Submitted:

29 October 2023

Posted:

30 October 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

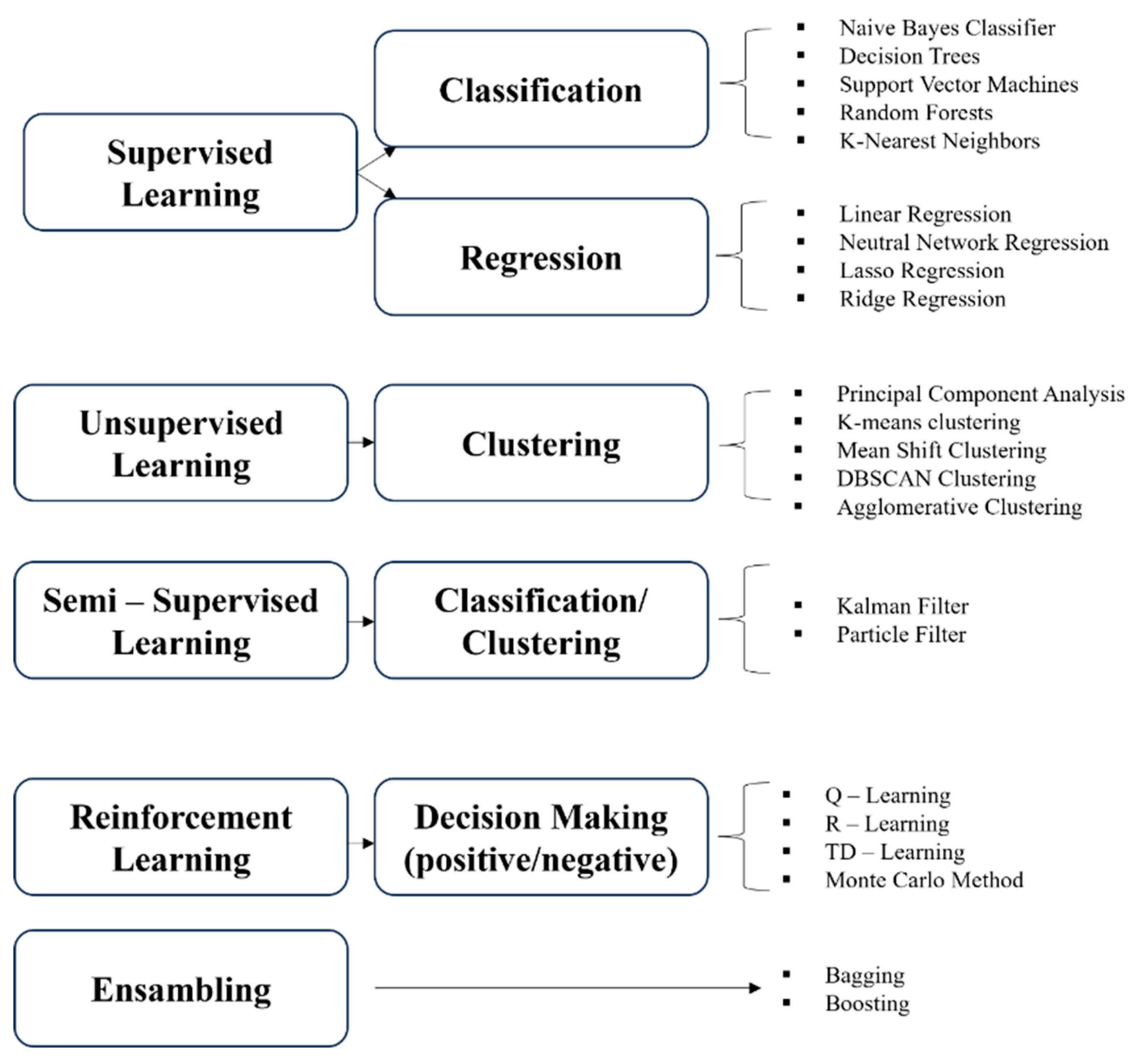

2. Machine Learning Algorithms – an overview

3. Machine Learning in investigation of MgO-C materials

3.1. Oxidation mechanism of MgO-C refractories

3.2. ML in laboratory testing and optimization of MgO-C refractories composition

3.3. Thermomechanical properties of MgO-C refractories in steel ladles

| Steel shell temperature [°C] |

Maximum tensile stress [MPa] |

Maximum compressive stress [MPa] | ||||

|---|---|---|---|---|---|---|

| modelling (FE) | predicted (BP-ANN) |

modelling (FE) | predicted (BP-ANN) |

modelling (FE) | predicted (BP-ANN) |

|

| Lining concept 1 | 280 | 276 | 1495 | 1433 | 512 | 517 |

| Lining concept 2 | 259 | 259 | 1539 | 1576 | 517 | 515 |

3.4. ML application for industrial data analysis

3.5. Benefits and limitations of ML techniques for investigation of MgO-C refractories

4. Conclusions

Conflicts of Interest

References

- Routschka, G.; Wuthnow, H. Handbook of Refractory Materials Design, Properties, Testings, 4th Ed. ed; Vulkan – Verlag Gmbh: Essen, Germany, 2012; pp. 92–98. [Google Scholar]

- Dai, Y.; Li, J.; Yan, W.; Shi, C. Corrosion mechanism and protection of BOF refractory for high silicon hot metal steelmaking process. J. Mater. Res Technol. 2020, 9, 4292–4308. [Google Scholar] [CrossRef]

- Guoguang, Z.; Husken, R.; Cappel, J. Experiance with long BOF campaign life and TBM bottom stirring technology. Stahl und Eisen. 2012, 132, 61–78. [Google Scholar]

- Husken, R.; Pottie, P.; Guoguang, Z.; Cappel, J. Overcoming the conflict between long BOF refractory lifetime and efficient bottom stirring: A case study at Meishan Steel in China. In 45⁰ Seminário de Aciaria - Internacional; Porto Alegre - Brasil, 2014. [Google Scholar] [CrossRef]

- Folco, L.; Kranjc, A. Steel Ladle Lining management: Comparision between different maintenance technologies to increase performance, reduce refractory consumption and waste disposal of used materials. In Proceedings of Unified International Conference on Refractories UITECR 2023, Frankfurt, Germany; 20 September 2023; pp. 351–354. [Google Scholar]

- Otunniyi, I.O.; Theko, Z.V.; Mokoena, B.L.E.; Maramba, B. Major deteminantion of service life in magnesia-graphite slagline refractory lining in secondary steelmaking ladle furnace. IOP Conf. Ser. Mater. Sci. Eng. 2019, 655, 012003. [Google Scholar] [CrossRef]

- Sun, C.; Zhu, L.; Yan, H.; et al. A novel route to enhance high-temperature mechanical property and thermal schock resistance of low-carbon MgO-C bricks by introducing ZrSiO4. Pol. J. Iron. Steel Res. Int. 2023.

- Korostelev, A.A.; S’emshchikov, N.S.; Semin, A.E.; et al. Increase in EAF lining life with use of hot-briquetted iron in charge. Refractories and Industrial Ceramics 2018, 59, 107–114. [Google Scholar] [CrossRef]

- Gubta, R.B. Innovation in Steel Ladle Life to 157 Heats at Rourkela Steel Plant through Optimization of Refractory Material & Service Conditions. Int. J. Eng. Res. Technol. 2017, 6, 767–771. [Google Scholar]

- Ewais, E.M.M. Carbon based refractories. J. Ceram. Soc. Japan. 2004, 112, 517–532. [Google Scholar] [CrossRef]

- Luz, A.P.; Souza, T.M.; Pagliosa, C.; Brito, M.A.M.; Pandolfelli, V.C. In situ hot elastic modulus evolution of MgO-C refractories containing Al, Si or Al-Mg antioxidants. Ceram. Int. 2016, 42, 9836–9843. [Google Scholar] [CrossRef]

- Xiao, J.; Chen, J.; Wei, Y.; Zhang, Y.; Zhang, S.; Li, N. Oxidation behaviors of MgO-C refractories with different Si/SiC ratio in the 1100–1500 °C range. Ceram. Int. 2019, 45, 21099–21107. [Google Scholar] [CrossRef]

- Gao, S.; Xu, L.; Chen, M.; Wang, N. Effect of Fe addition on the microstructure and oxidation behavior of MgO–C refractory. Mater. Chem. Phys. 2019, 238, 121935. [Google Scholar] [CrossRef]

- Atzenhofer, C.; Harmuth, H. Phase formation in MgO-C refractories with different antioxidants. J. Eur. Ceram. Soc. 2021, 41, 7330–7338. [Google Scholar] [CrossRef]

- Yang, P.; et al. Antioxidant properties of low-carbon magnesia-carbon refractories containing AlB2–Al–Al2O3 composites. Ceram. Int, vol. 2022, 48, 1375–1381. [Google Scholar] [CrossRef]

- Chen, Y.; Ding, J.; Deng, C.; Yu, C. Improved thermal shock stability and oxidation resistance of low-carbon MgO–C refractories with introduction of SiC whiskers. Ceram. Int. 2023, 49, 26871–26878. [Google Scholar] [CrossRef]

- Zhang, T.; Chen, J.; Zhang, Y.; Yan, W.; Zhang, S.; Li, N. Elucidating the role of Ti3AlC2 and Ti3SiC2 in oxidation mechanisms of MgO–C refractories. Ceram. Int. 2023, 49, 11257–11265. [Google Scholar] [CrossRef]

- Chen, Y.; Deng, C.; Wang, X.; Yu, C.; Ding, J.; Zhu, H. Evolution of c-ZrN nanopowders in low-carbon MgO–C refractories and their properties. J. Eur. Ceram. Soc. 2021, 41, 963–977. [Google Scholar] [CrossRef]

- Chandra, K.S.; Sarkar, D. Oxidation resistance, residual strength, and microstructural evolution in Al2O3-MgO–C refractory composites with YAG nanopowder. J. Eur. Ceram. Soc. 2021, 41, 3782–3797. [Google Scholar] [CrossRef]

- Zhong, H. The microstructure evolution and performance enhancement of MgO-C refractories by the addition of MA90 spinel micro-powder. J. Eur. Ceram. Soc. 2023. [Google Scholar] [CrossRef]

- Ren, X.; et al. Designing low-carbon MgO–Al2O3–La2O3–C refractories with balanced performance for ladle furnaces. J. Eur. Ceram. Soc. 2022, 42, 3986–3995. [Google Scholar] [CrossRef]

- Chen, Q.; et al. Enhanced performance of low-carbon MgO–C refractories with nano-sized ZrO2–Al2O3 composite powder. Ceram. Int. 2021, 47, 20178–20186. [Google Scholar] [CrossRef]

- Li, W.; et al. Application of Cr3C2/C composite powders synthesized via molten-salt method in low-carbon MgO–C refractories. Ceram. Int. 2022, 48, 15227–15235. [Google Scholar] [CrossRef]

- Chen, Y.; Ding, J.; Yu, C.; Lou, X.; Wu, Z.; Deng, C. Application of SiC whiskers synthesized from waste rice husk in low-carbon MgO–C refractories. J. Phys. Chem. Solids 2023, 177, 111304. [Google Scholar] [CrossRef]

- Luo, J.; et al. Recent progress in synthesis of composite powders and their applications in low-carbon refractories. J. Iron. Steel Res. Int 2022, 29, 1041–1051. [Google Scholar] [CrossRef]

- Guo, W. Improved slag corrosion resistance of MgO–C refractories with calcium magnesium aluminate aggregate and silicon carbide: Corrosion behavior and thermodynamic simulation. J. Eur. Ceram. Soc. 2023. [Google Scholar] [CrossRef]

- Han, J.S.; Heo, J.H.; Park, J.H. Interfacial reaction between magnesia refractory and ‘FeO’-rich slag: Formation of magnesiowüstite layer. Ceram. Int. 2019, 45, 10481–10491. [Google Scholar] [CrossRef]

- Liu, J.; Sheng, H.; Yang, X.; He, Z.; Hou, X. Research on the Wetting and Corrosion Behavior Between Converter Slag with Different Alkalinity and MgO-C Refractories. Oxid. Met. 2022, 97, 157–166. [Google Scholar] [CrossRef]

- Yehorov, A.; Ma, G.; Volkova, O. Interaction between MgO–C-bricks and ladle slag with a 1:1 CaO/Al2O3 ratio and varying SiO2 content. Ceram. Int. 2021, 47, 11677–11686. [Google Scholar] [CrossRef]

- Guo, M.; et al. Interaction of Al2O3-rich slag with MgO-C refractories during VOD refining-MgO and spinel layer formation at the slag/refractory interface. J. Eur. Ceram. Soc. 2009, 29, 1053–1060. [Google Scholar] [CrossRef]

- Heo, S.H.; Lee, K.; Chung, Y. Reactive wetting phenomena of MgO-C refractories in contact with CaO-SiO2 slag. Trans. Nonferrous Met. Soc. (English Edition) 2012, 12. [Google Scholar] [CrossRef]

- Liu, Z.; Yuan, L.; Jin, E.; Yang, X.; Yu, J. Wetting, spreading and corrosion behavior of molten slag on dense MgO and MgO-C refractory. Ceram. Int. 2019, 45, 718–724. [Google Scholar] [CrossRef]

- Lao, Y.; Li, G.; Gao, Y.; Yuan, C. Wetting and corrosion behavior of MgO substrates by CaO–Al2O3–SiO2–(MgO) molten slags. Ceram. Int. 2022, 48, 14799–14812. [Google Scholar] [CrossRef]

- Yehorov, A.; Ma, G.; Volkova, O. Interaction between MgO–C-bricks and ladle slag with a 1:1 CaO/Al2O3 ratio and varying SiO2 content. Ceram. Int. 2021, 47, 11677–11686. [Google Scholar] [CrossRef]

- Han, B.; Wang, C.; Yang, Q.; Changmin, K.; Chen, F.; Li, N. Corrosive Interaction between MgO-C Refractories and Vanadium-Recovery Slag. Interceram – Inter. Ceram. Rev. 2014, 63, 99–103. [Google Scholar] [CrossRef]

- Borisenko, O.N.; Semchenko, G.D.; Il’icheva, T.V. Slag resistance of periclase-carbon refractories based on modified phenol fomaldehyde resin. Refract. Ind. Ceram. 2010, 51, 41–44. [Google Scholar]

- Liu, Y.; Wang, Q.; Li, G.; Zhang, J.; Yan, W.; Huang, A. Role of graphite on the corrosion resistance improvement of MgO–C bricks to MnO-rich slag. Ceram. Int. 2020, 46, 7517–7522. [Google Scholar] [CrossRef]

- Benavidez, E.; Brandaleze, E.; Musante, L.; Galliano, P. Corrosion Study of MgO-C Bricks in Contact with a Steelmaking Slag. Procedia Mater. Sci. 2015, 8, 228–235. [Google Scholar] [CrossRef]

- Lee, S.; Chung, Y. The effect of C content in MgO–C on dissolution behavior in CaO–SiO2–Al2O3 slag. Ceram. Int. 2022, 48, 26984–26991. [Google Scholar] [CrossRef]

- Bai, R.; Liu, S.; Mao, F.X.; Zhang, Y.Y.; Yang, X.; He, Z. Wetting and corrosion behavior between magnesia–carbon refractory and converter slags with different MgO contents. J. Iron. Steel Res. Int. 2022, 29, 1073–1079. [Google Scholar] [CrossRef]

- Gehre, P.; et al. Thermodynamic calculation and microscopic examination of liquid phase formation in MgO–C refractories contain calcium magnesium aluminate. Mater. Chem. Phys. 2020, 256, 123723. [Google Scholar] [CrossRef]

- Preisker, T.; Gehre, P.; Schmidt, G.; Aneziris, C.G.; Wöhrmeyer, C.; Parr, C. Kinetics of the formation of protective slag layers on MgO–MgAl2O4–C ladle bricks determined in laboratory. Ceram. Int. 2020, 46, 452–459. [Google Scholar] [CrossRef]

- Wöhrmeyer, C.; Gao, S.; Ping, Z.; Parr, C.; Aneziris, C.G.; Gehre, P. Corrosion Mechanism of MgO–CMA–C Ladle Brick with High Service Life. Steel. Res. Int. 2020, 91, 1900436. [Google Scholar] [CrossRef]

- Ludwig, M.; et al. Recycled magnesia-carbon aggregate as the component of new type of MgO-C refractories. Constr. Build. Mater. 2021, 272, 121912. [Google Scholar] [CrossRef]

- Moritz, K.; et al. Recyclate-containing magnesia-carbon refractories – Influence on the non-metallic inclusions in steel. Open Ceram. 2023, 16, 100450. [Google Scholar] [CrossRef]

- Horckmans, L.; Nielsen, P.; Dierckx, P.; Ducastel, A. Recycling of refractory bricks used in basic steelmaking: A review. Resour., Conserv. Recycl. 2019, 140, 297–304. [Google Scholar] [CrossRef]

- Moritz, K.; Brachhold, N.; Küster, F.; Dudczig, S.; Schemmel, T.; Aneziris, C.G. Studies on the use of two different magnesia-carbon recyclates as secondary raw material for MgO–C refractories. Open Ceram. 2023, 15. [Google Scholar] [CrossRef]

- Steiner, R.; Lammer, G.; Spiel, C.; Jandl, C. Refractories 4.0. BHM Berg- Huttenmann. Monatsh 2017, 162, 514–520. [Google Scholar] [CrossRef]

- Ślusarczyk, B. Industry 4.0 – Are we ready? Pol. J. Manag. Stud. 2018, 17, 232–248. [Google Scholar] [CrossRef]

- Rajendra, P.; Girisha, A.; Naidu, T.G. Advancement of machine learning in materials science. Mater. Today. Proc. 2022, 62, 5503–5507. [Google Scholar] [CrossRef]

- Rydning, D.R.-J.G. The Digitization of the World From Edge to Core. International Data Corporation, Framingham, 2018.

- Pilania, G. Machine learning in materials science: From explainable predictions to autonomous design. Comput. Mater. Sci. 2021, 193, 110360. [Google Scholar] [CrossRef]

- Sarker, I.H. Machine Learning: Algorithms, Real-World Applications and Research Directions. SN Comput. Sci. 2021, 2. [Google Scholar] [CrossRef] [PubMed]

- Jain, N.; Kumar, R. A Review on Machine Learning & It’s Algorithms. Int. J. Soft Comp. Eng. 2022, 12, 1–5. [Google Scholar] [CrossRef]

- Pugliese, R.; Regondi, S.; Marini, R. Machine learning-based approach: Global trends, research directions, and regulatory standpoints. Data Sci. Manage. 2021, 4, 19–29. [Google Scholar] [CrossRef]

- Bhat, D.; Muench, S.; Roellig, M. Application of machine learning algorithms in prognostics and health monitoring of electronic systems: A review. Adv. Electr. Electron. Eng 2023, 4, 100166. [Google Scholar] [CrossRef]

- Nemati, Z.A.; Moetakef, P. Investigation of graphite oxidation kinetics in MgO-C composite via artificial neural network approach. Comput. Mater. Sci. 2007, 39, 723–728. [Google Scholar] [CrossRef]

- Nemati, A.; Nemati, E. Oxygen diffusion mechanism in MgO-C composites: An artificial neural network approach. Model Simul. Mat. Sci. Eng. 2012, 20. [Google Scholar] [CrossRef]

- Faghihi-Sani, M.A.; Yamaguchi, A. Oxidation kinetics of MgO-C refractory brick. Ceram. Int. 2002, 28, 835–839. [Google Scholar] [CrossRef]

- Sadrnezhaad, S.K.; Mahshid, S.; Hashemi, B.; Nemati, Z.A. Oxidation Mechanism of C in MgO-C Refractory Bricks. J. Am. Ceram. Soc. 2006, 89, 1308–1316. [Google Scholar] [CrossRef]

- Li, X.; Riguard, M.; Palco, S. Oxidation Kinetics of Graphite Phase in Magnesia-Carbon Refractories. J. Am. Ceram. Soc. 1995, 78, 965–971. [Google Scholar] [CrossRef]

- Mazloom, M.; Sarpoolaky, H.; Savabieh, H.R. Use of neural networks to optimize graphite content in magnesia-graphite refractories. Refract. Ind. Ceram. 2012, 53, 193–198. [Google Scholar] [CrossRef]

- Sado, S. Method of raw materials selection for production of the MgO-C bricks of comparable properties using PCA and K-medoids. Int. J. Appl. Ceram. Technol. 2023. [Google Scholar] [CrossRef]

- Akkurt, S. Prediction of the slag corrosion of MgO-C ladle refractories by the use of artificial neural networks. Key Eng. Mater. 2004, 264–268, 1727–1730. [Google Scholar] [CrossRef]

- Hou, A.; Jin, S.; Harmuth, H.; Gruber, D. Thermal and Thermomechanical Responses Prediction of a Steel Ladle Using a Back-Propagation Artificial Neural Network Combining Multiple Orthogonal Arrays. Steel Res. Int. 2019, 90. [Google Scholar] [CrossRef]

- Hou, A.; Jin, S.; Gruber, D.; Harmuth, H. Influence of variation/response space complexity and variable completeness on BP-ANN model establishment: Case study of steel ladle lining. Appl. Sci. 2019, 9. [Google Scholar] [CrossRef]

- Hou, A.; Jin, S.; Gruber, D.; Harmuth, H. Modelling of a steel ladle and prediction of its thermomechanical behavior by finite element simulation together with artificial neural network approaches. 2019. Available online: https://www.researchgate.net/publication/334304593.

- Borges, R.A.A.; Antoniassi, N.P.; Klotz, L.E.; de Carvalho Carneiro, C.; Silva, G.F.B.L.E. A Statistical and Self-Organizing Maps (SOM) Comparative Study on the Wear and Performance of MgO-C Resin Bonded Refractories Used on the Slag Line of Ladles of a Basic Oxygen Steelmaking Plant. Metall. Mater. Trans. B. 2022, 53, 2852–2866. [Google Scholar] [CrossRef]

- Jančar, D.; Machů, M.; Velička, M.; Tvardek, P.; Kocián, L.; Vlček, J. Use of Neural Networks for Lifetime Analysis of Teeming Ladles. Materials 2022, 15. [Google Scholar] [CrossRef] [PubMed]

- Yemelyanov, V.A.; Yemelyanova, N.Y.; Nedelkin, A.A.; Zarudnaya, M.V. Neural network to diagnose lining condition. In IOP Conference Series: Materials Science and Engineering; 2017; Volume 327. [Google Scholar] [CrossRef]

- Zelik, W.; Lech, R.; Sado, S.; Labuz, A.; Lasota, A.; Lis, S. Modelling the Wear of MC 98/15 Refractory Material in the Slag Spout Zone of an Oxygen Converter with the Use of Artificial Neural Networks. J. Ceram. Sci. Technol 2020, 11, 81–90. [Google Scholar] [CrossRef]

- Sado, S.; Zelik, W.; Lech, R. Use of Machine Learning for modelling the wear of MgO-C refractories in Basic Oxygen Furnace. J. Ceram. Process. Res. 2022, 23, 421–429. [Google Scholar] [CrossRef]

| Sample | Compressive strength [MPa] | Apparent porosity [%] |

|---|---|---|

| F1 | 381.20 | - |

| F2 | 375.91 | - |

| F3 | 371.25 | - |

| F4 | 377.54 | - |

| F5 | - | 7.05 |

| F6 | - | 7.18 |

| F7 | - | 7.09 |

| Average experimental value | 376.47 | 7.11 |

| Predicted value (ANN) | 365.16 | 7.08 |

| Error, %* | 1.30 | 0.35 |

| % Area loss - measured | % Area loss - predicted | Difference | % Error (absolute) |

|---|---|---|---|

| 10.57 | 12.43 | -1.86 | 17.6 |

| 10.85 | 14.57 | -3.72 | 34.3 |

| 14.65 | 14.85 | -0.20 | 1.4 |

| 18.99 | 18.94 | 0.05 | 0.3 |

| 19.20 | 18.05 | 1.15 | 6.0 |

| 32.34 | 24.80 | 7.54 | 23.3 |

| 15.67 | 18.27 | -2.60 | 16.6 |

| Average | - | - | 14.2 |

| End temperature [°C] |

Maximum tensile stress [MPa] |

Maximum compressive stress [MPa] | ||||

|---|---|---|---|---|---|---|

| Used algorithm | CFG | BR | CFG | BR | CFG | BR |

| RE_MAX [%] | 7.15 | 7.15 | 16.62 | 12.43 | 3.12 | 4.09 |

| MRE [%] | 1.02 | 1.76 | 2.43 | 2.37 | 0.93 | 0.78 |

| B | 0.9967 | 0.9908 | 0.9279 | 0.9348 | 0.9963 | 0.9966 |

| Thickness [mm] |

Thermal conductivity [W·m-1K-1] |

Young’s modulus [GPa] | Thermal expansion coefficient [10-6K-1] |

|

|---|---|---|---|---|

| Working lining | 155.0 | 9 | 40 | 12 |

| Permanent lining | 52.5 | 2.2 | 45 | 5 |

| Insulation (lining concept 1) |

37.5 | 0.5 | 3 | 6 |

| Insulation (lining concept 2) |

37.5 | 0.38 | 4 | 5.6 |

| Steel shell | 30 | 50 | 210 | 12.0 |

| Predicted wear class | Real wear class | |||||||||||

| 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | ∑ | ||

| 0 | 226 | 60 | 19 | 0 | 4 | 0 | 1 | 0 | 0 | 0 | 310 | |

| 1 | 63 | 128 | 2 | 0 | 4 | 0 | 12 | 0 | 0 | 0 | 209 | |

| 2 | 9 | 1 | 6 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 16 | |

| 3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 4 | 12 | 12 | 10 | 0 | 0 | 0 | 7 | 0 | 0 | 8 | 49 | |

| 5 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 6 | 0 | 6 | 0 | 0 | 5 | 0 | 5 | 0 | 0 | 0 | 16 | |

| 7 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 8 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 9 | 0 | 10 | 0 | 0 | 6 | 0 | 2 | 0 | 0 | 7 | 25 | |

| ∑ | 310 | 217 | 37 | 0 | 19 | 0 | 27 | 0 | 0 | 15 | 625 | |

| Training data set | |||||||

| Algorithm | SSE | MSE | RMSE | R2 | R | MAPE | MAE |

| CART | 6.811 | 0.004 | 0.065 | 0.559 | 0.747 | 24.673% | 0.057 |

| MARS | 4.195 | 0.002 | 0.051 | 0.716 | 0.846 | 17.987% | 0.047 |

| Boosted Trees | 1.590 | 0.001 | 0.031 | 0.899 | 0.948 | 11.086% | 0.029 |

| ANN | 3.521 | 0.002 | 0.047 | 0.789 | 0.886 | 16.012% | 0.041 |

| Testing data set | |||||||

| CART | 5.445 | 0.008 | 0.091 | 0.429 | 0.655 | 27.598% | 0.066 |

| MARS | 3.329 | 0.005 | 0.071 | 0.649 | 0.805 | 21.316% | 0.054 |

| Boosted Trees | 1.458 | 0.002 | 0.047 | 0.849 | 0.921 | 13.439% | 0.035 |

| ANN | 2.932 | 0.004 | 0.066 | 0.687 | 0.829 | 20.233% | 0.049 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).