plays a significant role in decreasing

biological activities, respiration rate and enzymatic activities, during

storage. Several studies have indicated that any delay in cooling harvested

fruits leads to water losses of up to 50% [4].

Etiolation of the fruit surface as well as changes in physical qualities (e.g.,

weight, density, and color) resulted from this water loss. Furthermore,

moisture losses may lead to an increase in sugar component [5].

Controlled

atmospheric storage ((CA) is a postharvest preservation technique involving the

meticulous regulation of the gaseous composition (oxygen, carbon dioxide, and

nitrogen) and the environmental conditions (temperature and relative humidity)

within enclosed storage facilities. CA storage slows ripening

by lowering oxygen levels and increasing carbon dioxide levels, thus extending the

shelf-life of various fruits and vegetables. Fruit stored in low O2

atmosphere slow the ripening, but they continued to ripen when left in the air [6]. Successful CA preservation of Barhi fruits was

achieved at storage temperature 0 °C where fruits kept fresh for up to 5 months

[7] where best quality was attained within the

first three months of storage.

Fruit ripening stages may be assessed using smart

agriculture technologies, which might help with quality management. Routine

measurements of physicochemical properties of foods are expensive and timely

consumed to evaluate food quality during the whole chain from harvest to

consumers. Frequently methods used to evaluate fruit quality includes: titrable

acidity (TA), starch content, pH, soluble solid content (SSC), ratio of SSC to

TA, tissue stiffness, and physical features including size, shape, color, and

appearance [8]. However, evaluating these elements

takes time and mostly causing damage to the sample. It is crucial for commercial

management to avoid destructive tests through a quick prediction of food

properties during various stages of processing.

The food quality index (Qi) [9, 10] can

describe a theoretical/empirical model developing to describe product general

characteristics. In research and commercial applications, objective measures

(instrumentally) are favored than sensorial tests. These technologies are more

accurate, eliminate arbitrator discrepancies, and provide consumers,

businesses, and academics with

one standardized language [11]. It is

important to track the food quality attributes over time with an effective prediction

model such as a quality index to assist food manufacturers and consumers acceptance. After

that, additional predictions for the quality index model can be made using a non-destructively

testing, namely, near-infrared spectroscopy (NIR).

Using near-infrared spectroscopy (NIR) is a

frequent non-destructive detection method for a fast assessment of fruit

qualities [12]. In

several studies, researchers employed near-infrared (NIR) spectroscopy in an

attempt to predict the chemical and physical characteristics of many foods,

both in their fresh state and after undergoing processing or storage [13, 14]. Furthermore,

spectroscopy and food sensory evaluation have been correlated in a number of

research studies [15]. The integration of appropriate statistical analysis with near-infrared

(NIR) spectroscopy can be deemed an effective technique for communicating both

quantifiable and qualitative aspects of food quality, including its inherent

attributes and sensory characteristics. By establishing a comprehensive quality

index model that incorporates NIR spectral data, the assessment of food quality

can be facilitated and optimized across the entire food chain, from initial

production through consumption, while simultaneously accounting for potential

variations during shelf life.

NIR models (range 300-2000 nm) were used to

estimate soluble sugar concentration in apple fruits with a relatively good R2

(0.91 to 0.97) [16, 17, 18, 19]. Cherry fruits were assessed for soluble sugar

content utilizing NIR spectra at (600–1100 nm) wave length with a standard

error 0.75 of (SEP) prediction [20]. For kiwi

fruits, physical parameters of SSC and Hue angle were conducted using near-infrared

estimation with R2 (0.82 and 0.93); respectively [21]. NIR spectroscopy was used [22] at (900-1700 nm) to classify Shahani dates into

four maturity phases: Kimiri, Khalal, Rutab, and Tamr where R2

values for moisture content and TSS were (0.98, 0.96; respectively) in the

predicted models. According to Gómez [23], mandarin

has (6) broadband peaks on its absorption curve. Spectroscopic

analysis performed in the near-infrared (NIR) region reveals a significant

absorption peak at 672 nm, suggesting the presence of pigments like

chlorophyll. The presence of chlorophyll leads to the distinctive green color

observed in the fruit.

While PLS

(Partial Least Squares) is a classic linear tool in chemometrics, ANNs

(Artificial Neural Networks) offer a powerful alternative for modeling complex

nonlinear relationships between input and output data.

Introduced relatively recently to the field, ANNs are finding diverse

applications in chemometrics, including mapping, regression, modeling,

clustering, and classification [24]. Notably,

their ability to interpret and quantify overlapping peaks and reduce

interference effects in mixed spectra makes them particularly valuable for food

investigations [25].

There is a need to investigate and quantify both

objective and subjective measurements of the fruits quality throughout the storage

period of controlled atmospheric storage (CA). The objective of this work was

to model a quality index (Qi) for Barhi fruits that involve sensory and

objective assessments, followed by investigating the possibility of forecasting

the Qi using a NIR non-destructively. This reduces the acquired

money, time, and labor for routine work and sensory evaluation of fresh and

stored produce throughout the processing and marketing chain.

2. Materials and Methods

2.1. Fruit samples preparation and storage

Barhi fruits, identified as having reached the

Khalal maturity stage, were harvested from a date palm farm situated within the

Riyadh region of Saudi Arabia. Thereafter, on the same day, the aforementioned

fruits were transported to the food processing laboratory located at King Saud

University. After being cleaned gently from dust with compressed air (3 bar),

Barhi fruits were sorted to three stages of maturation, ranging from 80 to 100%

yellowish. Quality attributes of Barhi fruits were measured and then combined

with scanning fruits with NIR spectrum. The fresh Barhi fruits quality was

evaluated, then stored at 3 systems; ambient (25 ºC), Cold (1 ºC), and CA (1 ºC

with 5%:5% O2:CO2, 85% RH) for up to 4 months.

2.2. Sensory Analysis

The sensory quality of both fresh and stored Barhi

fruits was assessed by 36 semi-trained panelists from King Saud Univ. at College

of Food & Agric. Sciences. The sensory evaluation process were accomplished

using the 9-point hedonic table [26, 27]. The selected sensory attributes were

taste, texture, color, and general acceptance. The mark of responses were

"1" denoting " extremely dislike " while "9"

denoting " extremely like."

2.3. Objective Analysis

Digital refractometer (Abbe 5 Refractometer,

Bellingham, Stanley (BS), Jena, Germany) was used at room temperature (25°C) to

measure the total soluble solids of Barhi fruits (expressed as a percentage) [28]. The color of the Barhi fruits was assessed using

a Hunter Lab scan XE and the fundamental color criteria L*, b*, and a*, where

L* stands for (brightness/darkness), a* for (redness/greenness), and b* for

(blueness/yellowness). Browning index (BI) and total color difference (∆E) were

derived from (L*, a*, and b*) values [29]

according to:

where:

To evaluate the fruits texture, (TA- HDi, Model HD_3128, Stable Micro Systems, Surrey, UK) texture analyzer was utilized. A whole fruit was compressed to a 5 mm depth at speed of 1.5 mm/s. Using the resulting deformation curves of the force-time, the hardness parameter was derived [

1].

2.4. Evaluation of the Quality Index (Qi)

The overall quality index (Q

i), which has a range of 0 to 1, is a tool used to model and normalize the variables under study in relation to the controlled variable's minimal value. Normalizations would help to ensure that the data in the quality index is compatible [

30]. The formula below can be implemented to normalize the parameters:

Where (

) is defined as the normalized value of the quality parameter (

x) where

() is the quality parameter of the measured value, and

are the minimum and maximum values of the quality parameter (x); respectively. Calculation of the quality index (Q

i) was according to:

Consequently, normalized sample characteristics and overall sensory acceptability data will be combined in the generated Qi. Subsequently, these quality index data would be further evaluated via non-destructive NIR spectra in order to predict Qi and food properties.

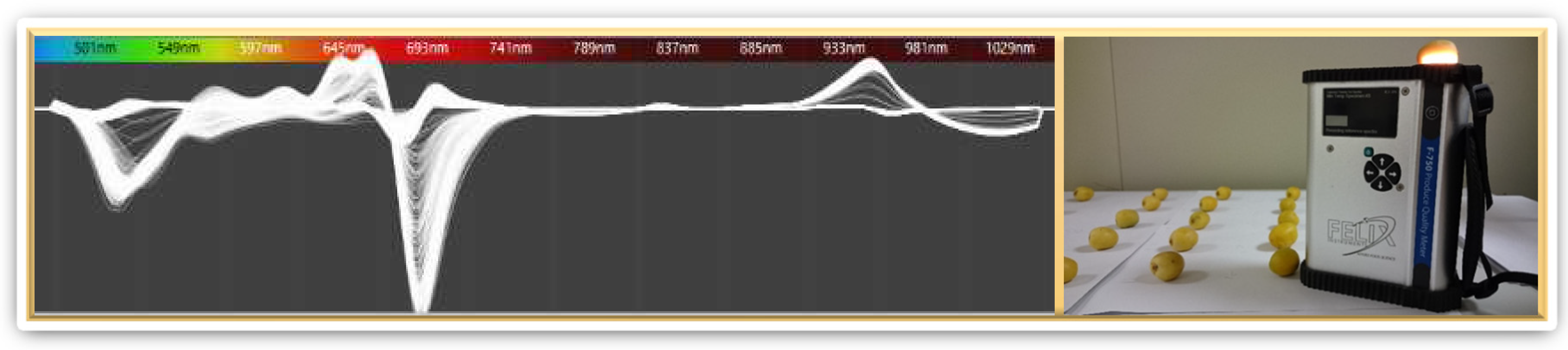

2.5. NIR Technique for Assessing Quality Index

Using a portable NIR spectrometer (F- 750, Firmware v_1_2_0 build 7041, Felix Inst., Camas, USA), NIR spectrum of fruits would help to assess sample characteristics as well as Qi non-destructively. Zeiss MMS1 VIS-NIR spectrometer with an interval of 3 nm was used to set the system. For every fruit sample, optical shot of the F750 were obtained prior to food measurements (sensory evaluation and objective attributes). The F-750 has a reference shutter that, while scanning with the lamp off, makes it possible to account for ambient light and dark current in each measurement. Three scans of the spectrum for each sample were collected and averaged. The three scans of each sample of the spectrum was captured then averaged. Spectra was acquired for a different group of samples at 5 °C for the same serving for the validation procedure. After spectra was recorded all data on F-750 SD card were transferred to a computer for further analysis. Using Data Viewer Software, the imported data was saved as (CSV format) and the spectra was pre-analysed utilizing the Savitzky-Golay 2nd derivative. Following the creation of the calibration model, the data set (272 spectra and 252 samples ) were used.

Partial least squares regression ( PLSR) and artificial neural network ( ANN) analysis tools were used to generate the models of calibration. The spectra are examined as a linear multivariate connection using the PLSR method [

31]. Prior to applying the multiple regression model, PLSR finds the high-dimensional vectors (latent variables, LVs) that are used to explain the data's most valuable variation. Exploring subspaces that boost predictor and response variable covariance leads to the discovery of latent variables [

32]. The highly developed nonlinear pattern recognition technique known as artificial neural networks (ANNs) can simulate complex biodiversity as well as instrument and environmental variability [

33]. In this study, App-Builder v.2.1.7 software (Felix Instr., Camas, USA) was used to examine the estimated data. Based on calibration and validation results, the performance of the prediction would be evaluated using correlation coefficient (R

2), square error of root mean in calibration (RMSEC), and cross validation (RMSECV) [

14].

2.6. Statistics and analysis

Utilizing a statistical software (SAS, V. 9.2, Cary, NC, USA), all objectively measured attributes were examined. Felix F750 AppBuilder v.2.1.7 software)was used to predict the performance of both calibration and cross- validation findings. Microsoft Office 365 was used to create graphs, plots, and other calculations.

3. Results

Based on the Barhi dates characteristics, the fruits shelf life objectively and subjectively were evaluated, then the quality index and NIR spectra were modeled.

3.1. Sensory Evaluation

Sample Selection

Fresh Barhi dates fruits (80–100% yellowish) were sensory evaluated by thirty-six evaluators. To conduct the planned sensory evaluation, safety and health precautions were taken. The average sensory evaluations of Barhi fruit characteristics by judges were displayed in

Table 1 which shows the significant variations determined utilizing Duncan multiple choice (p < 0.05)

Table 1 shows that the two most popular samples were 90% and 100% fruit yellowish. However, 90% yellowish dates would be favored compared to 100% yellow fruits to delay ripening and extending the shelf life of the stored fruits.

Table 1 shows that harvesting time (stage of maturity) had a significant influence (p>0.05) for all sensory acceptance parameters in which 80% yellowish date fruits were the least liked taste, color, and overall acceptance. Therefore, the recommended 90% yellowish date fruits were selected for the shelf-life storage for up to three months (120 days (CA), 40 days (cold), and 20 days (ambient, marketing temperature) based on their physical and sensory characteristics.

Sensory assessment of fruits during storage

Table 2 shows average of sensory attributes of the Barhi samples during the storage period of up to 120 days (CA), 40 days (cold) and 20 days (ambient conditions). The periods of storage were determined based on when 50% of the samples deteriorated. During storage, the sensory scores for the qualitative attributes (taste, texture, color , and overall acceptance) for all samples decreased over time. This indicated that the Barhi fruits deteriorate with storage. At the end for each of the storage period, the color scores in CA, cold, and ambient decreased from 8.9 to 3.30, 3.45 and 3.52 while texture assessments decreased from 8.4 to 3.13, 3.06 and 3.20 where taste average scores decreased from 8.7 to 3.8, 4.05 and 3.89; respectively. Furthermore, the evaluations for (overall acceptance) decreased from 8.5 to 2.84, 3.83 and 3.70, respectively. It can be noted, however, that fruit quality was much better at CA during storage compared to cold and ambient conditions for the 40 and 20 days storage periods., respectively

3.2. Evaluation of Barhi fruits physical properties during storage

Table 3 shows the influence of storage time on the physical properties of Barhi fruits. The TSS% scores for CA, Cold, and ambient (25 ºC) increased from 20.31 to 24.12, 23.39, and 25.03 % respectively, at the end of storage duration which reflects the loss of moisture during storage. ∆E increased from 0 (control, fresh fruit) to 11.68, 11.28, and 12.16 where the average BI score increased from 83.31 to 89.45, 91.45, and 89.76, for CA, cold, and ambient storage; respectively. Furthermore, the hardness decreased from 99.81 to 73.59, 76.85, and 52.29 N where MC% decreased from 70.99 to 62.64, 62.58, and 60.91% for CA, cold, and ambient storage; respectively. This reflects the gradual deterioration of fruits during storage but at different rates based on storage conditions.

3.3. Modeling of Quality Index (Qi)

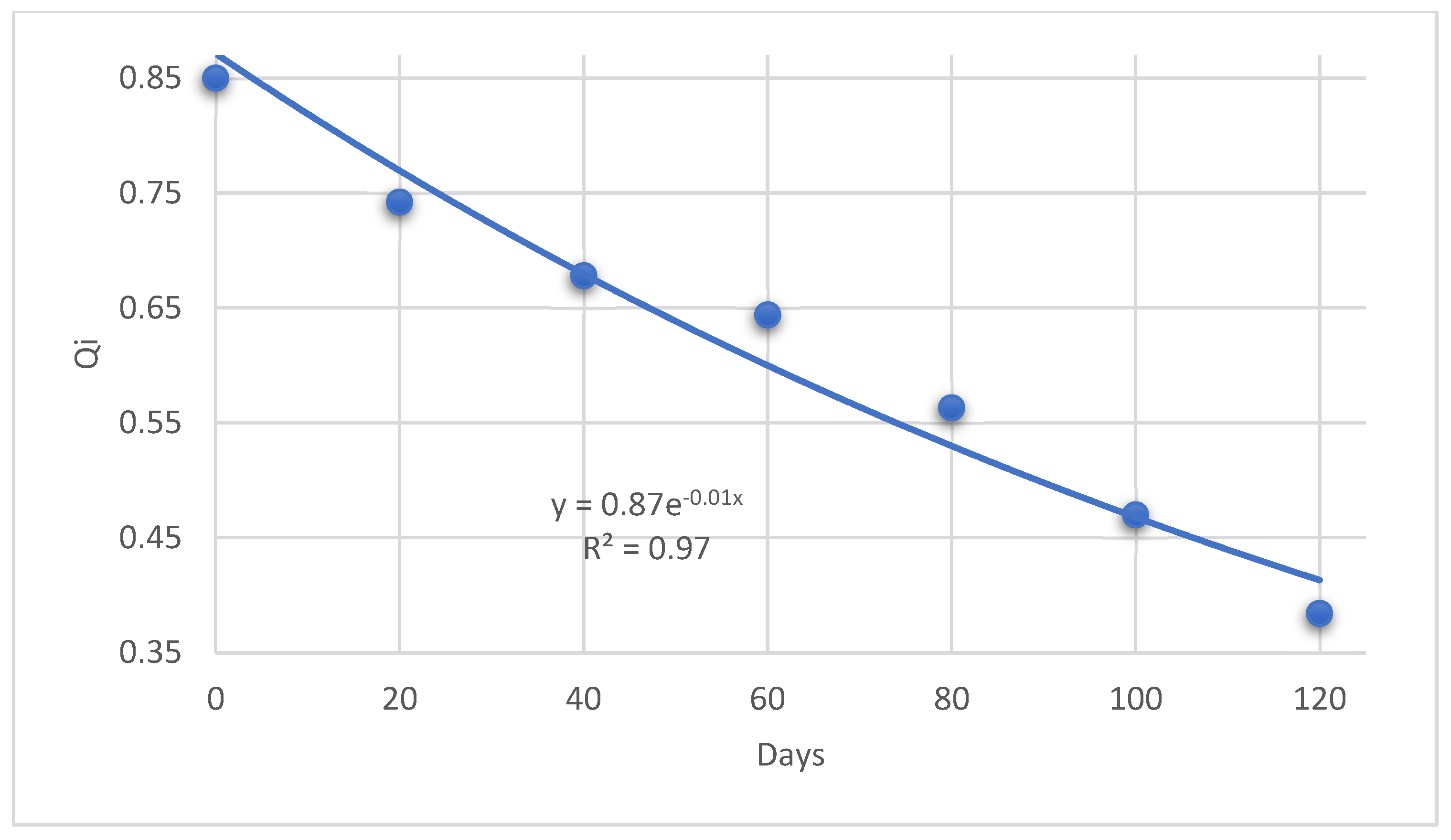

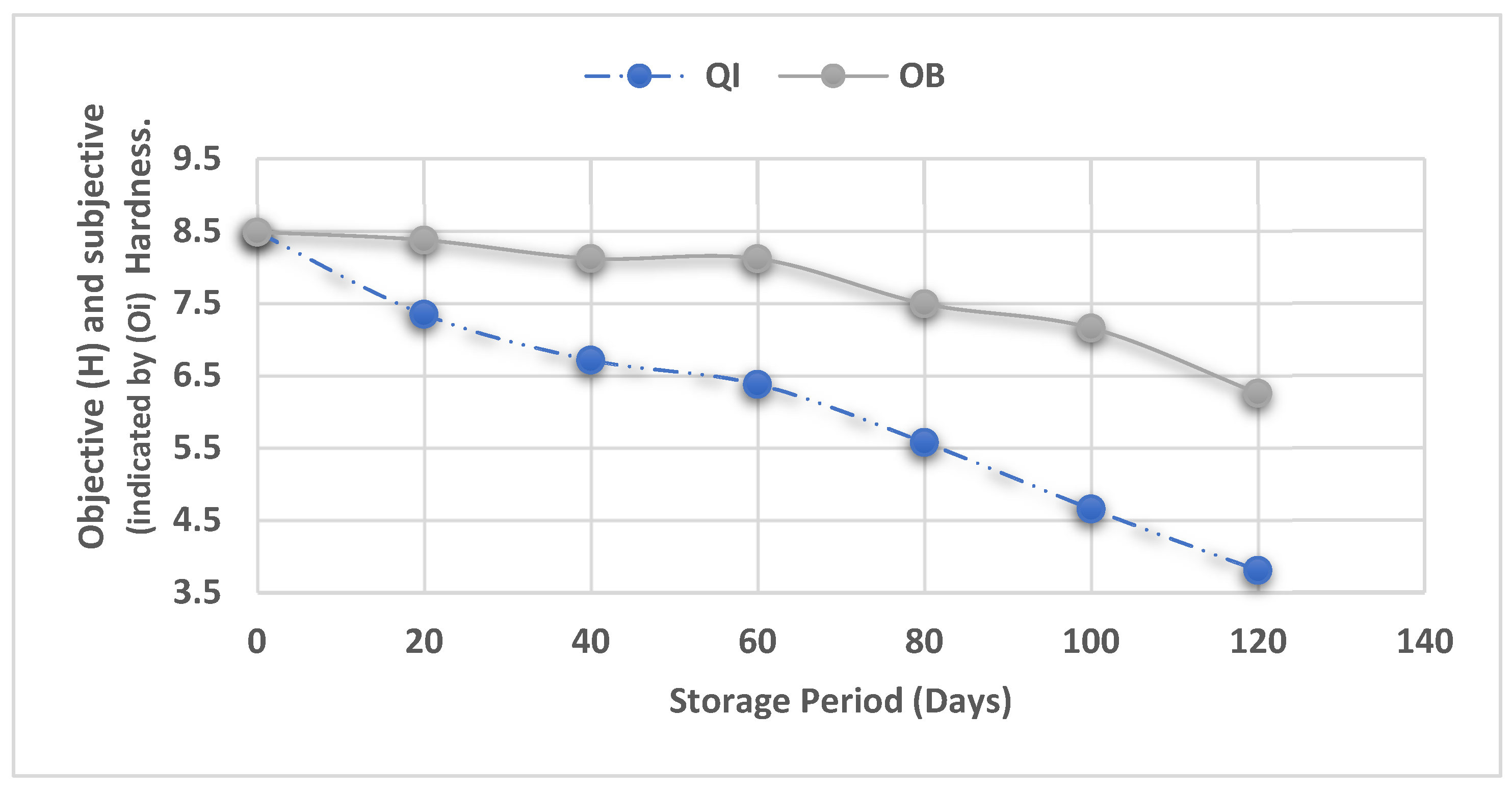

The fruits quality index (Q

i) for Barhi evaluates standard deviation of 10 characteristics, five of which are sensorial and five are physical. The Barhi fruits displayed consistent and ongoing changes for all assessed parameters during the storage period, as presented in

Figure 1. The Barhi fruits index of modeled quality began with a value of 0.85 and decreased to 0.38 at the end of the storage time.

The following model (with R

2 = 0.97) established a relationship of the normalized Q

i and with duration of shelf-life (days). The power law model could be used to analyze a food product's sensory evaluation [

34]. Thus, the relationship between quality index (Q

i) and the shelf life is as follows:

Once the power function's exponent approaching less than 1.0, the overall acceptance exhibited a downward curve in relation to the normalized quality index, and rose more slowly as the quality index increased.

It can be stated that the quality index aided in providing a reference for the actual shelf life of Barhi fruits. Furthermore, authorities may utilize Qi as a powerful tool to evaluate and determine the actual quality during the shelf life of Barhi fruits throughout the production, transportation, storage, and retail chain at tolerable precision.

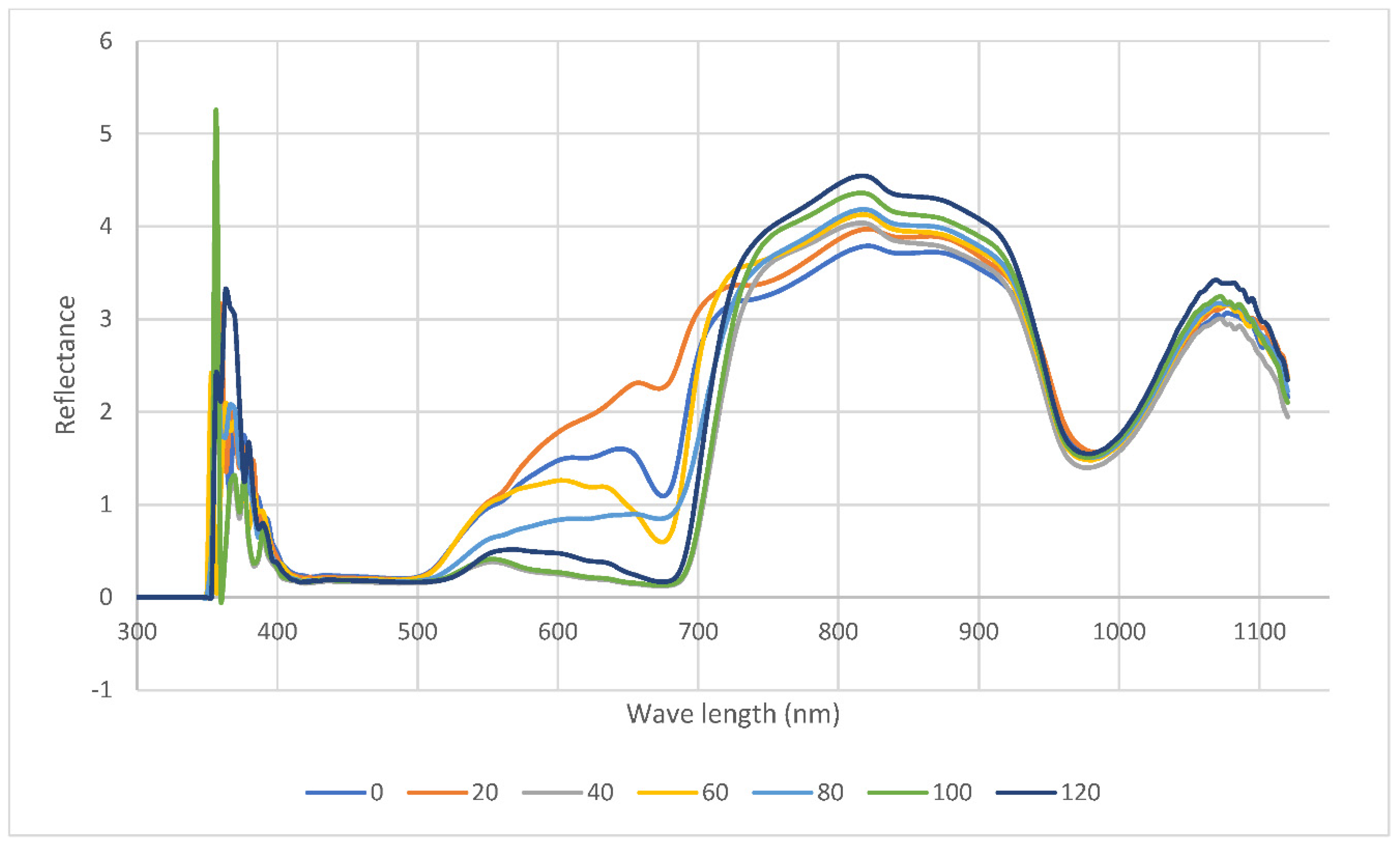

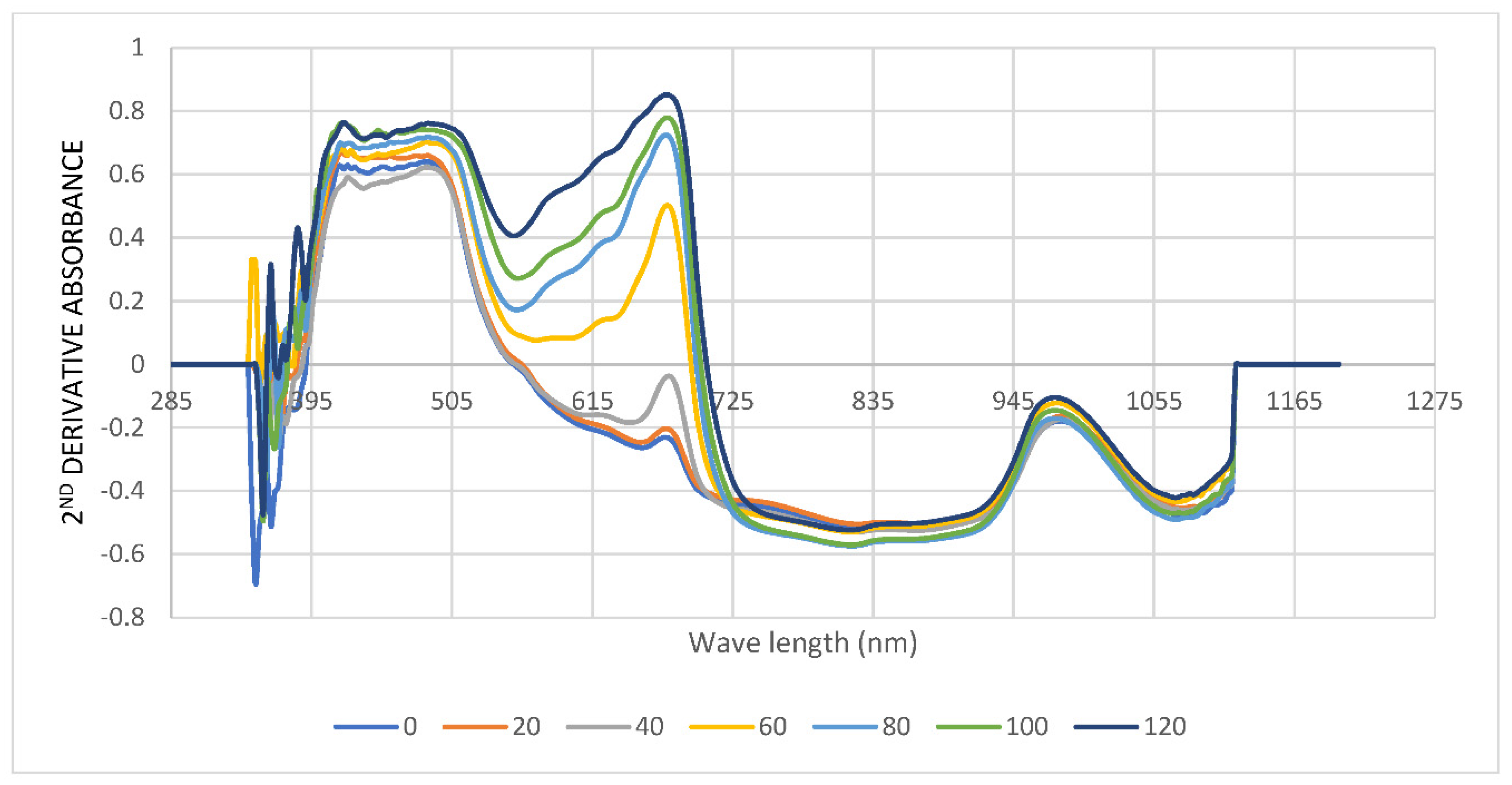

3.4. Quality Index Modeling (Qi) with NIR spectra

The NIR technology has recently acquired popularity in food applications for linking the spectrophotometer waves absorbance and reflectance with the physiochemical characteristics of fruit ingredients. To gain superior performance and powerful models, NIR spectrum data must be pre-processed. These derivatives can be quite beneficial in near infrared spectrum to eliminate some improper signals from the spectrum [

35]. The second derivative of NIR spectra was determined in this work. Figure (2) shows the average second derivative of spectra absorbance for date fruits shelf-life period within the wavelength shown.

The spectrum reflectance were typically in the visible region (from 475 to 650 nm) [

36].

Figure 3 depicts the spectra (reflectance (R)) with the longest storage span being 120 days where

Figure 4 shows the 2nd derivative of Barhi fruit spectra absorbance at different storage periods along the storage span of 120 days. It can be seen the distinctive variations of reflectance and 2nd derivative absorbance curves for the fruit quality along the wavelength spectra during storage periods.

NIR spectra will be further analyzed utilizing two powerful tools, namely PLSR and ANN, then will be modeled with quality index (Qi).

Partial Least Squares Regression (PLSR)

Table 4 presents cross-validation analysis and the calibration of PLSR for the Barhi fruits physical properties of TSS, ∆E, BI, Hardness, MC, as well as Q

i characteristics. In the calibration models, R

2 and RMSEC were 0.979, 0.659 for TSS, 0.961, 0.994 for ∆E, 0.881, 0.978 for BI, 0.903, 0.708 for hardness, 0.902, 2.119 for MC%, and 0.793, 0.110 for Q

i; respectively.

In cross-validation analysis, R2 and RMSECV were 0.910, 0.758 for TSS, 0.912, 0.979 for ∆E, 0.882, 0.902 for BI, 0.893, 0.777 for hardness, 0.901, 1.921 for MC%, and 0.783, 0.298 for Qi; respectively. The coefficient of correlation (R2) data was in range between 0.793 and 0.979. Such range proves a powerful performance of the model, with R2 greater than 0.70 regarded satisfactory in NIR models [37, 38]. This implies that the PLSR analysis is an effective statistical means for predicting both subjective and objective Barhi fruit quality indicators.

Artificial Neural Networks analysis(ANN)

The performance analysis of ANN for each calibration and cross-validation of the Barhi fruits characteristics is showed in

Table 5. In the calibration models, R

2 and RMSEC were 0.981and .0.857 for TSS, 0.950, 1.093 for ∆E, 0.891,0.681for BI, 0.891, 0.747 for hardness, 0.901, 1.82 for MC%, and 0.912, 0.308 for Q

i; respectively. Moreover, cross-validation performance, R

2 and RMSECV were 0.979, 0.705 for TSS, 0.949, 0.989 for ∆E, 0.889, 0.605 for BI, 0.893, 0.708 for hardness, 0.901, 1.129 for MC%, 0.912,0.308 for Q

i; respectively. The results showed that the ANN analysis is a powerful tool for estimation Barhi dates properties. It is interesting to note that compared to the PLSR model, the ANN model is typically better suited for predicting Barhi characteristics, as shown by the higher correlation coefficients of the ANN analysis.

RMSEC is a parameter that indicates how well the calibration model coincides with the calibration set. With the increases number of components, RMSEC decreases. The RMSECV, on the other hand, grows as more components are included. Compared to RMSEC, RMSECV is a more accurate prediction of future model performance [

39]. Therefore, in terms of calibration and cross-validation, the two analysis methods (PLSR and ANN) can be useful tools for modeling NIR data.

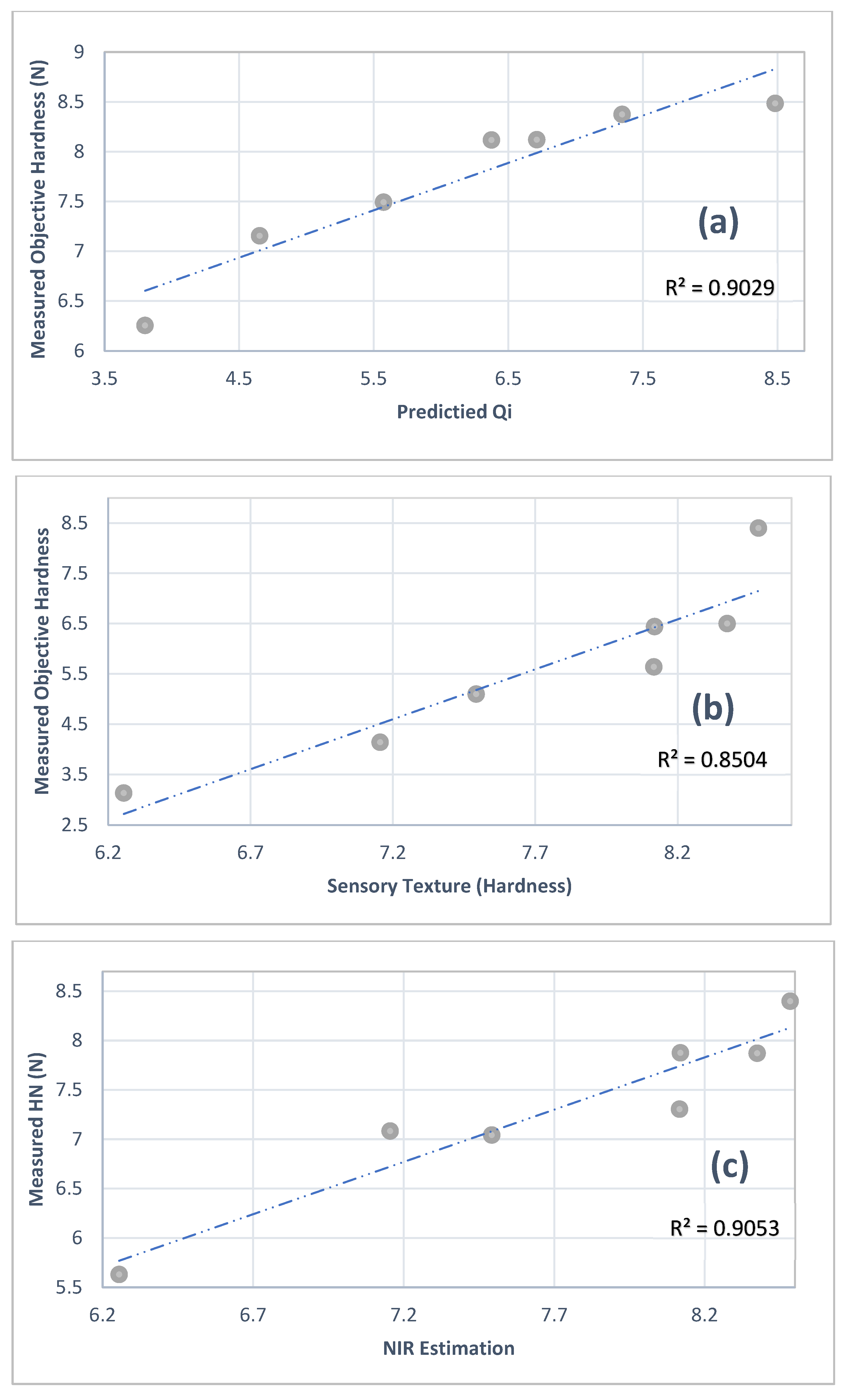

3.7. Performance of Prediction Models of Barhi Quality during Storage

As indicated above, an excellent model performance is achieved with R

2 values greater than 0.70, in which values ranging from 0.50 to 0.69 indicated a fair model performance [

40]. The findings of this study indicate the feasibility of correlating non-destructive parameters (Q

i, and NIR) with sensory estimating and texture parameters (Hardness, N) of Barhi samples at any storage time. This can be utilized in a commercial online fruit sorting instrumentation using NIR instrumentation and Q

i to predict the texture of fruit non-destructively.

Figure 5 shows a comparison of subjective (sensory predicted by Q

i) and objective TPA hardness tests. Both tests' curves showed a similar trend in a decrease with storage time. This indicates a link between the sensory, objective utilizing Q

i and NIR spectrums can be implemented in automation process of quality assurance.

Figure 6 (a) showed predicted Q

i and measured objective hardness. The correlation between these parameters was particularly good with a correlation coefficient of R

2 = 0.902.

Figure 6 (b) showed a good relation between sensorial and objective texture (hardness estimation) with a correlation coefficient of R

2 = 0.850.

Figure 5 (c) showed the relation between NIR estimation and measured objective hardness with a correlation coefficient R

2 = 0.905. This result proves how well NIR spectroscopy can correlated with textural measurements of Barhi fruits at different stages of maturity. Furthermore, this suggests that automated sorting of Barhi dates non-destructively based on fruit firmness is applicable using a near infrared spectroscopy. This can be used to help for marketing; for example fruit of less mature and relatively hard texture assigned to long-distance/international markets, while intermediate mature (mild texture) fruits assigned to intermediate distances, where soft fruits for immediate marketing in regional/local stores.

4. Discussion

According to the samples sensory analysis results , the acceptability of the arbitrators increases with fruit maturation. This is consistent with an increase in fruit maturity effect on sweetness (and, consequently, taste). These results agreed with earlier studies on the influence of harvesting stage on the storage duration of Barhi fruits [

41] with ranges 60 to 80% MC, 20 to 35% TSS, and yellow to green color based on sensory estimation that affect consumer acceptance of Barhi fruits during maturation process.

The preservation in the CA storage achieved the longest shelf-life compared to cold and ambient storages based on Barhi fruits sensory assessment in which CA can delay the deterioration up to 120 days. At ambient environment, the samples had the shorted shelf-life. This could be attributed to the accelerated enzyme activities and texture softening at room temperature that affect Barhi fruits quality during such storage [

42].

The increase of TSS of fruits throughout the storage probably due to the loss of moisture and more polysaccharides being enzymatically converted to simple sugars [

43]. The observed color variations and alterations may be related to differences in the enzymatic oxidation of phenolic chemicals. The cell structure of date flesh changes due to dehydration during storage and thus increases various enzymatic oxidation of phenolic compounds [

44]. Several studies [45, 46, 44] showed comparable results to this study. Hardness weakened during storage might related to cellular disintegration, which causes membrane porosity, or to the conversion of insoluble particles into soluble solids [

47].

In NIR cross-validation performance, (R2) were higher than 0.79 which indicates a strong model performance, in which R2 greater than 0.70 regarded satisfactory in NIR models [37, 38]. The ANN model's correlation coefficients are clearly greater than that of PLSR model, especially when considering the normalized quality index parameter. Therefore, it is advised that Qi estimation would be dependent on the ANN technique with (R2 = 0.891-0.981) rather than PLSR technique (R2 = 0.792-0.979).

The quality index (Q

i) of sensory and physical attributes simplified the assessment and comparison of products qualities, utilizing a non-destructive and simple NIR technique As a result of the analyses in this work, NIR interrelated well with quality index and hence with the Barhi fruits unique features. In general, Q

i can predict the fruit quality throughout the storage duration of Barhi dates and set by standard authorities [

48]. Thus, portable NIR spectra meter can be a helpful tool in the field by producers, manufacturers, storage, transportation, market, authorities, and throughout the entire chain to confirm the "quality" and "shelf life" of the commodities.

5. Conclusions

The generated Barhi quality index (Qi) in this study provides an approximate estimation of fruit quality during its storage duration. This approach provides a quick, non-destructive, and reliable method for evaluating quality that is simple to apply across the entire chain of processing, storage, and marketing chains. The NIR analysis correlated the absorbance and reflectance of spectrophotometer waves to the physical characteristics of food products. During the shelf life, both sensory and objective measurements can be followed and evaluated with the quality index (Qi) and immediately measured by an NIR analyzer. Both (PLSR) partial least-square regression and (ANN) artificial neural network analyses were helpful to examine NIR validity.

NIR successfully predicted Qi and fits well with normalized measured sample properties (total soluble solids (TSS), color (∆E and Bi), texture (hardness), moisture content (MC%) and sensory evaluation during the shelf-life period. NIR spectroscopy was helpful in estimating the quality index of Barhi fruits in calibration and cross validation with an R2 range (0.891 - 0.981).

In conclusion, NIR spectrophotometry can predict Qi non-destructively and can thus be used successfully by authorities, product manufacturers, processors, and throughout the entire production, processing, transport, preservation, and retail market chain to assess the "quality" along the "shelf life" of the commodity.

Funding

Deputy ship for Research & Innovation, Ministry of Education in Saudi Arabia for funding this research. (IFK-SURC-1-5623).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The datasets generated for this study are available on request to the corresponding author. Data supporting reported results can be requested from the author. Thanks to Mr. Ahmed Atiah for assisting in collecting data and reviewing this work.

Acknowledgments

The author extend his appreciation to the Deputyship for Research & Innovation, Ministry of Education in Saudi Arabia for funding this research. (IFK-SURC-1-5623).

Conflicts of Interest

The author declares no conflict of interest.

References

- Alhamdan, A. , Hassan, B., Alkahtani, H., Abdelkarim, D., Younis, M., Freezing of fresh Barhi dates for quality preservation during frozen storage. Saudi Journal of Biological Sciences. Saudi Journal of Biological Sciences. 2016. [Google Scholar] [CrossRef] [PubMed]

- Abdelkarim, D. O. , Mohamed Ahmed, I. A., Ahmed, K. A., Younis, M., Yehia, H. M., Zein El-Abedein, A. I., & Alhamdan, A. Extending the Shelf Life of Fresh Khalal Barhi Dates via an Optimized Postharvest Ultrasonic Treatment. Plants 2022, 11, 2029. [Google Scholar] [PubMed]

- Abu-Shama, H. S. , Abou-Zaid, F. O. F., & El-Sayed, E. Z. Effect of using edible coatings on fruit quality of Barhi date cultivar. Scientia Horticulturae 2020, 265, 109262. [Google Scholar]

- Duan, X. , Su, X., You, Y., Qu, H., Li, Y., & Jiang, Y. Effect of nitric oxide on pericarp browning of harvested longan fruit in relation to phenolic metabolism. Food Chemistry 2007, 104, 571–576. [Google Scholar]

- Adekanye, T. A. , & Babaremu, K. O. Evaluation of an active evaporative cooling device for storage of fruits and vegetables. Agricultural Engineering International: CIGR Journal 2019, 21, 203–208. [Google Scholar]

- Atia, A. , Abdelkarim, D., Younis, M., & Alhamdan, A. Effects of pre-storage dipping in calcium chloride and salicylic acid on the quality attributes of stored Khalal Barhi dates. International Journal of Agricultural and Biological Engineering 2020, 13, 206–212. [Google Scholar]

- Alhamdan, A. , Hassan, B., Alkahtani, H., Ismaiel, S. M., Utilization of Controlled Atmosphere (CA) Technology in Shelf Life Extension of Fresh Barhi Dates at Khalal Stage of Maturity at a Semi-Commercial Level Final Technical Project # AR.28-84, General Directorate of Research Grants Programs, King Abdulaziz City for Science and Technology, Riyadh, Kingdom of Saudi Arabia. 2012; 287–292. (In Arabic) [Google Scholar]

- Mesa, K. , Serra, S., Masia, A., Gagliardi, F., Bucci, D., & Musacchi, S. Seasonal trends of starch and soluble carbohydrates in fruits and leaves of ‘Abbé Fétel’pear trees and their relationship to fruit quality parameters. Scientia Horticulturae 2016, 211, 60–69. [Google Scholar]

- Cardello, A. V. Food quality: relativity, context and consumer expectations. Food quality and preference 1995, 6, 163–170. [Google Scholar] [CrossRef]

- Ismail, A. I. , Hassaballa, A. A., Almadini, A. M., & Daffalla, S. Analyzing the Spatial Correspondence between Different Date Fruit Cultivars and Farms’ Cultivated Areas, Case Study: Al-Ahsa Oasis, Kingdom of Saudi Arabia. Applied Sciences 2022, 12, 5728. [Google Scholar]

- Abbott, J. A. Quality measurement of fruits and vegetables. Postharvest biology and technology 1999, 15, 207–225. [Google Scholar] [CrossRef]

- Nicolai, B. M. , Beullens, K., Bobelyn, E., Peirs, A., Saeys, W., Theron, K. I., & Lammertyn, J. Nondestructive measurement of fruit and vegetable quality by means of NIR spectroscopy: A review. Postharvest biology and technology 2007, 46, 99–118. [Google Scholar]

- Ratcliffe, M. , & Panozzo, J. F. The application of near infrared spectroscopy to evaluate malting quality. Journal of the Institute of Brewing 1999, 105, 85–88. [Google Scholar]

- Alhamdan, A. M. , & Atia, A. Non-destructive method to predict Barhi dates quality at different stages of maturity utilising near-infrared (NIR) spectroscopy. International Journal of Food Properties 2017, 20(sup3), S2950–S2959. [Google Scholar]

- Cayuela, J. A. , & Camino, M. D. C. P. Prediction of quality of intact olives by near infrared spectroscopy. European journal of lipid science and technology 2010, 112, 1209–1217. [Google Scholar]

- Liu, Y. , & Ying, Y. Use of FT-NIR spectrometry in non-invasive measurements of internal quality of ‘Fuji’apples. Postharvest biology and technology 2005, 37, 65–71. [Google Scholar]

- Lu, R. , Guyer, D. E., & Beaudry, R. M. DETERMINATION OF FIRMNESS AND SUGAR CONTENT OF APPLES USING NEAR-INFRARED DIFFUSE REFLECTANCE 1. Journal of texture studies 2000, 31, 615–630. [Google Scholar]

- Nicolas, H. , & Walter, C. Detecting salinity hazards within a semiarid context by means of combining soil and remote-sensing data. Geoderma 2006, 134, 217–230. [Google Scholar]

- Peirs, A. , Schenk, A., & Nicolaı̈, B. M. Effect of natural variability among apples on the accuracy of VIS-NIR calibration models for optimal harvest date predictions. Postharvest biology and technology 2005, 35, 1–13. [Google Scholar]

- Carlini, P. , Massantini, R., & Mencarelli, F. Vis-NIR measurement of soluble solids in cherry and apricot by PLS regression and wavelength selection. Journal of Agricultural and Food Chemistry 2000, 48, 5236–5242. [Google Scholar]

- Schaare, P. N. , & Fraser, D. G. Comparison of reflectance, interactance and transmission modes of visible-near infrared spectroscopy for measuring internal properties of kiwifruit (Actinidia chinensis). Postharvest Biology and Technology 2000, 20, 175–184. [Google Scholar]

- Mireei, S. A. , Mohtasebi, S. S., Massudi, R., Rafiee, S., Arabanian, A. S., & Berardinelli, A. Non-destructive measurement of moisture and soluble solids content of Mazafati date fruit by NIR spectroscopy. Australian journal of crop science 2010, 4, 175–179. [Google Scholar]

- Gómez, A. H. , He, Y., & Pereira, A. G. Non-destructive measurement of acidity, soluble solids and firmness of Satsuma mandarin using Vis/NIR-spectroscopy techniques. Journal of food engineering 2006, 77, 313–319. [Google Scholar]

- Marini, F. , Bucci, R., Magrì, A. L., & Magrì, A. D. Artificial neural networks in chemometrics: History, examples and perspectives. Microchemical journal 2008, 88, 178–185. [Google Scholar]

- Hanrahan, G. Artificial neural networks in biological and environmental analysis; CRC Press, 2011. [Google Scholar]

- Lawless, H.; Heymann, H. Food Science Principles and Practices, Chapter 1. [CrossRef]

- Lim, J. Hedonic scaling: A review of methods and theory. Food Quality and Preference 2011, 22, 733–747. [Google Scholar] [CrossRef]

- AOAC (Association of Official Analytical Chemists – International). Official Methods of Analysis.

- Maskan, M. Kinetics of colour change of kiwifruits during hot air and microwave drying. Journal of food engineering 2001, 48, 169–175. [Google Scholar] [CrossRef]

- Camarinha-Matos, L. M., Falcão, A. J., Vafaei, N., & Najdi, S. (Eds.). (2016). Technological Innovation for Cyber-Physical Systems: 7th IFIP WG 5.5/SOCOLNET Advanced Doctoral Conference on Computing, Electrical and Industrial Systems, DoCEIS 2016, Costa de Caparica, Portugal, April 11-13, 2016, Proceedings ; Springer, 2016; Vol. 470.

- Nordey, T. , Joas, J., Davrieux, F., Chillet, M., & Léchaudel, M. Robust NIRS models for non-destructive prediction of mango internal quality. Scientia Horticulturae 2017, 216, 51–57. [Google Scholar]

- Kusumiyati, K. , Munawar, A. A., & Suhandy, D. Fast, simultaneous and contactless assessment of intact mango fruit by means of near infrared spectroscopy. AIMS Agriculture and Food 2021, 6, 172–184. [Google Scholar]

- Silalahi, D. D. , Reaño, C. E., Lansigan, F. P., Panopio, R. G., & Bantayan, N. C. Using genetic algorithm neural network on near infrared spectral data for ripeness grading of oil palm (Elaeis guineensis Jacq.) fresh fruit. Information Processing in Agriculture 2016, 3, 252–261. [Google Scholar]

- Singham, P. , Birwal, P., & Yadav, B. K. Importance of objective and subjective measurement of food quality and their inter-relationship. Journal of Food Processing & Technology 2015, 6, 1. [Google Scholar]

- Basile, T. , Marsico, A. D., & Perniola, R. Use of artificial neural networks and NIR spectroscopy for non-destructive grape texture prediction. Foods 2022, 11, 281. [Google Scholar] [PubMed]

- Jiang, Q. , Chen, Y., Guo, L., Fei, T., & Qi, K. Estimating soil organic carbon of cropland soil at different levels of soil moisture using VIS-NIR spectroscopy. Remote Sensing 2016, 8, 755. [Google Scholar]

-

Process analytical technology: spectroscopic tools and implementation strategies for the chemical and pharmaceutical industries; Bakeev, K. A., Ed.; John Wiley &, 2010. [Google Scholar]

- Irudayaraj, J. Nondestructive testing of food quality; Irudayaraj, J., Reh, C., Eds.; John Wiley & Sons; Vol. 18.

- Alhamdan, A. M. NIR Spectroscopy Assessment of Quality Index of Fermented Milk (Laban) Drink Flavored with Date Syrup during Cold Storage. Fermentation 2022, 8, 438. [Google Scholar] [CrossRef]

- Williams, P. and Norris, K.Near-Infrared Technology in the Agricultural and Food Industries. American Association of Cereal Chemists: USA, 2001.

- Jayalakshmi, T. , & Santhakumaran, A. Statistical normalization and back propagation for classification. International Journal of Computer Theory and Engineering 2011, 3, 1793–8201. [Google Scholar]

- Alhamdan, A. M. , Fickak, A., & Atia, A. R. Evaluation of sensory and texture profile analysis properties of stored Khalal Barhi dates nondestructively using Vis/NIR spectroscopy. Journal of Food Process Engineering 2019, 42, e13215. [Google Scholar]

- Hameed, F. , Kumar, A., & Hamid, N. Effect of thermal treatment and storage on the quality of apple juice. Journal of Pharmacognosy and Phytochemistry 2019, 8, 1976–1979. [Google Scholar]

- Ruenroengklin, N. , Zhong, J., Duan, X., Yang, B., Li, J., & Jiang, Y. Effects of various temperatures and pH values on the extraction yield of phenolics from litchi fruit pericarp tissue and the antioxidant activity of the extracted anthocyanins. International Journal of Molecular Sciences 2008, 9, 1333–1341. [Google Scholar]

- Duan, Y. , Wang, G. B., Fawole, O. A., Verboven, P., Zhang, X. R., Wu, D.,... & Chen, K. Postharvest precooling of fruit and vegetables: A review. Trends in Food Science & Technology 2020, 100, 278–291. [Google Scholar]

- Neog, M. , and Saikia, L. Control of post-harvest pericarp browning of litchi (Litchi chinensis Sonn). Journal of food science and technology 2010, 47, 100–104. [Google Scholar] [CrossRef]

- Brinson, K. , Dey, P. M., John, M. A., & Pridham, J. B. Post-harvest changes in Mangifera indica mesocarp cell walls and cytoplasmic polysaccharides. Phytochemistry 1988, 27, 719–723. [Google Scholar]

- Ketzenberg, M. , Gaukler, G., & Salin, V. Expiration dates and order quantities for perishables. European Journal of Operational Research 2018, 266, 569–584. [Google Scholar]

Figure 1.

Normalized Qi of Barhi fruits during controlled atmospheric storage.

Figure 1.

Normalized Qi of Barhi fruits during controlled atmospheric storage.

Figure 2.

Spectra view of 1000 samples of Barhi dates at the different maturity stages utilizing the Flex F750 instrument.

Figure 2.

Spectra view of 1000 samples of Barhi dates at the different maturity stages utilizing the Flex F750 instrument.

Figure 3.

Reflectance spectra of different storage periods from fresh (0 days) to 120 days of Barhi fruit.

Figure 3.

Reflectance spectra of different storage periods from fresh (0 days) to 120 days of Barhi fruit.

Figure 4.

The 2nd derivative absorbance of Barhi date fruits at different storage periods from fresh (0 days) to 120 days.

Figure 4.

The 2nd derivative absorbance of Barhi date fruits at different storage periods from fresh (0 days) to 120 days.

Figure 5.

Subjective (Qi) and objective hardness during storage at CA ( 5%O2, 5%CO2, 80%RH), H: hardness × 1/11.76 ; Qi: quality index*10.

Figure 5.

Subjective (Qi) and objective hardness during storage at CA ( 5%O2, 5%CO2, 80%RH), H: hardness × 1/11.76 ; Qi: quality index*10.

Figure 6.

(a) Predicted Qi and measured objective hardness, (b) sensory texture and measured objective hardness, and (c) relation between NIR estimation and measured objective hardness (H). H: hardness × 1/11.76 Qi: quality index*10.

Figure 6.

(a) Predicted Qi and measured objective hardness, (b) sensory texture and measured objective hardness, and (c) relation between NIR estimation and measured objective hardness (H). H: hardness × 1/11.76 Qi: quality index*10.

Table 1.

Sensorial analysis of fresh Barhi fruits at several maturity levels*.

Table 1.

Sensorial analysis of fresh Barhi fruits at several maturity levels*.

| # Ripening stage |

Texture |

Taste |

Color |

Overall Acceptance |

|

1 (80% yellowish)

|

8.9 ± 0.41a

|

7 ± 0.08b

|

6.9 ± 1.06b

|

6.8 ± 1.08 b

|

|

2 (90% yellowish)

|

8.4 ± 1.01ab

|

8.7 ± 0.86a

|

8.9 ± 0.49a

|

8.5 ± 0.38 a

|

|

3 (100% yellowish)

|

8.2 ± 0.21b

|

8.8 ± 0.97a

|

8.8 ± 0.69a

|

8.5 ± 0.44 a

|

Table 2.

Variance analysis for the effect of storage period on the sensory assessment of Barhi fruits *.**.

Table 2.

Variance analysis for the effect of storage period on the sensory assessment of Barhi fruits *.**.

| Days |

storage |

texture |

taste |

color |

Overall acceptance |

| 0 |

CA |

8.4 ± 1.01a

|

8.7 ± 0.86a

|

8.9 ± 0.49a

|

8.5 ± 0.58a

|

| Cold |

8.4 ± 1.01a

|

8.7 ± 0.86a

|

8.9 ± 0.49a

|

8.5 ± 0.58a

|

| 25 ºC |

8.4 ± 1.01a

|

8.7 ± 0.86a

|

8.9 ± 0.49a

|

8.5 ± 0.58a

|

| 20 |

CA |

7.02±0.61a

|

7.5±0.54a

|

7.12 ±0.05ab

|

7.42±0.79ab

|

| Cold |

6.52±0.41ab

|

6.74±0.93abc

|

6.94±0.52ab

|

6.64±0.39abc

|

| 25 ºC |

3.20±0.64de

|

3.89±0.71de

|

3.52±0.29e

|

3.70±0.43e

|

| 40 |

CA |

6.44±0.81ab

|

6.89±1.02ab

|

6.31±0.25bc

|

6.78±0.27ab

|

| Cold |

3.06±1.04e

|

4.05±0.13de

|

3.45±0.69e

|

3.83±0.57de

|

| 25 ºC |

N/ A |

N/ A |

N/ A |

N/ A |

| 60 |

CA |

5.64±0.97bc

|

6.31±0.52bc

|

5.53±1.12cd

|

6.44±0.87bc

|

| Cold |

N/ A |

N/ A |

N/ A |

N/ A |

| 25 ºC |

N/ A |

N/ A |

N/ A |

N/ A |

| 80 |

CA |

5.1±0.93c

|

5.70±1.62c

|

4.87±1.03d

|

5.63±1.62c

|

| Cold |

N/ A |

N/ A |

N/ A |

N/ A |

| 25 ºC |

N/ A |

N/ A |

N/ A |

N/ A |

| 100 |

CA |

4.14±1.07d

|

4.79±0.71d

|

3.93±0.94e

|

4.70±0.92d

|

| Cold |

N/ A |

N/ A |

N/ A |

N/ A |

| 25 ºC |

N/ A |

N/ A |

N/ A |

N/ A |

| 120 |

CA |

3.13±0.79e

|

3.80±0.09e

|

3.30±0.82e

|

3.84±0.19de

|

| Cold |

N/ A |

N/ A |

N/ A |

N/ A |

| 25 ºC |

N/ A |

N/ A |

N/ A |

N/ A |

Table 3.

Variance analysis for the influence of storage duration on the objective characteristics of Barhi fruits *, **.

Table 3.

Variance analysis for the influence of storage duration on the objective characteristics of Barhi fruits *, **.

| Days |

Storage |

TSS |

∆E |

BI |

Hardness (N) |

MC % |

| 0 |

CA |

20.31±1.08d

|

0g

|

83.31±0.64g

|

99.81±0.06a

|

70.99±0.36a

|

| Cold |

20.31±1.08d

|

0g

|

83.31±0.64g

|

99.81±0.06a

|

70.99±0.36a

|

| 25 ºC |

20.31±1.08d

|

0g

|

83.31±0.64g

|

99.81±0.06a

|

70.99±0.36a

|

| 20 |

CA |

20.46±0.35d

|

6.80±0.79f

|

83.33±0.06d

|

98.52±0.63a

|

68.35±0.91b

|

| Cold |

21.56±1.21d

|

9.06±0.02e

|

87.21±0.39b

|

83.65±1.20d

|

65.25±0.89d

|

| 25 ºC |

25.03±1.26a

|

12.16±0.06a

|

89.76±0.63g

|

52.29±1.64g

|

60.91±0.94g

|

| 40 |

CA |

20.69±0.86d

|

9.36±0.08de

|

83.71±0.16a

|

95.52±0.43b

|

66.27±0.49c

|

| Cold |

23.39±1.13bc

|

11.28±0.04bc

|

91.45±0.67f

|

76.85±0.92e

|

62.58±0.39f

|

| 25 ºC |

N/ A |

N/ A |

N/ A |

N/ A |

N/ A |

| 60 |

CA |

21.22±0.73d

|

9.95±0.82d

|

84.60±0.67e

|

95.49±0.92b

|

65.72±0.71cd

|

| Cold |

N/ A |

N/ A |

N/ A |

N/ A |

N/ A |

| 25 ºC |

N/ A |

N/ A |

N/ A |

N/ A |

N/ A |

| 80 |

CA |

21.58±1.06d

|

10.93±0.49c

|

86.21±0.92c

|

88.15±0.26c

|

65.35±0.84d

|

| Cold |

N/ A |

N/ A |

N/ A |

N/ A |

N/ A |

| 25 ºC |

N/ A |

N/ A |

N/ A |

N/ A |

N/ A |

| 100 |

CA |

22.64±0.96c

|

11.48±0.63b

|

87.94±0.08b

|

84.18±0.07d

|

64.13±0.53e

|

| Cold |

N/ A |

N/ A |

N/ A |

N/ A |

N/ A |

| 25 ºC |

N/ A |

N/ A |

N/ A |

N/ A |

N/ A |

| 120 |

CA |

24.12±1.16ab

|

11.68±0.37ab

|

89.45±0.83ab

|

73.59±1.21f

|

62.64±0.19f

|

| Cold |

N/ A |

N/ A |

N/ A |

N/ A |

N/ A |

| 25 ºC |

N/ A |

N/ A |

N/ A |

N/ A |

N/ A |

Table 4.

Performance of PLSR for Barhi fruits for both cross-validation models and calibration for TSS, ∆E, BI, Hardness, MC, and Qi.

Table 4.

Performance of PLSR for Barhi fruits for both cross-validation models and calibration for TSS, ∆E, BI, Hardness, MC, and Qi.

| Parameter |

Calibration |

Cross- validation |

| |

R2

|

RMSRC |

R2

|

RMSECV |

| TSS |

0.979 |

0.659 |

0.910 |

0.758 |

| ∆E |

0.961 |

0.994 |

0.912 |

0.979 |

| BI |

0.881 |

0.978 |

0.882 |

0.902 |

| Hardness |

0.903 |

0.708 |

0.893 |

0.777 |

| MC |

0.902 |

2.119 |

0.901 |

1.921 |

| Qi |

0.793 |

0.110 |

0.783 |

0.298 |

Table 5.

The model performance of ANNs for both calibration and cross-validation for ∆E, TSS, BI, Hardness, MC, and Qi of Barhi fruits .

Table 5.

The model performance of ANNs for both calibration and cross-validation for ∆E, TSS, BI, Hardness, MC, and Qi of Barhi fruits .

| Parameter, |

Calibration, |

Cross- validation, |

| |

R2

|

RMSRC |

R2

|

RMSECV |

| TSS |

0.981 |

0.857 |

0.979 |

0.705 |

| ∆E |

0.950 |

1.093 |

0.949 |

0.989 |

| BI |

0.891 |

0.681 |

0.889 |

0.605 |

| Hardness |

0.891 |

0.747 |

0.893 |

0.708 |

| MC |

0.901 |

1.822 |

0.901 |

1.129 |

| Qi |

0.912 |

0.308 |

0.912 |

0.308 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).