1. Introduction

Prefabrication in civil building represents a production and construction method now widely used in the realization of the great modern constructions. This approach can provide a number of benefits including: reduction of time/cost ratio, efficiency, reliability, quality control and sustainability of solutions in both new construction and retrofitting. Structures designed and built with reference to the latest seismic codes must also satisfy requirements aimed at ensuring adequate behavior of the structure during earthquakes. Dissipative structures must provide stiffness, strength and ductility at ultimate limit states in order to dissipate some of the input seismic energy by developing plasticization in specific areas of the structure in accordance with the principle of capacity design adopted by NTC18 [

1], Eurocode 3 [

2] and Eurocode 4 [

3].

In this paper, a type of ductile beam-column connection, which is very common in precast reinforced concrete structures involving composite precast truss beams, is considered. The connection element must ensure the continuity of beam and column reinforcement through the joint. If the beams are partially precast, the addition of rebars is required after the beams have been placed and before the concrete completion casting is carried out. Mechanically, the joints must have adequate resistance to shear stresses and must preserve the integrity of the column to allow the formation of plastic hinges in the beam sections near the joints.

Experimental tests on full-scale structural elements represent a fundamental instrument for the correct characterization of the mechanical, static and seismic behavior of structures. Experimental tests on beam-column joints referring to different types of joints, materials and construction technology, for years now, have been widespread and easily obtainable in the literature. These can be classified by modality of the test (monotonic, cyclic) and load application (quasi-static or dynamic tests) and by the type of joint (internal, external) and layout of specimen restraints.

Most of the solutions found in the literature, adopted for beam-column connections, involve the use of integrative trusses where plastic hinge formation occurs. This concept is in contradiction with the requirements of current Italian code NTC18 [

1] for which composite trussed elements shall not be used in dissipative zones.

To experimentally reproduce the effective stress distribution on the specimens, a series of constrain consisting of cylindrical hinges were applied. Studies conducted by [

4,

5,

6,

7] demonstrated the ductile behavior of the connection with the localization of plastic hinges at the ends of the beams when the joint is stressed by bending. Experimental testing can be characterized by the different point of application of the external force. In case of external joints, the specimens are simplified as they involve a single beam, a lower column and an upper column properly constrained [

6,

8]. Other authors in their experimental tests have adopted a scheme involving a cylindrical hinge at the base of the column, a connecting rod applied at the end of the beam, and an actuator that applies the force at the top of the column [

9,

10,

11]. A different load pattern was used by [

12,

13] during testing on a post-tensioned glulam beam-column joints, in addition to the seismic forces and axial stress applied to the column, additional masses were placed on the beam to simulate the shear stress due to gravitational loads present in seismic action combination.

In order to easily equipped with efficient and cost-effective seismic damage-proof connections of RC moment-resisting framed structures endowed with semi-prefabricated steel-trussed concrete beams and standard RC pillars cast-in-place, recent study have been developed specific energy dissipating systems for hybrid beam-to-column connections, using both experimental, numerical, and analytical methods [

14,

15,

16,

17].

In the present study, the experimental seismic performance of composite steel-trussed concrete beam ductile joint, patented as MTR® system by Metal-Ri s.r.l. [

18] (

www.metalri.it), is investigated by means of a numerical models simulating cyclic tests performed on two experimental joints extracted from the same prototype building. The experimental models were made with the same connection and were subjected to quasi-static cyclic tests with different experimental setups and test apparatus. The objective of the investigation is to verify the bending strength and ductility of the beam-to-column joints when shear stress are applied in accordance with the requirements provided in the Italian seismic code and to determine the global ductile behavior of the connection.

2. Experimental tests

2.1. Experimental specimens

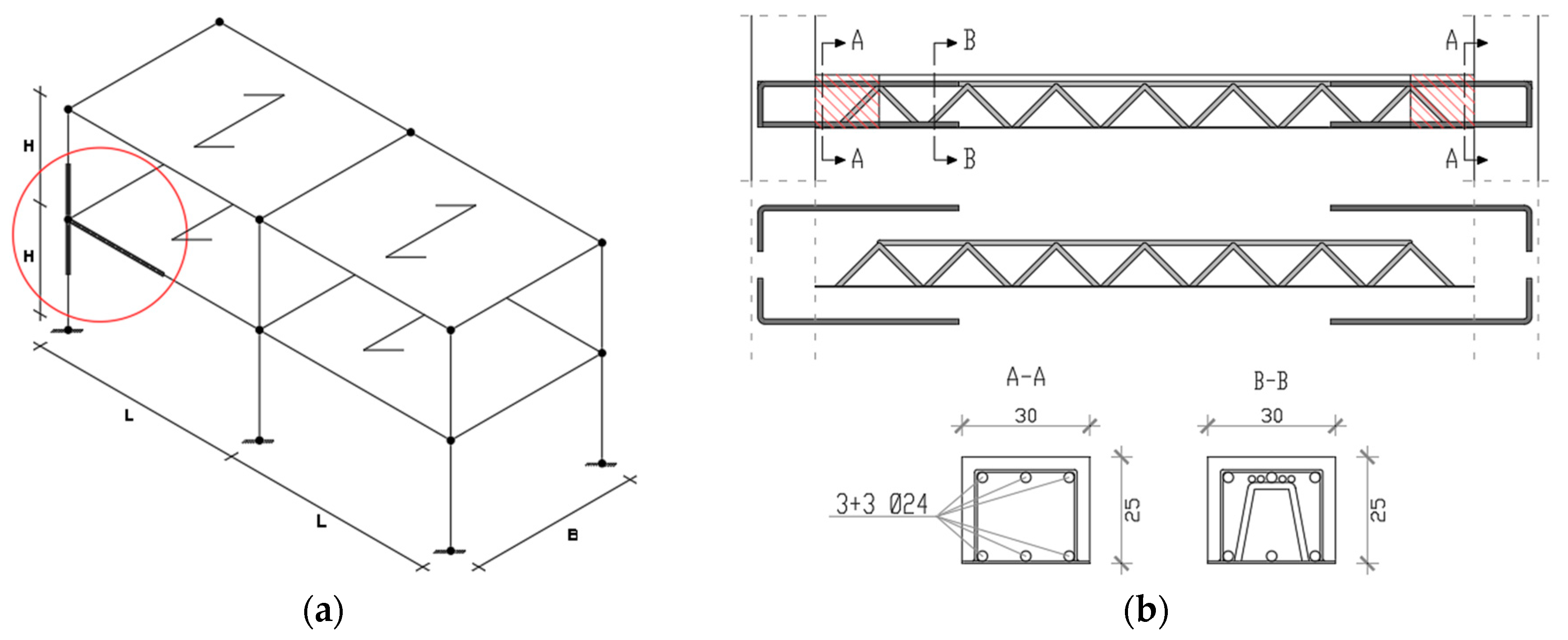

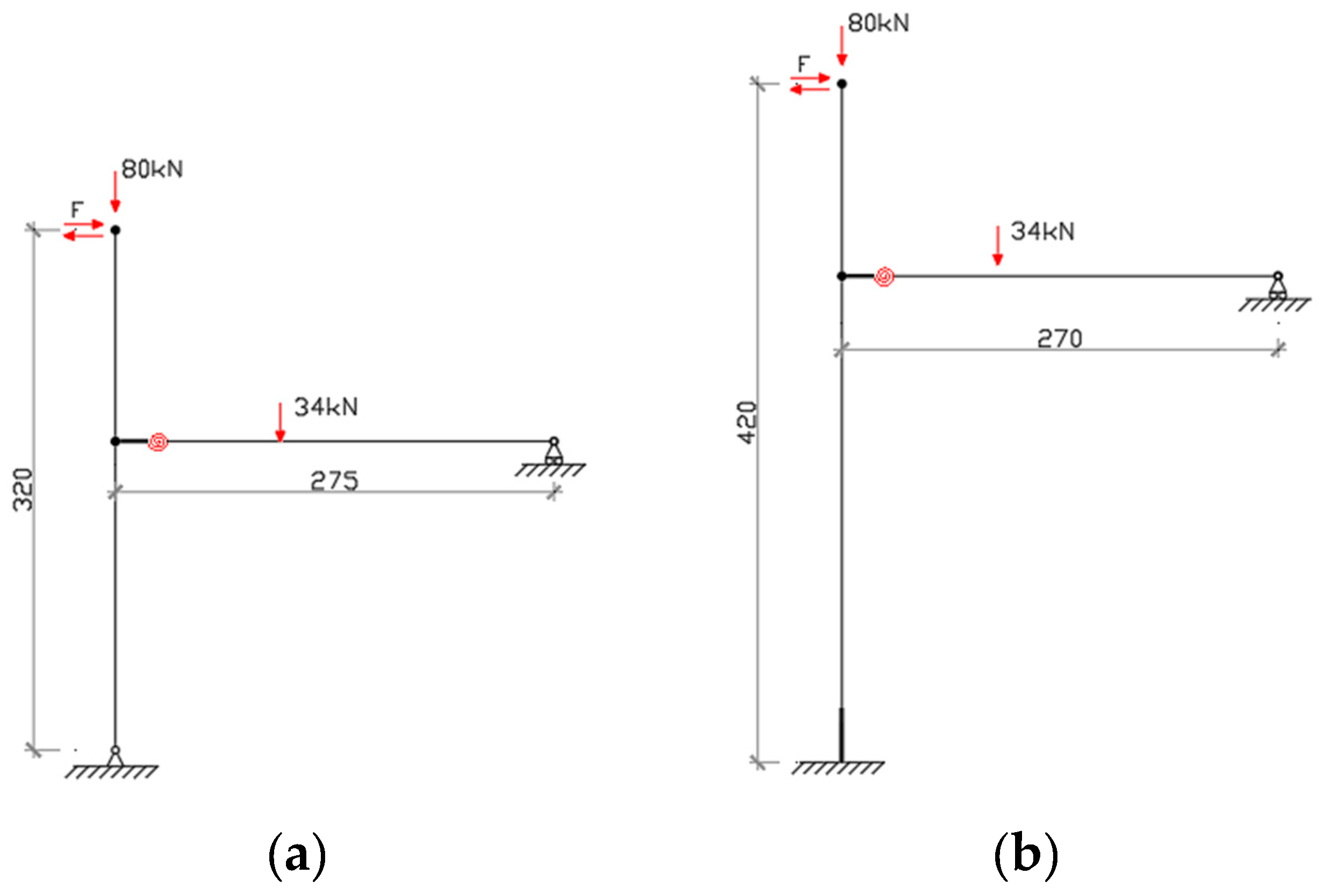

Two full-scale models of precast composite truss beam-column joints, extracted from an external joint of a three-dimensional residential prototype building (

Figure 1a), were tested with different constraint conditions at the base of the column. The prototype building was designed according to the Italian seismic codes NTC2018 [

1] considering the gravity loads and seismic action using a linear dynamic modal analysis with a response spectrum. The specimens are representative of joints in framed seismic structures, where MTR-A beams (

Figure 1b) are connected to an RC column cast in situ or a CFT column.

In particular, the specimens have the same composite precast truss beam which consists of 30x25cm rectangular cross section. In the central part of the composite beam, the steel truss ends immediately before the column element and the two end parts, consisting of simple reinforced concrete section, in which six 24 mm steel rebars are placed at the ends of the beam and anchored in the joint panel, provide the required strength and ductility for the beam section. Additional masses constitute by steel plates were placed on the beams to simulate gravitational loads. Then, external forces such as axial stress in the column and a cyclic horizontal force simulating earthquake, are applied to the model by hydraulic jacks. Additional masses, producing flexural and shear effects, allow the study of possible brittle mechanisms related to shear stresses.

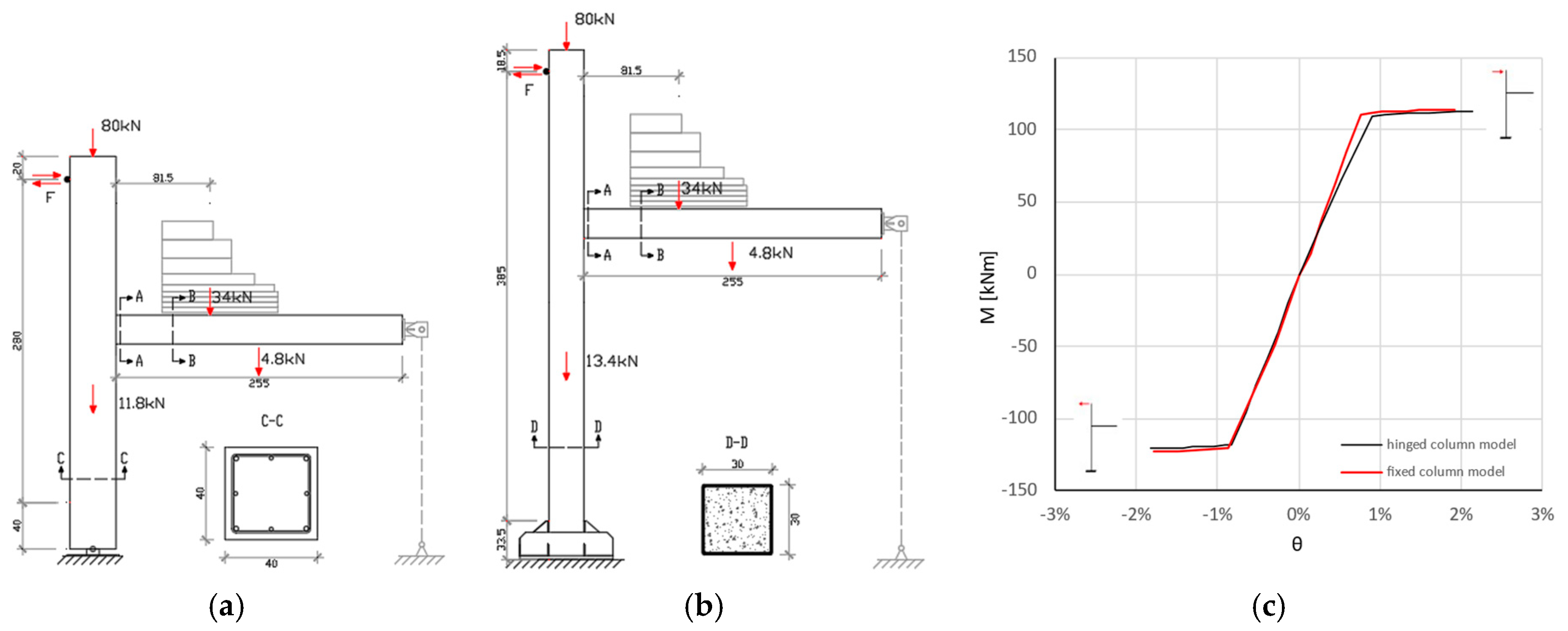

The specimens differ for the column type, length and base constraints. In the model 1 the reinforced concrete column (

Figure 2a) has a rectangular cross section of 40x40cm, the length is 3,00 m and it is hinged at the base (

Figure 3a). In the model 2 the composite concrete filled steel tube column (

Figure 2b) has rectangular cross section of 30x30cm, the length is 4,50 m and it is fixed to the base (

Figure 3b). The specimen 1 was made up with a C28/35 concrete while the specimen 2 of a C40/50 concrete. For both specimens reinforcement rebars and steel elements are referred to B450C and S355, respectively. The Moment-rotation of the cross sections of the end of beams from the design is reported in

Figure 3c. In the design, the resistant section in the proximity of the beam-to-column joint is considered to be made up only of concrete and the longitudinal reinforcement, neglecting the contribution provided by the upper chord and the bottom plate, of the steel truss. The constitutive material behavior is a simplified bilinear behavior for steel and concrete. The tensile strength of the concrete has been neglected in the design.

2.2. Test apparatus and load pattern

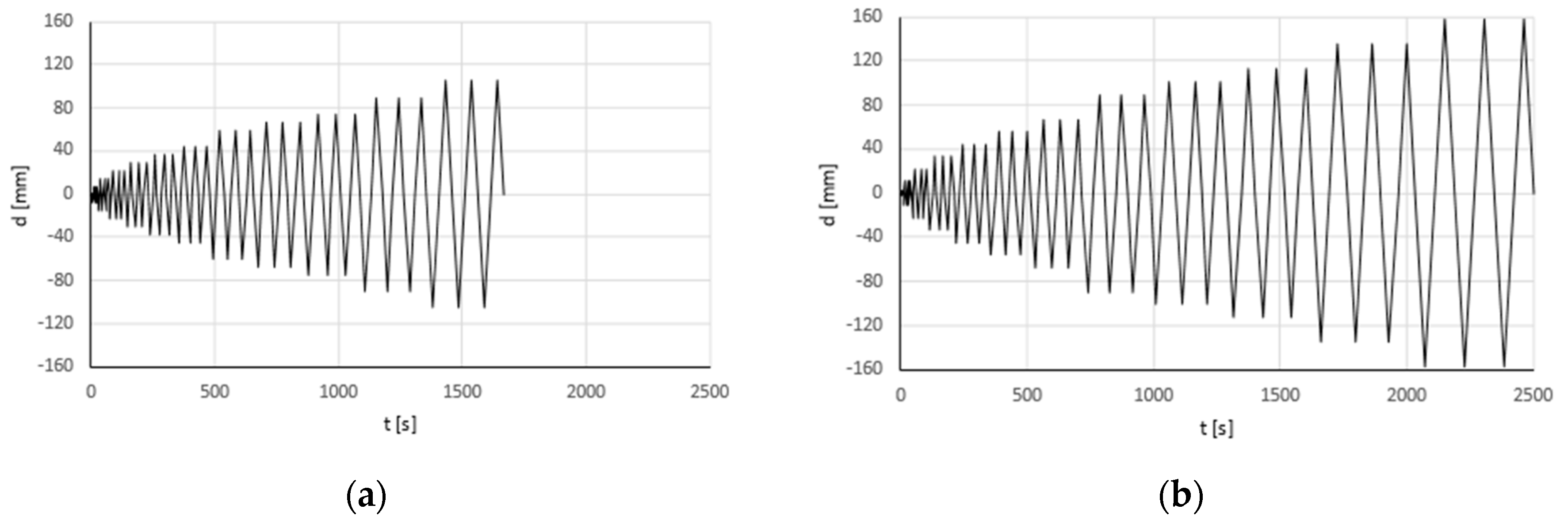

In order to reproduce on the experimental model the correct stress state provided by the prototype numerical model due to gravitational and seismic loads, a dual configuration of constraints and external loads is required. Consequently, two distinct experimental stages of loading have been considered. Stage 1 of loading is intended to reproduce the loading and specimen deformation due to only gravitational loads. An axial load of 80 kN of is applied to the column and a shear load with triangular shape of 34 kN is applied on the beam, when it is free to be deformed. The specimen is restrained by the horizontal actuator on the top of the upper column. During Stage 2 of loading, a connecting rod with a cylindrical hinge is installed at the end of the beam. In this way, the constraint boundary conditions of the specimen reproduce the inflection points of the elastic deformation in the prototype three-dimensional structure. In this phase, the application of the horizontal action simulating the earthquake occurs. Displacement-controlled quasi-static cyclic tests consist of almost 12 consecutive tests each composed of 3 displacement cycles imposed on the specimen. Each test corresponding to an increasing value of drift, calculated at the top of the column, according to the test program shown in

Figure 4 and

Table 1.

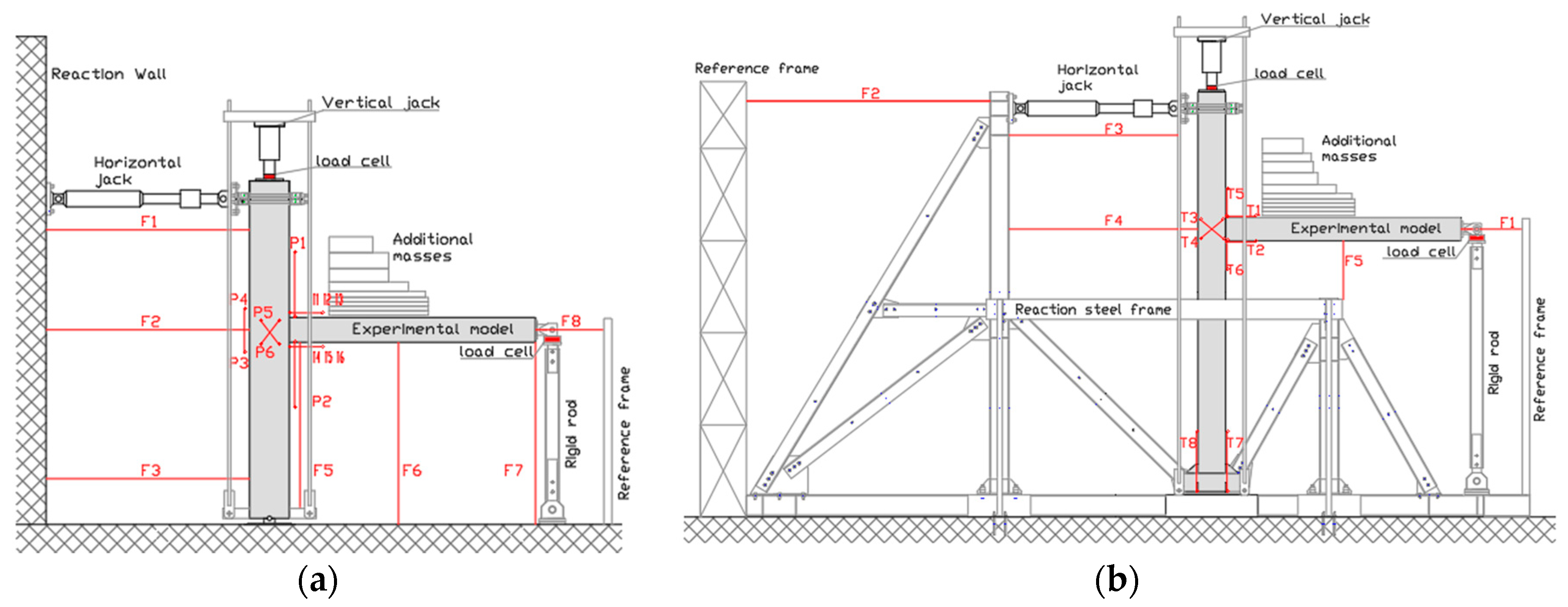

The test equipment consists in horizontal and vertical hydraulic jacks and a contrast structure, made by a reinforced concrete reaction wall for the hinged column model (

Figure 5a) and a reaction steel structure for the fixed column model (

Figure 5b). Potentiometric displacement transducers were installed on the specimen to monitoring and recording the global behavior (F) and the local deformations (P, T) of the joint panel and the base of the fixed column. Three load cells have been placed to record the force applied at the top of the columns in vertical and horizontal direction and the reaction force at the end of the vertical rigid rod elements placed at the end of the beams.

2.3. Experimental result

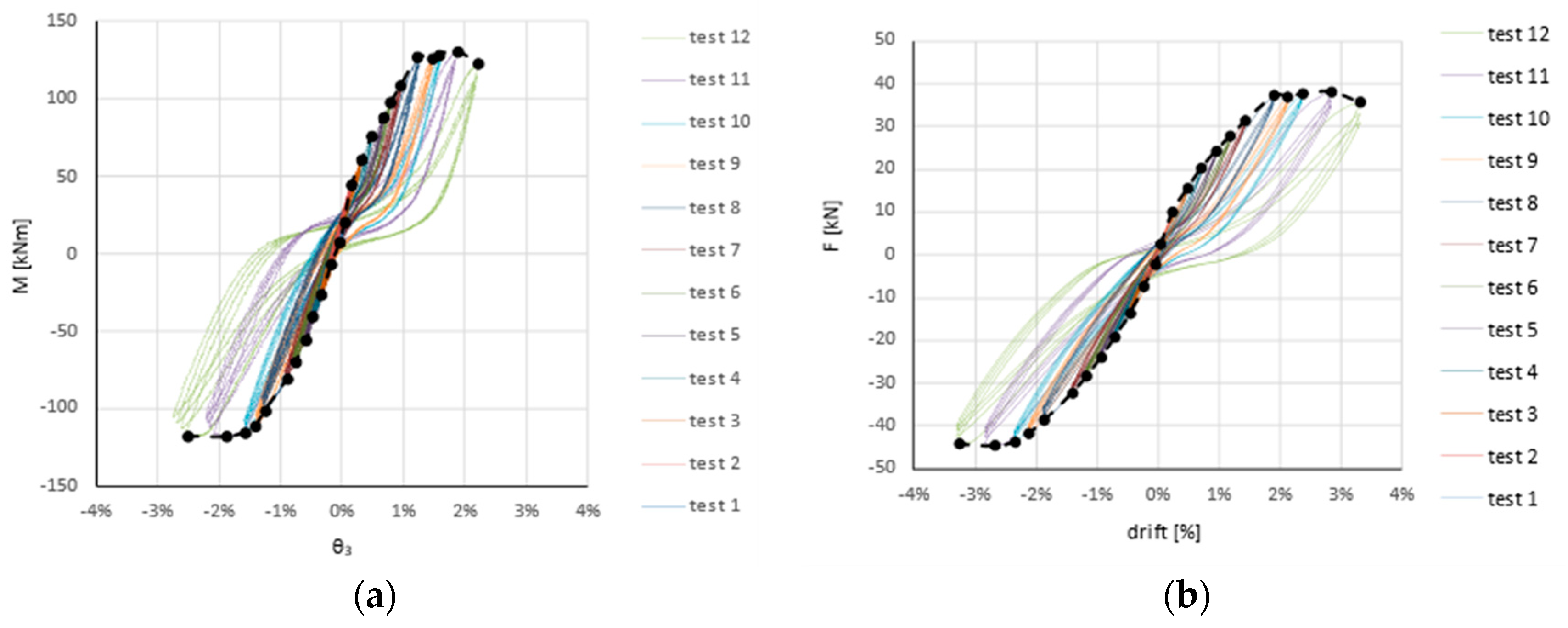

The results of experimental tests carried out on the hinged column model (test specimen 1) at the Materials and Structures Test Facility of the University of Basilicata in 2016 are shown in

Figure 6 in term of envelope of local moment-rotation of the connection element (

Figure 6a) and the envelope of global force-drift of the specimen (

Figure 6b). The force values considered are the values recorded at the actuator located at the top of the column, while the drift is calculated as the ratio between the displacement made by the actuator and the distance between the actuator and the cylindrical base hinge.

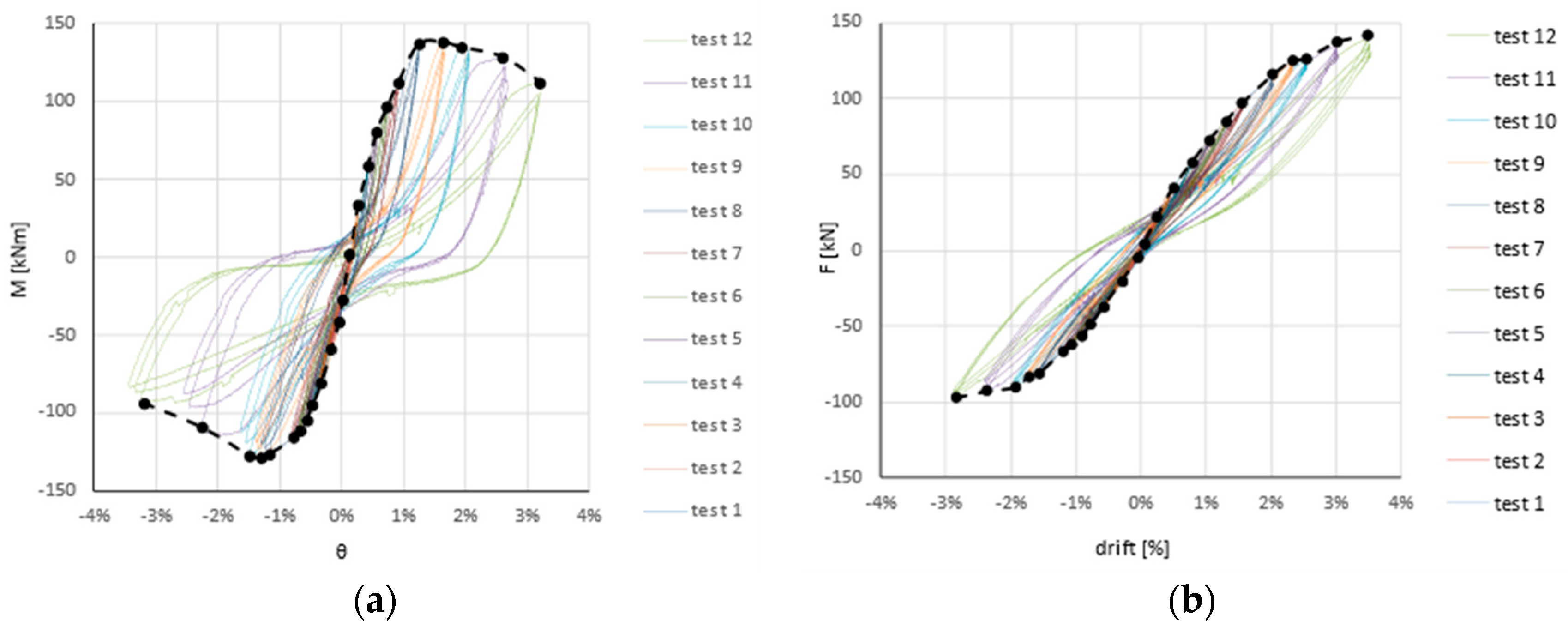

At the same way, the results of experimental tests carried out on the fixed column model (test specimen 2) at the Manufacturing Facility of Metal.Ri S.r.l. in 2023 are shown in

Figure 7. In this case, a reduction of the experimental drift compared to the theoretical drift in the actuator pull direction is observed, due to the different deformability in the two sides of the external steel reaction structure. The fixed-base column responded within its elastic range and contribute to increase the global force compared with hinged-base column.

In both cases the plastic hinge deformation can be observed at the end section of the beam starting from about 1% of drift. Good dissipative and ductile capacities are shown in

Figure 6a and

Figure 7a. The connections are able to support gravity loads despite the significant reduction of the global stiffness and strength related to the damage developed starting from test 9 or test 8, respectively.

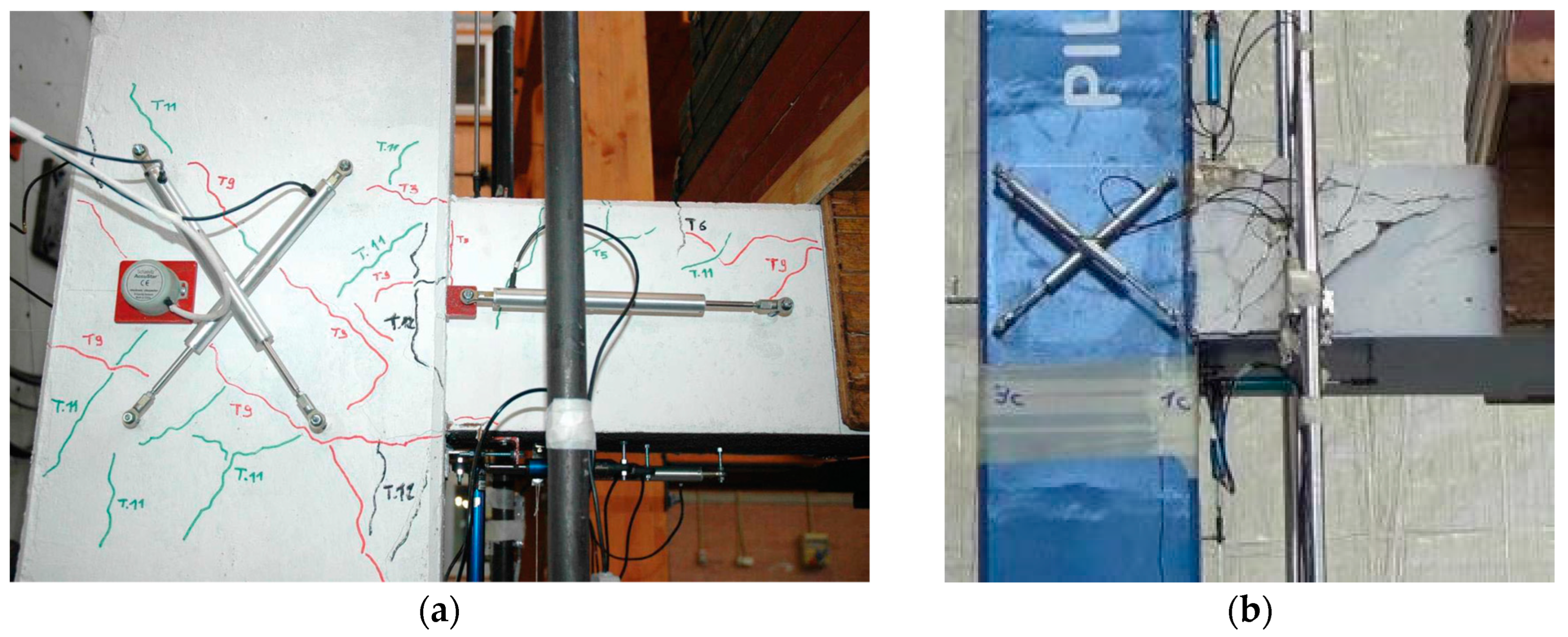

Figure 8 shows for both specimens the crack pattern detected at the end of the test. From

Figure 8a, referring to the hinged specimen, it can be observed the plasticization of the column beam connection section and a series of moderate cracks across the entire RC joint panel.

Figure 8b, related to the fixed specimen, shows the complete flexural plasticization of the beam-column connection element while the integrity of the CFFT column is preserved.

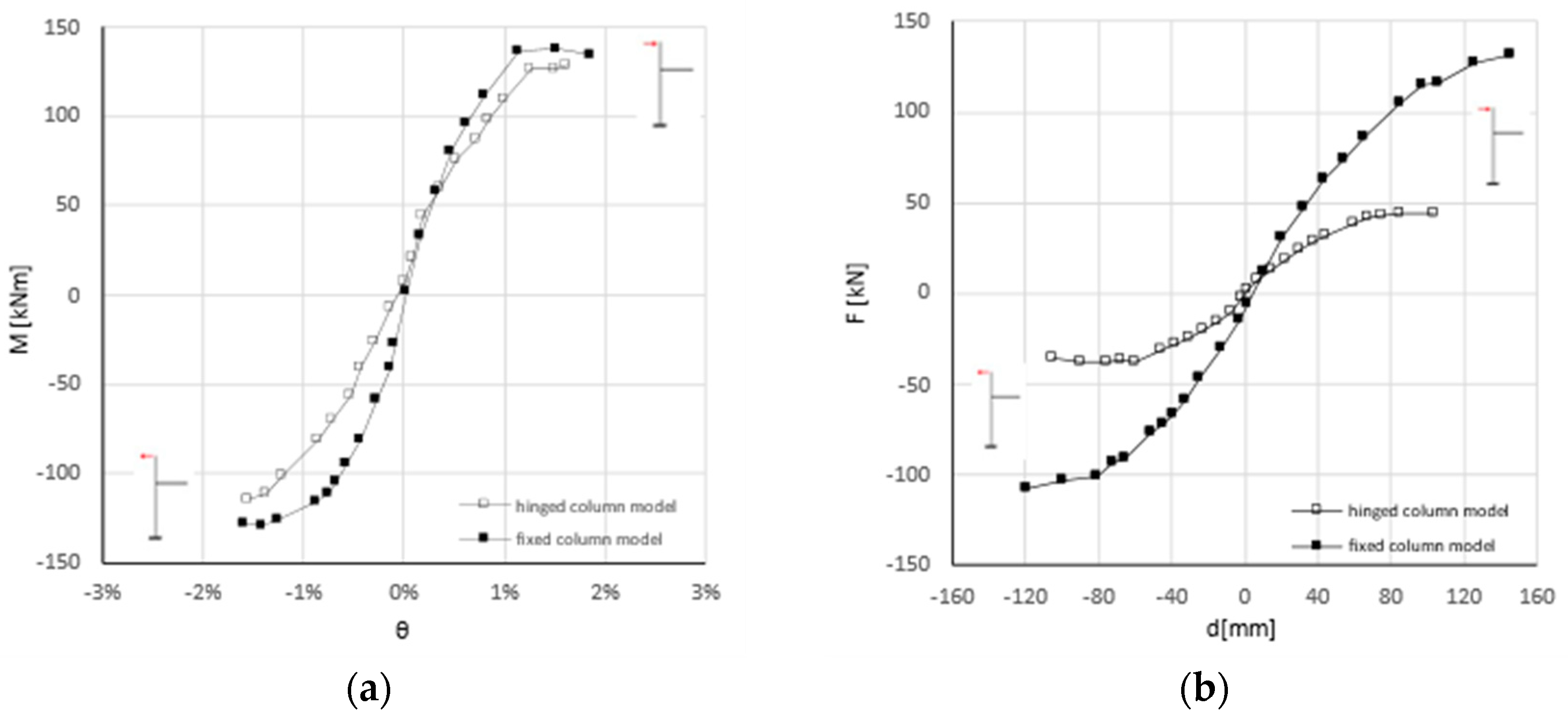

The direct comparison of experimental results is shown in

Figure 9. Both specimens are characterized by the same local behavior (

Figure 9a) of the joint connection, while the global behavior (

Figure 9b) of the fixed column model has a significantly higher strength and displacement capacity, due to the influence of different test scheme.

3. Numerical analysis

With the aim of validating and interpreting the experimental results, two different modeling approaches were considered using Sap2000 software [

19], based respectively on lumped plasticity or fiber modeling of the most stressed sections.

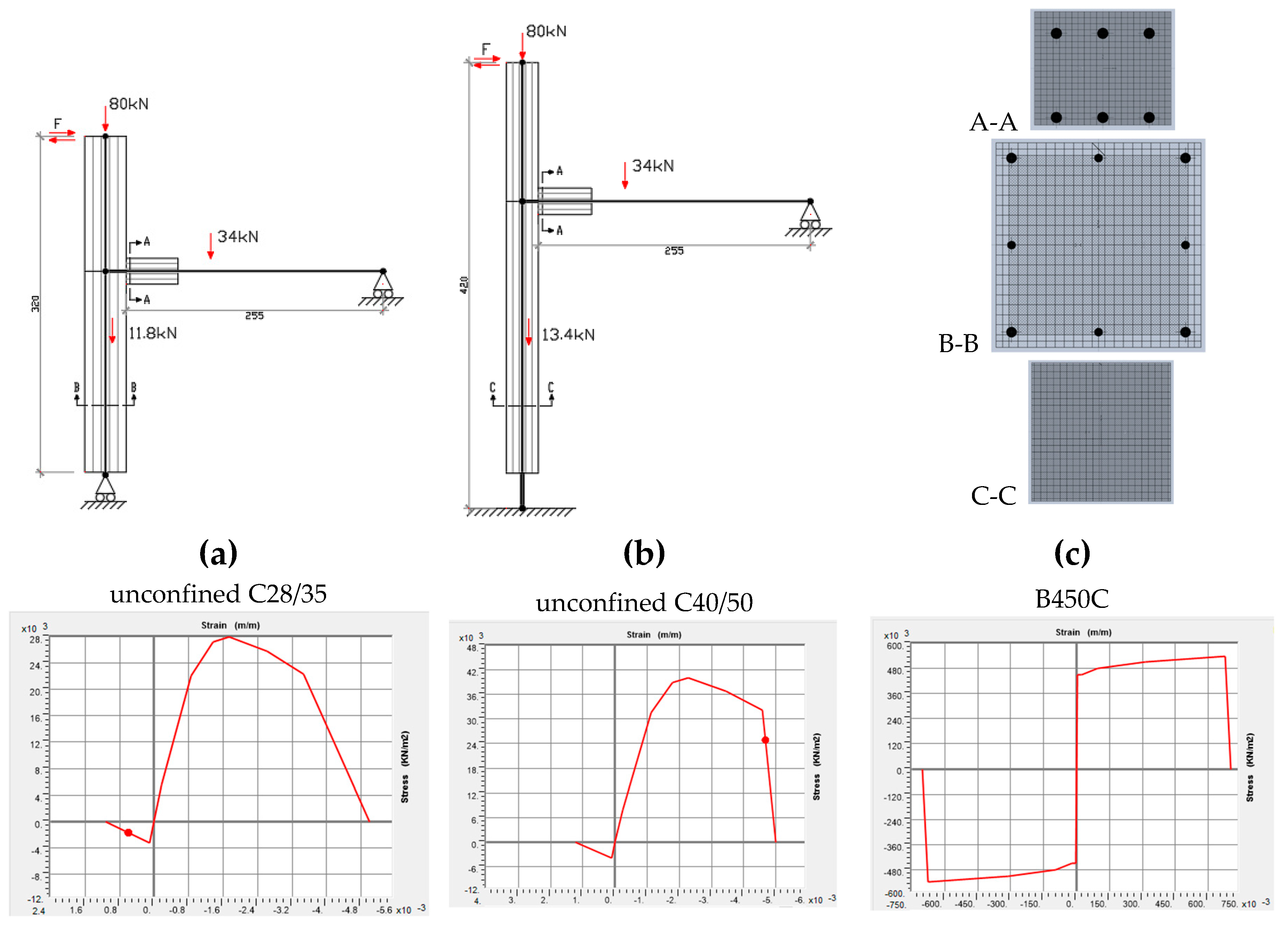

First modelling approach considers a lumped plasticity model [

20] composed by two elastic elements connected by a plastic hinge inserted at the end of the beam (

Figure 10). The overall dimensions and external restraints adopted for the models are reported in

Figure 10a for specimen 1 e

Figure 10b for specimen 2. In the lumped plasticity model the inelastic behavior is concentrated in zero-length plastic hinge composed by a nonlinear rotational spring calibrated on the basis of experimental responses of the both experimental tests. The reinforced concrete connection elements have the same geometric characteristics in both specimens, which, however, are made of different materials that affects the moment-rotation relationship. The overstrength capacity of the panel zone is defined in the model by means of rigid end offset. For the fixed column model, a rigid zone was also defined at the base of the column.

In the second modelling approach, numerical fiber element plasticity models [

21] able to take into account the yield of steel, including strain hardening, are defined to validate the nonlinear behavior of both experimental tests (

Figure 11a and

Figure 11b). In the fiber modelling the inelastic behavior is distributed plasticity model within the length of the deformable region, taking into account the spread of inelastic behavior both over the cross sections and along the member length. The proposed models may be easily implemented in a finite element software program adopting elastic and nonlinear mono-dimensional elements. With particular regard to the current case, column and beam elements were modeled with frame elements divided into a number of segments in which the section properties are assumed constant; the cross section of each segment is divided into a number of fibers

Figure 11(c) having nonlinear stress–strain relationship of both steel and concrete materials

Figure 11(d). Fiber sections are defined only on geometrical and mechanical properties without applying any empirical calibration procedure.

With the aim of accurately reproduce the distribution of the plastic strains in the first part of the beam close to the column edge, having the RC cross sections A-A represented in

Figure 1b, a dense discretization has been employed with a segment of size 50 mm for an extension equal to 2

h, where

h is the section element depth, while the remaining elements of the prefabricated beam with dimension 205 mm, having the cross sections B-B represented in

Figure 1b, has been considered elastic. The cross section of the beams has been discretized in 20 x 20 fibers of unconfined concrete and the steel reinforcement rebars. For the tensile concrete, a linear behavior with elasticity modulus

Ect =

Ec / 3 and tensile strength

fct =

fcu /10 has been employed. The contributions of stiffness and strength of the beam provided by the reinforcement of the truss and of the bottom steel plate in the proximity of the joint are neglected. In fact, the detail of the connection to the joint, characterized by the absence of connection devices and anchoring of both the truss and the bottom steel plate, as confirmed by the experimental results.

Within the definition of the fiber finite element of the columns, in order to model the constitutive law of the unconfined concrete in compression, the relationship proposed by Italian code [

1] has been used. Concerning the steel of the deformed bars and the plate, trilinear constitutive laws are assumed with reference to the empirical values. Rigid elements are used for modelling the joint panel, since during the experimental tests it remained intact without any shear deformation. External restraints for reproducing the test apparatus have been also introduced.

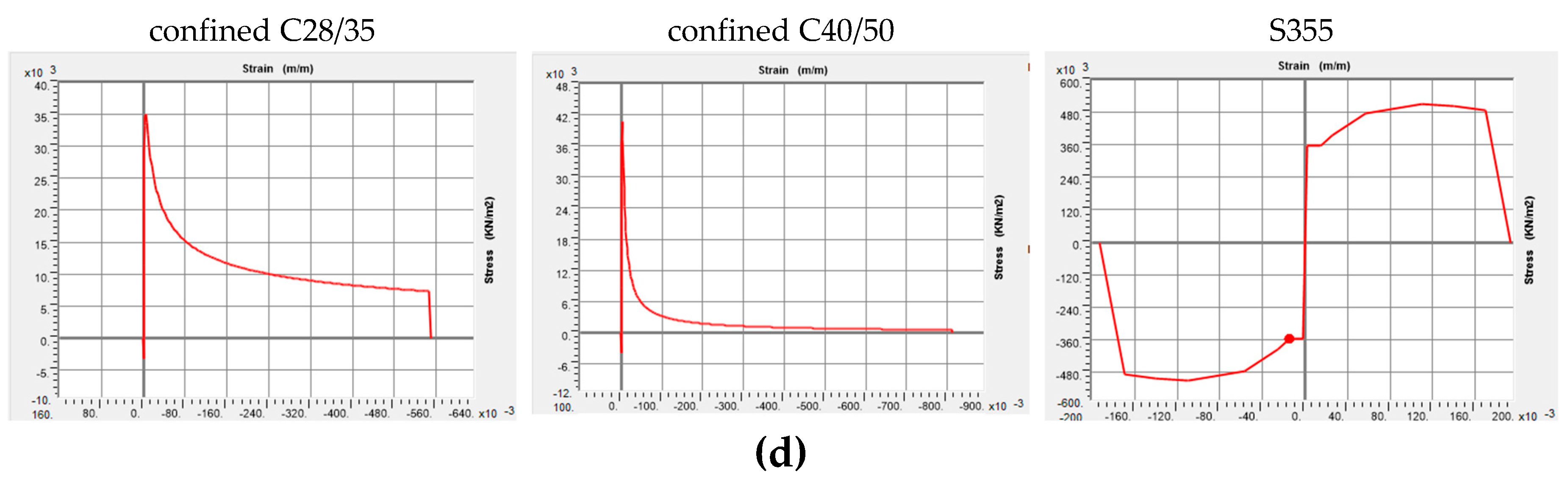

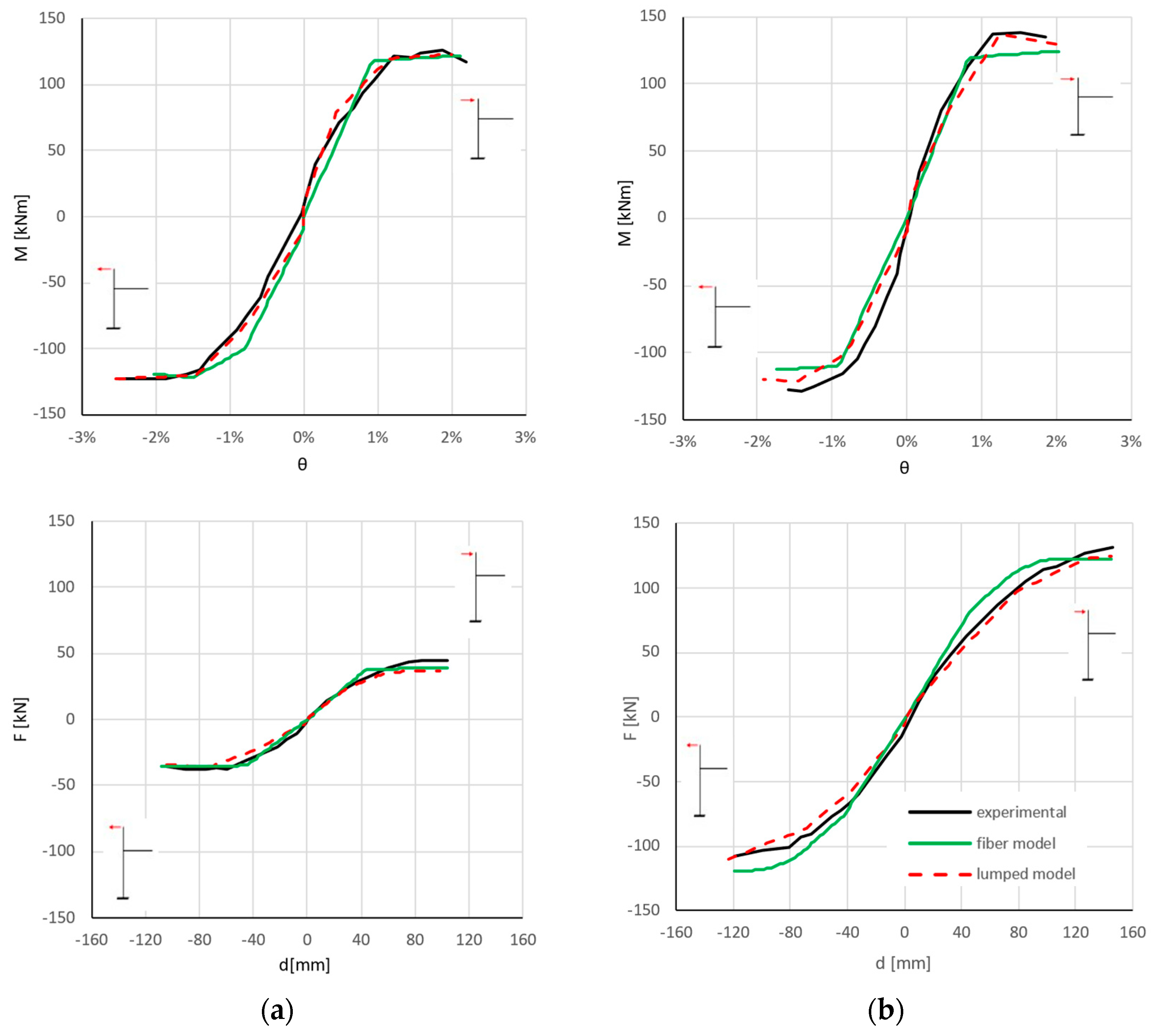

The comparison between experimental results and numerical simulations is shown in

Figure 12 in term of local and global behavior considering both experimental specimens and modelling approaches. Both numerical models provide the curves for monotonic load which represent the envelope of the cyclic behavior.

In

Figure 12 the local behaviors of the connections are shown in terms of moment-rotation of the end sections of the beams, while the global responses are shown in terms of horizontal Force-drift of the top of the columns. It can be observed that both numerical simulations, based on lumped plasticity or fiber models, are well correlated with the global experimental responses. The analyses performed on the fixed base model have also allowed verifying that the columns remain in the elastic range satisfying the capacity design criteria.

4. Conclusions

The ductility of the overall dissipative structure depends essentially on the behavior of the connection elements, which are able to develop the required plasticization mechanism imposed by the capacity design criteria of the seismic codes. In this paper, the ductile behavior of beam-column joint connections between composite truss beam and reinforced concrete column or concrete filled tube column have been experimentally proved by means of quasi-static cyclic tests.

Two experimental models characterized by the same beam sections and different solution for the column, the first entirely made by a reinforced concrete and with a hinged-base RC column, the second one made with a cast of lightly reinforced concrete in a steel tube and with a fixed-base, have been tested. Although the global response of the two models is significantly different due to the different geometric and constraint configuration, the experimental results show an essentially identical local behavior of the connection system despite the different class of concrete material. The tests were carried out in different facilities, at the seismic Laboratory of University of Basilicata and at the manufacturing site, deducing the repeatability of the experimental results. Both experimental specimens were able to support the shear stresses resulting from the gravitational loads and to develop the required levels of local rotation and global drift even after the connections themself were damaged. The plasticization of the section is characterized by a stable behavior with a significant amount of energy dissipation showing a limited reduction in strength and evidencing a predominantly flexural crack pattern.

Two simplified modelling approaches for the analysis of seismic-resistant frames built using partially prefabricated structural elements such as precast composite trussed beams were adopted for both specimens in order to simulate and to validate the test results. A lumped plasticity modelling calibrated on the experimental results and a blind fiber modelling defined only on the geometrical and mechanical properties have been implemented in SAP 2000 software. The simulations with the fiber models are in good agreement with the numerical results of simplified lamped plasticity models, verifying that the column remain in the elastic range satisfying the capacity design criteria, and are coherent with the experimental data, demonstrating the repeatability of the experimental behavior.

Author Contributions

Conceptualization and funding acquisition G.V.; Methodology and Experimental investigation A.D. and F.P.; Supervision and validation F.P.; Writing and editing, A.D. and P.B.; numerical analysis, A.D. and P.B.. All authors have read and agreed to the published version of the manuscript.

Funding

This research was financially supported by Info.MTR S.R.L. Company (Italy).

Institutional Review Board Statement

Not applicable.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

The authors would like to warmly thank Metal-Ri S.r.l. for providing the specimens and Domenico Nigro for assuring commendable technical support during the experimental campaign.

Conflicts of Interest

The authors declare no conflict of interest.

References

- D. Min. LL. PP. 17 gennaio 2018 Aggiornamento delle Norme Tecniche per le Costruzioni 2018.

- CEN. Eurocode 3: Design of steel structures Part 1-1: General rules and rules for buildings. Comité Européen de Normalisation: Bruxelles, 2003.

- CEN. Eurocode 4: Design of composite steel and concrete structures Part 1-1: General rules and rules for buildings. Comité Européen de Normalisation: Bruxelles, 2004.

- Colajanni, P. , La Mendola L., Monaco A., Spinella N., Cyclic behavior of composite truss beam-to-rc column joints in MRFS. Key Engineering Materials 2016, 711, 681–689. [Google Scholar] [CrossRef]

- Scotta, R. , Tesser L., Comportamento di nodi trave-pilastro sismo-resistenti in struttura mista di tipo tralicciato soggetti ad azioni cicliche. Progettazione Sismica.

- Amadio, C. , Macorini L., Sorgon S., Suraci G. Analisi di un sistema ibrido sismo-resistente costituito da elementi tralicciati in acciaio inglobati nel calcestruzzo. 17° Congresso C.T.E. Roma, 5-6-7-8 novembre 2008. http://hdl.handle.net/11368/2411299.

- Pampanin S., S. Sritharan, Analytical modeling of the seismic behavior of precast concrete frames designed with ductile connections. Journal of Earthquake Engineering 2001, 5, 329–367. [Google Scholar] [CrossRef]

- Zhang, J. , Zhao X., Rong X., Li Y., Experimental study of high-strength steel fiber concrete exterior beam-column joints with high-strength steel reinforcements. Bulletin of Earthquake Engineering 2023, 21, 2785–2815. [Google Scholar] [CrossRef]

- Palermo, A. , Pampanin S., Fragiacomo M., Buchanan A. H., Deam B. L., Pasticier L., Quasi-static cyclic tests on seismic-resistant beam-to-column and column-to-foundation subassemblies using Laminated Veneer Lumber (LVL) 2006. http://hdl.handle.net/10092/178.

- Masi, A. , Santarsiero G., Nigro D., Cyclic Tests on External RC Beam-Column Joints: Role of Seismic Design Level and Axial Load Value on the Ultimate Capacity. Journal of Earthquake Engineering 2013, 17.1, 110–136. [Google Scholar] [CrossRef]

- Laterza, M. , D'Amato M. , e Gigliotti R., Modeling of gravity-designed RC sub-assemblages subjected to lateral loads, Engineering Structures 2017, 130, 242–260. [Google Scholar] [CrossRef]

- Smith, T. , Ponzo F.C., Di Cesare A., Auletta G., Pampanin S., Carradine D., Palermo A., Nigro, D., Seismic performance of a post-tensioned glue laminated beam to column joint: Experimental and numerical results. Proc. of. World Conference on Timber Engineering WCTE 2012, 2, 385–393. [Google Scholar]

- Smith, T. , Ponzo F. C., Di Cesare A., Pampanin S., Carradine D., Buchanan A. H., Nigro D., Post-Tensioned Glulam Beam-Column Joints with Advanced Damping Systems: Testing and Numerical Analysis. Journal of Earthquake Engineering 2014, 18, 147–167. [Google Scholar] [CrossRef]

- Colajanni, P.; La Mendola, L.; Monaco, A.; Pagnotta, S. , Low-damage friction connections in hybrid joints of frames of reinforced-concrete buildings. Appl. Sci. 2023, 13, 7876. [Google Scholar] [CrossRef]

- Colajanni, P.; La Mendola, L.; Monaco, A.; Pagnotta, S. , Design of RC joints equipped with hybrid trussed beams and friction dampers. Eng. Struct. 2021, 227, 111442. [Google Scholar] [CrossRef]

- Colajanni, P.; La Mendola, L.; Monaco, A.; Pagnotta, S. , Seismic performance of earthquake-resilient RC frames made with HSTC beams and friction damper devices. J. Earthq. Eng. 2022, 26, 7787–7813. [Google Scholar] [CrossRef]

- Chisari, C.; Amadio, C. , An experimental, numerical and analytical study of hybrid RC-encased steel joist beams subjected to shear. Eng. Struct. 2014, 61, 84–98. [Google Scholar] [CrossRef]

- Metal-Ri, s.r.l. Via Giuseppe Abbruzzese 42, 70020, Bitetto (BA). www.metalri.

- SAP2000 Structural Analysis and Design. Available online: https://www.csiamerica.com/products/sap2000.

- Bruschi, E. , Calvi P. M., Quaglini V., Concentrated plasticity modelling of RC frames in time-history analyses. Engineering Structures, 2021, 243, 112716. [Google Scholar] [CrossRef]

- Colajanni, P. , La Mendola L., Monaco A., Stiffness and strength of composite truss beam to RC column connection in MRFS. Journal of Constructional Steel Research 2015, 113, 86–100. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).