Submitted:

14 August 2023

Posted:

15 August 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Assumptions

- -

- The thermal load of the typical household is estimated at 950 kWhth/year.

- -

- Because of the physicochemical and economic properties of pure CCS, RWT, BNP, and SGC briquettes, four types of mixture briquettes are studied: BNP-CCS, SGC-CCS, BNP-RWT, and SGC-RWT.

- -

- -

- The price of mixed briquettes is assumed to be proportional to that of pure briquettes.

- -

- The ratio considered are percentage by weight

- -

- Life Cycle Cost is applying as recommended by [1].

2.2. Determination of optimized mixture briquettes price

2.3. Life Cycle Cost

2.4. Annualized cost of heat

3. Results and Discussion

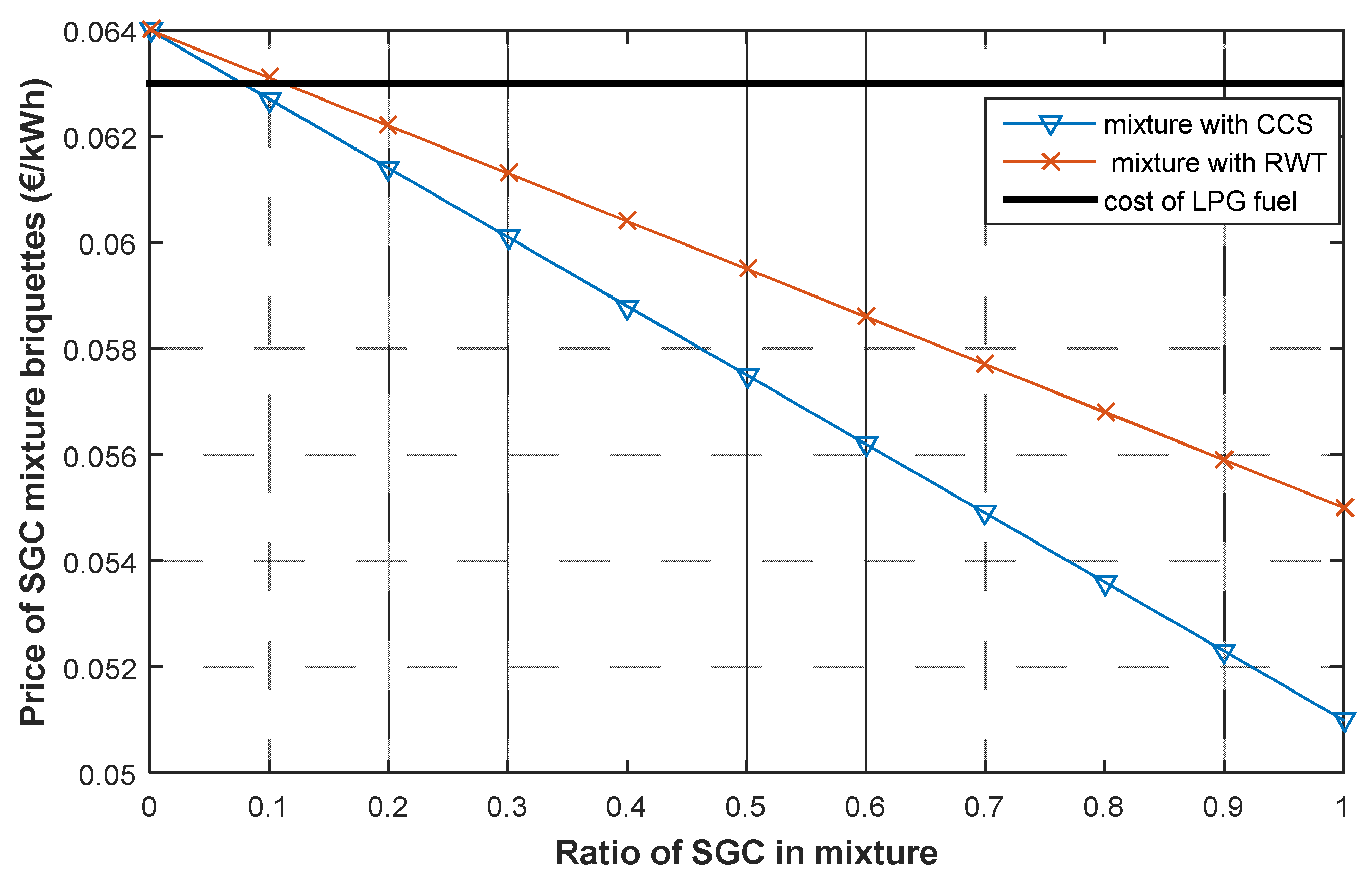

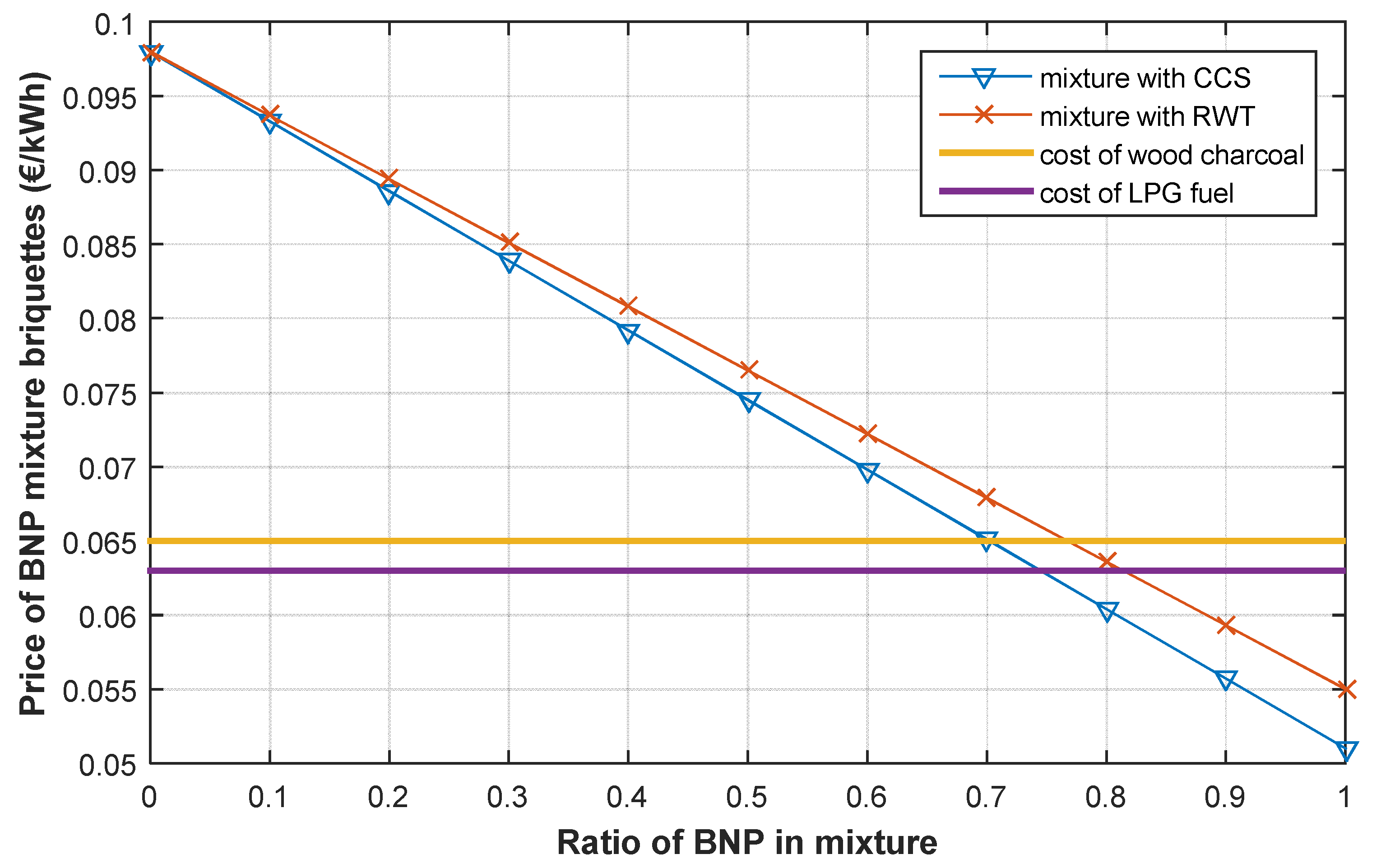

3.1. Price of mixed briquettes

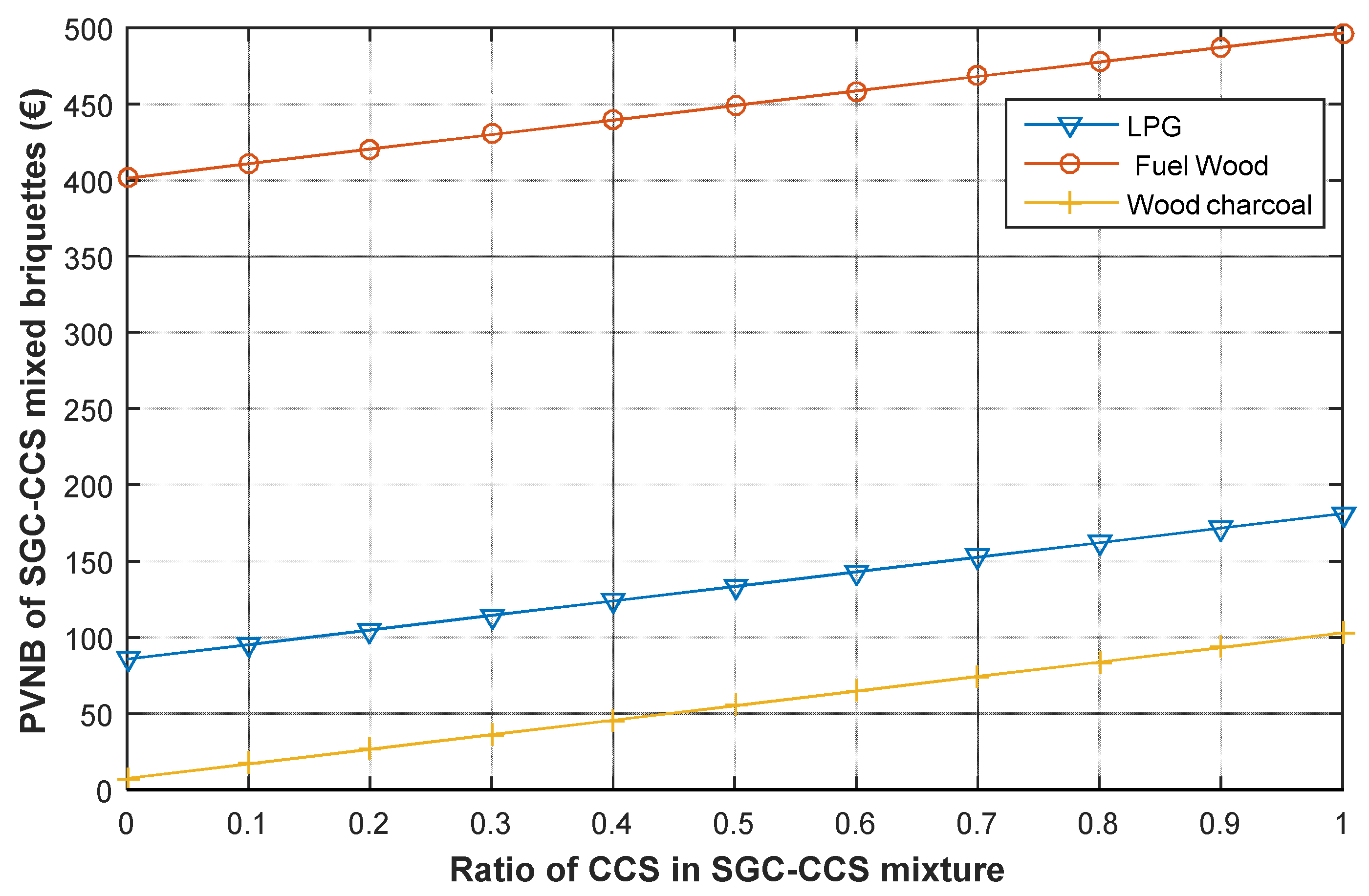

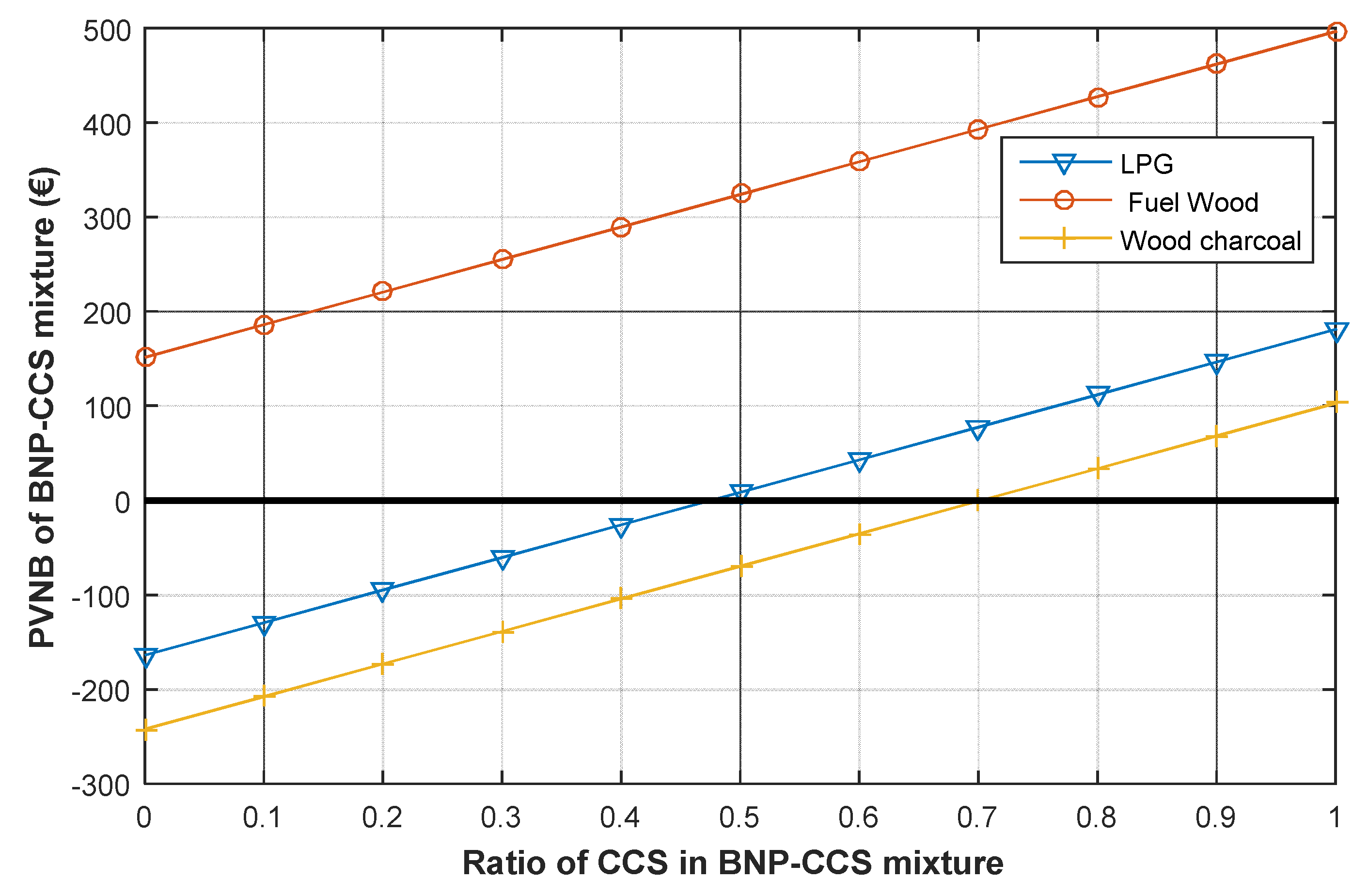

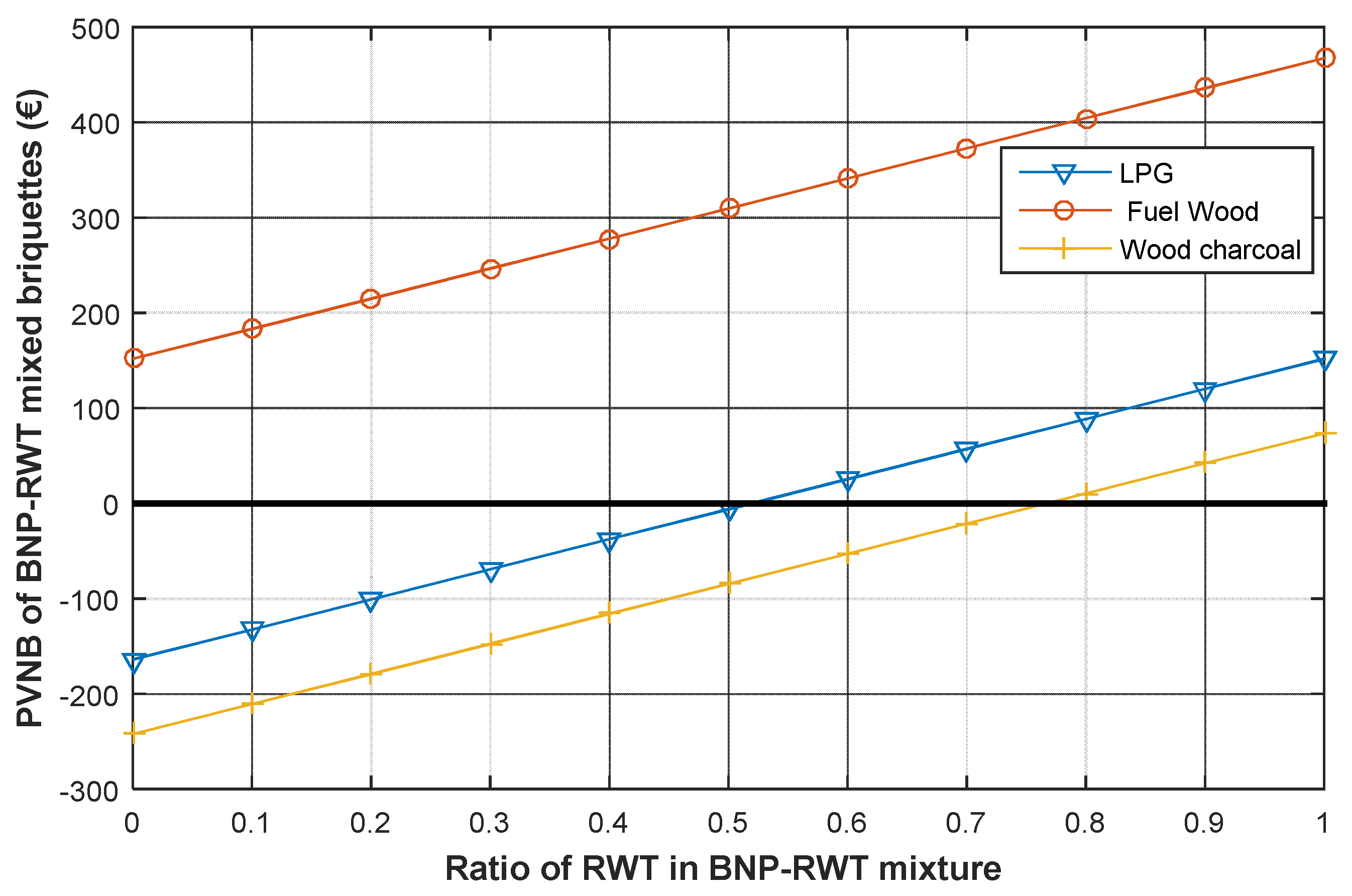

3.2. Present Value of Net Benefit

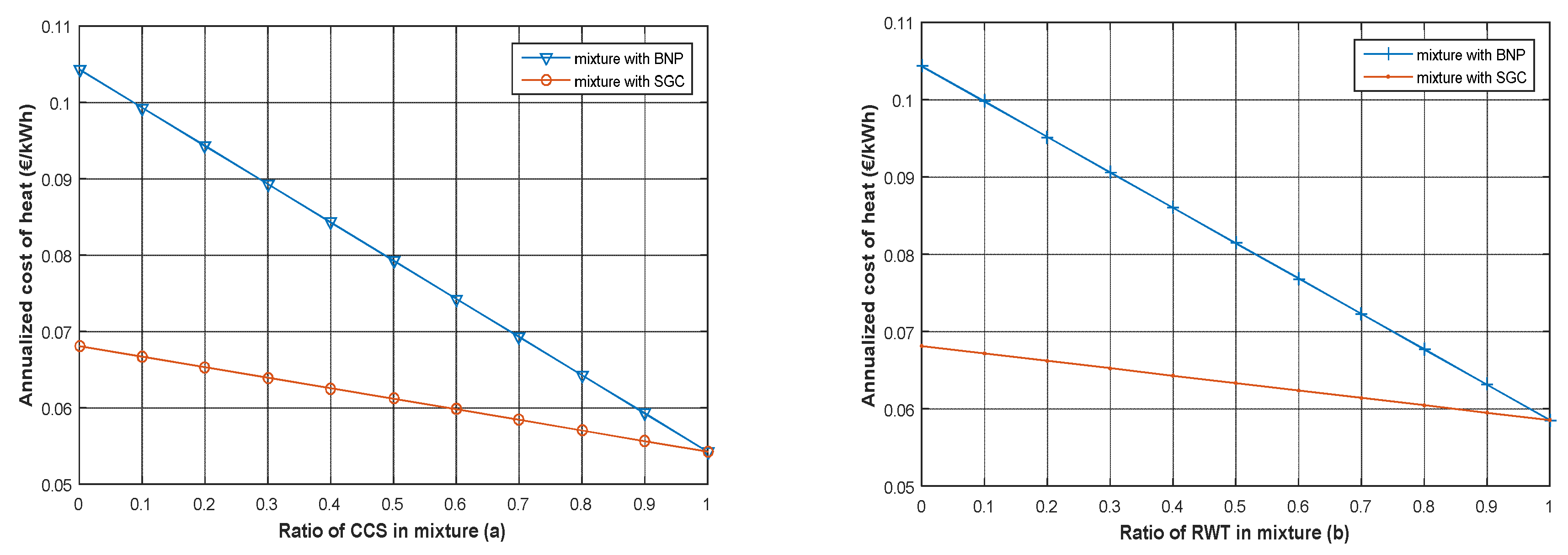

3.3. Annualized cost of heat

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| ACOH | Annualized Cost Of Heat, €/kWhth |

| ACT | Annual cash flow at the year T, € |

| BNP | Banana peels |

| BNP-CCS | Banana peels and Coconut shells mixture |

| BNP-RWT | Banana peels and Rattan waste mixture |

| CCS | Coconut shells |

| d | Discount rate, % |

| Ed | Energy demand, kWhth |

| FC | Fuel cost, €/kwhth |

| GHG | Greenhouse Gases |

| i | Fuel cost inflation rate, % |

| INV | Initial investment cost, € |

| j | Maintenance cost inflation rate,% |

| kWhth | kilowatt-hour thermal |

| LCC | Life Cycle Cost, € |

| LCCbio | Life Cycle Cost of biomass briquette, € |

| LCCconv | Life Cycle Cost of conventional fuel, € |

| LPG | Liquefied Petroleum Gas |

| MC | Cost of mixture, €/kg |

| ME | Energy of mixture, kWhth/kg |

| NM | Number of mixtures |

| PVNB | Present Value of Net Benefit, € |

| PVt | Present Value at the year t, € |

| RC | Cost of replaced energy €/kWhth |

| RWT | Rattan waste |

| SGC | Sugarcane bagasse |

| SGC-CCS | Sugarcane Bagasse and Coconut shells mixture |

| SGC-RWT t |

Sugarcane Bagasse and Rattan waste mixture Year of simulation |

References

- B. V. Bot, P. J. Axaopoulos, O. T. Sosso, E. I. Sakellariou, and J. G. Tamba, “Economic analysis of biomass briquettes made from coconut shells, rattan waste, banana peels and sugarcane bagasse in households cooking,” Int. J. Energy Environ. Eng., no. 0123456789, 2022. [CrossRef]

- E. I. Sakellariou, P. J. Axaopoulos, B. V. Bot, and I. E. Sarris, “Energy Performance Evaluation of a Solar PVT Thermal Energy Storage System Based on Small Size Borefield,” Energies, vol. 15, no. 21, p. 7906, 2022. [CrossRef]

- F. A. Armah, B. Ekumah, D. O. Yawson, J. O. Odoi, A. R. Afitiri, and F. E. Nyieku, “Predictive Probabilities of Access to Clean Cooking: Evidence from the Demographic and Health Surveys in 31 Countries in Sub-Saharan Africa,” Environ. Justice, vol. 12, no. 3, pp. 118–131, 2019. [CrossRef]

- I. Garba and R. Bellingham, “Energy poverty: Estimating the impact of solid cooking fuels on GDP per capita in developing countries - Case of sub-Saharan Africa,” Energy, vol. 221, p. 119770, 2021. [CrossRef]

- W. T. Tomen, B. S. Diboma, B. V. Bot, and J. G. Tamba, “Physical and Combustion properties investigation of hybrid briquettes from tropical Sawdust: Case study of Iroko (Milicia excelsa) and Padouk (Pterocarpus soyauxii),” Energy Reports, vol. 9, pp. 3177–3191, 2023. [CrossRef]

- E. Atyi et al., “Étude de l’importance économique et sociale du secteur forestier et faunique au Cameroun: Rapport final,” 2013.

- B. S. Diboma, V. H. Atiotsia, L. C. Che, P. B. Essomba, B. V. Bot, and J. G. Tamba, “Gasification of charcoal derived from tropical wood residues in an updraft fixed bed reactor,” Bioresour. Technol. Reports, vol. 21, no. October 2022, p. 101308, 2023. [CrossRef]

- F. Lambe, M. Jürisoo, H. Wanjiru, and J. Senyagwa, “Bringing clean, safe, affordable cooking energy to Kenyan households: an agenda for action,” New Clim. Econ., p. 38, 2015, [Online]. Available: www.newclimateeconomy.report.

- G. K. Ngusale, Y. Luo, and J. K. Kiplagat, “Briquette making in Kenya: Nairobi and peri-urban areas,” Renew. Sustain. energy Rev., vol. 40, pp. 749–759, 2014.

- D. Kauter, I. Lewandowski, and W. Claupein, “Quantity and quality of harvestable biomass from Populus short rotation coppice for solid fuel use—a review of the physiological basis and management influences,” Biomass and Bioenergy, vol. 24, no. April 2016, pp. 411–427, 2003.

- B. V. Bot, O. T. Sosso, J. G. Tamba, E. Lekane, J. Bikai, and M. K. Ndame, “Preparation and characterization of biomass briquettes made from banana peels , sugarcane bagasse , coconut shells and rattan waste,” Biomass Convers. Biorefinery, no. 0123456789, 2021. [CrossRef]

- B. V. Bot et al., “Preparation and characterization of biomass briquettes made from banana peels , sugarcane bagasse , coconut shells and rattan waste,” Biomass Convers. Biorefinery, vol. 354, no. 0123456789, p. 119430, 2022. [CrossRef]

- B. V. Bot, P. J. Axaopoulos, E. I. Sakellariou, O. T. Sosso, and J. G. Tamba, “Energetic and economic analysis of biomass briquettes production from agricultural residues,” Appl. Energy, vol. 321, no. May, p. 119430, 2022. [CrossRef]

- C.-S. Chou, S.-H. Lin, and W.-C. Lu, “Preparation and characterization of solid biomass fuel made from rice straw and rice bran,” Fuel Process. Technol., vol. 90, no. 7–8, pp. 980–987, 2009.

- J. Oladeji, “Fuel characterization of briquettes produced from corncob and rice husk resides,” Pacific J. Sci. Technol., vol. 11, no. 1, pp. 101–106, 2010, [Online]. Available: http://www.akamaiuniversity.us/PJST11_1_101.pdf.

- I.I. Ikelle, A. Chukwuma, and O. S. Philip Ivoms, “The Characterization of the Heating Properties of Briquettes of Coal and Rice Husk,” IOSR J. Appl. Chem., vol. 7, no. 5, pp. 100–105, 2014. [CrossRef]

- O.F. Obi, “Evaluation of the physical properties of composite briquette of sawdust and palm kernel shell,” Biomass Convers. Biorefinery, vol. 5, no. 3, pp. 271–277, 2015. [CrossRef]

- O.F. Obi and K. C. Okongwu, “Characterization of fuel briquettes made from a blend of rice husk and palm oil mill sludge,” Biomass Convers. Biorefinery, vol. 6, no. 4, pp. 449–456, 2016. [CrossRef]

- Y. Yuliah, M. Kartawidjaja, S. Suryaningsih, and K. Ulfi, “Fabrication and characterization of rice husk and coconut shell charcoal based bio-briquettes as alternative energy source,” IOP Conf. Ser. Earth Environ. Sci., vol. 65, no. 1, 2017. [CrossRef]

- S. A. Rahaman and P. A. Salam, “Characterization of cold densified rice straw briquettes and the potential use of sawdust as binder,” Fuel Process. Technol., vol. 158, pp. 9–19, 2017. [CrossRef]

- M. Lubwama and V. A. Yiga, “Development of groundnut shells and bagasse briquettes as sustainable fuel sources for domestic cooking applications in Uganda,” Renew. Energy, vol. 111, pp. 532–542, 2017. [CrossRef]

- M. Lubwama and V. A. Yiga, “Characteristics of briquettes developed from rice and coffee husks for domestic cooking applications in Uganda,” Renew. energy, vol. 118, pp. 43–55, 2018.

- P. Ofori and O. Akoto, “Production and Characterisation of Briquettes from Carbonised Cocoa Pod Husk and Sawdust,” OALib, vol. 07, no. 02, pp. 1–20, 2020. [CrossRef]

- C. J. L. G. Navalta, K. G. C. Banaag, V. A. O. Raboy, A. W. Go, L. K. Cabatingan, and Y. H. Ju, “Solid fuel from Co-briquetting of sugarcane bagasse and rice bran,” Renew. Energy, vol. 147, pp. 1941–1958, 2020. [CrossRef]

- J. Nagarajan and L. Prakash, “Preparation and characterization of biomass briquettes using sugarcane bagasse, corncob and rice husk,” Mater. Today Proc., vol. 47, no. xxxx, pp. 4194–4198, 2021.

- S. Duangkham and P. Thuadaij, “Characterization of charcoal briquettes produced from blending rice straw and banana peel,” Heliyon, vol. 9, no. 6, p. e16305, 2023. [CrossRef]

- H. Aliah et al., “Physical properties of briquettes composite from coffee husks (Coffea arabica L) and corncob (Zea mays) for alternative fuel,” AIP Conf. Proc., vol. 2646, no. January, 2023. [CrossRef]

- E. I. Sakellariou, P. J. Axaopoulos, and A. J. Wright, “Energy and economic evaluation of a solar assisted ground source heat pump system for a north Mediterranean city,” Energy Build., vol. 231, p. 110640, 2021. [CrossRef]

- E. I. Sakellariou, A. J. Wright, and P. J. Axaopoulos, “Energy, economic and emission assessment of a solar assisted shallow earth borehole field heat pump system for domestic space heating in a north European climate,” Geothermics, vol. 95, no. April, p. 102159, 2021. [CrossRef]

- INS, “Agriculture. Annuaire statistique. Chapitre 13,” 2017.

- B. V. Bot, J. Gaston, T. Olivier, T. Sosso, and M. Pascal, “Assessment of biomass briquette energy potential from agricultural residues in Cameroon,” Biomass Convers. Biorefinery, no. 0123456789, 2022. [CrossRef]

- J. G. Tamba, “LPG consumption and economic growth, 1975-2016: evidence from Cameroon,” Int. J. Energy Sect. Manag., vol. 15, no. 1, pp. 195–208, 2021. [CrossRef]

- N. Doggart et al., “The influence of energy policy on charcoal consumption in urban households in Tanzania,” Energy Sustain. Dev., vol. 57, pp. 200–213, 2020. [CrossRef]

- E. D. Wiafe, “Fuel-wood usage assessment among rural households in Ghana,” Spanish J. Rural Dev., no. June, pp. 41–48, 2013. [CrossRef]

- A. Sana, B. Kafando, M. Dramaix, N. Meda, and C. Bouland, “Household energy choice for domestic cooking: distribution and factors influencing cooking fuel preference in Ouagadougou,” Environ. Sci. Pollut. Res., vol. 27, no. 15, pp. 18902–18910, 2020. [CrossRef]

- S. E. Uhunamure, N. S. Nethengwe, and A. Musyoki, “Driving forces for fuelwood use in households in the Thulamela municipality, South Africa,” J. Energy South. Africa, vol. 28, no. 1, pp. 25–34, 2017. [CrossRef]

- A. G. Dagnachew, A. F. Hof, P. L. Lucas, and D. P. van Vuuren, “Scenario analysis for promoting clean cooking in Sub-Saharan Africa: Costs and benefits,” Energy, vol. 192, p. 116641, 2020.

- Y. Ayuketah, S. Gyamfi, F. A. Diawuo, and A. S. Dagoumas, “Assessment of low-carbon energy transitions policies for the energy demand sector of Cameroon,” Energy Sustain. Dev., vol. 72, no. January, pp. 252–264, 2023. [CrossRef]

| Pure biomass briquettes | Convectional fuels | ||||||

| Coconut shells | Rattan waste | Banana peels | Sugarcane bagasse | LPG | Fuelwood | Wood charcoal | |

| Calorific value (kWh/kg) |

8.92 |

8.34 |

4.67 |

7.19 |

12.64 |

5.08 |

8.33 |

| Price (€/kg) | 0.46 | 0.46 | 0.46 | 0.46 | 0.79 | 0.30 | 0.54 |

| Price (€/kWh) | 0.051 | 0.055 | 0.098 | 0.064 | 0.063 | 0.12 | 0.065 |

| Parameters | Values |

|---|---|

| Cook stove cost for wood charcoal (€) | 10 |

| Cook stove cost for biomass briquettes (€) | 10 |

| LPG cylinder and cook stove cost (€) | 60 |

| Maintenance cost of LPG cook stove (€) | 5 |

| Inflation rate of maintenance cost (%) | 5 |

| Inflation rate of fuel cost (%) | 2.4 |

| Discount rate (%) | 7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).