1. Introduction

The rotary table plays a crucial role in the field of high-precision angle measurement. They can be broadly classified as mechanical, electromagnetic and photoelectric, with photoelectric rotary tables being the most widely used, offering the advantages of high accuracy[

1], a wide measurement range and high immunity to interference. The photoelectric rotary table consists of a rotating shaft, a photoelectric reading head and an internal circular grating. During the rotation process, the relative movement of the grating pair produces changing moiré fringe, and the moiré signal corresponding to the displacement output by the photoelectric reading head[

2]. There are quite a few factors affecting the accuracy of the rotary table[

3], which can be roughly divided into inherent error and application-dependent error[

4], of which the eccentricity error in application-dependent error is the most important factor affecting the accuracy of angle measurement[

5,

6,

7], therefore separating the eccentricity error is of great value to ensure the accuracy of the rotary table.

The separation methods for the eccentricity error of the rotary table can be divided into two types[

8,

9,

10,

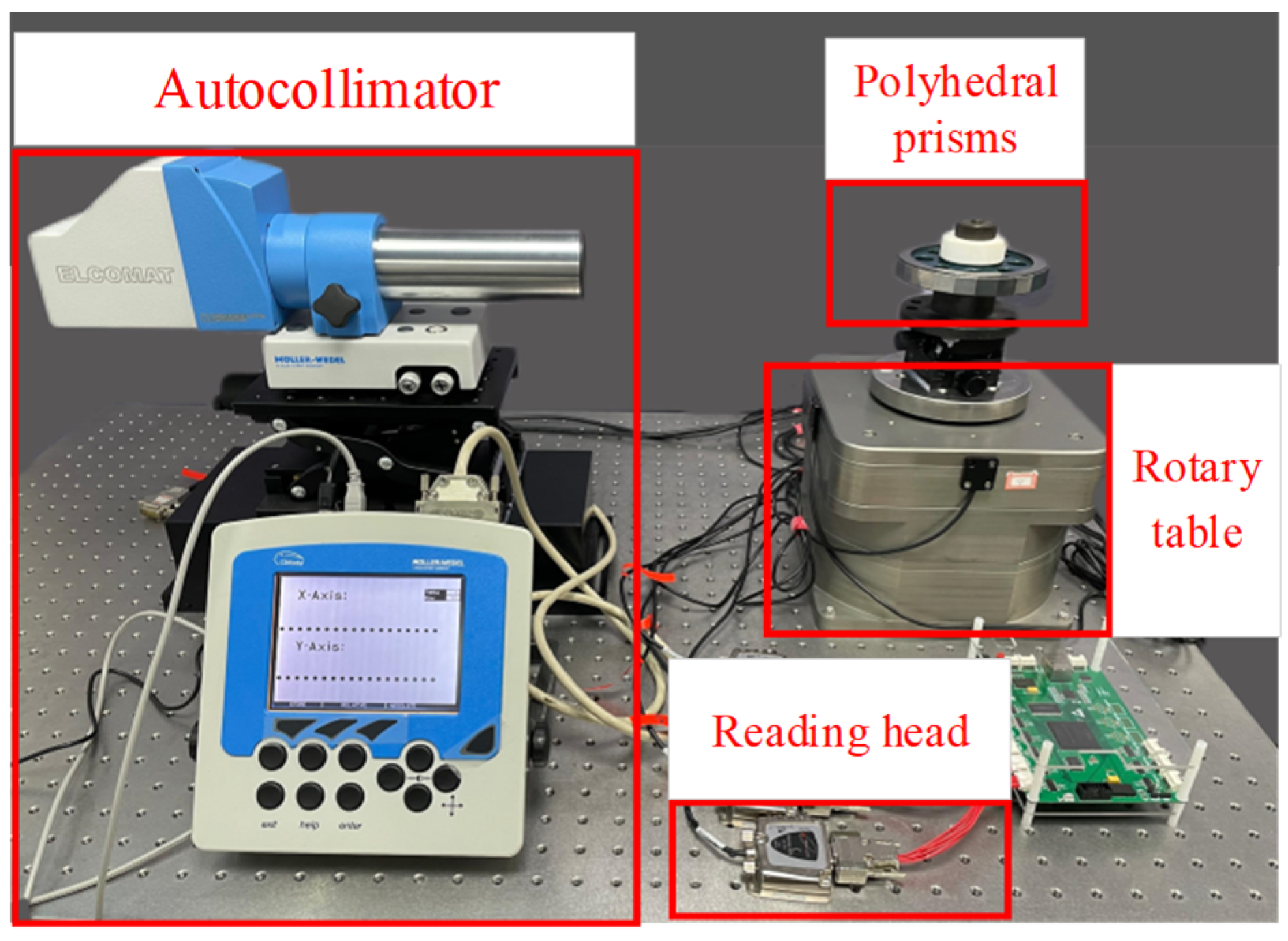

11]. One is based on the fundamental of circumferential closure property, external calibration devices are used to separate the eccentricity error components of the rotary table by calibrating the discrete positioning error curve of the entire circumference of the rotary table. Chen Xi-jun et al.[

12] established the moiré fringe equation with eccentricity error, derived the equation of angle measurement error caused by eccentricity error, calibrated rotary table using a polyhedral prism, and fitted the angle measurement error equation of the rotary table and the eccentricity error of the rotary table. Mi Xiao-tao et al.[

13] analyzed the relationship between the angular measurement results and the error caused by the eccentricity error, calibrated the discrete angular measurement error by polyhedral prism and autocollimator, fitted the angular measurement error function through the least-squares fitting method , and separated the eccentricity error of the circular grating. Zheng Da-teng, et al.[

14] established the relationship model between the eccentricity error and the angle measurement error of AACMM (Articulated Arm Coordinate Measuring Machine), calibrated the angle measurement error with polyhedral prism, and fitted the compensation function of the angle measurement error and the eccentricity error with nonlinear least square method. Although this kind of methods have high accuracy in separating eccentricity error, it has high requirements for the operating environment and device accuracy, and there is a difficulty of cumbersome operating steps.

Another kind of methods are realized with various sensors to achieve eccentricity error separation in the rotary table[

15,

16,

17]. Ai Cheng-guang et al.[

18] proposed an eccentricity error separation model based on non-diametric dual reading heads, compared the phase difference of the moiré signals received by the dual reading heads and separated the eccentricity error and the eccentricity error direction of the circular grating in the platform by synthesizing the Lissajous graph of the signals. Feng Chao-peng et al.[

19] developed a model for the eccentricity error of dual reading heads, derived a self-calibration equation for the eccentricity error parameters of a circular grating based on the dual reading heads, and solved for the eccentricity error parameters by experimentally self-calibrating the eccentricity error parameters of a circular grating with double reading heads installed diametrically opposite, thereby achieving the separation of the eccentricity error of a circular grating. A fast least square fitting method for calculating eccentricity error was proposed by Zhu San-ying et al.[

20], who combined a laser displacement sensor with the proposed fast algorithm to accurately and quickly separate the eccentricity error of the device. Wang Ya-zhou et al.[

21] proposed a grating eccentricity error detection system based on image-based angular displacement measurement and used two pairs of diameter image sensors to separate the grating eccentricity error. This kind of methods are relatively simple and fast, but multiple sensors are required and the internal structure of the rotary table often needs to be exposed.

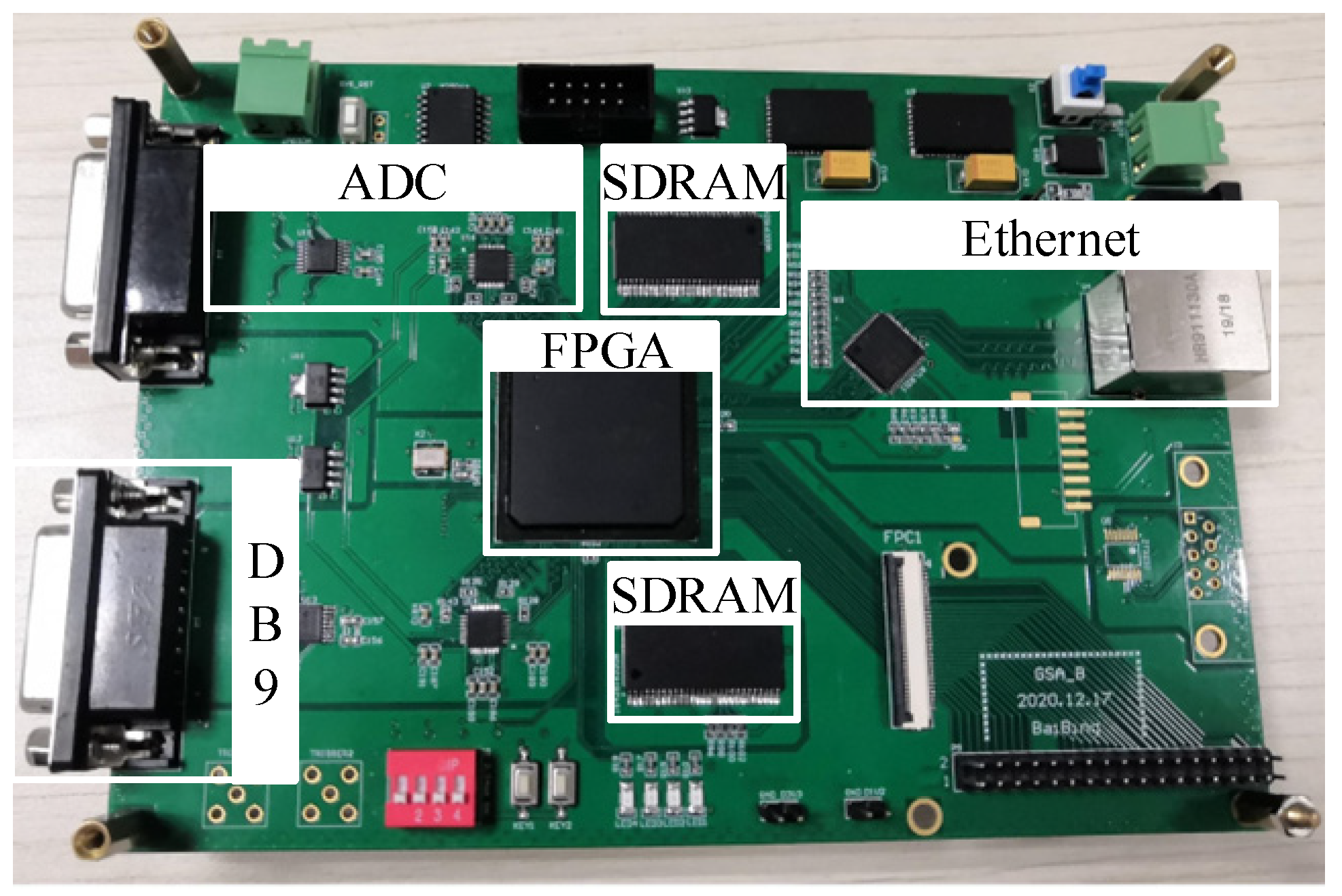

Focus on the limitations of the two kinds of eccentricity error separation methods, a method for separating eccentricity error based on the signal of single reading head of the rotary table is proposed in this paper. By establishing grating pair transmission model, the influence of eccentricity error on the phase feature of the moiré signal in the rotation course of the rotary table is clarified, thereby a model for the relationship between the phase spectrum components and eccentricity error is established. The verification and comparison experiments of the eccentricity error separation method are carried out based on the laboratory-made circuit system, and the experimental results prove the effectiveness and accuracy of the proposed method.

2. Model of the proposed method

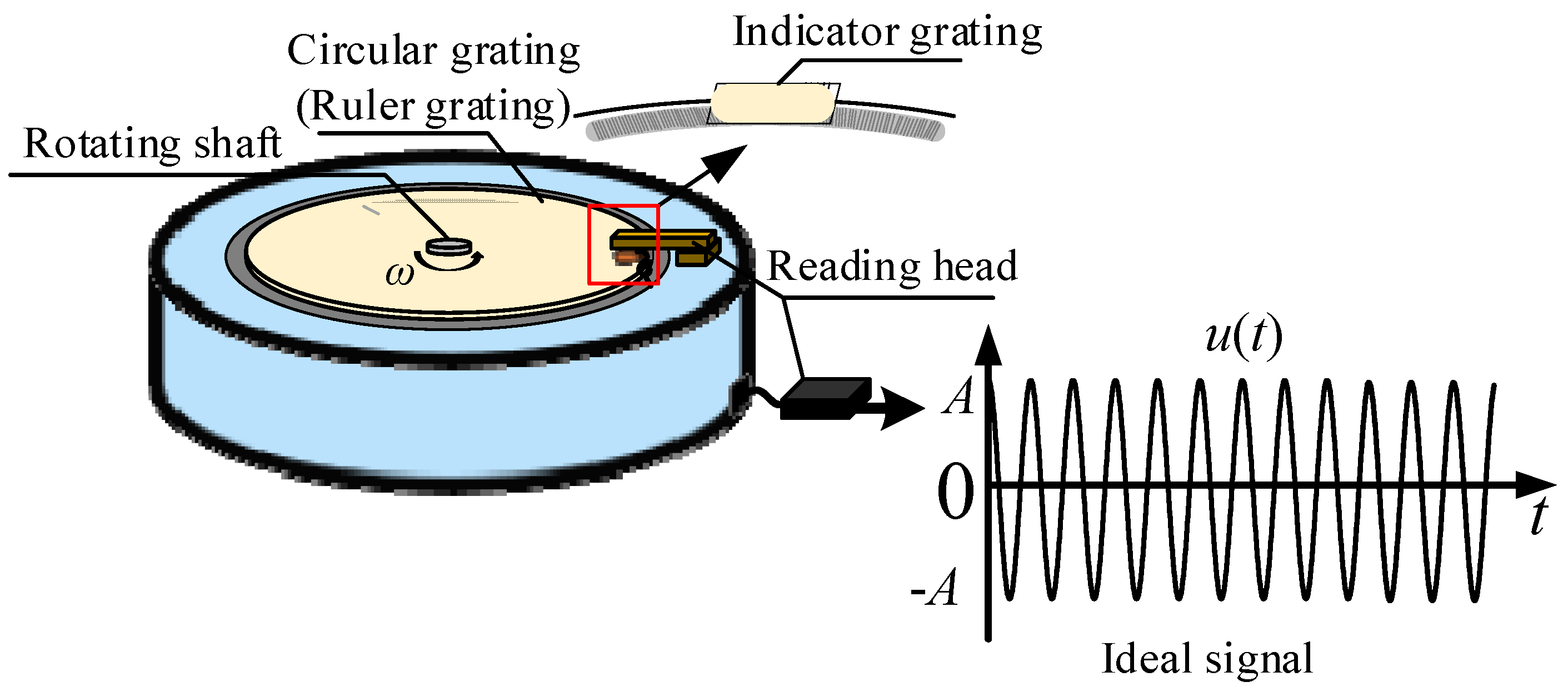

The photoelectric rotary table is mainly composed of a rotating shaft, an internal circular grating and a grating reading head. The internal grating in the reading head is the indicative grating and the circular grating is the scale grating. The two of them form the grating pair. The schematic of the structure of rotary table is shown in

Figure 1.

As shown in

Figure 1, when rotating at a constant speed

ω, the output moiré signal, defined as

u(

t), is with constant frequency and amplitude. The period of

u(

t) corresponds to the indexing angle of the grating line.

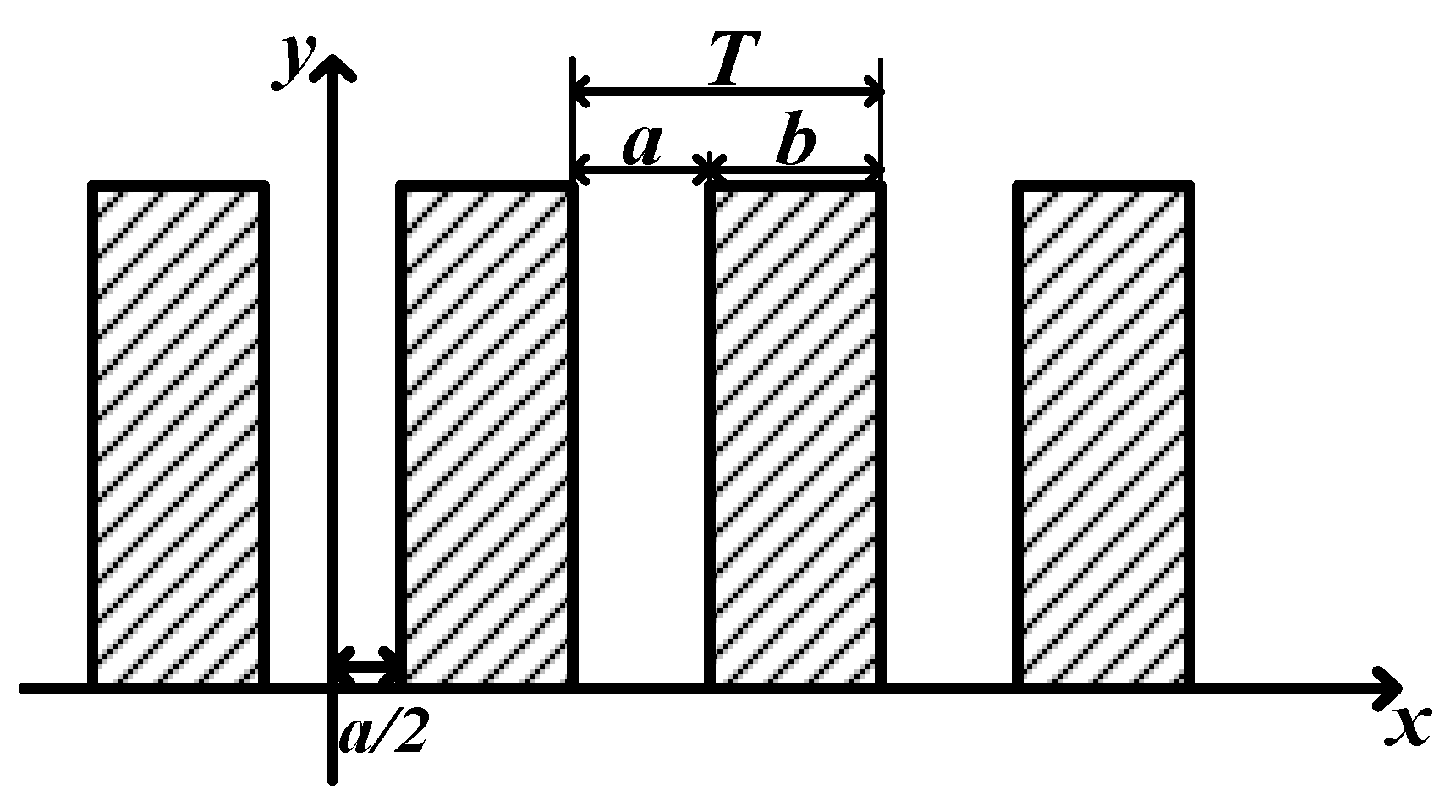

Due to the small receiving field of the reading head, usually at the millimeter level, the indicative grating and scale grating of the rotary table can both be regarded as a single rectangular grating as shown in

Figure 2.

In the

xoy plane where the grating lines are located, the

x direction is the vertical grating line direction and the grating lines are evenly distributed. Setting the grating pitch is

T, the length of the shading area is

b and the light transmittance is zero while the length of the light-transmitting area is

a and the light transmittance is equal to one. For the parallel light emitted from the reading head, grating transmission function

L(

x) can be described as

Extend the Fourier Series on

L(

x), and its complex form can be written as

Where

v is the spatial frequency of the grating and

v=1/

T. An is the Fourier coefficient and

n=0,±1,±2,… . The expression of An is shown in equation (3).

Where β=a/T. The transmission functions of the scale grating and the indicative grating follow the above basic equation.

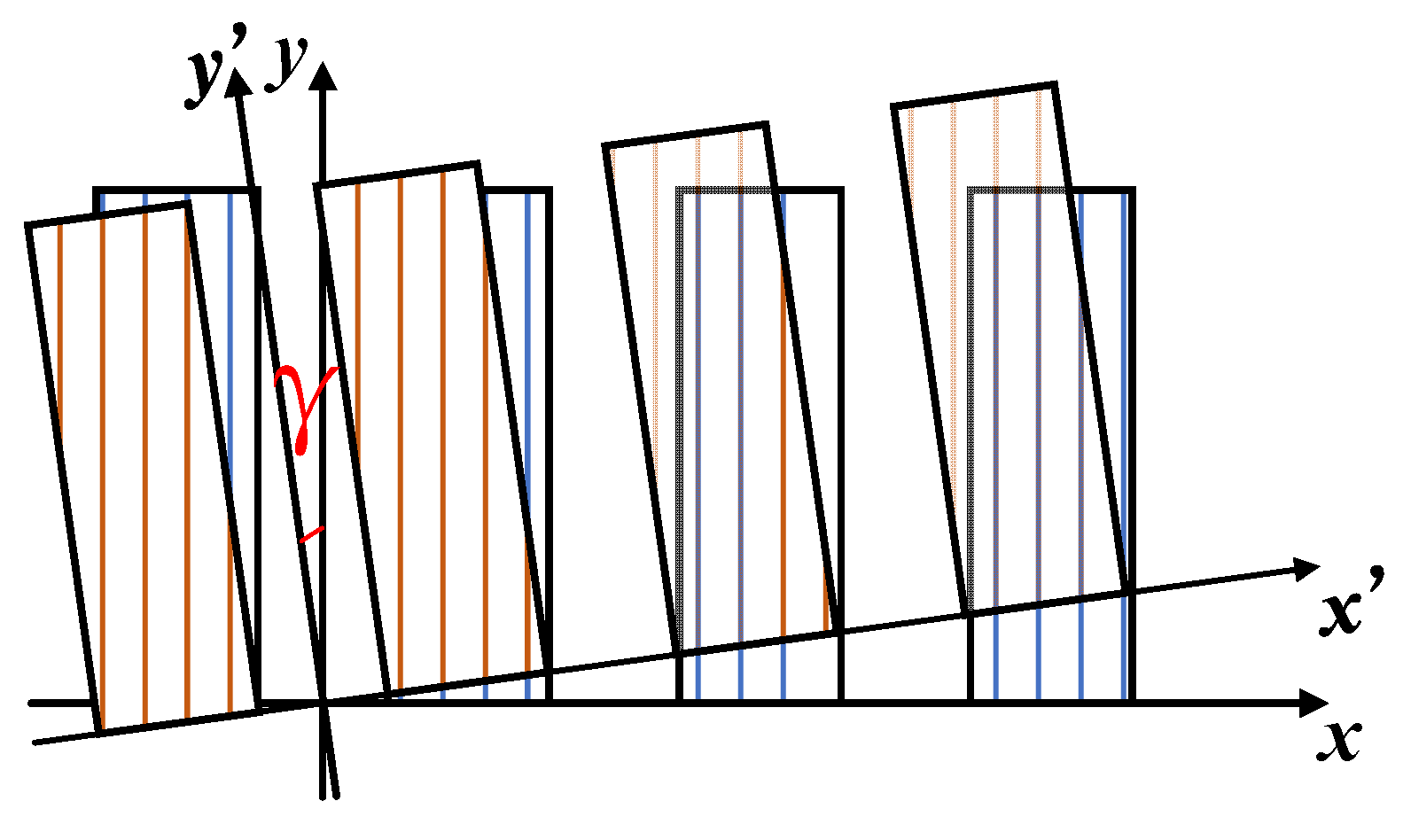

In the actual measurement process, the indicative grating and the scale grating are not completely overlapping, and there is a certain angle of

γ. The schematic diagram of the relative position of the two gratings is shown in

Figure 3.

When the indicative grating and the scale grating are superimposed, the indicative grating decomposes the incident light into plane wave arrays in different propagation directions, namely expands the incident light into the amplitude distribution of the cosine primitive. For the scale grating, the plane waves in each direction of the indicative grating are incident waves, that is to say the indicative grating decomposes the parallel light and the scale grating subsequently modulates the decomposed light field. The transmission functions of

L1(

x) and

L2(

x ,

y) of the two gratings can be expressed as

Where

v1 and

v2 are the spatial frequencies of the indicative grating and scale grating respectively.

An and

Bm are the Fourier Series of the two transmission functions, respectively. The transmission function

M(

x,

y) of the moiré fringe composed of the scale grating and the indicative grating is

equation (5) is the transmission function of the grating pair inside the rotary table under the ideal condition.

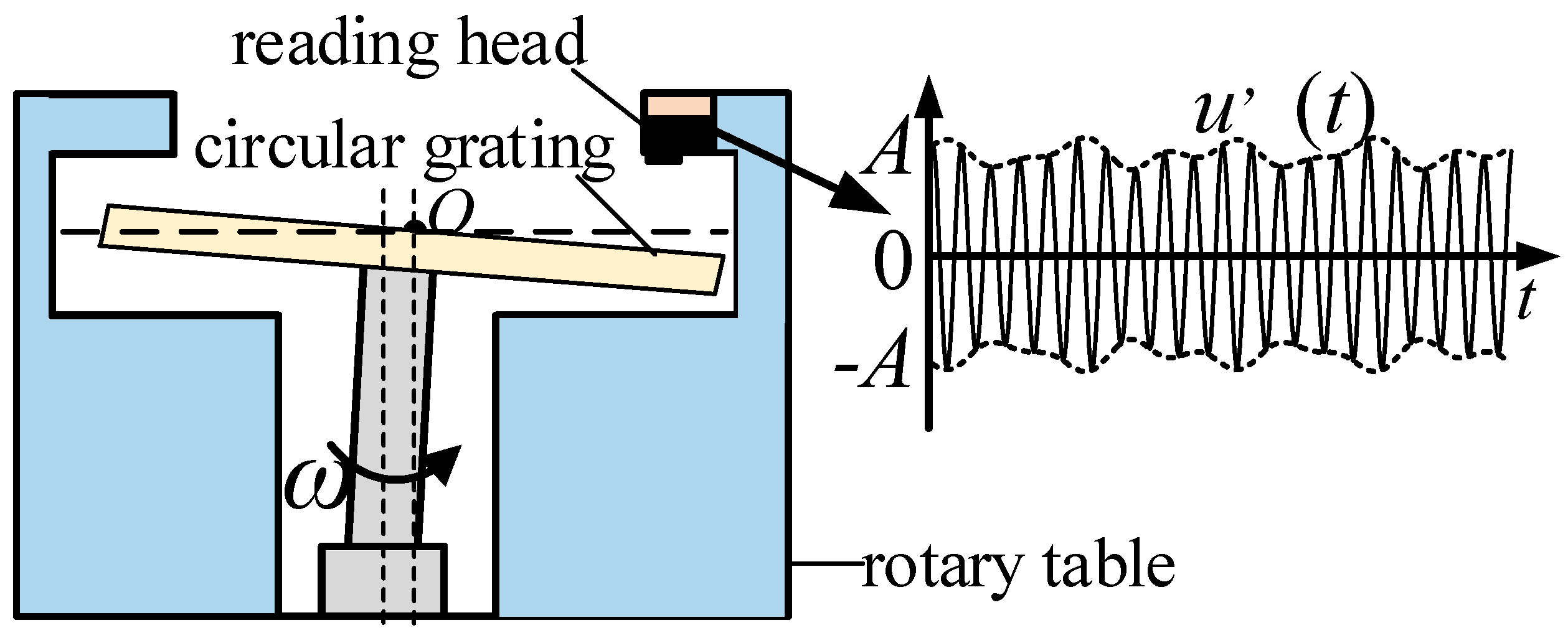

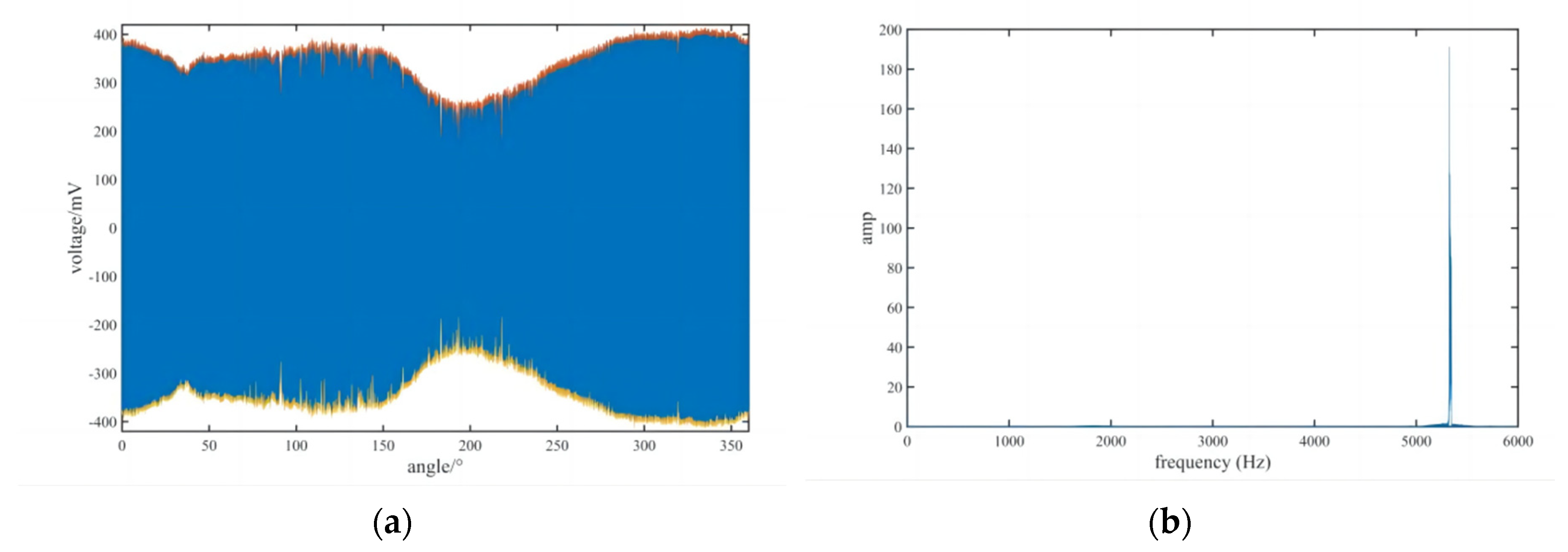

In actual working situation, the rotary table is affected by factors such as mechanical wear, installation errors, thereby the internal attitude will deviate. The actual structure of the internal section of the rotary table and the output moiré signal, which is defined as

u’(

t), are shown in

Figure 4.

It can be seen from

Figure 4 that due to the change of the internal attitude of the rotary table, the relative position of the indicative grating and the scale grating is displaced. The output light intensity of the incident light irradiated in the grating pair changes, subsequently the output moiré signal is different from the ideal moiré signal. The difference in amplitude and phase between the output moiré signal and the ideal moiré signal is collectively called the feature of moiré signal.

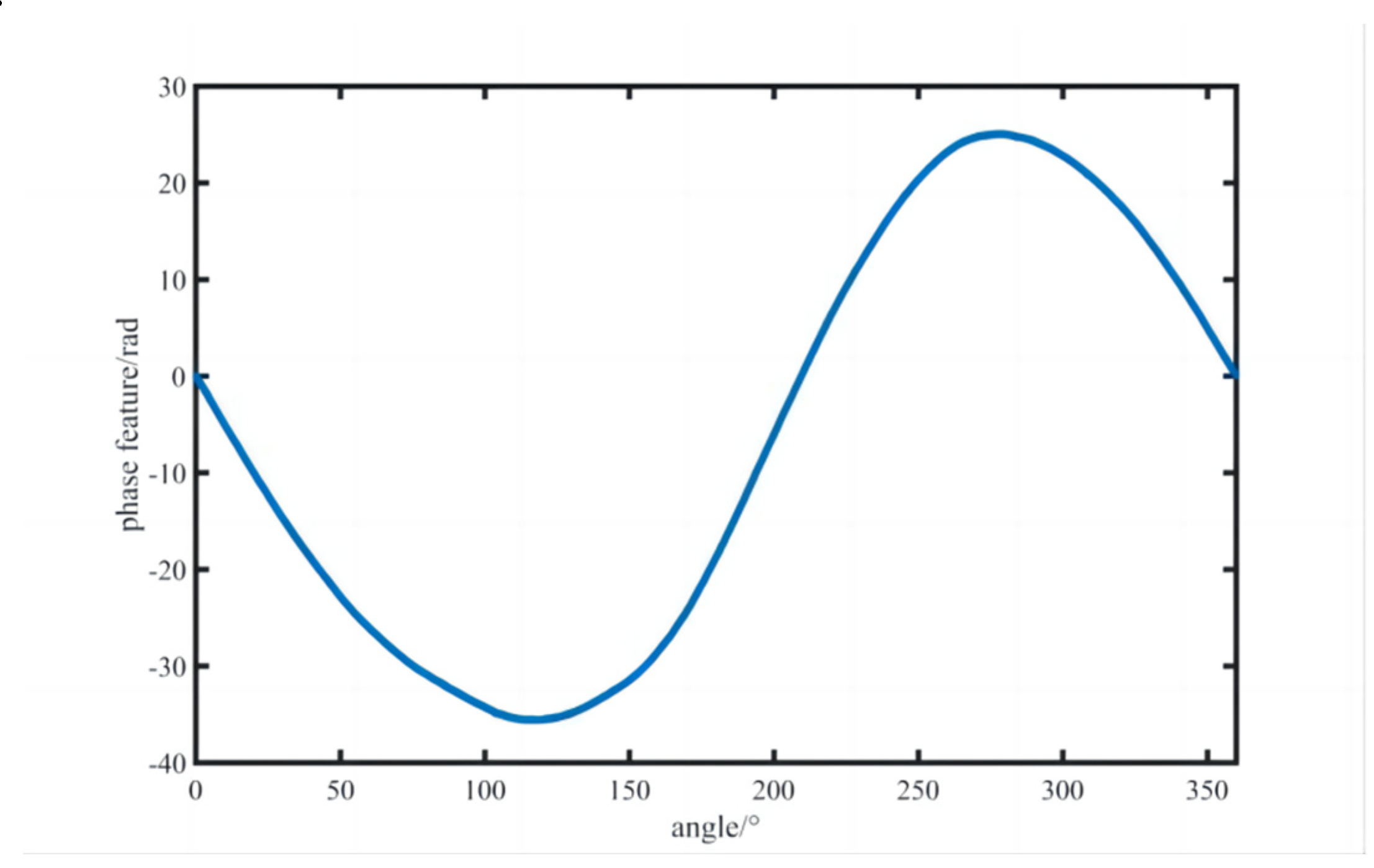

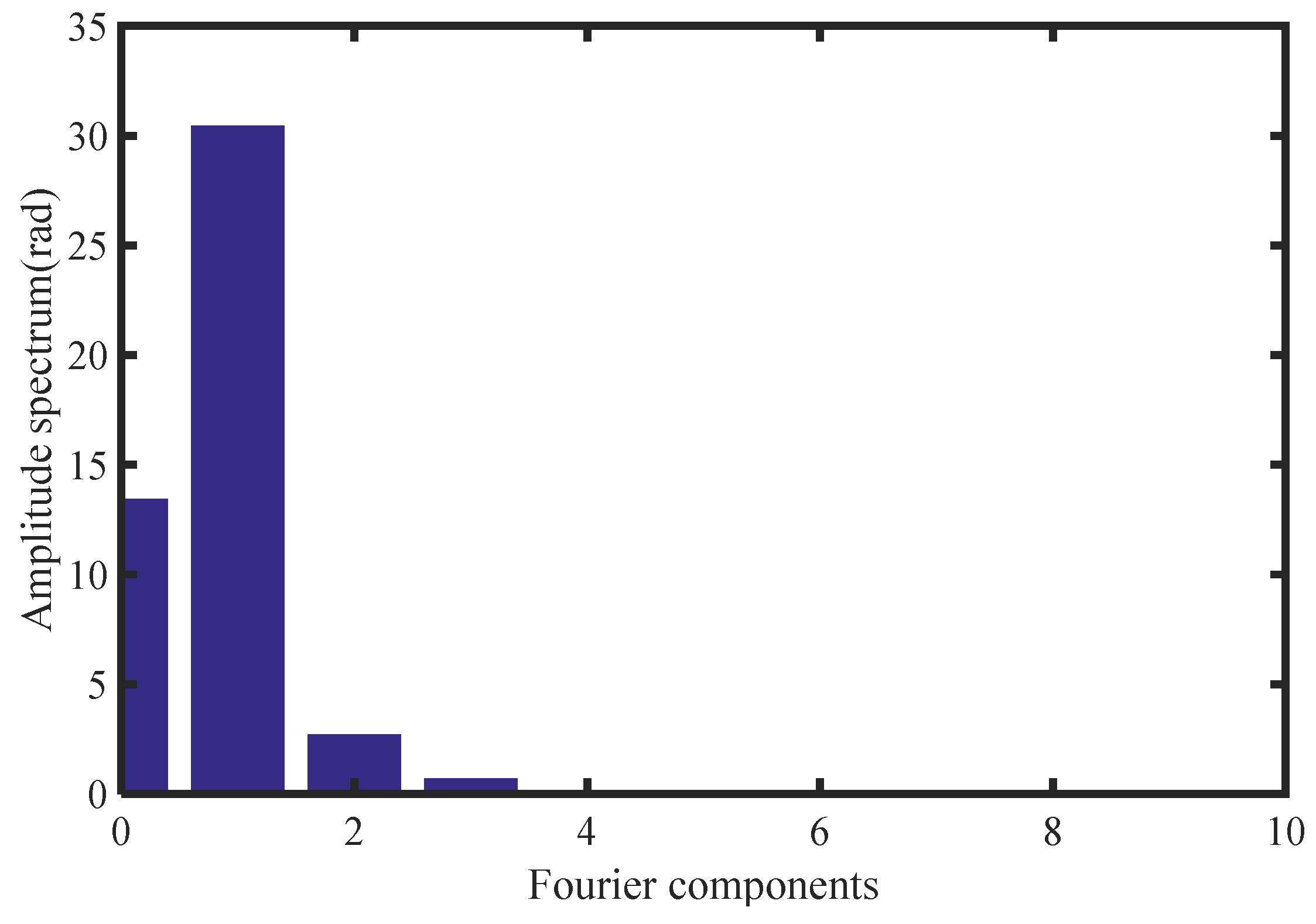

The phase feature of moiré signal, defined as

φm(

t), is used to realize the eccentricity error separation of the rotary table in this paper. Since the rotary table is affected by quite a few factors in the actual rotation, the

φm(

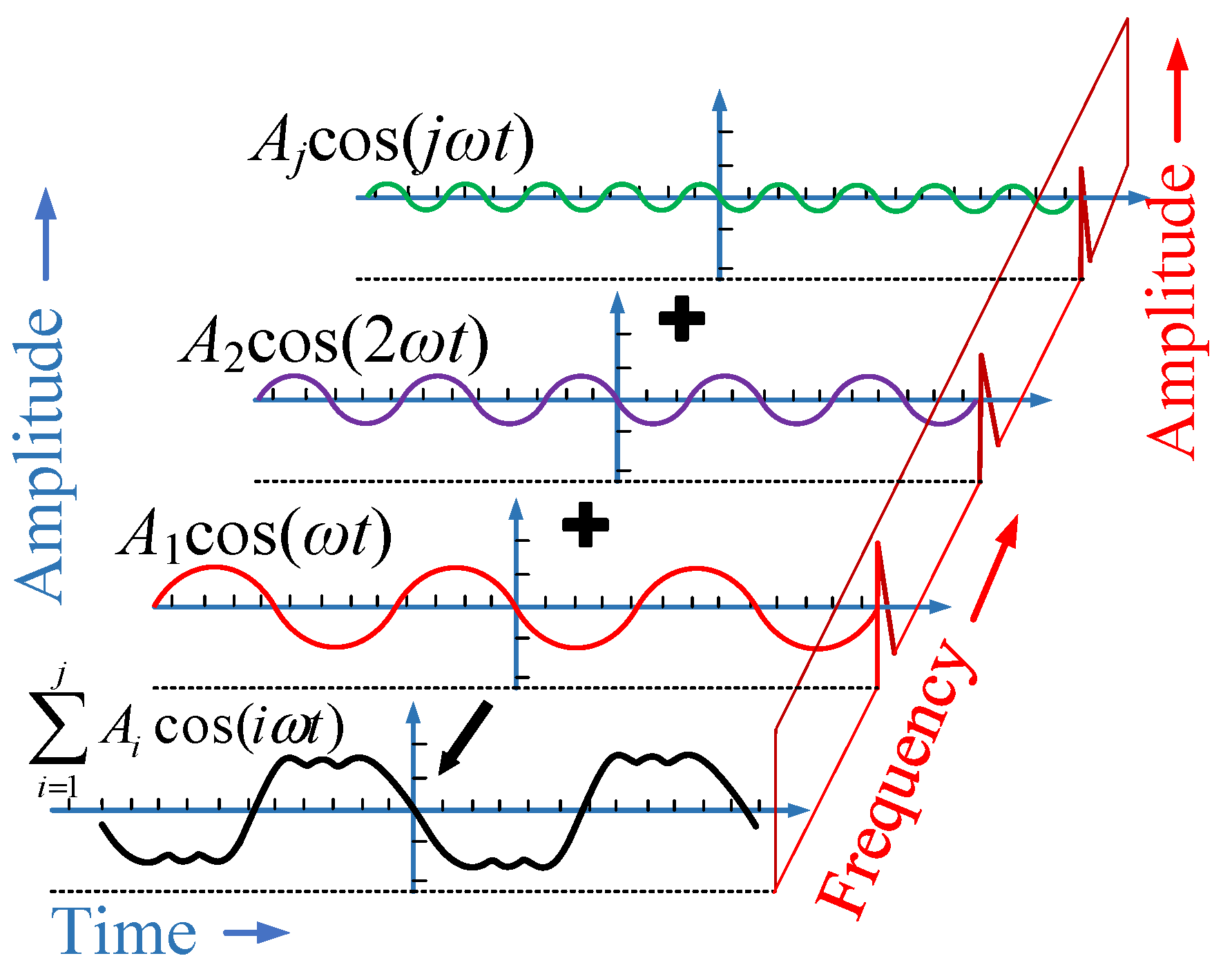

t) can be regarded as a composite waveform formed by the superposition and mixture of various frequency harmonics, as shown in

Figure 5.

In this figure, Aicos(iωt), i=1,2…are the harmonic components of the feature of moiré signal caused by system error factors of the rotary table, where Ai are the amplitude of the harmonic and i is the order of the harmonic. The feature of moiré signal of the rotary table is formed by superposition and addition of harmonic components of each order. Since the period of the eccentricity error of the rotary table is 2π, the phase feature of moiré signal caused by eccentricity error, defined as φme(t), corresponds to the first-order component of φm(t), which accounts for the largest proportion in the feature of moiré signal, namely has the greatest influence on the amplitude and phase of the moiré signal.

The schematic diagram of the displacement error of the rotary table affected by the eccentricity error is shown in

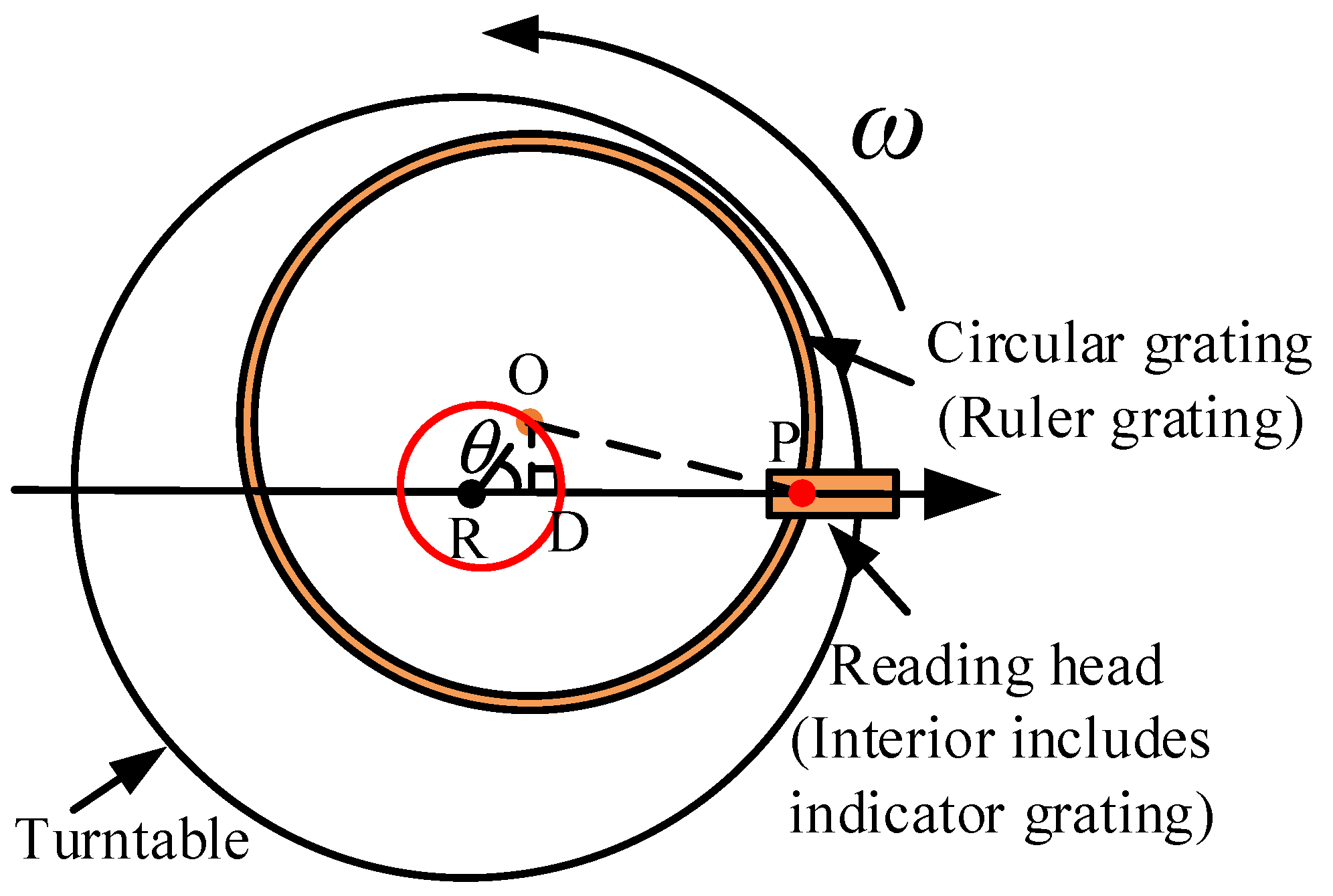

Figure 6.

As shown in

Figure 6, when the rotary table rotates at the speed of

ω, due to the eccentricity error, defined as

e, the grating rotation center, R, and the geometric center,

O, do not coincide. A displacement error, defined as

Le(

θ), will be generated during the rotation of the grating with the rotary table.

Establish the x-axis from the grating rotation center, R, to the reading head as the positive direction. The intersection point between the outer side of marking line of the circular grating and the positive semi-axis of the x-axis is defined as P. Subsequently, OP is the radius of the grating, and the variation of RP with the angular position of the rotary table , θ, is defined as Le(θ), namely the displacement error of rotary table.

Since

OD⊥

RP as well as

RO and

RD are in micron level in actual working conditions, it is thus clear that

The

Le(

θ) can be described as

Le(

θ), which is introduced by eccentricity error of rotary table, will affects the transmission function of the grating pair of the rotary table. The transmission function of the scale grating affected by the eccentricity error, defined as

L2’(

x-

x’(

θ),

y), can be expressed as

Where

x’(

θ) is the relative displacement of the two gratings, which is changing with

θ, caused by the attitude error of the rotary table. At this time, the transmission function of the moiré fringe composed of the scale grating and the indicative grating,

M(

x,

y), can be described as

The moiré fringe consist of contents produced by the beat phenomenon between two gratings. The content of the largest spatial period in the light intensity distribution constitutes the fundamental wave of the moiré fringe, and the general expression of the largest period moiré fringe produced by the beat phenomenon is obtained by taking

m= -

n in equation (9).

In (10),

Vx and

Vy are the components of the spatial frequency of the light intensity function in the

x-axis and

y-axis directions respectively and both of them are constants. Defined the intensity of the parallel light emitted from the reading head as

Ir, the outgoing light intensity generated by the light passing through the indicative grating and scale grating , defined as

Ic(

x-

x’(

θ),

y), can be expressed as

When the photoelectric conversion rate of the photoelectric receiver is

k and the rotational speed of the rotary table is

ω, the output moiré signal by the rotary table,

u’(

t), can be expressed as

From (12), it can be seen that the rotary table is affected by the eccentricity error during the rotation process, and the introduced phase feature of moiré signal,

φme(

t), can be expressed as

When the grating pitch is 20μm, the spatial frequency

v2 of the scale grating in the rotary table is 1/20μm. In the actual working condition, the angle of

γ between the indicative grating and the scale grating in the rotary table is insignificant, and the cos

γ in (13) is approximately equal to one, so (13) can be simplified as

Since

φme(

t) is the first-order component of

φm(

t) in the frequency domain and the corresponding frequency-domain amplitude is

A(1), according to (14), the relationship between the first-order amplitude,

A(1), and the eccentricity error, e, is as follows

The expression of the eccentricity error of the rotary table is

Since v2 is the spatial frequency of the scale grating, which is a constant in a fixed rotary table, it can be seen that the eccentricity error of the rotary table is directly proportional to the first-order component of φm(t) in the frequency domain.