Submitted:

21 August 2023

Posted:

22 August 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

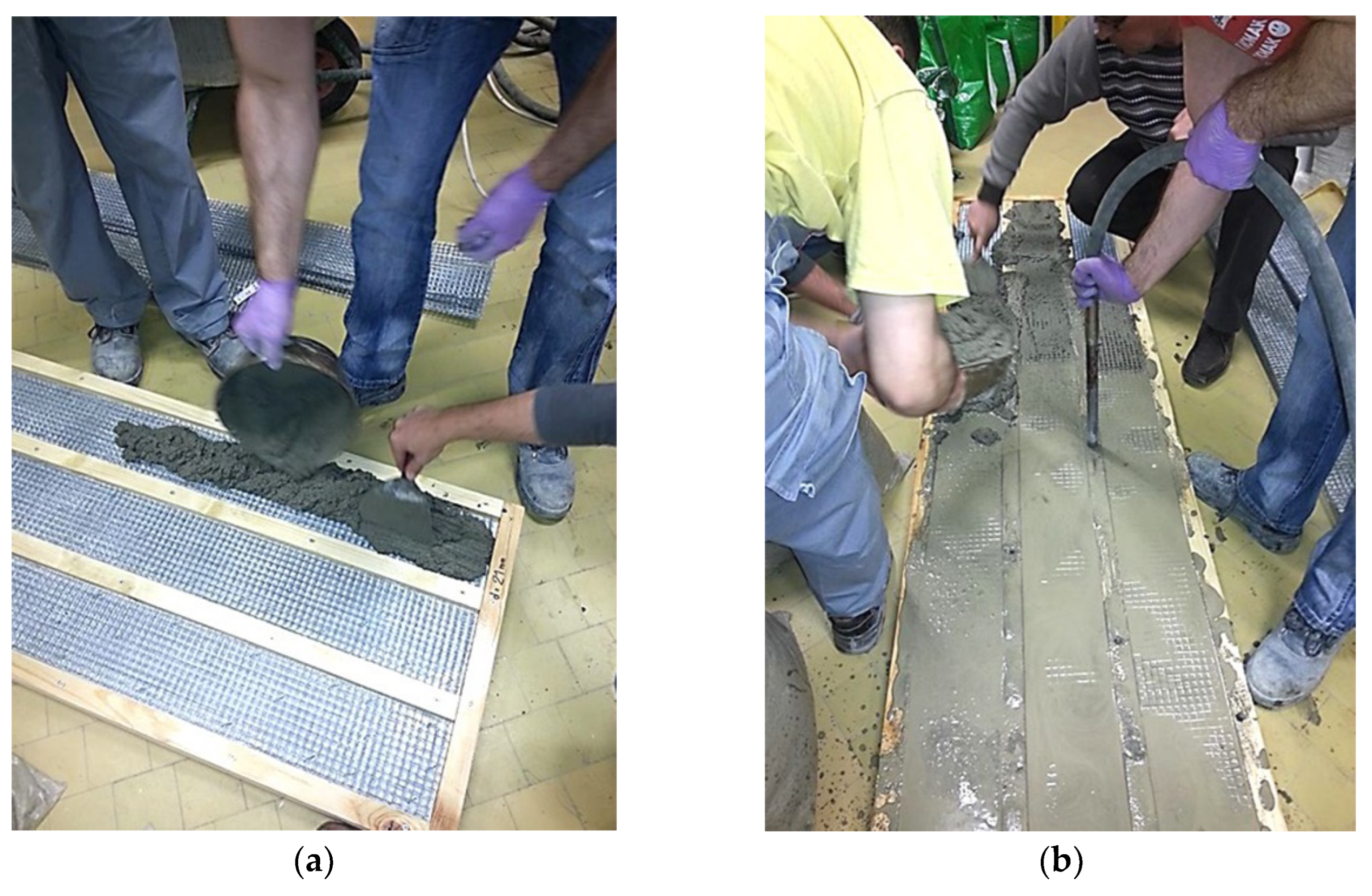

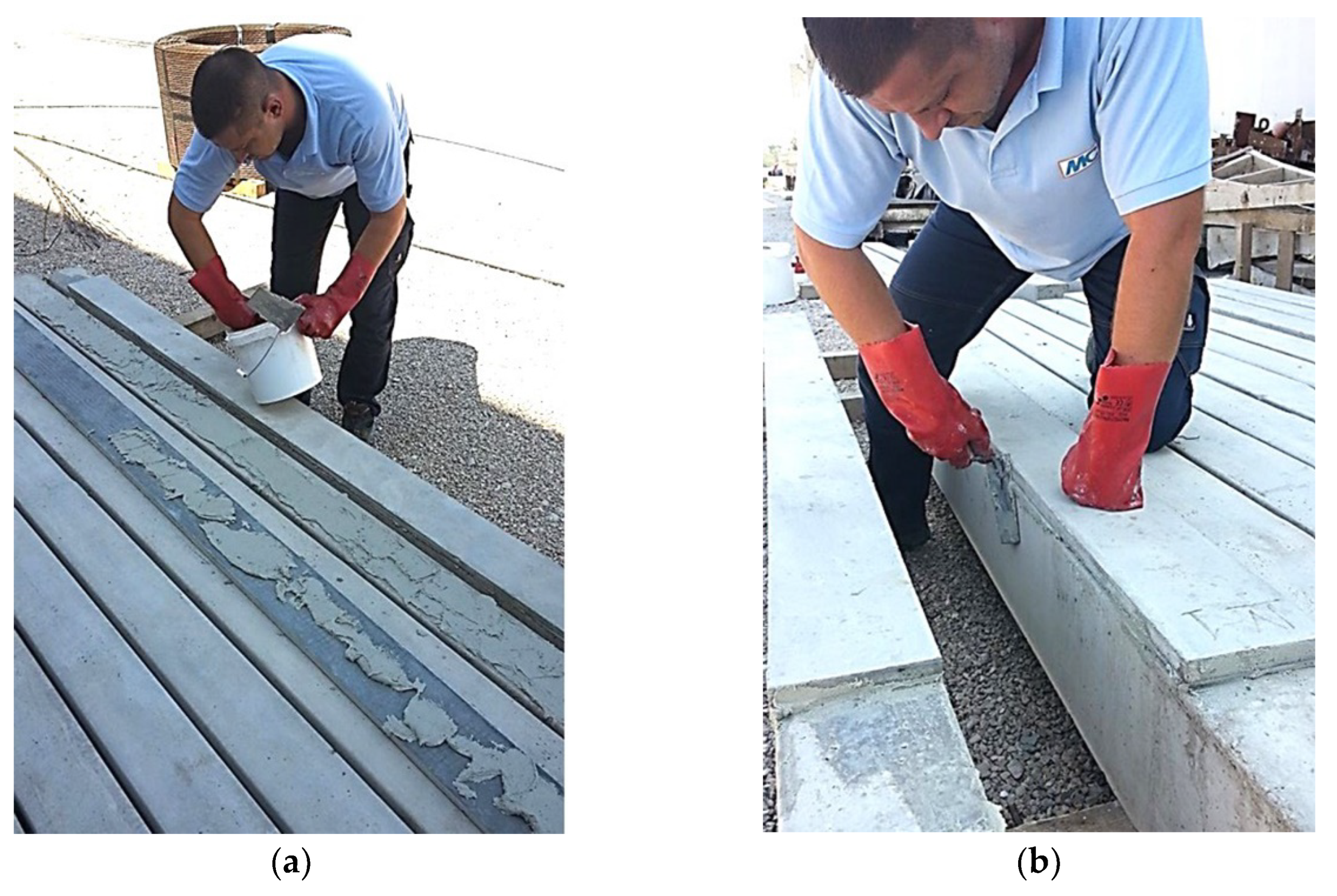

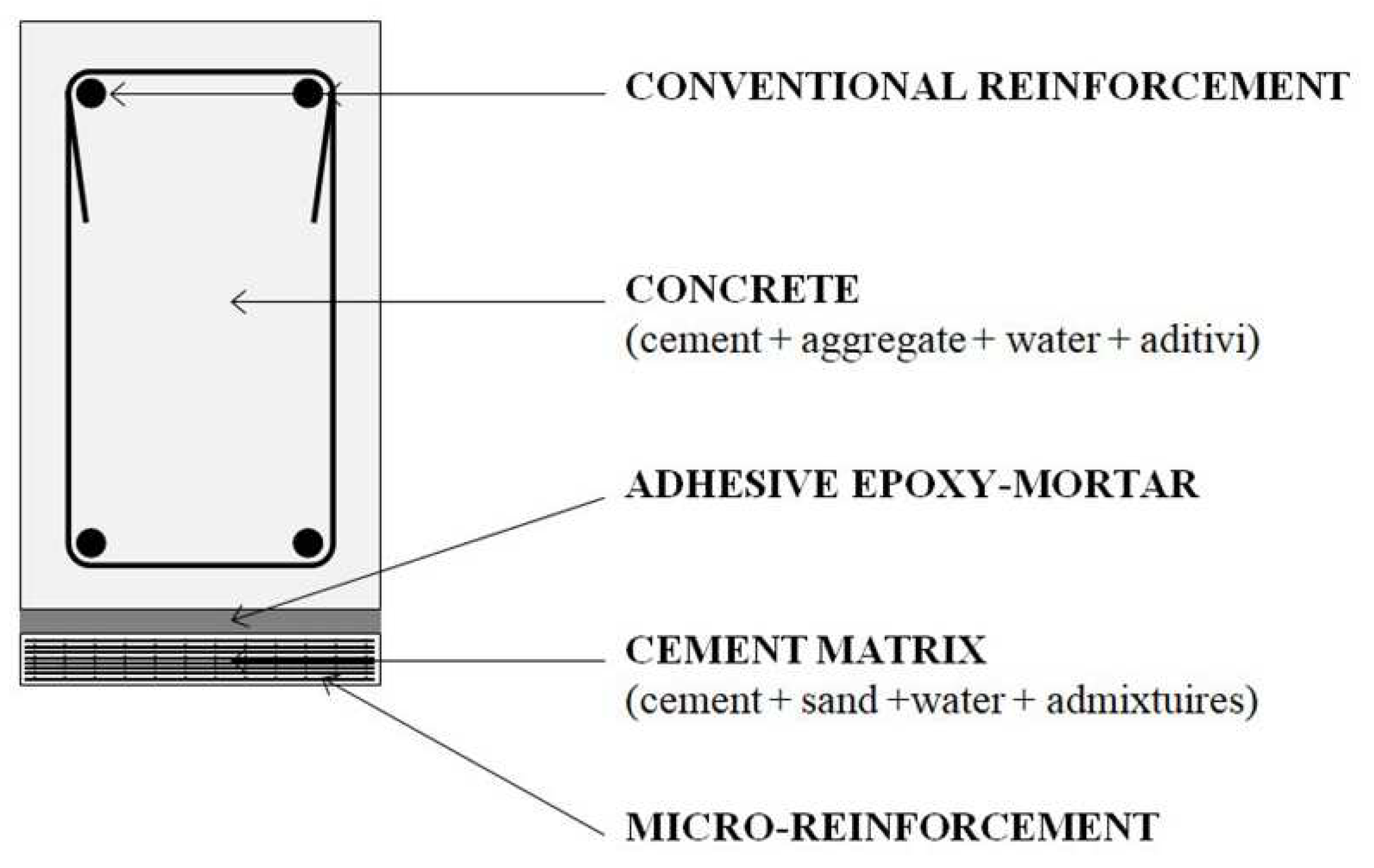

2. Theoretical basis of the calculation and analytical, experimental and numerical modeling of RC beams strengthened with ferrocement

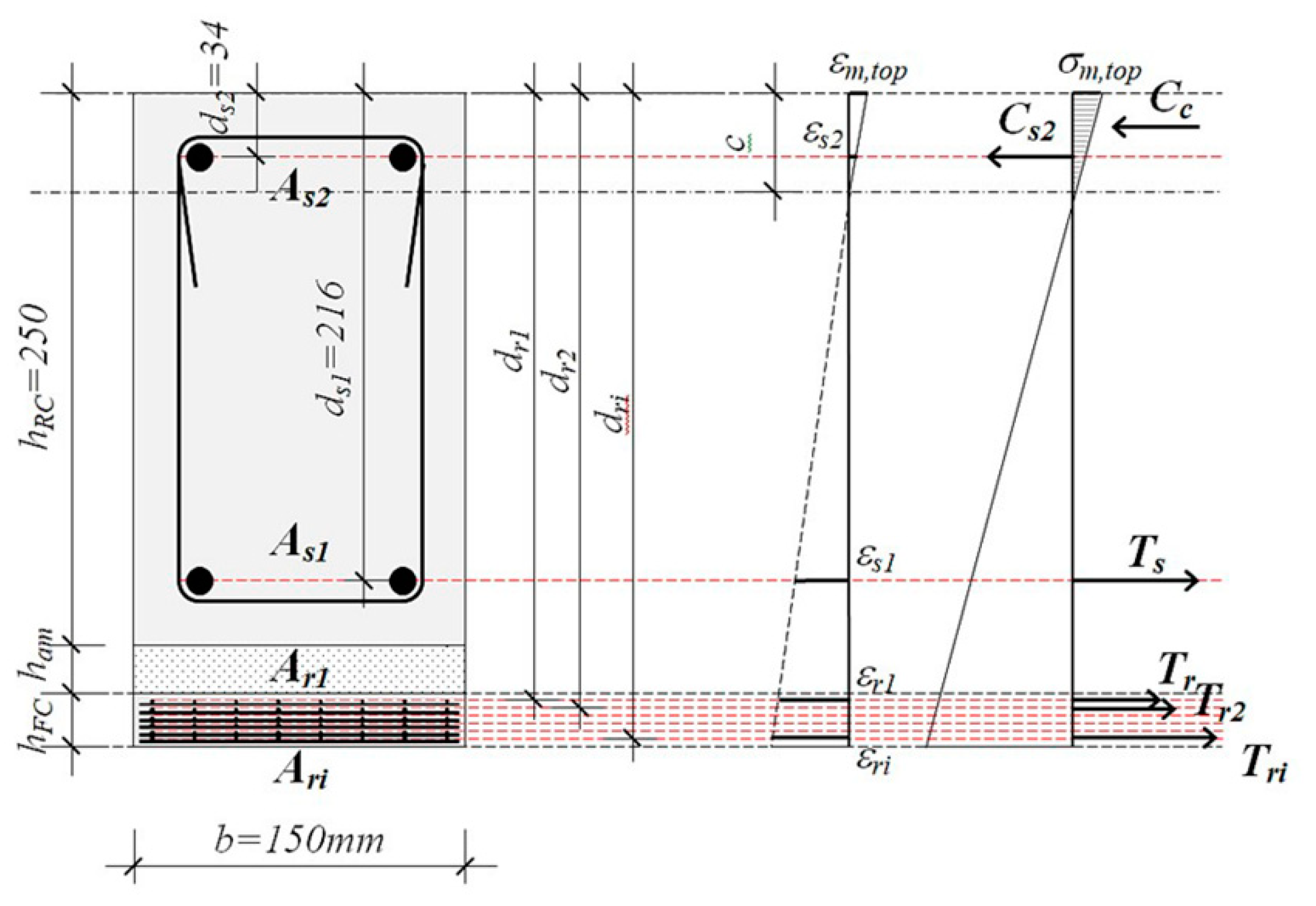

- strains change linearly with the distance from the neutral axis.

- stress-strain relation is linear for mortar, concrete, micro-reinforcement, and reinforcement, for the stresses lower or equal to the permissible operational stresses.

- mortar and concrete do not resist tension.

- ideal adhesion between mortar and micro-reinforcement, i.e., concrete and conventional reinforcement is achieved.

- Tensile stress in reinforcement due to the service load caused by tension, bending or their combination, should not exceed the value of 0,60·fy (fy - yield strength of the reinforcement), nor the value of 400MPa. The limitation of 400MPa can be increased in the case of use of high strength reinforcement meshes, if their effect is experimentally proven.

- The maximum compressive stress in the mortar matrix under bending should not exceed the value of 0,45·fc’ (fc’- specified design compressive strength, obtained by examining the test cylinders).

2.4.1. Adopted characteristics of constitutive materials

3. Results and discussion

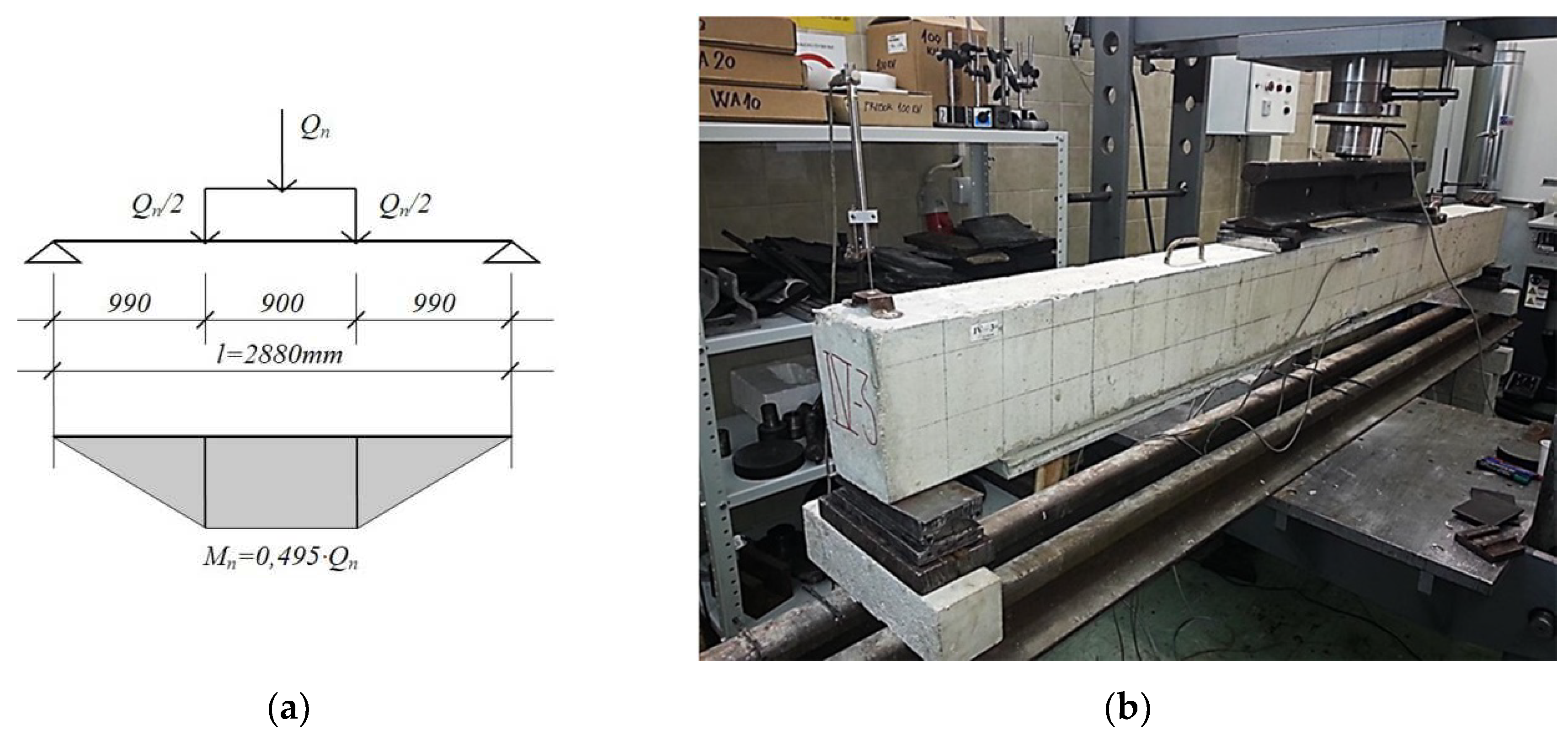

3.1. Experimental test results

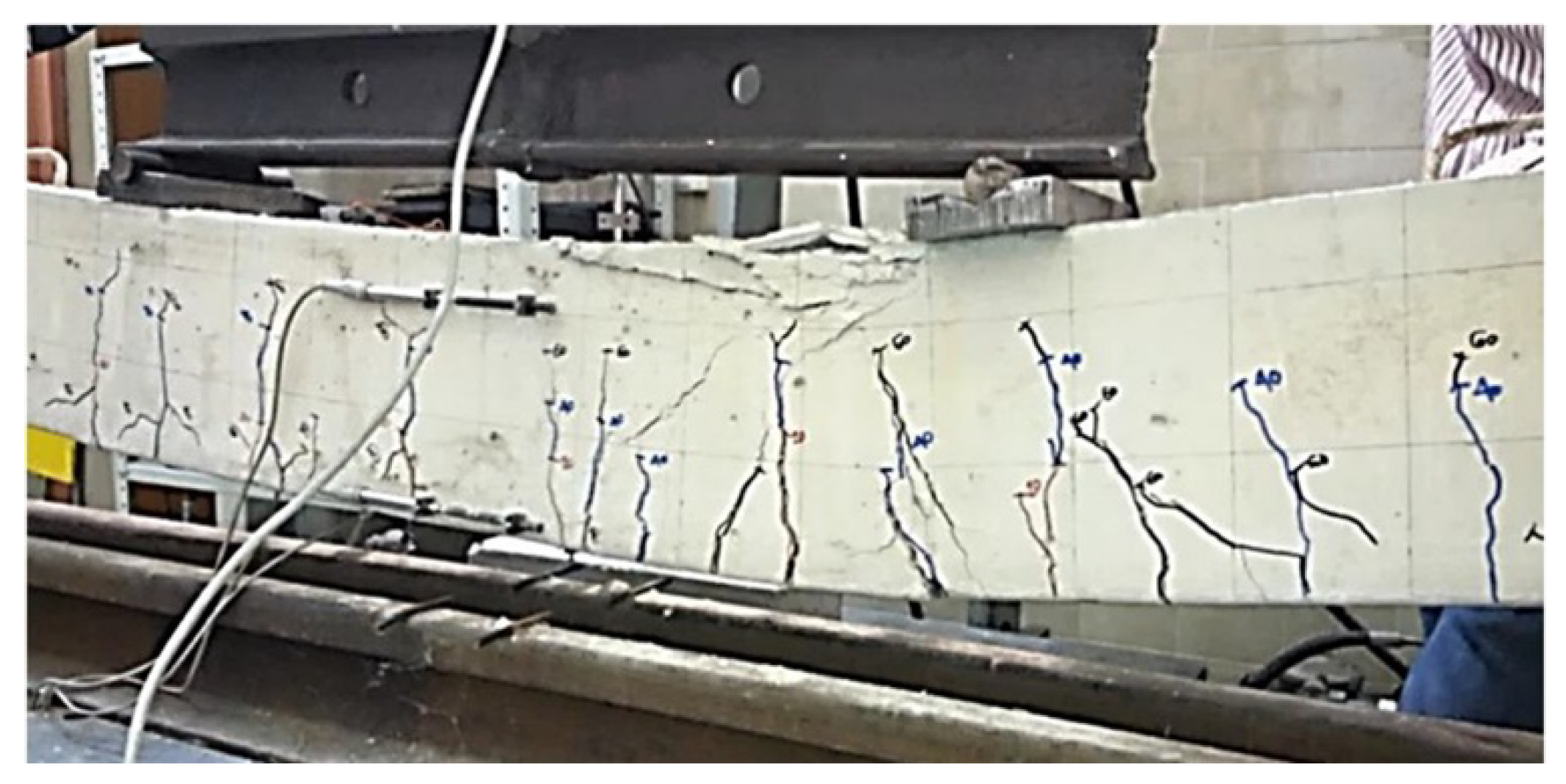

3.1.1. Failure mechanism of control (non-strengthened) RC beams

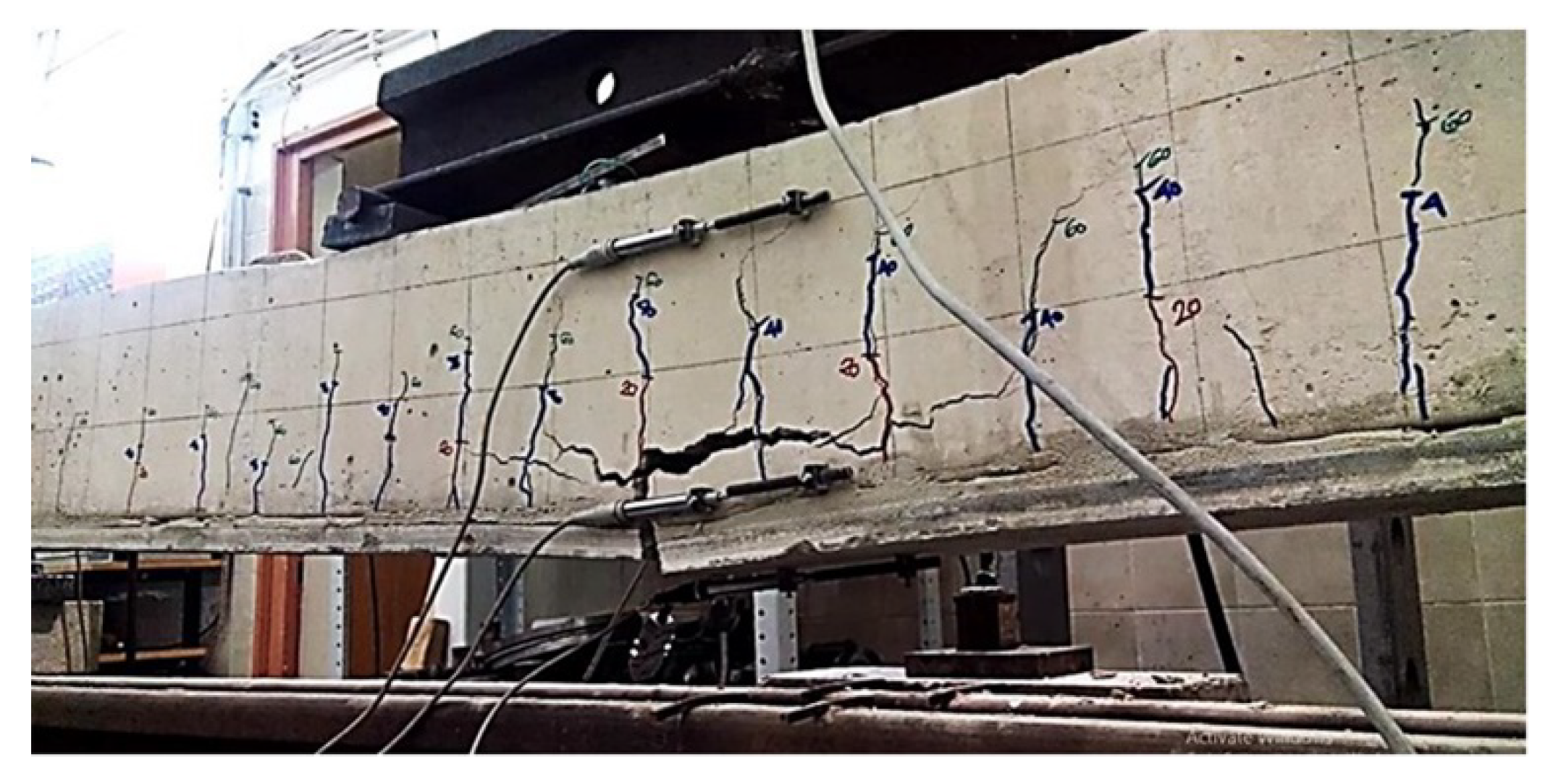

3.1.2. Failure mechanism of strengthened RC beams

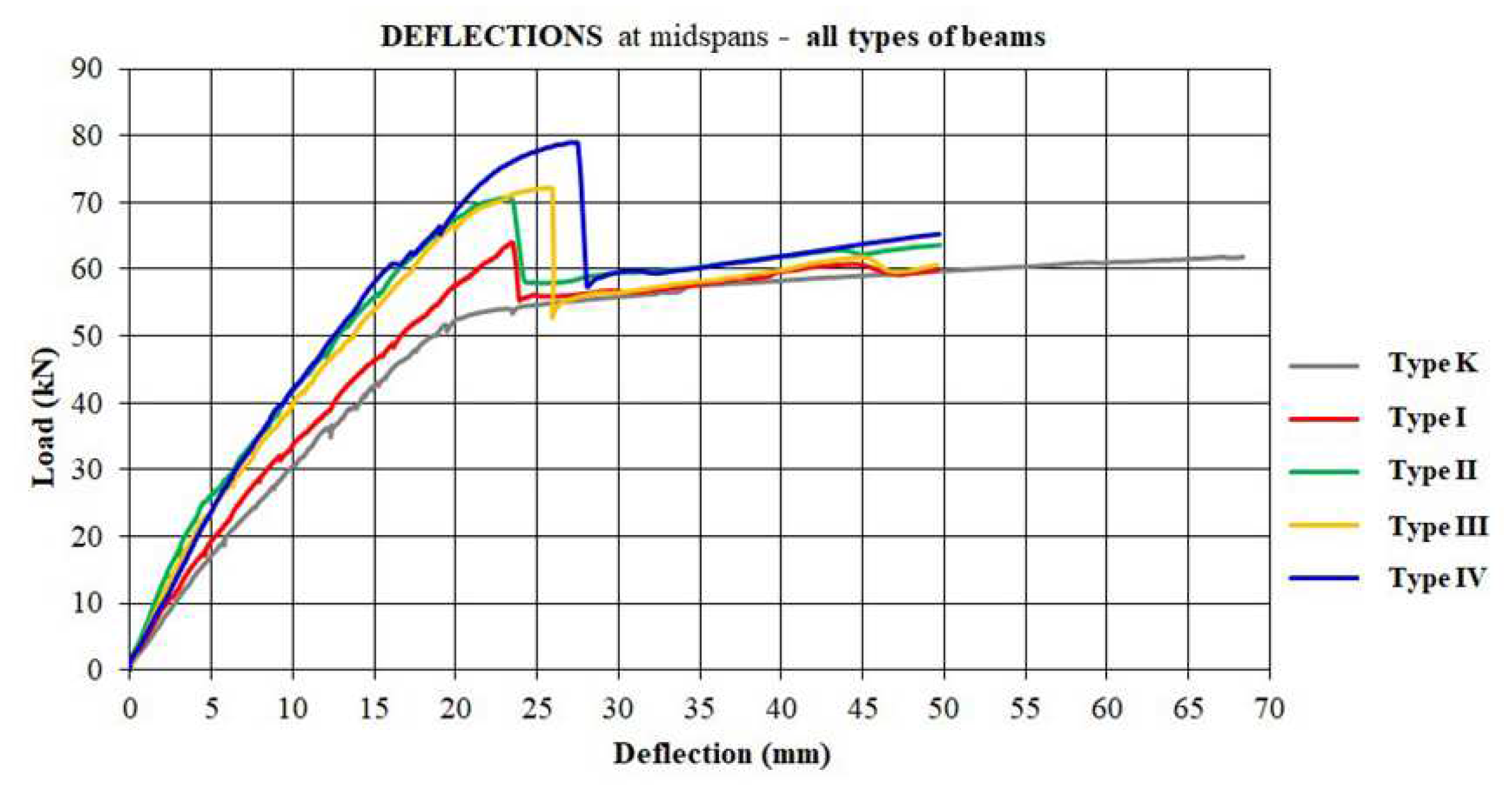

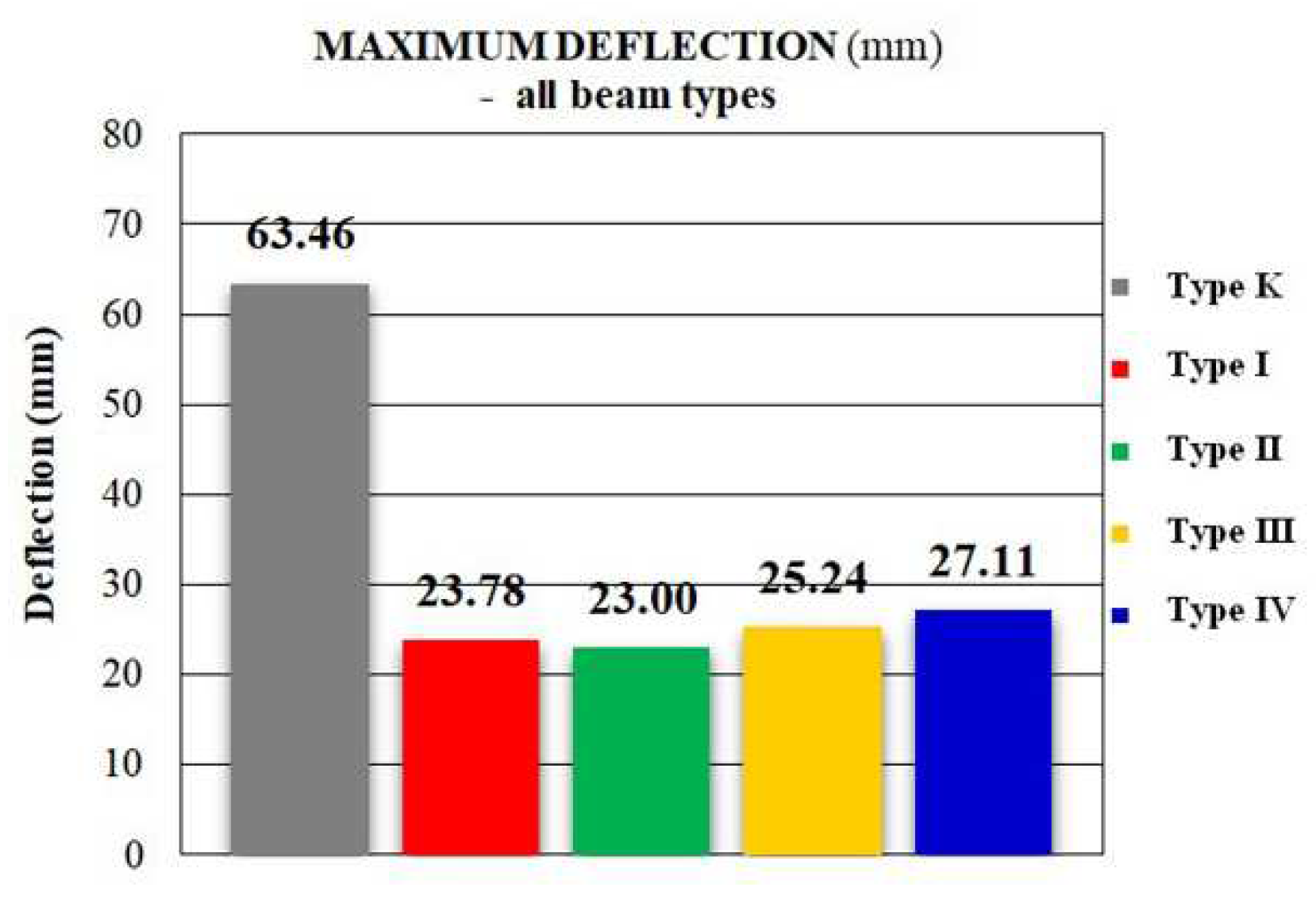

3.1.3. Experimental results of ultimate deflection

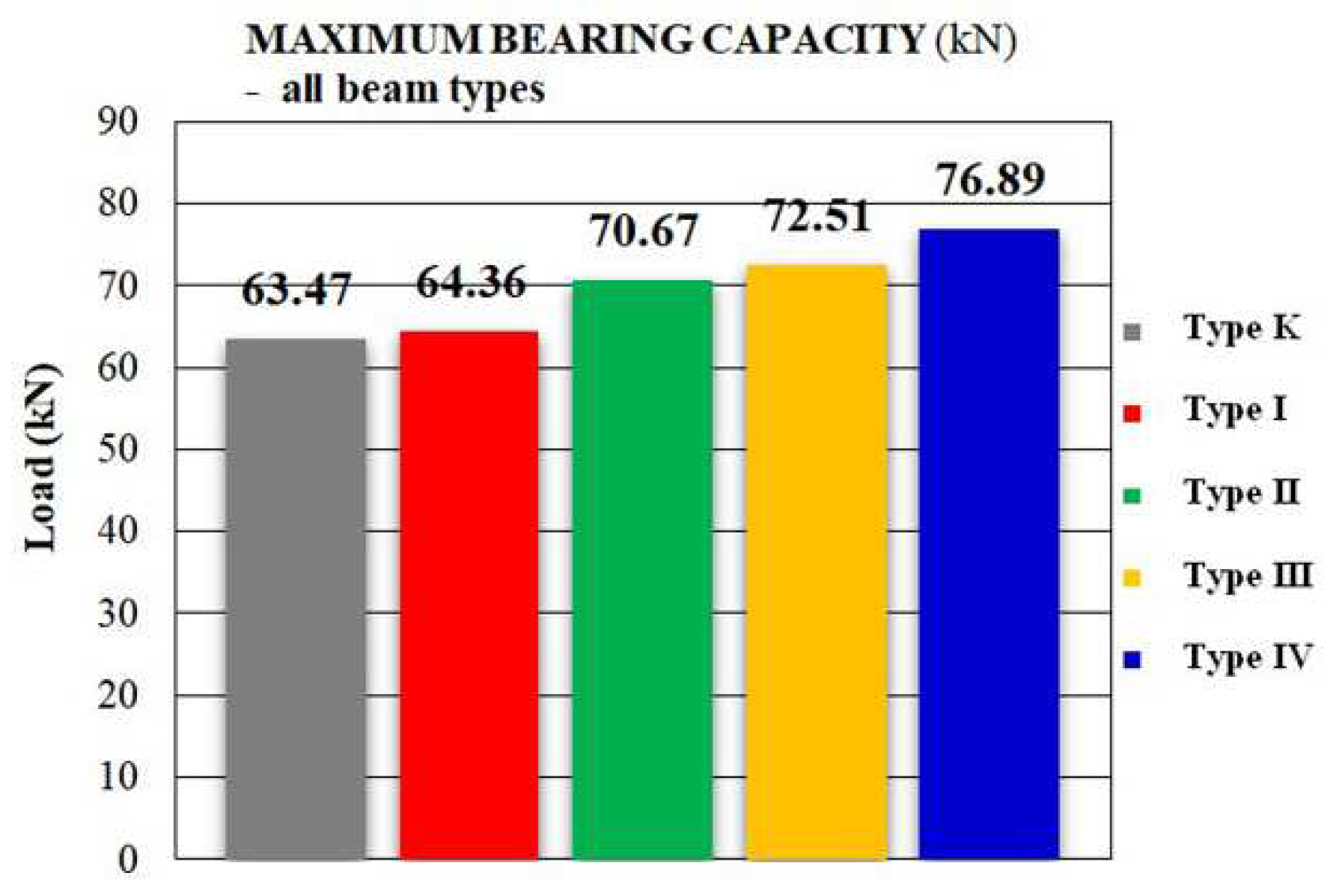

3.1.4. Experimental results of ultimate load capacity

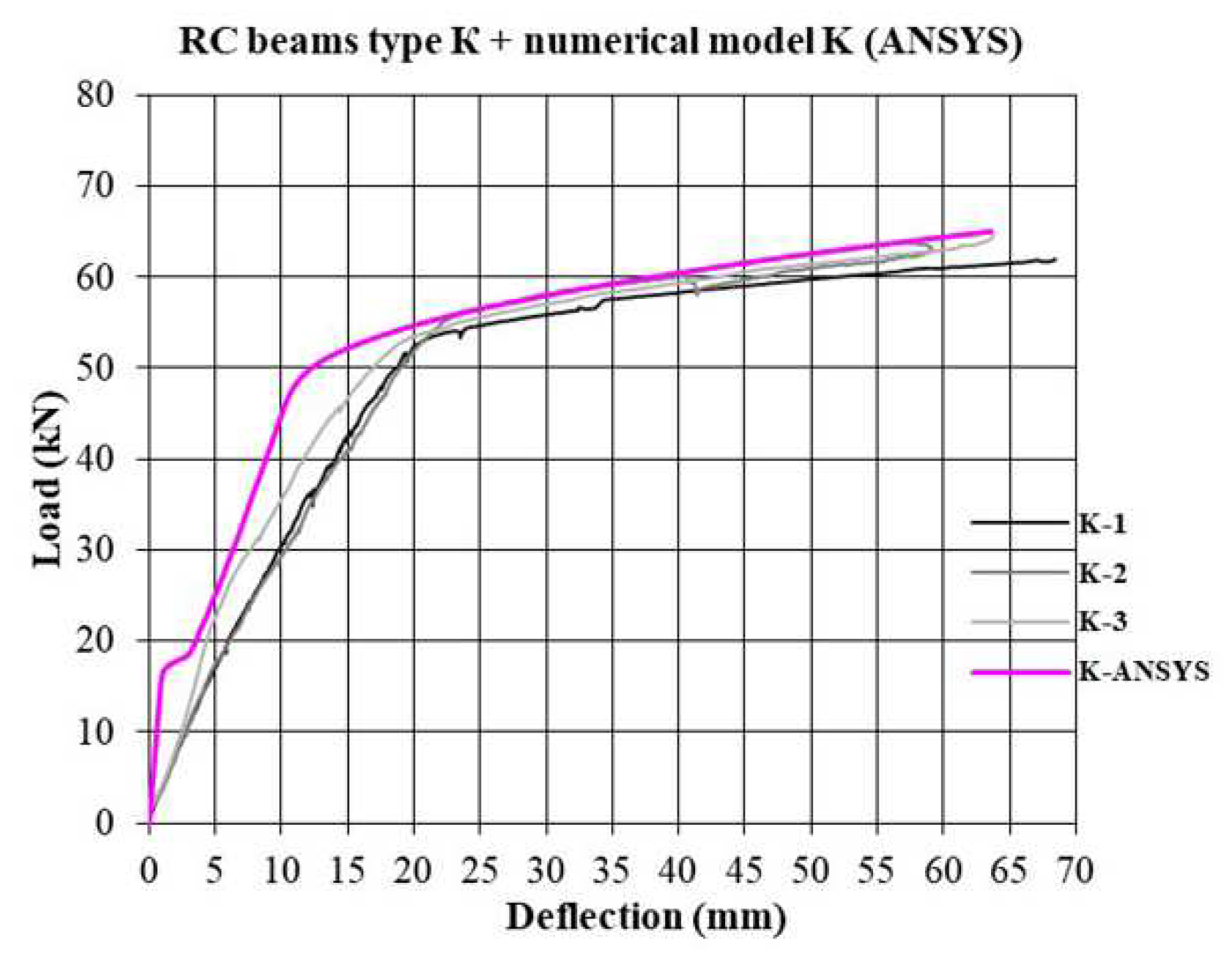

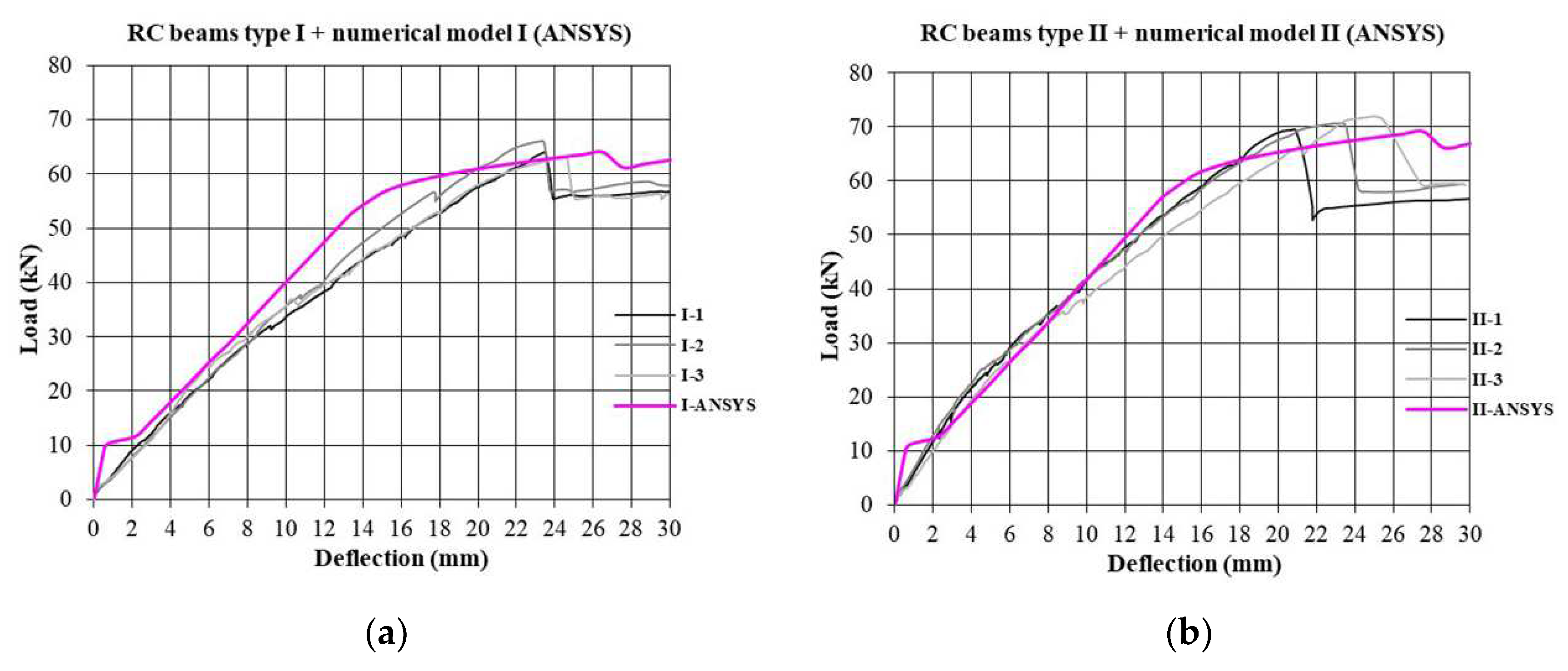

3.3. The results of analysis of numerical models

3.4. Comparative analysis of the results of RC beams in bending strengthened with ferrocement

4. Conclusions

- The chosen method of coupling reinforced concrete and ferrocement by gluing is an effective, simple and easily applicable method of strengthening the RC beam to bending. It can be very interesting for inaccessible beams, given that it is constructed quickly and does not require special fitting and curing conditions.

- The bond made with adhesive epoxy-mortar effectively joins the materials and guarantees the joint resistance of reinforced concrete and ferrocement. At the failure of the bearing capacity and the occurrence of fracture of all tested strengthened RC beams, the ferrocement strips remained attached to the reinforced concrete, regardless of their longitudinal failing and loss of the strengthening function.

- Ferrocement obeys the same laws and design principles and is dimensioned according to the same theories as conventionally reinforced concrete. Analytical calculation of reinforced beams according to the mentioned generally accepted theoretical methods showed agreement with the results of experimental research and the results of numerical simulation (Table 9).

- All the mentioned analytical methods can be applied, with the note that the transformed area method for the cracked section gives the service bending moment. For the calculation of the nominal bending moment, it is necessary to first select the appropriate partial safety coefficient. The recommended values of 1.5 and 1.7 define the final calculation results sufficiently well (Table 9).

- Load bearing capacity of the tested strengthened RC beams was 21,14% higher than the non-strengthened beams (Figure 16), all depending on the reinforcement type (thickness of ferrocement strip and number of micro-reinforcement mesh layers).

- Strengthening the RC beams with ferrocement strips had a very favorable effect on the limit state of serviceability. At the load which causes the failure of non-strengthened beams, the values of maximum deflections of tested strengthened beams were 36% to 43% of the maximum deflection of non-strengthened beams (Figure 15).

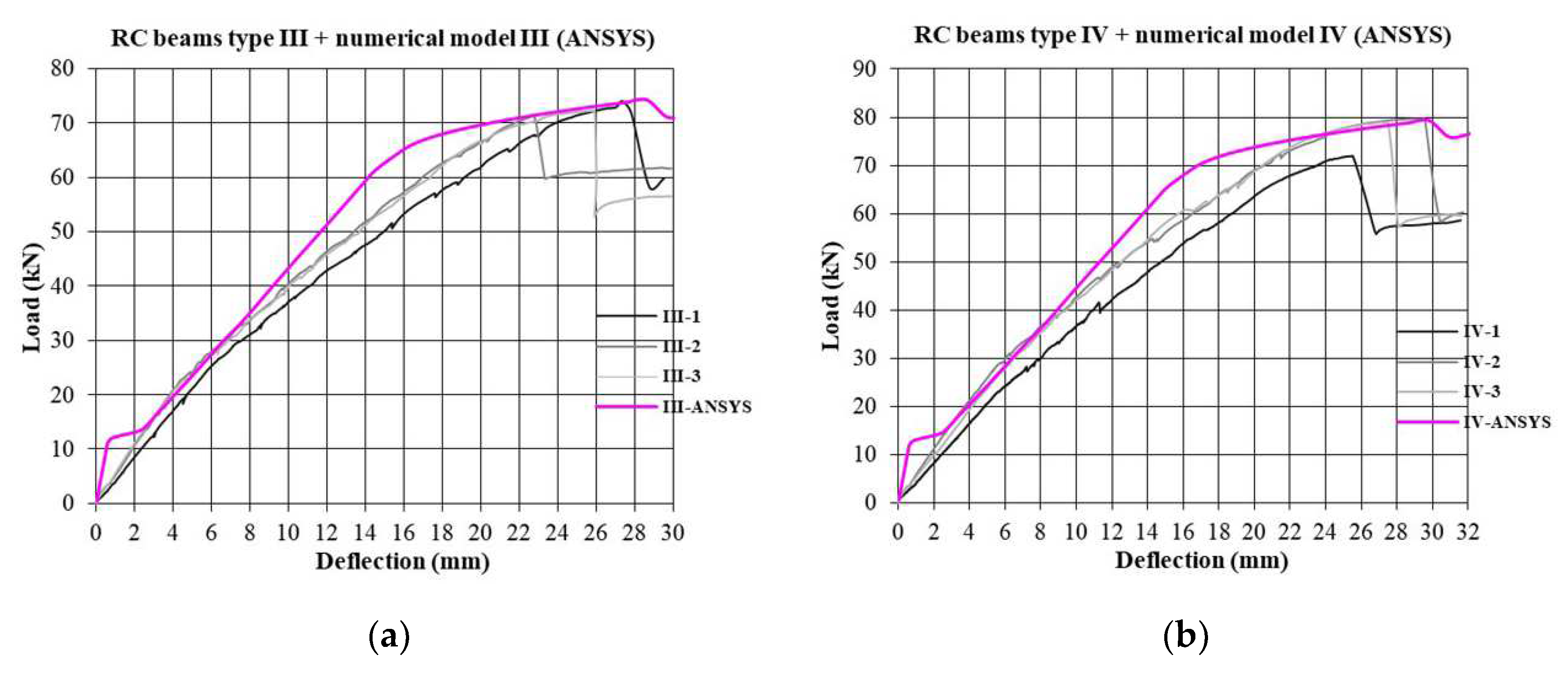

- The non-linear analysis that used numerical models provided a display of the characteristic phases that the experimental beams went through during load application, but it is extremely demanding due to the large number of input parameters (a large number of different materials and simulation of their interconnections). For this reason, there are certain deviations (Figure 17, Figure 18 and Figure 19), mainly related to the idealization of the physical and mechanical characteristics of the constituent elements of composite beams and their mutual interaction.

- Numerical simulation of non-strengthened and strengthened models provides the values of the failure force for strengthened and non-strengthened beams which are in good agreement with the experimentally and analytically obtained values (Table 9).

References

- Xiong, G.J.; Wu, X.Y.; Li, F.F.; Yan, Z. Load Carrying Capacity and Ductility of Circular Concrete Columns Confined by Ferrocement Including Steel Bars, Construction and Building Materials, 2011, 25, 2263-2268. [CrossRef]

- Mourad, S.M.; Shannag, M.J. Repair and Strengthening of Reinforced Concrete Square Columns using Ferrocement Jackets, Cement & Concrete Composites, 2012, 34, 288–294. [CrossRef]

- Kaish, A.B.M.A.; Jamil, M.; Raman, S.N.; Zain, M.F.M. Axial Behavior of Ferrocement Confined Cylindrical Concrete Specimens with Different Sizes, Construction and Building Materials, 2015, 78, 50-59. [CrossRef]

- Al-Kubaisy, M.A.; Jumaat, M.Z. Flexural Behaviour of Reinforced Concrete Slabs with Ferrocement Tension Zone Cover, Construction and Building Materials, 2000, 14, 245-252. [CrossRef]

- Li, B.; Lam, E.S.; Wu, B.; Wang, Y. Experimental Investigation on Reinforced Concrete Interior Beam–Column Joints Rehabilitated by Ferrocement Jackets, Engineering Structures, 2013, 56, 897-909. [CrossRef]

- Shannag, M.J.; Mourad, S.M. Flowable Hhigh Strength Cementitious Matrices for Ferrocement Applications, Construction and Building Materials, 2012, 36, 933-939. [CrossRef]

- Shannag MJ; Ziyyad TB Flexural response of ferrocement with fibrous cementitious matrices. Construction and Building Materials, 2007, 21, 1198–205. [CrossRef]

- Gaidhankar, D.G.; Kulkarni, M.S.; Jaiswal, A.R. Ferrocement Composite Beams under Flexure, International Research Journal of Engineering and Technology (IRJET), 2017, Volume 04 Issue10, 117-124.

- Shang S.P.; Zeng, L.O.; Peng, H. Flexural Strengthening of Reinforced Concrete Beam with Ferrocement, 28th Conference on Our World in Concrete & Structures, Singapore, 28-29 August 2003.

- Makki, R.F. Response Of Reinforced Concrete Beams Retrofitted By Ferrocement, International Journal of Scientific & Technology Research, 2014, Volume 3, Issue 9.

- Zisan, B.; Biswas, B.K.; Hasan, A.; Chanda, M.; Dhar, A. Flexural Performance of Reinforced Concrete Beams Retrofitted Using Ferrocement Wire Mesh, Architecture and Engineering, 2023,Volume 8 Issue 1, 71-81. [CrossRef]

- Fahmy, E.H.; Shaheen, Y.B.I.; Abdelnaby, A.M. Applying the Ferrocement Concept in Construction of Concrete Beams Incorporating Reinforced Mortar Permanent Forms, International Journal of Concrete Structures and Materials, 2014, Vol.8, No.1, pp.83–97. [CrossRef]

- El-Wafa, M.A.; Fukuzawa, K. Flexural Behavior of Lightweight Ferrocement Sandwich Composite Beams, Journal of Science & Technology, 2010, Vol. (15) No.(1) JST 3.

- Miah, M.J.; Miah, M.S.; Alam, W.B.; Lo Monte, F.; Lie, Y. Strengthening of RC beams by ferrocement made with unconventional concrete, Magazine of Civil Engineering, 2019, 89(5), 94-105. [CrossRef]

- Bashandy A.A. Experiments on Flexural Strengthening of Reinforced Concrete Beams using Valid Strengthening Techniques, Acta Technica Napocensis: Civil Engineering & Architecture, 2013, Vol. 56, No. 1.

- Sridhar, J.; Malathy, R.; Sangeetha, R.K. Flexural Strengthening of Reinforced Concrete Beamsusing Ferrocement Laminates with Partial Replacement of Fine Aggregate by Steel Slag, Journal of Engineering and Technology, 2014, Volume 4, Issue 2, 123-126.

- Reddy, M.V.; Reddy, E.M. Rehabilitation of Shear Deficient RC Beams, International Journal of Earth Sciences and Engineering, 2011, Vol. 04, No. 06, pp. 1125-1128.

- Sivagurunathan, B.; Vidivelli, B. Strengthening of Predamaged Reinforced Concrete Beams by Ferrocement Plates, International Journal of Current Engineering and Technology, 2012, Vol.2, No.4.

- Naaman, A.E. Ferrocement & Laminated Cementitious Composites, Techno press 3000, Michigan, USA, 2000.

- IFS Committee 10 Ferrocement Model Code, Building Code Recommendations for Ferrocement (IFS 10-01), Reported by IFS Committee 10.

- https://www.mc-bauchemie.sg/products/concrete-cosmetics/speciality-mortars/sx-481-e.html.

- ANSYS User’s Manual Revision 5.5, ANSYS, Inc. Canonsburg, Pennsylvania, 2006.

- Kachlakev, D.; Miller, T. FE Modeling of Reinforced Concrete Structures Strengthened with FRP Lamiates, Final Report SPR 316, Oregon State University (2001).

- CEN. Eurocode 2: Design of concrete structures - Part 1-1 : General rules and rules for buildings, EN 1992-1-1:2004. European Committee for Standardization, Belgium, 2004.

- ACI 318.R-95 Building Code Requirements for Reinforced Concrete and Commentary, ACI Committee 318, American Concrete Institute, Detroit, 1995.

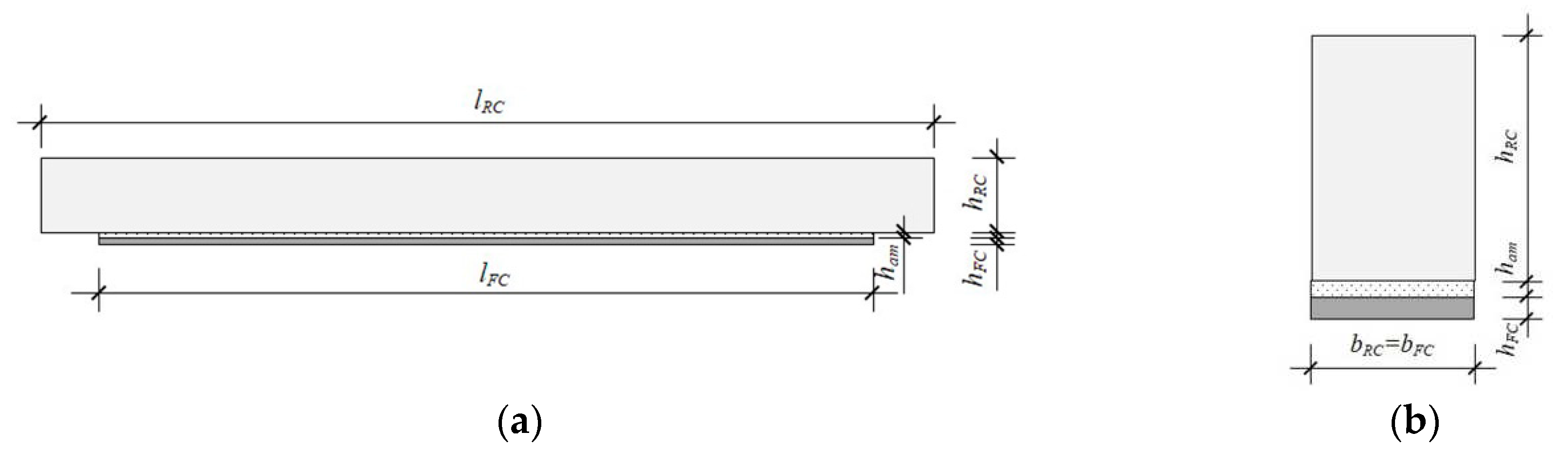

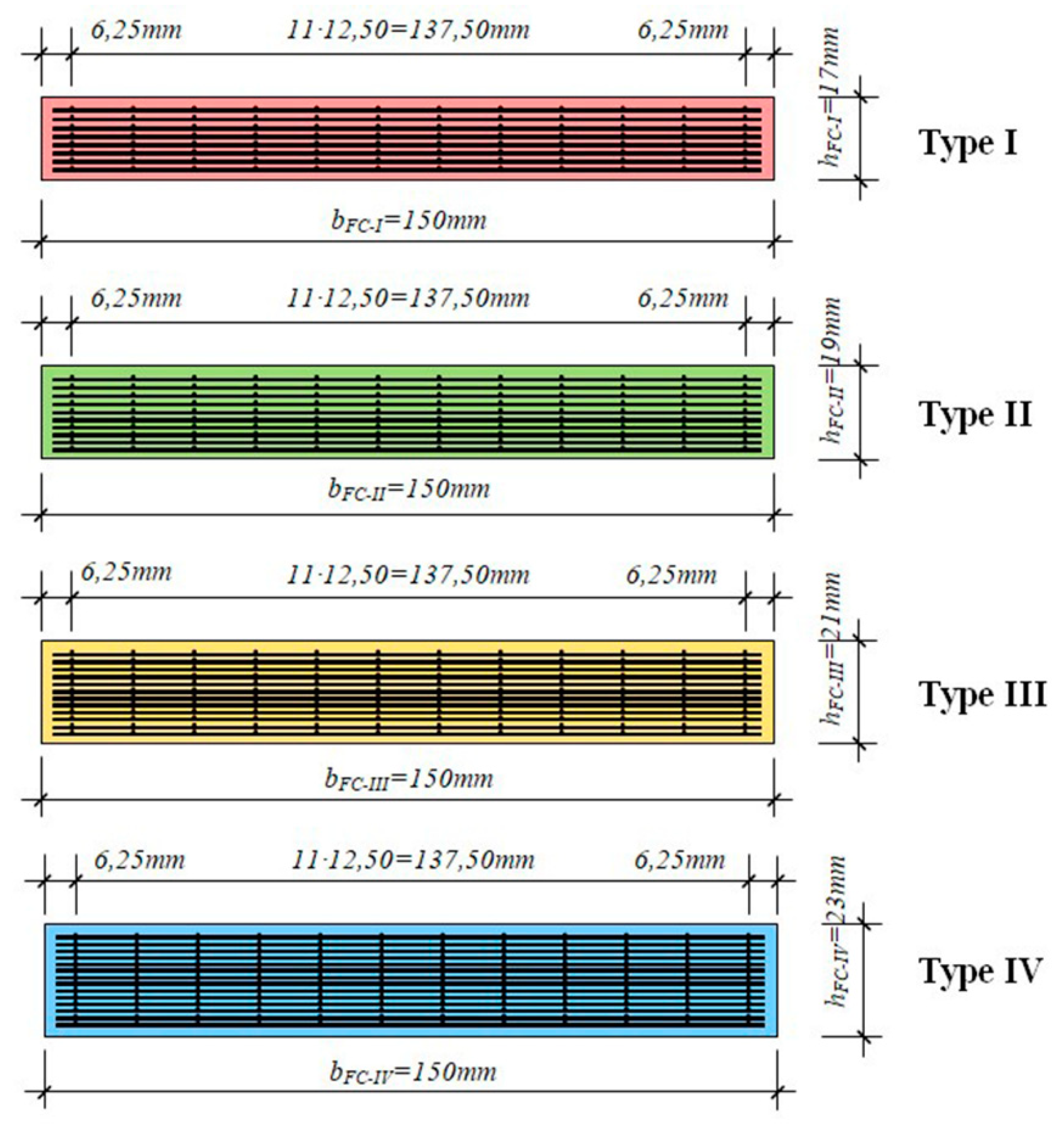

| Type of ferrocement element (strip) | Thickness of ferrocement element (mm) | Number of micro-reinforcement layers |

|---|---|---|

| I | 17 | 8 |

| II III IV |

19 21 23 |

10 12 14 |

| Properties | Value |

|---|---|

| Compressive strength of concrete | fc,c=47,92MPa |

| Modulus of elasticity of concrete | Ec=28,05GPa |

| Yield strength of the reinforcement | fsy=580,30MPa |

| Ultimate tensile strength of the reinforcement | fsu=730,93MPa |

| Modulus of elasticity of reinforcement | Es=200,0GPa |

| Compressive strength of adhesive epoxy-mortar | fam,c=45,0MPa |

| Modulus of elasticity of adhesive epoxy-mortar | Eam=5,20GPa |

| Compressive strength of cement-based mortar | fm,c=43,0MPa |

| Modulus of elasticity of cement-based mortar | Em=20,0GPa |

| Yield strength of the micro-reinforcement (mesh) | fry=562,27MPa |

| Ultimate tensile strength of the micro-reinforcement (mesh) | fru=670,43MPa |

| Modulus of elasticity of micro-reinforcement (mesh) | Er=200,0GPa |

| Point | Value |

|---|---|

| 0 | Initial point (zero state of stress and strain) |

| 1 | Based on the Hooke’s law and expression the result is |

| 2, 3, 4 | Based on the expression with strain calculated from the expression |

| 5 | data Maximum compression stress at strain |

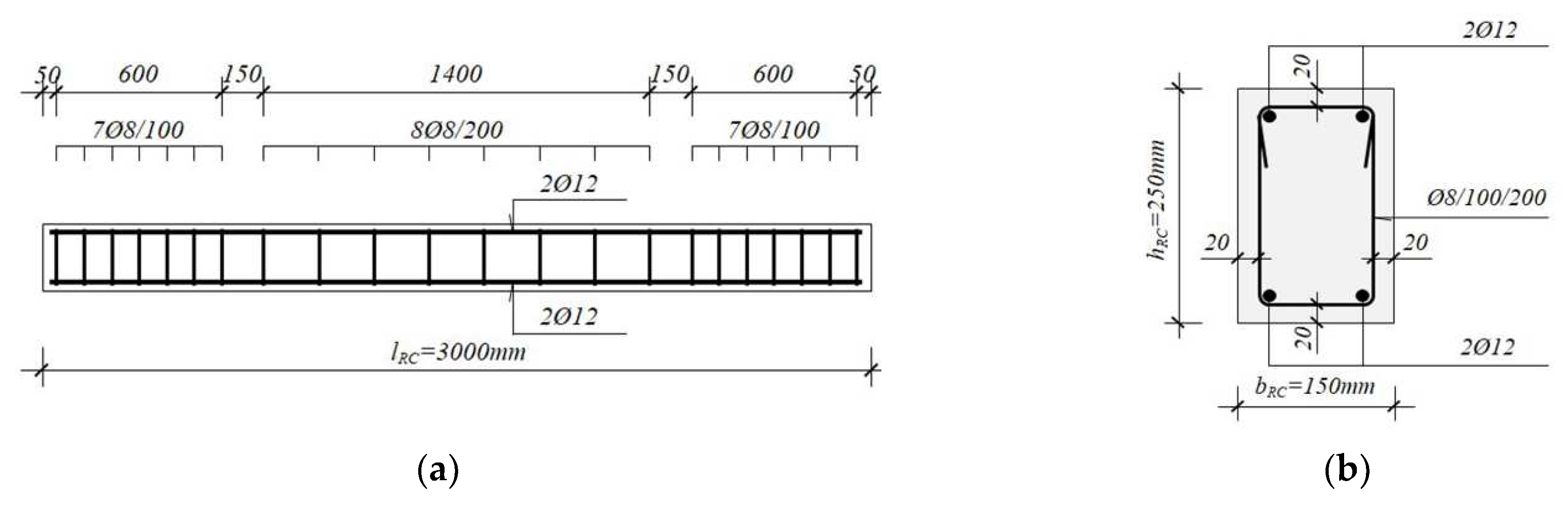

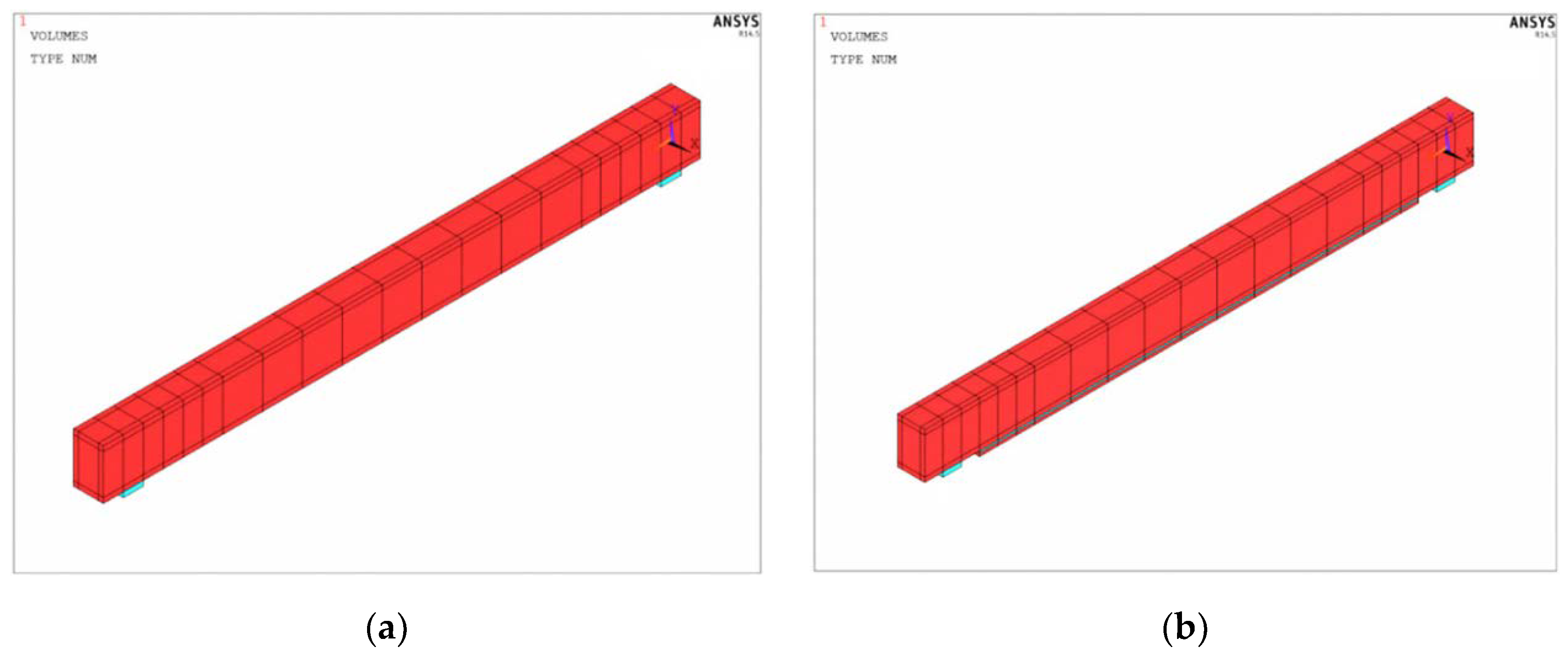

| Material of experimental beam models | Finite element type | Element dimensions (mm) |

|---|---|---|

| Concrete | SOLID 65 | 25×25×25 hexagonal |

| Conventional Steel reinforcement |

LINK 180 | l=25 linear |

| Ferrocement (cement-based matrix + steel micro-reinforcement) |

SOLID 65 | 25×25×17 (type I) 25×25×19 (type II) 25×25×21 (type III) 25×25×23 (type IV) hexagonal |

| Adhesive epoxy-mortar |

SOLID 185 | 25×25×10 hexagonal |

| RC beam type |

Mservice1 (kNm) |

Mservice2 (kNm) |

|---|---|---|

| I | 18,37 | 21,80 |

| II | 19,15 | 22,30 |

| III | 19,94 | 22,80 |

| IV | 20,75 | 23,29 |

| K | 15,40 | 19,77 |

| RC beam type |

Mservice1 | ||

|---|---|---|---|

| I | 18,37 | 27,56 | 30,62 |

| II | 19,15 | 28,73 | 31,92 |

| III | 19,94 | 29,91 | 33,23 |

| IV | 20,75 | 31,13 | 34,58 |

| K | 15,40 | 23,10 | 25,67 |

| RC beam type |

Mservice1 | ||

|---|---|---|---|

| I | 18,37 | 31,23 | 34,70 |

| II | 19,15 | 32,56 | 36,17 |

| III | 19,94 | 33,90 | 37,66 |

| IV | 20,75 | 35,28 | 39,19 |

| K | 15,40 | 26,18 | 29,09 |

| RC beam type |

Transformed area method for the cracked section |

Transformed area method for the cracked section |

Compatibility method | Simplified method based on all tensile reinforcement yielding |

|---|---|---|---|---|

| I | 30,62 | 34,70 | 30,45 | 30,46 |

| II | 31,92 | 36,17 | 31,43 | 31,43 |

| III | 33,23 | 37,66 | 32,40 | 32,40 |

| IV | 34,58 | 39,19 | 33,38 | 33,38 |

| K | 25,67 | 29,09 | 26,65 | 26,63 |

| RC beam type |

Transformed area method for the cracked section |

Transformed area method for the cracked section |

Compatibility method | Simplified method based on all tensile reinforcement yielding | Mean failure force of experimental models | Failure force of numerical models |

|---|---|---|---|---|---|---|

| Figure 8(a) | Figure 8(a) | Figure 8(a) | Figure 8(a) | Figure 16 | Figures 17,18,19 | |

| I | 61,86 | 64,36 | 61,52 | 61,54 | 64,36 | 64,42 |

| II | 64,49 | 70,67 | 63,50 | 63,50 | 70,67 | 69,88 |

| III | 67,13 | 72,51 | 65,46 | 65,46 | 72,51 | 74,36 |

| IV | 69,86 | 76,89 | 67,43 | 67,43 | 76,89 | 79,92 |

| K | 51,85 | 63,47 | 53,84 | 53,80 | 63,47 | 65,21 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).