Submitted:

13 November 2023

Posted:

14 November 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Biogas and its importance

2.1. Biogas Characteristics

2.2. Advantages of Biogas Technologies

3. Main Principles in Biogas Production

3.1. Fundamentals of Anaerobic Digestion

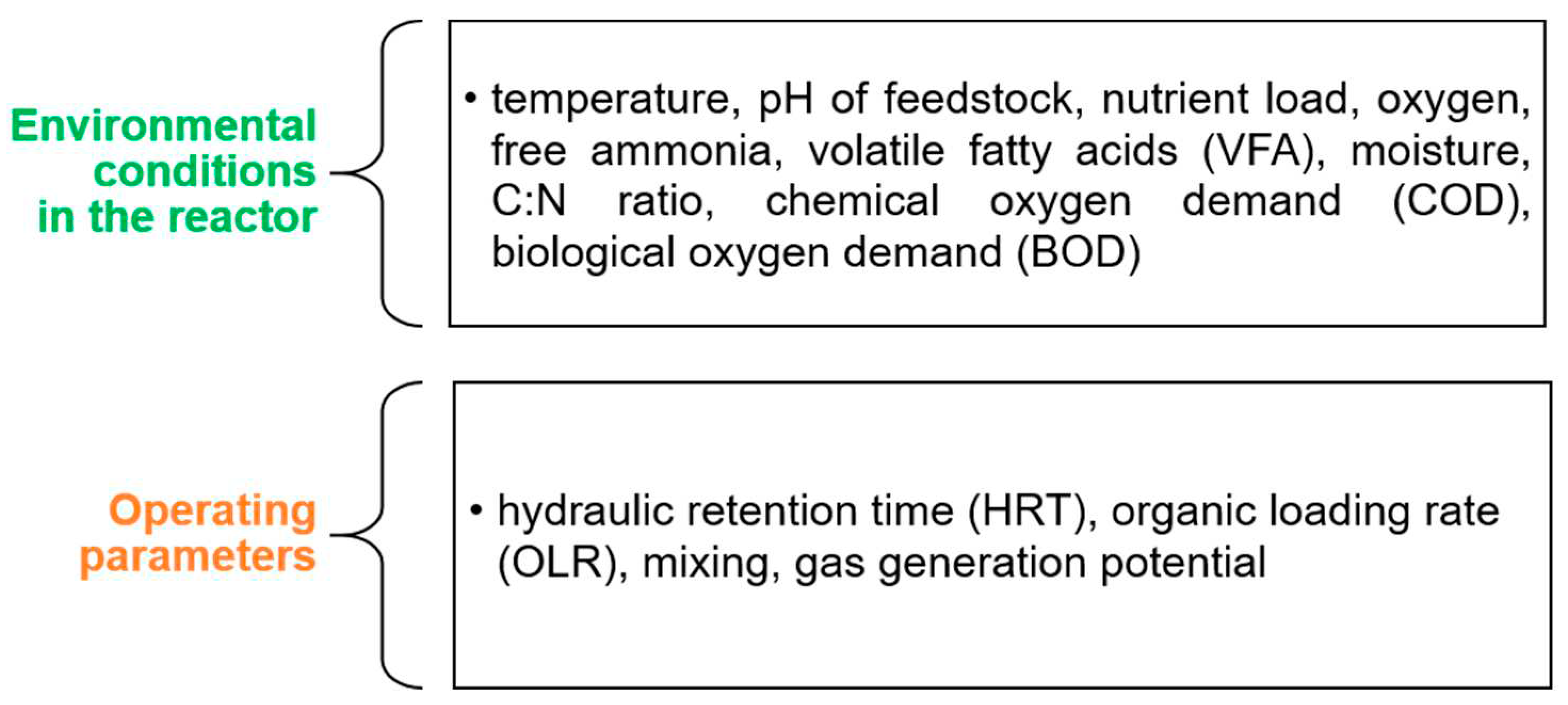

3.2. Key Parameters of the Process

3.3. Substrates for Biogas Production

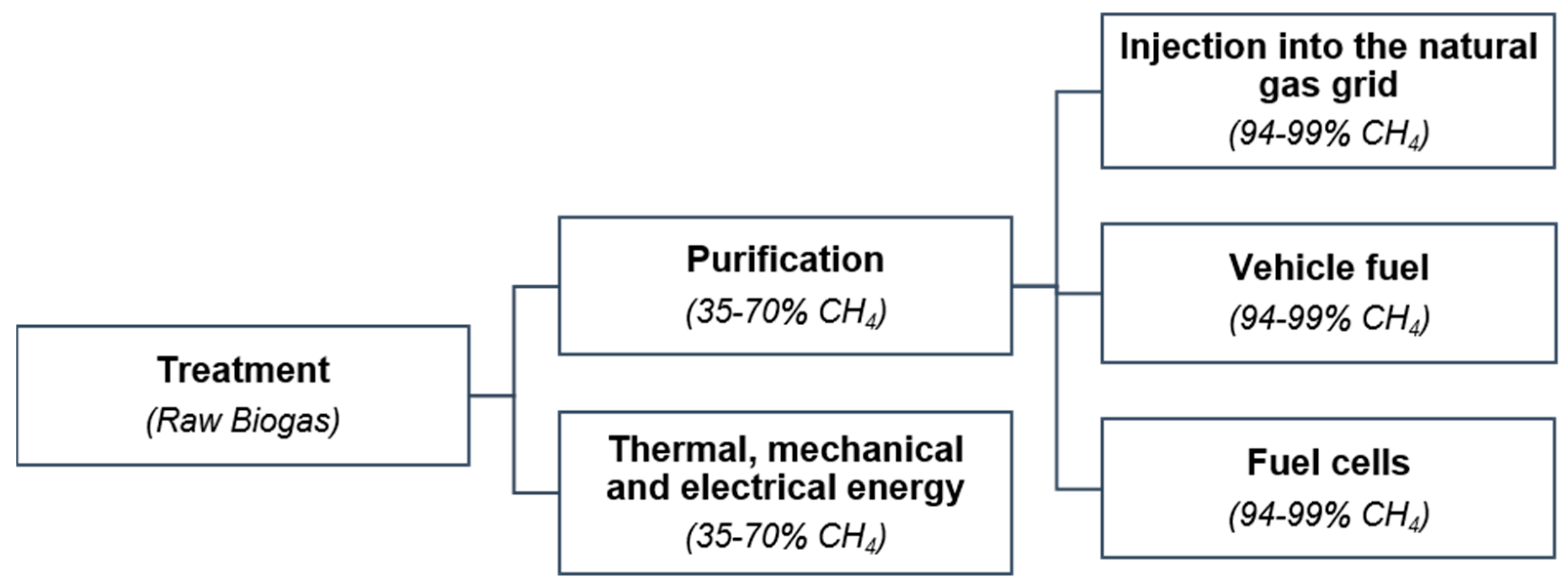

3.4. Biogas treatment and purification

4. Biogas plants

4.1. Overview of common biogas plant types

4.2. Analysis and implications for biogas plant design

4.3. Administrative aspects of the construction of biogas plants

4.3.1. Legal assessment and permit acquisition

4.3.2. Environmental regulations

4.3.3. Health and safety considerations

4.4. Operation of biogas plants

4.5. Economic aspects and profitability

- Investment Costs

- Operating Costs

- Availability and Costs of Feedstock

- Production and Utilization of Energy

- Environmental and Social Benefits

5. Global Prospects and Barriers in the Development of Biogas Plants

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Igliński, B.; Kiełkowska, U.; Pietrzak, M.; Skrzatek, M.; Kumar, G.; Piechota, G. The regional energy transformation in the context of renewable energy sources potential. Renew. Energy 2023, 218, 119246. [Google Scholar] [CrossRef]

- Pilarski, K.; Pilarska, A.A.; Boniecki, P.; Niedbała, G.; Durczak, K.; Witaszek, K.; Mioduszewska, N.; Kowalik, I. The efficiency of industrial and laboratory anaerobic digesters of organic substrates: The use of the Biochemical Methane Potential Correction Coefficient. Energies 2020, 13, 1280. [Google Scholar] [CrossRef]

- Pilarski, K.; Pilarska, A.A.; Boniecki, P.; Niedbała, G.; Witaszek, K.; Piekutowska, M.; Idzior-Haufa, M.; Wawrzyniak, A. Degree of biomass conversion in the integrated production of bioethanol and biogas. Energies 2021, 14, 7763. [Google Scholar] [CrossRef]

- Igliński, B.; Piechota, G.; Kiełkowska, U.; Kujawski, W.; Pietrzak, M.B.; Skrzatek, M. The assessment of solar photovoltaic in Poland: The photovoltaics potential, perspectives and development. Clean Technol. Environ. Policy 2023, 25, 281–298. [Google Scholar] [CrossRef]

- Bond, T.; Templeton, M.R. History and future of domestic biogas plants in the developing world. Energy Sustain. Dev. 2011, 15, 347–35. [Google Scholar] [CrossRef]

- Bhat, P.R.; Chanakya, H.N.; Ravindranath, N.H. Biogas plant dissemination: success story of Sirsi, India. Energy Sustain. Dev. 2001, 5, 39–46. [Google Scholar] [CrossRef]

- Perea-Moreno, M.A.; Samerón-Manzano, E.; Perea-Moreno, A.J. Biomass as renewable energy: Worldwide research trends. Sustainability 2019, 11, 863. [Google Scholar] [CrossRef]

- Nsair, A.; Cinar, S.O.; Alassali, A.; Qdais, H.A.; Kuchta, K. Operational parameters of biogas plants: A review and evaluation study. Energies 2020, 13, 3761. [Google Scholar] [CrossRef]

- Pilarski, K.; Pilarska, A.A.; Kolasa-Więcek, A.; Suszanowicz, D. An agricultural biogas plant as a thermodynamic system: A study of efficiency in the transformation from primary to secondary energy. Energies 2023, 16, 7398. [Google Scholar] [CrossRef]

- Kozłowski, K.; Dach, J.; Lewicki, A.; Cieślik, M.; Czekała, W.; Janczak, D.; Michał Brzoski, M. Laboratory simulation of an agricultural biogas plant start-up. Chem. Eng. Technol. 2018, 41, 711–716. [Google Scholar] [CrossRef]

- Nevzorova, T.; Kutcherov, V. Barriers to the wider implementation of biogas as a source of energy: A state-of-the-art review. Energy Strategy Rev. 2019, 26, 100414. [Google Scholar] [CrossRef]

- Sitorusa, B.; Sukandarb; Panjaitanc, S.D. Biogas recovery from anaerobic digestion process of mixed fruit-vegetable wastes. Energy Proc. 2013, 32, 176–182. [Google Scholar] [CrossRef]

- Bozym, M.; Florczak, I.; Zdanowska, P.; Wojdalski, J.; Klimkiewicz, M. An analysis of metal concentrations in food wastes for biogas production. Renew. Energy 2015, 77, 467–472. [Google Scholar] [CrossRef]

- Kozłowski, K.; Pietrzykowski, M.; Czekała, M.; Dach, J.; Kowalczyk-Juśko, A.; Jóźwiakowski, K.; Brzoski, M. Energetic and economic analysis of biogas plant with using the dairy industry waste. Energy 2019, 183, 1023–1031. [Google Scholar] [CrossRef]

- Amigun, B.; Sigamoney, R.; von Blottnitz, H. Commercialisation of biofuel industry in Africa: a review. Renew. Sustain. Energy Rev. 2008, 12, 690–711. [Google Scholar] [CrossRef]

- Kurchania, A.K.; Panwar, N.L.; Pagar, S.D. Development of domestic biogas stove. Biomass Conv. Bioref. 2011, 1, 99–103. [Google Scholar] [CrossRef]

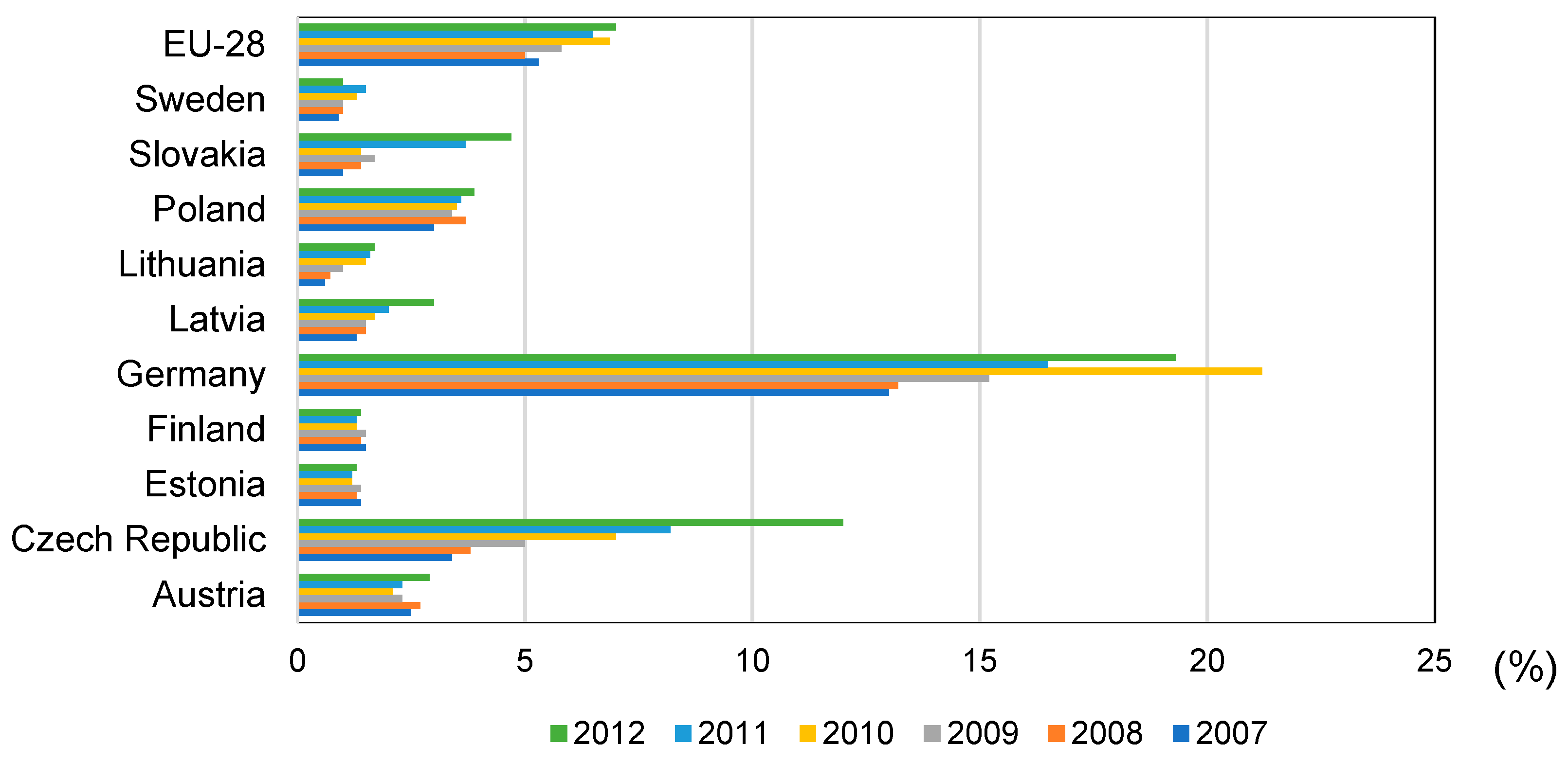

- Scarlat, N.; Dallemand, J.F.; Fahl, F. Biogas: Developments and perspectives in Europe. Renew. Energy 2018, 129, 457–472. [Google Scholar] [CrossRef]

- Weiland, P. Biogas Production: Current state and perspectives. Appl. Microbiol. Biotechnol. 2010, 85, 849–860. [Google Scholar] [CrossRef] [PubMed]

- Khan, I.U.; Othman, M.H.D.; Hashim, H.; Matsuura, T.; Ismail, A.F.; Rezaei-DashtArzhandi, M.; Azelee, I.W. Biogas as a renewable energy fuel–A review of biogas upgrading, utilisation and storage. Energy conversion and management, 2017, 150, 277–294. [Google Scholar] [CrossRef]

- Esteves, B.; Sen, U.; Pereira, H. Influence of chemical composition on heating value of biomass: A review and bibliometric analysis. Energies 2023, 16, 4226. [Google Scholar] [CrossRef]

- Díaz, I.; Lopes, A.C.; Pérez, S.I.; Fdz-Polanco, M. Performance evaluation of oxygen, air and nitrate for the microaerobic removal of hydrogen sulfide in biogas from sludge digestion. Bioresour. Technol. 2010, 101, 7724–7730. [Google Scholar] [CrossRef]

- Alayi, R.; Shamel, A.; Kasaeian, A.; Harasii, H.; Topchlar, M.A. The role of biogas to sustainable development (aspects environmental, security and economic). J. Chem. Pharm. Res. 2016, 8, 112–118. [Google Scholar]

- Akter, H.; Howlader, H.O.R.; Nakadomari, A.; Islam, M.R.; Saber, A.Y.; Senjyu, T. A short assessment of renewable energy for optimal sizing of 100% renewable energy based microgrids in remote islands of developing countries: A case study in Bangladesh. Energies 2022, 15, 1084. [Google Scholar] [CrossRef]

- Saracevic, E.; Frühauf, S.; Miltner, A.; Karnpakdee, K.; Munk, B.; Lebuhn, M.; Wlcek, B.; Leber, J.; Lizasoain, J.; Friedl, A.; Gronauer, A.; Bauer, A. Utilization of food and agricultural residues for a flexible biogas production: process stability and effects on needed biogas storage capacities. Energies 2019, 12, 2678. [Google Scholar] [CrossRef]

- Friedlingstein, P.; O'sullivan, M.; Jones, M.W.; Andrew, R.M.; Hauck, J.; Olsen, A.; Zaehle, S. Global carbon budget. Earth Sys. Sci. Data 2020, 12, 3269–3340. [Google Scholar] [CrossRef]

- Korberg, A.D.; Skov, I.R.; Mathiesen, B.V. The role of biogas and biogas-derived fuels in a 100% renewable energy system in Denmark. Energy, 2020, 199, 117426. [Google Scholar] [CrossRef]

- Bhattacharjee, S.; Miah, M.Y.; Sazzad, M.H. Bio-fuel and bio-fertilizer from municipal solid waste: conversion of waste management problem into a renewable energy generating solution. LAP Lambert Academic Publishing: London, United Kingdom, 2013. [Google Scholar]

- Abbasi, G.; Khoshalhan, F.; Hosseininezhad, S.J. Municipal solid waste management and energy production: A multi-objective optimization approach to incineration and biogas waste-to-energy supply chain. Sustain. Energy Technol. Assess. 2022, 54, 102809. [Google Scholar]

- Kiselev, A.; Magaril, E.; Magaril, R.; Panepinto, D.; Ravina, M.; Zanetti, M.C. Towards circular economy: Evaluation of sewage sludge biogas solutions. Resources, 2019, 8, 91. [Google Scholar] [CrossRef]

- Pilarska, A.A.; Pilarski, K.; Wolna-Maruwka, A.; Boniecki, P.; Zaborowicz, M. Use of confectionery waste in biogas production by the anaerobic digestion process. Molecules 2019, 24, 37. [Google Scholar] [CrossRef]

- Makara, L.; Lytour, L.; Chanmakara, M. Practical biogas plant development handbook: Potential Biogas resources, Legal Review, and Good Practice of Biogas Construction in Cambodia. Biogas Technology and Information Center (BTIC): Phnom Penh, Cambodia, 2021. [Google Scholar]

- Deublein, D.; Steinhauser, A. Biogas from Waste and Renewable Resources, 2nd ed.; Wiley-VCH Verlag GmbH & Co.KGaA: Weinheim, Germany, 2011. [Google Scholar]

- Kabalci, E. Hybrid renewable energy systems and microgrids. Elsevier Inc.: Amsterdam, The Netherlands, 2020. [Google Scholar]

- Amani, T.; Nosrati, M.; Sreekrishnan, T.R. Anaerobic digestion from the viewpoint of microbiological, chemical, and operational aspects – A review. Environ. Rev. 2010, 18, 255–278. [Google Scholar] [CrossRef]

- Monson, K.; Esteves, S.; Guwy, A. Dinsdale R. Anaerobic digestion of biodegradable municipal wastes: a review.; University of Glamorgan: Pontypridd, United Kingdom, 2007. [Google Scholar]

- Ghodrat, A.G.; Tabatabaei, M.; Aghbashlo, M.; Mussatto, S.I. Waste Management Strategies; the State of the Art. In Tabatabaei, M. and Ghanavati, H. (Eds.), Biogas. Fundamentals, Process and Operation. Springer. Biofuel Bioprod. Biorefin. 2018, 6, 1–33. [Google Scholar]

- Li, Y.; Hu, J.; Zhang, Q.; Zhou, Q.; Chen, J.; Zhang, P. Optimization of biogas production from agricultural residues using response surface methodology. Energy Convers. Manag. 2019, 181, 432–442. [Google Scholar]

- Zhang, L.; Sun, Y.; Xi, B.; Yang, Y.; Zhang, Y.; Liu, Y. Effect of feedstock composition on anaerobic digestion and biogas production from agricultural residues. Energy, 2017, 120, 668–677. [Google Scholar]

- Ndiweni, P.N.; Gueguim Kana, E.B.; Gueguim Kana, J.B. Comparative study of the biogas potential of selected agricultural waste: Cattle manure, poultry droppings and maize cobs. Renew. Energy, 2019, 132, 1353–1358. [Google Scholar]

- Kifukwe, G.R. Thinking outside the box: a case for promoting the charcoal industry in Tanzania; UONGOZI Institute: Dodoma, Tanzania, 2013. [Google Scholar]

- The biodigestion process. In: Kunz, A.; Steinmetz, R.L.R.; do Amaral, A.C. Fundamentals of anaerobic digestion, biogas purification, use and treatment of digestate. The Brazilian Agricultural Research Corporation (Embrapa) Brasilia, Brazil, 2022, (pp. 13–26).

- Kythreotou, N.; Florides, G.; Tassou, S.A. A review of simple to scientific models for anaerobic digestion. Renew. Energy 2014, 71, 701–714. [Google Scholar] [CrossRef]

- Ward, A.J.; Hobbs, P.J.; Holliman, P.J.; Jones, D.L. Optimisation of the anaerobic digestion of agricultural resources. Bioresour. Technol. 2008, 99, 7928–7940. [Google Scholar] [CrossRef]

- Xue, S.; Wang, Y.; Lyu, X.; Zhao, N.; Song, J.; Wang, X.; Yang, G. Interactive effects of carbohydrate, lipid, protein composition and carbon/nitrogen ratio on biogas production of different food wastes. Bioresour. Technol. 2020, 312, 123566. [Google Scholar] [CrossRef]

- Chandra, R.; Takeuchi, H.; Hasegawa, T. Methane production from lignocellulosic agricultural crop wastes: A review in context to second generation of biofuel production. Renew. Sustain. Energy Rev. 2012, 16, 1462–1476. [Google Scholar] [CrossRef]

- Gkamarazi, N. Implementing anaerobic digestion for municipal solid waste treatment: challenges and prospects. In International Conference on Environmental Science and Technology, CEST, Rhodes, Greece, 2015 (pp. 3–5).

- De Mes, T.Z.D.; Stams, A.J.M.; Reith, J.H.; Zeeman, G. Methane production by anaerobic digestion of wastewater and solid wastes. In: Bio-methane & Bio-hydrogen Status and perspectives of biological methane and hydrogen production (Ed. by Reith, J.H.; Wijffels, R.H.; Barten, H.), Dutch Biological Hydrogen Foundation, Petten, Netherlands, 2003, (pp. 58–102).

- Pilarska, A.A.; Pilarski, K.; Wolna-Maruwka, A. Cell immobilization on lignin–polyvinylpyrrolidone material used for anaerobic digestion of waste wafers and sewage sludge. Environ. Eng. Sci. 2019, 36, 478–490. [Google Scholar] [CrossRef]

- Kalyuzhnyi, S.; Veeken, A.; Hamelers, B. Two-particle model of anaerobic solid-state fermentation. Water Sci. Technol. 2000, 41, 43–50. [Google Scholar] [CrossRef]

- Pilarska, A.A. Anaerobic co-digestion of waste wafers from the confectionery production with sewage sludge. Polish J. Environ. Stud. 2018, 27, 237–245. [Google Scholar] [CrossRef] [PubMed]

- Wellinger, A.; Murphy, J.D.; Baxter, D. (Eds.) The biogas handbook: science, production and applications. Elsevier, Amsterdam, Holandia, 2013.

- Khalid, A.; Arshad, M.; Anjum, M.; Mahmood, T.; Dawson, L. The anaerobic digestion of solid organic waste. Waste Manage. 2011, 31, 1737–1744. [Google Scholar] [CrossRef]

- Pilarska, A.A.; Pilarski, K.; Waliszewska, B.; Zborowska, M.; Witaszek, K.; Waliszewska, H.; Kolasiński, M.; Szwarc-Rzepka, K. Evaluation of bio-methane yields for high-energy organic waste and sewage sludge: Apilot-scale study for a wastewater treatment plant. Environ. Eng. Manag. J. 2019, 18, 2023–2034. [Google Scholar] [CrossRef]

- Moset, V.; Poulsen, M.; Wahid, R.; Højberg, O.; Møller, H.B. Mesophilic versus thermophilic anaerobic digestion of cattle manure: methane productivity and microbial ecology. Microbial Biotechnol. 2015, 8, 787–800. [Google Scholar] [CrossRef]

- Kreuger, E.; Nges, I.A.; Björnsson, L. Ensiling of crops for biogas production: effects on methane yield and total solids determination. Biotechnol. Biofuels 2011, 4, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Kothari, R.; Pandey, A.K.; Kumar, S.; Tyagi, V.V.; Tyagi, S.K. Different aspects of dry anaerobic digestion for bio-energy: An overview. Renew. Sustain. Energy Rev. 2014, 39, 174–195. [Google Scholar] [CrossRef]

- Launay, C.; Houot, S.; Frédéric, S.; Girault, R.; Levavasseur, F.; Marsac, S.; Constantin, J. Incorporating energy cover crops for biogas production into agricultural systems: benefits and environmental impacts. A review. Agron. Sustain. Dev. 2022, 42, 57. [Google Scholar] [CrossRef]

- Friehe, J.; Weiland, P.; Schattauer, A. Guide to biogas – from production to use. Fachagentur Nachwachsende Rohstoffe e. V. (FNR) with support of the Federal Ministry of Food, Agriculture and Consumer Protection Gülzow, Niemcy, 2010.

- Ghosh, P., Shah, G., Sahota, S., Singh, L., & Vijay, V. K. (2020). Biogas production from waste: Technical overview, progress, and challenges. Bioreactors, 89-104.

- Pilarska, A.A.; Pilarski, K.; Witaszek, K.; Waliszewska, H.; Zborowska, M.; Waliszewska, B.; Kolasiński, M.; Szwarc-Rzepka, K. Treatment of dairy waste by anaerobic co-digestion with sewage sludge. Ecol. Chem. Eng. S, 2016, 23, 99–115. [Google Scholar] [CrossRef]

- Abatzoglou, N.; Boivin, S. A review of biogas purification processes. Biofuels, Bioprod. Biorefin. 2009, 3, 42–71. [Google Scholar] [CrossRef]

- Hendrickson, R.G.; Chang, A.; Hamilton, R.J. Co-worker fatalities from hydrogen sulfide. Am. J. Ind. Med. 2004, 45, 346–350. [Google Scholar] [CrossRef]

- Ni, J.Q.; Heber, A.J.; Diehl, C.A.; Lim, T.T.; Duggirala, R.K.; Haymore, B.L. Burst releases of hydrogen sulfide in mechanically ventilated swine buildings. In Conference Proceedings Odors and VOC Emissions; Water Environment Federation, Cincinnati, Unites States, 2000 (pp. 16–19).

- Habeeb, O.A.; Kanthasamy, R.; Ali, G.A.; Sethupathi, S.; Yunus, R.B.M. Hydrogen sulfide emission sources, regulations, and removal techniques: a review. Rev. Chem. Eng. 2018, 34, 837–854. [Google Scholar] [CrossRef]

- Garcia-Arriaga, V.; Alvarez-Ramirez, J.; Amaya, M.; Sosa, E. H2S and O2 influence on the corrosion of carbon steel immersed in a solution containing 3 M diethanolamine. Corros. Sci. 2010, 52, 2268–2279. [Google Scholar] [CrossRef]

- Latha, K.M.; Badarinath, K.V.S. Correlation between black carbon aerosols, carbon monoxide and tropospheric ozone over a tropical urban site. Atmos. Res. 2004, 71, 265–274. [Google Scholar] [CrossRef]

- He, P.J. Anaerobic digestion: an intriguing long history in China. Waste Manage. 2010, 30, 549–550. [Google Scholar] [CrossRef] [PubMed]

- Bond, T.; Templeton, M.R. History and future of domestic biogas plants in the developing world. Energy Sustain. Dev. 2011, 15, 347–354. [Google Scholar] [CrossRef]

- Chodkowska-Miszczuk, J.; Szymańska, D. Agricultural biogas plants – A chance for diversification of agriculture in Poland. In: Renew. Sust. Energ. Rev. 2013, 20, 514–518. [Google Scholar] [CrossRef]

- Prakash, O.; Anil, K.; Pandey, A.; Kumara, A.; Laguria, V. A review on biogas plant. Int. J. New Technol. Sci. Eng. 2015, 2, 2349–0780. [Google Scholar]

- Li, J.; Kong, C.; Duan, Q.; Luo, T.; Mei, Z.; Lei, Y. Mass flow and energy balance plus economic analysis of a full-scale biogas plant in the rice–wine–pig system. Bioresour. Technol. 2015, 193, 62–67. [Google Scholar] [CrossRef] [PubMed]

- Arnold, K. Greenhouse gas balance of bio-methane–which substrates are suitable? Energy Sci. Technol. 2011, 1, 67–75. [Google Scholar]

- Bai, D.; Jain, V.; Tripathi, M.; Ali, S.A.; Shabbir, M.S.; Mohamed, M.A.; Ramos-Meza, C.S. Performance of biogas plant analysis and policy implications: Evidence from the commercial sources. Energy Policy 2022, 169, 113173. [Google Scholar] [CrossRef]

- Scholwin, F.; Nelles, M. Energy flows in biogas plants: Analysis and implications for plant design. In The biogas handbook, Woodhead Publishing, Sawston, United Kingdom, 2013 (pp. 212-227).

- Hakawati, R.; Smyth, B.M.; McCullough, G.; De Rosa, F.; Rooney, D. What is the most energy efficient route for biogas utilization: heat, electricity or transport. Appl. Energy, 2017, 206, 1076–1087. [Google Scholar] [CrossRef]

- Norm VDI 4630; Fermentation of Organic Materials Characterization of the Substrate, Sampling, Collection of Material Data, Fermentation Tests. German Engineers Club: Düsseldorf, Germany, 2006.

- Curkowski. A.; Oniszk-Popławska, A.; Mroczkowski, P.; Owsik, M.; Wiśniewski, G. A guide for investors interested in construction of agricultural biogas plants. Institute for Renewable Energy, Warsaw, Poland, 2011.

- Kimuyu, P.; Mutua, J.; Wainaina, J. Role of renewable energy in promoting inclusive and sustainable development in Kenya. European Report on Development. Overseas Development Institute (ODI) in partnership with the Deutsches Institut für Entwicklungspolitik (DIE) and the European Centre for Development Policy Management (ECDPM). London, United Kingdom, 2011/2012.

- Paolini, V.; Petracchini, F.; Segreto, M.; Tomassetti, L.; Naja, N.; Cecinato, A. Environmental impact of biogas: A short review of current knowledge. J. Environ. Sci. Health A 2018, 53, 899–906. [Google Scholar] [CrossRef]

- Wiśniewska, M. Methods of assessing odour emissions from biogas plants processing municipal waste. J. Ecol. Eng. 2020, 21, 140–147. [Google Scholar] [CrossRef]

- Nsair, A.; Onen Cinar, S.; Alassali, A.; Abu Qdais, H.; Kuchta, K. Operational parameters of biogas plants: A review and evaluation study. Energies, 2020, 13, 3761. [Google Scholar] [CrossRef]

- Wu, D.; Peng, X.; Li, L.; Yang, P.; Peng, Y.; Liu, H.; Wang, X. Commercial biogas plants: Review on operational parameters and guide for performance optimization. Fuel, 2021, 303, 121282. [Google Scholar] [CrossRef]

- Dach, J.; Boniecki, P.; Przybył, J.; Janczak, D.; Lewicki, A.; Czekała, W.; Witaszek, K.; Rodríguez Carmona, P.C.; Cieślik, M. Energetic efficiency analysis of the agricultural biogas plant in 250 kWe experimental installation. Energy, 2014, 69, 34–38. [Google Scholar] [CrossRef]

- Sarker, S.A.; Wang, S.; Adnan, K.M.; Sattar, M.N. Economic feasibility and determinants of biogas technology adoption: evidence from Bangladesh. Renew. Sustain. Energy Rev. 2020, 123, 109766. [Google Scholar] [CrossRef]

- Salerno, M.; Gallucci, Frances, C.; Pari, L.; Zambon, I.; Sarri, D.; Colantoni, A. Costs-benefits analysis of a small-scale biogas plant and electric energy production. Bulg. J. Agric. Sci. 2017, 23, 357–362. [Google Scholar]

- Klimek, K.; Kapłan, M.; Syrotyuk, S.; Bakach, N.; Kapustin, N.; Konieczny, R.; Dobrzyński, J.; Borek, K.; Anders, D.; Dybek, B.; Karwacka, A.; Wałowski, G. Investment model of agricultural biogas plants for individual farms in Poland. Energies, 2020, 14, 7375. [Google Scholar] [CrossRef]

- Menind, A.; Olt, J. Biogas plant investment analysis, cost benefit and main factors. In Proceedings of the 8th International Scientific Conference Engineering for Rural Development, Jelgava, Latvia, 2009 (pp. 28-29).

- Kalinichenko, A.; Havrysh, V.; Perebyynis, V. Evaluation of biogas production and usage potential. Ecol. Chem. Eng. S 2016, 23, 387–400. [Google Scholar] [CrossRef]

- Skovsgaard, L.; Jacobsen, H.K. Economies of scale in biogas production and the significance of flexible regulation. Energy Policy 2017, 101, 77–89. [Google Scholar] [CrossRef]

- Carlsson, M.; Lagerkvist, A.; Morgan-Sagastume, F. The effects of substrate pre- -treatment on anaerobic digestion systems: a review. Waste Manage. 2012, 32, 1634–1650. [Google Scholar] [CrossRef] [PubMed]

- Igliński, B.; Buczkowski, R.; Iglińska, A.; Cichosz, M.; Piechota, G.; Kujawski, W. Agricultural biogas plants in Poland: Investment process, economical and environmental aspects, biogas potential. Renew. Sustain. Energ. Rev. 2012, 16, 4890–4900. [Google Scholar] [CrossRef]

- Boniecki, P.; Nowakowski, K.; Ślósarz, P.; Dach, J.; Pilarski, K. Neural image analysis for estimating aerobic and anaerobic decomposition of organic matter based on the example of straw decomposition. 4th International Conference on Digital Image Processing, Proceedings of SPIE, vol. 8334, Kuala Lumpur, Malaysia 2012.

- Bhatt, A.H.; Tao, L. Economic perspectives of biogas production via anaerobic digestion. Bioengineering 2020, 7, 74. [Google Scholar] [CrossRef]

- Capodaglio, A.G.; Callegari, A.; Lope, M.V. European framework for the diffusion of biogas uses: emerging technologies, acceptance, incentive strategies, and institutional–regulatory support. Sustainability 2016, 8, 298. [Google Scholar] [CrossRef]

- Szymańska, D.; Lewandowska, A. Biogas power plants in Poland – structure, capacity, and spatial distribution. Sustainability 2015, 7, 16801–16819. [Google Scholar] [CrossRef]

- Pizarro-Loaiza, C.A.; Antón, A.; Torrellas, M.; Torres-Lozada, P.; Palatsi, J.; Bonmatí, A. Environmental, social and health benefits of alternative renewable energy sources. Case study for household biogas digesters in rural areas. J. Clean. Prod. 2021, 297, 126722. [Google Scholar] [CrossRef]

- van Foreest, F. Perspectives for Biogas in Europe.; Oxford Institute for Energy Studies: Oxford, United Kingdom, 2012. [Google Scholar]

- Lewandowski, I; Weger, J.; Van Hooijdonk, A.; Havlickova, K.; Van Dam, J.; Faaij, A. The potential biomass for energy production in the Czech Republic. Biomass Bioenerg. 2006, 30, 405–421. [Google Scholar] [CrossRef]

- Chasnyk, O.; Sołowski, G.; Shkarupa, O. Historical, technical and economic aspects of biogas development: Case of Poland and Ukraine. Renew. Sust. Energy Rev. 2015, 52, 227–239. [Google Scholar] [CrossRef]

- Bednarek, A.; Klepacka, A.M.; Siudek, A. Development barriers of agricultural biogas plants in Poland. Econ. Environ. 2023, 1, 229–258. [Google Scholar] [CrossRef]

- Monjurul Hasan, A.S.M.; Kabir, M.A.; Hoq, M.T.; Johanssond, M.T.; Thollanderd, P. Drivers and barriers to the implementation of biogas technologies in Bangladesh. Biofuels 2022, 13, 643–655. [Google Scholar] [CrossRef]

- Situmeang, R.; Mazancová, J.; Roubík, H. Technological, economic, social and environmental barriers to adoption of small-scale biogas plants: Case of Indonesia energies. 2022, 15, 5105.

- Ghimire, P.C. SNV supported domestic biogas programmes in Asia and Africa. Renew. energy 2013, 49, 90–94. [Google Scholar] [CrossRef]

- Bensah, E.C.; Mensah, M.; Antwi, E. Status and prospects for household biogas plants in Ghana – lessons, barriers, potential, and way forward. Int. J. Energ. Eviron. 2011, 2, 887–898. [Google Scholar]

- Clemens, H.; Bailis, R.; Nyambane, A.; Ndung'u, V. Africa biogas partnership program: A review of clean cooking implementation through market development in East Africa. Energ. Sustain. Develop. 2018, 46, 23–31. [Google Scholar] [CrossRef]

- Shane, A.; Gheewala, S.H.; Kasali, G. Potential, barriers and prospects of biogas production in Zambia. J. Sustain. Energ. Environ. 2015, 6, 21–27. [Google Scholar]

- ICF International, Inc. The DHS program STAT compiler, ICF (Inner City Fund) International, Reston, United States, 2015.

- IRENA, Biogas for domestic cooking: Technology brief. IRENA (International Renewable Energy Agency), Abu Dhabi, United Arab Emirates, 2017.

- Putti, V.R.; Tsan, M.; Mehta, S.; Kammila, S. The state of the global clean and improved cooking sector. ESMAP technical paper: no. 007/15Washington, DC: World Bank, Washington, United States, 2015.

- Zuzhang, X. Domestic biogas in a changing China: Can biogas still meet the energy needs of China's rural households? International Institute for Environment and Development (IIED), Road, London, United Kingdom, 2013.

- Wang, X.; Lu, X.; Yang, G.; Feng, Y.; Ren, G.; Han, X. Development process and probable future transformations of rural biogas in China. Renew. Sustain. Energy Rev., 2016, 55, 703–712. [Google Scholar] [CrossRef]

- Mustafayev, F.; Kulawczuk, P.; Orobello, C. Renewable energy status in Azerbaijan: Solar and wind potentials for future development. Energies 2022, 15, 401. [Google Scholar] [CrossRef]

- Vidadili, N.; Suleymanov, E.; Bulut, C.; Mahmudlu, C. Transition to renewable energy and sustainable energy development in Azerbaijan. Renew. Sustain. Energy Rev. 2017, 80, 1153–1161. [Google Scholar] [CrossRef]

- Hasanov, F.J.; Mukhtarov, S.; Suleymanov, E. The role of renewable energy and total factor productivity in reducing CO2 emissions in Azerbaijan. Fresh insights from a new theoretical framework coupled with Autometrics. Energy Strategy Rev. 2023, 47, 101079. [Google Scholar] [CrossRef]

- Felver, T.B. How can Azerbaijan meet its Paris Agreement commitments: assessing the effectiveness of climate change-related energy policy options using LEAP modeling. Heliyon 2020, 6, e04697. [Google Scholar] [CrossRef]

- Gurbanov, S. Role of natural gas consumption in the reduction of CO2 emissions: case of Azerbaijan. Energies 2021, 14, 7695. [Google Scholar] [CrossRef]

- Mao, C.; Feng, Y.; Wang, X.; Ren, G. Review on research achievements of biogas from anaerobic digestion. Renew. Sustain. Energ. Rev. 2015, 45, 540–555. [Google Scholar] [CrossRef]

- Náthia-Neves, G.; Berni, M.; Dragone, G.; Mussatto, S.I.; Forster-Carneiro, T. Anaerobic digestion process: technological aspects and recent developments. Int. J. Environ. Sci. Technol. 2018, 15, 2033–2046. [Google Scholar] [CrossRef]

- Meng, Z.; He, J.; Xu, D. How do peer effects affect the transformation of farmers' willingness and behavior to adopt biogas. J. Clean. Prod. 2023, 415, 137857. [Google Scholar] [CrossRef]

- Budzianowski, W. A review of potential innovations for production, conditioning and utilization of biogas with multiple-criteria assessment. Renew. Sustain. Energ. Rev. 2016, 54, 1148–1171. [Google Scholar] [CrossRef]

- Nevzorova, T.; Kutcherov, V. Barriers to the wider implementation of biogas as a source of energy: A state-of-the-art review. Energy Strategy Rev. 2019, 26, 100414. [Google Scholar] [CrossRef]

- Ali, S.; Yan, Q.; Irfan, M.; Chen, Z. Evaluating barriers on biogas technology adoption in China: The moderating role of awareness and technology understanding. Front. Environ. Sci. 2022, 10, Article–887084. [Google Scholar] [CrossRef]

- Pathak, H.; Jain, N.; Bhatia, A.; Mohanty, S.; Navindu Gupta, N. Global warming mitigation potential of biogas plants in India. Environ. Monit. Assess. 2009, 157, 407–418. [Google Scholar] [CrossRef]

- Torrijos, M. State of development of biogas production in Europe. International Conference on Solid Waste Management, 5IconSWM 2015. Proced. Environ. Sci. 2016, 35, 881–889. [Google Scholar] [CrossRef]

- Hall, P.; Jack, M. Bioenergy Options for New Zealand. Pathways analysis. Scion, Energy Group, Rotorua, New Zealand, 2008.

- Carlu, E.; Truong, T.; Kundlevski, M. Biogas opportunities for Australia. ENEA Consulting, Paris, France, 2019.

- Umetsu, K.; Ying, C.; Kikuchi, S.; Iwasaki, M.; Takeuchi, Y.; Oi, M.; Shiroishi, K.; Uematsu, S.; Yasui, S. Integration of centralized biogas plant in cold-snowy region in Japan. Biotechnol. Anim. Husb. 2011, 27, 405–414. [Google Scholar] [CrossRef]

- Beck P. The Market for biogas plants in Japan and opportunitiesfor EU companies. Osnabrueck, Germany ECOS GmbH, and EU-Japan Centre for industrial cooperation, Tokyo, Japan, 2021.

- Kim, Y.S.; Yoon, Y.M.; Kim, C.H.; Giersdorf, J. Status of biogas technologies and policies in South Korea. Renew. Sustain. Energ. Rev. 2012, 16, 3430–3438. [Google Scholar] [CrossRef]

- Granado, R.L.; de Souza Antune, A.M.; da Fonseca, F.V.; Sánchez, A.; Raquel Barrena, R.; Font, X. Technology overview of biogas production in anaerobic digestion plants: A european evaluation of research and development. Renew. Sustain. Energ. Rev. 2017, 80, 44–53. [Google Scholar] [CrossRef]

- Theuerl, S.; Herrmann, C.; Heiermann, M.; Grundmann, P.; Landwehr, N.; Kreidenweis, U.; Prochnow, A. The future agricultural biogas plant in Germany: A vision. Energies 2019, 12, 396. [Google Scholar] [CrossRef]

| Parameter | Hydrolosis/Acidogenesis | Methanogesis |

|---|---|---|

| Temperature (°C) | 25 – 35 | 32 – 42 |

| pH | 5.2 – 6.3 | 6.7 – 7.5 |

| C:N ratio | 10 – 45 | 20 – 30 |

| Dry matter concentration (%) | < 40 | < 30 |

| Redox potential (mV) | +400 to ˗300 | < ˗200 |

| Required C:N:P:S ratio | 500:15:5:3 | 600:15:5:3 |

| Substrate |

Biogas (Nm3·t-1 substrate) |

Methane (Nm3·t-1 substrate) |

| Cattle slurry | 25 | 14 |

| Pig slurry | 28 | 17 |

| Cattle dung | 80 | 44 |

| Poultry manure | 140 | 90 |

| Country | Program start | Number of biogas installations in 2008 |

Number of biogas installations in 2009 |

Cumulative of biogas installations numer up to 2009 |

|---|---|---|---|---|

| Asia | ||||

| Nepal | 1992 | 14,002 | 18,902 | 205,762 |

| Vietnam | 2003 | 17,012 | 25,764 | 75,820 |

| Bangladesh | 2006 | 2648 | 5050 | 10,019 |

| Cambodia | 2006 | 2340 | 2616 | 6402 |

| Lao PDR | 2006 | 188 | 722 | 1020 |

| Indonesia | 2009 | - | 50 | 50 |

| Pakistan | 2009 | - | 100 | 100 |

| Africa | ||||

| Rwanda | 2007 | 120 | 213 | 434 |

| Ethiopia | 2008 | 98 | 30 | 128 |

| Kenya | 2008 | - | 3 | 3 |

| Tanzania | 2008 | 3 | 103 | 106 |

| Uganda | 2008 | - | 40 | 40 |

| Burkina Faso | 2009 | - | 1 | 1 |

| Cameroon | 2009 | - | 23 | 23 |

| Total | 36,411 | 53,617 | 299,908 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).