Submitted:

23 August 2023

Posted:

23 August 2023

You are already at the latest version

Abstract

Keywords:

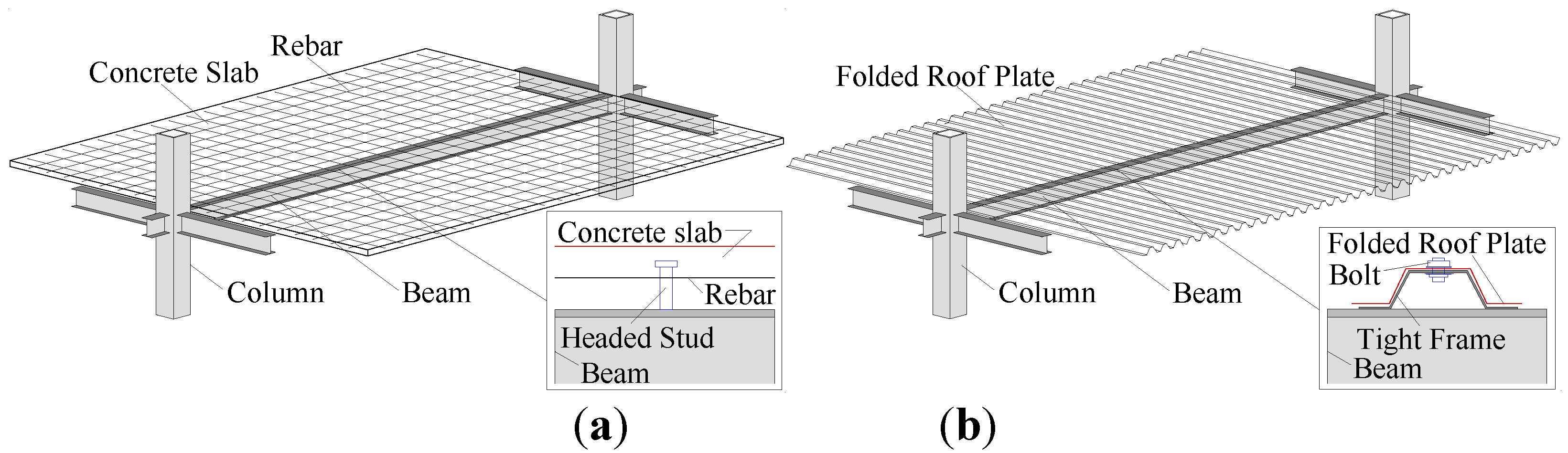

1. Introduction

2. Structural Damage Detection of a Concrete Slab using Piezoelectric Sensors

2.1. Outline of experiment

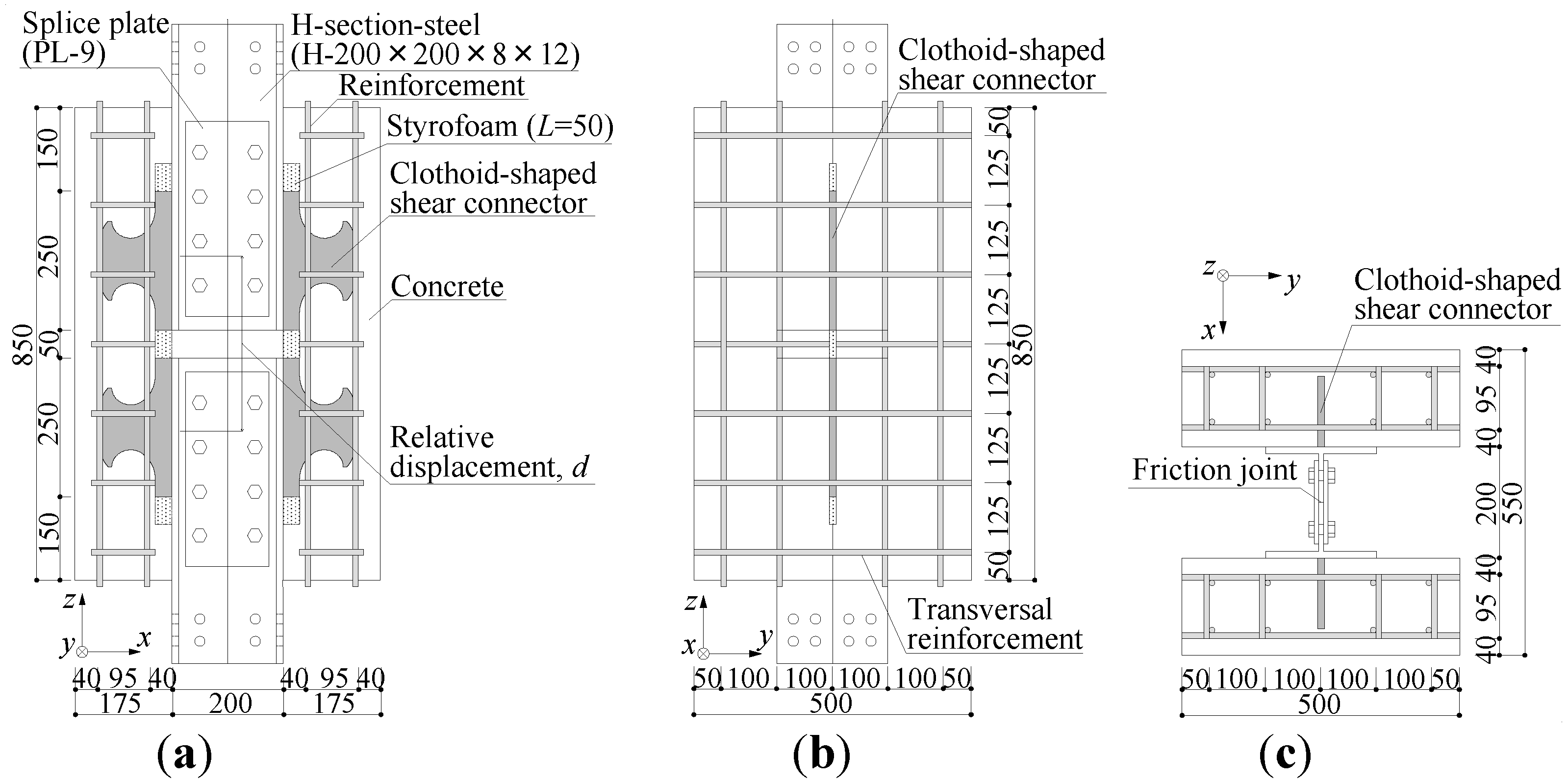

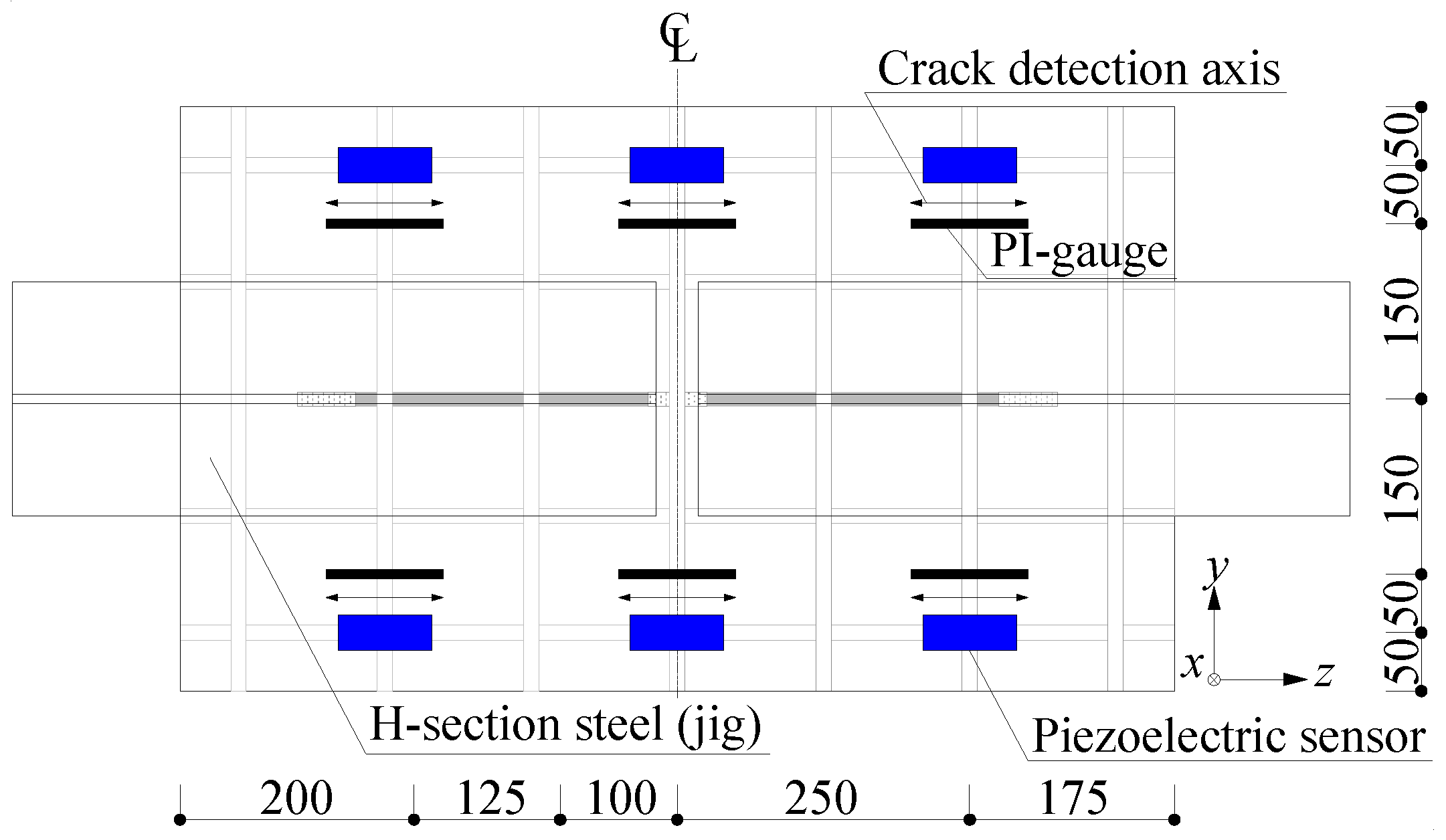

2.1.1. Specimen configuration

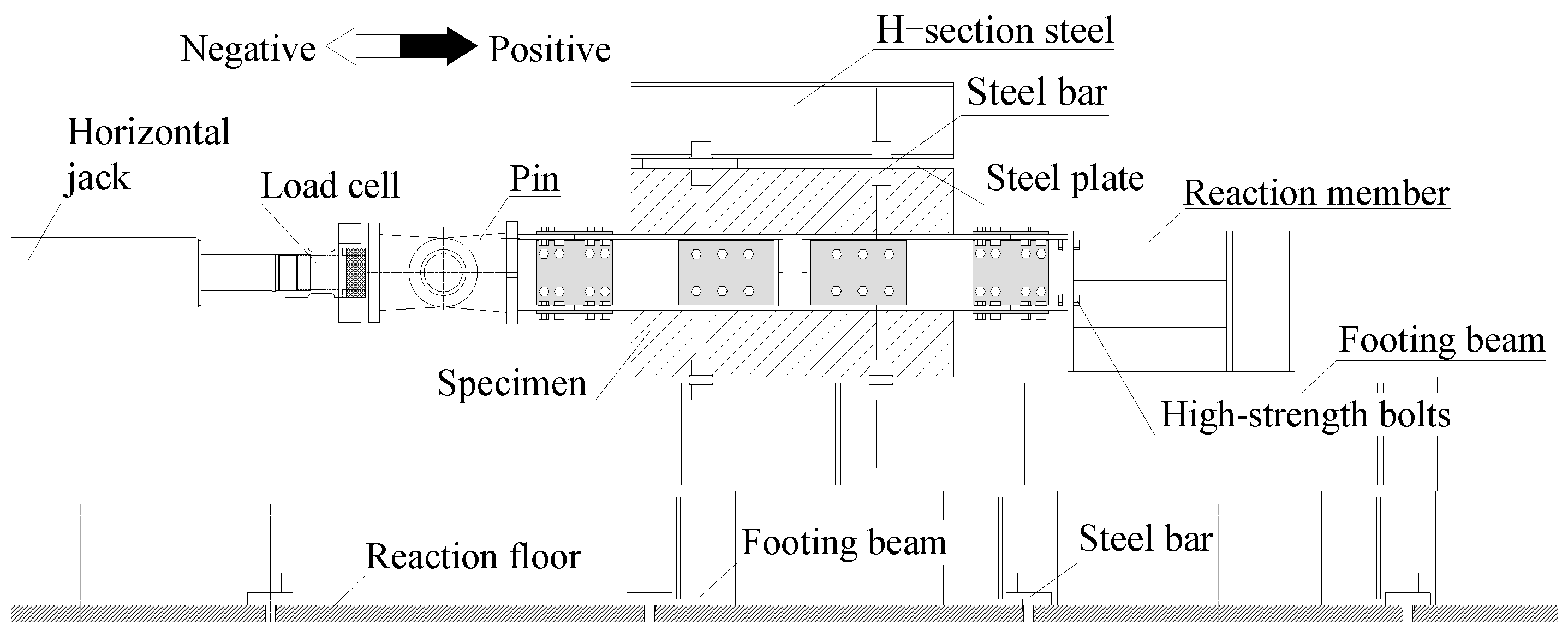

2.1.2. Loading protocols

2.1.3. Material properties

2.1.4. Curing conditions

2.2. Outline of finite element analysis

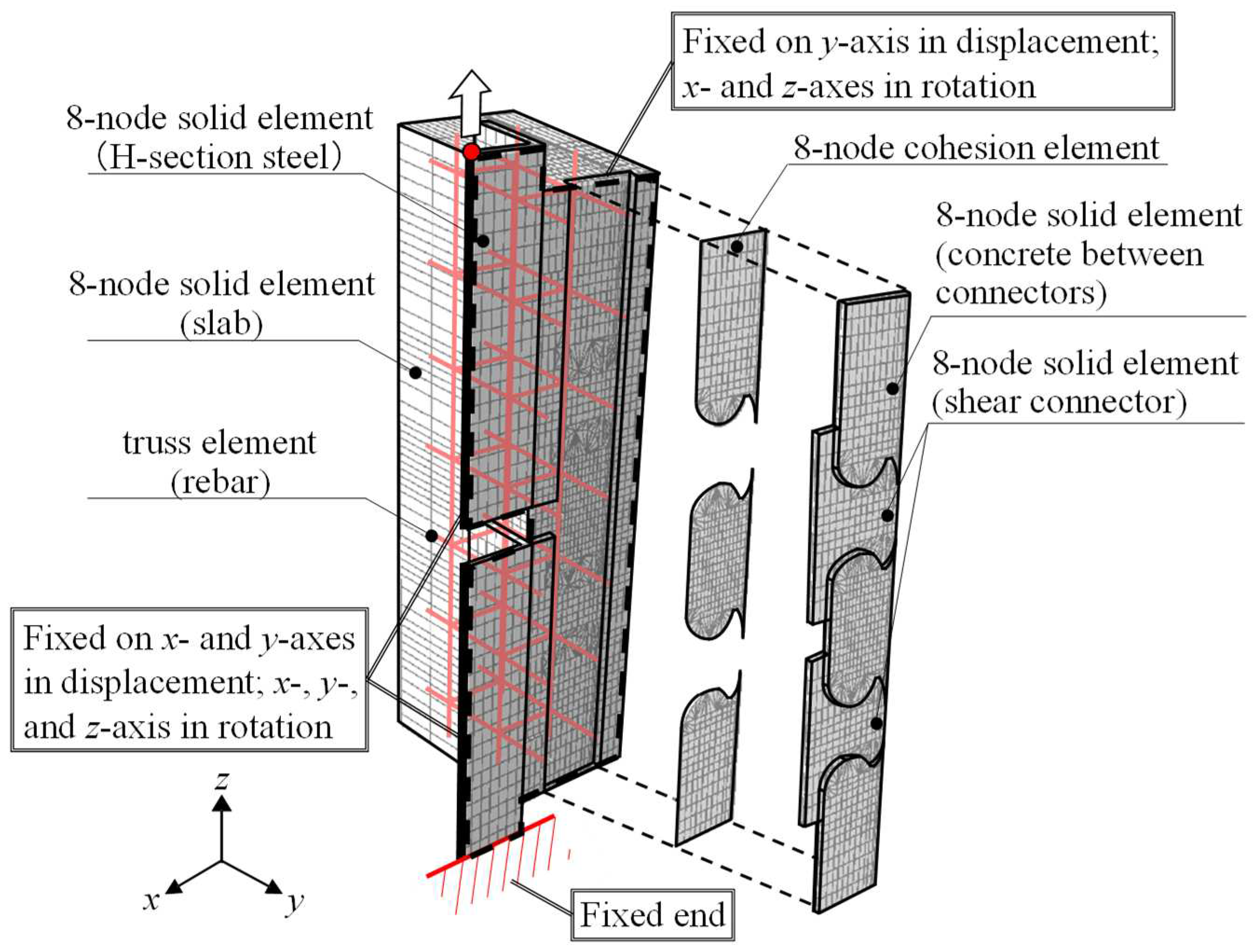

2.2.1. Configuration of finite element analysis

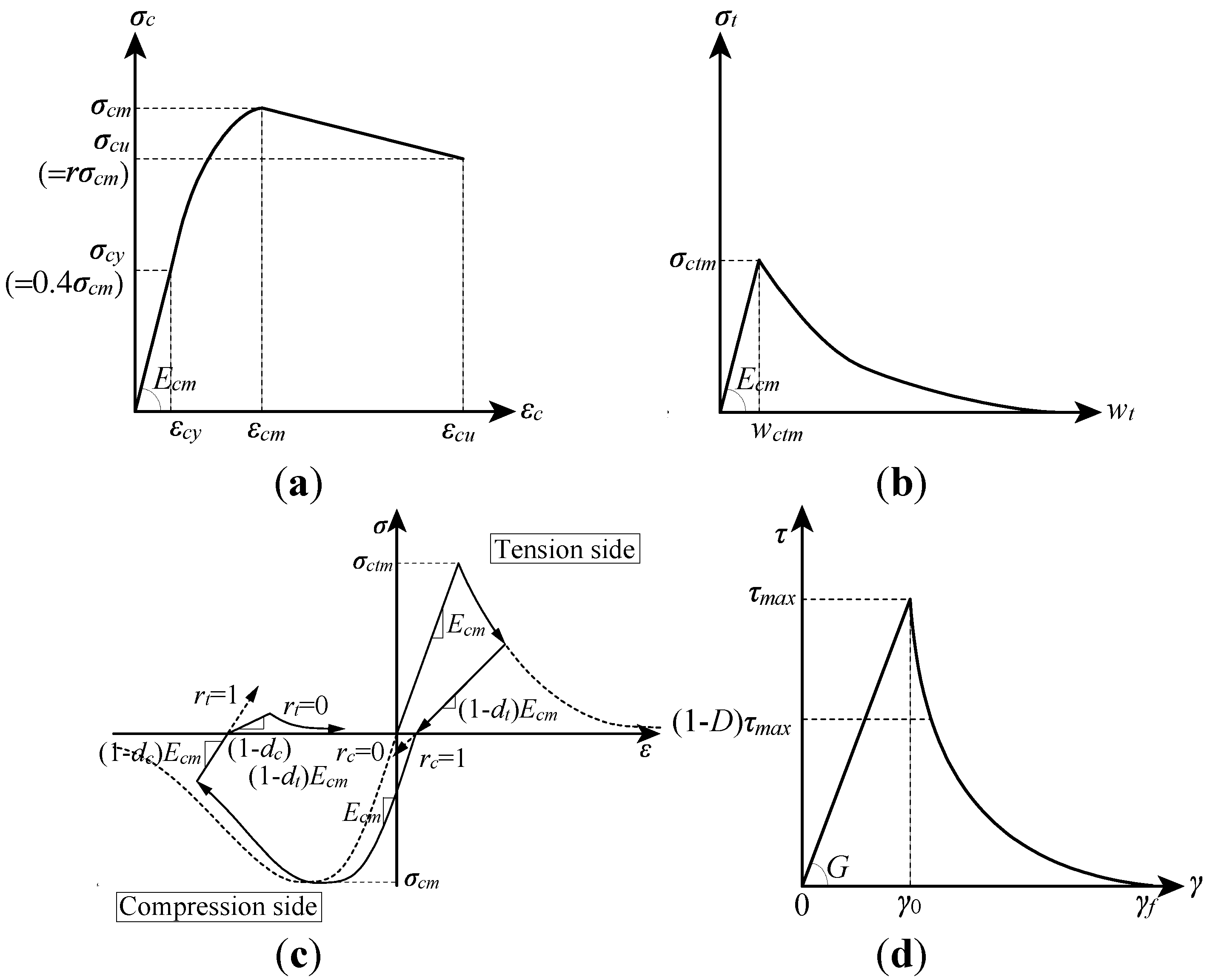

2.2.2. Constitutive law of concrete and slab separation

2.2.3. Constitutive law of cohesion element

2.2.4. Constitutive law of shear connector and rebar

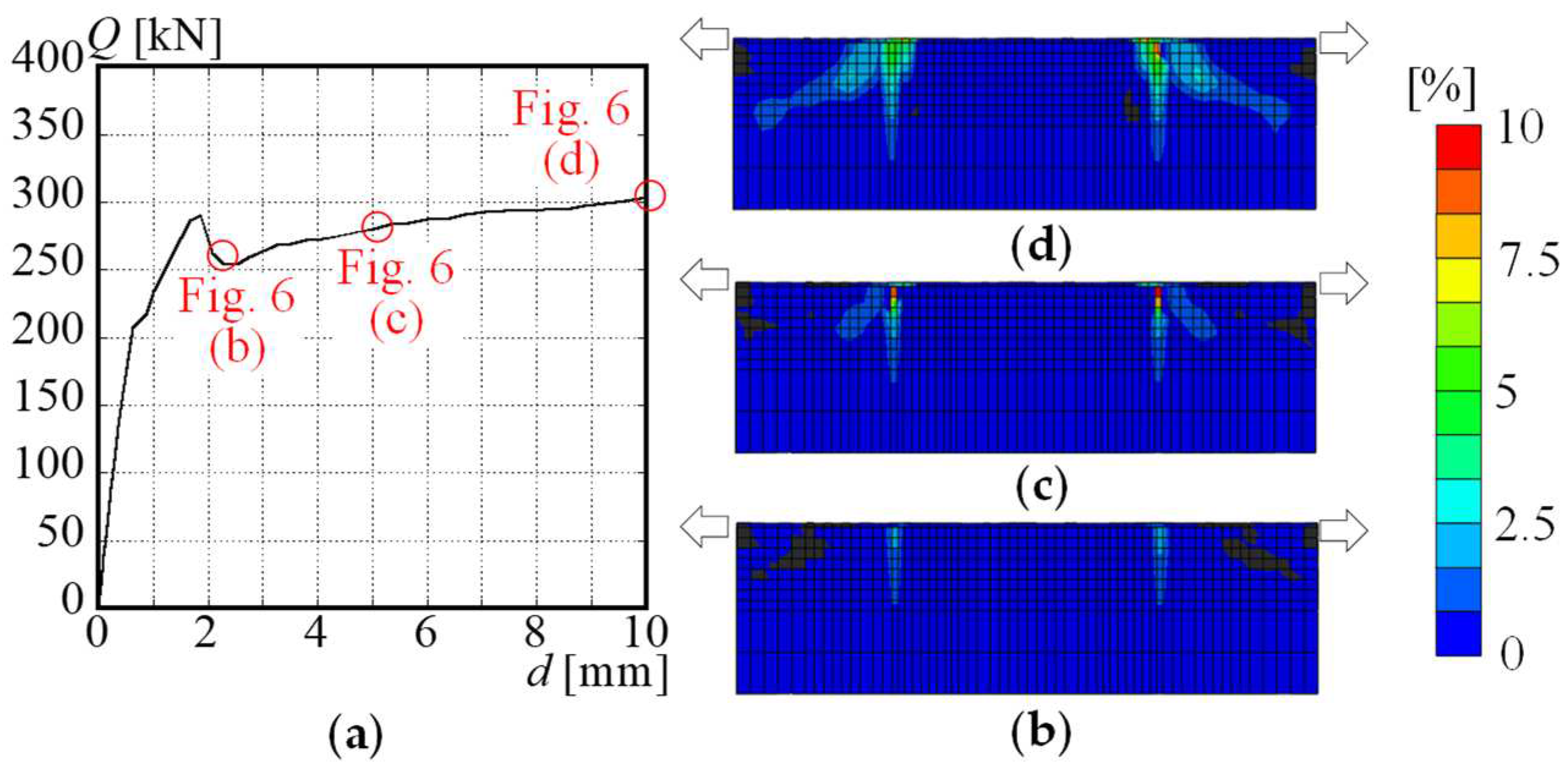

2.2.5. Finite element analysis results and piezoelectric sensor positions

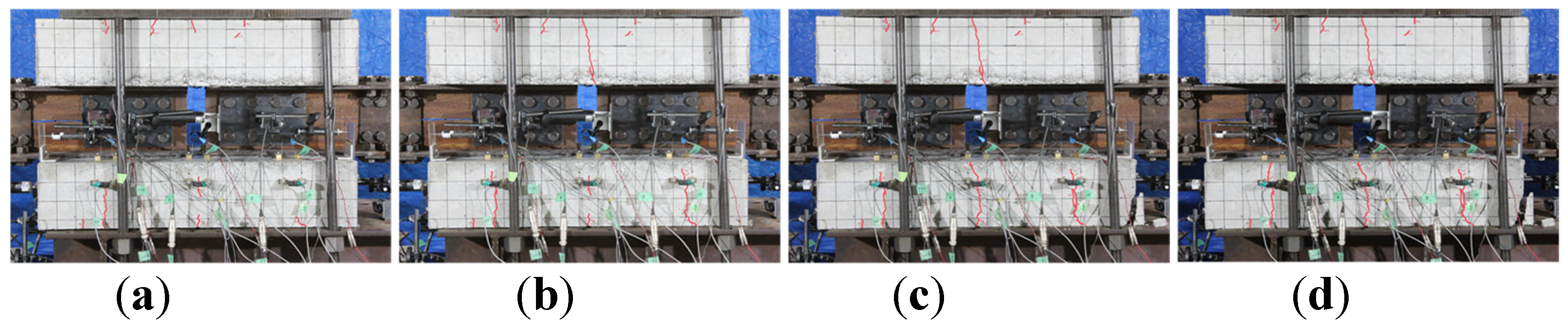

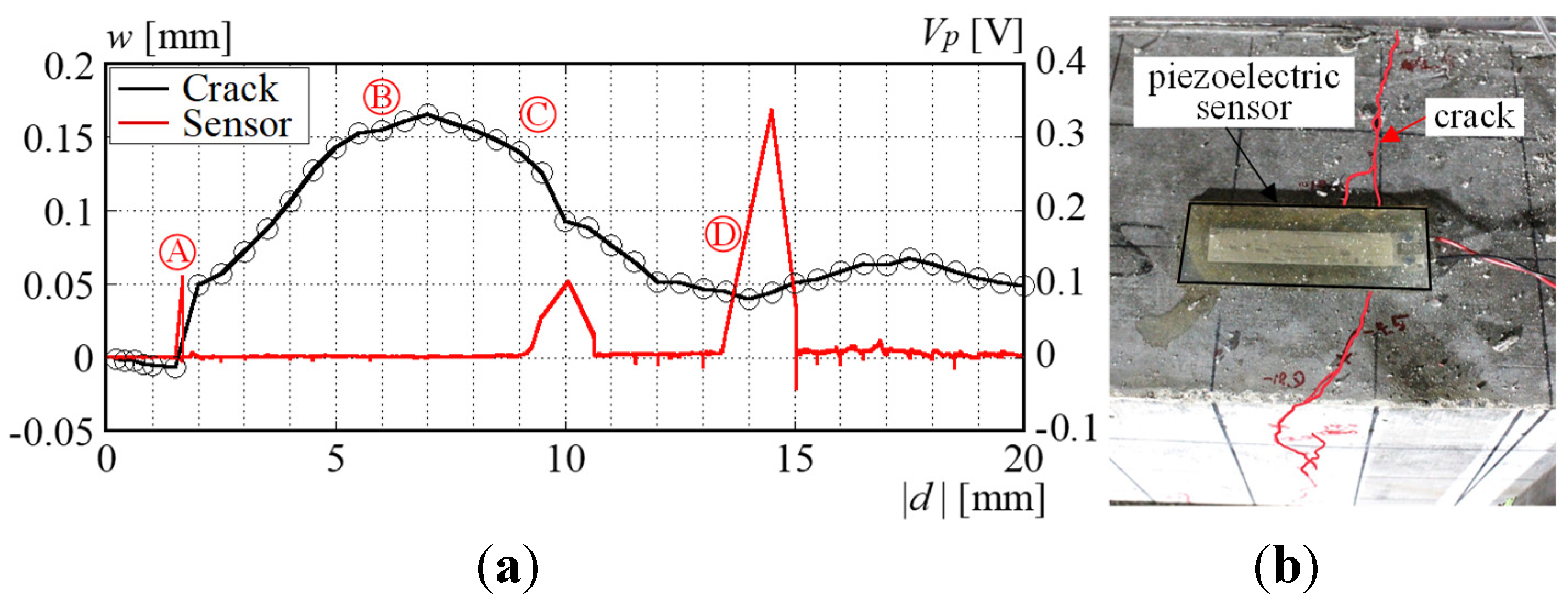

2.3. Results of experiments and damage detection

3. Damage Detection of Folded Roof Plate using Piezoelectric Sensor

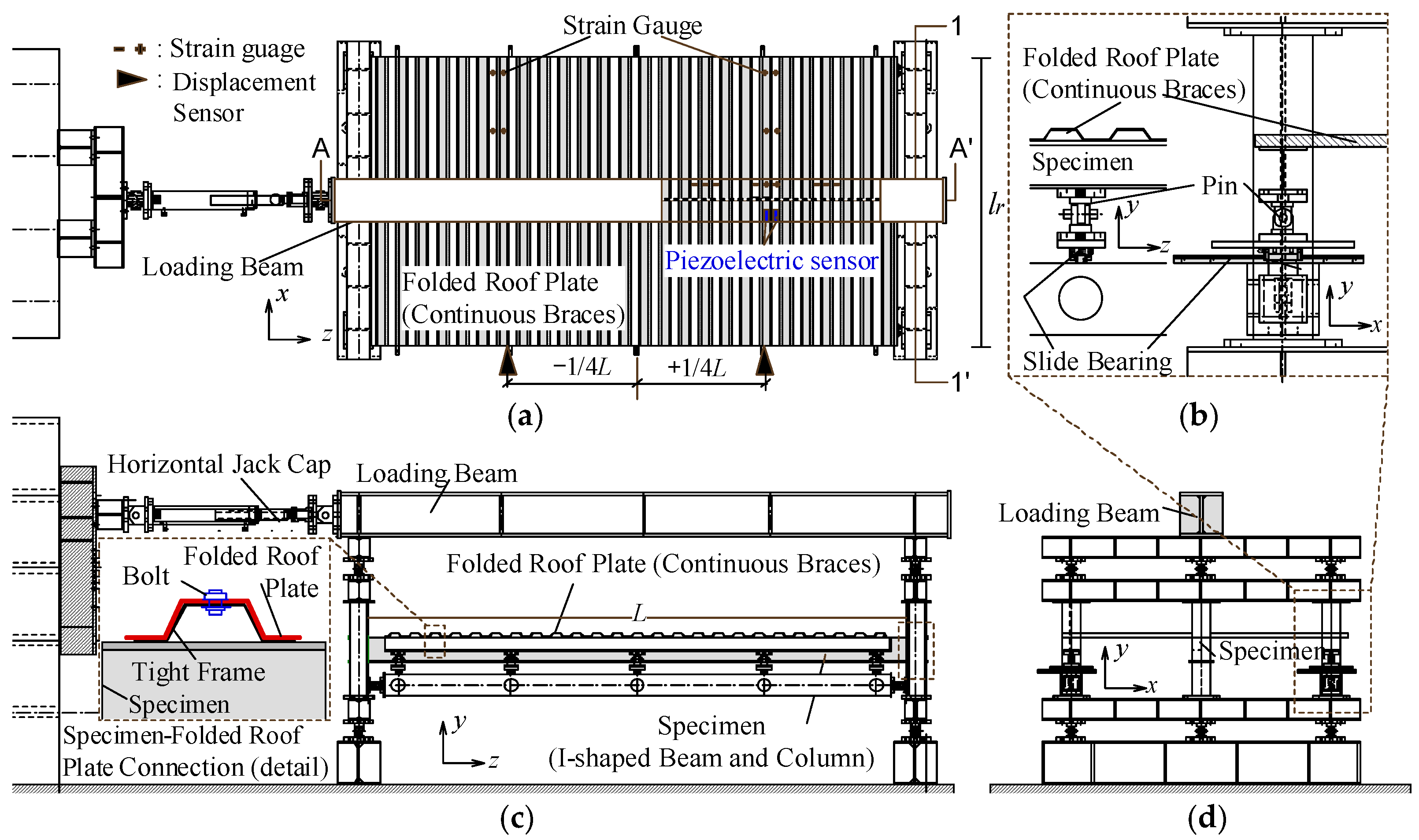

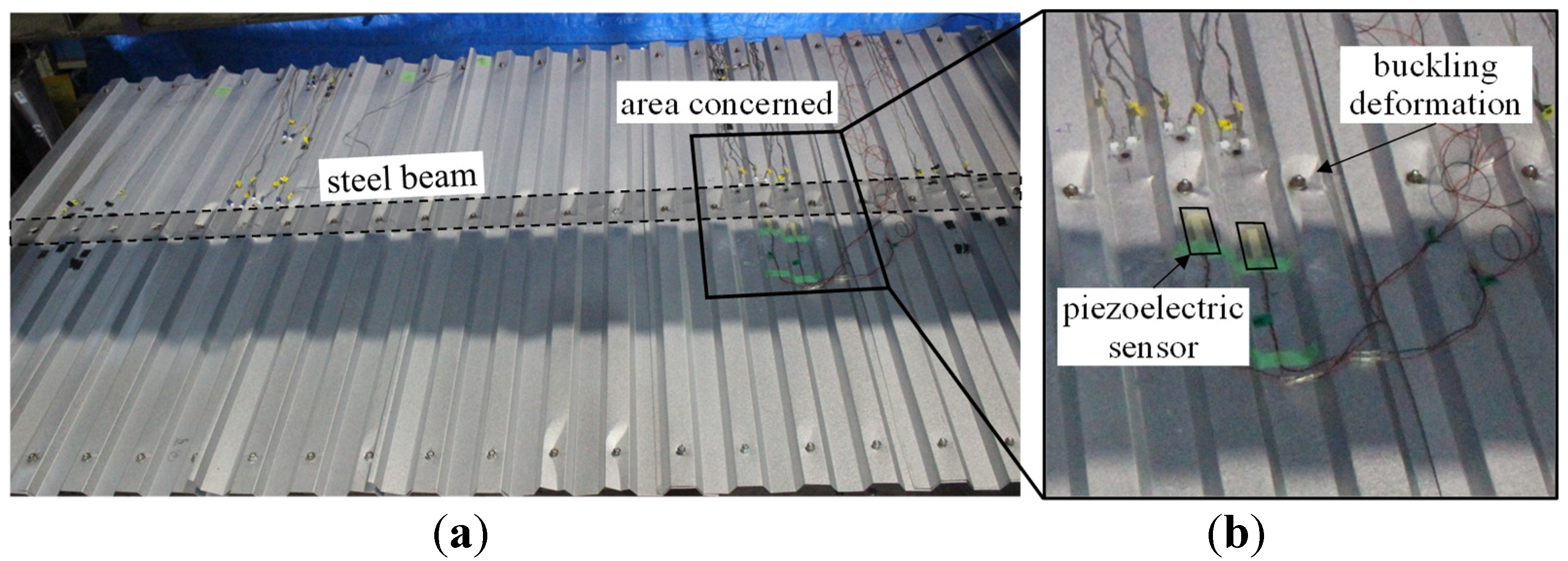

3.1. Test setup of cyclic loading test on I-shaped beam with folded roof plate

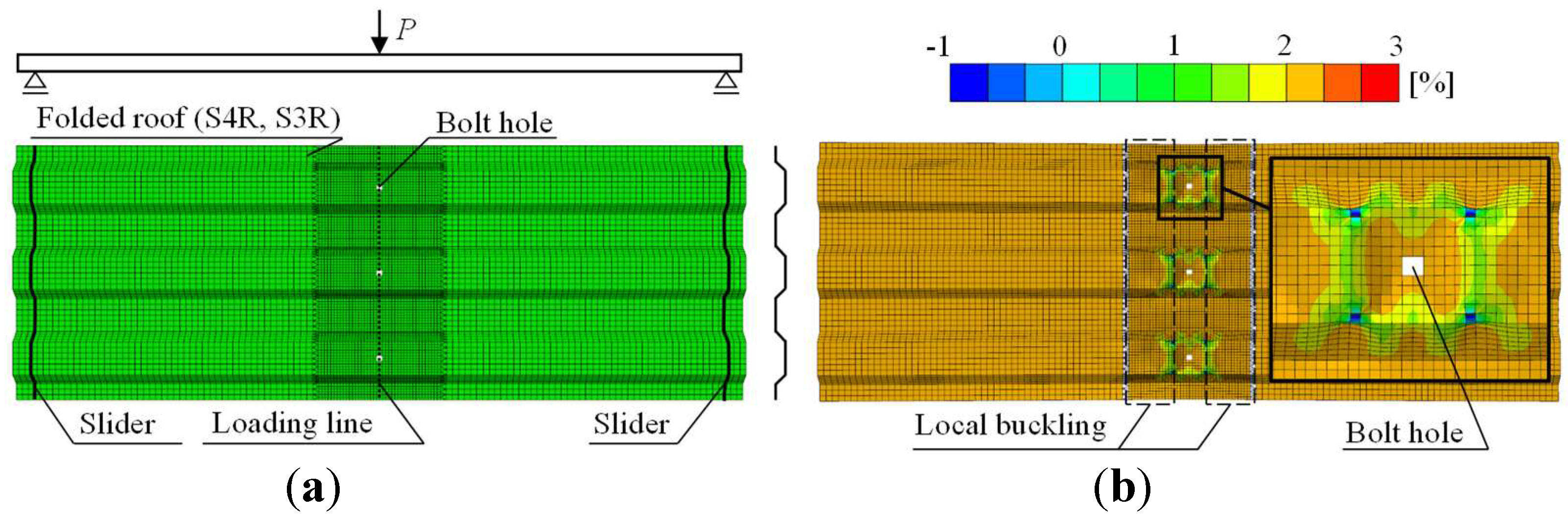

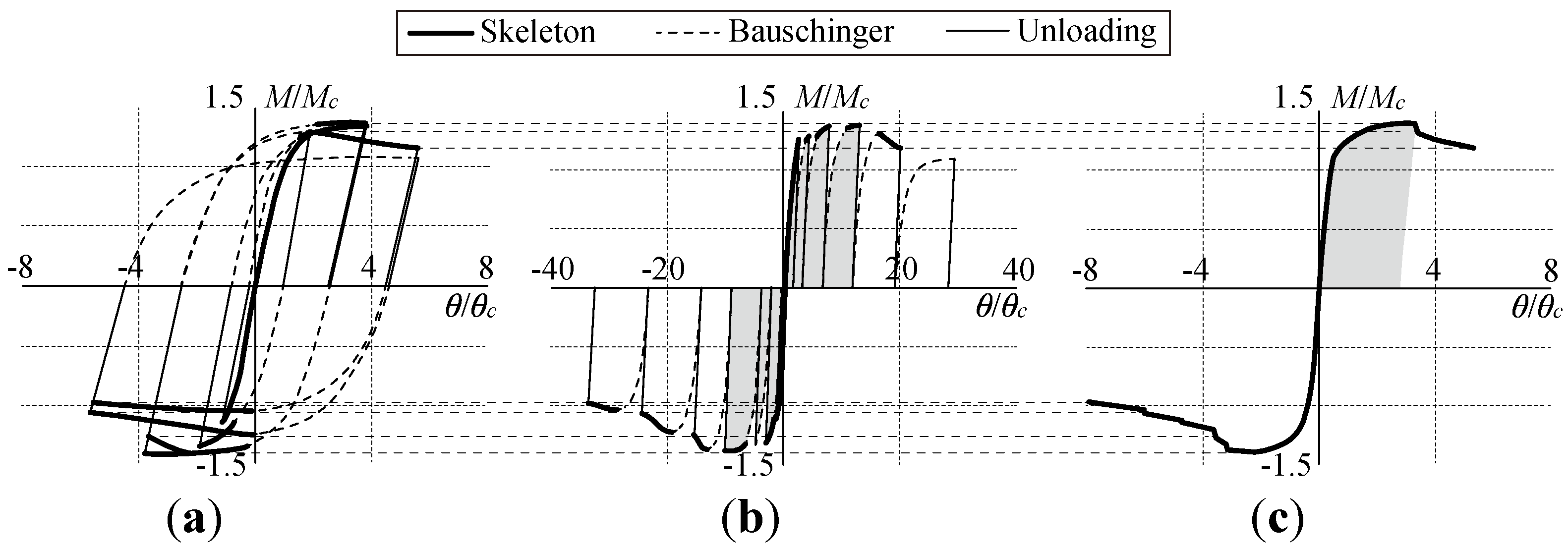

3.2. Preliminary analysis of folded roof plates and piezoelectric sensor installation

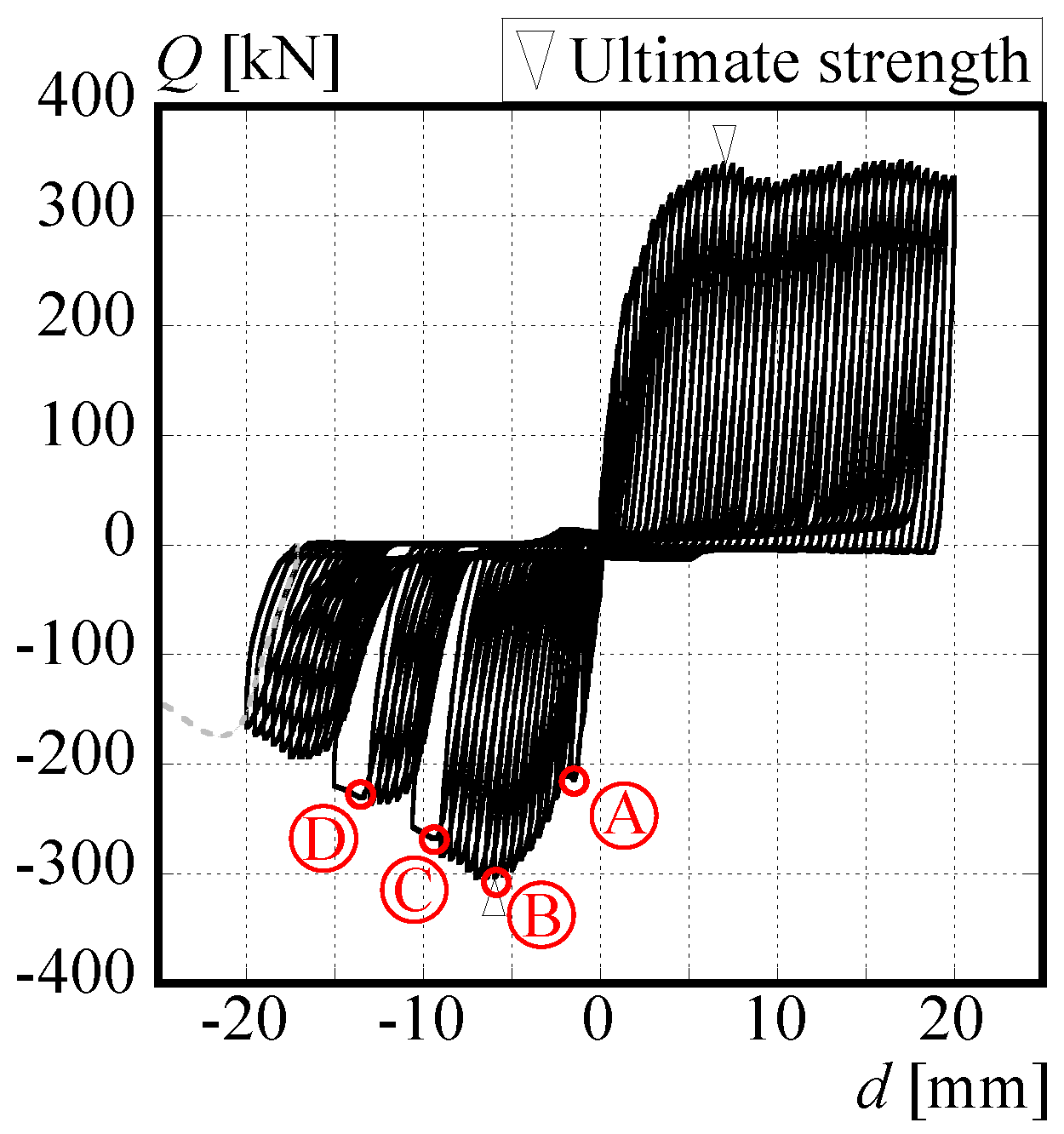

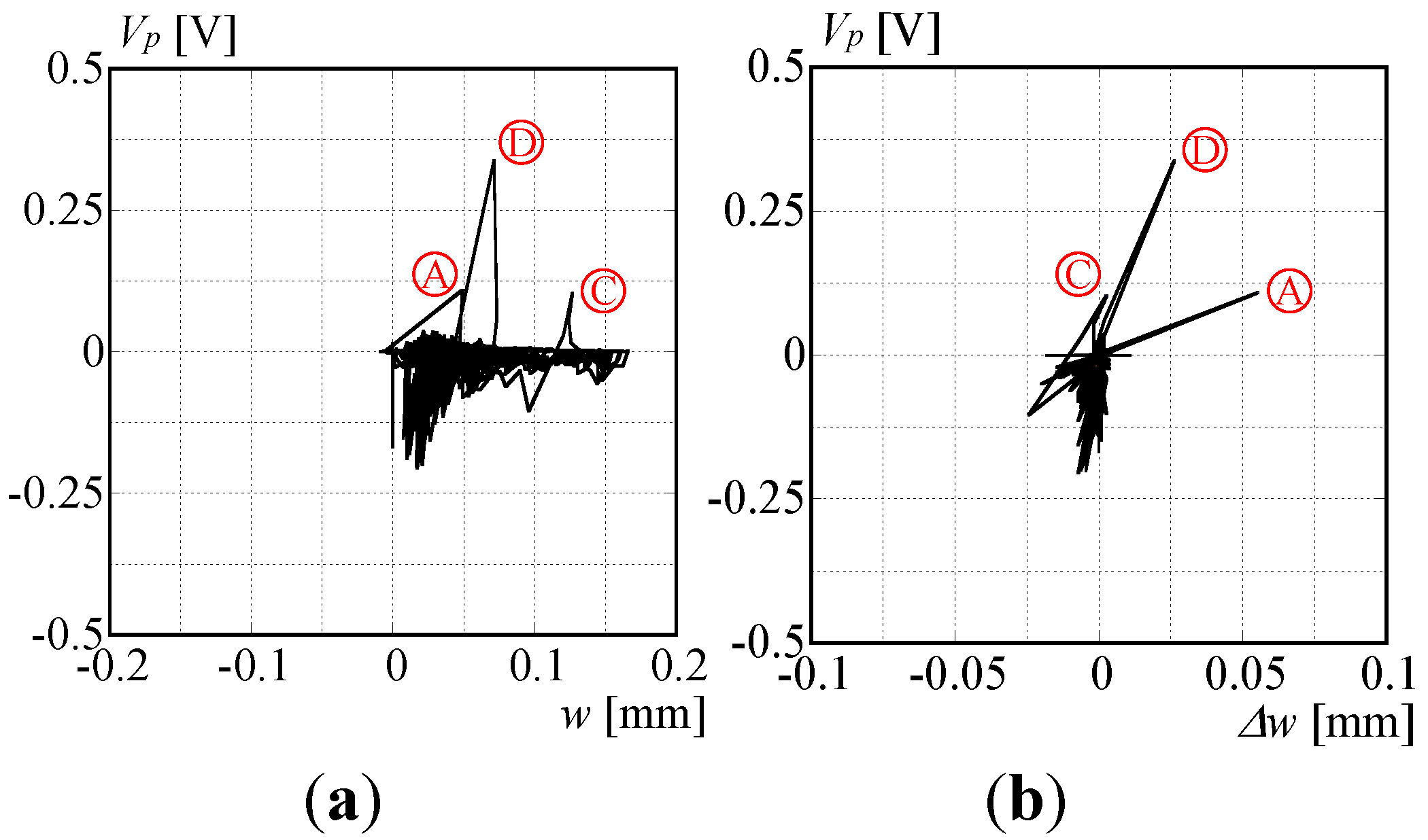

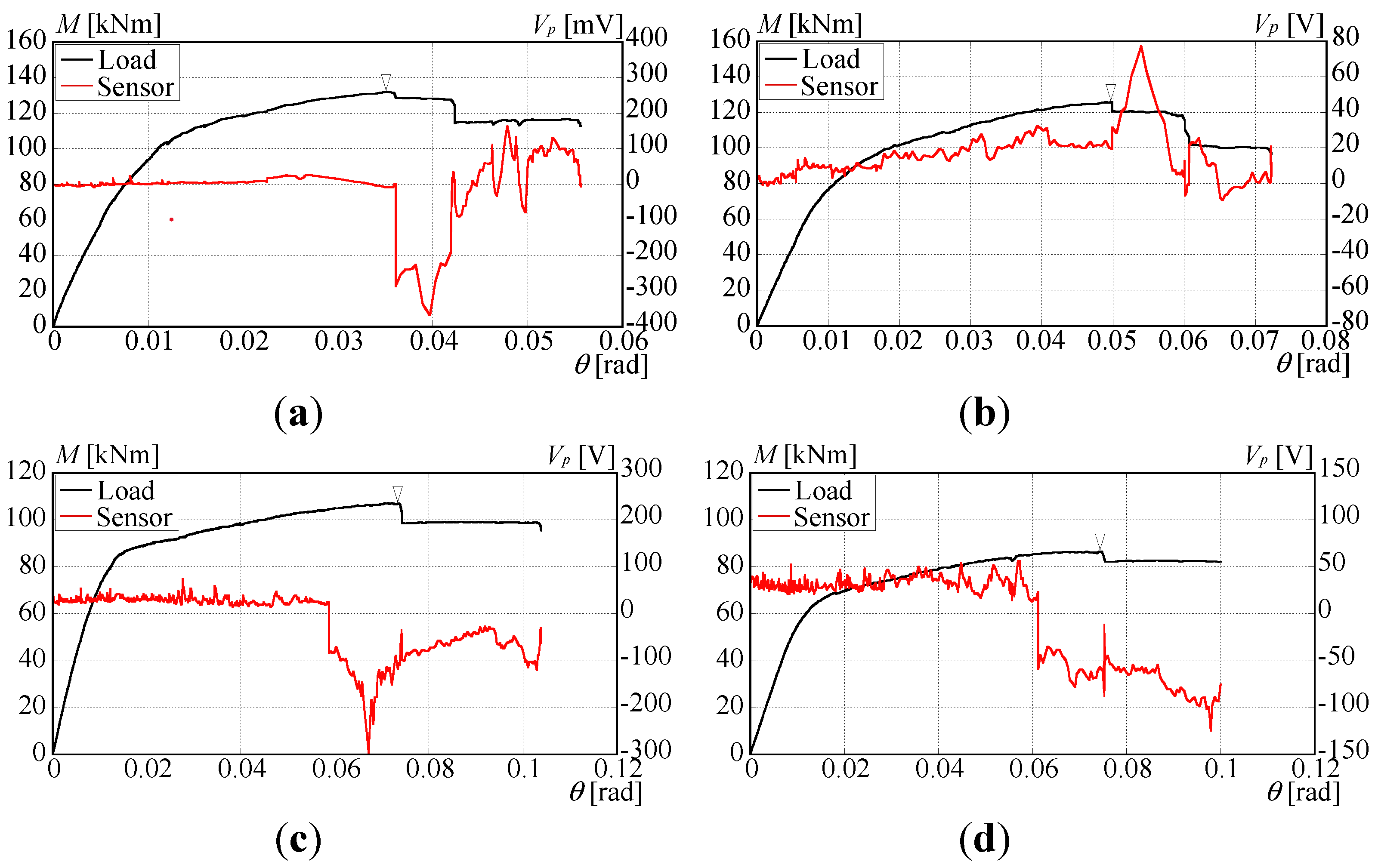

3.3. Results of cyclic loading tests and piezoelectric sensor output

4. Conclusion

- 1)

- The optimal sensor location for the concrete slab was retrieved to be beside the embedded position of the shear connector. That position in the case of the folded roof plate was found to be around the bolt connection.

- 2)

- The piezoelectric sensor produces prominent output when the concrete crack penetrates the sensor. Unlike standard strain gauges, the piezoelectric sensor can detect damage occurrence several times, which is a preferable characteristic for long-term monitoring.

- 3)

- The piezoelectric sensor detects the forced deformation of a folded roof plate by beam torsion, thereby demonstrating the applicability of monitoring lateral buckling origination during the cyclical application of stress.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Japan International Cooperation Agency (JICA). The project for assessment of earthquake disaster risk for the Kathmandu Valley in Nepal, Final Report, Volume 2 Main Report, 2018, JICA.

- Y. Matsumoto, S. Yamada, J. Iyama, T. Koyama, S. Kishiki, Y. Shimada, H. Asada, M. Ikenaga. Damage to steel educational facilities in the 2011 East Japan Earthquake: Part 1 Outline of the reconnaissance and damage to major structural components. 15th World Conference on Earthquake Engineering, Lisbon, Portugal, 24-28 September 2012.

- Suzuki, T. Fujita, Y. Kimura. Identifying damage mechanisms of gymnasium structure damaged by the 2011 Tohoku earthquake based on biaxial excitation. Structures 2022, 35, 1321–1338. [CrossRef]

- H. Chida, N. Takahashi. Study on image diagnosis of timber houses damaged by earthquake using deep learning. Japan Architectural Review 2021, 4(3), 420–430. [CrossRef]

- P.C. Chang, A. Flatau, S.C. Liu. Review paper: health monitoring of civil infrastructure. Structural Health Monitoring 2003, 2(3), 257–267. [CrossRef]

- E.P. Carden, P. Fanning. Vibration based condition monitoring: a review. Structural Health Monitoring 2004, 3(4), 355–377. [CrossRef]

- X. Ji, G.L. Fenves, K. Kajiwara, M. Nakashima. Seismic damage detection of a full-scale shaking table test structure. Journal of Structural Engineering 2011, 137(1), 14–21. [CrossRef]

- K. Okada, R. Shiroishi, Y. Morii, R. Sagawa. Method of structural health monitoring after earthquake using limited accelerometer – case study of large-scale shaking table test on six story RC building. Concrete Journal 2017, 55(2), 138–145. (in Japanese).

- G.P. Gislason, Q. Mei, M. Gul. Rapid and automated damage detection in buildings through ARMAX analysis of wind induced vibrations. Frontiers in Built Environment 2019, 5(16), 1–15. [CrossRef]

- S. Alampalli, G. Fu, E.W. Dillon. Signal versus noise in damage detection by experimental modal analysis. Journal of Structural Engineering 1997, 123(2), 237–245. [CrossRef]

- M. Ju, Z. Dou, J. Li, X. Qiu, B. Shen, S. Zhang, F. Yao, W. Gong, K. Wang. Piezoelectric materials and sensors for structural health monitoring: fundamental aspects, current status, and future perspectives. Sensors 2023, 23(1), 543. [CrossRef]

- S. Kishiki, Y. Iwasaki, Evaluation of residual strength based on local buckling deformation of steel column – quick inspection method for steel structures based on the visible damage Part 3, Journal of Structural and Construction Engineering (Transactions of AIJ) 2017, 82(735), 735–743. (in Japanese). [CrossRef]

- Aabid, B. Parveez, M.A. Raheman, Y.E. Ibrahim, A. Anjum, M. Hrairi, N. Parveen, J.M. Zayan. A review of piezoelectric material-based structural control and health monitoring techniques for engineering structures: challenges and opportunities. Actuators 2021, 10(5), 101. [CrossRef]

- T. Harada, K. Yokoyama, K. Tanabe, Study of crack detection of civil infrastructure using PVDF film sensor. Journal of Structural Engineering 2013, 59A, 47–55.

- N. Shimoi, T. Nishida, A. Obata, K. Nakasho, H. Madokoro, C. Cuadra. Comparison of displacement measurements in exposed type column base using piezoelectric dynamic sensors and static sensors. American Journal of Remote Sensing 2016, 4(5), 23–32. [CrossRef]

- N. Shimoi, C. Cuadra, H. Madokoro, K. Nakasho. Comparison of displacement measurements and simulation on fillet weld of steel column base. International Journal of Mechanical Engineering and Applications 2020, 8(5), 111–117. [CrossRef]

- Suzuki, Y. Kimura. Cyclic behavior of component model of composite beam subjected to fully reversed cyclic loading. Journal of Structural Engineering 2019, 145(4), 04019015. [CrossRef]

- Suzuki, K. Abe, Y. Kimura. Restraint performance of stud connection during lateral-torsional buckling under synchronized in-plane displacement and out-of-plane rotation. Journal of Structural Engineering 2020, 146(4), 04020029. [CrossRef]

- Suzuki, K. Abe, K. Suzuki, Y. Kimura. Cyclic behavior of perfobond shear connectors subjected to fully reversed cyclic loading. Journal of Structural Engineering 2021, 147(3), 04020355. [CrossRef]

- Suzuki, K. Suzuki, Y. Kimura. Ultimate shear strength of perfobond shear connectors subjected to fully reversed cyclic loading. Engineering Structures 2021 248, 113240. [CrossRef]

- Suzuki, Y. Kimura. Mechanical performance of stud connection in steel–concrete composite beam under reversed stress. Engineering Structures 2021, 249, 113338. [CrossRef]

- K. Suzuki, A. Suzuki, Y. Kimura. Ultimate shear strength of component model of composite beam with perfobond shear connector. Materials Science Forum, Virtual, Online, 26-28 June 2021. [CrossRef]

- Suzuki, K. Hiraga, Y. Kimura. Cyclic behavior of steel-concrete composite dowel by clothoid-shaped shear connectors under fully reversed cyclic stress. Journal of Advanced Concrete Technology 2023, 21, 76–91. [CrossRef]

- Suzuki, K. Hiraga, Y. Kimura. Mechanical performance of puzzle-shaped shear connectors subjected to fully reversed cyclic stress. Journal of Structural Engineering 2023, 149(7), 04023087. [CrossRef]

- Y. Liu, B. Sun, Experimental investigation and finite element analysis for mechanical behavior of steel–concrete composite beams under negative bending. International Conference on Mechanics and Civil Engineering, Wuhan, China, 13-14 December 2014. [CrossRef]

- Y. Kimura, Y. Sato, A. Suzuki. Effect of fork restraint of column on lateral buckling behavior for H-shaped steel beams with continuous braces under flexural moment gradient. Journal of Structural and Construction Engineering (Transactions of AIJ) 2022, 87(793), 316–327. (in Japanese). [CrossRef]

- W. Liao, Y. Yoshino, Y. Kimura, Experimental study on the effect of H-shaped beam-folded roof plate joints on the rotational bracing stiffness of folded roof plates as continuous braces. Steel Construction Engineering 2021, 28(112), 101–110.

- Japan Society of Steel Construction (JSSC). Guideline of standard push-out tests of headed stud and current situation of research on stud shear connectors. Japan Society of Steel Construction: Tokyo, Japan, 1996.

- Japan Industrial Standards (JIS). Method of test for compressive strength of concrete JIS A 1108. Japan Standard Association: Tokyo, Japan, 2006.

- Japan Industrial Standards (JIS). Method of test for splitting tensile strength of concrete JIS A 1113. Japan Standard Association: Tokyo, Japan, 2006.

- Japan Industrial Standards (JIS). Metallic materials – tensile testing method of test at room temperature JIS Z 2241. Japan Standard Association, Tokyo, Japan. 2011.

- Eurocode-4. Design of composite steel and concrete structures Part 1–1: rules for buildings. European Committee for Standardization, Brussels, Belgium, 2004.

- T.N. Huu, S.E. Kim. Finite element modeling of push-out tests for large stud shear connectors. Journal of Constructional Steel Research 2009, 65, 1909–1920.

- Hillerborg. Stability problems in fracture mechanics testing in fracture of concrete and rock. International Conference on Recent Developments in the Fracture of Concrete and Rocks 1989, 369-378.

- T. Noguchi, F. Tomosawa. Relationship between compressive strength and various mechanical properties of high strength concrete. Journal of Structural and Construction Engineering (Transactions of AIJ) 1995, 472, 11–16. (in Japanese). [CrossRef]

- Y. Kitsutaka, S. Nakamura, H. Mihashi. Simple evaluation method for the bilinear type tension softening constitutive law of concrete. Proceedings of the Japan Concrete Institute 1998, 20, 181–186.

- Y. Goto, K.P. Ghosh, N. Kawanishi. Nonlinear finite-element analysis for hysteretic behavior of thin-walled circular steel columns with in-filled concrete. Journal of Structural Engineering 2010, 136(11), 1413–1422. [CrossRef]

- Y. Doukan, K. Fujii, Y. Tamiya, T. Fujii. Consideration of load transfer mechanism of perforated rib shear connectors. Journal of Structural Engineering 2014, 60A, 827–836.

- Y. Kimura, A. Suzuki, K. Kasai. Estimation of plastic deformation capacity for I-shaped beams with local buckling under compressive and tensile forces. Journal of Structural and Construction Engineering (Transactions of AIJ) 2016, 81(730), 2133–2142. [CrossRef]

- Suzuki, Y. Kimura, K. Kasai. Plastic deformation capacity of H-shaped beams collapsed with combined buckling under reversed axial forces. Journal of Structural and Construction Engineering (Transactions of AIJ) 2019, 83(744), 297–307. [CrossRef]

- Suzuki, Y. Kimura, K. Kasai. Rotation capacity of I-shaped beams collapsed with lateral-torsional buckling under reversed axial forces. Japan Architectural Review 2019, 2(4), 451-464. [CrossRef]

- Suzuki, Y. Kimura, K. Kasai. Rotation capacity of I-shaped beams under alternating axial forces based on buckling-mode transitions. Journal of Structural Engineering 2020, 146(6), 04020089. [CrossRef]

- Suzuki, Y. Kimura. Rotation capacity of I-shaped beam failed by local buckling in buckling-restrained braced frames with rigid beam-column connections. Journal of Structural Engineering 2023, 149(2), 04022243. [CrossRef]

- S. M. Fujak, Y. Kimura, A. Suzuki. Estimation of elastoplastic local buckling capacities and novel classification of I-beams based on beam’s elastic local buckling strength. Structures 2022, 39, 765-781. [CrossRef]

- S. M. Fujak, A. Suzuki, Y. Kimura. Estimation of ultimate capacities of Moment-Resisting Frame’s subassemblies with Mid-Storey Pin connection based on elastoplastic local buckling. Structures 2023, 48, 410-426. [CrossRef]

- Y. Yoshino, W. Liao, Y. Kimura. Restraint effect on lateral buckling load of continuous braced H-shaped beams based on partial frame loading tests. Journal of Structural and Construction Engineering (Transactions of AIJ) 2022, 87(797), 634–645. (in Japanese). [CrossRef]

- Y. Kimura. Effect of loading hysteretic program on plastic deformation capacity and cumulative plastic deformation capacity for H-shaped beam with local buckling – database of experimentally obtained results for cantilever with H-section. Journal of Structural and Construction Engineering (Transactions of AIJ) 2011, 76(664), 1143–1151. (in Japanese).

| W/C | s/a | Unit materials content [kg/m3] | ||||

| Water | Cement | Sand | Gravel | Admixture | ||

| 53.0 | 47.5 | 178 | 336 | 829 | 933 | 4.36 |

| Compressive strength [N/mm2] |

Tensile strength [N/mm2] |

Modulus of elasticity [N/mm2] |

| 26.4 | 2.1 | 22,836 |

| Part | Thickness [mm] |

Yield strength [N/mm2] |

Ultimate strength [N/mm2] | Elongation [%] |

| Connector | 16 | 285 | 436 | 46 |

| Web | 8 | 293 | 458 | 37 |

| Flange | 12 | 257 | 440 | 43 |

| Diameter [mm] | Yield strength [N/mm2] | Ultimate strength [N/mm2] | Elongation [%] |

| 10 | 378 | 509 | 28 |

| Part | Specimen | Thickness [mm] | Yield strength [N/mm2] | Ultimate strength [N/mm2] |

| Flange | No. 1 | 6 | 313.9 | 465.9 |

| No. 2 | 6 | 294.8 | 443.5 | |

| Web | No. 1 | 9 | 368.3 | 475.1 |

| No. 2 | 8 | 334.1 | 456.2 | |

| Folded roof plate | No. 1 | 0.5 | 347.4 | 393.1 |

| No. 2 | 0.5 | 341.7 | 389.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).