Submitted:

22 September 2023

Posted:

22 September 2023

You are already at the latest version

Abstract

Keywords:

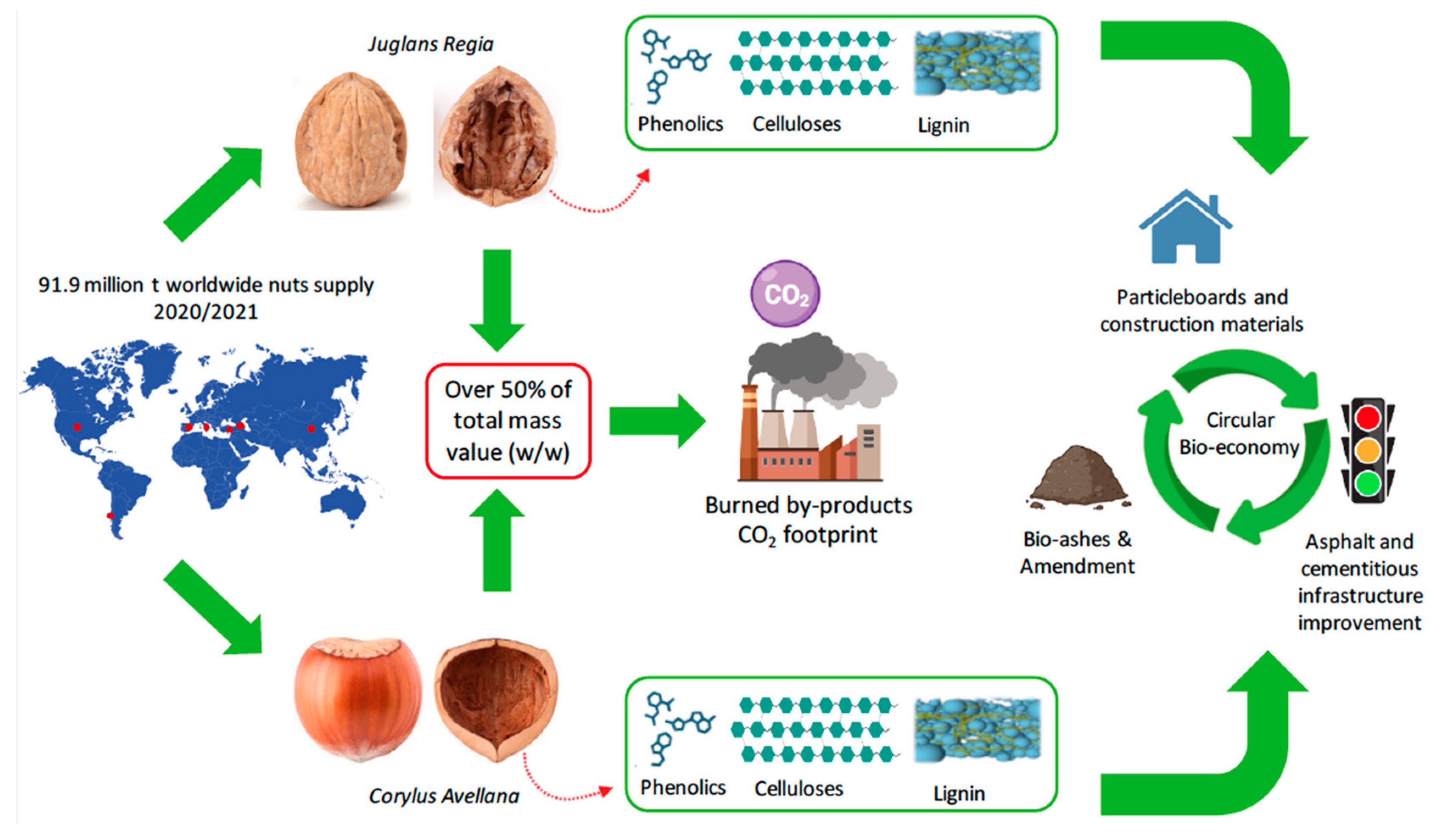

Introduction

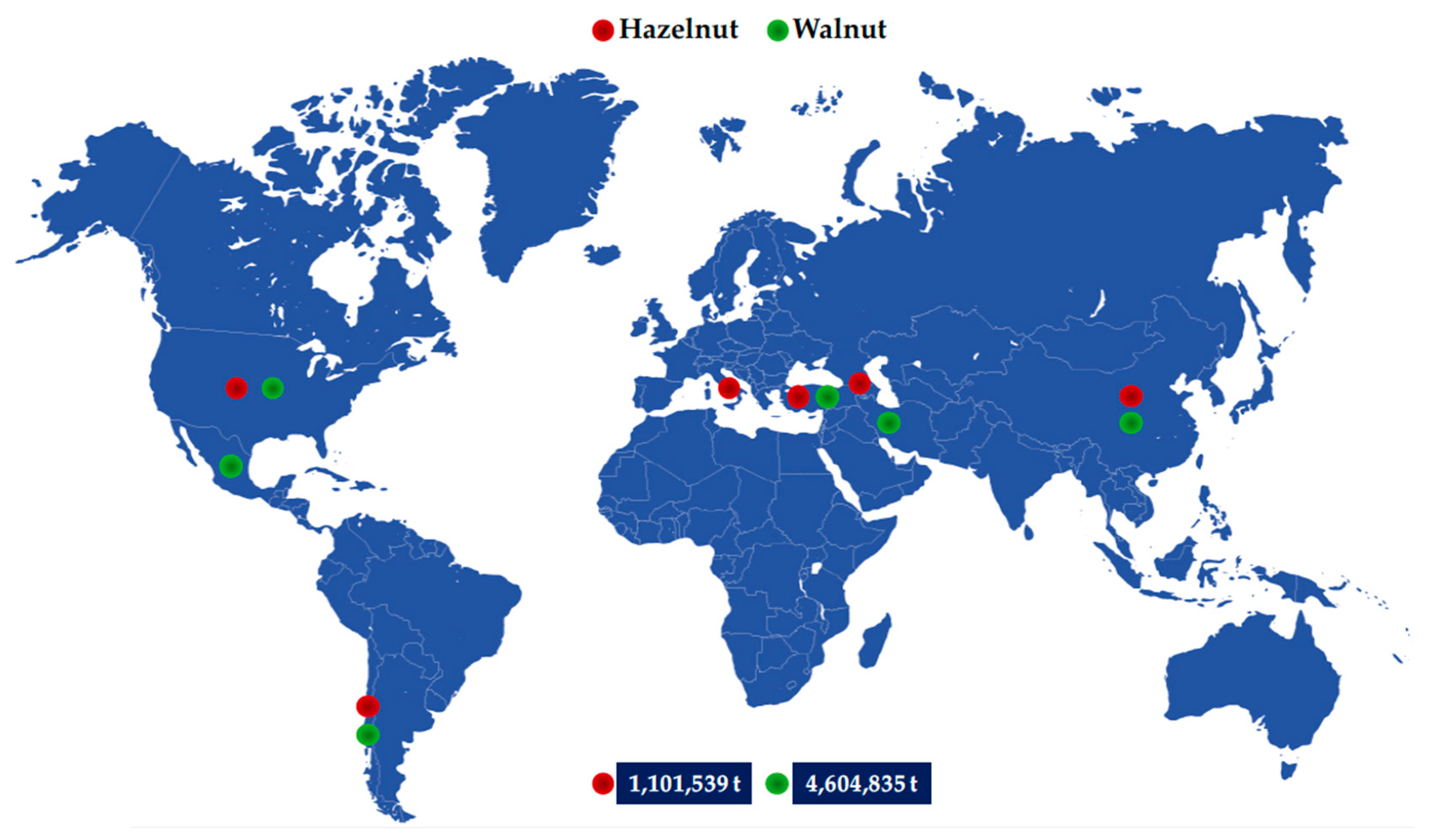

2. Productive context and expectative of hazelnut and walnut shells: Potential by-product availability/accessibility

3. Nutshell as source of valuable biochemical components

3.1. Main chemical composition

3.2. Antioxidant properties

4. Physical features of hazelnut and walnut shells

4.1. Density and solubility

4.2. Mass yield and morphological features

4.3. Nutshell cracking point

5. Industrial reincorporation for potential applications

6. Outlooks

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- USDA, Tree nuts: World Markets and Trade. https://usda.library.cornell.edu/concern/publications/tm70mv16z?locale=en. Accessed 03, November 2022.

- Du, F., and Tan, T. (2021). Recent Studies in Mechanical Properties of Selected Hard Shelled Seeds: A Review. JOM, 73(6), 1723-1735. [CrossRef]

- FAOSTAT. (2023). Agriculture data. Available online: https://www.fao.org/faostat/es/#data/QCL. (Accessed on May 03th, 2023).

- Demirbas, A (1999). Properties of charcoal derived from hazelnut shell and the production of briquettes using pyrolytic oil. Energy, 24, 141–150. [CrossRef]

- Haykiri-Acma, H., Yaman, S., and Kucukbayrak, S. (2017). Effects of torrefaction on lignin-rich biomass (hazelnut shell): Structural variations. J. Renew. Sustain. Energy, 9(6). [CrossRef]

- Rivas, S., Moure, A., and Parajó, J. C. (2020). Pretreatment of hazelnut shells as a key strategy for the solubilization and valorization of hemicelluloses into bioactive compounds. Agronomy, 10(6), 760. [CrossRef]

- Barbu, M.C.; Reh, R.; and Çavdar, A.D. (2017). Non-Wood Lignocellulosic Composites. In Materials Science and Engineering: Concepts, Methodologies, Tools, and Applications; IGI Global: Hershey, PA, USA, pp. 947–977.

- ChileNut, Reportes de Embarques (2021). Disponible en https://www.chilenut.cl/ourharvest/. Accessed October 5, 2022.

- Manterola-Barroso, C., Godoy, K., Alarcón, D., Padilla, D., and Meriño-Gergichevich, C. (2022). Antioxidants in Shell and Nut Yield Components after Ca, Mg and K Preharvest Spraying on Hazelnut Plantations in Southern Chile. Plants, 11(24), 3536. [CrossRef]

- Contini, M.; Baccelloni, S.; Massantini, R.; and Anelli, G. (2008). Extraction of natural antioxidants from hazelnut (Corylus avellana L.) shell and skin wastes by long maceration at room temperature. Food Chem. 110, 659–669. [CrossRef]

- Pirayesh, H., Khazaeian, A., and Tabarsa, T. (2012). The potential for using walnut (Juglans regia L.) shell as a raw material for wood-based particleboard manufacturing. Compos. B: Eng., 43(8), 3276-3280. [CrossRef]

- Hoşgün, E.Z.; Berikten, D.; Kıvanç, M.; and Bozan, B. (2017). Ethanol production from hazelnut shells through enzymatic saccharification and fermentation by low-temperature alkali pretreatment. Fuel, 196, 280–287. [CrossRef]

- Queirós, C. S., Cardoso, S., Lourenço, A., Ferreira, J., Miranda, I., Lourenço, M.J.V., and Pereira, H. (2020). Characterization of walnut, almond, and pine nut shells regarding chemical composition and extract composition. Biomass Convers. Biorefin., 10(1), 175-188. [CrossRef]

- Argenziano, R., Moccia, F., Esposito, R., D’Errico, G., Panzella, L., and Napolitano, A. (2022). Recovery of lignins with potent antioxidant properties from shells of edible nuts by a green ball milling/deep eutectic solvent (des) based protocol. Antioxidants, 11(10), 1860. [CrossRef]

- Sandoval, G., Thenoux, G., Molenaar, A. A. A., and Gonzalez, M. (2019). The antioxidant effect of grape pomace in asphalt binder. Int. J. Pavement Eng., 20(2), 163-171. [CrossRef]

- Denise Isperto, C., Labra, K.L., Landicho, J.M.B., and De Jesus, R. (2019). Optimized preparation of rice husk ash (RHA) as a supplementary cementitious material. Int. J. GEOMATE 16, 56-61.

- Baran, Y., Gökçe, H. S., and Durmaz, M. (2020). Physical and mechanical properties of cement containing regional hazelnut shell ash wastes. J. Clean. Prod., 259, 120965. [CrossRef]

- Agrichile Ferrero Hazelnut Company. Available online: https://agrichile.cl/noticias/agrichile-participa-en-webinaroportunidades-dedesarrollo-de-la-agroindustria-en-la-araucania-produccion-de-avellano-europeo/ (accessed on December, 2022).

- Meriño-Gergichevich, C., Luengo-Escobar, A., Alarcón, D., Reyes-Díaz, M., Ondrasek, G., Morina, F., and Ogass, K. (2021). Combined spraying of boron and zinc during fruit set and premature stage improves yield and fruit quality of European hazelnut cv. Tonda di Giffoni. Front. Plant Sci. 12, 984.

- Rivas, S., Moure, A., and Parajó, J. C. (2020). Pretreatment of hazelnut shells as a key strategy for the solubilization and valorization of hemicelluloses into bioactive compounds. Agronomy, 10(6), 760. [CrossRef]

- Husainie, S. M., Deng, X., Ghalia, M. A., Robinson, J., and Naguib, H. E. (2021). Natural fillers as reinforcement for closed-molded polyurethane foam plaques: Mechanical, morphological, and thermal properties. Mater.Today Commun., 27, 102187. [CrossRef]

- Kocaman, S., and Ahmetli, G. (2020). Effects of various methods of chemical modification of lignocellulose hazelnut shell waste on a newly synthesized bio-based epoxy composite. J. Polym. Environ., 28(4), 1190-1203. [CrossRef]

- Domingos, I., Ferreira, J., Cruz-Lopes, L. P., and Esteves, B. (2022). Liquefaction and chemical composition of walnut shells. Open Agric., 7(1), 249 256. [CrossRef]

- Wei, Q., Ma, X., Zhao, Z., Zhang, S., and Liu, S. (2010). Antioxidant activities and chemical profiles of pyroligneous acids from walnut shell. JAAP, 88(2), 149-154. [CrossRef]

- Jovičić, N., Antonović, A., Matin, A., Antolović, S., Kalambura, S., and Krička, T. (2022). Biomass valorization of walnut shell for liquefaction efficiency. Energies, 15(2), 495.

- Pelvan, E., Olgun, E. Ö., Karadağ, A., and Alasalvar, C. (2018). Phenolic profiles and antioxidant activity of Turkish Tombul hazelnut samples (natural, roasted, and roasted hazelnut skin). Food Chem., 244, 102-108. [CrossRef]

- Masullo, M., Cerulli, A., Mari, A., de Souza Santos, C. C., Pizza, C., and Piacente, S. (2017). LC-MS profiling highlights hazelnut (Nocciola di Giffoni PGI) shells as a byproduct rich in antioxidant phenolics. Food Res. Int., 101, 180-187. [CrossRef]

- Di Michele, A., Pagano, C., Allegrini, A., Blasi, F., Cossignani, L., Raimo, E. D., Faieta, M., Oliva, E., Pittia, P., Primavilla, S., Sergi, M., Vicino, C., Ricci, M., Schirone, B., and Perioli, L. (2021). Hazelnut shells as source of active ingredients: Extracts preparation and characterization. Molecules, 26(21), 6607. [CrossRef]

- Yuan, B., Lu, M., Eskridge, K. M., Isom, L. D., and Hanna, M. A. (2018). Extraction, identification, and quantification of antioxidant phenolics from hazelnut (Corylus avellana L.) shells. Food Chem., 244, 7-15. [CrossRef]

- Samaranayaka, A. G. P., John, J. A., and Shahidi, F. (2008). Antioxidant activity of english walnut (Juglans regia L.). J. Food Lipids, 15, 384–397.

- Stampar, F., Solar, A., Hudina, M., Veberic, R., and Colaric, M. (2006). Traditional walnut liqueur – Cocktail of phenolics. Food Chem., 95, 627–631. [CrossRef]

- Han, H., Wang, S., Rakita, M., Wang, Y., Han, Q., and Xu, Q. (2018). Effect of ultrasound-assisted extraction of phenolic compounds on the characteristics of walnut shells. Food Nutr. Sci., 9(8), 1034-1045. [CrossRef]

- Herrera, R., Hemming, J., Smeds, A., Gordobil, O., Willför, S., and Labidi, J. (2020). Recovery of bioactive compounds from hazelnuts and walnuts shells: Quantitative–qualitative analysis and chromatographic purification. Biomolecules, 10(10), 1363. [CrossRef]

- Zhang, Z., Liao, L., Moore, J., Wu, T., and Wang, Z. (2009). Antioxidant phenolic compounds from walnut kernels (Juglans regia L.). Food Chem., 113, 160–165. [CrossRef]

- Balart, J. F., Fombuena, V., Fenollar, O., Boronat, T., and Sánchez-Nacher, L. (2016). Processing and characterization of high environmental efficiency composites based on PLA and hazelnut shell flour (HSF) with biobased plasticizers derived from epoxidized linseed oil (ELO). Compos. B: Eng., 86, 168-177. [CrossRef]

- Balart, J. F., Montanes, N., Fombuena, V., Boronat, T., and Sánchez-Nacher, L. (2018). Disintegration in compost conditions and water uptake of green composites from poly (lactic acid) and hazelnut shell flour. J. Polym. Environ., 26, 701-715. [CrossRef]

- Barczewski, M., Sałasińska, K., and Szulc, J. (2019). Application of sunflower husk, hazelnut shell and walnut shell as waste agricultural fillers for epoxy-based composites: A study into mechanical behavior related to structural and rheological properties. Polym. Test., 75, 1-11.

- Matin, A., Krička, T., Grubor, M., Jurišić, V., Majdak, T., Špelić, K., Majdak, J., Matin, B., Jovičić, N., Antonović, A., and Brandić, I. (2023). Energy properties of agricultural biomass after the pyrolysis. J. Process. Energy Agric., 27(1), 39-44.

- Matin, A., Brandić, I., Voća, N., Bilandžija, N., Matin, B., Jurišić, V., Antonović, A. and Krička, T. (2023). Changes in the Properties of Hazelnut Shells Due to Conduction Drying. Agriculture, 13(3), 589. [CrossRef]

- Milosevic, T., and Milosevic, N. (2017). Determination of size and shape features of hazelnuts using multivariate analysis. Acta Sci. Pol. Hortorum Cultus, 16(5), 49-61.

- Ozkan, G., and Koyuncu, M. A. (2005). Physical and chemical composition of some walnut (Juglans regia L.) genotypes grown in Turkey. Grasas Aceites, 56(2), 141-146.

- Angmo, S., Acharyya, P., and Hasan, M. A. (2013). Performance of indigenous walnut selections under climatic conditions of Ladakh. In International Symposium on Agri-Foods for Health and Wealth. Bangkok, Thailand (pp. 167-176).

- Koyuncu, M. A., Ekinci, K. A. M. İ. L., and Savran, E. (2004). Cracking characteristics of walnut. Biosyst. Eng. 87(3), 305-311. [CrossRef]

- Demirbas, A. (2010). Direct and alkaline glycerol liquefaction of hazelnut shell. Energy Source. A: Recovery, Util., Environ. Eff., 32(8), 689-696. [CrossRef]

- Valentini, N., Moraglio, S. T., Rolle, L., Tavella, L., and Botta, R. (2015). Nut and kernel growth and shell hardening in eighteen hazelnut cultivars (Corylus avellana L.). Hortic. Sci. 42(3), 149-158. [CrossRef]

- Kabas, O. (2020). Cracking simulation of hazelnut shell using finite element method. Mitteilungen Klosterneuburg, 70, 148-156.

- Cetin, N., Yaman, M., Karaman, K., and Demir, B. (2020). Determination of some physicomechanical and biochemical parameters of hazelnut (Corylus avellana L.) cultivars. Turk. J. Agric. For., 44(5), 439-450. [CrossRef]

- Sharifian, F., and Derafshi, M. H. (2008). Mechanical behavior of walnut under cracking conditions. J. Appl. Sci., 8(5), 886-890.

- Zhang, H., Shen, L., Lan, H., Li, Y., Liu, Y., Tang, Y., and Li, W. (2018). Mechanical properties and finite element analysis of walnut under different cracking parts. Int. J. Agric. Biol. Eng., 11(6), 81-88. [CrossRef]

- Merkel, K.; Rydarowski, H.; Kazimierczak, J., and Bloda, A. (2014). Processing and characterization of reinforced polyethylene composites made with lignocellulosic fibres isolated from waste plant biomass such as hemp. Compos. B Eng. 67, 138–144. [CrossRef]

- Yu, X.; and Xu, H. (2014). Lightweight Composites Reinforced by Agricultural Byproducts. In Lightweight Materials from Biopolymers and Biofibers; American Chemical Society: Omaha, NE, USA, pp. 209–238.

- Akbari, V., Jamei, R., Heidari, R., and Esfahlan, A. J. (2012). Antiradical activity of different parts of Walnut (Juglans regia L.) fruit as a function of genotype. Food chem., 135(4), 2404-2410. [CrossRef]

- ODEPA-CIREN (2022). Catastro frutícola y principales resultados, Región de La Araucanía. Available online: https://www.odepa. (Accessed on December, 2022).

- Han, H.; Lee, K. (2022). Systematic approach to mimic phenolic natural polymers for biofabrication. Polymers, 14, 1282. [CrossRef]

- Saheb, D. N., and Jog, J. P. (1999). Natural fiber polymer composites: a review. Advances in Polymer Technology: Journal of the Polymer Processing Institute, 18(4), 351-363.

- Wang, X.; Zhao, M.; Su, G.; Cai, M.; Zhou, C.; and Huang, J.; Lin, L. (2015) The antioxidant activities and the xanthine oxidase inhibition effects of walnut (Juglans regia L.) fruit, stem and leaf. Int. J. Food Sci. Technol. 50, 233–239.

- Wang, J., Liu, E., and Li, L. (2019). Characterization on the recycling of waste seashells with Portland cement towards sustainable cementitious materials. J. Clean. Prod. 220, 235e252. [CrossRef]

| Nutshell Species | Lignin | Hemicellulose | Cellulose | Extractives | RSA | TPC | AC | References |

| (%) | (μg TE g‒1 DW) | (mg GAE g‒1 DW) | (μmol TE g‒1 DW) | |||||

| Hazelnut | 36 – 46 | 21 – 30 | 26 – 34 | 3 – 3.4 | - | 56.6 | - | Barbu et al., 2017; Pirayesh et al., 2012; Argenziano et al., 2022; Kocaman; Ahmetli., 2020; Contini et al., 2008; Manterola-Barroso et al., 2022; Masullo et al., 2017; Di Michele et al., 2021; Yuan et al., 2018; and Pelvan et al., 2018. |

| 1,110 | 0.18 | 2,119 | ||||||

|

- |

0.34 |

- |

||||||

|

- |

3.5 - 12 |

- |

||||||

| - | 72.25 | - | ||||||

| 1.01 mg mL‒1 | - | 1,219 | ||||||

| Walnut | 29 – 53 | 21 – 24.9 | 25 – 32 | 4 – 10.6 | 18,860 | 31.79 | - | Domingos et al., 2022; Wei et al., 2010; Jovicic et al., 2022; Queirós et al., 2019; Herrera et al., 2020; and Han et al., 2018. |

| 3.14 – 7.17 μg mL‒1 | 3.49 μg g‒1 | - | ||||||

| Nutshell Species | Density | Solubility | Morphology (nut traits) | References | |||

| NaOH | H2O | Len | Wid | STh | |||

| (g cm‒3) | (%) | (mm) | |||||

| Hazelnut | 1 - 1.3 | 50 - 50.4 | 18 - 20 | 18.8 - 25.9 | 17.2 - 22.7 | 1.3 - 1.7 |

Barczewski et al., 2019 Matin et al., 2023 Pirayesh et al., 2012 Manterola-Barroso et al., 2022 Meriño-Gergichevich et al., 2021 |

| Walnut | 1.1 - 1.2 | 35.2 | 7 - 10 | 38.2 - 50.4 | 29.2 - 34.4 | 1.1 - 1.7 |

Barczewski et al., 2019 Pirayesh et al., 2012 |

| Nutshell Species | Cracking Point | References | ||

| Longitudinal (L) | Transverse (T) | Suture (S) | ||

| (Newton) | ||||

| Hazelnut | 138 - 140 | 55 | 89 | Kabas et al., 2020; Cetin et al., 2020 |

| Walnut | 270 - 333 | 472 - 499 |

424 - 441 |

Koyuncu et al., 2004; Sharifian and Derafshi., 2008 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).