Submitted:

20 September 2023

Posted:

22 September 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

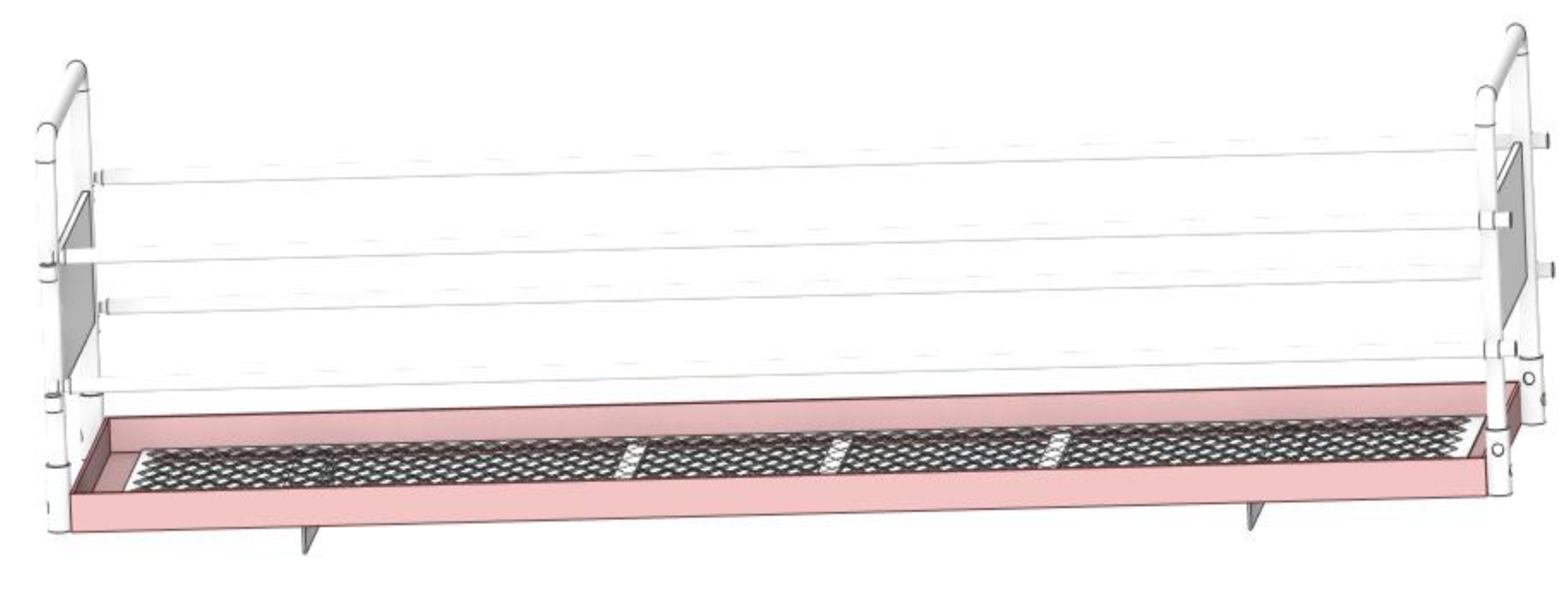

2. Overall structure design and key components research of mountain orchard transporter

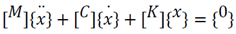

2.1. Overall structure design of orchard transporter

2.2.1. Overall design solution

2.1.2. Overall structure design

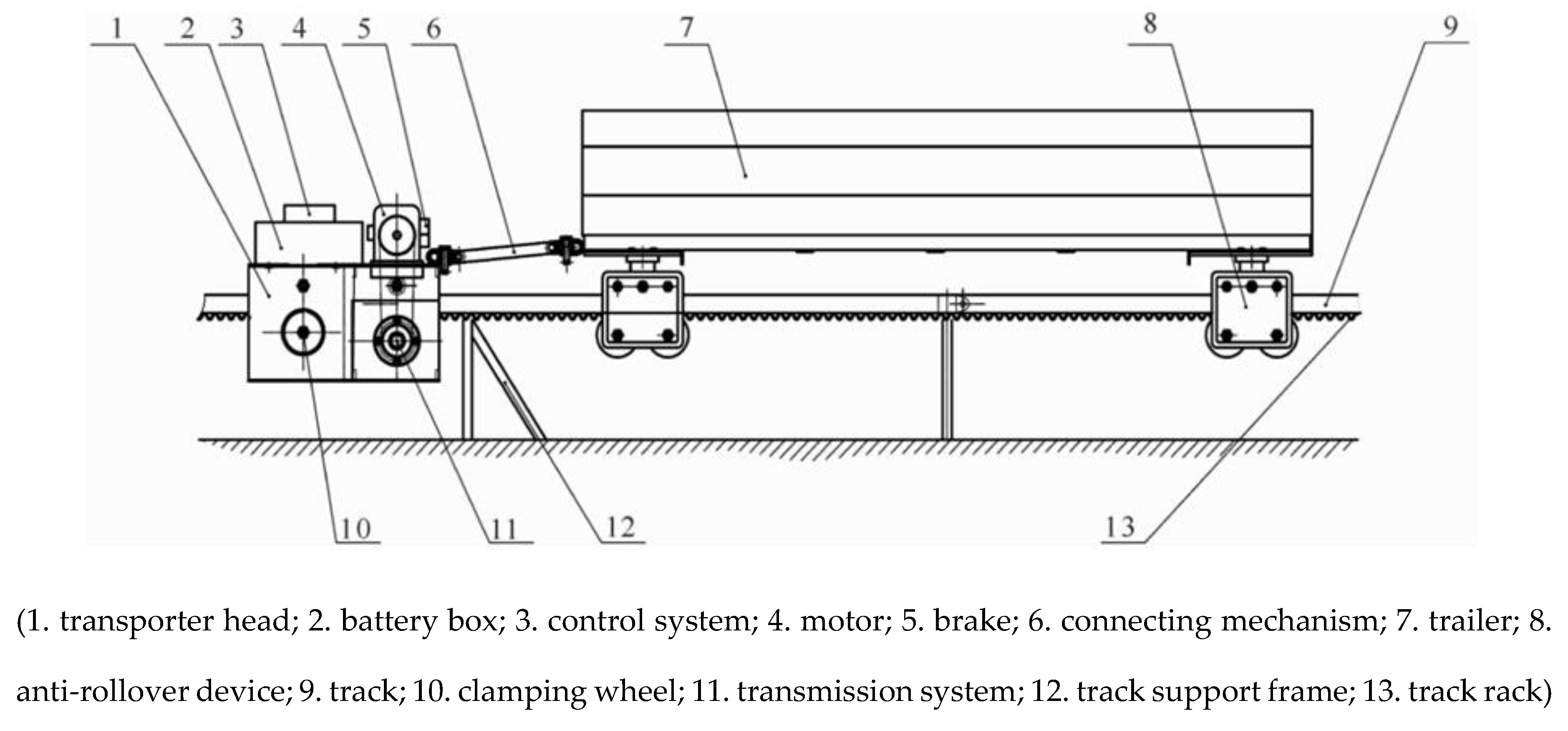

2.2. Working principle of orchard transporter

3. Vibration testing of mountain orchard transporter

3.1. Analysis of vibration causes in transporter

3.1.1. Vibration excitation sources for transporter

3.1.2. Theoretical study on vibration smoothness of transporter

3.2. Vibration test of transporter

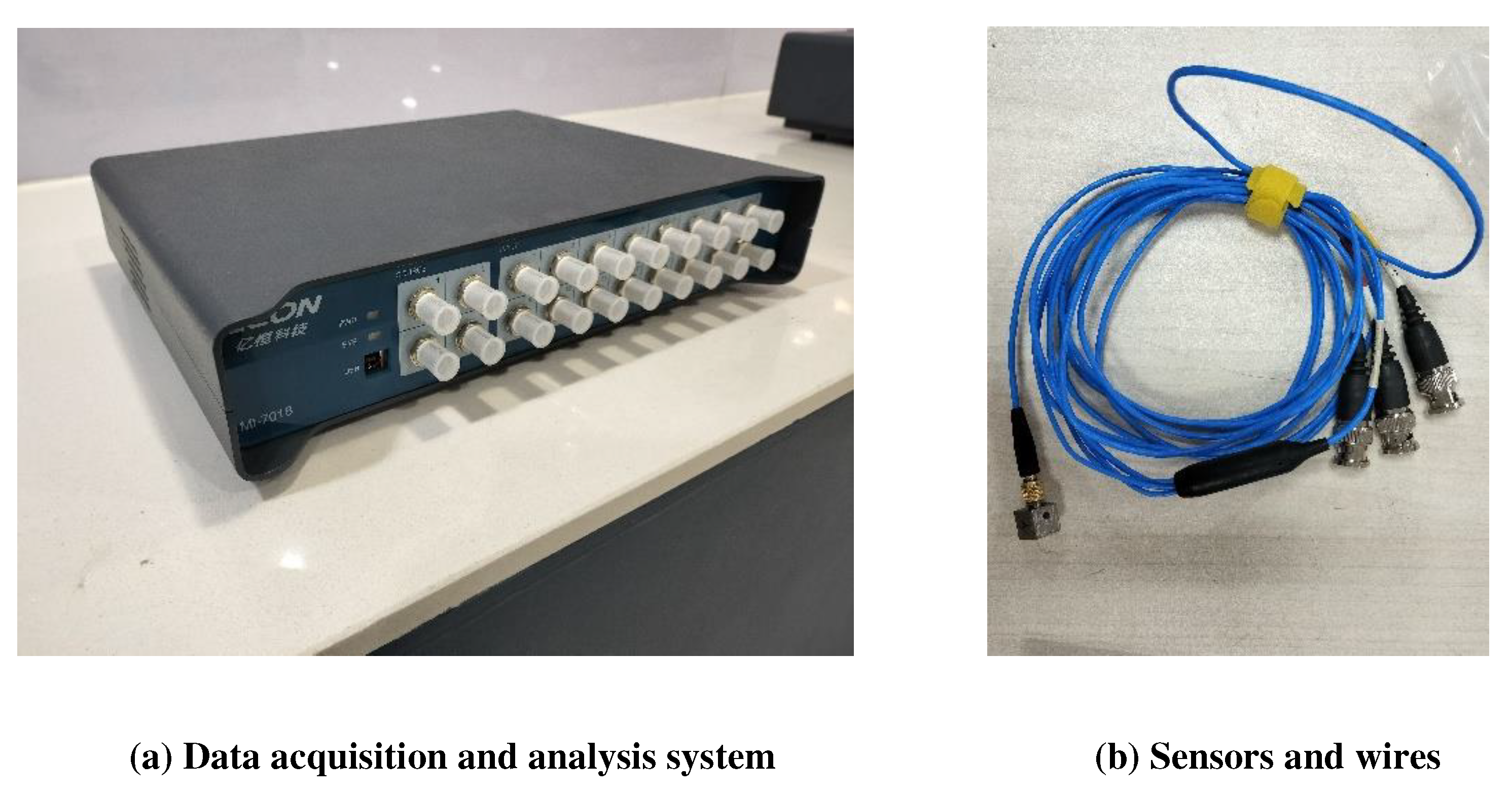

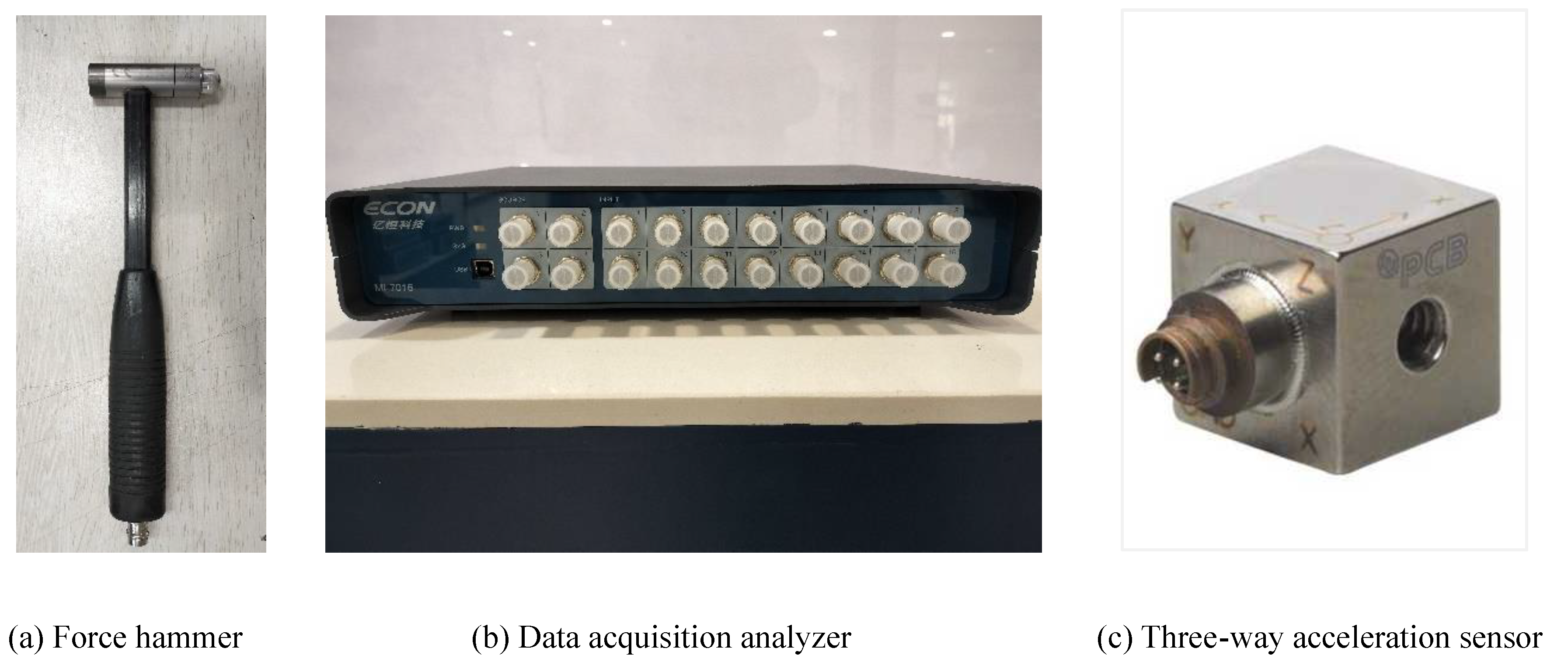

3.2.1. Testing Instruments

3.2.2. Experimental scheme

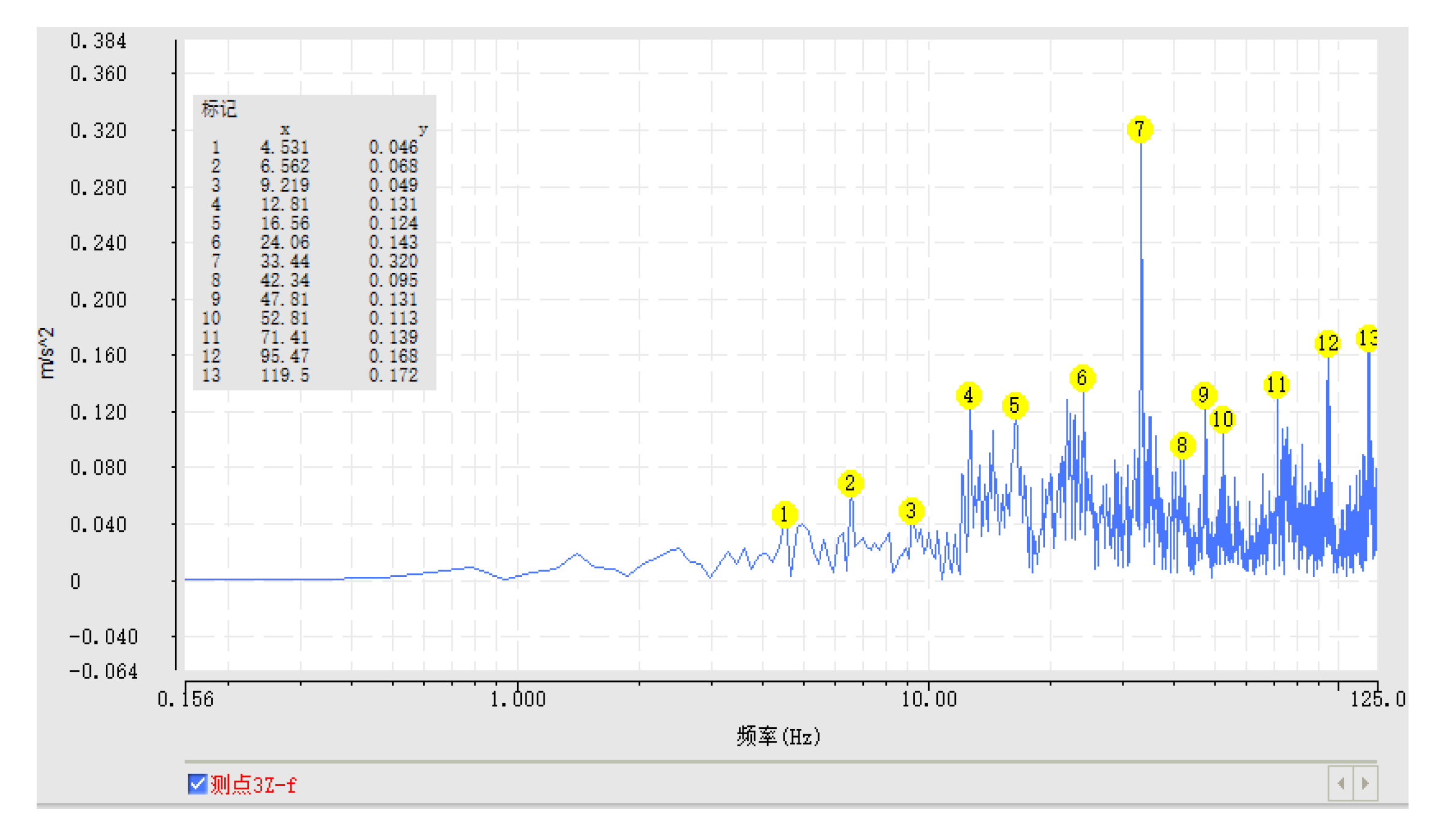

3.3. Experimental results and analysis

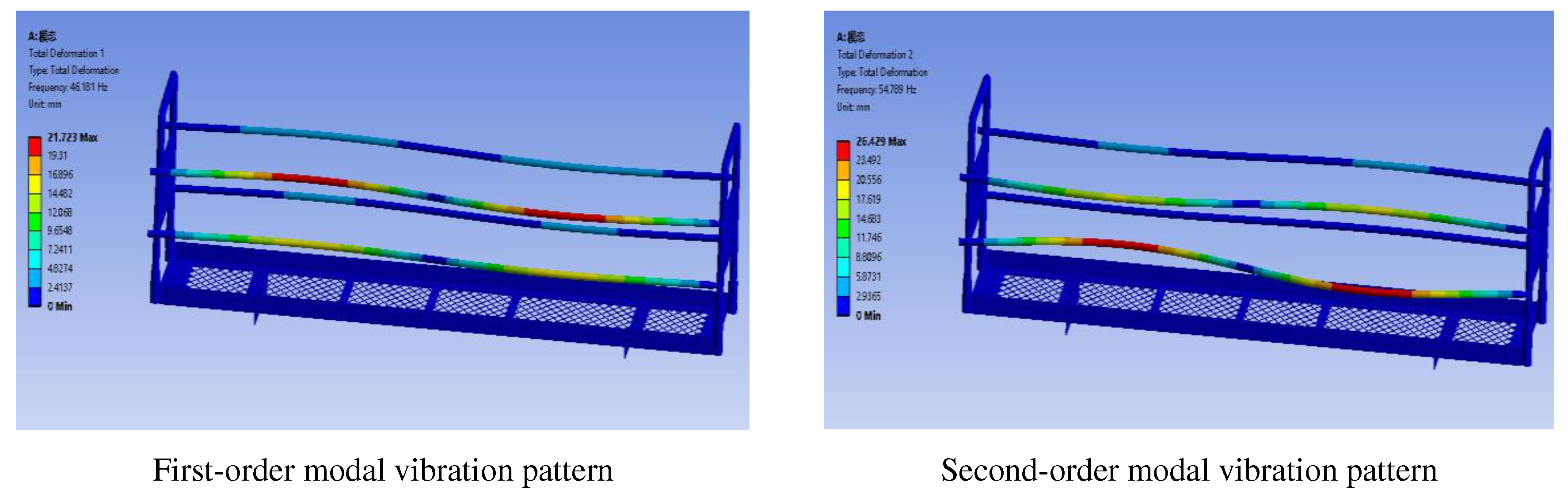

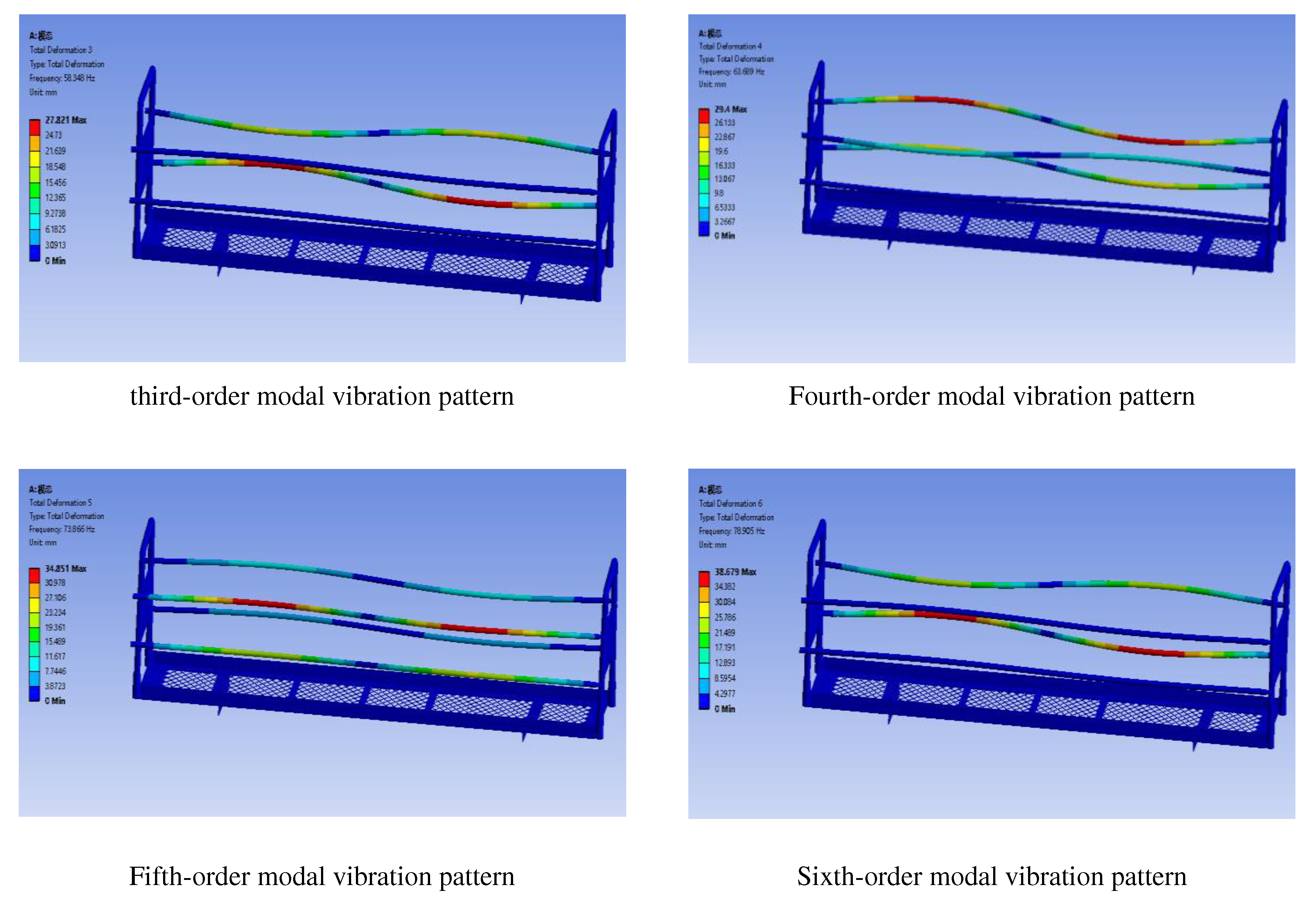

4. Modal analysis of mountain orchard transporter trailer

4.1. Modal Analysis Theory

4.2. Finite element modal analysis of transporter trailer

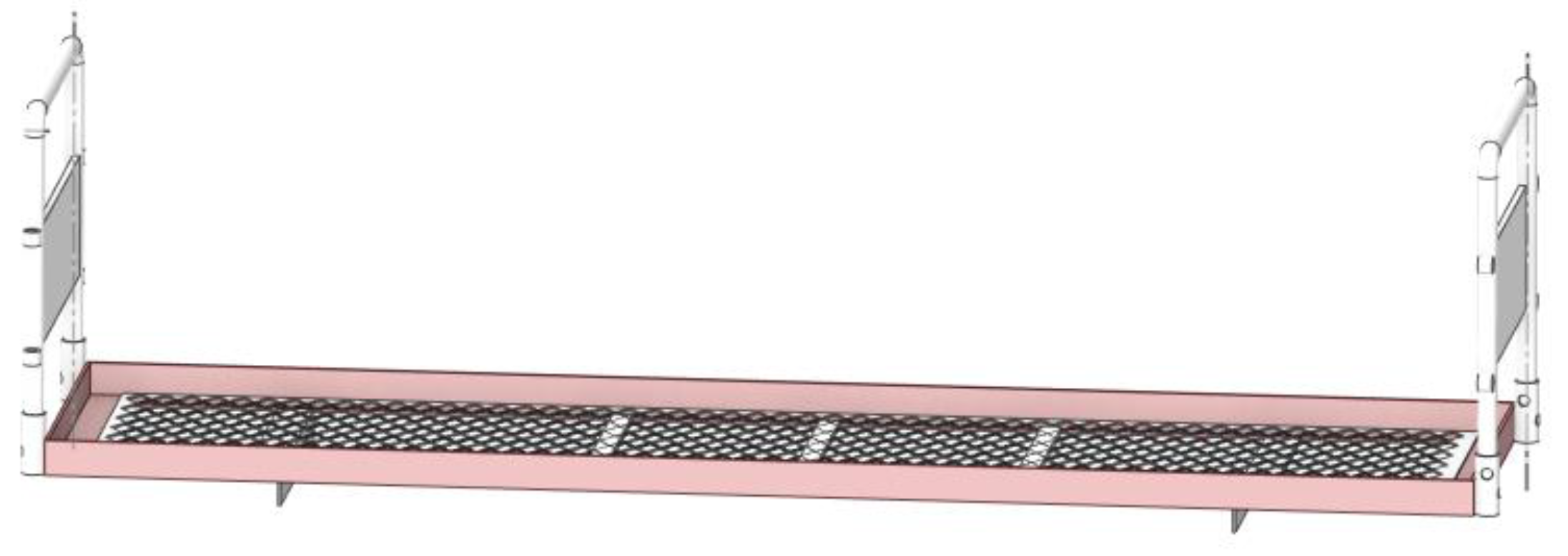

4.2.1. Trailer model building

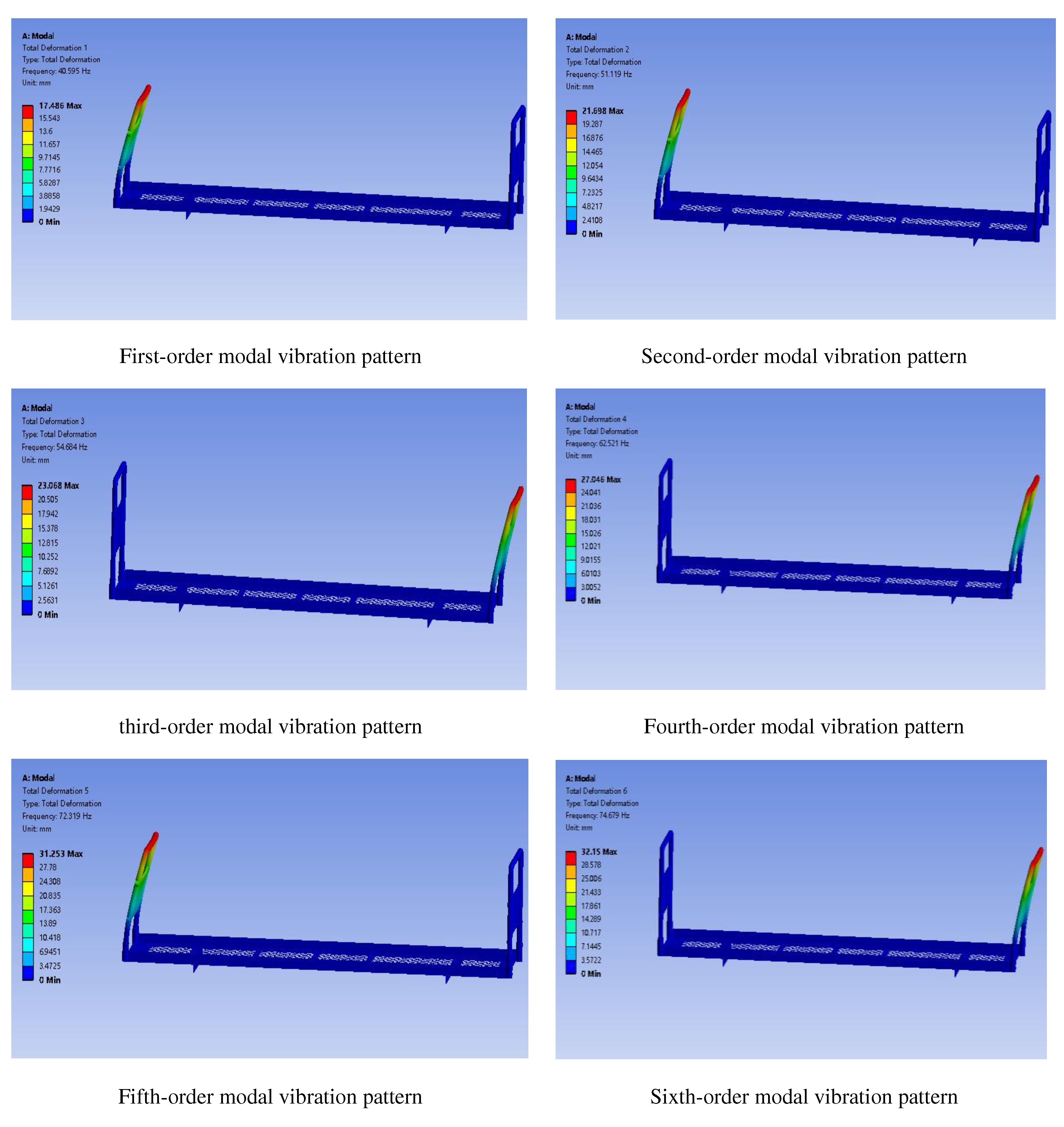

4.2.2. Trailer modal analysis

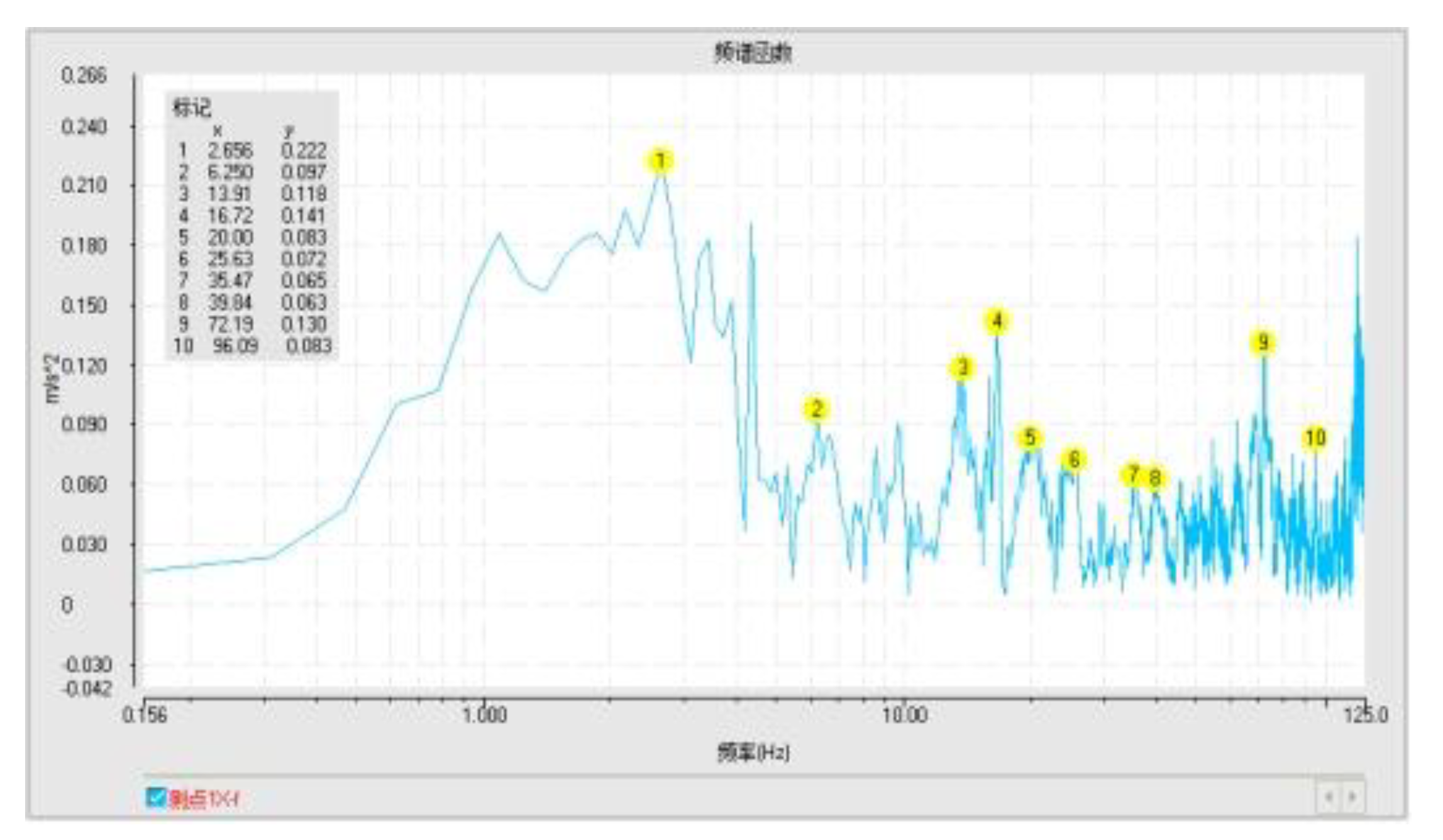

4.3. Trailer modal test of transporter

4.3.1. Testing instruments and analytical equipment

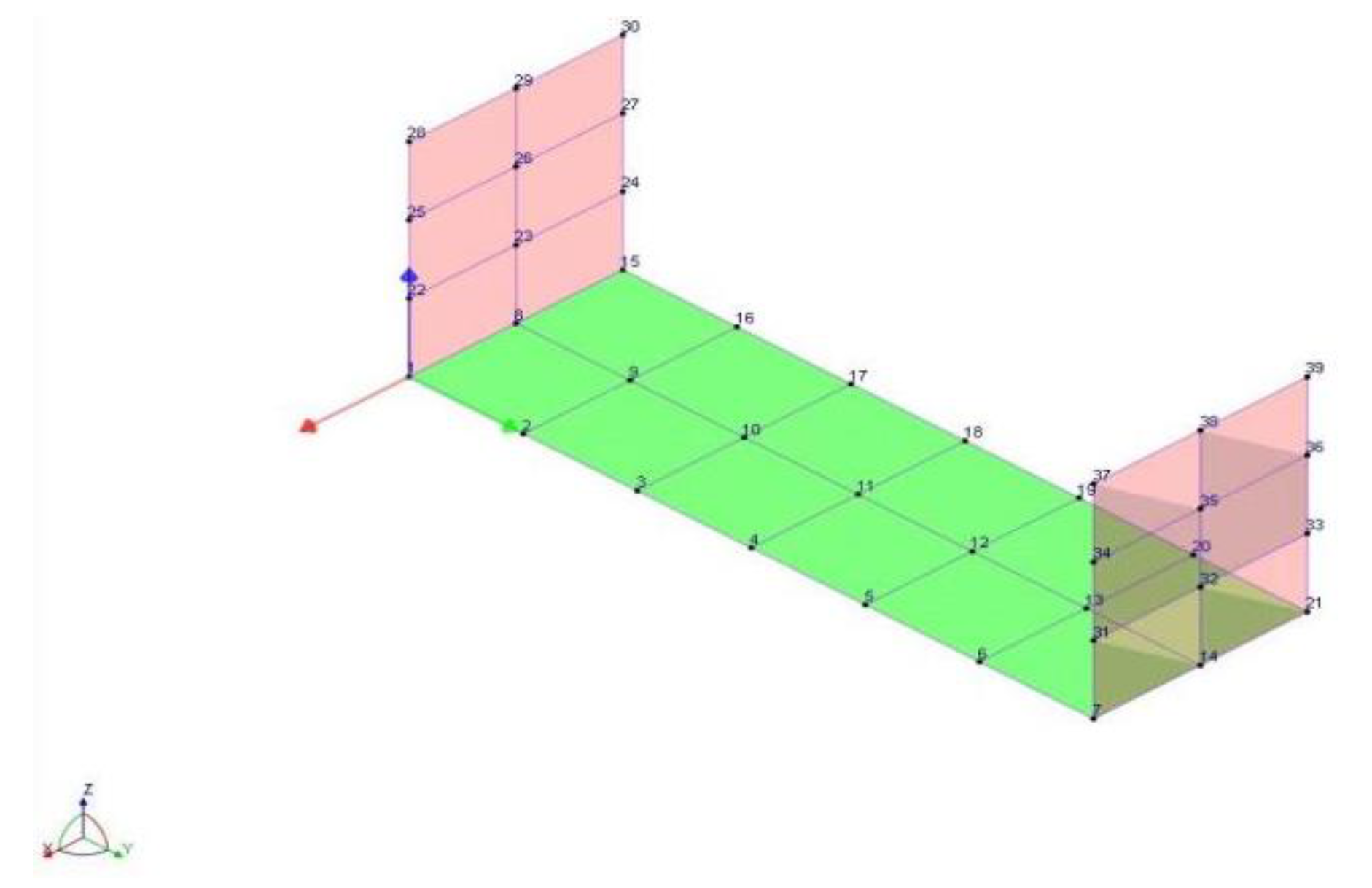

4.3.2. Measurement point arrangement and Choice of excitation method

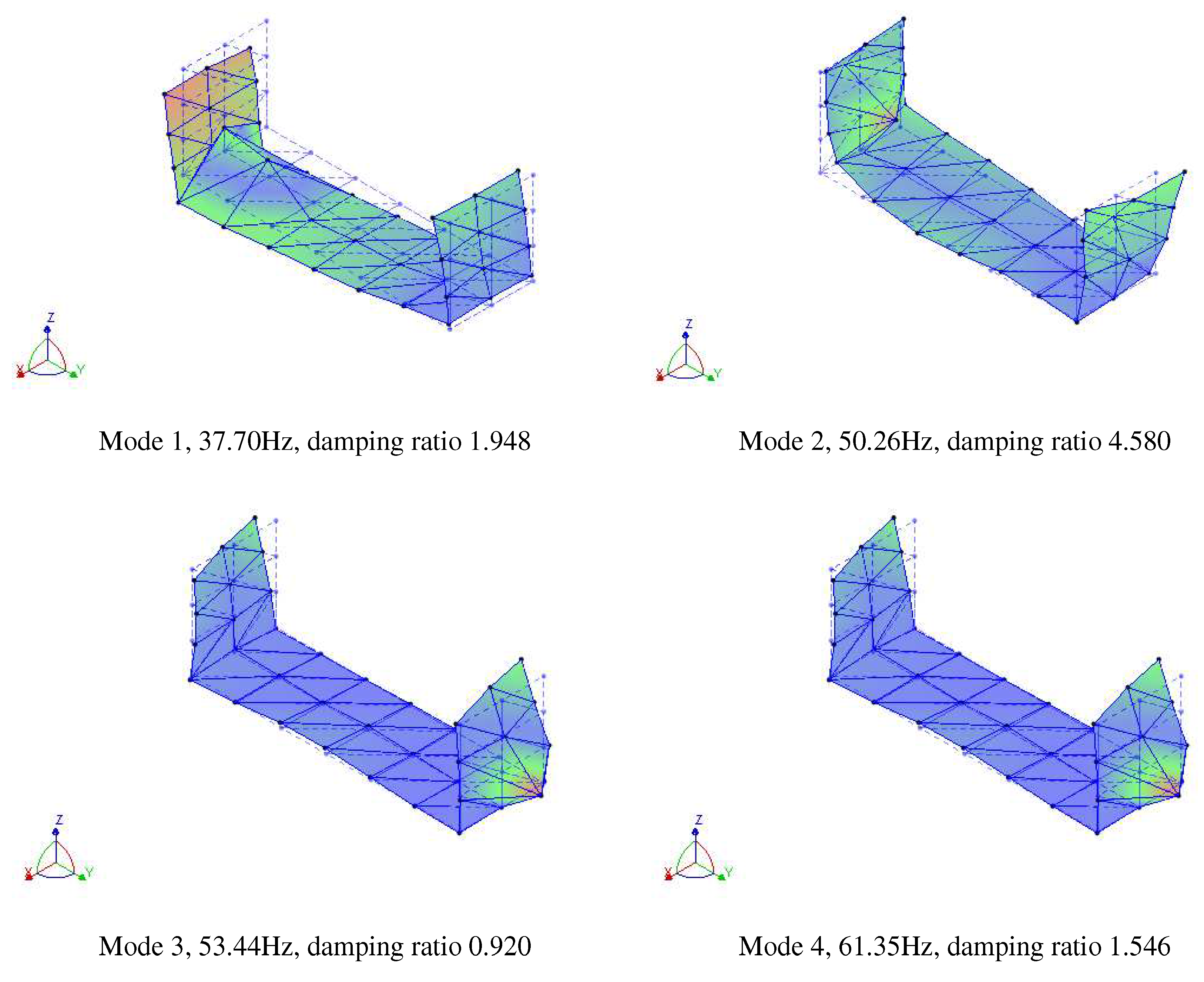

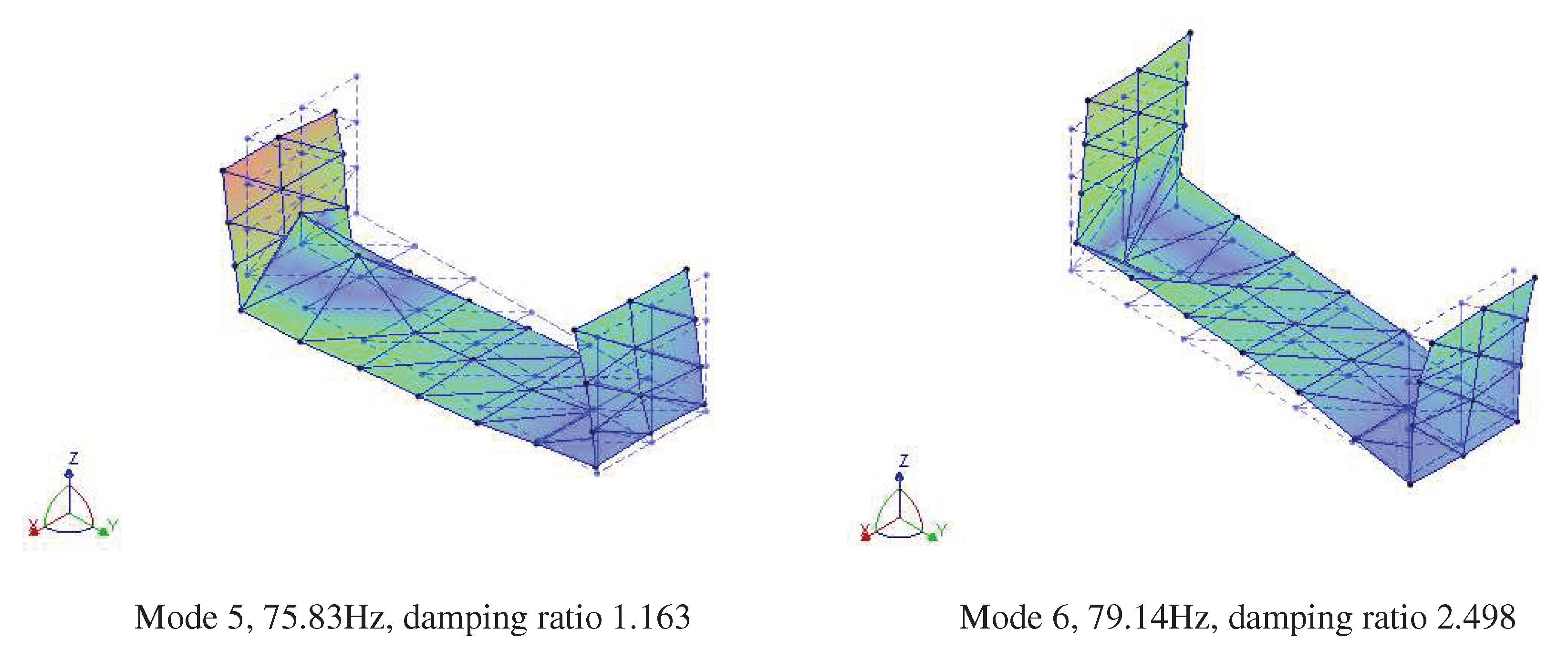

4.3.3. Analysis and verification of modal results

4.4. Comparison of finite element modal and experimental modal of transporter trailer

4.5. Optimization of transporter trailer structure

5. Vibration performance testing of mountain orchard transporter after structure optimization

5.1. Vibration performance testing of transporter

5.1.1. Selection of the test site

5.1.2. Experimental scheme

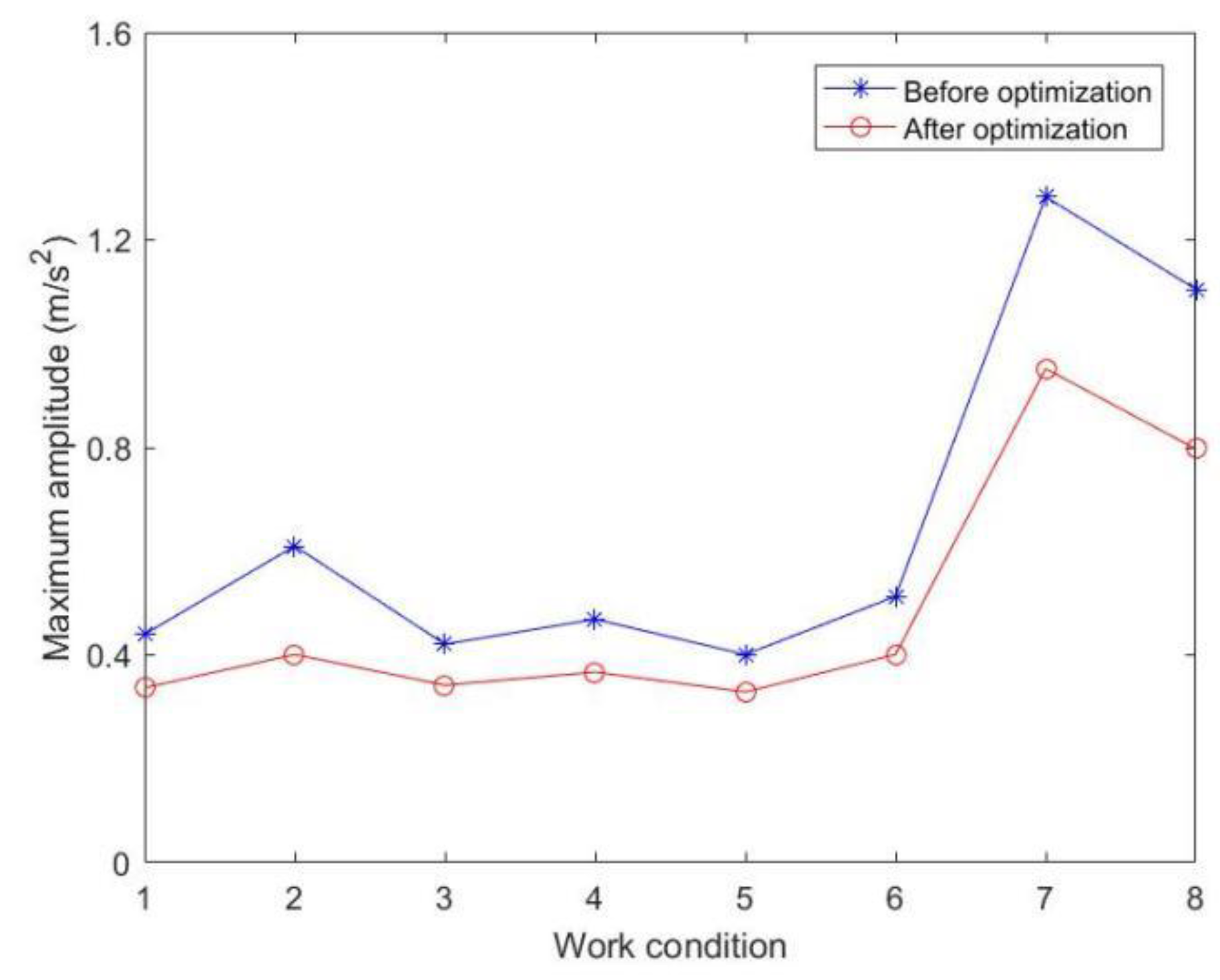

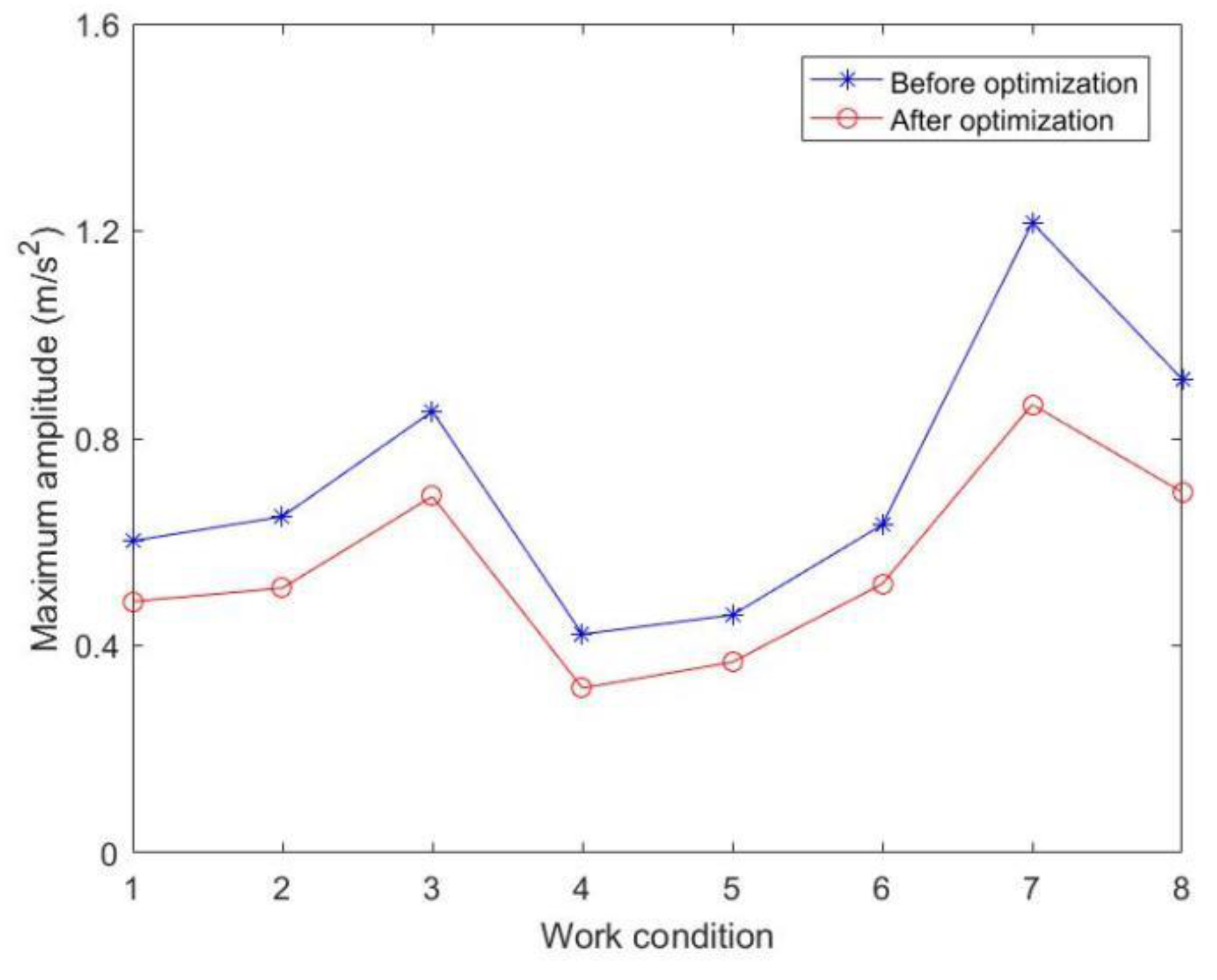

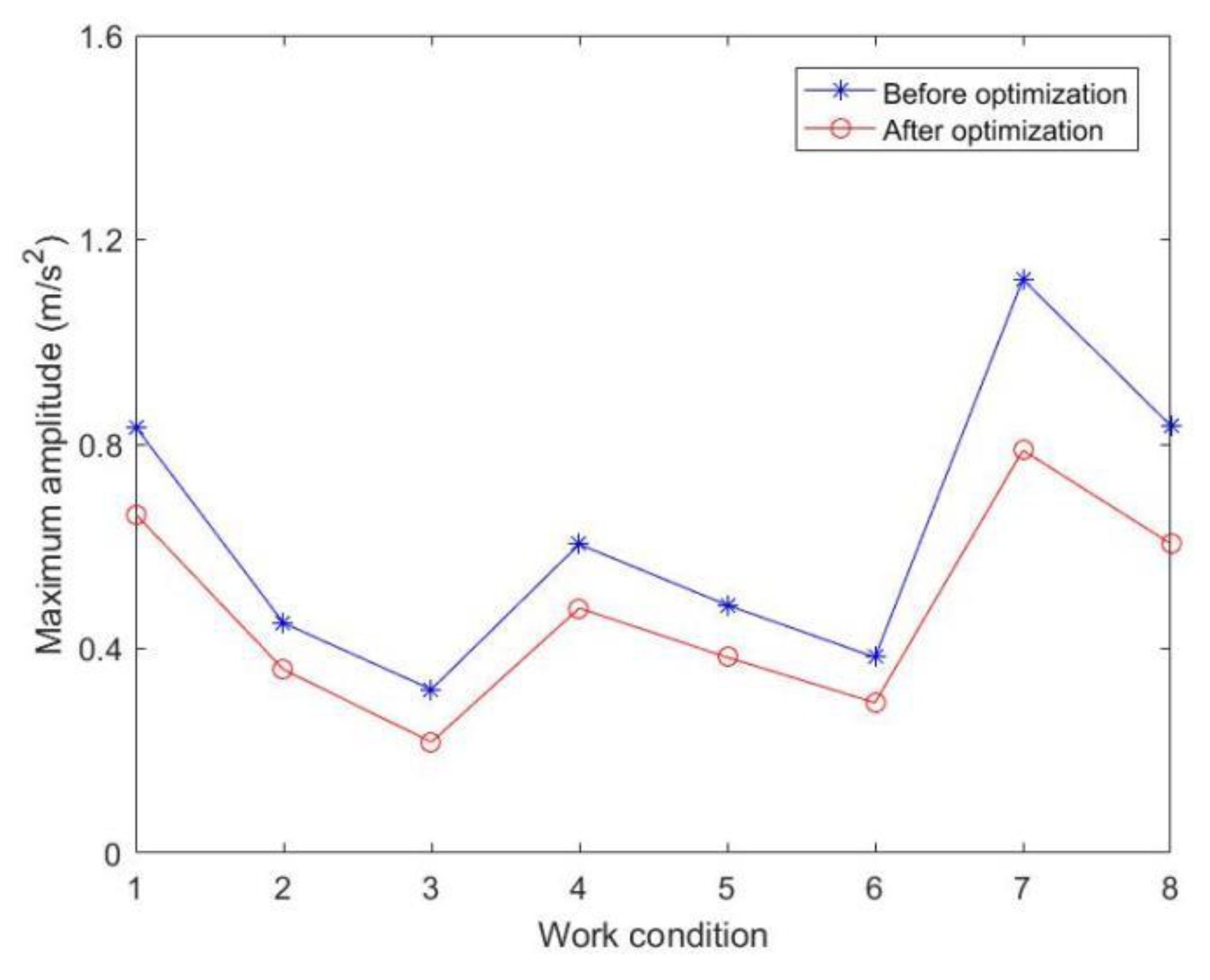

5.2. Comparative analysis of the maximum amplitude of transporter in different working conditions

5.3. Comparative analysis of the maximum amplitude of transporter in different directions

6. Conclusions

Funding

Authorship and Acknowledgements

Data Availability Statement

Conflicts of Interest

References

- Zhang, C.; Wu, W. B.; Yang, X. B.; Zhang, W.; Chang, X. L. Review of Test-bed for Mountain Orchard Conveyor, Modern Agricultural Equipment, 2017, 3, 34-37.

- Chen, W. L.; Chen, Z. W.; Yue, D. D.; Li, M. T.; He, L. Research progress and optimization measures of hilly mountain agricultural rope-rail transport machinery, China Southern Agricultural Machinery, 2022,53, 13-16+26.

- Wu, W. B.; Zhao, B.; Zhu, Y. Q.; Wang, H. L.; Zhi, L.; Feng, Z. F. Research progress of hilly orchard transporter, Journal of Huazhong Agricultural University, 2013, 32, 135-142.

- Hong, T. S.; Su, J.; Zhu, Y. Q.; Yang, Z.; Yue, X. J.; Song, S. R. Circular Chain Ropeway for Cargo Transportation in Mountain Citrus Orchard, Transactions of the Chinese Society for Agricultural Machinery, 2011, 42, 108-111.

- Wang, Z.; Zhang, J. F.; Xiao, J.; Luo, Y. Y.; Tian, M. Z.; He, Y. S.; Zhou, C. Research progress and prospect of orchard transportation equipment and digital orchard, Hubei Agricultural Sciences, 2021, 60, 11-14.

- Zhou, Y., Li; X. P.; Li, J.; Hong, T. S.; Xue, K. P. Transversal Vibration of Chain Ropeway System Having Support Boundary Conditions with Polygonal Action, Shock and Vibration, 2015, 15, 1-9. [CrossRef]

- Zhang, J. F.; Li, J. Y.; Zhang, Y. L.; Li, S. J.; Meng, L. Design of Remote Control Monorail Transporter for Mountainous Orchard, Transactions of the Chinese Society for Agricultural Machinery, 2012, 43, 90-95.

- .

- Li, Z. Y. Transporter in the Mountainous Orchard Research and Optimization on Ride Performance of Wheeled, Mar. Elect. China., South China Agricultural University, 2019.

- Zheng, P. L. Development and Experiment of a miniature battery-driven Crawler Transporter for Mountain Orchards, Mar. Elect. China., South China Agricultural University, 2016.

- Wang, X. M.; Chen, M.; Wu, W. B.; Chen, S.; Hong, T. S.; Zhang, W.; Chen, Z. Y. Design and test of electric self-propelled double-track transporter for hilly orchard, Journal of Huazhong Agricultural University, 2020, 39, 96-104.

- Ishiguri, K.; Kobayashi, Y.; Tomioka, T.; Hoshino, Y. Vibration analysis of a railway carbody using a shell model, Journal of System Design and Dynamics, 2008, 2, 22-28. [CrossRef]

- Li, C. Design and Implementation of Field Monorail Transport Prototype, Mar. Elect. China., Hubei University of Technology, 2020.

- Yang, X. B. Design of self-propelled electric double-track transporter in nursery field, Mar. Elect. China., South China Agricultural University, 2019.

- Li, X. B.; Zhang, H. B.; Chen, N. Research on Dynamic Characteristics of Vibrating Conveyor System, Mechanical Research & Application, 2021, 34, 43-48.

- Yang, H. Y.; Ma, H. Z.; Shi, Y.; Huang, J. F.; Gao, J. H. Design of Track Vibration Test System Based on LabVIEW, Journal of Shanghai University of Engineering Science, 2015, 29, 239-242+248.

- Li, S. J.; Liu, H.; Zhang, Y. L.; Chen, H.; Meng, L.; Ma, P. Y.; Zhang, C. Y.; Zhang, C. Optimization of rack tooth forms of monorail mountain orchard transporter, Transactions of the Chinese Society of Agricultural Engineering, 2018, 34, 52-57.

- Liu, Y.; Hong, T. S.; Li, Z. Influence of Toothed Rail Parameters on Impact Vibration Meshing of Mountainous Self-Propelled Electric Monorail Transporter, Sensors, 2020, 20, 588. [CrossRef]

- Huang, S. H. The Vibration System of Mountain Orchard track conveyor, Mar. Elect. China., South China Agricultural University, 2016.

- Liu, F. L.; Yang, X. B.; Wu, W. B.; Hong, T. S.; Zhang, Z. B.; Chen, H. Y. Vibration performance test and analysis of 7SGH mountain orchard dual-track transporter, Journal of Hebei Agricultural University, 2018, 41, 124-129.

- Zhang, J. L.; Yue, D. D.; Wu, W. B.; Hong, T. S.; Yang, X. B.; Chen, M.; Zheng, Z. F. Design and test of a self-propelled electric double-track transporter for nursery field, Journal of Huazhong Agricultural University, 2020, 39, 113-120.

- Mao, Z. P.; Chen, Y. Z.; Ren, W. P.; Ma, Z. Y.; Zhu, L. X. Design and simulation of small tracked vehicle for banana transportation in field, Journal of Zhongkai University of Agriculture and Engineering, 2015,28, 37-41.

- Cheng, F. P.; Tuo, H. Z.; Yi, W. Y.; Wang, P.; Yang, C. M.; Zhang, w. Design and test of mountain monorail electric remote control transporter, Journal of Chinese Agricultural Mechanization, 2022, 43, 107-112.

- Shao, J. Study on Active and Passive Mixed Control Method for Vibration of Lifting Machinery, Machine Building & Automation, 2021, 50, 72-75+79.

- Xu, Z.; Zhu, F. T. Application of mechanical vibration mechanics in modern industry, Internal Combustion Engine & Parts, 2021, 333, 210-211.

- Lei, X. Y.; Wang, P. S.; Weng, L. X.; Luo, K. Analysis of Vibration Characteristics of Elevated Box Girder Structure Induced by High-Speed Train at 300 km/h, Journal of East China Jiaotong University, 2021, 38,18-26.

- Guan, R. G.; Gu, L.; Wu, X. C. Discussion on vibration charac teristic of machinery and methodes of reducing vibration, Machinery Design & Manufacture, 2001, 25, 67-68.

- Xu, L. Z.; Li, Y. M.; Sun, P. P.; Pang, J. Vibration measurement and analysis of tracked-whole feeding rice combine harvester, Transactions of the Chinese Society of Agricultural Engineering, 2014, 30, 49-55.

- Chandru, B. T.; Suresh, P. M.; Sathya, J.; Maruthi, B. H. Modal Analysis of Car Hood with Viscoelastic Damper, Materials Today: Proceedings, 2018, 5, 22293-22302. [CrossRef]

- Li, X. Z.; Yue, X. B.; Huang, W.; Dong, X. J.; Peng, Z. K. Vibration response transmissibility and operational modal analysis methods: a review and comparative study, Journal of Vibration and Shock, 38, 24-34+45,2019.

- Dong, M. X.; Han, S. J.; Liang, L. W.; Yang, C. N.; Zhang, E. Analysis of boom vibration response of fiat head tower crane during rotary motion, Chinese Journal of Construction Machinery, 2019, 17, 419-422.

- Feng, R. H. Mast Structure Vibration of Tower Cranes, Mar. Elect. China., Shandong Jianzhu University, 2021.

- Liu, J.; Gao, J. L.; Mu, G. Z.; Xie, W. L. An improved experimental modal analysis system with hammering method, Journal of Vibration and Shock, 2009, 28, 174-177+208.

- Liang, J. W.; Liu, B. G.; Feng, W.; Mei, J. W.; Yang, H. W. Vibration modeling and modal test of rotor system of electromagnetic balancing head, Journal of Mechanical & Electrical Engineering, 2021, 38, 1355-1360.

| Work conditions | Load | Slope | Road conditions |

|---|---|---|---|

| 1 | 0kg | Uphill | Horizontal |

| 2 | 0kg | Uphill | Turning |

| 3 | 100kg | Uphill | Horizontal |

| 4 | 100kg | Downhill | Turning |

| 5 | 100kg | Uphill | Turning |

| 6 | 100kg | Downhill | Horizontal |

| 7 | 200kg | Downhill | Turning |

| 8 | 200kg | Downhill | Horizontal |

| Measurement points | X | Y | Z | |||

| Frequency (Hz) |

Maximum amplitude (m s-2) |

Frequency (Hz) |

Maximum amplitude (m s-2) |

Frequency (Hz) |

Maximum amplitude (m s-2) |

|

| 1 | 2.81 | 0.209 | 33.44 | 0.383 | 48.57 | 0.834 |

| 2 | 24.22 | 0.270 | 95.47 | 0.602 | 124.5 | 0.322 |

| 3 | 48.57 | 0.443 | 95.47 | 0.175 | 33.44 | 0.320 |

| 4 | 95.47 | 0.222 | 6.56 | 0.108 | 97.34 | 0.293 |

| 5 | 80.47 | 0.397 | 7.96 | 0.196 | 24.22 | 0.186 |

| Measurement points | X | Y | Z | |||

| Frequency (Hz) |

Maximum amplitude (m s-2) |

Frequency (Hz) |

Maximum amplitude (m s-2) |

Frequency (Hz) |

Maximum amplitude (m s-2) |

|

| 1 | 2.65 | 0.229 | 33.44 | 0.321 | 95.78 | 0.320 |

| 2 | 95.78 | 0.381 | 33.44 | 0.649 | 43.44 | 0.330 |

| 3 | 2.65 | 0.208 | 95.78 | 0.186 | 95.78 | 0.278 |

| 4 | 94.69 | 0.218 | 17.03 | 0.121 | 48.57 | 0.450 |

| 5 | 48.57 | 0.610 | 8.43 | 0.163 | 95.62 | 0.168 |

| Measurement points | X | Y | Z | |||

| Frequency (Hz) |

Maximum amplitude (m s-2) |

Frequency (Hz) |

Maximum amplitude (m s-2) |

Frequency (Hz) |

Maximum amplitude (m s-2) |

|

| 1 | 3.12 | 0.231 | 33.44 | 0.391 | 47.81 | 0.246 |

| 2 | 95.47 | 0.621 | 48.57 | 0.852 | 33.44 | 0.241 |

| 3 | 3.12 | 0.214 | 23.91 | 0.166 | 33.44 | 0.320 |

| 4 | 95.47 | 0.117 | 16.56 | 0.094 | 92.03 | 0.139 |

| 5 | 87.19 | 0.340 | 10.16 | 0.126 | 92.03 | 0.169 |

| Measurement points | X | Y | Z | |||

| Frequency (Hz) |

Maximum amplitude (m s-2) |

Frequency (Hz) |

Maximum amplitude (m s-2) |

Frequency (Hz) |

Maximum amplitude (m s-2) |

|

| 1 | 2.18 | 0.310 | 49.53 | 0.256 | 49.53 | 0.255 |

| 2 | 2.18 | 0.271 | 49.53 | 0.304 | 24.06 | 0.322 |

| 3 | 2.65 | 0.212 | 6.25 | 0.170 | 96.87 | 0.199 |

| 4 | 48.57 | 0.469 | 48.57 | 0.365 | 48.57 | 0.604 |

| 5 | 2.18 | 0.300 | 48.57 | 0.422 | 48.57 | 0.397 |

| Measurement points | X | Y | Z | |||

| Frequency (Hz) |

Maximum amplitude (m s-2) |

Frequency (Hz) |

Maximum amplitude (m s-2) |

Frequency (Hz) |

Maximum amplitude (m s-2) |

|

| 1 | 2.65 | 0.239 | 2.18 | 0.459 | 95.00 | 0.385 |

| 2 | 95.94 | 0.346 | 49.53 | 0.304 | 33.28 | 0.301 |

| 3 | 48.57 | 0.401 | 23.75 | 0.169 | 95.00 | 0.199 |

| 4 | 47.50 | 0.234 | 10.78 | 0.133 | 99.69 | 0.188 |

| 5 | 92.34 | 0.345 | 10.78 | 0.123 | 48.57 | 0.485 |

| Measurement points | X | Y | Z | |||

| Frequency (Hz) |

Maximum amplitude (m s-2) |

Frequency (Hz) |

Maximum amplitude (m s-2) |

Frequency (Hz) |

Maximum amplitude (m s-2) |

|

| 1 | 2.18 | 0.213 | 50.62 | 0.183 | 50.47 | 0.165 |

| 2 | 29.53 | 0.225 | 50.47 | 0.269 | 50.47 | 0.269 |

| 3 | 50.62 | 0.266 | 50.62 | 0.188 | 2.65 | 0.383 |

| 4 | 48.57 | 0.513 | 48.57 | 0.633 | 105.9 | 0.176 |

| 5 | 48.57 | 0.368 | 24.22 | 0.323 | 87.81 | 0.150 |

| Measurement points | X | Y | Z | |||

| Frequency (Hz) |

Maximum amplitude (m s-2) |

Frequency (Hz) |

Maximum amplitude (m s-2) |

Frequency (Hz) |

Maximum amplitude (m s-2) |

|

| 1 | 48.57 | 1.283 | 48.57 | 1.216 | 48.57 | 1.122 |

| 2 | 33.44 | 0.583 | 2.56 | 0.602 | 24.22 | 0.460 |

| 3 | 2.65 | 1.249 | 95.47 | 1.147 | 24.22 | 1.100 |

| 4 | 95.47 | 0.502 | 2.65 | 0.526 | 95.47 | 0.538 |

| 5 | 2.65 | 0.641 | 33.44 | 0.486 | 95.47 | 0.655 |

| Measurement points | X | Y | Z | |||

| Frequency (Hz) |

Maximum amplitude (m s-2) |

Frequency (Hz) |

Maximum amplitude (m s-2) |

Frequency (Hz) |

Maximum amplitude (m s-2) |

|

| 1 | 48.57 | 1.015 | 48.57 | 0.914 | 48.57 | 0.836 |

| 2 | 33.44 | 0.381 | 2.65 | 0.511 | 24.22 | 0.326 |

| 3 | 2.65 | 0.742 | 95.47 | 0.485 | 24.22 | 0.805 |

| 4 | 95.47 | 0.378 | 2.65 | 0.530 | 95.47 | 0.339 |

| 5 | 2.65 | 0.441 | 2.65 | 0.326 | 95.47 | 0.457 |

| Frequency Order |

Finite element modal natural frequency | Force hammer excitation test modal | Error | ||

| Frequency /Hz |

Modal vibration pattern | Frequency /Hz |

Modal vibration pattern | ||

| 1 | 40.59 | Left end U-shaped rod and baffle bent inward and deformed | 37.70 | Left end U-shaped rod and baffle bent inward and deformed | 7.1% |

| 2 | 51.12 | Left end U-shaped rod and baffle bent inward and deformed | 50.26 | Left end U-shaped rod and baffle bent inward and deformed | 1.7% |

| 3 | 54.68 | Right end U-bar and baffle plate twisted and bent outward | 53.44 | Right end U-bar and baffle plate twisted and bent outward | 2.3% |

| 4 | 62.52 | Right end U-bar and baffle plate twisted and bent outward | 61.35 | Right end U-bar and baffle plate twisted and bent outward | 1.8% |

| 5 | 72.32 | Bending deformation of U-rod at both ends | 75.83 | Bending deformation of U-rod at both ends | 4.2% |

| 6 | 74.68 | Bending deformation of U-rod at both ends | 79.14 | Bending deformation of U-rod at both ends | 6.0% |

| Frequency Order |

Before optimization | After optimization | Frequency Change value /Hz |

||

| Frequency /Hz |

Modal vibration pattern | Frequency /Hz |

Modal vibration pattern | ||

| 1 | 40.59 | Left end U-shaped rod and baffle bent inward and deformed | 46.18 | Right side crossbar bending deformation | 5.59 |

| 2 | 51.12 | Left end U-shaped rod and baffle bent inward and deformed | 54.79 | Right side crossbar bending deformation | 3.67 |

| 3 | 54.68 | Right end U-bar and baffle plate twisted and bent outward | 58.35 | Upper crossbar bending deformation | 3.67 |

| 4 | 62.52 | Right end U-bar and baffle plate twisted and bent outward | 63.69 | Upper crossbar bending deformation | 1.17 |

| 5 | 72.32 | Bending deformation of U-rod at both ends | 73.87 | Right side crossbar bending deformation | 1.55 |

| 6 | 74.68 | Bending deformation of U-rod at both ends | 78.91 | Upper crossbar bending deformation | 4.23 |

| Measurement points | X | Y | Z | |||

| Frequency<B/>(Hz) | Maximum amplitude<B/>(m s-2) | Frequency<B/>(Hz) | Maximum amplitude<B/>(m s-2) | Frequency<B/>(Hz) | Maximum amplitude<B/>(m s-2) | |

| 1 | 2.65 | 0.222 | 33.59 | 0.358 | 48.57 | 0.663 |

| 2 | 78.91 | 0.221 | 48.57 | 0.485 | 33.59 | 0.188 |

| 3 | 48.57 | 0.337 | 96.09 | 0.154 | 16.72 | 0.174 |

| 4 | 79.22 | 0.226 | 7.65 | 0.131 | 12.81 | 0.121 |

| 5 | 2.65 | 0.218 | 16.09 | 0.148 | 96.09 | 0.210 |

| Measurement points | X | Y | Z | |||

| Frequency (Hz) |

Maximum amplitude (m s-2) |

Frequency (Hz) |

Maximum amplitude (m s-2) |

Frequency (Hz) |

Maximum amplitude (m s-2) |

|

| 1 | 3.98 | 0.120 | 33.44 | 0.235 | 23.83 | 0.080 |

| 2 | 21.64 | 0.170 | 48.57 | 0.511 | 33.44 | 0.163 |

| 3 | 49.84 | 0.119 | 95.47 | 0.104 | 33.44 | 0.140 |

| 4 | 3.75 | 0.136 | 33.44 | 0.101 | 24.22 | 0.359 |

| 5 | 95.47 | 0.401 | 9.14 | 0.111 | 95.47 | 0.180 |

| Measurement points | X | Y | Z | |||

| Frequency (Hz) |

Maximum amplitude (m s-2) |

Frequency (Hz) |

Maximum amplitude (m s-2) |

Frequency (Hz) |

Maximum amplitude (m s-2) |

|

| 1 | 4.06 | 0.253 | 33.44 | 0.363 | 47.81 | 0.212 |

| 2 | 95.47 | 0.342 | 48.57 | 0.688 | 43.28 | 0.207 |

| 3 | 4.06 | 0.228 | 71.41 | 0.132 | 48.57 | 0.217 |

| 4 | 2.65 | 0.247 | 6.25 | 0.101 | 106.4 | 0.152 |

| 5 | 95.47 | 0.149 | 16.56 | 0.111 | 98.44 | 0.131 |

| Measurement points | X | Y | Z | |||

| Frequency (Hz) |

Maximum amplitude (m s-2) |

Frequency (Hz) |

Maximum amplitude (m s-2) |

Frequency (Hz) |

Maximum amplitude (m s-2) |

|

| 1 | 4.53 | 0.149 | 49.77 | 0.165 | 49.84 | 0.157 |

| 2 | 23.83 | 0.129 | 49.77 | 0.172 | 23.45 | 0.135 |

| 3 | 4.53 | 0.134 | 8.75 | 0.092 | 95.47 | 0.107 |

| 4 | 48.57 | 0.367 | 48.57 | 0.301 | 48.57 | 0.479 |

| 5 | 33.44 | 0.156 | 48.57 | 0.318 | 24.22 | 0.265 |

| Measurement points | X | Y | Z | |||

| Frequency (Hz) |

Maximum amplitude (m s-2) |

Frequency (Hz) |

Maximum amplitude (m s-2) |

Frequency (Hz) |

Maximum amplitude (m s-2) |

|

| 1 | 2.81 | 0.146 | 48.57 | 0.368 | 119.4 | 0.209 |

| 2 | 123.3 | 0.246 | 48.57 | 0.220 | 123.3 | 0.213 |

| 3 | 2.65 | 0.329 | 24.22 | 0.092 | 16.72 | 0.100 |

| 4 | 2.81 | 0.159 | 24.22 | 0.072 | 98.67 | 0.115 |

| 5 | 2.81 | 0.166 | 24.22 | 0.058 | 48.57 | 0.383 |

| Measurement points | X | Y | Z | |||

| Frequency (Hz) |

Maximum amplitude (m s-2) |

Frequency (Hz) |

Maximum amplitude (m s-2) |

Frequency (Hz) |

Maximum amplitude (m s-2) |

|

| 1 | 1.25 | 0.192 | 50.47 | 0.190 | 50.47 | 0.233 |

| 2 | 124.1 | 0.257 | 50.47 | 0.314 | 123.1 | 0.278 |

| 3 | 50.47 | 0.189 | 50.47 | 0.104 | 95.47 | 0.294 |

| 4 | 95.47 | 0.401 | 48.57 | 0.519 | 114.1 | 0.220 |

| 5 | 93.12 | 0.213 | 7.96 | 0.099 | 97.81 | 0.171 |

| Measurement points | X | Y | Z | |||

| Frequency (Hz) |

Maximum amplitude (m s-2) |

Frequency (Hz) |

Maximum amplitude (m s-2) |

Frequency (Hz) |

Maximum amplitude (m s-2) |

|

| 1 | 48.57 | 0.986 | 48.57 | 0.865 | 48.57 | 0.788 |

| 2 | 95.47 | 0.359 | 48.57 | 0.259 | 95.47 | 0.283 |

| 3 | 48.57 | 0.614 | 2.65 | 0.583 | 95.47 | 0.655 |

| 4 | 2.65 | 0.185 | 24.22 | 0.271 | 95.47 | 0.298 |

| 5 | 2.65 | 0.301 | 24.22 | 0.259 | 95.47 | 0.304 |

| Measurement points | X | Y | Z | |||

| Frequency (Hz) |

Maximum amplitude (m s-2) |

Frequency (Hz) |

Maximum amplitude (m s-2) |

Frequency (Hz) |

Maximum amplitude (m s-2) |

|

| 1 | 48.57 | 0.797 | 48.57 | 0.696 | 48.57 | 0.605 |

| 2 | 95.47 | 0.261 | 95.47 | 0.217 | 95.47 | 0.237 |

| 3 | 2.65 | 0.386 | 2.65 | 0.242 | 95.47 | 0.425 |

| 4 | 2.65 | 0.182 | 24.22 | 0.249 | 95.47 | 0.146 |

| 5 | 2.65 | 0.238 | 24.22 | 0.175 | 48.57 | 0.202 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).