Submitted:

04 September 2023

Posted:

05 September 2023

You are already at the latest version

Abstract

Keywords:

0. Introduction

1. Mathematical Equation

1.1. Rock Deformation

1.2. Fluid Flow in Porous Media

1.3. Fluid Flow within Fractures

1.4. Fracture Initiation Law

1.1. Fracture Propagation Law

2. Model Establishment and Simulation Methods

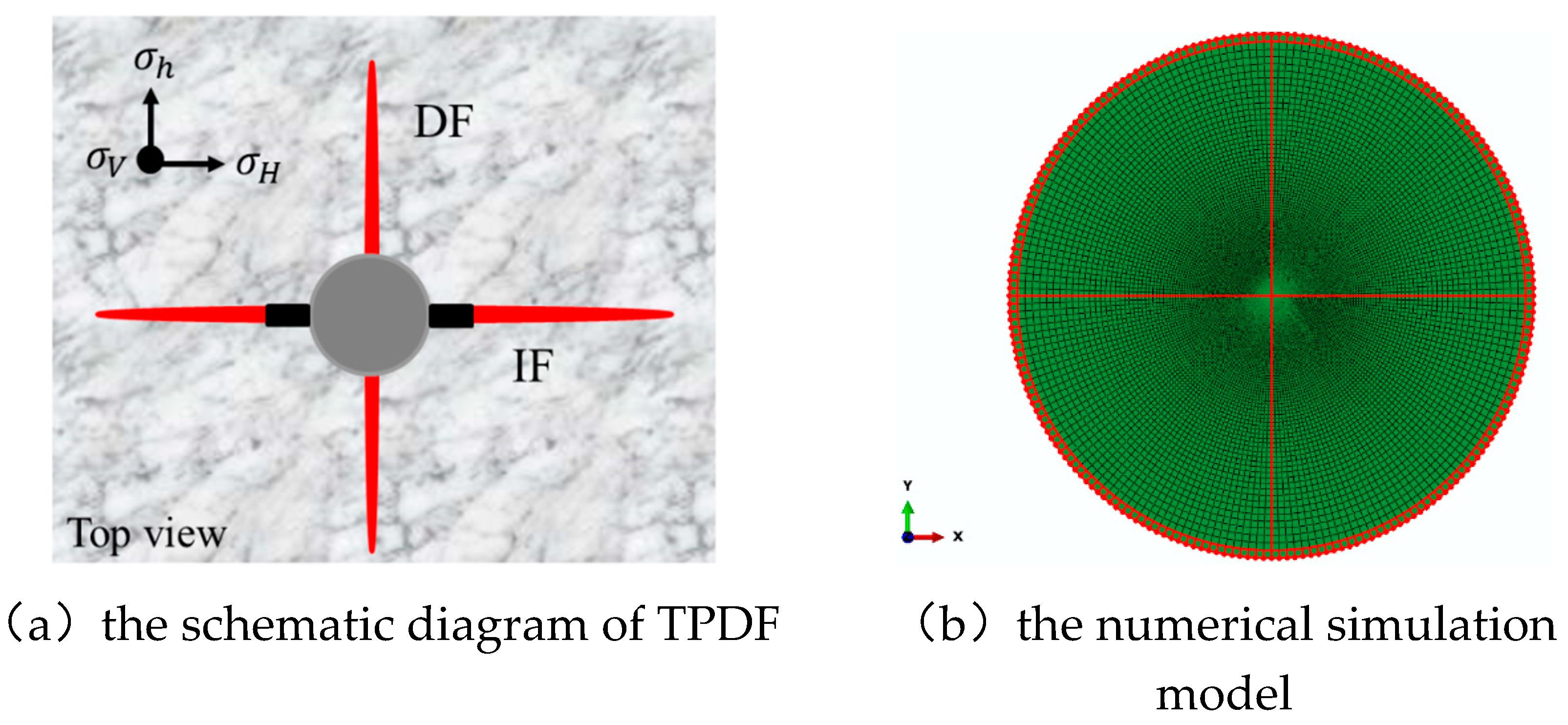

2.1. Model Establishment

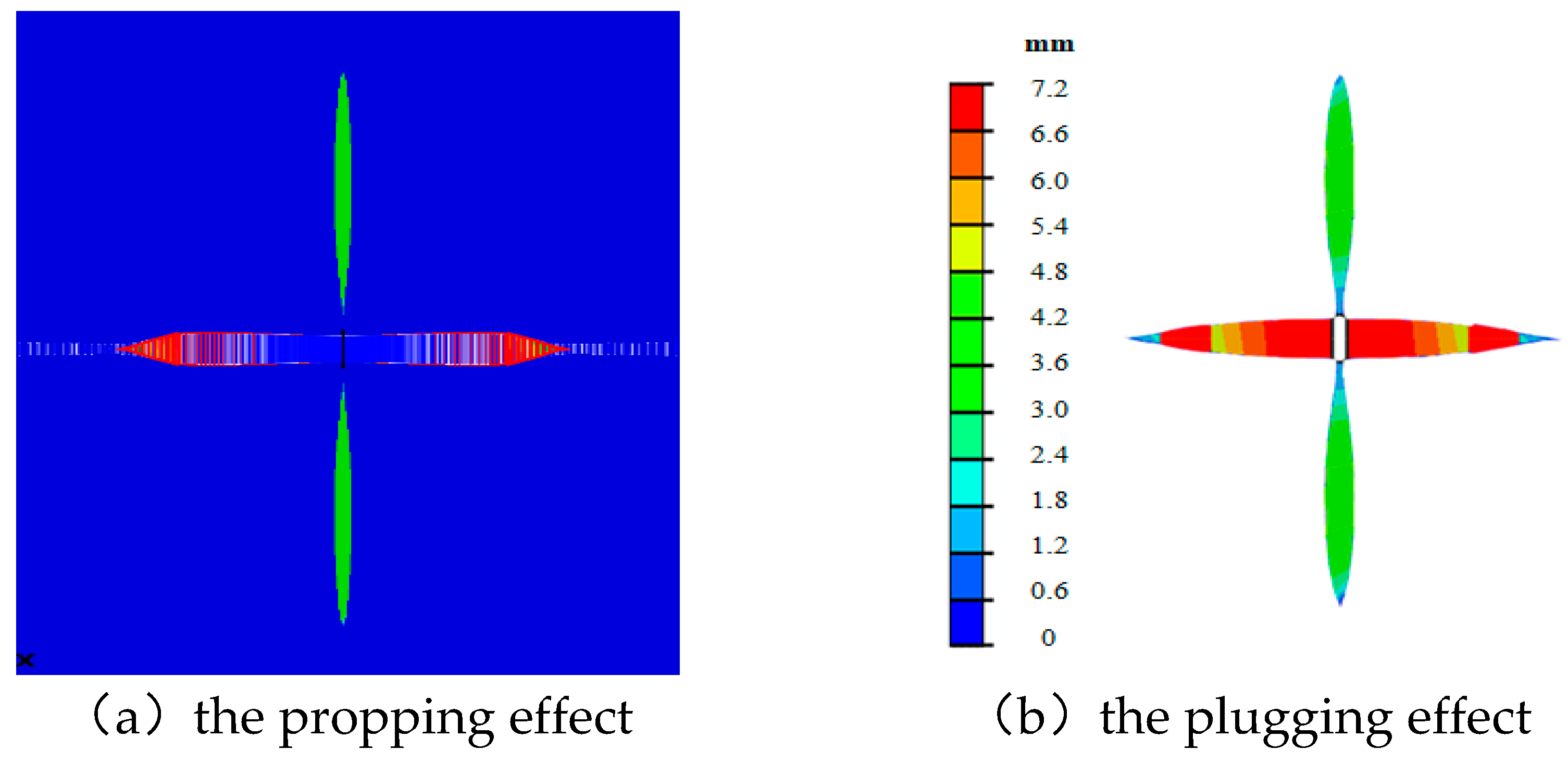

2.2. The Propping Effect of the Proppant

2.3. The Plugging Effect of the Tight Plug

2.4. Model Input Parameters

3. Simulation Results

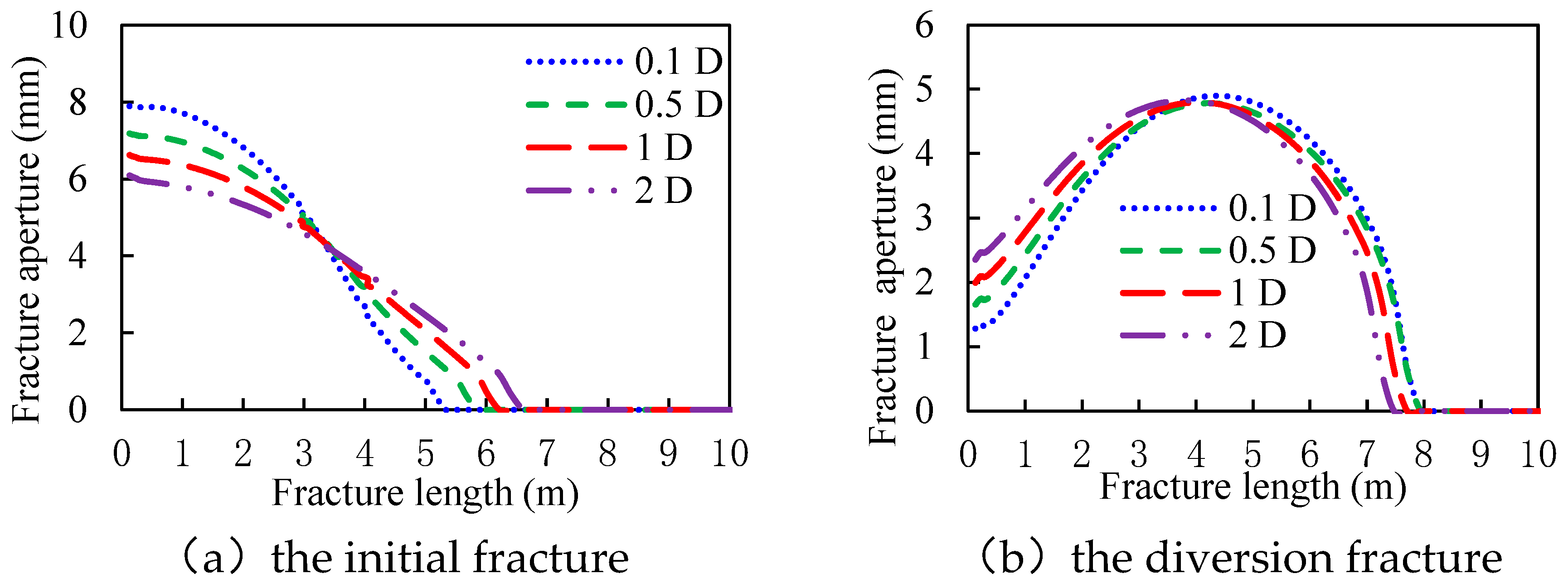

3.1. The Permeability of the Tight Plug

3.2. The Length of the Tight Plug

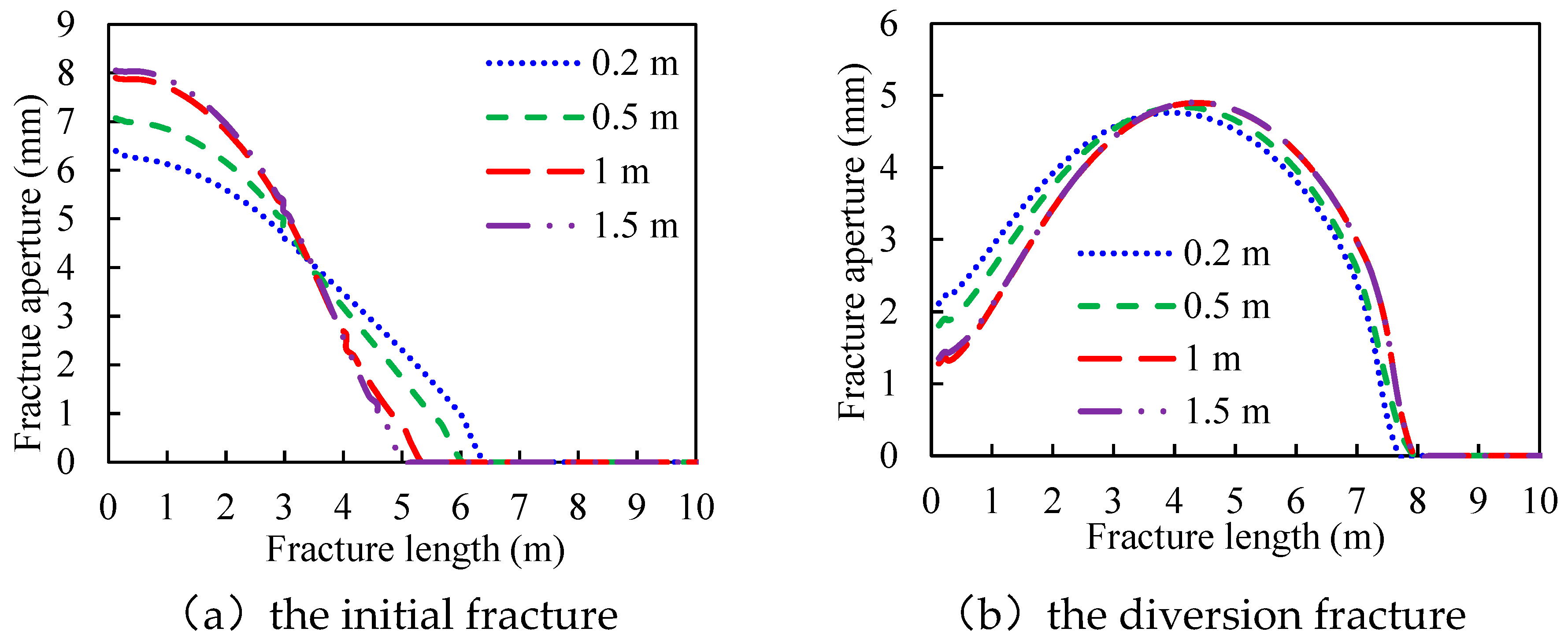

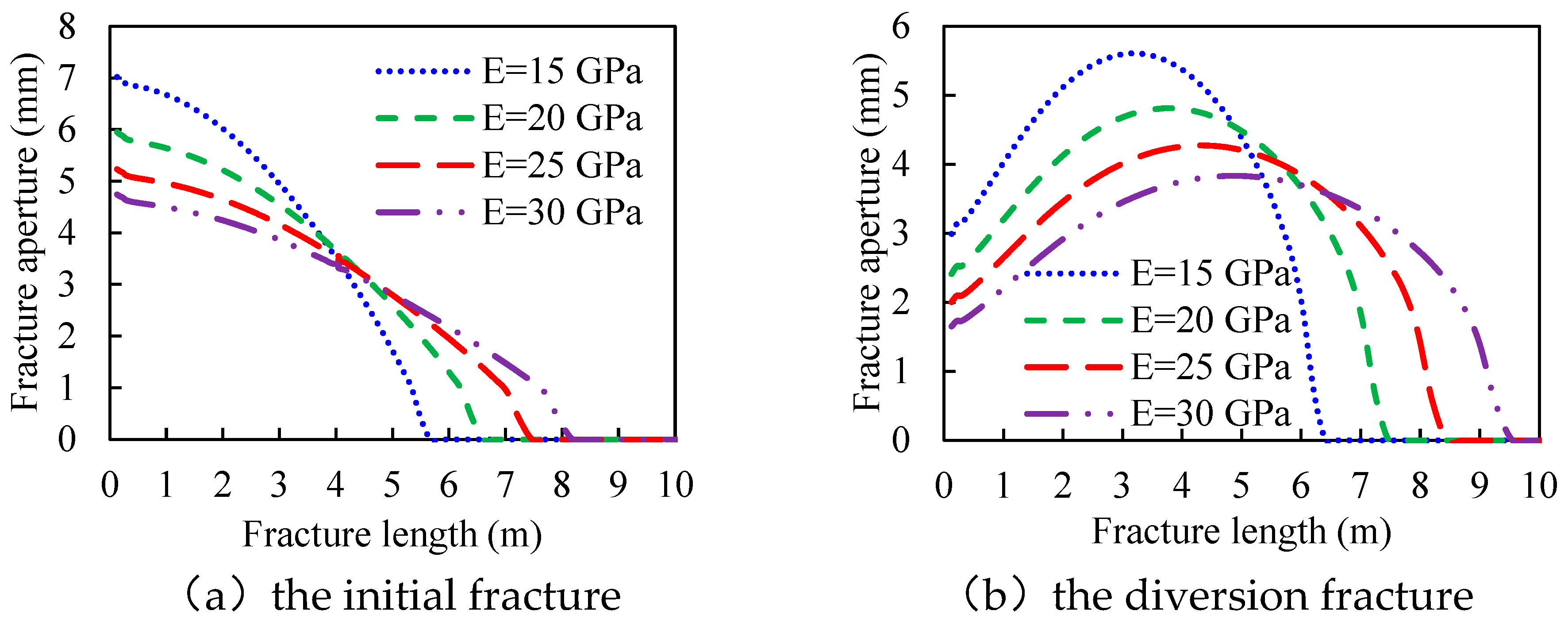

3.3. Young’s Modulus

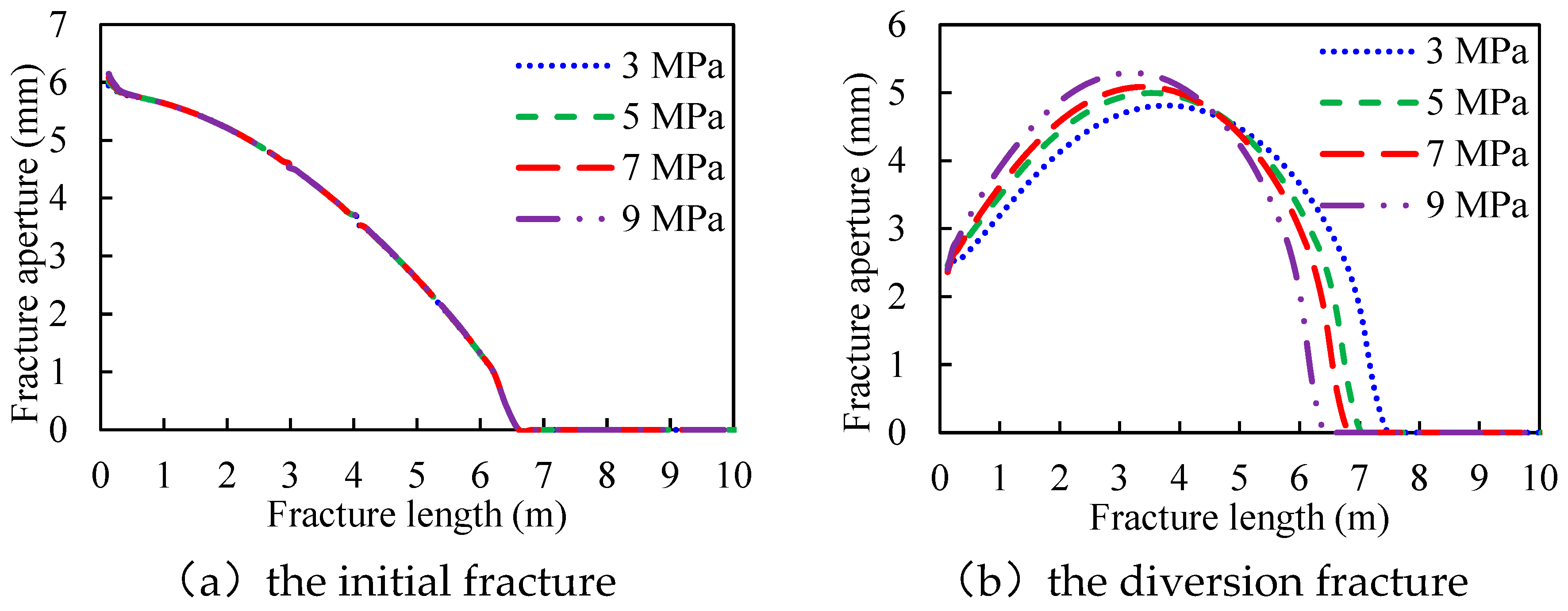

3.4. Rock Tensile Strength

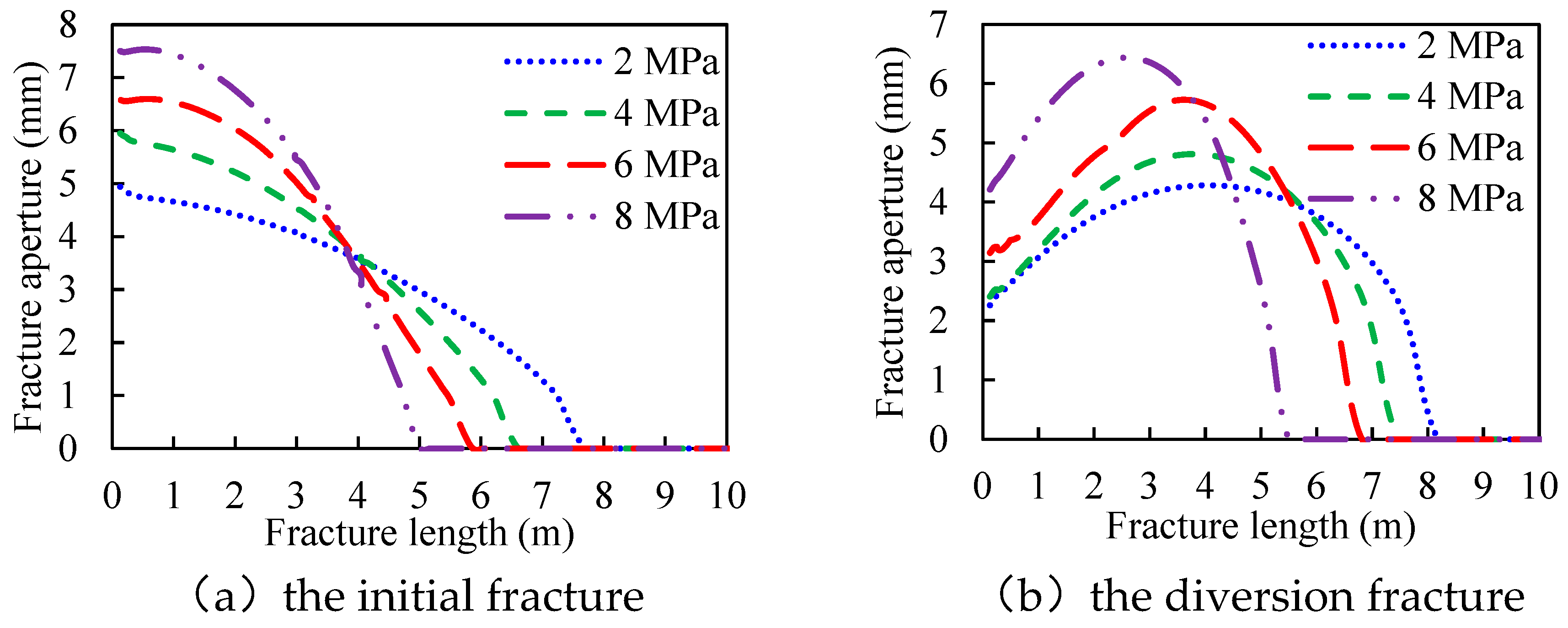

3.5. In-Situ Stress Contrast

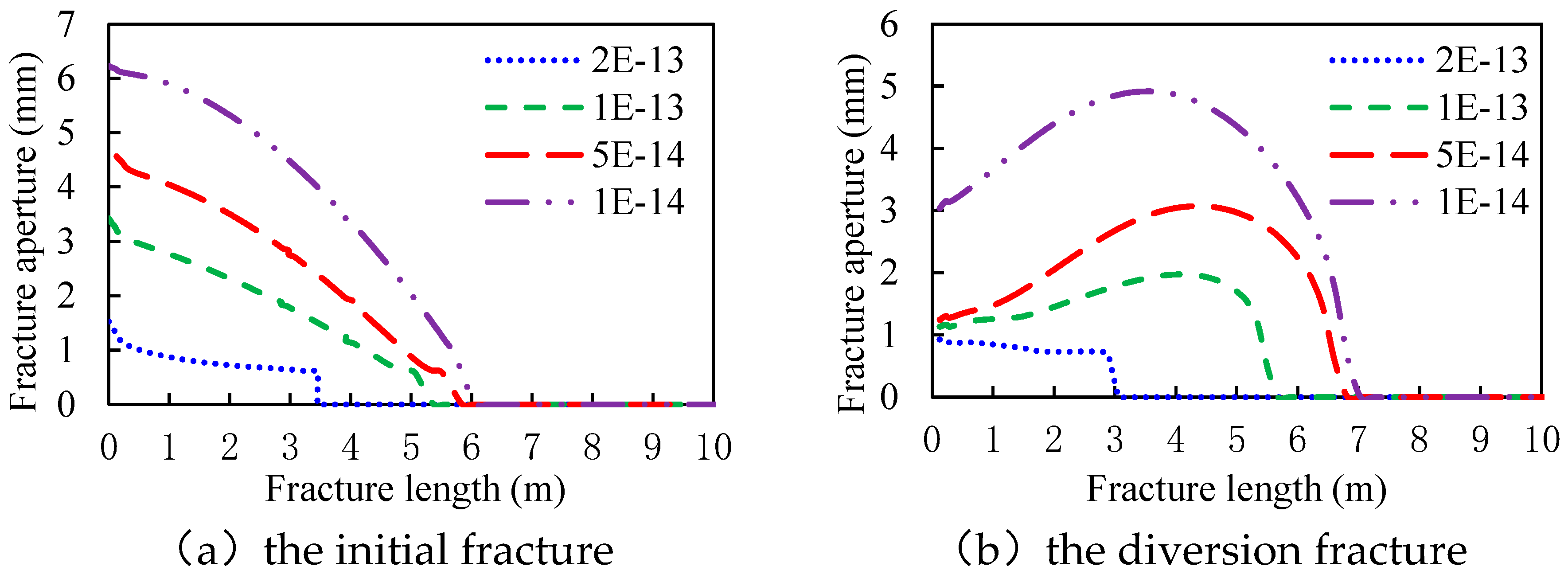

3.6. The Leak-Off Coefficient of the Fracture Surface

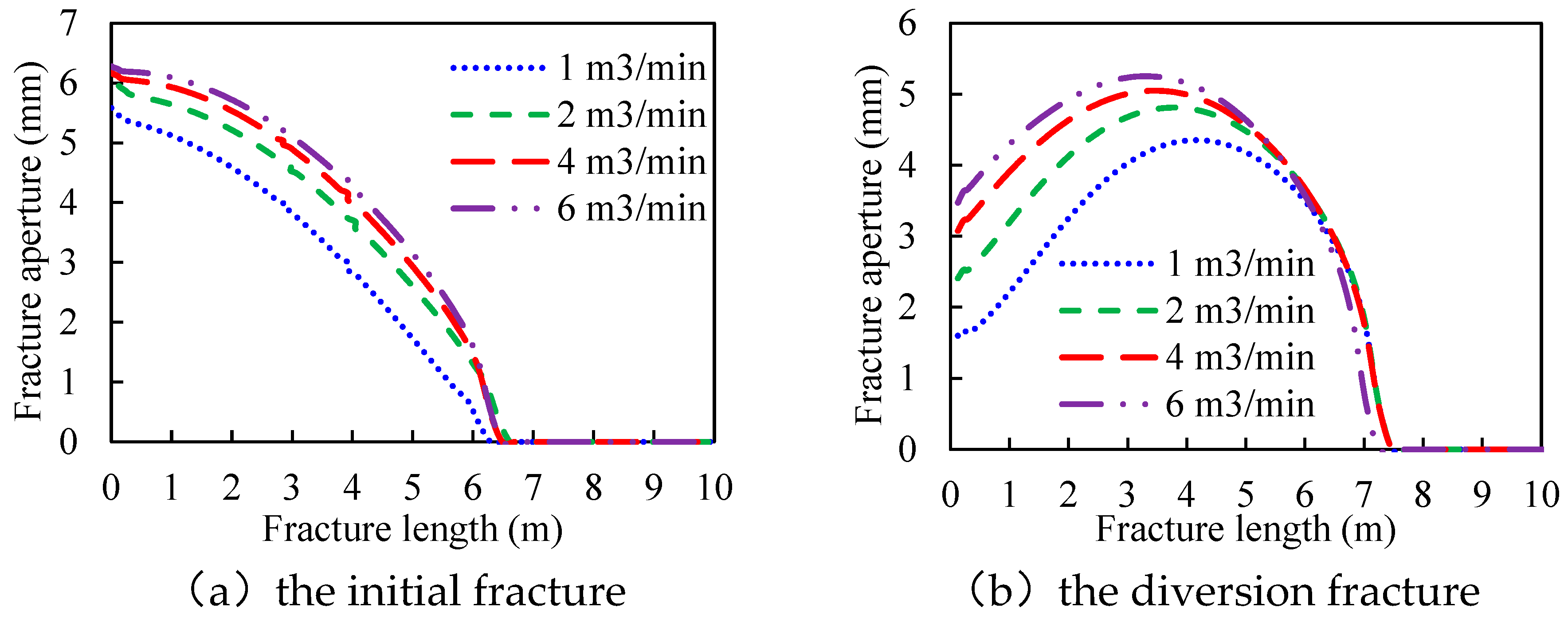

3.7. Fluid Injection Rate

4. Discussion

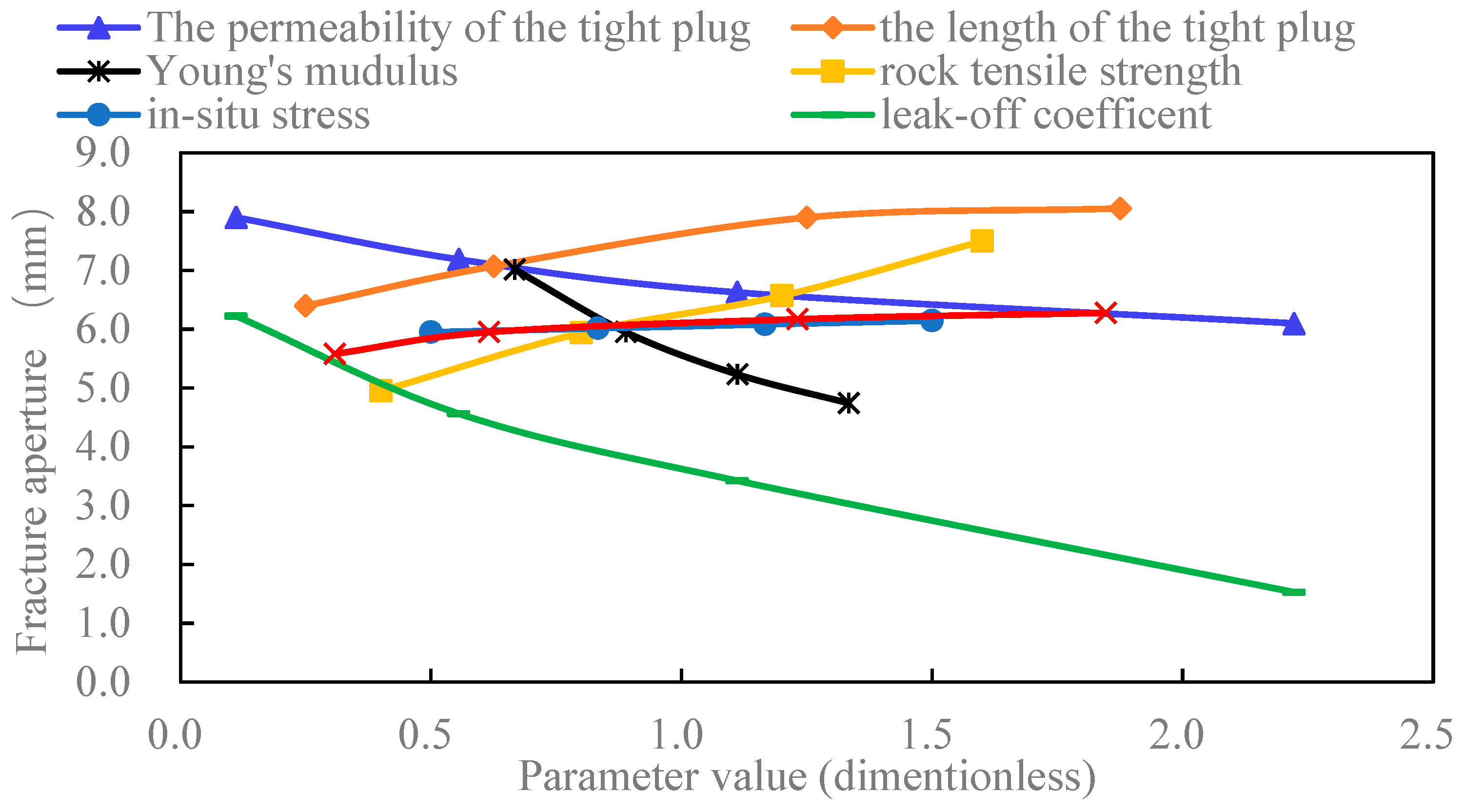

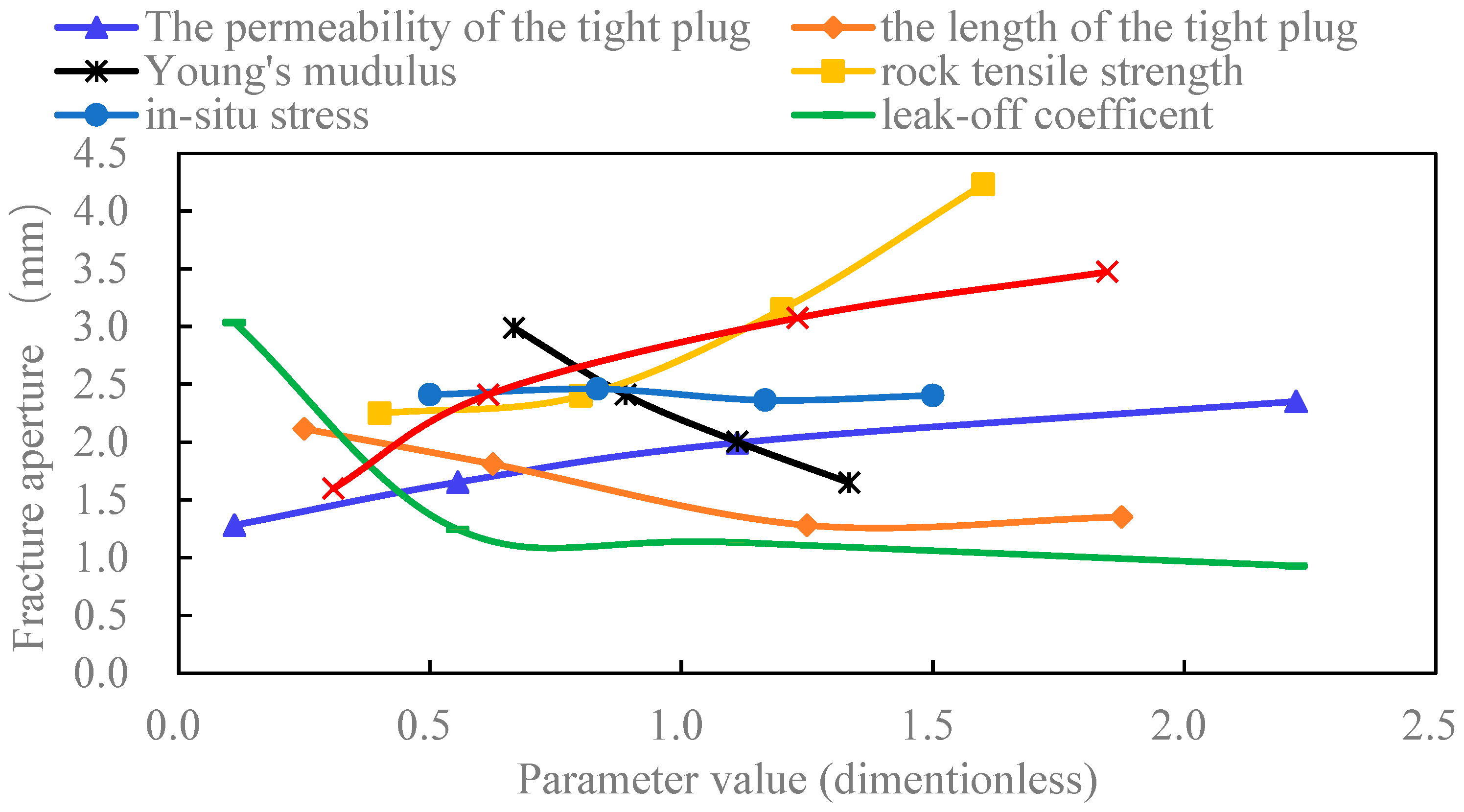

4.1. Multi-Parameter Comparative Analysis

4.2. The Risk of Screenout

5. Conclusions

- (1)

- The aperture at the initial or the diversion fracture mouth has a positive correlation with the rock tensile strength and the fluid injection rate. It has a negative correlation with Young’s modulus and the leak-off coefficient.

- (2)

- The aperture at the initial fracture mouth increases with the length of the tight plug and decreases with the permeability of the tight plug. The aperture at the diversion fracture mouth decreases with the length of the tight plug and increases with the permeability of the tight plug.

- (3)

- Screenout tends to occur at the mouth of the diversion fracture. And factors influencing the aperture at the diversion fracture mouth can be sorted by sensitivity (strong to weak): Young’s modulus, rock tensile strength, fluid injection rate, the length of the tight plug, the permeability of the tight plug, the leak-off coefficient, and in-situ stress contrast.

- (4)

- Reservoirs with low Young’s modulus and high rock tensile strength will generate wide initial and diversion fracture, which ensures the safe transportation of proppant at the fracture mouth. Moreover, increasing the fluid injection rate can effectively enlarge the fracture aperture and ensure safe construction.

Acknowledgment

References

- Tong, X.; Zhang, G.; Wang, Z.; et al. Distribution and potential of global oil and gas resources. Petroleum Exploration and Development 2018, 45, 779–789. [Google Scholar] [CrossRef]

- Isaac, O.; Hui, P.; Oni, B.; et al. Surfactants employed in conventional and unconventional reservoirs for enhanced oil recovery—A review. Energy Reports 2022, 8, 2806–2830. [Google Scholar] [CrossRef]

- Chen, B.; Barboza, B.; Sun, Y.; et al. A review of hydraulic fracturing simulation. Archives of Computational Methods in Engineering 2021, 1–58. [Google Scholar] [CrossRef]

- Zhou, H.; Wu, X.; Song, Z.; et al. A review on mechanism and adaptive materials of temporary plugging agent for chemical diverting fracturing. Journal of Petroleum Science and Engineering 2022, 212, 110256. [Google Scholar] [CrossRef]

- Wang, B.; Zhou, F.; Wang, D.; et al. Numerical simulation on near-wellbore temporary plugging and diverting during refracturing using XFEM-Based CZM. Journal of Natural Gas Science and Engineering 2018, 55, 368–381. [Google Scholar] [CrossRef]

- Sneddon, I. N.; Elliot, H. A.; Elliot, H.A. The opening of a Griffith crack under internal pressure. Quarterly of Applied Mathematics 1946, 4, 262–267. [Google Scholar] [CrossRef]

- Perkins, T.; Kern, L. R. Widths of hydraulic fractures. Journal of petroleum technology 1961, 13, 937–949. [Google Scholar] [CrossRef]

- Palmer, I.; Carroll, H. B. Three-dimensional hydraulic fracture propagation in the presence of stress variations. Society of Petroleum Engineers Journal 1983, 23, 870–878. [Google Scholar] [CrossRef]

- Morales, R. ; Microcomputer analysis of hydraulic fracture behavior with a pseudo-three-dimensional simulator. SPE production engineering 1989, 4, 69–74. [Google Scholar] [CrossRef]

- Todd, B.; Choudhary, Y.; Bhamidipati, S. Fracture-width estimation for an arbitrary pressure distribution in porous media. In Brasil Offshore. OnePetro 2011.

- Guo, Q.; Feng, Y. Z.; Jin, Z. Fracture aperture for wellbore strengthening applications. In ARMA US Rock Mechanics/Geomechanics Symposium (pp. ARMA-11). ARMA 2011.

- Shahri, M.; Oar, T.; Safari, R.; et al. Advanced geomechanical analysis of wellbore strengthening for depleted reservoir drilling applications. In SPE/IADC Drilling Conference and Exhibition (pp. SPE-167976). SPE 2014.

- Zhang, J.; Alberty, M.; Blangy, J. A semi-analytical solution for estimating the fracture width in wellbore strengthening applications. In SPE deepwater drilling and completions conference. OnePetro 2016.

- Liu, Y.; Jin, G.; Wu, K.; et al. Hydraulic-fracture-width inversion using low-frequency distributed-acoustic-sensing strain data—Part I: Algorithm and sensitivity analysis. SPE Journal 2021, 26, 359–371. [Google Scholar] [CrossRef]

- Xu, C.; Yang, X.; Liu, C.; et al. Dynamic fracture width prediction for lost circulation control and formation damage prevention in ultra-deep fractured tight reservoir. Fuel 2022, 307, 121770. [Google Scholar] [CrossRef]

- Zheng, H.; Pu, C.; Wang, Y.; et al. Experimental and numerical investigation on influence of pore-pressure distribution on multi-fractures propagation in tight sandstone. Engineering Fracture Mechanics 2020, 230, 106993. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, S.; Zou, Y.; et al. Experimental investigation into simultaneous and sequential propagation of multiple closely spaced fractures in a horizontal well. Journal of Petroleum Science and Engineering 2021, 202, 108531. [Google Scholar] [CrossRef]

- Xu, W.; Zhao, Y.; Wang, L.; et al. Experimental investigation of hydraulic fracture propagation behavior in layered continental shale. Energy Reports 2022, 8, 14362–14373. [Google Scholar] [CrossRef]

- Shi, H.; Zhao, H.; Zhou, J.; et al. Experimental investigation on the propagation of hydraulic fractures in massive hydrate-bearing sediments. Engineering Fracture Mechanics 2023, 289, 109425. [Google Scholar] [CrossRef]

- Chang, X.; Xu, E.; Guo, Y.; et al. Experimental study of hydraulic fracture initiation and propagation in deep shale with different injection methods. Journal of Petroleum Science and Engineering 2022, 216, 110834. [Google Scholar] [CrossRef]

- Shi, X.; Qin, Y.; Gao, Q.; et al. Experimental study on hydraulic fracture propagation in heterogeneous glutenite rock. Geoenergy Science and Engineering 2023, 225, 211673. [Google Scholar] [CrossRef]

- Wang, B.; Zhou, F.; Liang, T.; et al. Evaluations of fracture injection pressure and fracture mouth width during separate-layer fracturing with temporary plugging. Mathematical Problems in Engineering 2018, 2018. [Google Scholar] [CrossRef]

- Wang, B.; Zhou, F.; Yang, C.; et al. Experimental study on injection pressure response and fracture geometry during temporary plugging and diverting fracturing. SPE Journal 2020, 25, 573–586. [Google Scholar] [CrossRef]

- Wu, K.; Olson, J.; Balhoff; et al. Numerical analysis for promoting uniform development of simultaneous multiple-fracture propagation in horizontal wells. SPE production & operations 2017, 32, 41–50.

- Wang, B.; Zhang, G.; Zhou, F. Insights into the activation characteristics of natural fracture during in-fracture temporary plugging and diverting fracturing. Computers and Geotechnics 2023, 162, 105655. [Google Scholar] [CrossRef]

- Guo, J.; Zhao, X.; Zhu, H.; et al. Numerical simulation of interaction of hydraulic fracture and natural fracture based on the cohesive zone finite element method. Journal of Natural Gas Science and Engineering 2015, 25, 180–188. [Google Scholar] [CrossRef]

- Zhang, G. M.; Liu, H.; Zhang, J.; et al. Three-dimensional finite element simulation and parametric study for horizontal well hydraulic fracture. Journal of Petroleum Science and Engineering 2010, 72, 310–317. [Google Scholar] [CrossRef]

- Feng, Y.; &, *!!! REPLACE !!!*; Gray, K. E.; Gray, K.E. A fracture-mechanics-based model for wellbore strengthening applications. Journal of Natural Gas Science and Engineering 2016, 29, 392–400. [Google Scholar] [CrossRef]

- Chen, M.; Zhang, S.; Li, S.; et al. An explicit algorithm for modeling planar 3D hydraulic fracture growth based on a super-time-stepping method. International Journal of Solids and Structures 2020, 191, 370–389. [Google Scholar] [CrossRef]

- Chen, M.; Zhang, S.; Zhou, T.; et al. Optimization of in-stage diversion to promote uniform planar multifracture propagation: A numerical Study. SPE Journal 2020, 25, 3091–3110. [Google Scholar] [CrossRef]

| Category | Parameter | Value |

|---|---|---|

| Rock property | Young’s modulus, E (GPa) | 25 |

| Poisson’s ratio, v | 0.22 | |

| Permeability, k (mD) | 0.58 | |

| Fracture property | Tensile strength of HF, σt (MPa) | 8 |

| Leak-off coefficient (m/s/Pa) | 1e-14 | |

| Tight plug property | Permeability of the tight plug, (mD) | 500 |

| Length of the tight plug, (m) | 0.5 | |

| In-situ stress | Minimum principle horizontal stress, σh (MPa) | 55 |

| Maximum principle horizontal stress, σH (MPa) | 60 | |

| Fluid parameter | Fluid viscosity, μ/(Pa·s) | 0.1 |

| Injection rate, Q/( m3/min) | 4 | |

| Initial condition | Initial pore pressure, po /(MPa) | 37 |

| Void ratio, Φ | 0.08 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).