1. Introduction

In an era of growing environmental concerns, the need for environmentally friendly materials has never been more pressing. This pursuit becomes even more critical when considering the diverse industries that use materials with exceptional mechanical properties, durability and sustainability. Exploring plant fibres as alternative reinforcements in composites offers hope for the search of materials compatible with sustainable development goals. This article is dedicated to the intriguing fusion of two different but complementary materials: kenaf (K) and glass-reinforced (G) pultruded composites targeted for structural applications. Pultruded composite profiles are gaining increasing attention and are in significant demand across a range of industries. Pultrusion is a manufacturing process that produces continuous fibre-reinforced polymer (FRP) composite profiles with high strength and stiffness. These profiles have excellent corrosion resistance, high durability and low maintenance requirements, making them attractive for various applications [

1,

2,

3]. Some industries with the potential for pultruded profile applications are demonstrated in

Table 1.

Automotive, aerospace, marine, transportation and others industries require materials that strike a balance between strength, weight and environmental impact. Traditional materials often fail to meet these requirements due to their energy-intensive production processes, limited renewability and unfavourable disposal paths. This has prompted a shift towards alternative materials, and among these, plant fibres such as kenaf, flax, hemp and jute and advanced composites are gaining attention as they offer a unique synergy of properties. Kenaf, a fast-growing plant with high availability known for its fibrous stalks, has emerged as a promising natural reinforcement due to its exceptional mechanical properties, renewability and biodegradability. In addition, when combined with polymer matrices through pultrusion, kenaf fibres can yield lightweight but strong composites with unique advantages for various industries [

8,

9]. Simultaneously, the integration of glass fibres into pultruded composites increases stiffness, strength and resistance to environmental factors, resulting in materials well suited for demanding applications. Hence, hybridising the strengths of kenaf and glass fibres in the creation of pultruded structural profiles holds the promise of harnessing the combined advantages of these materials.

A little research has been done on kenaf fibre composites and kenaf/glass fibre hybrid composites, investigating their fatigue and impact properties. Asumani and Paskaramoorthy [

10] examined the fatigue and impact strength of kenaf fibre-reinforced polypropylene composites by manipulating the fibre loading in the composites and the concentration of fibre treatment alkali. The findings indicated that fibre loading at 30 wt.% and alkali concentration at 5-6% significantly improved the fatigue and impact properties of kenaf composites. Feng et al. [

11] studied the fatigue properties of a fibre-metal laminate fabricated using kenaf, glass fibres and aluminium. The results show that the fatigue sensitivity and strength decrease as the ratio of kenaf fibre (K) to glass fibre (G) increases. They also found that the K/G/K stacking sequence showed optimum fatigue resistance and is therefore suitable for low load applications. Miah et al. [

12] compared the fatigue properties of kenaf mat/unsaturated polyester and glass/unsaturated polyester composites after thermal ageing. The researchers noted that although kenaf-reinforced composites showed lower mechanical strength than glass fibre-reinforced composites, they exhibited stable low-cycle fatigue and better energy absorption properties compared to glass fibre composites.

According to Supian et al. [

13], kenaf/glass hybrid composite tubes with high kenaf fibre fraction shown better energy absorption values compared to pure glass fibre tubes. Ismail et al. [

14] mentioned that kenaf/glass hybrid composites with 25% kenaf and 75% glass fibre by weight demonstrated the highest tensile strength. The hybrid specimen can also absorb dissipated low-velocity impact energy up to 40 J. Owen et al. [

15] found that the application of an epoxy coating to kenaf/abs composites improved fatigue strength. Their results also indicated that the fatigue and impact strength of the epoxy-coated kenaf/abs composites increased at 200°C of processing temperature compared to 220 and 240°C. A different approach was used by Shahar et al. [

16], developing 3D printed kenaf composites for biomedical applications. PLA composites reinforced with kenaf particles recorded an increase in fatigue strength with increasing filler loading. Similarly, Mechi and Al-Waily [

17] applied kenaf fibres to develop a below-knee prosthesis. The kenaf-reinforced composite recorded a maximum fatigue life of 18.35 × 10

5 cycles, which meets the safety requirements for a biomedical device.

While the advantages of kenaf and glass-reinforced hybrid composites are obvious, there is a gap in exploring their potential in structural applications. Their durability in structural applications remains a question despite ongoing research. While numerous studies have addressed their properties and applications, the combined potential of these materials in pultruded profiles has still not been comprehensively explored. Our research endeavour aims to fill this gap by developing pultruded profiles made from kenaf and glass fibres and delving into the fatigue and impact properties of hybrid composites for structural applications

, such as bolted joints [

18,

19,

20]. Researchers can unlock insights that will resonate across multiple sectors by delving into the interaction between natural and synthetic fibres. Therefore, the successful development of pultruded composites reinforced with kenaf and glass could pave the way for lightweight, durable and sustainable alternatives to conventional materials, potentially changing the way in which industries approach material selection for structural profile applications.

2. Materials and Methods

Using kenaf fibres in mat form, unidirectional E-glass fibre yarns and unsaturated polyester resin as key ingredients, structural profiles with different cross-sections have been meticulously produced by a pultrusion process.

2.1. Materials

Materials used in this research include reinforcing fibres, thermosetting resin and surfacing veils. For the reinforcing fibres, the selected kenaf fibres were hybridised with E-glass fibres. The kenaf fibres were purchased locally in Malaysia, while the glass fibres were purchased in China. The matrix material used in the study was chosen to be unsaturated polyester resin, which is curable at room temperature. By combining the strength of E-glass fibres with the environmentally friendly properties of Kenaf fibres, our research aimed to create a composite material with improved mechanical properties and sustainability.

2.1.1. Kenaf

For the production of glass and plant fibre reinforced hybrid composites, kenaf fibres were purchased in woven form from Lembaga Kenaf dan Tembakau Negara (LKTN) in Malaysia. Kenaf fibres are widely available in Malaysia, making it a readily available and sustainable reinforcement material for composites.

Figure 1 shows the woven kenaf fibre mat used in this study. The kenaf fibre mats were alkali treated in 5% sodium hydroxide (NaOH) at room temperature to strengthen the fibre surface.

Woven kenaf fibres provide a well-organised and uniform distribution of plant fibres in the composite, which is essential for improving mechanical properties and overall structural performance. Besides, one of the main objectives of this research is to ideally replace the woven glass fibre mats used in the pultruded composite industry. By using locally sourced kenaf fibres, the composite manufacturing process benefits from reduced transport costs and supports the domestic agricultural industry, making it an environmentally friendly and cost-effective approach to composite manufacturing.

2.1.2. E-Glass

E-glass fibres in the form of both woven mats and direct roving have been purchased in China. These glass fibre materials are commonly used in the pultrusion industry to produce a variety of pultruded profile sections, mainly for structural applications.

Figure 2 shows direct roving E-glass fibres as continuous bundles of untwisted fibres. On the other hand,

Figure 3 shows E-glass fibres in the form of a stitched woven mat in which the fibres are arranged in an organised and interlocked pattern.

The availability of both direct roving and woven mat E-glass fibres provides flexibility in the manufacturing process, enabling the production of a variety of composite profiles with specific mechanical properties and performance characteristics. The use of high quality E-glass fibres ensures consistency and reliability in the composite manufacturing process, contributing to the production of robust and durable structural components suitable for a wide range of industries.

2.1.3. Unsaturated Polyester Resin

Unsaturated polyester resin is widely recognised as economically viable for composite applications. Unlike other thermosetting resins, such as vinyl esters and epoxies, unsaturated polyester resin stands out for its highly cost-effective nature. The affordable price of this resin makes it the preferred choice for a wide range of industries seeking cost-effective solutions for their composite needs. The resin and hardener are mixed at a weight ratio of 10:1, according to the manufacturer's specifications. This precise mixing ratio ensures optimum curing and mechanical properties of the resulting composite. By using unsaturated polyester resin in combination with plant and glass fibres, the research aims to develop environmentally sustainable and economically viable pultruded hybrid composites suitable for structural applications. The cost-effectiveness of this resin system and its favourable mechanical properties make it a promising candidate for increasing the commercial viability of advanced composite materials and their widespread use.

2.1.4. Surfacing Veil

Surfacing veils are well known in composite applications due to their unique advantages in improving the surface finish and performance of composite materials.

Figure 4 shows the surface veils purchased in China that were used in this study to produce pultruded composites. The surfacing veils act as a protective layer, reducing surface defects such as porosity and fibre translucency, which are common in pultruded composites. These veils also provide additional UV resistance, preventing premature degradation and colour fading due to prolonged exposure to sunlight.

2.2 Pultruded Profile Fabrication

The production of pultruded profiles was carried out at Mui Fatt Sdn Bhd, a local composites manufacturing company based in Port Klang, Malaysia. A hydraulic pultrusion machine was used to produce woven glass/unidirectional glass composites and woven kenaf/unidirectional glass hybrid square profiles. Woven glass fibres and unidirectional glass rovings are conventionally used to produce pultruded glass fibre products. This research uses woven kenaf fibres to replace conventional glass fibres and develop hybrid composites for pultrusion applications. The pultrusion process parameters are summarised in

Table 2.

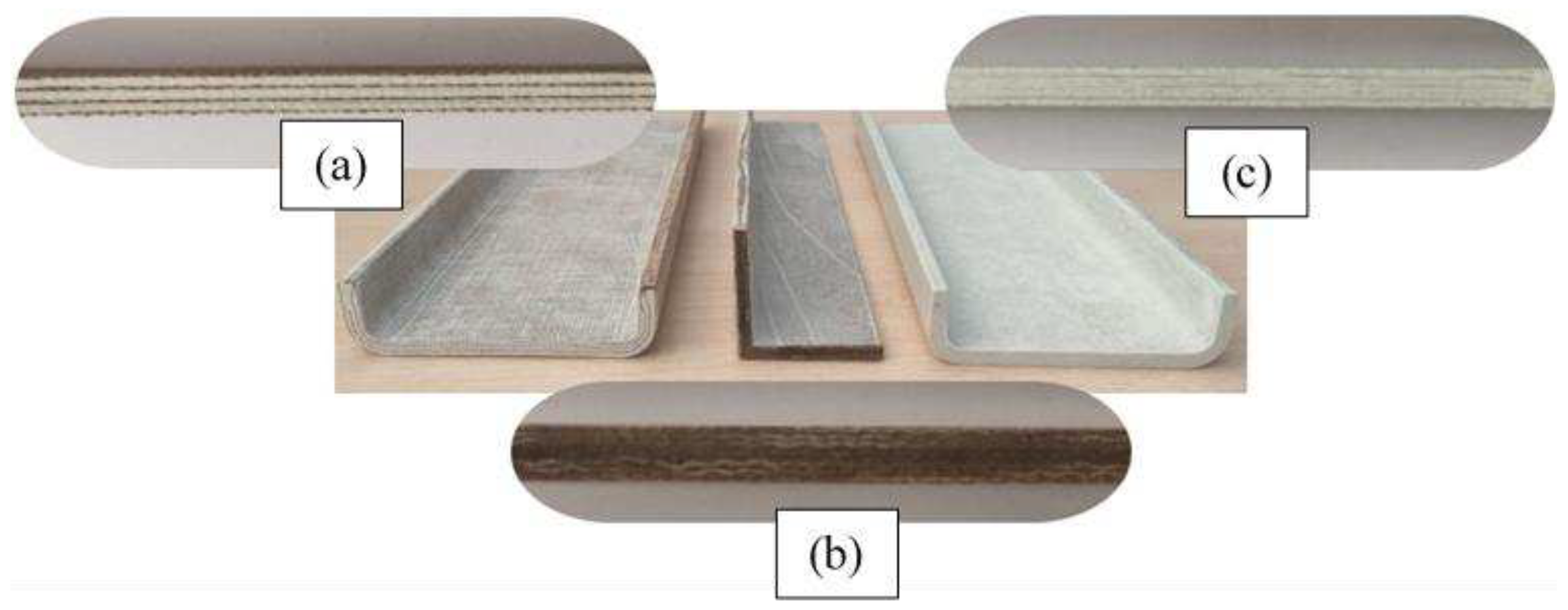

The overall fibre to matrix ratio was set at 55/45. The profiles were controlled with seven layers of approximately 6 mm thickness (

Table 3). Unsaturated polyester resin was used as the matrix, and dibenzol peroxide (BPO) and tert-butyl peroxybenzonate (TPBP) were used as curing agents to form the composite profile matrix. The pigments were added at 3% of the total resin weight. Calcium carbonate and aluminium hydroxide were used as fillers at 40% of the total resin weight to improve the mechanical properties of the profiles. The fabricated profiles are shown in

Figure 5 and the stacking sequences in

Figure 6.

Indications: WK – woven kenaf, WG – woven glass, UG – unidirectional glass roving

2.3. Experimental Testing

2.3.1. Tensile Tests

Tensile tests were carried out for each group of kenaf/glass fibre hybrid composites and glass fibre composites. The tensile test specimen preparation and testing procedure were carried out in accordance with ASTM D638 [

21] at a crosshead speed of 5 mm/min. The tensile tests were conducted on a Zwick/Roell Z400 universal testing machine with a 100 kN load cell. The dimensions of the tensile test specimen were 165 mm × 19 mm × 6 mm. Five specimens of each composite variety were tested and the average value was determined and recorded. Tensile strength and tensile modulus were recorded. The ultimate tensile strength (UTS) values were used for fatigue analyses.

2.3.2. Fatigue Tests

Uniaxial fatigue tests were carried out using an INSTRON 8801 testing machine, with a 100 kN load cell (

Figure 7). Two specimens were prepared for each level expressed as a proportion of UTS for all variants.

The fatigue test procedure used in this study was based on ASTM D7791 [

22] (Type I), in which the specimens were loaded under tension-tension stress. The tests were conducted with a sine wave of 20 Hz at different levels of applied stress and at a stress ratio:

where

Qmin is the minimum stresses in fatigue testing and

Qmax is the maximum stresses in fatigue testing (

Table 4).

The analysis was conducted at 23±2°C and 50±5% relative humidity under room condition. Stress levels were set to 80%, 70%, 60% and 50% of the UTS value.

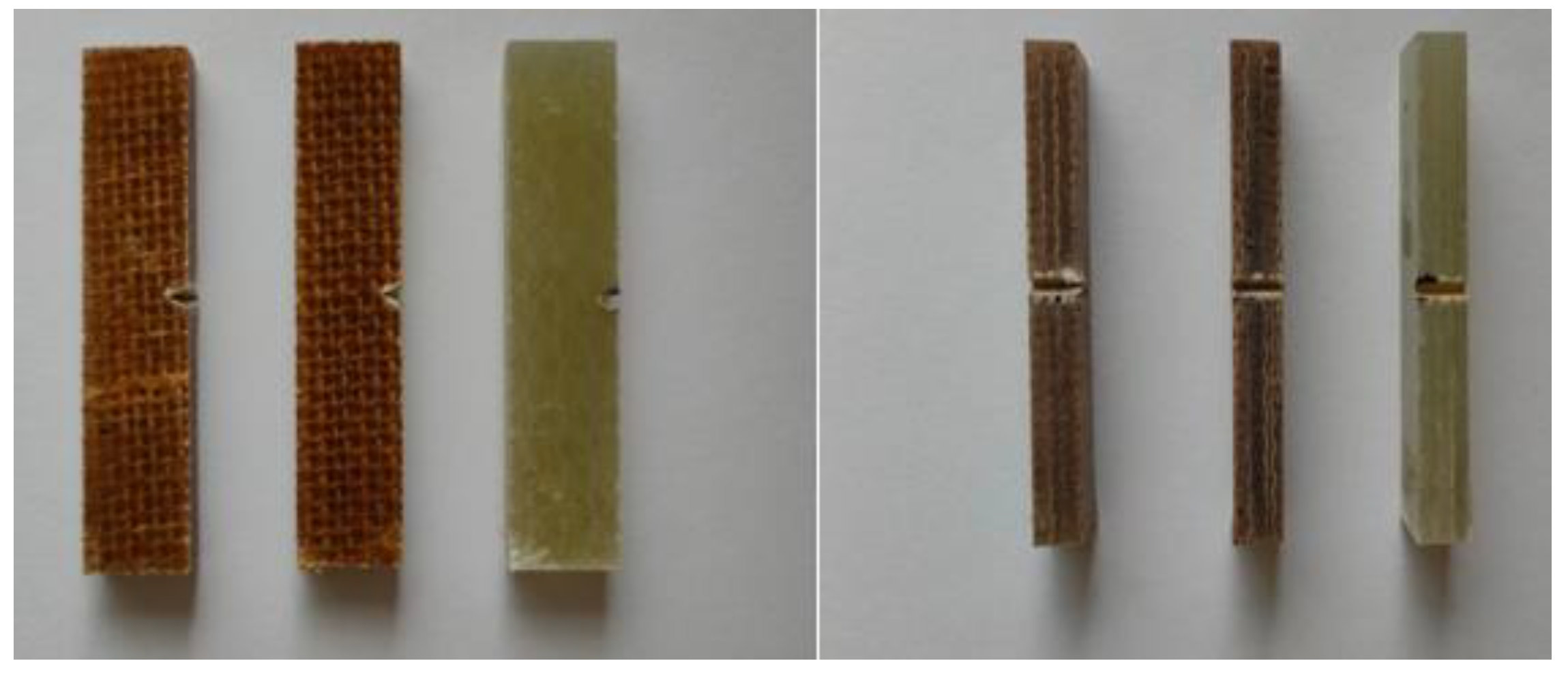

2.3.3. Izod Tests

The procedure for the Izod tests was based on ASTM D256 [

23] (Test C). Izod impact tests were carried out on an INSTRON CEAST 9050 testing machine (

Figure 8).

The hammer energy varied from 0.5 to 50 J. Five notched specimens of 20 pieces were prepared for each variant, as shown in

Figure 9. The specimens were then conditioned at 23°C for 48 hours after notching before testing. The tests were performed at a laboratory temperature of 21°C. The average value from five replicates was recorded.

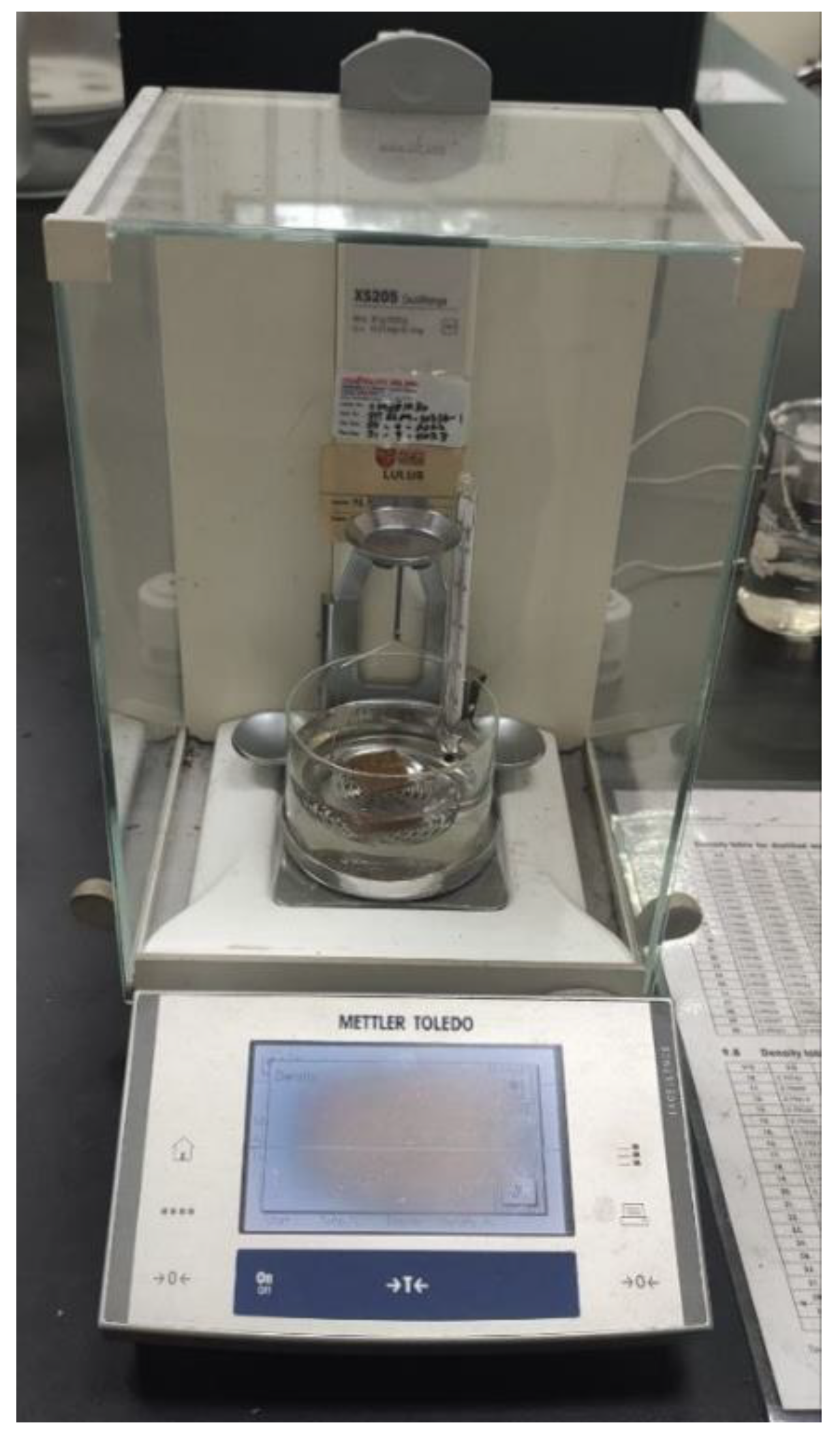

2.3.4. Density Tests

Density tests were carried out in accordance with ASTM D792 [

24] (

Figure 10). Three 20 × 20 × 6 mm square specimens were prepared for each variant. The specimens were conditioned at room temperature for two days before the density test. Distilled water was used as an immersion liquid at room temperature (27°C) for the tests. The mass of the specimens in air was first determined before immersing the specimens in the liquid. After immersion in distilled water, its apparent mass was determined and its specific gravity calculated and recorded. The experiment was repeated three times and the average value recorded.

The density r

c was calculated according to the following equation:

where

wc is the weight of composite in the air and

ww is the weight of composite in water.

2.3.5. Cost and Weight Analysis

The weight of a square hollow pultruded profile made of hybrid and non-hybrid composites with a volume of 3.277 × 10-4 m3 was compared and analysed. The weight was obtained by multiplying the volume of the profile by the density of the material.

3. Results and Discussion

As the main part of this experiment, the durability properties of hybrid and non-hybrid pultruded composites are analysed through fatigue and Izod impact testing. Each sample’s ultimate tensile strength has been recorded from tensile testing, and the UTS data is used for fatigue analysis.

3.1. Static Properties

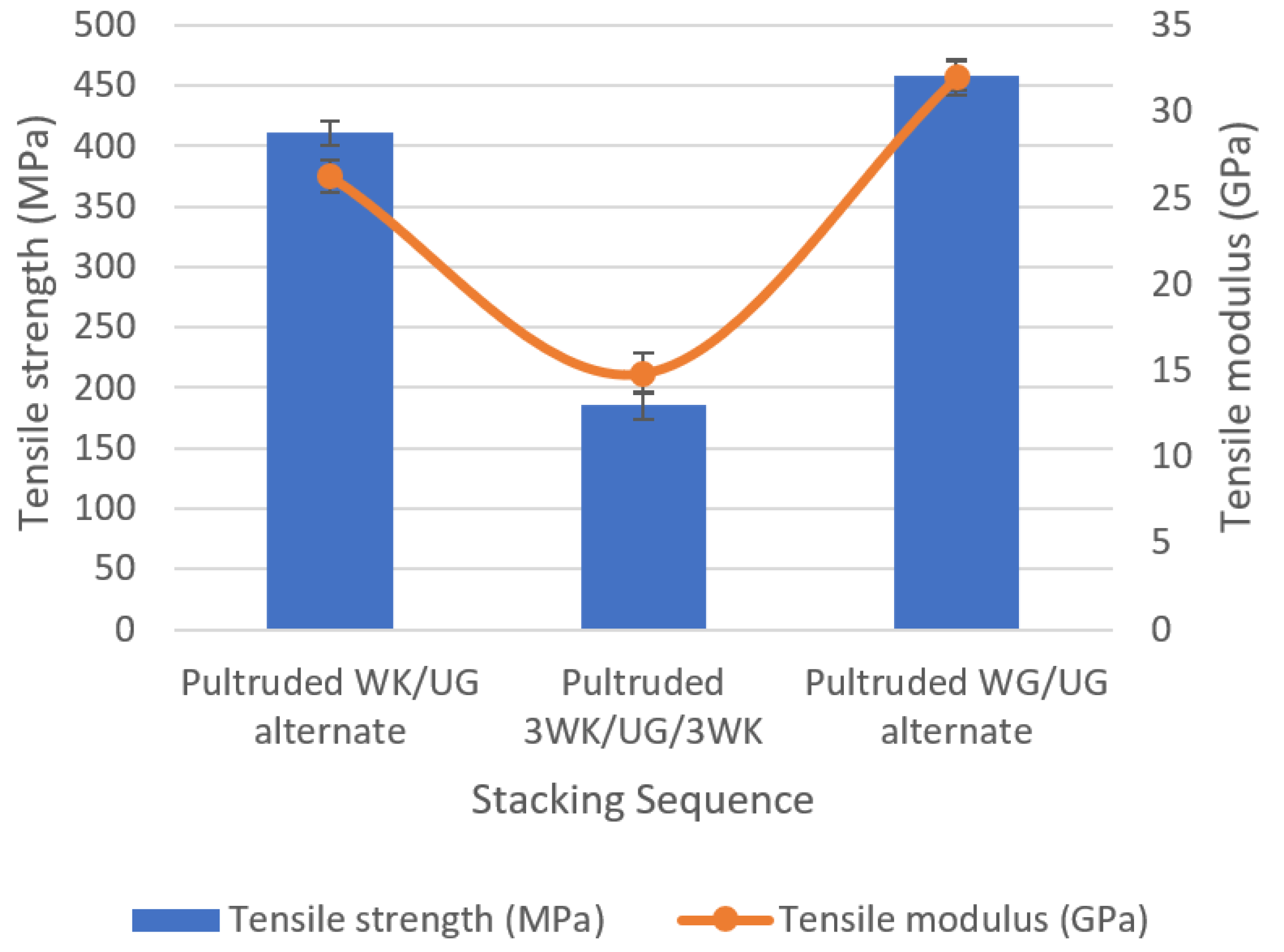

Figure 11 shows the tensile strength and modulus of the hybrid and non-hybrid pultruded composites. The non-hybrid pultruded WG/UG samples showed the highest tensile strength (458.28 MPa) and modulus (32 GPa) of the three pultruded laminates. This is due to the higher tensile properties of the individual glass fibres compared to a single kenaf fibre. However, interesting results were obtained when kenaf fibres with lower tensile strength were replaced with woven glass fibres and hybridised with unidirectional glass fibre rovings. The hybrid specimens pultruded with alternating WK/UG achieved a tensile strength of 410.6 MPa and an elastic modulus of 26 GPa. The specimens experienced a 10.4% decrease in strength and 18.75% decrease in elastic modulus compared to the pultruded WK/UG composites. However, the 3WK/1UG/3WK hybrid sample recorded the lowest tensile strength and elastic modulus at 185 MPa and 15 GPa, respectively. The higher ratio of kenaf to glass fibre resulted in a significant reduction in strength of about 59.6% and a reduction in modulus of about 53.13% compared to the conventional glass fibre sample.

As shown in

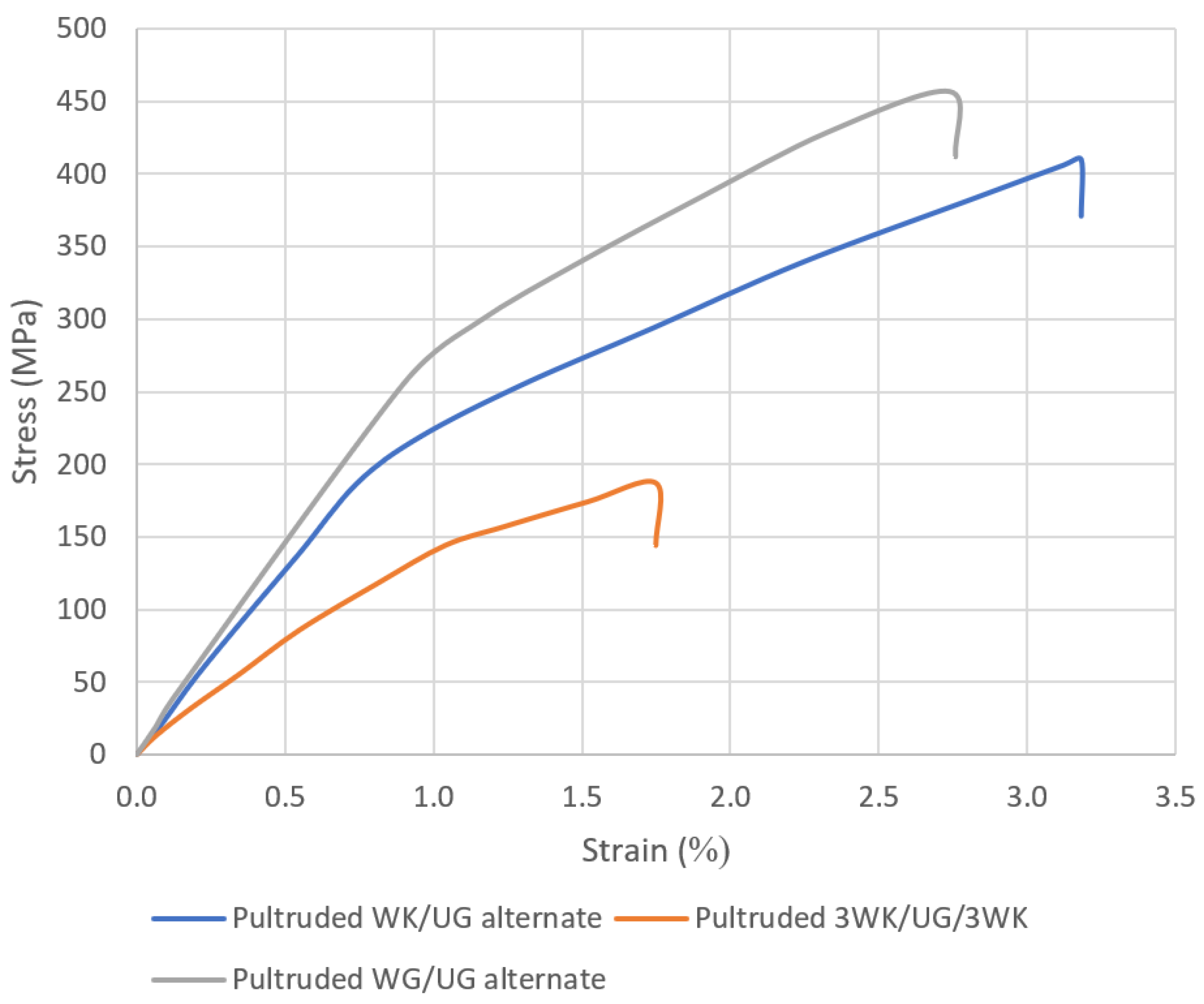

Figure 12, the stress-strain profiles show the tensile properties of the hybrid and non-hybrid (control) specimens. The graph shows a linear increase up to failure. The brittle behaviour of the composites is explained when the graph suddenly drops when the specimens reach ultimate tensile strength. Once the peak load is reached, all the specimens fracture in a brittle manner. However, the maximum displacement of the specimens shows that the alternately extruded WK/UG specimens are slightly more ductile in the plastic region compared to the alternately extruded WG/UG specimens. The tensile modulus explains that the pure glass fibre composition achieved the highest stiffness compared to the hybrid samples. However, among the hybrid samples, the alternating WK/UG laminates showed better stiffness than the 3WK/UG/3WK laminates. In general, the load is applied in the direction of the fibres, and the properties of the individual fibres determine the tensile strength and modulus of the composites. Experimental results show a decrease in tensile strength and modulus as the volume proportion of glass fibres is reduced and replaced by kenaf fibres.

3.2. Fatigue Analysis

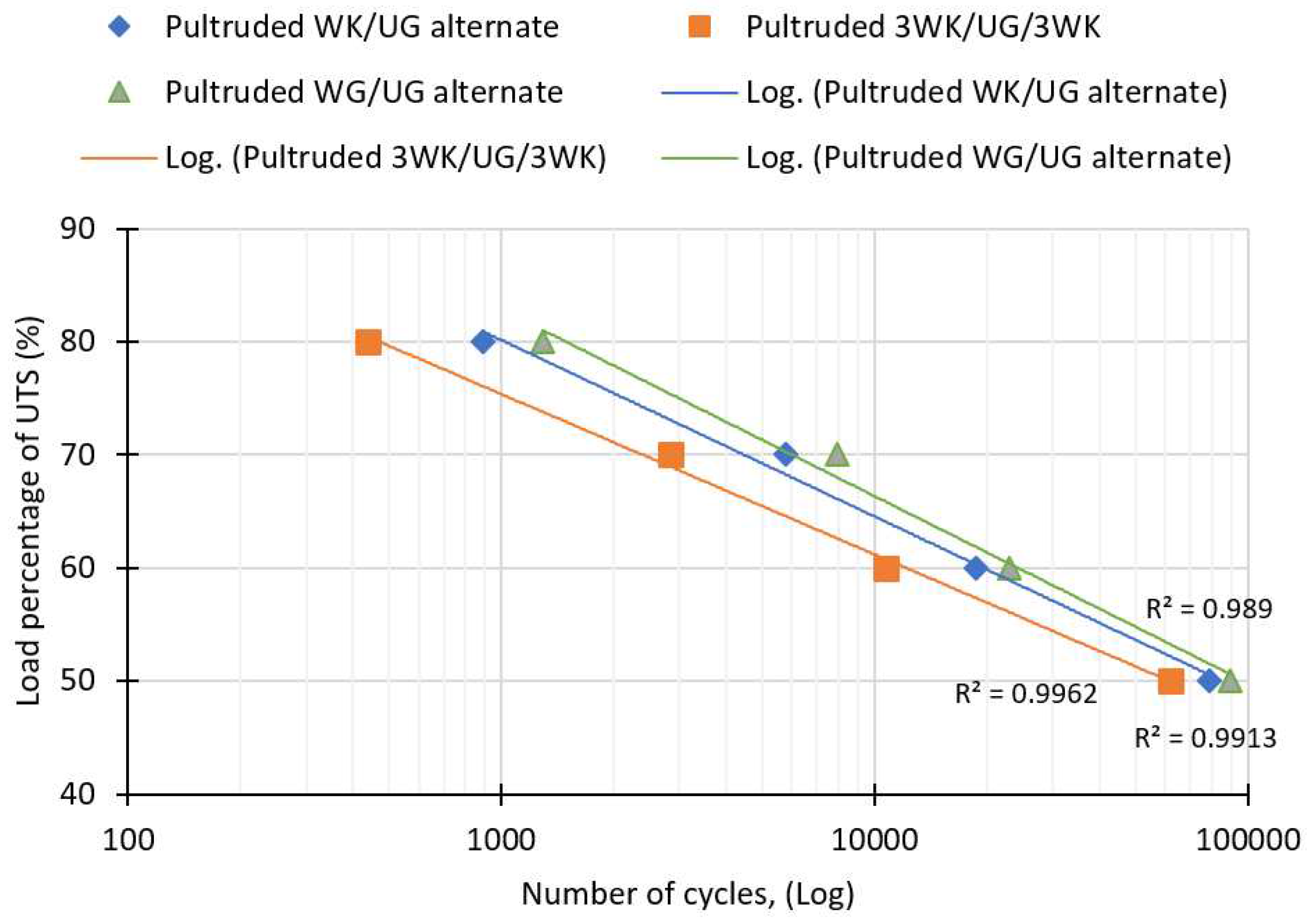

The composite specimens were subjected to repeated tensile-tensile loading until fracture. The stress on the specimens was systematically reduced in 10% increments, starting at 80% UTS and ending at 50% UTS. Force values corresponding to the stress amplitude and average stress were calculated and applied to the specimens. A plot of stress (S) as a function of the number of cycles to failure (N), known as the S-N curve or Wöhler curve, was generated to illustrate the test results (

Figure 13). This curve represents the relationship between the amplitude of cyclic stress and the number of cycles required for failure to occur.

By analysing the S-N curve, it becomes evident that a reduction in the applied stress leads to an increase in the number of life cycles, indicating better fatigue resistance. The hybridisation of kenaf fibres and glass fibres and the varying ratio of kenaf fibres to glass fibres in the hybridised pulp extruded composites significantly affected the fatigue life. This indicates significant differences in fatigue properties between hybridised pultruded composites and conventional pultruded composites made entirely of glass fibre.

Fatigue strength is compared between materials using a Wöhler curve by analysing the stress amplitudes at a specified number of cycles to failure. The material with the higher stress amplitude at a specified number of cycles has a higher fatigue strength. The data obtained show that the highest fatigue strength is achieved by the WG/UG pultruded sample, followed by the WK/UG pultruded sample and the 3WK/1UG/3WK pultruded sample. The hybrid pultruded composites reinforced with kenaf/glass fibre achieved slightly lower fatigue strengths than the non-hybrid samples. Compared to glass fibres, kenaf fibres tend to have lower tensile strength and fatigue resistance. Therefore, increasing the proportion of kenaf fibres in the hybrid composite reduces the overall fatigue strength of the material.

On the other hand, the fatigue sensitivity between materials is analysed based on the slope of the S-N curves. A steeper slope indicates a higher rate of fatigue strength degradation, which implies greater fatigue sensitivity. Materials with a steeper slope have a faster fatigue life degradation as the stress amplitude increases. The data show that the WG/UG pultruded specimen achieves the highest fatigue sensitivity, followed by the WK/UG pultruded specimen and the 3WK/1UG/3WK pultruded specimen. It is noteworthy that an increase in the kenaf-to-glass ratio resulted in a decrease in fatigue sensitivity. Sharba et al. [

25] found that increasing the kenaf-to-glass ratio in hybrid composites resulted in a reduction in fatigue sensitivity, which is a desirable property for materials in low-load applications. A study of plant fibre composites by Liang et al. [

26] found similar properties, with flax fibre-reinforced composites showing reduced fatigue sensitivity and strength compared to glass fibre composites.

Being of plant origin, kenaf fibres have inherent damping properties. The incorporation of kenaf fibres into a hybrid composite improves the damping properties [

27,

28]. Damping refers to the material's ability to dissipate energy during cyclic loading, reducing the magnitude of stress fluctuations. This damping effect helps to absorb and dissipate energy, alleviating stress concentrations and reducing fatigue sensitivity. Therefore, kenaf fibres in hybrid composites show less sensitivity to fatigue damage compared to non-hybrid glass fibre composites. Due to their lower elastic modulus and excellent damping properties, kenaf fibres show better damage tolerance compared to brittle glass fibres [

29]. Hadiji et al. [

30] found that plant fibre composites such as flax-PP, hemp-PP and kenaf-PP showed better damping properties compared to glass fibre composites.

Similarly, the results of Diharjo et al. [

31] show that increasing the ratio of kenaf to glass fibres leads to an improved damping ratio and reduced elastic modulus of the hybrid composite. The increased kenaf content in the hybrid composite introduces additional energy absorption and crack deflection mechanisms, increasing the resistance of the composite to fatigue crack initiation and propagation [

32]. These findings were confirmed by Sharba et al. [

33], when composites with kenaf fibres showed slower stiffness degradation compared to composites with glass fibres. The researchers also noted that woven kenaf fibres offer an excellent balance of static and fatigue strength with low fatigue sensitivity in bidirectional planes compared to glass fibres, making them attractive for low to moderate load structural applications [

34].

Fatigue is usually divided into two distinct areas: high-cycle fatigue and low-cycle fatigue. High-cycle fatigue manifests itself as failure after exceeding 10 000 cycles at relatively low stress levels. Low-cycle fatigue, on the other hand, occurs at a lower number of cycles, usually below 10 000, accompanied by increased plastic deformation [

16]. After examining the S-N curve, it was observed that when the stress level reaches 60% of the ultimate tensile strength (UTS), all data points are in the high-cycle fatigue region. Therefore, the WK/UG and 3WK/1UG/3WK hybrid specimens show good fatigue resistance and durability, especially under high-cycle fatigue conditions. The materials withstand a high number of cycles, in excess of 10,000, at relatively low stress levels with no signs of failure. This indicates that the material has the potential for long-term reliability in structural applications involving cyclic loading [

35,

36].

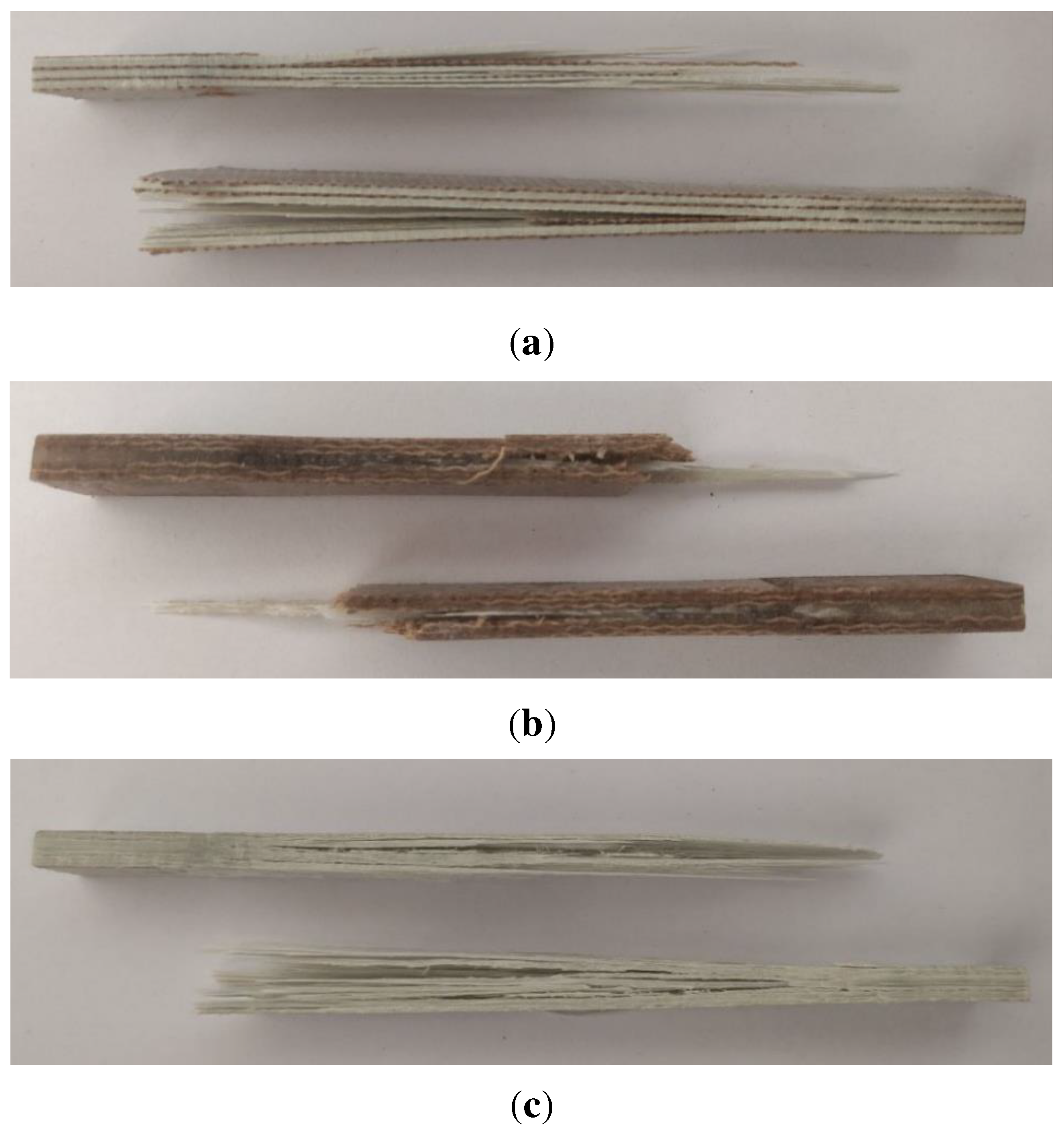

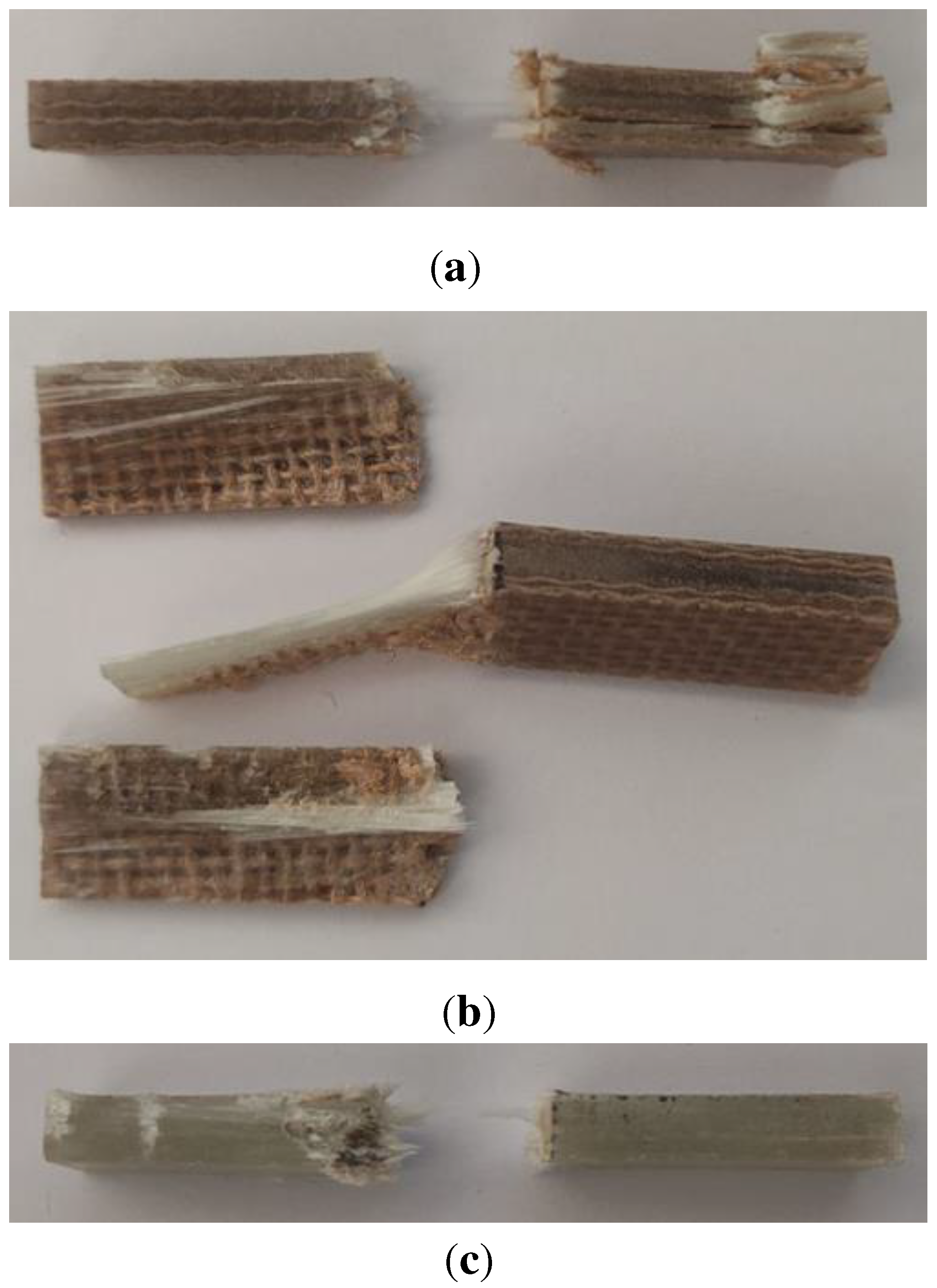

Figure 14 shows the fatigue test results, focusing on the failure modes at 60% fatigue life. It is noteworthy that all tested specimens failed through a combination of fibre pull-out, fibre breakage, delamination, detachment and matrix breakage.

The observation suggests that the applied stress was effectively distributed along the specimens, leading to significant delamination in the material. The kenaf/glass hybrid specimens exhibited unique failure modes that provide valuable insight into the interfacial adhesion between the kenaf fibres and the direct roving of the glass fibres. Sufficient interfacial adhesion indicates good bonding and interaction between the less dense kenaf fibres and the direct roving. Proper wetting, which is the process of impregnating the fibres with resin during composite production, probably contributed to the increased interfacial adhesion [

37]. Improved interfacial adhesion between kenaf fibres and direct roving is important for composite performance.

Overall, the different proportions resulted in varying fatigue properties, highlighting the importance of fibre composition in achieving the desired durability. The hybridisation of kenaf and glass fibres introduced new dynamics in the fatigue behaviour of the material. These hybrid composites showed altered fatigue characteristics due to the combined properties of kenaf and glass fibres, resulting in different fatigue life cycles.

3.3. Impact Analysis

The Izod impact test is a mechanical test used to assess the impact strength or toughness of a material. It measures the energy required to fracture a specimen under a single high-velocity impact. This test is particularly important for assessing a material's ability to withstand a sudden impact or shock load, which is a critical aspect of its durability in various applications [

10]. It involves striking a standardised notched specimen with a pendulum hammer and measuring the energy absorbed during fracture. Structural applications often include materials that need to withstand impacts or sudden loads. The Izod impact test provides valuable information on a material's ability to withstand and absorb energy during impacts. This data is crucial for assessing the safety and reliability of structural components, as it helps identify materials that can withstand unexpected or dynamic loading conditions without catastrophic failure.

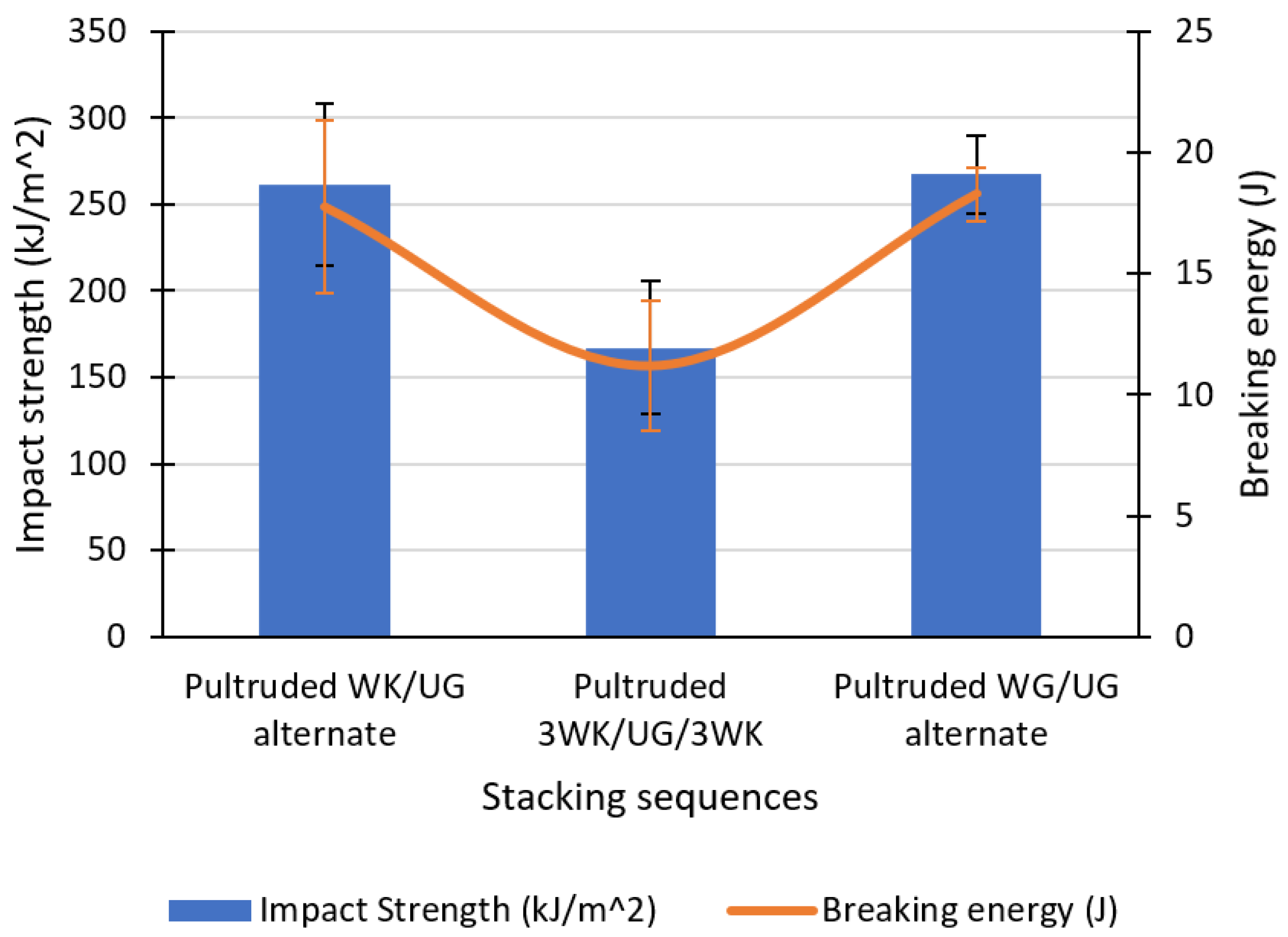

Pultruded alternating hybrid WK/UG composites show similar impact strength to pultruded alternating non-hybrid WG/UG composites at approximately 260 kJ/m

2. Kenaf fibres and glass fibres have different mechanical properties. While glass fibres are known for their high stiffness and strength, kenaf fibres offer good impact resistance and toughness [

38]. Combining these two fibre types in hybrid composites can result in a complementary blend of properties. Singh et al. [

39] noted that kenaf/glass hybrid composites exhibit significantly higher impact strength than pure kenaf composites. Therefore, the inherent impact strength of kenaf fibres combined with the strength of glass fibres may contribute to a similar overall impact strength compared to non-hybrid glass fibre composites. However, further increasing the ratio of kenaf to glass resulted in a slight decrease in impact strength. Similar discussions on hybrid plant/fibreglass composites were carried out by Saroj and Nayak [

40] and Ghani et al. [

41], where the impact strength decreased with significant increases in the kenaf-to-glass and jute-to-glass ratios, respectively. The impact strength of the pultruded 3WK/UG/3WK material is 37.5% lower than that of the pultruded WG/UG material. Therefore, the pultruded WK/UG replacement was found to have the optimum kenaf-to-glass ratio and lay-up sequence, as the composites show almost similar impact properties compared to conventional non-hybrid glass fibre.

Figure 16 effectively illustrates the Izod impact test results, clearly showing the failure modes of the various samples. Of the specimens tested, the hybrid kenaf/glass specimen, the pultruded WK/UG specimen and the pultruded 3WK/UG3WK specimen showed severe de-lamination during the impact test. In addition, more visible fibre pulling was observed in the hybrid specimens. The observed damage in the hybrid samples can be attributed to the damping properties of the kenaf fibres. The kenaf fibres have inherent damping characteristics, which contributes to a more ductile failure behaviour in the hybrid specimens. The damping properties of kenaf fibres allow them to deform and absorb energy more significantly during impact, leading to delamination and fibre pull-out as the material redistributes stresses to absorb impact energy [

42,

43].

On the other hand, the pultruded glass fibre specimen showed a failure mode that showed no signs of delamination. This is consistent with the nature of glass fibres, known for their high tensile modulus and brittle properties. Glass fibres have excellent stiffness and strength, but are relatively brittle and more prone to sudden cracking under impact loading. As a result, the failure observed in the glass fibre specimen was more brittle, with less delamination than in the hybrid specimens. The lack of delamination in the glass fibre specimen can be attributed to the higher stiffness and reduced damping capacity of the glass fibres. In contrast to kenaf fibres, glass fibres are less deformable and have a lower energy absorption capacity. Consequently, when glass fibres are subjected to impact forces, they tend to break abruptly and deform minimally, leading to brittle failure with limited delamination.

Finding the right balance between kenaf and glass fibres in hybrid composites is crucial to achieving the desired combination of properties. When choosing the right kenaf-to-glass ratio for a specific composite application, factors such as the specific application requirements and the trade-off between weight reduction and impact strength must be considered.

3.4. Density Analysis

One factor that plays a key role in defining the properties of a composite material is its density. Density determines whether a material can offer a better strength-to-weight or cost-to-weight ratio when designing different applications. This aspect is crucial in pultruded profile applications because of the advantages of lighter structural products. Lighter profiles are easier to handle and transport, making them more convenient to install, assemble and maintain. They are less cumbersome and pose less risk of injury during handling and installation. In addition, in applications such as aviation, automotive and the renewable energy sector, lighter pultruded profiles contribute to lower energy consumption, leading to increased fuel efficiency, longer battery life and optimised system performance.

Table 6 shows the average density values obtained from the density tests. The table presents that as the ratio of kenaf to glass fibre increases, the density of the pultruded composites decreases, resulting in lighter materials.

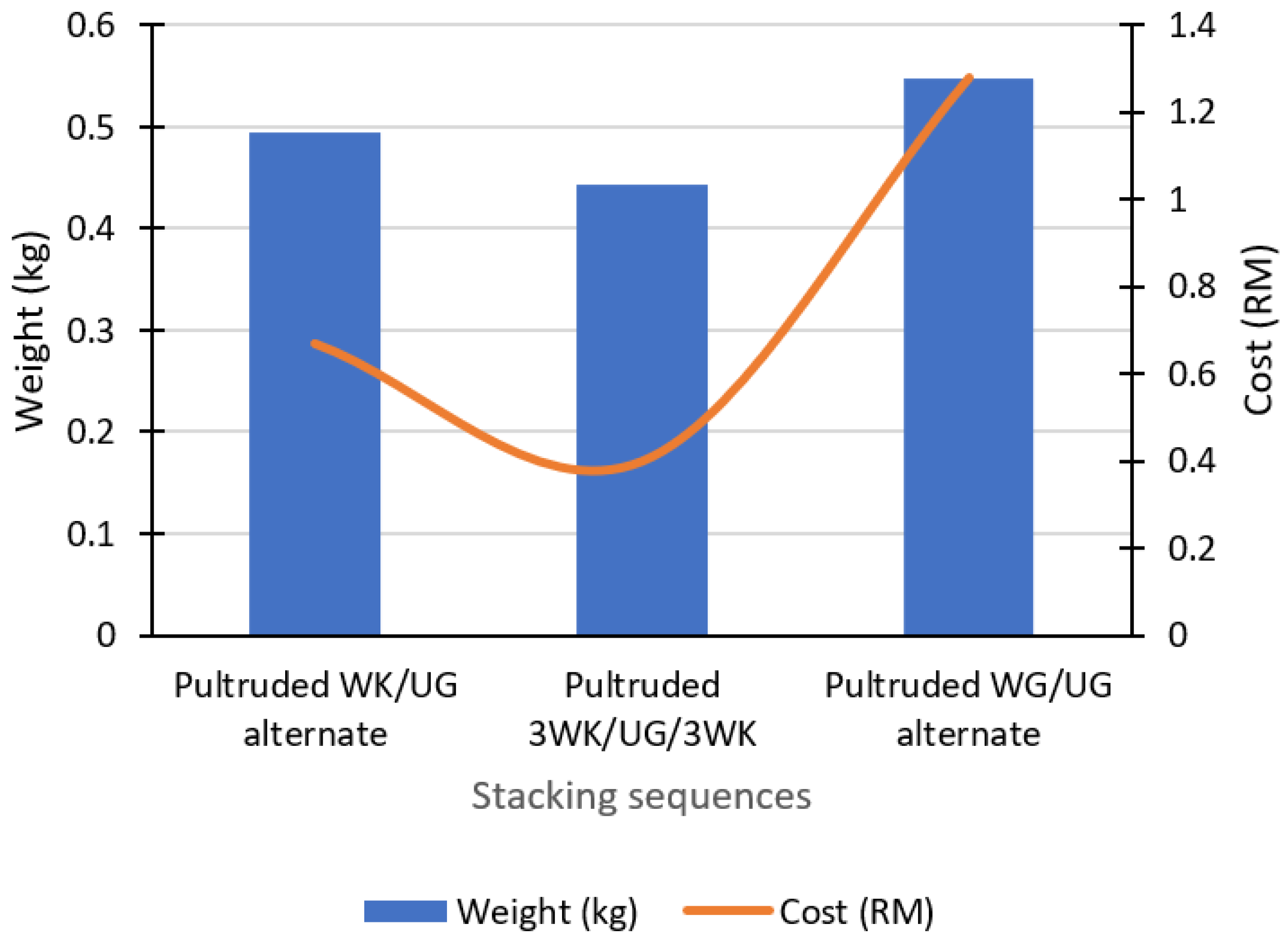

3.5. Cost and Weight Analysis

A weight and cost analysis was carried out for pultruded square tubes reinforced with kenaf/glass (

Figure 17). The weight ranking, from heavy to light, was determined as follows: pultruded WG/UG alternate ranked heaviest, followed by pultruded WK/UG alternate, and finally pultruded 3WK/UG/3WK as the lightest of the three. The pultruded WK/UG alternative recorded a weight 9.6% lower than the pultruded WG/UG alternative. This weight reduction highlights the advantage of incorporating kenaf fibre into the pultruded profile, which contributes to a lighter structural element. Furthermore, the pultruded 3WK/UG/3WK profile showed an even greater weight reduction of 19.1% compared to a conventional glass fibre profile. This significant weight reduction signifies the significant benefits of using plant fibres, such as kenaf, in pultruded profiles, offering the potential for lightweight structural parts in a variety of applications.

Similarly, the cost analysis resulted in the following rankings from highest to lowest cost: the pultruded WG/UG replacement with the highest cost, followed by the pultruded WK/UG replacement, and finally the pultruded 3WK/UG/3WK replacement with the lowest cost of all three. The pultruded WK/UG replacement showed a significant cost reduction of 47.7% compared to the pultruded WG/UG replacement. This significant cost reduction demonstrates the economic advantages of using kenaf fibre in pultruded profiles, making them a cost-effective alternative without compromising on performance. Furthermore, the pultruded 3WK/UG/3WK profile showed an exceptional cost reduction of 68.8% compared to a conventional pure glass fibre reinforced profile. This remarkable cost-saving potential makes pultruded profiles with plant fibres such as kenaf an attractive option for a variety of industries looking to reduce raw material costs while maintaining structural integrity.

Weight and cost analysis shows the positive implications of incorporating plant fibres, such as kenaf, into pultruded profiles. The use of kenaf contributes to lightweight structural parts, offering potential benefits in terms of weight reduction and increased performance. Additionally, it significantly reduces the cost of the raw material, making it a cost-effective and environmentally friendly alternative to traditional glass fibre reinforcement. These plant fibre-based composites have the potential to reduce automotive costs by 20% and reduce weight by 30% [

44]. Lighter profiles reduce transport costs as less energy is required to move them. This is particularly beneficial when transporting large quantities of profiles or shipping over long distances. They also contribute to environmental sustainability by reducing raw material and energy consumption during production and transport. These results highlight the promising prospects of plant fibre-reinforced pultruded profiles as a viable solution for various industries looking for lightweight and cost-effective structural components.

4. Conclusions

In summary, the results of the fatigue analysis reveal that, of the pultruded hybrid composites tested, the pultruded WG/UG alternate samples show the highest fatigue strength, followed by the pultruded WK/UG alternate and the pultruded 3WK/1UG/3WK alternate samples. Surprisingly, however, the pultruded WG/UG alternate specimens also show the highest fatigue sensitivity, followed by the pultruded WK/UG alternate and pultruded 3WK/1UG/3WK, suggesting that an increase in the kenaf-to-glass ratio leads to a decrease in fatigue strength and sensitivity. Furthermore, the low fatigue sensitivity observed in the kenaf/glass hybrid composites implies the presence of damping properties in these materials. Interestingly, Izod impact analysis shows that the impact strength of pultruded WK/UG hybrid composites is similar to that of pultruded non-hybrid WG/UG composites. However, a further increase in the ratio of kenaf to glass fibre in pultruded WK/UG hybrid composites results in a decrease in impact strength. In addition, a comprehensive weight and cost assessment highlights the beneficial potential of incorporating plant fibres into pultruded profiles, contributing to lightweight structural components while reducing raw material costs. This may be particularly relevant for the use of these components in unmanned aerial vehicles (UAVs) [

45,

46,

47] or unmanned ground vehicles (UGVs) [

48,

49,

50] construction. Together, these results highlight the complex interaction between fibre composition, hybridisation and resultant mechanical properties, providing valuable insight into the strategic design and optimisation of pultruded profiles.

Author Contributions

Conceptualisation, T.S.B.; methodology, T.S.B.; formal analysis, T.S.B.; investigation, T.S.B.; resources, M.T.H.S.; data curation, T.S.B.; writing—original draft preparation, T.S.B.; writing—review and editing, M.T.H.S., F.S.S., T.A.S., A.A.B., A.U.M.S., J.J., R.G. and A.Ł.; visualisation, T.S.B., R.G. and F.S.S.; supervision, M.T.H.S., A.A.B., A.U.M.S., J.J. and T.A.S.; project administration, F.S.S. and A.Ł.; funding acquisition, M.T.H.S., J.J. and A.Ł. All authors have read and agreed to the published version of the manuscript.

Funding

The authors would like to thank Universiti Putra Malaysia for the financial support through Geran Inisiatif Putra Siswazah (GP-IPS) with grant number 9739200. The activities of the Polish Metrological Union are financed from the funds of the Ministry of Education and Science as part of a targeted subsidy for the implementation of the task titled ”Establishment and Coordination of the activities of the Polish Metrological Union (PUM)” under contract No. MEiN/2021/DPI/179. This research was partially financed by the Ministry of Science and Higher Education of Poland with allocation to the Faculty of Mechanical Engineering, Bialystok University of Technology, for the WZ/WM-IIM/5/2023 academic project in the mechanical engineering discipline.

Data Availability Statement

The authors confirm that the data supporting the findings of this study are available within the article.

Acknowledgements

The authors would like to thank the Department of Aerospace Engineering, Faculty of Engineering, Universiti Putra Malaysia, and Laboratory of Biocomposite Technology, Institute of Tropical Forestry and Forest Product (INTROP), Universiti Putra Malaysia for the close collaboration in this research.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Sandberg, M.; Yuksel, O.; Baran, I.; Hattel, J. H.; Spangenberg, J. Numerical and experimental analysis of resin-flow, heat-transfer, and cure in a resin-injection pultrusion process. Compos. Part A Appl. Sci. Manuf. 2021, 143, 106231. [CrossRef]

- Esfandiari, P.; Silva, J. F.; Novo, P. J.; Nunes, J. P.; Marques, A. T. Production and processing of pre-impregnated thermoplastic tapes by pultrusion and compression moulding. J. Compos. Mater. 2022, 56, 1667–1676. [CrossRef]

- Volk, M.; Yuksel, O.; Baran, I.; Hattel, J. H.; Spangenberg, J.; Sandberg, M. Cost-efficient, automated, and sustainable composite profile manufacture: A review of the state of the art, innovations, and future of pultrusion technologies. Compos. Part B: Eng. 2022, 246, 110135. [CrossRef]

- Vedernikov, A.; Safonov, A.; Tucci, F.; Carlone, P.; Akhatov, I. Pultruded materials and structures: A review. J. Compos. Mater. 2020, 54, 4081–4117. [CrossRef]

- Barkanov, E.; Akishin, P.; Namsone, E.; Auzins, J.; Morozovs, A. Optimization of pultrusion processes for an industrial application. Mech. Compos. Mater. 2021, 56, 697–712. [CrossRef]

- Gemi, L.; Madenci, E.; Özkılıç, Y. O.; Yazman, Ş.; Safonov, A. Effect of fiber wrapping on bending behavior of reinforced concrete filled pultruded GFRP composite hybrid beams. Polymers 2022, 14, 3740. [CrossRef]

- Correia, J. R. Pultrusion of advanced composites. In Woodhead Publishing Series in Civil and Structural Engineering, Advanced Fibre-Reinforced Polymer (FRP) Composites for Structural Applications, 2nd ed.; Bai, J., Ed.; Woodhead Publishing: Sawston, United Kingdom, 2023, pp. 137–177. [CrossRef]

- Hamidon, M. H.; Sultan, M. T. H.; Ariffin, A. H.; Shah, A. U. M. Effects of fibre treatment on mechanical properties of kenaf fibre reinforced composites: A review. J. Mater. Res. Technol. 2019, 8, 3327–3337. [CrossRef]

- Chethan, N.; Nagesh, S. N.; Babu, L. S. Mechanical behaviour of kenaf-jute-E-glass reinforced hybrid polymer composites. Mater. Today Proc. 2021, 46, 4454–4459. [CrossRef]

- Asumani, O.; Paskaramoorthy, R. Fatigue and impact strengths of kenaf fibre reinforced polypropylene composites: Effects of fibre treatments. Adv. Compos. Mater. 2020, 30, 103–115. [CrossRef]

- Feng, N. L.; DharMalingam, S.; Zakaria, K. A.; Selamat, M. Z. Investigation on the fatigue life characteristic of kenaf/glass woven-ply reinforced metal sandwich materials. J. Sandw. Struct. Mater. 2019, 21, 2440–2455. [CrossRef]

- Miah, M. S.; Yu, J.; Yang, Y.; Memon, H.; Rashid, M. A. Durability and notch sensitivity analysis of environmental ageing induced glass fibre mat and kenaf fibre mat-reinforced composites. J. Ind. Text. 2021, 51, 24–47. [CrossRef]

- Supian, A. B. M.; Sapuan, S. M.; Jawaid, M.; Zuhri, M. Y. M.; Ilyas, R. A.; Syamsir, A. Crashworthiness response of filament wound kenaf/glass fibre-reinforced epoxy composite tubes with influence of stacking sequence under intermediate-velocity impact load. Fibers Polym. 2022, 23, 222–233. [CrossRef]

- Ismail, M. F.; Sultan, M. T. H.; Hamdan, A.; Shah, A. U. M.; Jawaid, M. Low velocity impact behaviour and post-impact characteristics of kenaf/glass hybrid composites with various weight ratios. J. Mater. Res. Technol. 2019, 8, 2662–2673. [CrossRef]

- Owen, M. M.; Achukwu, E. O.; Arukalam, I. O.; Romli, A. Z. Effect of varying processing temperatures on the mechanical and microstructural properties of kenaf fibre-ABS composites for moderate temperature applications. Polym. Renew. Resour. 2022, 13, 154–169. [CrossRef]

- Shahar, F. S.; Sultan, M. T. H.; Safri, S. N. A.; Jawaid, M.; Talib, A. R. A.; Basri, A. A.; Shah, A. U. M. Fatigue and impact properties of 3D printed PLA reinforced with kenaf particles. J. Mater. Res. Technol. 2022, 16, 461–470. [CrossRef]

- Mechi, S. A.; Al-Waily, M.; Fatigue characterizations modifying for below knee prosthesis composite materials by using natural knitted kenaf reinforcement fibers. Int. J. Energy Environ. 2021, 12, 87–102.

- Grzejda, R. Modelling Nonlinear Multi-Bolted Connections: A Case of Operational Condition. In Proceedings of the 15th International Scientific Conference Engineering for Rural Development 2016, Jelgava, Latvia, 25-27 May 2016, pp. 336–341.

- Grzejda, R.; Warzecha, M.; Urbanowicz, K. Determination of pretension in bolts for structural health monitoring of multi-bolted connection: FEM approach. Lubricants, 2022, 10, 75. [CrossRef]

- Jaszak, P.; Skrzypacz, J.; Borawski, A.; Grzejda, R. Methodology of leakage prediction in gasketed flange joints at pipeline deformations. Materials, 2022, 15, 4354. [CrossRef]

- ASTM D638. Standard Test Method for Tensile Properties of Plastics; American Society for Testing and Materials, Washington, USA, 2022.

- ASTM D7791, Standard Test Method for Uniaxial Fatigue Properties of Plastics; American Society for Testing and Materials, Washington, USA, 2022.

- ASTM D256, Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics; American Society for Testing and Materials, Washington, USA, 2023.

- ASTM D792, Standard Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement; American Society for Testing and Materials, Washington, USA, 2020.

- Sharba, M. J.; Leman, Z.; Sultan, M. T. H.; Ishak, M. R.; Hanim, M. A. A. Partial replacement of glass fiber by woven kenaf in hybrid composites and its effect on monotonic and fatigue properties. Bioresources 2016, 11, 2665–2683. [CrossRef]

- Liang, S.; Gning, P. B.; Guillaumat, L. A comparative study of fatigue behaviour of flax/epoxy and glass/epoxy composites. Compos. Sci. Technol. 2012, 72, 535–543. [CrossRef]

- Hassan, F.; Zulkifli, R.; Ghazali, M. J.; Azhari, C. H. Kenaf fiber composite in automotive industry: An overview. Int. J. Adv. Sci. Eng. Inf. Technol. 2017, 7, 315–321. [CrossRef]

- Asyraf, M. R. M.; Rafidah, M.; Azrina, A.; Razman, M. R. Dynamic mechanical behaviour of kenaf cellulosic fibre biocomposites: A comprehensive review on chemical treatments. Cellulose 2021, 28, 2675–2695. [CrossRef]

- Sivakumar, D.; Ng, L. F.; Lau, S. M.; Lim, K. T. Fatigue life behaviour of glass/kenaf woven-ply polymer hybrid biocomposites. J. Polym. Environ. 2018, 26, 499–507. [CrossRef]

- Hadiji, H.; Assarar, M.; Zouari, W.; Pierre, F.; Behlouli, K.; Zouari, B.; Ayad, R. Damping analysis of nonwoven natural fibre-reinforced polypropylene composites used in automotive interior parts. Polym. Test. 2020, 89, 106692. [CrossRef]

- Diharjo, K.; Susilo, D. D.; Sudargo, P. H.; Kaleg, S. Vibration-damping factor of glass/kenaf/polyester hybrid composite. Key Eng. Mater. 2018, 772, 38–42. [CrossRef]

- Ramraji, K.; Rajkumar, K.; Subbiah, M.; Balachandar, K.; Kumar, P. S. Stacking layer effect on mechanical and vibration behaviour of woven glass intertwined with kenaf fiber polymeric composites. Mater. Today Proc. 2022, 62, 1356–1360. [CrossRef]

- Sharba, M. J.; Leman, Z.; Sultan, M. T. H.; Ishak, M. R.; Hanim, M. A. A. Monotonic and fatigue properties of kenaf/glass hybrid composites under fully reversed cyclic loading. IOP Conf. Ser.: Mater. Sci. Eng. 2015, 100, 012055. [CrossRef]

- Sharba, M. J.; Leman, Z.; Sultan, M. T. H.; Ishak, M. R.; Hanim, M. A. A. Effects of kenaf fiber orientation on mechanical properties and fatigue life of glass/kenaf hybrid composites. Bioresources 2016, 11, 1448–1465. [CrossRef]

- Noël, M. Probabilistic fatigue life modelling of FRP composites for construction. Constr. Build. Mater. 2019, 206, 279–286. [CrossRef]

- Gao, Q.; Xin, H.; Correia, J. A. F. O.; Mosallam, A. S.; Berto, F. Probabilistic fatigue life analysis considering mean stress effects of fiber reinforced polymer (FRP) composites. Int. J. Fatigue 2022, 162, 106951. [CrossRef]

- Hashim, M. K. R.; Majid, M. S. A.; Jamir, M. R. M.; Kasim, F. H.; Sultan, M. T. H.; Shah, A. U. M.; Ahmad, K. A.; Basri, A. A. The effect of stacking sequence on fatigue behaviour of hybrid pineapple leaf fibre/carbon-fibre-reinforced epoxy composites. Polymers 2021, 13, 3936. [CrossRef]

- Nadzri, S. N. Z. A.; Sultan, M. T. H.; Shah, A. U. M.; Safri, S. N. A.; Basri, A. A. A review on the kenaf/glass hybrid composites with limitations on mechanical and low velocity impact properties. Polymers 2020, 12, 1285. [CrossRef]

- Singh, K.; Das, D.; Nayak, R. K.; Khandai, S.; Kumar, R.; Routara, B. C. Effect of silanizion on mechanical and tribological properties of kenaf-carbon and kenaf-glass hybrid polymer composites. Mater. Today Proc. 2020, 26, 2094–2098. [CrossRef]

- Saroj, S.; Nayak, R. K. Improvement of mechanical and wear resistance of natural fiber reinforced polymer composites through synthetic fiber (glass/carbon) hybridization. Trans. Indian Inst. Met. 2021, 74, 2651–2658. [CrossRef]

- Ghani, M. U.; Siddique, A.; Abraha, K. G.; Yao, L.; Li, W.; Khan, M. Q.; Kim, I.-S. Performance evaluation of jute/glass-fiber-reinforced polybutylene succinate (PBS) hybrid composites with different layering configurations. Materials 2022, 15, 1055. [CrossRef]

- Zhang, J.; Khatibi, A. A.; Castanet, E.; Baum, T.; Komeily-Nia, Z.; Vroman, P.; Wang, X. Effect of natural fibre reinforcement on the sound and vibration damping properties of bio-composites compression moulded by nonwoven mats. Compos. Commun. 2019, 13, 12–17. [CrossRef]

- Azammi, A. M. N.; Sapuan, S. M.; Ishak, M. R.; Sultan, M. T. H. Physical and damping properties of kenaf fibre filled natural rubber/thermoplastic polyurethane composites. Def. Technol. 2020, 16, 29–34. [CrossRef]

- Sathish, S.; Karthi, N.; Prabhu, L.; Gokulkumar, S.; Balaji, D.; Vigneshkumar, N.; Farhan, T. S. A.; Akilkumar, A.; Dinesh, V. P. A review of natural fiber composites: Extraction methods, chemical treatments and applications. Mater. Today Proc. 2021, 45, 8017–8023. [CrossRef]

- Grodzki, W.; Łukaszewicz, A. Design and manufacture of umanned aerial vehicles (UAV) wing structure using composite materials. Mater. Sci. Eng. Technol. 2015, 46, 269–278. [CrossRef]

- Łukaszewicz, A.; Szafran, K.; Józwik, J. CAx Techniques Used in UAV Design Process. In Proceedings of the 2020 IEEE 7th International Workshop on Metrology for AeroSpace (MetroAeroSpace), Pisa, Italy, 22-24 June 2020, pp. 95–98, https:/doi.org/10.1109/MetroAeroSpace48742.2020.9160091.

- Šančić, T.; Brčić, M.; Kotarski, D.; Łukaszewicz, A. Experimental characterization of composite-printed materials for the production of multirotor UAV airframe parts. Materials 2023, 16, 5060. [CrossRef]

- Silarski, M.; Nowakowski, M. Performance of the SABAT neutron-based explosives detector integrated with an unmanned ground vehicle: A simulation study. Sensors 2022, 22, 9996. [CrossRef]

- Nowakowski, M. Perception technology for conversion of off-road vehicles for the purposes of unmanned missions. J. Civ. Eng. Transp. 2023, 5, 15–27, . [CrossRef]

- Nowakowski, M.; Kurylo, J. Usability of perception sensors to determine the obstacles of unmanned ground vehicles operating in off-road environments. Appl. Sci. 2023, 13, 4892. [CrossRef]

Figure 1.

Woven kenaf fibres.

Figure 1.

Woven kenaf fibres.

Figure 2.

Direct roving E-glass fibres.

Figure 2.

Direct roving E-glass fibres.

Figure 3.

Error! No text of specified style in document.. Woven E-glass fibres.

Figure 3.

Error! No text of specified style in document.. Woven E-glass fibres.

Figure 4.

Surfacing veil.

Figure 4.

Surfacing veil.

Figure 5.

Kenaf/glass fibre reinforced pultruded hybrid profiles (left) and glass fibre reinforced pultruded profiles (right).

Figure 5.

Kenaf/glass fibre reinforced pultruded hybrid profiles (left) and glass fibre reinforced pultruded profiles (right).

Figure 6.

Stacking sequences of hybrid and non-hybrid pultruded profiles: (a) WK/UG alternate; (b) 3WK/UG/3WK; (c) WG/UG alternate.

Figure 6.

Stacking sequences of hybrid and non-hybrid pultruded profiles: (a) WK/UG alternate; (b) 3WK/UG/3WK; (c) WG/UG alternate.

Figure 7.

Fatigue testing stand.

Figure 7.

Fatigue testing stand.

Figure 8.

Izod impact testing.

Figure 8.

Izod impact testing.

Figure 9.

Specimens used in Izod impact tests.

Figure 9.

Specimens used in Izod impact tests.

Figure 10.

Density testing.

Figure 10.

Density testing.

Figure 11.

Tensile properties of pultruded composites.

Figure 11.

Tensile properties of pultruded composites.

Figure 12.

Tensile stress-strain curves of pultruded composites.

Figure 12.

Tensile stress-strain curves of pultruded composites.

Figure 13.

Fatigue test analysis of the pultruded composites.

Figure 13.

Fatigue test analysis of the pultruded composites.

Figure 14.

Damage on samples after fatigue testing: (a) WK/UG alternate; (b) 3WK/UG/3WK alternate; (c) WG/UG alternate.

Figure 14.

Damage on samples after fatigue testing: (a) WK/UG alternate; (b) 3WK/UG/3WK alternate; (c) WG/UG alternate.

Figure 15.

Impact strength of pultruded composites.

Figure 15.

Impact strength of pultruded composites.

Figure 16.

Damage on samples after Izod impact testing: (a) WK/UG alternate; (b) 3WK/UG/3WK alternate; (c) WG/UG alternate.

Figure 16.

Damage on samples after Izod impact testing: (a) WK/UG alternate; (b) 3WK/UG/3WK alternate; (c) WG/UG alternate.

Figure 17.

Cost and weight analysis of pultruded composites.

Figure 17.

Cost and weight analysis of pultruded composites.

Table 1.

Industries and applications of pultruded profiles [

4,

5,

6,

7].

Table 1.

Industries and applications of pultruded profiles [

4,

5,

6,

7].

| Industries |

Applications |

| Aerospace and Defence |

Aircraft components, such as structural beams, floors, and panels.

Interior components, such as overhead bins, seating structures, and cabin partitions.

Military vehicle components, such as chassis elements, weapon mounts, and armour supports. |

| Automotive |

Chassis components, such as frame rails, cross members, and subframes.

Interior panels, such as door panels, dashboard supports, and seat structures. |

| Construction |

Bridge components, such as beams, decks, and railings.

Building facades, such as cladding, sunshades, and louvres.

Railing systems, such as stairs, balconies, and elevated platforms. |

| Marine |

Boat and shipbuilding components, such as hull reinforcements, deck supports, bulkheads, and superstructure elements.

Decking and Flooring, such as non-slip decking and flooring solutions for marine vessels, docks, and decks. |

Table 2.

Pultrusion process parameters.

Table 2.

Pultrusion process parameters.

| Parameters |

Values |

| Pull speed |

30 cm/min |

| Pull Force |

6 Bar |

| Die Temperature |

159°C |

Table 3.

Stacking sequence of pultruded kenaf/glass hybrid composites and pure glass fibre composites.

Table 3.

Stacking sequence of pultruded kenaf/glass hybrid composites and pure glass fibre composites.

| Samples |

Stacking sequence |

Fibre Weight Percentage (wt.%) |

| Kenaf content |

Glass content |

| Pultruded WK/UG alternate |

WK/UG/WK/UG/WK/UG/WK |

45 |

55 |

| Pultruded 3KUG3K |

WK/WK/WK/UG/WK/WK/WK |

81.7 |

18.3 |

| Pultruded WG/UG alternate |

WG/UG/WG/UG/WG/UG/WG |

0 |

100 |

Table 4.

Applied stress on fatigue testing.

Table 4.

Applied stress on fatigue testing.

| Type of composites |

Ultimate Tensile Strength (UTS), MPa |

Percentage of applied load with respect to UTS, % |

Maximum Stress (Qmax), MPa |

Minimum Stress (Qmin), MPa |

| PultrudedWK/UG alternate |

410.6 |

80 |

328.48 |

32.85 |

| 70 |

287.42 |

28.74 |

| 60 |

246.36 |

24.64 |

| 50 |

205.30 |

20.53 |

| Pultruded 3WK/UG/3WK |

185.13 |

80 |

148.10 |

14.81 |

| 70 |

129.59 |

12.96 |

| 60 |

111.08 |

11.11 |

| 50 |

92.57 |

9.26 |

| PultrudedWG/UG alternate |

458.28 |

80 |

366.62 |

36.66 |

| 70 |

320.80 |

32.08 |

| 60 |

274.97 |

27.50 |

| 50 |

229.14 |

22.91 |

Table 5.

Cost of reinforcing fibres in Malaysia.

Table 5.

Cost of reinforcing fibres in Malaysia.

| Reinforcing Fibres |

Cost per kg (Euro) |

| Glass Fibre Direct Roving |

0.70 |

| Woven Glass Fibre Mat |

1.04 |

| Woven Kenaf Fibre Mat |

0.24 |

Table 6.

Average density of pultruded kenaf/glass hybrid and non-hybrid glass fibre composites.

Table 6.

Average density of pultruded kenaf/glass hybrid and non-hybrid glass fibre composites.

| Material |

Kenaf/glass alternate |

3K/UG/3K |

Glass fibre |

| Average density (g/cm3) |

1.5101 |

1.3504 |

1.6697 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).