Submitted:

17 August 2023

Posted:

21 August 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Bio-inspired coatings for aerospace applications

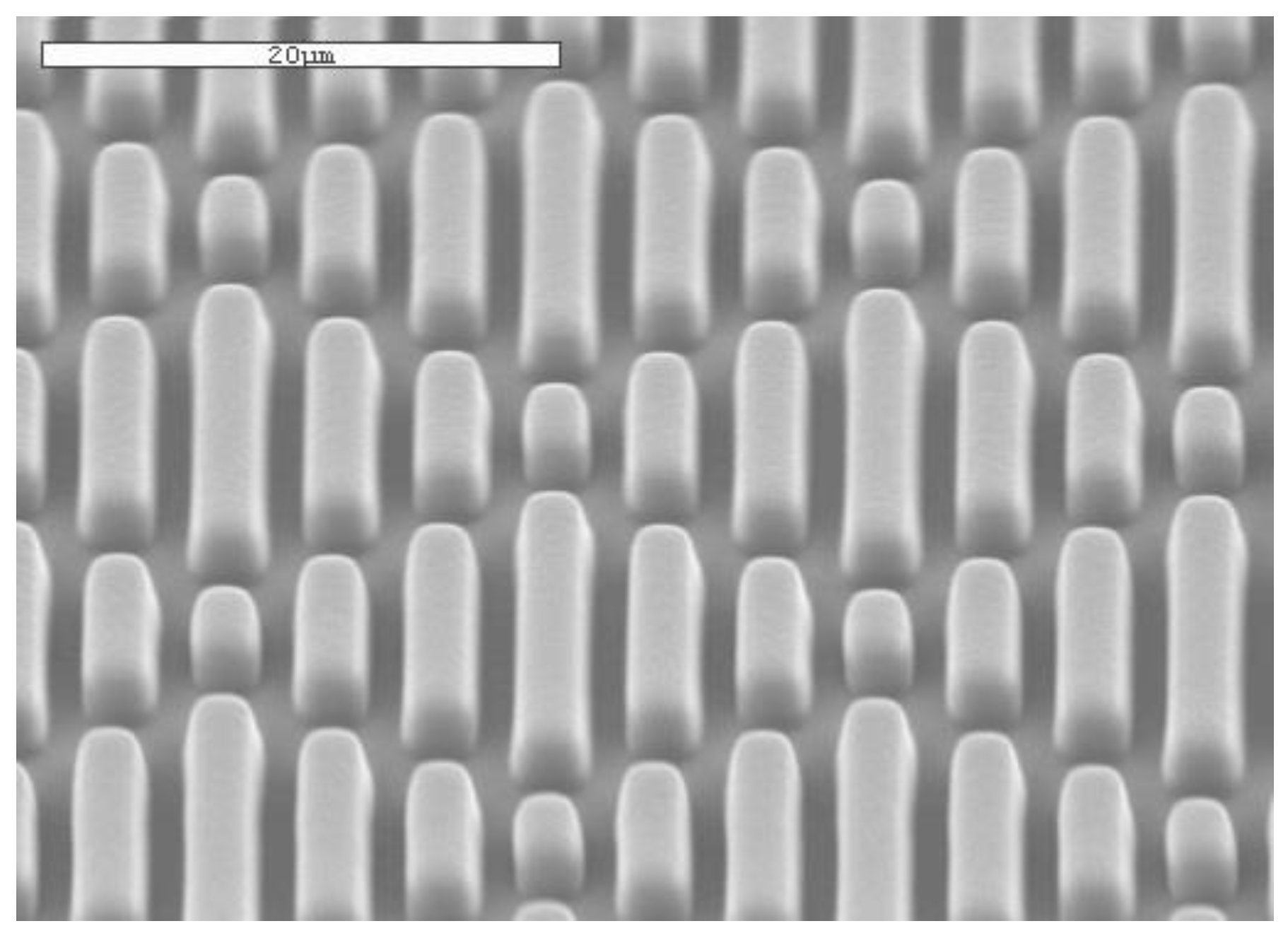

2.1. Sharkskin Inspired Coatings

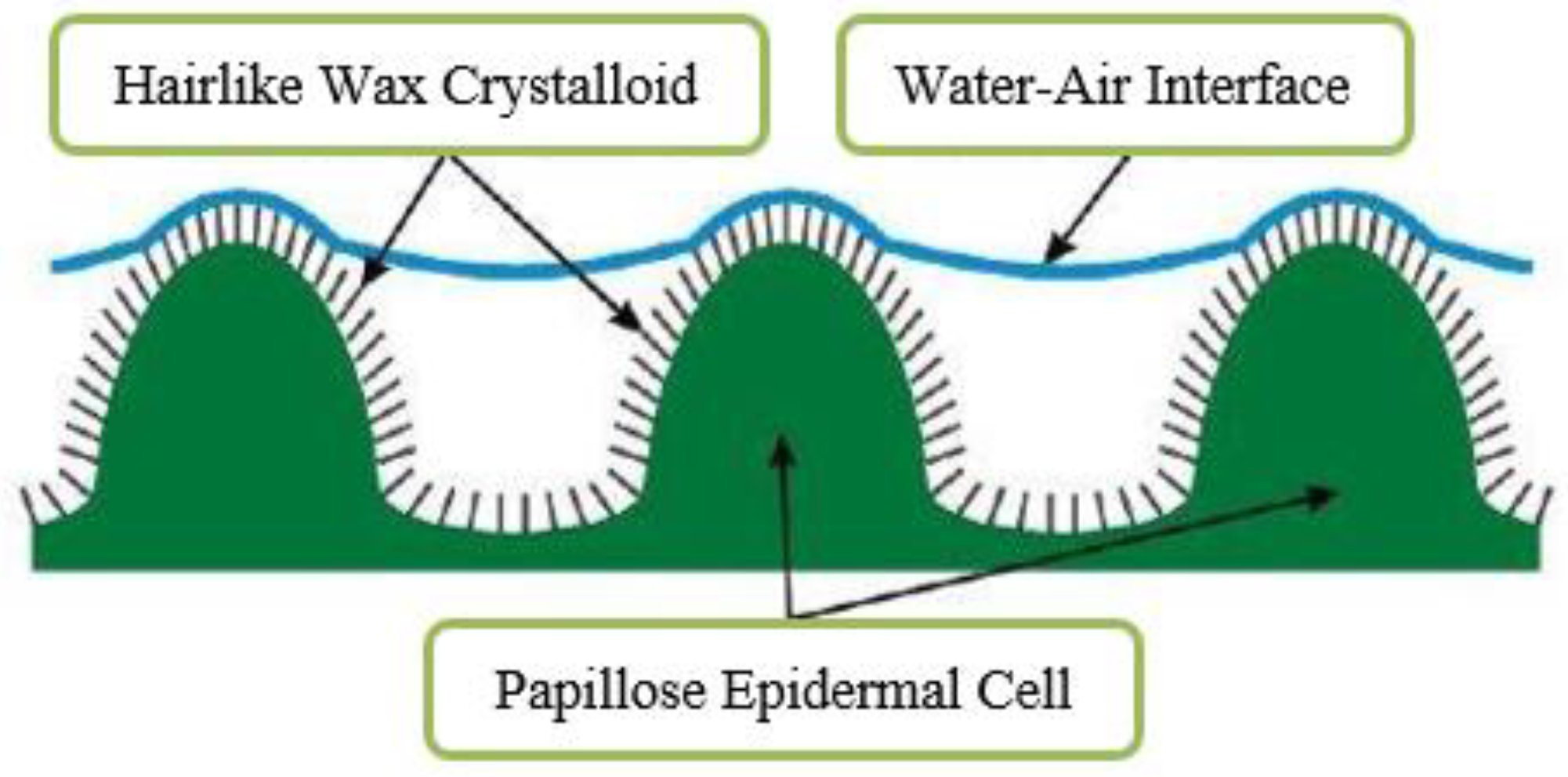

2.2. Lotus Leaf Inspired Coatings

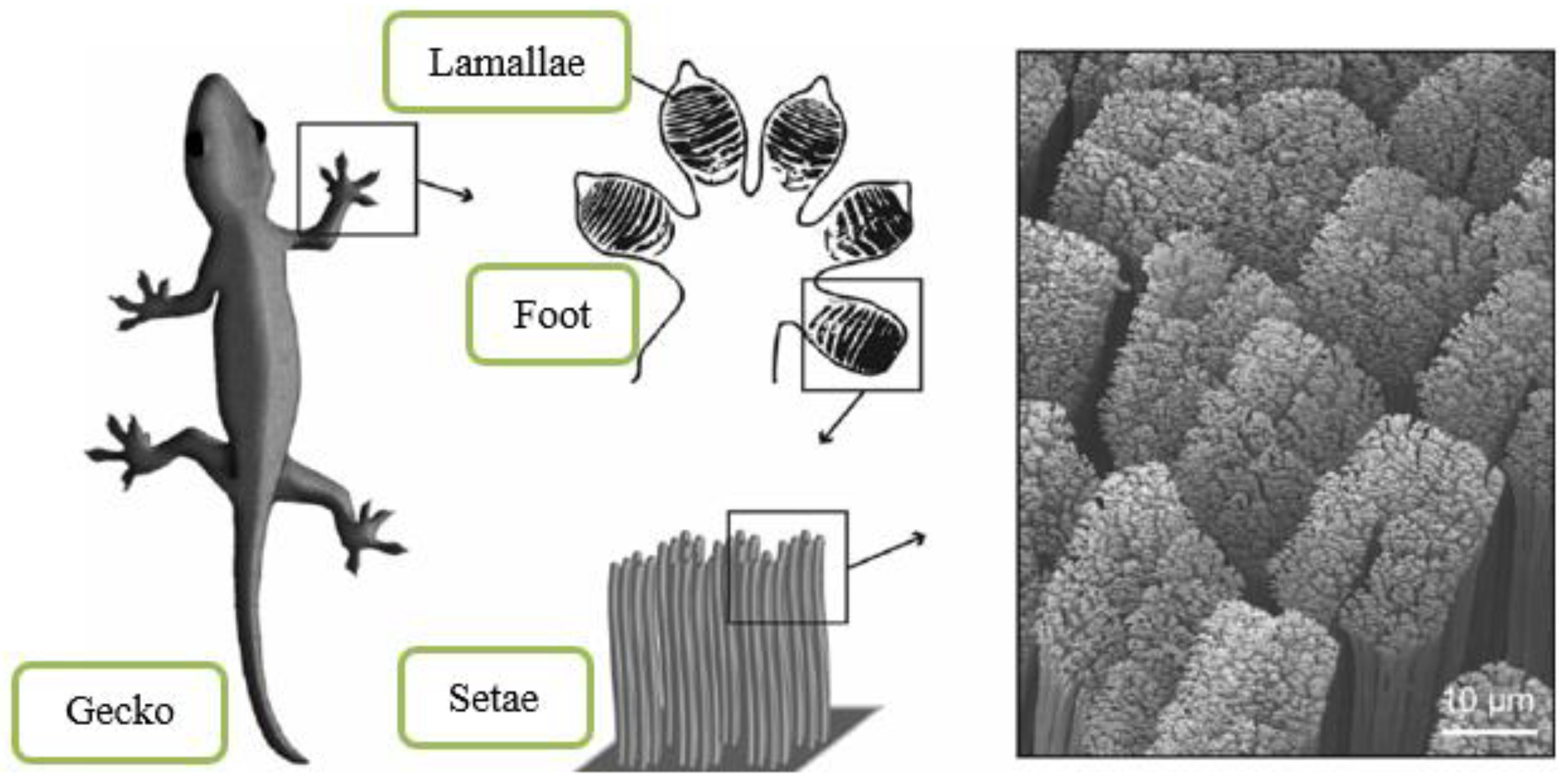

2.3. Gecko Inspired Coatings

2.4. Butterfly Wing Inspired Coatings

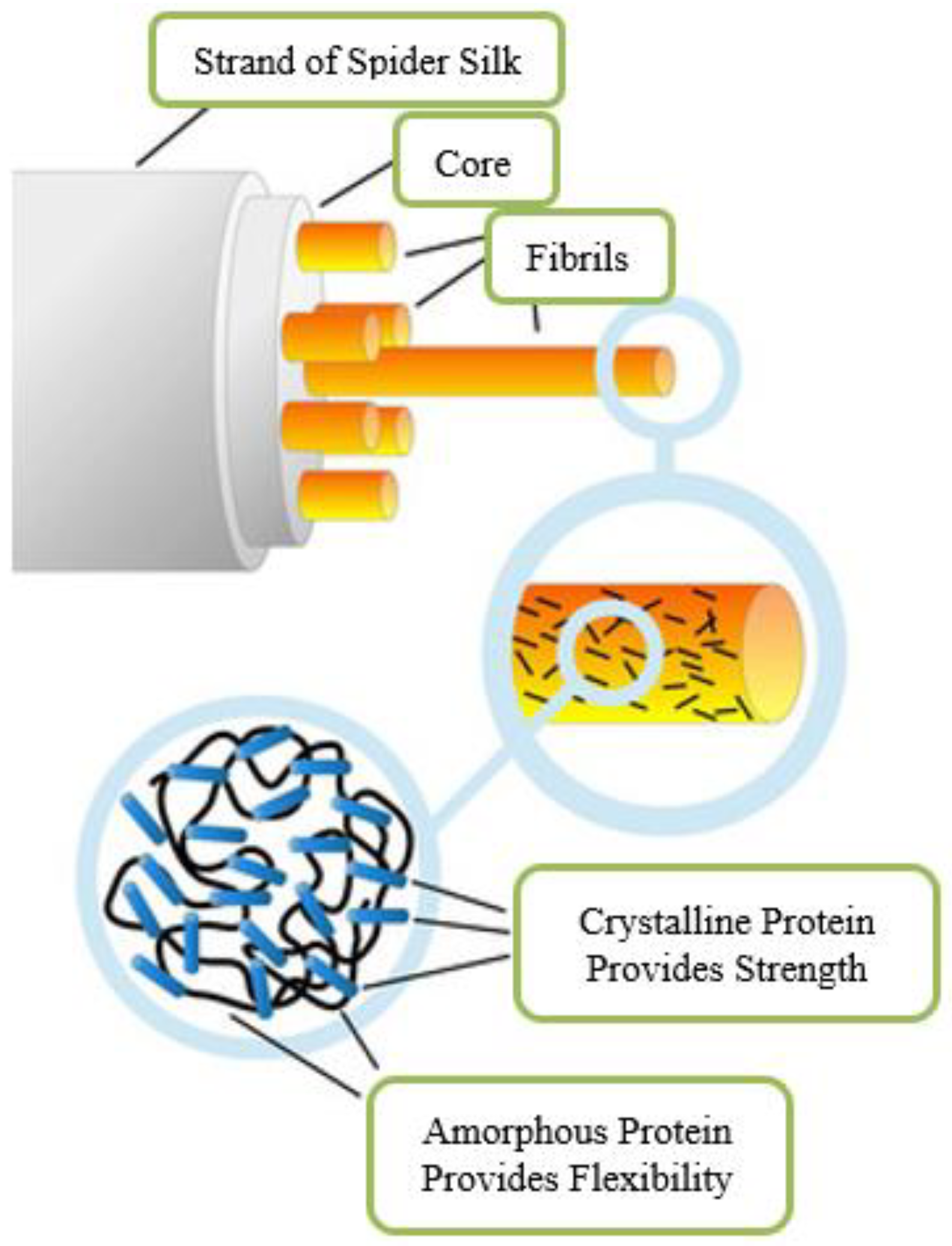

2.5. Spider Silk Coatings

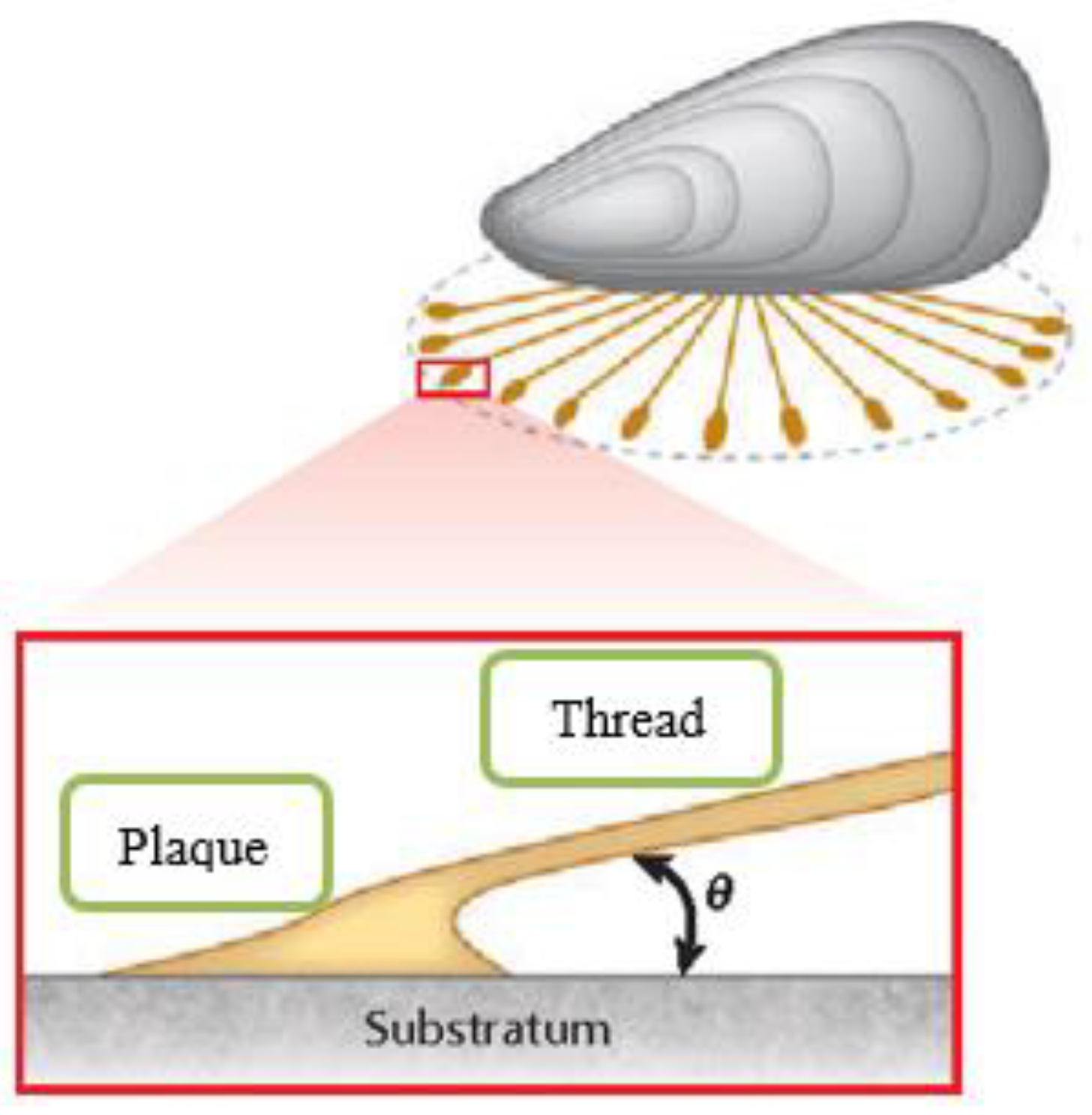

2.6. Mussel Inspired Coatings

3. Future research and development

4. Conclusion

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bhushan, B. Biomimetics: Lessons from nature - An overview. Philos. Trans. R. Soc. A: Math., Phys. Eng. Sci. 2009, 367, 1445–1486. [Google Scholar] [CrossRef] [PubMed]

- Lian, M.; Huang, Y.; Liu, Y.; Jiang, D.; Wu, Z.; Li, B.; Xu, Q.; Murugadoss, V.; Jiang, Q.; Huang, M.; Guo, Z. An overview of regenerable wood-based composites: preparation and applications for flame retardancy, enhanced mechanical properties, biomimicry, and transparency energy saving. Adv. Compos. Hybrid Mater. 2022, 5, 1612–1657. [Google Scholar] [CrossRef]

- Pytka, J.; Budzyński, P.; Józwik, J.; Michałowska, J.; Tofil, A.; Łyszczyk, T.; Błażejczak, D. Application of GNSS/INS and an optical sensor for determining airplane takeoff and landing performance on a grassy airfield. Sensors 2019, 19, 5492. [Google Scholar] [CrossRef] [PubMed]

- Michałowska, J.; Tofil, A.; Józwik, J.; Pytka, J.; Legutko, S.; Siemiątkowski, Z.; Łukaszewicz, A. Monitoring the risk of the electric component imposed on a pilot during light aircraft operations in a high-frequency electromagnetic field. Sensors 2019, 19, 5537. [Google Scholar] [CrossRef]

- Pytka, J.; Budzyński, P.; Łyszczyk, T.; Józwik, J.; Michałowska, J.; Tofil, A.; Błażejczak, D.; Laskowski, J. Determining wheel forces and moments on aircraft landing gear with a dynamometer sensor. Sensors 2020, 20, 227. [Google Scholar] [CrossRef]

- Vijayan, P.P; Puglia, D. Biomimetic multifunctional materials: a review. Emerg. Mater. 2019, 2, 391–415. [Google Scholar] [CrossRef]

- H. Jin, L. Tian, W. Bing, J. Zhao, and L. Ren, Bioinspired marine antifouling coatings: Status, prospects, and future, Prog Mater Sci, vol. 124, p. 100889. [CrossRef]

- G. D. Bixler and B. Bhushan, “Bioinspired rice leaf and butterfly wing surface structures combining shark skin and lotus effects,” Soft Matter 8, 11271–11284. [CrossRef]

- W. Wang et al., Biomaterials- and biostructures Inspired high-performance flexible stretchable strain sensors: A review, Chemical Engineering Journal 425, 129949. [CrossRef]

- J. Wei et al., Bioinspired Additive Manufacturing of Hierarchical Materials: From Biostructures to Functions, Research 6. [CrossRef]

- S. Liu, J. S. Liu, J. Bao, Y. Lu, J. Li, S. Lu, and X. Sun, Digital twin modeling method based on biomimicry for machining aerospace components, J Manuf Syst 58, pp. 180–195. [CrossRef]

- L. S. Puumala et al., Biofunctionalization of Multiplexed Silicon Photonic Biosensors, Biosensors 2023, 13, 53. [CrossRef]

- M. Soler and L. M. Lechuga, Biochemistry strategies for label-free optical sensor biofunctionalization: advances towards real applicability, Anal Bioanal Chem 414, 5071–5085. [CrossRef]

- et al. , Review on nanocomposites based on aerospace applications, Nanotechnol Rev 10, 237–253. [CrossRef]

- M. K. Ahamed, H. Wang, and P. J. Hazell, From biology to biomimicry: Using nature to build better structures – A review, Constr Build Mater 320. [CrossRef]

- Z. Han et al., Biomimetic multifunctional surfaces inspired from animals, Adv Colloid Interface Sci 234, 27–50. [CrossRef]

- X. Huang et al., A survey of icephobic coatings and their potential use in a hybrid coating/active ice protection system for aerospace applications, Progress in Aerospace Sciences 105, 74–97. [CrossRef]

- Y. Zhu, K. Cao, M. Chen, and L. Wu, Synthesis of UV-Responsive Self-Healing Microcapsules and Their Potential Application in Aerospace Coatings, ACS Appl Mater Interfaces 11, 33314–33322. [CrossRef]

- J. S. George, P. Vijayan P, A. T. Hoang, N. Kalarikkal, P. Nguyen-Tri, and S. Thomas, Recent advances in bio-inspired multifunctional coatings for corrosion protection, Prog Org Coat 168, 106858. [CrossRef]

- S. Mishra, Z. Yılmaz-Serçinoğlu, H. Moradi, D. Bhatt, C. İ. Kuru, and F. Ulucan-Karnak, Recent advances in bioinspired sustainable sensing technologies, Nano-Structures and Nano-Objects 34. [CrossRef]

- N. Mishra and B. Kandasubramanian, Biomimetic Design of Artificial Materials Inspired by Iridescent Nacre Structure and Its Growth Mechanism, Polymer - Plastics Technology and Engineering 57, 1592–1606. [CrossRef]

- Y. Zhang, J. Mei, C. Yan, T. Liao, J. Bell, and Z. Sun, Bioinspired 2D Nanomaterials for Sustainable Applications, Advanced Materials 32, 1902806. [CrossRef]

- S. M. Allameh and A. Lenihan, Introduction to bio-inspired materials: Design, processing and applications, Biomimicry for Materials, Design and Habitats: Innovations and Applications, 25–56. [CrossRef]

- Grzejda, R. New method of modelling nonlinear multi-bolted systems. In Advances in Mechanics: Theoretical, Computational and Interdisciplinary Issues, 1st ed.; Kleiber, M., Burczyński, T., Wilde, K., Gorski, J., Winkelmann, K., Smakosz, Ł., Eds.; CRC Press: Leiden, Netherlands, 2016; pp. 213–216. [Google Scholar]

- Grzejda, R.; Warzecha, M.; Urbanowicz, K. Determination of pretension in bolts for structural health monitoring of multi-bolted connection: FEM approach. Lubricants 2022, 10, 75. [Google Scholar] [CrossRef]

- Jaszak, P.; Skrzypacz, J.; Borawski, A.; Grzejda, R. Methodology of leakage prediction in gasketed flange joints at pipeline deformations. Materials 2022, 15, 4354. [Google Scholar] [CrossRef]

- Chen, Y. Liu, H. Chen, and D. Zhang, Bio-inspired drag reduction surface from sharkskin, Biosurf Biotribol 4, 39–45. [CrossRef]

- G. Domel, M. Saadat, J. C. Weaver, H. Haj-Hariri, K. Bertoldi, and G. V. Lauder, Shark skin-inspired designs that improve aerodynamic performance, J R Soc Interface 2018, 15. [CrossRef]

- G. Domel, G. Domel, J. C. Weaver, M. Saadat, K. Bertoldi, and G. V. Lauder, Hydrodynamic properties of biomimetic shark skin: Effect of denticle size and swimming speed, Bioinspir Biomim 13. [CrossRef]

- Home - Sharklet Technologies, Inc. Available online: https://www.sharklet.com/ (accessed on 29 March 2023).

- M. K. Gabler-Smith and G. V. Lauder, Ridges and riblets: Shark skin surfaces versus biomimetic models, Front Mar Sci 9, p. 975062. [CrossRef]

- X. Li, J. Deng, H. Yue, D. Ge, and X. Zou, Wear performance of electrohydrodynamically atomized WS2 coatings deposited on biomimetic shark-skin textured surfaces, Tribol Int 134, 240–251. [CrossRef]

- L. C. Pan et al., Self-Assembly of Shark Scale-Patterned Tunable Superhydrophobic/Antifouling Structures with Visual Color Response, ACS Appl Mater Interfaces, 2023. [CrossRef]

- X. Biomimetic, H. Liu, Z. Zhang, C. Wu, K. Su, and X. Kan, Biomimetic Superhydrophobic Materials through 3D Printing: Progress and Challenges. Micromachines 2023, 14, 1216. [CrossRef]

- F. Dundar Arisoy, K. W. Kolewe, B. Homyak, I. S. Kurtz, J. D. Schiffman, and J. J. Watkins, Bioinspired Photocatalytic Shark-Skin Surfaces with Antibacterial and Antifouling Activity via Nanoimprint Lithography, ACS Appl Mater Interfaces 10, 20055–20063. [CrossRef]

- M. V. Ankhelyi, D. K. Wainwright, and G. V. Lauder, Diversity of dermal denticle structure in sharks: Skin surface roughness and three-dimensional morphology, J Morphol 279, 1132–1154. [CrossRef]

- M. 11 0661. [CrossRef]

- Bhushan and Y., C. Jung, Micro- and nanoscale characterization of hydrophobic and hydrophilic leaf surfaces, Nanotechnology 17, 2758–2772. [CrossRef]

- M. Collins and M. Safiuddin, Lotus-Leaf-Inspired Biomimetic Coatings: Different Types, Key Properties, and Applications in Infrastructures, Infrastructures (Basel) 7. [CrossRef]

- A. Abdulrazzaq et al., Enhancement of low carbon steel corrosion resistance in acidic and saline media using superhydrophobic nanocomposite, Experimental and Theoretical NANOTECHNOLOGY, pp. 77–87. [CrossRef]

- J. Yang et al., Design of mechanical robust superhydrophobic Cu coatings with excellent corrosion resistance and self-cleaning performance inspired by lotus leaf, Colloids Surf A Physicochem Eng Asp 627, 127154. [CrossRef]

- S. Li et al., Bio-inspired (GO + CNTs)-PU hydrophobic coating via replication of Lotus leaf and its enhanced mechanical and anti-corrosion properties, Prog Org Coat 159, 106414. [CrossRef]

- K. Jin, Y. Tian, J. S. Erickson, J. Puthoff, K. Autumn, and N. S. Pesika, Design and fabrication of Gecko-inspired adhesives, Langmuir 28, 5737–5742. [CrossRef]

- L. Wang, Y. Hui, C. Fu, Z. Wang, M. Zhang, and T. Zhang, Recent advances in Gecko-inspired adhesive materials and application. [CrossRef]

- N. Singh and A. Ghatak, Gecko-inspired hierarchically rough surface used as a reprintable paper, Chemical Engineering Journal Advances 12, 100420. [CrossRef]

- Kerst, S. A. Suresh, M. Ferro, and M. Cutkosky, PEDOT: PSS coating improves gecko-inspired adhesive performance, J Micro Nanomanuf 8. [CrossRef]

- W. R. Hansen and K. Autumn, Evidence for self-cleaning in gecko setae, Proc Natl Acad Sci U S A 102, 385–389. [CrossRef]

- M. T. Northen, C. Greiner, E. Arzt, and K. L. Turner, A Gecko-Inspired Reversible Adhesive, Advanced Materials 20, 3905–3909. [CrossRef]

- B. Bhushan, Adhesion of multi-level hierarchical attachment systems in gecko feet, J Adhes Sci Technol 21, no. 12–13, pp. 1213–1258. [CrossRef]

- Z. Han, L. Wu, Z. Qiu, and L. Ren, Microstructure and structural color in wing scales of butterfly Thaumantis diores, Chinese Science Bulletin 54, 535–540. [CrossRef]

- R. E. Rodríguez et al., Biotemplated Morpho Butterfly Wings for Tunable Structurally Colored Photocatalysts, ACS Appl Mater Interfaces 10, 4614–4621. [CrossRef]

- De, Bellis; et al. , Color Modulation in Morpho Butterfly Wings Using Liquid Crystalline Elastomers, Advanced Intelligent Systems 2, 2000035. [CrossRef]

- H. Zhao et al., Synthetic Butterfly Scale Surfaces with Compliance-Tailored Anisotropic Drop Adhesion, Advanced Materials 31, 1807686. [CrossRef]

- H. Ding et al., Broader-Band and Flexible Antireflective Films with the Window-like Structures Inspired by the Backside of Butterfly Wing Scales, ACS Appl Mater Interfaces 13, 19450–19459. [CrossRef]

- T. Chen, Q. Cong, Y. Qi, J. Jin, and K. L. Choy, Hydrophobic durability characteristics of butterfly wing surface after freezing cycles towards the design of nature inspired anti-icing surfaces, PLoS One 13, e0188775. [CrossRef]

- Z. He et al., Bioinspired spiderweb-liked protective hydrophobic layer for improving the durability of superhydrophilic/air superoleophobic coatings, Compos Struct 321, 117309. [CrossRef]

- G. Greco, H. Mirbaha, B. Schmuck, A. Rising, and N. M. Pugno, Artificial and natural silk materials have high mechanical property variability regardless of sample size. Scientific Reports 2022, 12, 1–9. [CrossRef]

- P. Kiseleva, P. V. Krivoshapkin, and E. F. Krivoshapkina, Recent Advances in Development of Functional Spider Silk-Based Hybrid Materials, Front Chem 8, 543104. [CrossRef]

- Mayank, A. Bardenhagen, V. Sethi, and H. Gudwani, Spider-silk composite material for aerospace application, Acta Astronaut 193, 704–709. [CrossRef]

- Sci-Hub | Consequences of Ultra-Violet Irradiation on the Mechanical Properties of Spider Silk. Journal of Functional Biomaterials, 6, 901–916. [CrossRef]

- W. L. Lai and K. L. Goh, Consequences of Ultra-Violet Irradiation on the Mechanical Properties of Spider Silk. Journal of Functional Biomaterials 2015, 6, 901–916. [CrossRef]

- T. Koga, T. Morishita, Y. Harumoto, S. N. Nishimura, and N. Higashi, Spider silk-inspired peptide multiblock hybrid copolymers for self-healable thin film materials, Mater Adv 2, 7851–7860. [CrossRef]

- Airbus might make planes out of AMSilk’s biofabricated silk. Available online: https://www.fastcompany.com/90235263/the-airplane-of-the-future-might-have-synthetic-spider-silk-inside-it (accessed on 3 April 2023).

- S. Da Wu, W. T. Chuang, J. C. Ho, H. C. Wu, and S. H. Hsu, Self-Healing of Recombinant Spider Silk Gel and Coating. Polymers 2023, 15, 1855. [CrossRef]

- Z. Wang et al., Mussel-inspired nanostructured coatings assembled using polydopamine nanoparticles and hydroxyapatite nanorods for biomedical applications, Biosurf Biotribol 3, 1–10. [CrossRef]

- B. P. Lee, P. B. Messersmith, J. N. Israelachvili, and J. H. Waite, Mussel-Inspired Adhesives and Coatings, Annu Rev Mater Res 41, 99. [CrossRef]

- Z. Huang, J. Chen, R. Li, S. Shi, and Y. K. Gong, Mussel adhesion and cell membrane antifouling mimetic strategies for durable fouling-resistant coating, Prog Org Coat 182. [CrossRef]

- P. Tang, G. Ma, P. Nickl, C. Nie, L. Yu, and R. Haag, Mussel-Inspired Polyglycerol Coatings for Surface Modification with Tunable Architecture, Adv Mater Interfaces, 2023, 2300165. [CrossRef]

- W. R. Balkenende, S. M. Winkler, and P. B. Messersmith, Marine-inspired polymers in medical adhesion, Eur Polym J 116, 134–143. [CrossRef]

- B. P. Lee, P. B. Messersmith, J. N. Israelachvili, and J. H. Waite, Mussel-Inspired Adhesives and Coatings. 41, 99–132. [CrossRef]

- L. Chen et al., Biomimetic surface coatings for marine antifouling: Natural antifoulants, synthetic polymers and surface microtopography, Science of The Total Environment 766, 144469. [CrossRef]

- M. S. Selim, S. A. El-Safty, M. A. Shenashen, S. A. Higazy, and A. Elmarakbi, Progress in biomimetic leverages for marine antifouling using nanocomposite coatings, J Mater Chem B 8, 3701–3732. [CrossRef]

- P. Hu, R. Xie, Q. Xie, C. Ma, and G. Zhang, Simultaneous realization of antifouling, self-healing, and strong substrate adhesion via a bioinspired self-stratification strategy, Chemical Engineering Journal 449, 137875. [CrossRef]

- H. W. Chien, X. Y. Chen, W. P. Tsai, and M. Lee, Inhibition of biofilm formation by rough shark skin-patterned surfaces, Colloids Surf B Biointerfaces 186, 110738. [CrossRef]

- M. D. Ibrahim, S. Philip, S. S. Lam, and Y. Sunami, Evaluation of an Antifouling Surface Inspired by Malaysian Sharks Negaprion Brevirostris and Carcharhinus Leucas Riblets, Tribology Online 16, 70–80. [CrossRef]

- X. Feng, X. Zhang, and G. Tian, Recent advances in bioinspired superhydrophobic ice-proof surfaces: challenges and prospects, Nanoscale 14, 5960–5993. [CrossRef]

- Yang, Q. Liu, Z. Lin, Y. Liang, and C. Liu, Investigations of interfacial heat transfer and phase change on bioinspired superhydrophobic surface for anti-icing/de-icing, International Communications in Heat and Mass Transfer 134, p. 105994. [CrossRef]

- S. Jiang, Y. Diao, and H. Yang, “Recent advances of bio-inspired anti-icing surfaces,” Adv Colloid Interface Sci 308, 102756. [CrossRef]

- W. Cai et al., Self-assembly of hierarchical MXene@SnO2 nanostructure for enhancing the flame retardancy, solar de-icing, and mechanical property of polyurethane resin, Compos B Eng 244, 110204. [CrossRef]

- Z. Wang et al., Rapid Fabrication of Bio-inspired Antireflection Film Replicating From Cicada Wings, J Bionic Eng 17, 34–44. [CrossRef]

- Zhang, Dissipative particle dynamics for anti-icing on solid surfaces, Chem Phys 568, 111824. [CrossRef]

- E. Mann et al., Surface micropattern limits bacterial contamination, Antimicrob Resist Infect Control 3. [CrossRef]

- Zabara, Q. Ren, H. Amenitsch, and S. Salentinig, Bioinspired Antimicrobial Coatings from Peptide-Functionalized Liquid Crystalline Nanostructures, ACS Appl Bio Mater 4, 5295–5303. [CrossRef]

- et al. , Bioinspired Multifunctional Protein Coating for Antifogging, Self-Cleaning, and Antimicrobial Properties, ACS Appl Mater Interfaces 11, 24504–24511. [CrossRef]

- S. Kumari et al., Engineered spider silk-based 2D and 3D materials prevent microbial infestation, Materials Today 41, 21–33. [CrossRef]

- Gond, P. Pradhan, and A. Bajpai, Preparation and application of biomimetic and bioinspired membranes based on chitosan, Handbook of Chitin and Chitosan: Volume 3: Chitin- and Chitosan-based Polymer Materials for Various Applications, 307–339. [CrossRef]

- J. Xv et al., Anti-biofouling and functionalizable bioinspired chitosan-based hydrogel coating via surface photo-immobilization, Journal of Biomaterials Science, Polymer Edition 30, 398–414. [CrossRef]

- Shanmugam, R. Pugazhendhi, R.M. Elavarasan, P. Kasiviswanathan, and N. Das, Anti-Reflective Coating Materials: A Holistic Review from PV Perspective, Energies 2020, 13, 2631. [Google Scholar] [CrossRef]

- E. Wetzel et al., Bioinspired microstructured polymer surfaces with antireflective properties, Nanomaterials 11, 2298. [CrossRef]

- L. Feng, F. Wang, H. Luo, and B. Qiu, Review of recent advancements in the biomimicry of structural colors, Dyes and Pigments 210, 111019. [CrossRef]

- Z. Han, Z. Jiao, S. Niu, and L. Ren, Ascendant bioinspired antireflective materials: Opportunities and challenges coexist, Prog Mater Sci 103, 1–68. [CrossRef]

- K. Shanks and R. Ffrench-Constant, Understanding the anti-reflective glasswing butterfly for enhanced solar concentrator optics. 12214, 54–59. [CrossRef]

- S. Mattaparthi and C. S. Sharma, Bio-inspired Micro and Nano-textured Self-cleaning and Antireflective Polymer Surfaces, 2019.

- S. Pourhashem et al., Polymer/Inorganic nanocomposite coatings with superior corrosion protection performance: A review, Journal of Industrial and Engineering Chemistry 88, 29–57. [CrossRef]

- J. Ding, H. Zhao, and H. Yu, Bio-inspired Multifunctional Graphene-Epoxy Anticorrosion Coatings by Low-Defect Engineered Graphene, ACS Nano 16, 710–720. [CrossRef]

- Ehrlich; et al. , Conchixes: organic scaffolds which resemble the size and shapes of mollusks shells, their isolation and potential multifunctional applications, Appl Phys A Mater Sci Process 126, 1–13. [CrossRef]

- E. S. Nour and E. S. Nouh, “sing coral skeletons for monitoring of heavy metals pollution in the Red Sea Coast, Egypt, Arabian Journal of Geosciences 13, 1–12. [CrossRef]

- C. Yu et al., Bio-inspired drag reduction: From nature organisms to artificial functional surfaces, Giant 2, 100017. [CrossRef]

- V. Panwar and T. Dutta, Diatom Biogenic Silica as a Felicitous Platform for Biochemical Engineering: Expanding Frontiers, ACS Appl Bio Mater 2, 2295–2316. [CrossRef]

- G. Tian, Y. Zhang, X. Feng, and Y. Hu, Focus on Bioinspired Textured Surfaces toward Fluid Drag Reduction: Recent Progresses and Challenges, Adv Eng Mater 24. [CrossRef]

- Z. Li, X. Wang, H. Bai, and M. Cao, Advances in Bioinspired Superhydrophobic Surfaces Made from Silicones: Fabrication and Application. Polymers 2023, 15, 543. [CrossRef]

- Manabe, M. Nakano, K. Miyake, and Y. Norikane, Bioinspired extremely rapid self-repairing coatings for long-life repeated features, Chemical Engineering Journal 424, 130568. [CrossRef]

- B. Asha et al., Bioinspired antifouling and antibacterial polymer coating with intrinsic self-healing property, Biomater Sci 11, 128–139. [CrossRef]

- Z. Huang, J. Chen, R. Li, S. Shi, and Y. K. Gong, Mussel adhesion and cell membrane antifouling mimetic strategies for durable fouling-resistant coating, Prog Org Coat 182. [CrossRef]

- H. Tian, Y. Zhan, L. Tian, and J. Sun, Corrosion resistance self-healing coating with bioinspired interfacial structure. Prog Org Coat 174, 107303. [CrossRef]

- Z. Ma et al., Bioinspired, Highly Adhesive, Nanostructured Polymeric Coatings for Superhydrophobic Fire-Extinguishing Thermal Insulation Foam, ACS Nano 15, 11667–11680. [CrossRef]

- Y. Wang, D. Shou, S. Shang, K. L. Chiu, and S. Jiang, Cooling performance of a bioinspired micro-crystal-bars coated composite fabric with solar reflectance, Composites Communications 27, p. 100814. [CrossRef]

- Z. Sun, T. Liao, W. Li, Y. Qiao, and K. Ostrikov, Beyond Seashells: Bioinspired 2D Photonic and Photoelectronic Devices, Adv Funct Mater 29, 1901460. [CrossRef]

- Malshe, K. Rajurkar, A. Samant, H. N. Hansen, S. Bapat, and W. Jiang, Bio-inspired functional surfaces for advanced applications, CIRP Annals 62, 607–628. [CrossRef]

- Gopal Krishna and, S. Tiwari, Bioinspired solar cells: contribution of biology to light harvesting systems, Sustainable Material Solutions for Solar Energy Technologies: Processing Techniques and Applications, pp. 593–632. [CrossRef]

- Y. Wang, P. Liu, F. Vogelbacher, and M. Li, Bioinspired multiscale optical structures towards efficient light management in optoelectronic devices, Mater Today Nano 19, p. 100225. [CrossRef]

- Ding, H. Zhao, and H. Yu, Superior and durable graphene-based composite coatings by bioinspired interfaces and alignment. Compos Sci Technol 214, p. 108967. [CrossRef]

- B. Zhang, Q. Han, J. Zhang, Z. Han, S. Niu, and L. Ren, Advanced bio-inspired structural materials: Local properties determine overall performance, Materials Today 41, pp. 177–199. [CrossRef]

- H. Wu, J. Li, Z. Zhu, L. Ma, N. Gao, and F. Liu, Bioinspired ultra-tough, exceptionally stretchable, and self-recoverable bio-based coating for visual damage detection and self-healing, Prog Org Coat 182, p. 107663. [CrossRef]

- S. An et al., Biological and Bioinspired Thermal Energy Regulation and Utilization, Chem Rev, 2023. Chem Rev. [CrossRef]

- Yang; et al. , Bioinspired ‘skin’ with Cooperative Thermo-Optical Effect for Daytime Radiative Cooling, ACS Appl Mater Interfaces 12, 25286–25293. [CrossRef]

- Y. Wang, S. Shang, K. lok Chiu, and S. Jiang, Mimicking Saharan silver ant’s hair: A bionic solar heat shielding architextile with hexagonal ZnO microrods coating, Mater Lett 261, p. 127013. [CrossRef]

- Y. Yang et al., Recent Progress in Biomimetic Additive Manufacturing Technology: From Materials to Functional Structures, Advanced Materials 30, no. 36. [CrossRef]

- Y. Li et al., Bioinspired Functional Surfaces Enabled by Multiscale Stereolithography, Adv Mater Technol 4, 1800638. [CrossRef]

- P. Johnson et al., Bioinspired and biomimetic micro- and nanostructures in biomedicine, Journal of Controlled Release 343, pp. 724–754. [CrossRef]

- J. Sun and B. Bhushan, Nanomanufacturing of bioinspired surfaces, Tribol Int 129, pp. 67–74. [CrossRef]

- X. Yan et al., Recent Advancements in Biomimetic 3D Printing Materials With Enhanced Mechanical Properties, Front Mater 8. [CrossRef]

- du, Plessis; et al. , Beautiful and Functional: A Review of Biomimetic Design in Additive Manufacturing, Addit Manuf 27, pp. 408–427. [CrossRef]

- D. Wang, D. Chen, and Z. Chen, Recent Progress in 3D Printing of Bioinspired Structures, Front Mater 7, p. 530065. [CrossRef]

- S. Gharde et al., Recent advances in additive manufacturing of bio-inspired materials, Biomanufacturing, pp. 35–68. [CrossRef]

- H. Himel, B. Sikder, T. Ahmed, and S. M. Choudhury, Biomimicry in nanotechnology: a comprehensive review, Nanoscale Adv 5, 596–614. [CrossRef]

- Kumar; et al. , Functional nanomaterials, synergisms, and biomimicry for environmentally benign marine antifouling technology, Mater Horiz 8, 3201–3238. [CrossRef]

- S. Raj and M. Channegowda, Biomimicry: Recent Updates on Nanotechnology Innovations Inspired by Nature Creations, Curr Nanosci 17, 659–669. [CrossRef]

- S. Damiati, R. Mhanna, S. A. Awan, R. Kodzius, and B. Schuster, Editorial: The Dual-Use Dilemma for Biomimicry, Front Mol Biosci 9, p. 915663. [CrossRef]

- Q. Zhao, Y. Wang, H. Cui, and X. Du, Bio-inspired sensing and actuating materials, J Mater Chem C Mater 7, 6493–6511. [CrossRef]

- D. L. Á. Ortega Del Rosario, K. Beermann, and M. Chen Austin, Environmentally Responsive Materials for Building Envelopes: A Review on Manufacturing and Biomimicry-Based Approaches, Biomimetics 8, 52. [CrossRef]

- S. Abedanzadeh, M. Nourisefat, and Z. Moosavi-Movahedi, Bioinspiration and Biomimicry in Lifestyle, 2021, pp. 9–29. [CrossRef]

- Sandak, Engineered living materials for sustainable and resilient architecture, Nature Reviews Materials 2023 8:6 8, 357–359. [CrossRef]

- Y. Lee, J. Park, A. Choe, S. Cho, J. Kim, and H. Ko, Mimicking Human and Biological Skins for Multifunctional Skin Electronics, Adv Funct Mater 30, 1904523. [CrossRef]

- Z. Li et al., Bioinspired marine antifouling coatings: Antifouling mechanisms, design strategies and application feasibility studies, Eur Polym J 190, p. 111997. [CrossRef]

- M. Zhang et al., Bio-inspired gallic acid-gelatin coating: A novel strategy for eco-friendly interfacial modification of carbon fiber composites, Composites Communications 26, p. 100790. [CrossRef]

- C. Zhang, X. Zhang, Y. Ling, M. Liang, and H. Zou, Chitosan-doped carbon nanotubes encapsulating spread carbon fiber composites with superior mechanical, thermal, and electrical properties, Compos Sci Technol 230. [CrossRef]

- C. Zhai, T. Li, H. Shi, and J. Yeo, Discovery and design of soft polymeric bio-inspired materials with multiscale simulations and artificial intelligence, J Mater Chem B 8, 6562–6587. [CrossRef]

- K. Guo, Z. Yang, C. H. Yu, and M. J. Buehler, Artificial intelligence and machine learning in design of mechanical materials, Mater Horiz 8, 1153–1172. [CrossRef]

- R. Batra, L. Song, and R. Ramprasad, Emerging materials intelligence ecosystems propelled by machine learning, Nat Rev Mater 6, 655–678. [CrossRef]

- L. Bassman, M. Urbanek, M. Metcalf, J. Carter, A. F. Kemper, and W. A. De Jong, Simulating quantum materials with digital quantum computers, Quantum Sci Technol 6, 043002. [CrossRef]

- B. Bauer, S. Bravyi, M. Motta, and G. Kin-Lic Chan, Quantum Algorithms for Quantum Chemistry and Quantum Materials Science, Chem Rev 120, 12685–12717. [CrossRef]

- From quantum computing to biomimicry: the technologies of the future - New Digital Age. Available online: https://newdigitalage.co/technology/from-quantum-computing-to-biomimicry-the-technologies-of-the-future/ (accessed on 10 April 2023).

- J. Ding, H. Zhao, and H. Yu, Bioinspired strategies for making superior graphene composite coatings, Chemical Engineering Journal 435, p. 134808. [CrossRef]

- M. Eder, S. Amini, and P. Fratzl, Biological composites-complex structures for functional diversity, Science 362, 543–547. [CrossRef]

- S. Ha and G. Lu, A review of recent research on bio-inspired structures and materials for energy absorption applications, Compos B Eng 181, p. 107496. [CrossRef]

- Šančić, T.; Brčić, M.; Kotarski, D.; Łukaszewicz, A. Experimental characterization of composite-printed materials for the production of multirotor UAV airframe parts. Materials 2023, 16, 5060. [Google Scholar] [CrossRef]

- Łukaszewicz, A.; Miatluk, K. Reverse engineering approach for object with free-form surfaces using standard surface-solid parametric CAD system. Solid State Phenom. 2009, 147–149, 706–711. [Google Scholar] [CrossRef]

- Łukaszewicz, A.; Panas, K.; Szczebiot, R. Design Process of Technological Line to Vegetables Packaging using CAx Tools. In Proceedings of the 17th International Scientific Conference on Engineering for Rural Development, Jelgava, Latvia, 23-25 May 2018; pp. 871–876. [Google Scholar]

- Łukaszewicz, A.; Szafran, K.; Jozwik, J. CAx Techniques used in UAV Design Process. In Proceedings of the 2020 IEEE 7th International Workshop on Metrology for AeroSpace (MetroAeroSpace), Pisa, Italy, 22-24 June 2020; pp. 95–98. [Google Scholar]

- Dziedzic, K.; Pashechko, M.; Barszcz, M.; Józwik, J. : Structure and Construction Assessment of the Surface Layer of Hardfaced Coating after Friction, Advances in Science and Technology Research Journal 11, Issue 3, 17, pp. 253–260. 20 September. [CrossRef]

- Michałowska, J.; Józwik, J. : Prediction of the parameters of magnetic field of CNC machine tools, Przeglad Elektrotechniczny. vol. 95, Issue 1, pp. 134–136. [CrossRef]

| Type of Coatings | Description | Bio-inspiration | Aerospace Applications |

|---|---|---|---|

| Anti-Fouling Coatings | Marine organisms, like barnacles and algae, often attach themselves to submerged structures, causing increased drag and fuel consumption. Bio-inspired anti-fouling polymer coatings can be developed to prevent the attachment of organisms to aircraft surfaces, reducing maintenance requirements and improving performance [71,72,73]. | Sharkskin [74,75] Butterfly wings Lotus leaves |

- Engine Components - Propellers and Rotors |

| Anti-Icing Coatings | Ice accumulation on aircraft surfaces can affect aerodynamic performance and increase fuel consumption. Polymer coatings that mimic the microstructure of lotus leaves or insect wings, which have water-repellent properties, can be applied to aircraft surfaces. These coatings reduce ice adhesion and promote easy ice removal, improving flight safety and efficiency [76,77]. | Lotus leaves [78] Cicada wings [79,80] Gecko feet [81] |

- Aircraft Wings - Sensors and Avionics - Windshield and Windows |

| Anti-Microbial Coatings | In environments where cleanliness and hygiene are critical, such as in aerospace interiors or medical transport aircraft, bio-inspired anti-microbial coatings can be applied. These coatings mimic the properties of natural antimicrobial substances and help inhibit the growth of bacteria, viruses, and fungi, reducing the risk of contamination and improving cabin air quality [82,83,84]. | Spider Silk [85] Sharkskin Chitosan [86,87] |

- Aircraft Interiors - Ventilation Systems - Food Storage and Preparation Surfaces |

| Anti-Reflective Coatings | Certain organisms, like moths and butterflies, have evolved unique structures on their wings to minimize reflection and enhance light absorption [88,89,90]. Bio-inspired anti-reflective coatings can be used on aircraft windows, camera lenses, and optical sensors to reduce glare, improve visibility, and enhance optical performance. | Moths [91] Butterfly wings [92] Rose petals [93] |

- Satellite Optics - Optical Telescopes and Observatories - Satellite Solar Panels |

| Corrosion Resistance Coatings | Polymer coatings can be designed to provide enhanced corrosion resistance by emulating the protective properties of natural materials [94]. For example, applying coatings that mimic the structure of mollusk shells or coral skeletons can provide a barrier against corrosion and extend the lifespan of aerospace components exposed to harsh environments [98]. | Mollusk shells [96] Coral skeletons [97] Mussel |

- Fuel Tanks and Pipelines - Undercarriage and Landing Gear |

| Drag Reduction Coatings | The surface texture of shark skin has inspired the development of coatings that reduce aerodynamic drag. These coatings mimic the microscopic riblets found on shark skin, which decrease drag by reducing the size and intensity of turbulent air flow over the surface. Applying such coatings to aircraft wings and bodies can lead to improved fuel efficiency and increased range. | Sharkskin European Sea Bass scales [98] Pufferfish skin [98] |

- Aircraft Wings and Fuselage - Rotorcraft and Rotor blades |

| Heat Shielding Coatings | For spacecraft and re-entry vehicles, heat shielding is crucial during atmospheric re-entry. Bio-inspired coatings can be developed to mimic the heat resistance and thermal insulation properties of materials like the silica shells of diatoms. These coatings help protect the vehicle from extreme temperatures and ensure the safety of the crew and payload. |

Diatom frustules [99] |

- Launch and Re-entry Vehicles - Exhaust Systems |

| Noise Reduction Coatings | Surface microstructures with noise reduction properties has inspired the development of bio-inspired coatings that reduce aerodynamic noise . These coatings can be applied to aircraft surfaces to suppress noise generated during takeoff, landing, and high-speed flight, leading to quieter operations and improved passenger comfort. | Riblet [100] Mushroom-like microstructure [100] |

- Aircraft Engines - Air Traffic Control Towers |

| Self-Cleaning Coatings | Aerospace components often encounter dust, dirt, and other contaminants during flight. Self-cleaning polymer coatings inspired by the lotus effect, or the self-cleaning ability of butterfly wings can be applied to aircraft surfaces. These coatings repel dirt particles and allow rain or airflows to remove contaminants, reducing maintenance needs and improving aerodynamic efficiency. | Lotus leaves Butterfly wings Fly eye [101] |

- Satellite Optics - Satellite Solar Panels -Windows and Windshields |

| Self-Healing Coatings | Self-healing coatings inspired by mussel and tree frog toe can be applied to various aircraft structures and components, such as turbine blades, wings, fuselage, and control surfaces [102]. These coatings can help mitigate the effects of wear, fatigue, and environmental damage, thereby extending the service life of critical aerospace components. By autonomously repairing cracks, scratches, or delamination, these coatings ensure structural integrity and reduce the need for frequent inspections and maintenance. | Mussel [103,104] Tree frog toes [105,106] |

- Windows and Windshields - Fighter Jet Skin |

| Solar Energy Harvesting Coatings | Bio-inspired coatings can be used to improve the efficiency of solar panels installed on aircraft. By emulating the light-trapping structures found in plant leaves or photosynthetic bacteria, these coatings can enhance light absorption, optimize energy conversion, and increase the overall power output of solar panels [107,108]. | Plant leaves [109] Cyanobacteria [110] Moth eye [111] |

- Solar Sail Propulsion - Satellite Solar Panels - Energy Harvesting Sensors |

| Structural Strengthening Coatings | Some bio-inspired coatings draw inspiration from the structure and composition of materials found in nature, such as bones or seashells [112,113]. These coatings can be applied to strengthen and reinforce structural components of aircraft, improving their durability and resistance to impact or fatigue. | Spidersilk [114] Bones Seashells |

- Aerospace Structures and Framework - Engine Mounts and Attachments |

| Thermal Management Coatings | Managing heat distribution and dissipation is crucial in aerospace applications. Bio-inspired coatings that replicate the cooling mechanisms found in the skin of certain animals, such as polar bear fur or penguins, can be used to enhance thermal management [115,116]. These coatings can assist in heat dissipation and reduce thermal stress on critical components. | Penguins Polar bear fur Saharan silver ant hair [117] |

- Satellite Surfaces and Components - Power Generators or Energy Storage Units |

| Advanced Bio-inspired Coating Technology | Description |

|---|---|

| Additive Manufactured Coatings [122,123,124,125] | Additive manufacturing, specifically 3D printing, offers unique opportunities for the development of bio-inspired polymer coatings in the aerospace industry. Future research should focus on utilizing 3D printing techniques to fabricate polymer based coatings with intricate designs, complex geometries, and precise control over material composition. By integrating bio-inspired features directly into the coating's structure, such as hierarchical patterns or biomimetic textures, it is possible to achieve enhanced functionalities and performance tailored to specific aerospace applications. |

| Biomimetic Nanomaterials [126,127,128] | Advancements in nanotechnology provide exciting opportunities for the development of bio-inspired polymer coatings at the nanoscale. Researchers can explore the synthesis and characterization of biomimetic nanomaterials that replicate the unique properties found in natural systems. By incorporating nanomaterials with specific functionalities, such as super hydrophobicity, anti-reflectivity, or enhanced heat resistance, novel coatings can be created to improve the durability, performance, and safety of aerospace components. |

| Biomimetic Sensing and Actuation [129,130,131] | Exploring the incorporation of biomimetic sensing and actuation mechanisms within coatings opens exciting possibilities for aerospace functionality. By mimicking biological systems such as Mimosa pudica, coatings could react to environmental changes, such as airflow, temperature fluctuations, or chemical exposures, to adjust surface properties and optimize aerodynamic performance. This bio-inspired approach could lead to aircraft with enhanced fuel efficiency, reduced drag, and improved maneuverability. Future research should focus on understanding and harnessing these adaptive characteristics to create polymer coatings that adapt to different temperatures, pressures, or exposure to chemicals and radiation. |

| Multifunctional Coatings [132,133,134] | One promising avenue for future research is the development of multifunctional coatings inspired by nature. While current bio-inspired coatings focus primarily on mimicking specific properties, such as anti-icing or self-cleaning, there is a need to integrate multiple functionalities into a single coating. For instance, exploring the incorporation of structural coloration with anti-corrosion or drag-reducing capabilities could lead to coatings that provide enhanced performance and efficiency in aerospace applications. |

| Sustainable and Eco-friendly Coatings [135,136,137] | As the aerospace industry strives for more sustainable practices, future research should focus on developing bio-inspired coatings that are environmentally friendly. This includes exploring alternative bio-based polymers, eco-friendly fabrication processes, and biodegradable polymer coatings that minimize the environmental impact without compromising performance. By integrating sustainable principles into bio-inspired coatings, the aerospace industry can contribute to a greener and more sustainable future. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).