1. Introduction

The COVID-19 pandemic has led to the global consumption of billions of face masks, contributing to significant plastic waste [

1,

2]. Despite polypropylene (PP) being a cost-effective primary material in personal protective equipment, concerns have arisen regarding its reliance on diminishing petroleum sources and its significant environmental impact [

3]. Consequently, there has been a noticeable drive in recent years to substitute various petroleum-based products with natural, sustainable, and eco-friendly alternatives [

4,

5]. This pursuit has prompted an exploration of sustainable materials across industries, particularly a keen interest in natural fibers for composite materials. This interest is mainly because of its renewability, low cost, low density, and low abrasiveness of the natural materials in the polymer industry [

6,

7].

Numerous research studies on natural fibers for nonwoven materials have been published. For instance, milkweed has demonstrated potential for blending with bicomponent fibers and hot-pressing to create a composite web, offering a potentially environmentally friendly alternative to current petroleum-based disposable surgical gown [

8]. Fages et al. [

9] combined flax with polypropylene fibers using a wet-laid process, preparing them for subsequent hot-press molding. The combination of wet-laid techniques with hot-press molding processes enables the utilization of high natural fiber content in composite webs while maintaining acceptable properties. Ghali et al. [

10] utilized the needle-punching method to blend alfa fibers with cotton, polyester, Tencel®, and wool. Their observations indicated that the air permeability of nonwoven blends generally increased with the higher ratio of alfa fiber, except in the wool blend. Additionally, Möhl et al. [

11] employed cellulosic fibers sourced from textile waste along with polymers derived from renewable raw materials, proposing a potential approach for upcycling textile waste.

Among natural fibers, cattail and kapok fibers have gained recent attention owing to their widespread availability and notable features, including low density and hydrophobic-oleophilic properties [

12,

13,

14]. Cattail, known as water candle, is an aquatic plant found in temperate and tropical regions across both hemispheres, thriving in various aquatic environments such as lakes, rivers, swamps, ponds, and ditches. When reaching maturity, cattail grass exhibits a unique behavior, bursting and releasing a substantial amount of cattail fibers, posing potential risks of pollution or fires [

12]. Similarly, kapok fiber, known for its thin cell wall and large lumen, has traditionally found use as stuffing material in items like pillows and life jackets [

14,

15]. In addition, the development of environmentally friendly bio-based materials has also been accelerated by the pursuit of sustainable practices; one such material is polylactic acid (PLA), which has been used to have a significant impact. PLA is a biodegradable and bioactive polyester derived from renewable resources such as corn, potato, sugarcane or other carbohydrate sources [

16,

17]. It is commonly used in various applications, including packaging [

18], biomedical devices [

19], 3D printing [

19], and textiles [

19,

20,

21], due to its eco-friendly nature and biodegradability [

22,

23].

In this research, the focus was on developing a medical nonwoven material with specific properties such as antibacterial qualities, water repellency, light weight, and proper air permeability. To achieve this, both milkweed and kapok fibers was utilized, known for their low density and hydrophobic properties. Blending them with PLA bicomponent fiber, a biodegradable polymer, was the approach taken to create the desired nonwoven material with the targeted properties for medical applications.

2. Materials and Methods

2.1. Materials

A sheath-core polylactic acid bicomponent fiber with a length of 38 mm and 2.24 dtex was purchased from Tianjin Glory Tang Textile Co., Ltd. (Tianjin, China). Kapok and cattail fibers were collected locally in Bangkok, Thailand. Seeds and other impurities in the kapok and cattail fibers were manually removed. The fibers were used in their raw state in the experiment without any chemical cleaning or pre-treatment processes.

2.2. Preparation of natural fiber/polylactic acid bicomponent fiber composite webs

The natural fiber/polylactic acid bicomponent fiber composites were produced with blend ratios ranging from 0/100 to 30/70 by weight using carding and hot-press techniques. A Y275A hand-operated drum-carding machine (SDL Atlas Limited, Hong Kong) was used to card the hand-blended fiber. This procedure was repeated 3 times to ensure that the materials were thoroughly mixed and to ensure that the fibers were distributed uniformly. After the carding process, the webs are placed into a circular mold with an 11 cm diameter on a heat press machine and then manually hot-pressed at 135°C for 1 minute to achieve a target weight of 100 g/m2.

2.3. Characterizations

SEM images of the fibers and composite webs were recorded using Jeol JSM-6400 scanning electron microscope (Jeol Ltd., Japan). A 204 F1 Phoenix model differential scanning calorimetry (DSC) instrument (Netzsch-Gerätebau GmbH, Germany) was used to determine specific heat capacity of both natural and bicomponent fibers. The samples in an aluminum pan were heated from room temperature to 450°C at a rate of 10°C/min under a nitrogen atmosphere. The thickness values of composite webs at various ratios were measured using a 547-401A Mitutoyo digital thickness gauge (Mitutoyo, Japan).

2.4. Properties

2.4.1. Color measurement

The CIE L*a*b* values and whiteness of composite webs were measured using the Datacolor Check II spectrophotometer (Datacolor, USA) under D65 illuminant and a 10-degree observer angle.

2.4.2. Contact angle measurements

The tests were performed according to BS EN 828:2013 standard using DM-CE1 contact angle meters (Kyowa Interface Science Co. Ltd., Japan). Briefly, each droplet of deionized water, precisely 2 μL in volume, was carefully deposited onto the sample surface and measured after a 10 second interval. All measurements were conducted at a temperature of 21 ± 1 °C and a relative humidity of 65 ± 2%. Each sample underwent testing at a minimum of three different locations.

2.4.3. Antibacterial Activity

The PLA, cattail fiber, and kapok fiber were evaluated against the Gram-negative bacteria K. pneumoniae and Gram-positive bacteria S. aureus following the ASTM E2149 standard. Dynamic conditions involved 100 rpm at 37C for 18 hours. The experiment was conducted in triplicate. After incubation, colonies were counted to determine the bacterial count. The percentage of bacterial reduction (R, %) was calculated in accordance with Equation 1:

where R is the percentage of reduction bacteria viability

C0 is the number of bacteria colonies at contact time = 0 h

C is the number of bacteria colonies after contact time

2.4.4. Mechanical test

The tensile properties were evaluated using a M350-5AT Testometric universal testing machine (Testometric Company Ltd., UK) with a crosshead speed of 5 mm/min and a load cell capacity of 50 kN. Rectangular specimens, sized at 10 × 60 mm, were cut using compression molded plates for the tests with a gauge length of 40 mm. A minimum of five samples were tested for each group of samples.

2.4.5. Water vapor permeability analysis

The water vapor permeability was assessed using the evaporative dish method, in accordance with the BS 7209 standard. The test involved securing the test specimen over the open mouth of a dish filled with water and measuring the initial weight of the cup. After a 6-hour period, the weight was recorded again to assess any changes. Water vapor permeability (WVP) was calculated (Equation 2).

where M is the loss in mass (g) of water vapor through the fabric specimen

A is the internal area of the dish (m2)

T is the time between weighing (h)

3. Results and Discussion

3.1. Characterization of fibers

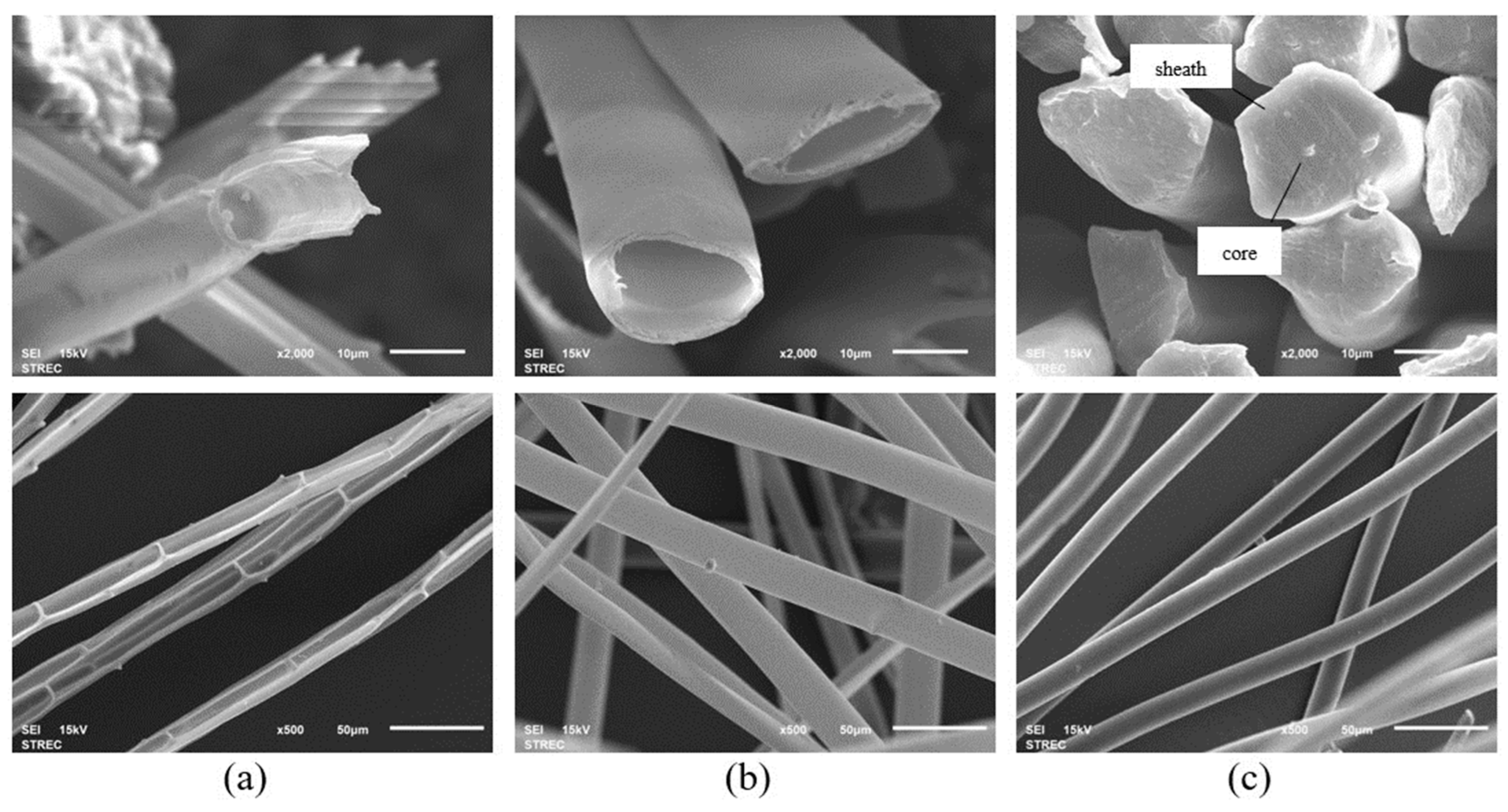

Waste natural fibers, including cattail and kapok fibers, have distinct characteristics. Cattail fibers feature a multi-cavity structure, bamboo-shaped and average length of 10 mm, while kapok fibers have an average length of 20 mm and a hollow lumen structure (

Figure 1a,b). The sheath-core PLA bicomponent fiber, depicted in

Figure 1c, has a diameter of approximately 20 μm, with the sheath measuring around 2 μm in thickness.

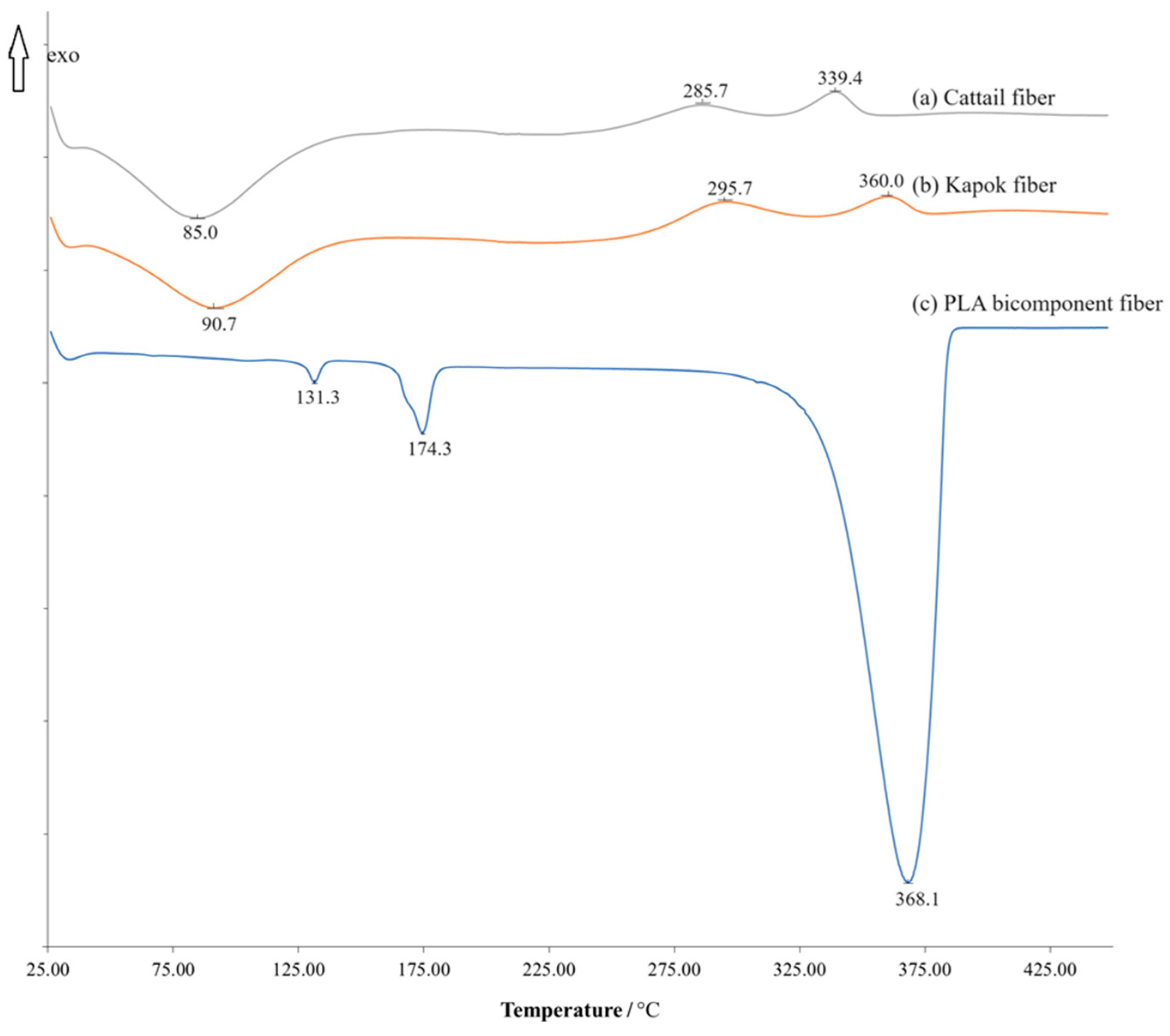

DSC thermograms for both kapok fiber and cattail fiber exhibited similarity (

Figure 2a,b). The results from the thermograms suggest that the initial weight loss occurred below 100°C, attributed to the presence of water in the fiber [

24]. The first exothermic peak appeared around 280-310°C, indicating the degradation of cellulose. The second exothermic peak at 330-370°C is likely associated with the oxidation of the char [

25,

26]. The used PLA bicomponent fiber exhibits two melting peaks at 131.3°C and 174.3°C. It is worth noting that the degradation temperature of PLA falls within the range of 330-380°C (

Figure 2c). These findings are similar to those of Kervran et al. 2022 [

27], where PLA degrades in one step around 350°C.

From the literature review, it is indicated that both cattail and kapok fibers exhibit natural antibacterial activity due to their high lignin content [

28,

29,

30]. Cattail fiber contains an approximate lignin content of 16.5% [

30], while kapok fiber exhibits a lignin content ranging from 13% to 22% [

29]. In this study, the antibacterial efficacy of these fibers was evaluated according to the ASTM E2149 standard against

S. aureus and

K. pneumoniae. The results are presented in the

Table 1.

It appears that all the tested fibers did not exhibit antibacterial activity against K. pneumoniae. However, they showed a limited antibacterial effect against S. aureus. Kapok fiber demonstrated the most substantial reduction in bacterial activity when compared to both cattail and PLA bicomponent fibers. The antibacterial properties of the composite web samples were not tested since all tested fibers displayed minimal antibacterial activity.

3.2. Characterization of composite webs

After the carding process, the obtained webs exhibited a fluffy texture and had low mechanical properties, primarily attributed to the absence of chemical or physical bonding among the fibers. To improve adhesion, chemical or thermal binders are commonly used. In this study, the carded webs were hot-pressed at 135°C, a temperature higher than the melting point of the sheath but lower than the melting point of the core fibers. The composite webs underwent testing for thickness, color, and mechanical properties.

3.2.1. Thickness

The thickness values of the composite webs are presented in

Table 2.

As shown in

Table 2, the increase in both cattail and kapok fiber content led to an augmentation in the thickness of the composite webs. This outcome can be attributed to the notably low density of both cattail and kapok fibers. In nonwoven materials determined by weight (g/m

2), the incorporation of these fibers with the same weight resulted in thicker nonwoven structures due to their low density. These observations are consistent with a previous study involving poly(lactic acid)/poly(butylene succinate) (PLA/PBS) fiber and milkweed fiber. In that study, it was noted that increasing the ratio of milkweed fiber resulted in enhanced thickness in the composite material [

8]. Additionally, when comparing PLA: kapok fiber composite webs to PLA: cattail fiber composite webs at the same ratio, the composite webs from PLA: kapok fiber exhibited greater thickness. Kapok fiber holds the distinction of being the lightest natural fiber globally. Studies by Mwaikambo (2006) [

31] and Sekar et al. [

32] report the bulk density of kapok at 0.38 g/cm

3, whereas cattail fiber's density is recorded at 0.62 g/cm

3 [

33].

3.2.2. Color measurement

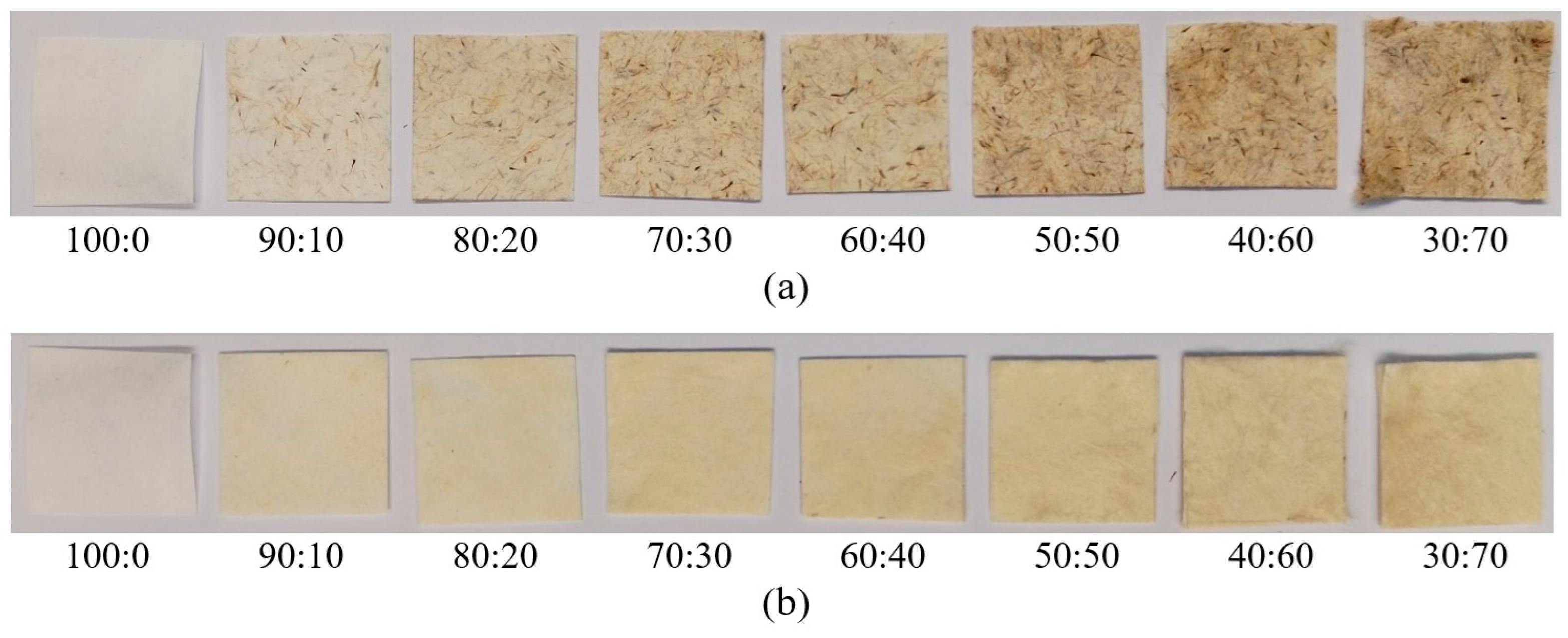

The images of composite webs were depicted in

Figure 3, while measurements for whiteness index and CIE L*a*b* values of these composite webs were recorded and presented in

Table 3.

The whiteness index tends to decrease with an increase in the content of natural fibers added to the PLA fiber. Additionally, the whiteness index of composite webs made from cattail fiber is lower than that of kapok fiber at the same ratio. (

Table 3). The color differentiation between kapok and cattail fibers is commonly observed, with kapok fibers typically appearing creamy -yellowish white, while cattail fibers tend to have a light yellowish-brown shade.

The CIE L*a*b* system comprises three values: L* (white-black), a* (red-green), and b* (yellow-blue). Higher L* values indicate a whiter appearance, while higher a* and b* values suggest more reddish and yellowish tones, respectively. With an increased natural fiber content in both cattail and kapok fibers, there is a decrease in the L* value, indicating a darker hue, and an increase in the b* value, suggesting a more yellowish coloration. Furthermore, the a* values of composite webs show a slight increase with higher natural fiber content, indicating a tendency towards a more reddish hue in these webs.

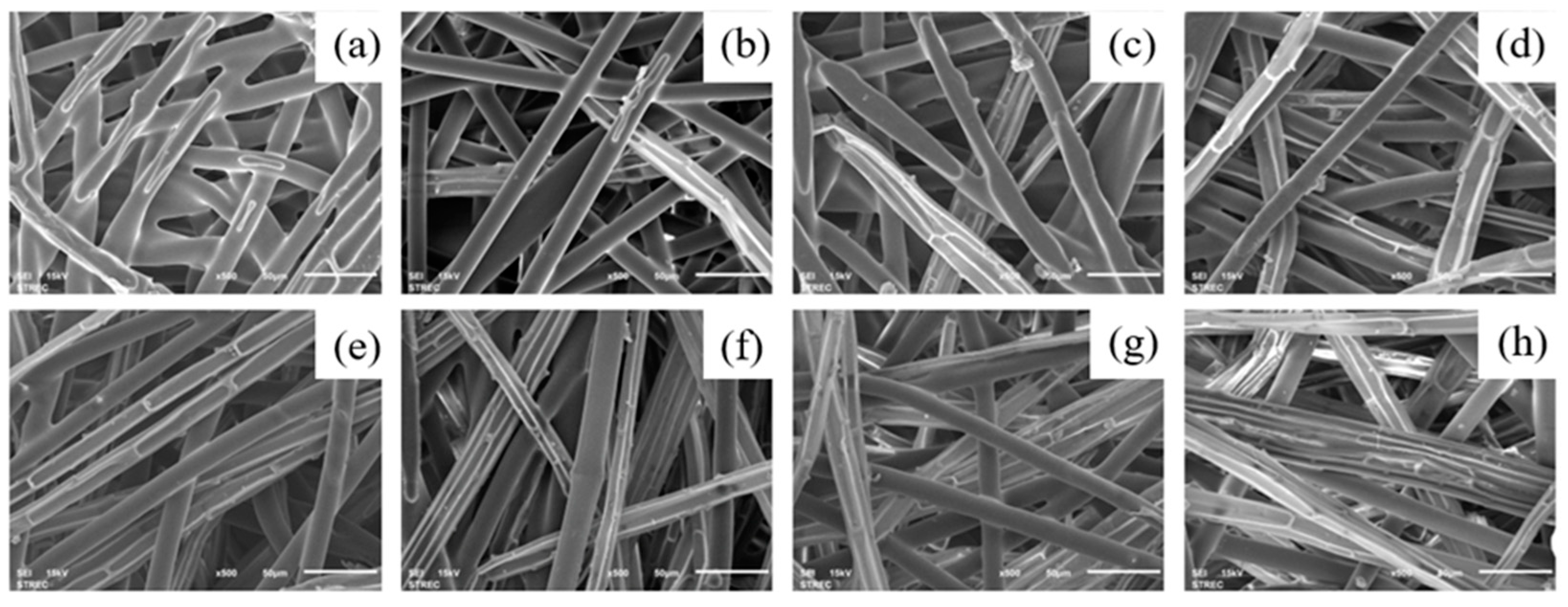

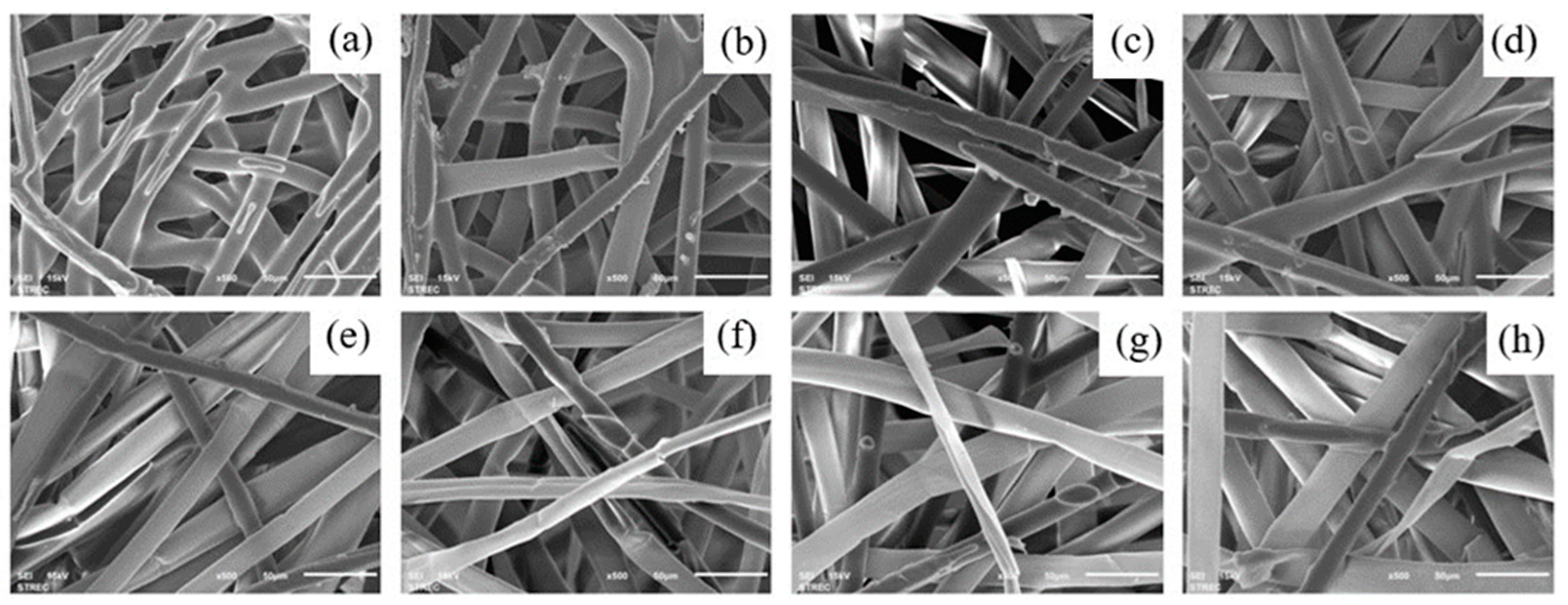

3.2.3. Morphology of composite webs

During the hot-press process at a temperature of 135°C, the bicomponent fibers experience partial melting, which subsequently leads to the adhesion of natural fibers and bicomponent fibers together, as depicted in the

Figure 4 and

Figure 5. At this specific hot-press temperature, the core of the PLA bicomponent remains solid, preserving the fibrous structure instead of forming a film-like structure. Meanwhile, the molten PLA sheath possesses adhesive properties, enabling it to adhere to neighboring fibers. As the proportion of natural fiber increases, the presence of PLA bicomponent fibers diminishes. When the PLA ratio exceeds 50%, it becomes challenging for the PLA to retain both natural fibers. Consequently, the composite webs might exhibit the fluffiness characteristic of natural fibers at this stage (

Figure 3).

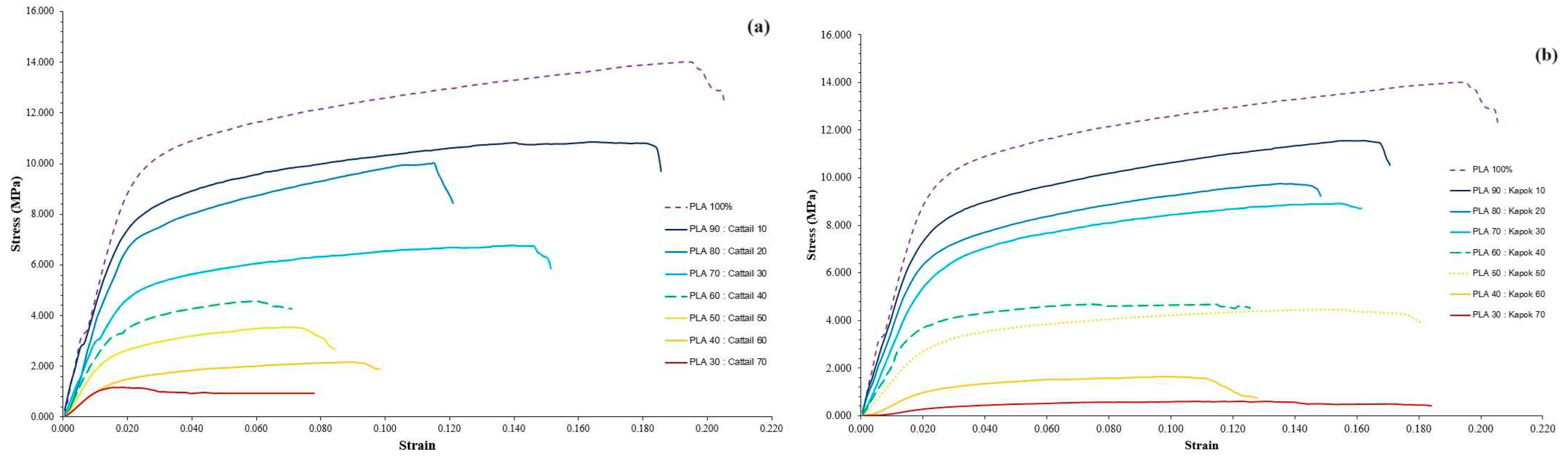

3.2.4. Mechanical test

The mechanical properties of the composite webs were tested and the data are presented in

Table 4. Additionally, the stress-strain curves of these composite webs are displayed in

Figure 6.

Higher natural fiber content in the PLA bicomponent fiber composite webs results in reduced ultimate load, Young’s modulus, yield strength, and yield strain. At the same natural fiber level, composite webs with kapok fiber generally exhibit better mechanical properties than those mixed with cattail fiber, except in the case of PLA: cattail fiber at a 30:70 ratio. This could be attributed to the longer fiber length of kapok fiber, leading to improved interfacial bonding properties. As noted by Du et al. [

34], long glass fiber composite materials tend to exhibit superior mechanical properties compared to short glass fiber composites. At a 30:70 ratio of PLA: kapok fiber, the lower density of kapok fibers compared to cattail fibers results in a higher fiber content within the composite webs. Consequently, the PLA bicomponent fibers may struggle to effectively bind all the fibers, leading to significantly reduced mechanical properties

In our study, only the sheath of the bicomponent fibers melts and acts as an adhesive to bind the natural fibers. However, a high ratio of natural fibers coupled with a low density results in the adhesive being unable to secure all natural fibers, leading to reduced mechanical properties (

Table 4). Composite webs containing over 40% natural fibers exhibit diminished mechanical properties, a trend consistent with the findings of Mula et al.'s study [

8]. This finding aligns with the observation that at higher ratios of natural fibers in these composite webs, a fluffy appearance emerges, attributed to an increased content of fibers within the web structure (

Figure 3). In addition, according to the EN 13795-2: 2019 standard, the tensile strength requirement for protective clothing in the dry state is equal to or greater than 20 N. In this context, when the natural fiber ratio equals or falls below 30, the material demonstrates an ultimate load higher than this specified standard.

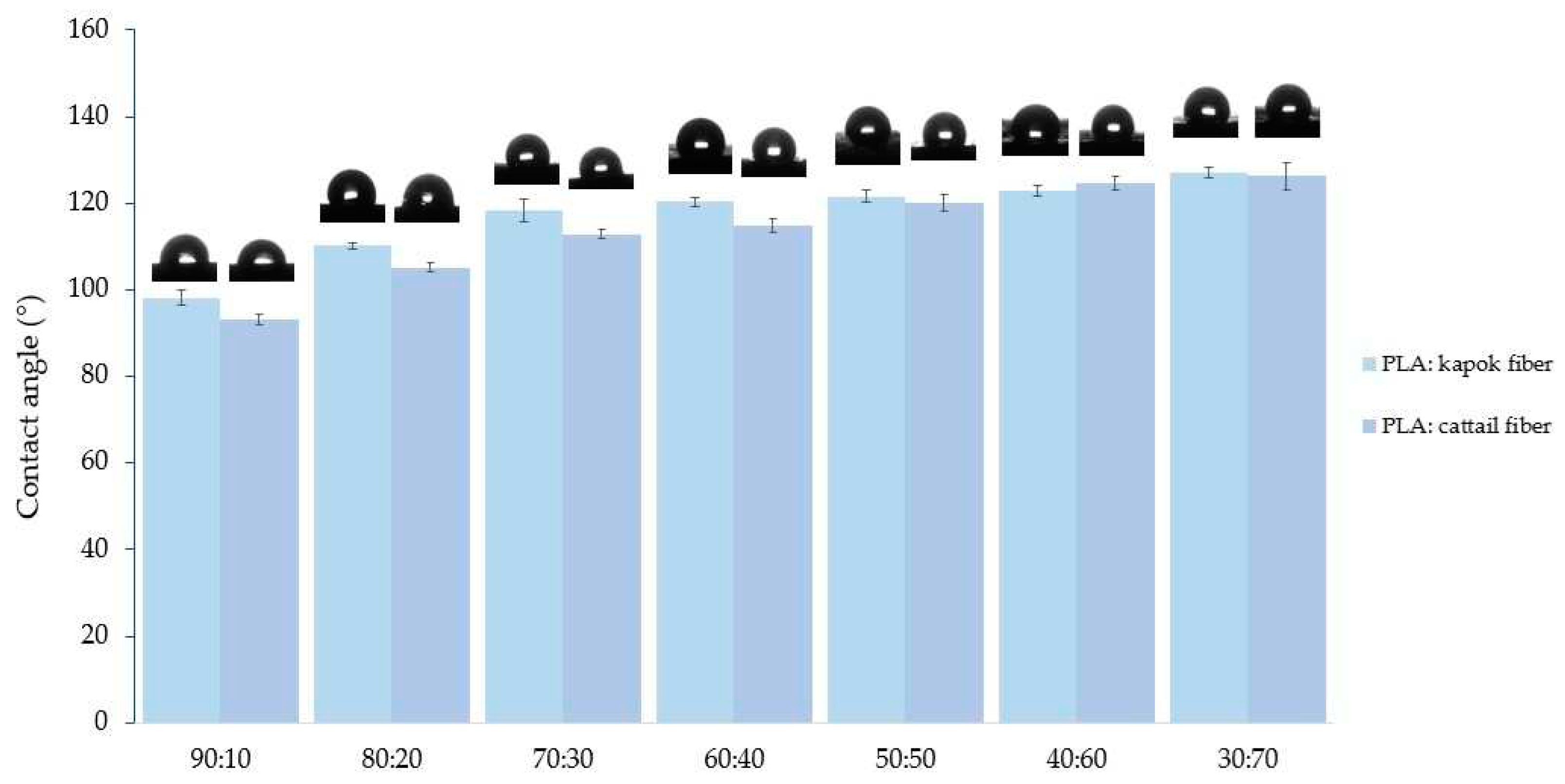

3.2.5. Water contact angle measurement

Surgical gowns should repel blood, body fluids, and other contaminants to ensure that these substances do not penetrate the gown. This characteristic helps maintain the sterility of the gown and prevents the transmission of infectious agents between the medical professional and the patient during surgical procedures. The contact angle of a water drop on the composite webs is illustrated in

Figure 7.

Contact angle values range between 0° and 180°. A contact angle of 0° corresponds to complete wetting, while an angle of 180° indicates non-wetting. A material is considered superhydrophobic if the contact angle is greater than 150°.

The PLA bicomponent web cannot detect water contact angles as it absorbs water immediately. However, the water contact angle increased with a higher natural fiber content in composite webs, as depicted in the

Figure 7. Ranging from 98° to 127°, the water contact angle of composite webs highlights their hydrophobic nature. This phenomenon is attributed to the surface wax present in both cattail and kapok fibers, contributing to their hydrophobic and oleophilic properties [

35,

36,

37]. Studies by Abdullah et al. [

38] reported a wax content of approximately 3% in kapok fiber, while Draman et al. [

39] noted a higher content of 5.51%. Based on Soxhlet extraction, Wu et al. [

40] reported that wax on the surface of cattail fibers accounted for 11.5%. When comparing both natural fibers at the same ratio, cattail fiber in composite webs exhibits a slightly lower water contact angle than kapok fiber. This difference may be attributed to the lower density of kapok fiber. Consequently, at an equivalent weight, kapok fiber possesses a higher volume of fibers compared to cattail fiber. The results indicate that blending natural fibers with PLA bicomponent fibers aids in providing better protection against blood and body fluids compared to using only PLA bicomponent fiber webs.

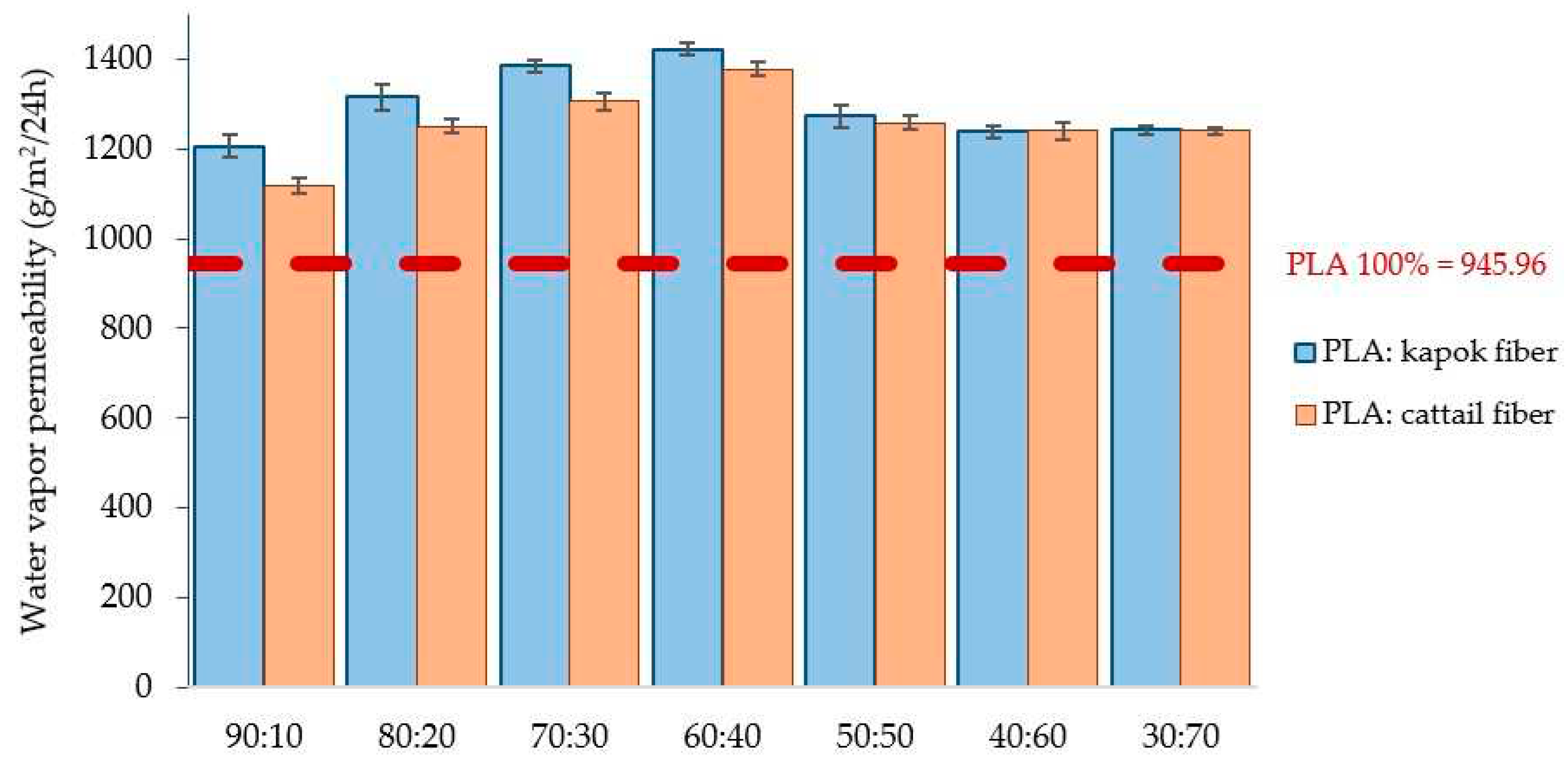

3.2.6. Water vapor permeability analysis

Breathability is the ability of textile allowing water vapor from the body through it while preventing liquid from entering from the outside [

41]. This characteristic plays a crucial role in determining comfort, often assessed through the measurement of moisture vapor transmission rate. The water vapor permeability of the composite webs was tested, and the results are presented in

Figure 8.

Incorporating natural fibers into the composite webs enhances their water vapor permeability compared to 100% PLA bicomponent webs. Interestingly, composite webs made from cattail fibers exhibit lower water vapor permeability than those crafted from kapok fibers at identical ratios. Several factors influence water vapor permeability, including sample thickness; thicker samples increase the distance and time needed for water vapor to travel, resulting in reduced permeability. Despite composite webs from kapok fibers being slightly thicker than those from cattail fibers at the same ratio, the significant lumen present in kapok fibers contributes to their higher water vapor permeability [

42].

The information from Kannekens [

43] and Behera and Arora [

41] classifies the water vapor permeability rates of breathable surgical gowns at 20°C into different categories: moderate (360 g/m²/24h), high (1392 g/m²/24h), and very high (2400 g/m²/24h). All composite webs show moderate rates, ranging from 945-1384 g/m²/24h, except for the PLA: kapok fiber at 60:40, which exhibits a high water vapor permeability rate of 1421 g/m²/24h. There might be a need in future work to reduce the thickness of composite webs to enhance water vapor permeability.

4. Conclusions

Composite webs composed of polylactic acid bicomponent fibers combined with both waste natural fibers were successfully prepared. Cattail fiber was bamboo-shaped structure, while kapok fiber exhibited a hollow tube structure. SEM images demonstrated that the composite web maintained a fibrous structure rather than forming a film-like structure. Evaluation of mechanical and physical properties was conducted, revealing distinctive color characteristics—creamy yellowish-white for kapok fiber-based webs and yellowish-brown for cattail fiber-based webs. While the incorporation of natural fibers might reduce the mechanical properties of the composite web, it has a beneficial impact on enhancing water vapor permeability and achieving a higher water contact angle, thereby protecting against water droplets penetrating the fabric.

Author Contributions

Conceptualization, P.K.; methodology, P.K.; investigation, P.K. and T.S.; resources, P.K. and K.C.; writing—original draft preparation, P.K. and T.S.; writing—review and editing, P.K..; visualization, P.K. and T.S.; supervision, P.K. All authors have read and agreed to the published version of the manuscript.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Benson, N.U.; Bassey, D.E.; Palanisami, T. COVID Pollution: Impact of COVID-19 Pandemic on Global Plastic Waste Footprint. Heliyon. 2021, 7, e06343. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Li, S.; Ahmad, I.M.; Zhang, G.; Sun, Y.; Wang, Y.; Sun, C.; Jiang, C.; Cui, P.; Li, D. Global Face Mask Pollution: Threats to the Environment and Wildlife, and Potential Solutions. Sci Total Environ. 2023, 887, 164055. [Google Scholar] [CrossRef]

- Cubas, A.L.V.; Moecke, E.H.S.; Provin, A.P.; Dutra, A.R.A.; Machado, M.M.; Gouveia, I.C. The Impacts of Plastic Waste from Personal Protective Equipment Used during the COVID-19 Pandemic. Polymers. 2023, 15, 3151. [Google Scholar] [CrossRef]

- Singh, N.; Ogunseitan, O.A.; Wong, M.H.; Tang, Y. Sustainable Materials Alternative to Petrochemical Plastics Pollution: A Review Analysis. Sustainable Horizons. 2022, 2, 100016. [Google Scholar] [CrossRef]

- Mangal, M.; Rao, C.V.; Banerjee, T. Bioplastic: An Eco-Friendly Alternative to Non-Biodegradable Plastic. Polym. Int. 2023, 72, 984–996. [Google Scholar] [CrossRef]

- Jawahar, V.; Gabriel, M.; Santhanam, S.; Selvaraj, S.K. Sustainable Waste Cotton and Pigeon Pea Stalk Fibers Composite Materials for Acoustics and Thermal Properties. J. Eng. Fibers Fabr. 2023, 18. [Google Scholar] [CrossRef]

- Maiti, S.; Islam, M.R.; Uddin, M.A.; Afroj, S.; Eichhorn, S.J. Karim, N. Sustainable Fiber-Reinforced Composites: A Review. Adv. Sustain. Syst. 2022, 6, 2200258. [Google Scholar] [CrossRef]

- Mula, M.; Tekbaş, R.N.; Cengiz, F.; Yüksek, İ.Ö.; Gürarslan, A. Sustainable Milkweed Fiber Composites for Medical Textile Application. ACS Sustainable Chem. Eng. 2023, 11, 12523–12531. [Google Scholar] [CrossRef]

- Fages, E.; Gironés, S.; Sánchez-Nacher, L.; García-Sanoguera, D.; Balart, R. Use of Wet-Laid Techniques to form Flax-Polypropylene Nonwovens as Base Substrates for Eco-Friendly Composites by Using Hot-Press Molding. Polym. Compos. 2012, 33, 253–261. [Google Scholar] [CrossRef]

- Ghali, L.; Halimi, M.T.; Hassen, M.B.; Sakli, F. Effect of Blending Ratio of Fibers on the Properties of Nonwoven Fabrics Based of Alfa Fibers. AMPC. 2014, 4, 116–125. [Google Scholar] [CrossRef]

- Möhl, C.; Weimer, T.; Caliskan, M.; Baz, S.; Bauder, H.-J.; Gresser, G.T. Development of Natural Fibre-Reinforced Semi-Finished Products with Bio-Based Matrix for Eco-Friendly Composites. Polymers. 2022, 14, 698. [Google Scholar] [CrossRef]

- Cui, F.; Li, H.; Chen, C.; Wang, Z.; Liu, X.; Jiang, G.; Cheng, T.; Bai, R.; Song, L. Cattail Fibers as Source of Cellulose to Prepare a Novel Type of Composite Aerogel Adsorbent for the Removal of Enrofloxacin in Wastewater. Int. J. Biol. Macromol. 2021, 191, 171–181. [Google Scholar] [CrossRef]

- Zheng, Y.; Wang, J.; Zhu, Y.; Wang, A. Research and Application of Kapok Fiber as an Absorbing Material: A Mini Review. J. Environ. Sci. 2015, 27, 21–32. [Google Scholar] [CrossRef]

- Zerga, A.Y.; Tahir, M. Biobased Kapok Fiber Nano-Structure for Energy and Environment Application: A Critical Review. Molecules. 2022, 27, 8107. [Google Scholar] [CrossRef]

- Sangalang, R. Kapok Fiber- Structure, Characteristics and Applications: A Review. Orient. J. Chem. 2021, 37, 513–523. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Harussani, M.M.; Hakimi, M.Y.A.Y.; Haziq, M.Z.M.; Atikah, M.S.N.; Asyraf, M.R.M.; Ishak, M.R.; Razman, M.R.; Nurazzi, N.M.; Norrrahim, M.N.F.; Abral, H.; Asrofi, M. Polylactic Acid (PLA) Biocomposite: Processing, Additive Manufacturing and Advanced Applications. Polymers. 2021, 13, 1326. [Google Scholar] [CrossRef]

- Wu, Y.; Gao, X.; Wu, J.; Zhou, T.; Nguyen, T.T.; Wang, Y. Biodegradable Polylactic Acid and Its Composites: Characteristics, Processing, and Sustainable Applications in Sports. Polymers. 2023, 15, 3096. [Google Scholar] [CrossRef]

- Shao, L.; Xi, Y.; Weng, Y. Recent Advances in PLA-Based Antibacterial Food Packaging and Its Applications. Molecules. 2022, 2022. 27, 5953. [Google Scholar] [CrossRef]

- Pérez-Davila, S.; González-Rodríguez, L.; Lama, R.; López-Álvarez, M.; Oliveira, A.L.; Serra, J.; Novoa, B.; Figueras, A.; González, P. 3D-Printed PLA Medical Devices: Physicochemical Changes and Biological Response after Sterilisation Treatments. Polymers. 2022, 14, 4117. [Google Scholar] [CrossRef]

- Eutionnat-Diffo, P.A.; Chen, Y.; Guan, J.; Cayla, A.; Campagne, C.; Zeng, X.; Nierstrasz, V. Stress, Strain and Deformation of Poly-Lactic Acid Filament Deposited onto Polyethylene Terephthalate Woven Fabric Through 3D Printing Process. Sci. Rep. 2019, 9, 14333. [Google Scholar] [CrossRef]

- Spahiu, T.; Canaj, E.; Shehi, E. 3D Printing for Clothing Production. J. Eng. Fibers Fabr. 2020, 15, 1–8. [Google Scholar] [CrossRef]

- Kalita, N.K.; Damare, N.A.; Hazarika, D.; Bhagabati, P.; Kalamdhad, A.; Katiyar, V. Biodegradation and Characterization Study of Compostable PLA Bioplastic Containing Algae Biomass as Potential Degradation Accelerator. Environ. Chall. 2021, 3, 100067. [Google Scholar] [CrossRef]

- Buddhakala, M.; Buddhakala, N. Physical, Mechanical and Antibacterial Properties of Biodegradable Bioplastics from Polylactic Acid and Corncob Fibers with Added Nano Titanium Dioxide. Trends Sci. 2023, 20, 6473. [Google Scholar] [CrossRef]

- Tsioptsias, C.; Tsivintzelis, I. On the Thermodynamic Thermal Properties of Quercetin and Similar Pharmaceuticals. Molecules. 2022, 27, 6630. [Google Scholar] [CrossRef]

- Syed Draman, S.F.; Daik, R.; Abdul Latif, F.; El-Sheikh, S.M. Characterization and Thermal Decomposition Kinetics of Kapok (Ceiba pentandra L.)–Based Cellulose. BioResources 2013, 9, 8–23. [Google Scholar] [CrossRef]

- Neto, J.S.S.; de Queiroz, H.F.M.; Aguiar, R.A.A.; Banea, M.D. A Review on the Thermal Characterisation of Natural and Hybrid Fiber Composites. Polymers. 2021, 13, 4425. [Google Scholar] [CrossRef]

- Karvran, M.; Vagner, C.; Cochez, M.; Ponçot, M.; Saeb, M.R.; Vahabi, H. Thermal Degradation of Polylactic Acid (PLA)/Polyhydroxybutyrate (PHB) Blends: A Systematic Review. Polym. Degrad. Stab. 2022, 201, 109995. [Google Scholar] [CrossRef]

- Du, Q.; Chen, Y.N. R & D Status and Countermeasures of Natural Functional Kapok Fiber. Adv. Mat. Res. 2013, 796, 199–204. [Google Scholar] [CrossRef]

- Hu, L. , Wang, F., Xu, G., Xu, B. Unique Microstructure of Kapok Fibers in Longitudinal Microscopic Images. Text. Res. J. 2017, 87, 2255–2262. [Google Scholar] [CrossRef]

- Koschevic, M.T.; Araújo, R.P.; Garcia, V.A.; Fakhouri, F.M.; Oliveira, K.M.P.; Arruda, E.J.; Dufresne, A.; Martelli, S.M. Antimicrobial Activity of Bleached Cattail Fibers (Typha domingensis) Impregnated with Silver Nanoparticles and Benzalkonium Chloride. J. Appl. Polym. Sci. 2021, 138, 50885. [Google Scholar] [CrossRef]

- Mwaikambo, L.Y. Review of the History, Properties and Application of Plant Fibres. AJST. 2006, 7, 120–133. [Google Scholar]

- Sekar, V.; Fouladi, M.H.; Namasivayam, S.N.; Sivanesan, S. Additive Manufacturing: A Novel Method for Developing an Acoustic Panel Made of Natural Fiber-Reinforced Composites with Enhanced Mechanical and Acoustical Properties. J. Eng. 2019, 4546863. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, J.; Li, C.; Wang, F.; Shi, L.; Tao, M.; Weng, B.; Yan, B.; Guo, Y.; Chen, Y. Characterization of Potential Cellulose Fiber from Cattail Fiber: A Study on Micro/Nano Structure and Other Properties. Int. J. Biol. Macromol. 2021, 193, 27–37. [Google Scholar] [CrossRef]

- Du, B.; Li, Z.; Bai, H.; Li, Q.; Zheng, C.; Liu, J.; Qiu, F.; Fan, Z.; Hu, H.; Chen, L. Mechanical Property of Long Glass Fiber Reinforced Polypropylene Composite: From Material to Car Seat Frame and Bumper Beam. Polymers. 2022, 14, 1814. [Google Scholar] [CrossRef]

- Lim, T.T.; Huang, X. Evaluation of Hydrophobicity/Oleophilicity of Kapok and Its Performance in Oily Water Filtration: Comparison of Raw and Solvent-Treated Fibers. Ind. Crops Prod. 2007, 26, 125–134. [Google Scholar] [CrossRef]

- Futalan, C.M.; Choi, A.E.S.; Soriano, H.G.O.; Cabacungan, M.K.B.; Millare, J.C. Modification Strategies of Kapok Fiber Composites and Its Application in the Adsorption of Heavy Metal Ions and Dyes from Aqueous Solutions: A Systematic Review. Int. J. Environ. Res. Public Health. 2022, 19, 2703. [Google Scholar] [CrossRef]

- Cui, Y.; Xu, G.; Liu, Y. Oil Sorption Mechanism and Capacity of Cattail Fiber Assembly. J. Ind. Text. 2014, 43, 330–337. [Google Scholar] [CrossRef]

- Abdullah, M.A.; Rahmah, A.U.; Man, Z. Physicochemical and Sorption Characteristics of Malaysian Ceiba pentandra (L.) Gaertn. as a Natural Oil sorbent. J. Hazard Mater. 2010, 177, 683–91. [Google Scholar] [CrossRef]

- Draman, S.F.S.; Daik, R.; Latif, F.A.; El-Sheikh, S.M. Characterization and Thermal Decomposition Kinetics of Kapok (Ceiba pentandra L.)–Based Cellulose. Bioresour. 2014, 9, 8–23. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, J.; Li, C.; Wang, F.; Shi, L.; Tao, M.; Weng, B.; Yan, B.; Guo, Y.; Chen, Y. Characterization of Potential Cellulose Fiber from Cattail Fiber: A Study on Micro/Nano Structure and Other Properties. Int. J. Biol. Macromol. 2021, 193, 27–37. [Google Scholar] [CrossRef]

- Behera, B.K.; Arora, H. Surgical Gown: A Critical Review. J. Ind. Text. 2009, 38, 205–231. [Google Scholar] [CrossRef]

- Baraniak, J.; Kania-Dobrowolska, M. Multi-Purpose Utilization of Kapok Fiber and Properties of Ceiba Pentandra Tree in Various Branches of Industry. J. Nat. Fibers. 2023, 20, 2192542. [Google Scholar] [CrossRef]

- Kannekens, A. Breathable Coatings and Laminates. J. Coated Fabrics. 1994, 24, 51–59. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).