Submitted:

11 August 2023

Posted:

14 August 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

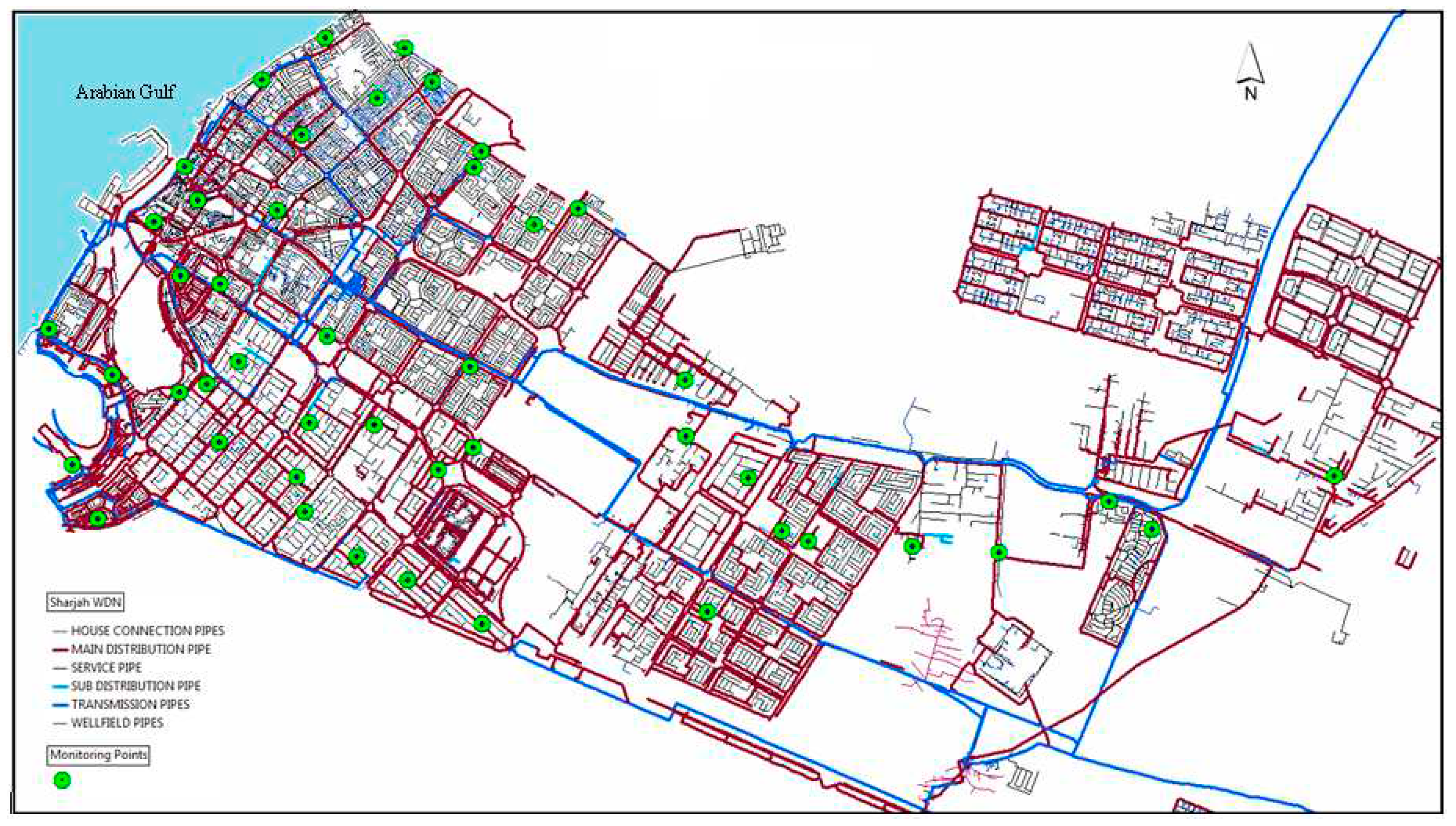

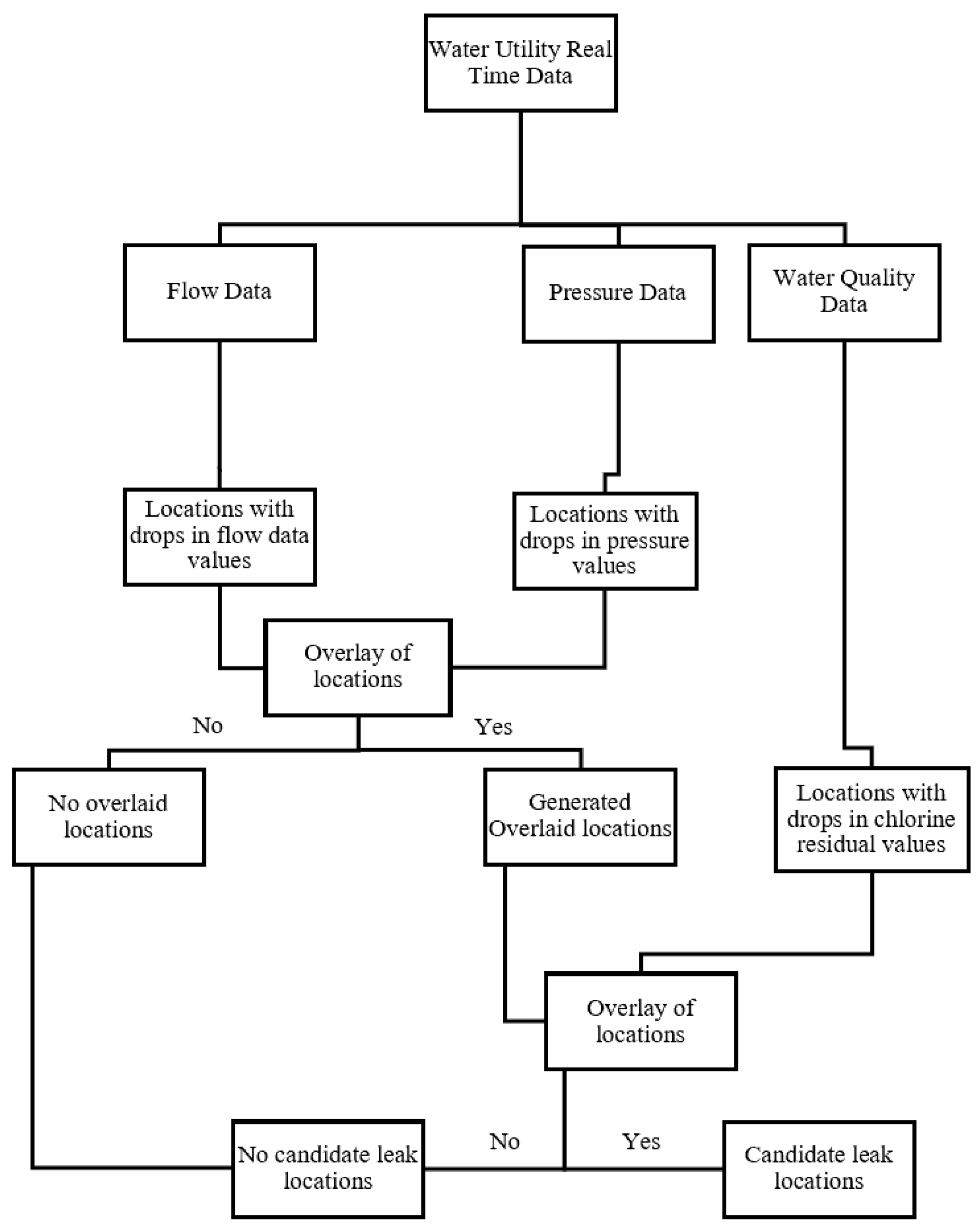

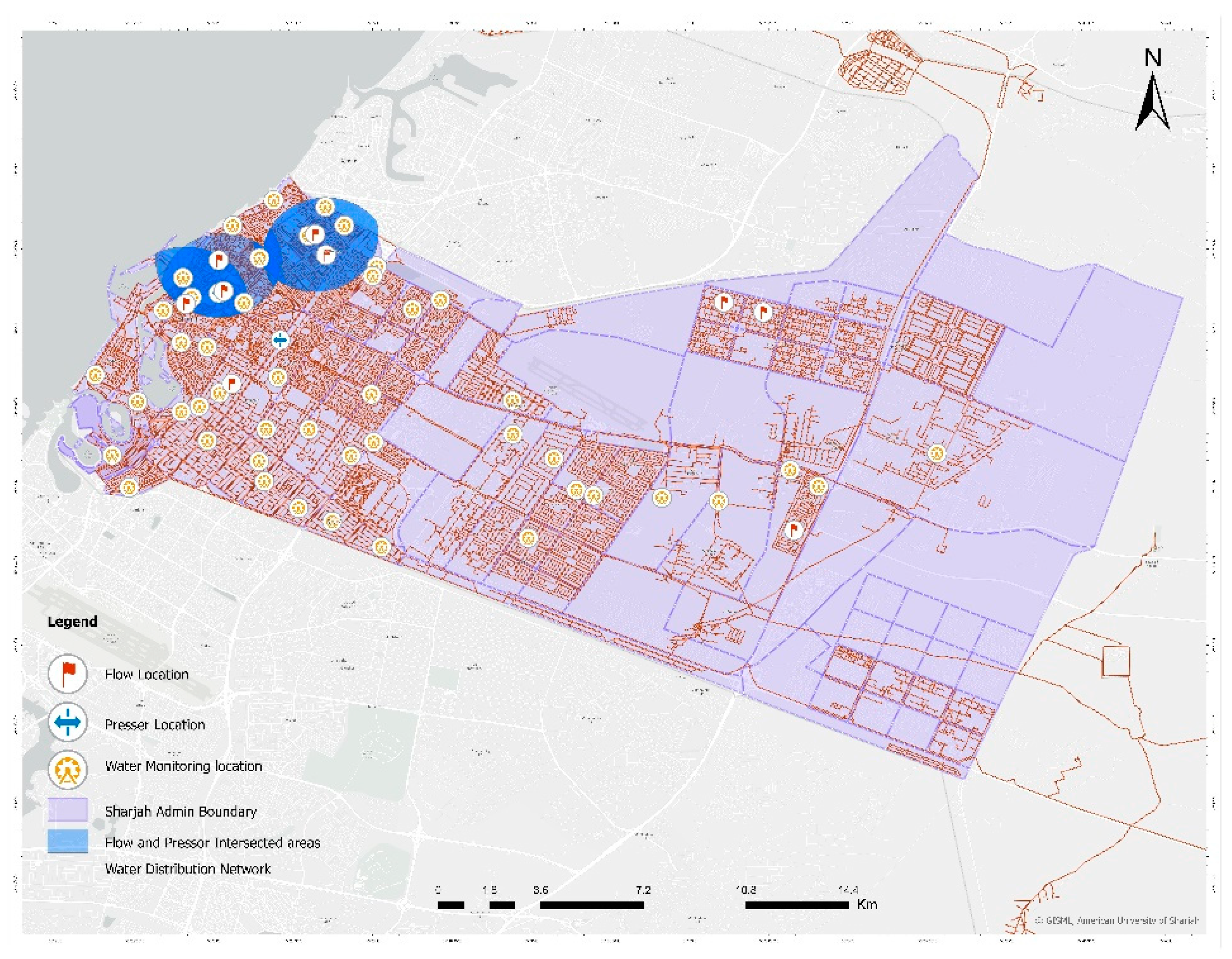

2.1. Phase 1: GIS Application

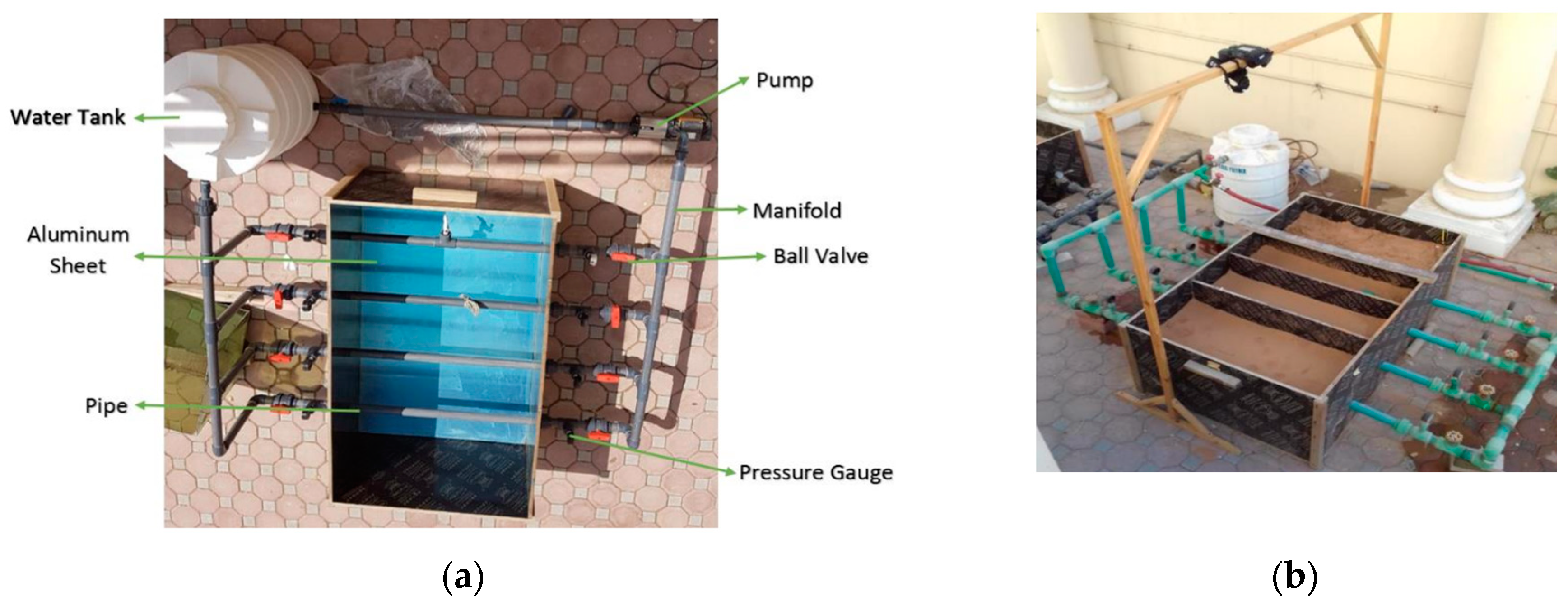

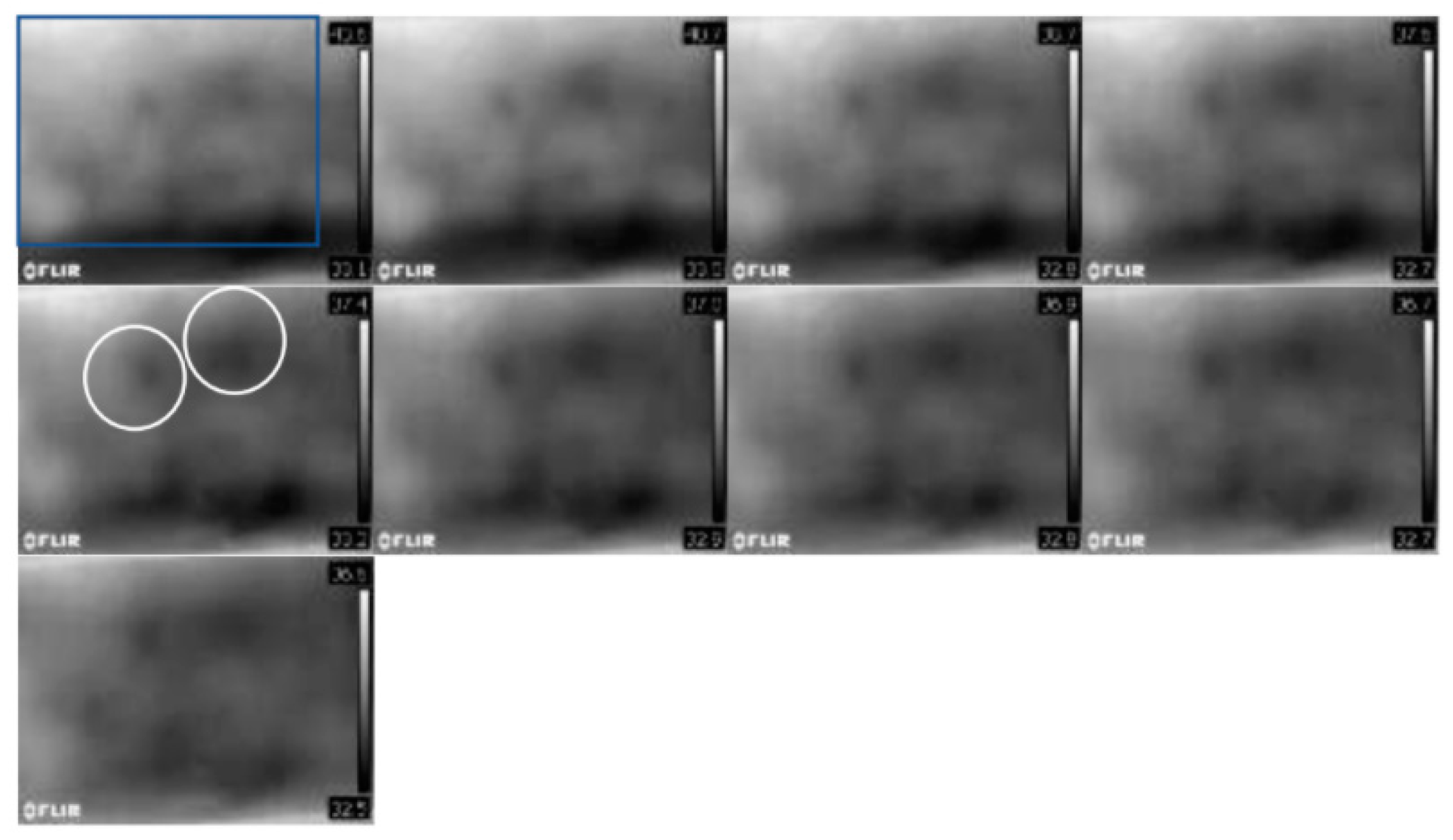

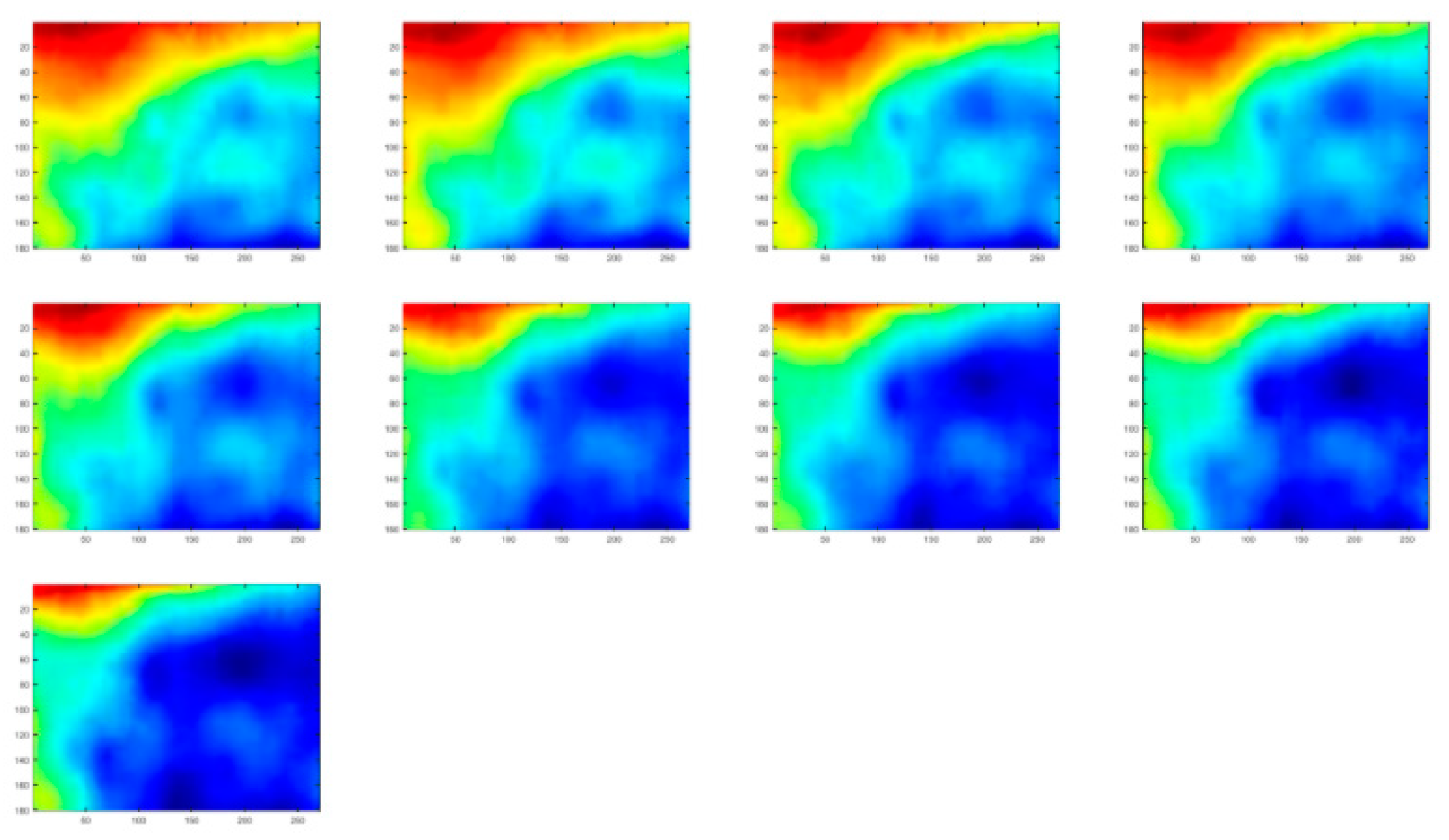

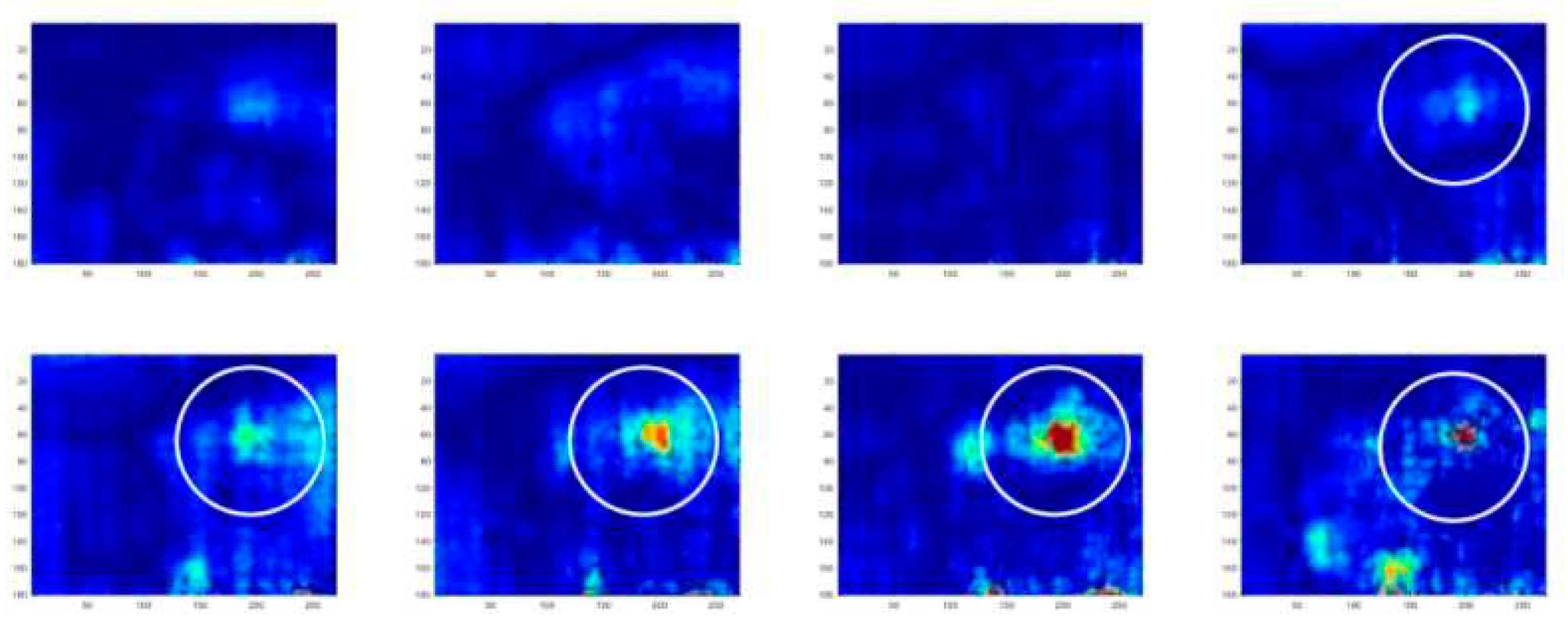

2.2. Phase 2: Remote Sensing with Infrared Camera

3. Results and Discussion

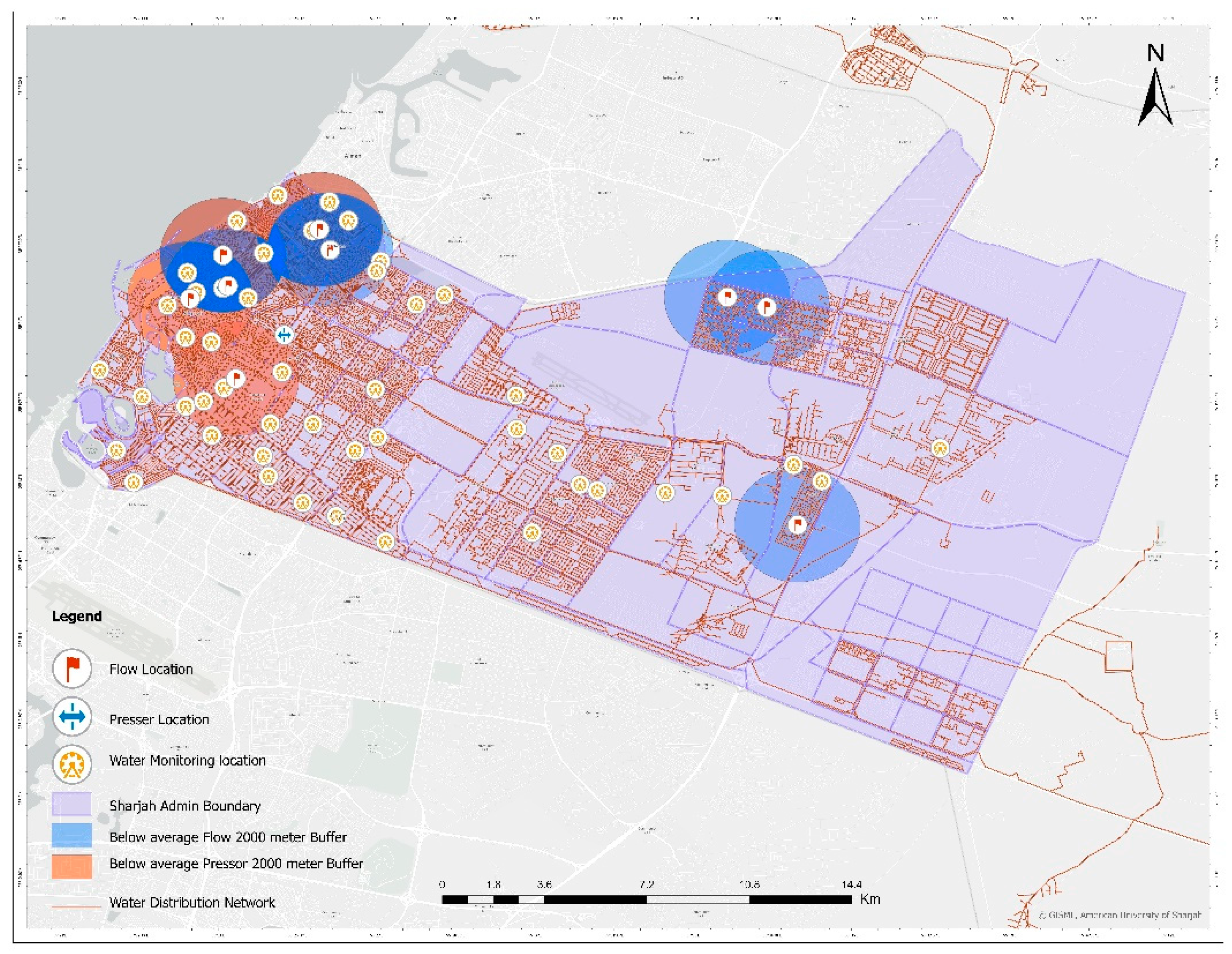

3.1. GIS Application

3.1.1. Case Scenario 1: No Detection of Leakage Location(s)

3.1.2. Case Scenario 2: Detection of Leakage Location(s)

3.2. Remote Sensing & IR Camera

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Moser, G.; German Paal, S.; Smith, I. F. C. Performance comparison of reduced models for leak detection in water distribution networks. Advanced Engineering Informatics 2015, 29(3):714–726. [CrossRef]

- Britton, T. C.; Stewart, R. A.; O'Halloran, K.R. Smart metering: Enabler for rapid and effective post meter leakage identification and water loss management. Journal of Cleaner Production 2013, 54:166-176. doi:10.1016/j.jclepro.2013.05.018.

- El-Zahab, S.; Zayed, T. Leak detection in water distribution networks: An introductory overview. Smart Water 2019, 4(1):1-23. doi:10.1186/s40713-019-0017-x.

- Aslam, H.; Kaur, M.; Sasi, S.; Yehia, S.; Mortula, M.M.; Ali, T. Detection of Leaks in Water Distribution System using Non-Destructive Techniques. International Conference on Future Environment and Energy 2018.

- Şahin, E.; Yüce, H. Prediction of Water Leakage in Pipeline Networks Using Graph Convolutional Network Method. Appl. Sci. 2023, 13, 7427. [CrossRef]

- Marzola, I.; Mazzoni, F.; Alvisi, S.; Franchini M. Leakage detection and localization in a water distribution network through comparison of observed and simulated pressure data. Journal of Water Resources Planning and Management 2021, 148(1):04021096. [CrossRef]

- Colombo, A. F.; Karney, B.W. Energy and costs of leaky pipes: Toward comprehensive picture. Journal of Water Resources Planning and Management 2002, 128(6): 441-450. [CrossRef]

- Price, M.; Reed, D.W. The influence of mains leakage and urban drainage on groundwater levels beneath conurbations in the UK. Proceedings of the Institution of Civil Engineers 1989, 86(1): 31-39. [CrossRef]

- Rathi, S.N.M.A. Critical Review of Leakage Detection strategies including Pressure and Water Quality Sensor Placement in Water Distribution Systems – Sole and Integrated approaches for leakage and contamination intrusion. In Proceedings of the 2nd International Joint Conference on Water Distribution Systems Analysis & Computing and Control in the Water Industry, Valencia, Spain, July 18 2022. 10.4995/WDSA-CCWI2022.2022.

- Aslam, H.; Mortula, M.M.; Yehia, S.; Ali, T.; Kaur, M. Evaluation of the factors impacting the water pipe leak detection ability of GPR, infrared cameras, and spectrometers under controlled conditions. Appl. Sci. 2022, 12(3):1683. [CrossRef]

- Zaman, D.; Tiwari, M. K.; Gupta, A.K.; Sen, D. A review of leakage detection strategies for pressurised pipeline in steady-state. Engineering Failure Analysis 2020, 109:104264. [CrossRef]

- Atef, A.; Zayed, T.; Hawari, A.; Khader, M.; Moselhi, O. Multi-tier method using infrared photography and GPR to detect and locate water leaks. Automation in Construction 2016, 61:162–170. [CrossRef]

- Yahia, M.; Gawai, R.; Ali, T.; Mortula, M.M.; Albasha, L.; Landolsi, T. "Non-Destructive Water Leak Detection Using Multitemporal Infrared Thermography," IEEE Access, 2021,. 9, pp. 72556-72567, doi: https://10.1109/ACCESS.2021.3078415 .

- Fan, H.; Tariq, S.; Zayed, T. Acoustic leak detection approaches for water pipelines. Automation in Construction 2022, 138:1-17. doi: 10.1016/j.autcon.2022.104226.

- Awwad, A.; Yahyia, M.; Albasha, L.; Mortula, M.M.; Ali, T. Communication Network for Ultrasonic Acoustic Water Leakage Detectors. IEEE Access, 2020; 8, pp. 29954-29964, doi: https://10.1109/ACCESS.2020.2972648 .

- Hadjimitsis, D.G.; Themistocleous, K.; Alexakis, D.D.; Toulios, G.; Perdikou, S.; Sarris, A.; Toulios, L.; Clayton, C. Detection of Water Pipes and Leakages in Rural Water Supply Networks Using Remote Sensing Techniques. In Remote Sensing of Environment: Integrated Approaches; InTechOpen, 2013; pp 155–180. 10.5772/39309.

- Aburawe, S.M.; Mahmud, A. R. Water loss control and real-time leakage detection using GIS technology. In Proceedings of Geomatics Technologies in the City Symposium 2011.

- Ayad, A.; Khalifa, A.; Fawy, M.E.L.; Moawad, A. An integrated approach for non-revenue water reduction in water distribution networks based on field activities, optimisation, and GIS applications. Ain Shams Engineering Journal 2021, 12(4):3509–3520. [CrossRef]

- Alzarooni, E.; Ali, T.; Atabay, S.; Yilmaz, A.G.; Mortula, M.M.; Fattah, K.P.; Khan, Z. GIS-Based Identification of Locations in Water Distribution Networks Vulnerable to Leakage. Appl. Sci. 2023, 13, 4692. [CrossRef]

- Krapez, J.-C.; Sanchis Muñoz, J.; Mazel, C.; Chatelard, C.; Déliot, P.; Frédéric, Y.M.; Barillot, P.; Hélias, F.; Barba Polo,, J.; Olichon, V.; Serra, G.; Brignolles, C.; Carvalho, A.; Carreira, D.; Oliveira, A.; Alves, E.; Fortunato, A.B.; Azevedo, A.; Benetazzo, P.; Le Goff, I. Multispectral optical remote sensing for water-leak detection. Sensors 2022, 22(3):1057. [CrossRef]

- González, C.; Sánchez, S.; Paz, A.; Resano, J.; Mozos, D.; Plaza, A. Use of FPGA or GPU-based architectures for remotely sensed hyperspectral image processing. Integration 2013, 46(2): 89–103. [CrossRef]

- Hoetz, A.F.; Vane, G.; Solomon, J.E.; Rock, B.N. Imaging spectrometry for Earth remote sensing. Science 1985, 228(4704): 1147–1153. 10.1126/science.228.4704.1147.

- Green, R.O.; Eastwood, M.L.; Sarture, C.M.; Chrien, T.G.; Aronsson, M.; Chippendale, B.J.; Faust, J.A.; Pavri, B.E.; Chovit, C.J.; Solis, M.; Olah, M.R.; Williams, O. Imaging spectroscopy and The airborne visible/infrared imaging spectrometer (AVIRIS). Remote Sensing of Environment 1998, 65(3): 227–248. [CrossRef]

- Plaza, A.; Benediktsson, J.A.; Boardman, J.W.; Brazile, J.; Bruzzone, L.; Camps-Valls, G.; Chanussot, J.; Fauvel, M.; Gamba, P.; Gualtieri. A.; Marconcini, M.; Tilton, J.C.; Trianni, G. Recent advances in techniques for hyperspectral image processing. Remote Sensing of Environment 2009, 113: S110–S122. [CrossRef]

- Fahmy, M.; Moselhi, O. Automated detection and location of leaks in water mains using infrared photography. Journal of Performance of Constructed Facilities 2010, 24(3): 242–248. [CrossRef]

- Agapiou, A.; Alexakis, D.D.; Themistocleous, K.; Hadjimitsis, D.G. Water leakage detection using remote sensing, field spectroscopy and GIS in semiarid areas of Cyprus, Urban Water Journal 2016, 13:3, 221-231, DOI: 10.1080/1573062X.2014.975726.

- Hunaidi, O. Detecting Leaks in Water Distribution Pipes Construction. In Construction Technology Update; Institute for Research in Construction: Canada, 2000: Volume 40.

- Ayad, A.,; Khalifa, A.; Fawy, M.. A Model - Based Approach for Leak Detection in Water Distribution Networks Based on Optimisation and GIS Applications. Civil and Environmental Engineering, 2021, 17(1), pp.277-285. [CrossRef]

- Cantos, W.P.,; Juran I.,; Tinelli, S. Machine-learning–based risk assessment method for leak detection and geolocation in a water distribution system. Journal of Infrastructure Systems. 2020 Mar 1;26(1):04019039.

- Tysiąc, P.; Strelets, T.; Tuszyńska, W. The Application of Satellite Image Analysis in Oil Spill Detection. Appl. Sci. 2022, 12, 4016. [CrossRef]

| DMA_New | D1 | D2 | D3 | D4 | D5 | D6 | D7 | D8 | D9 | D10 | D11 | D12 | D13 | D14 | D15 | D16 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AL RAHMANYA – 1 | 740 | 760 | 660 | 680 | 710 | 770 | 710 | 670 | 600 | 790 | 580 | 740 | 500 | 600 | 0 | 650 |

| AL RAHMANYA – 3 | 960 | 1100 | 1030 | 970 | 1200 | 1140 | 1210 | 1120 | 600 | 1160 | 990 | 1190 | 1140 | 670 | 1250 | 1210 |

| INDUSTRIAL AREA - 4 | 4500 | 5070 | 5440 | 6930 | 5430 | 5450 | 5120 | 5110 | 4760 | 4730 | 4960 | 5180 | 5380 | 5150 | 5150 | 5350 |

| INDUSTRIAL AREA - 4 | 30 | 20 | 10 | 0 | 40 | 30 | 40 | 40 | 20 | 10 | 0 | 10 | 20 | 40 | 10 | 30 |

| BARASHI | 410 | 570 | 160 | 630 | 670 | 930 | 1180 | 2260 | 2070 | 1800 | 1220 | 1420 | 640 | 780 | 1060 | 830 |

| MAYSALOON | 440 | 650 | 800 | 450 | 170 | 100 | 240 | 1310 | 1710 | 2540 | 2780 | 3120 | 2620 | 2670 | 2940 | 3110 |

| AL FAYAH | 980 | 980 | 1020 | 970 | 1030 | 1050 | 1070 | 1080 | 1010 | 1060 | 1060 | 1080 | 1070 | 1060 | 960 | 1020 |

| AL GHUWAIR | 3340 | 4230 | 8190 | 3800 | 4650 | 5290 | 2870 | 3850 | 830 | 790 | 870 | 860 | 1200 | 890 | 950 | 1070 |

| BU TINA | 6500 | 6490 | 6600 | 7280 | 7270 | 7120 | 7010 | 7040 | 6930 | 7410 | 7800 | 7420 | 7410 | 7150 | 7200 | 7150 |

| AL SABKHA | 3740 | 3730 | 3690 | 3670 | 3770 | 3760 | 3680 | 3730 | 3700 | 3870 | 3810 | 3720 | 3840 | 3970 | 3780 | 3830 |

| AL SABKHA | 890 | 880 | 900 | 830 | 800 | 860 | 740 | 880 | 850 | 820 | 800 | 730 | 640 | 690 | 700 | 630 |

| AL GHAPHIA | 1270 | 1140 | 750 | 220 | 550 | 1170 | 610 | 830 | 1060 | 740 | 350 | 690 | 830 | 730 | 850 | 760 |

| AL GHAPHIA | 1160 | 1070 | 950 | 780 | 860 | 1070 | 930 | 1060 | 1050 | 800 | 680 | 740 | 650 | 640 | 750 | 750 |

| DMA_New | D17 | D18 | D19 | D20 | D21 | D22 | D23 | D24 | D25 | D26 | D27 | D28 | D29 | D30 | D31 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AL RAHMANYA – 1 | 660 | 780 | 600 | 730 | 720 | 660 | 660 | 670 | 600 | 680 | 640 | 710 | 670 | 560 | 710 |

| AL RAHMANYA – 3 | 1180 | 900 | 1000 | 1270 | 1200 | 1210 | 1150 | 1390 | 1010 | 1180 | 1140 | 1230 | 1160 | 1200 | 1360 |

| INDUSTRIAL AREA - 4 | 5310 | 5180 | 5060 | 5340 | 5090 | 5220 | 5330 | 5250 | 4830 | 4950 | 5380 | 5160 | 5350 | 5380 | 5000 |

| INDUSTRIAL AREA - 4 | 30 | 40 | 20 | 0 | 10 | 20 | 20 | 30 | 80 | 110 | 50 | 80 | 60 | 60 | 80 |

| BARASHI | 660 | 1260 | 920 | 970 | 1690 | 1370 | 1160 | 820 | 1220 | 1580 | 2070 | 1580 | 1710 | 1480 | 1270 |

| MAYSALOON | 2850 | 2850 | 2190 | 1870 | 2090 | 2380 | 2390 | 2020 | 2650 | 2000 | 1740 | 0 | 1530 | 1400 | 1380 |

| AL FAYAH | 1050 | 1050 | 1130 | 1010 | 1050 | 980 | 1010 | 990 | 1030 | 1170 | 1040 | 1060 | 1100 | 1020 | 1090 |

| AL GHUWAIR | 1060 | 1050 | 950 | 950 | 940 | 920 | 980 | 950 | 1150 | 1450 | 260 | 210 | 210 | 220 | 200 |

| BU TINA | 7040 | 7690 | 7380 | 7070 | 6950 | 6860 | 7050 | 7070 | 7320 | 7380 | 7200 | 7220 | 7470 | 7220 | 7150 |

| AL SABKHA | 3790 | 3860 | 3790 | 3790 | 3760 | 3700 | 3770 | 3700 | 3730 | 3750 | 3680 | 3690 | 3780 | 3750 | 3770 |

| AL SABKHA | 620 | 670 | 690 | 710 | 720 | 770 | 750 | 720 | 700 | 640 | 620 | 630 | 630 | 680 | 740 |

| AL GHAPHIA | 640 | 160 | 60 | 360 | 730 | 750 | 900 | 780 | 460 | 510 | 550 | 440 | 230 | 180 | 550 |

| AL GHAPHIA | 790 | 720 | 720 | 810 | 800 | 800 | 920 | 760 | 910 | 800 | 770 | 830 | 750 | 740 | 820 |

| DMA_New | AVG (m3/day) |

|---|---|

| AL RAHMANYA - 1 | 651.9354839 |

| AL RAHMANYA - 3 | 1113.548387 |

| INDUSTRIAL AREA - 4 | 5210.967742 |

| INDUSTRIAL AREA - 4 | 33.5483871 |

| BARASHI | 1173.870968 |

| MAYSALOON | 1773.870968 |

| AL FAYAH | 1041.290323 |

| AL GHUWAIR | 1780 |

| BU TINA | 7156.452 |

| AL SABKHA | 3761.290323 |

| AL SABKHA | 739.6774194 |

| AL GAPHIA | 640.3225806 |

| AL GAPHIA | 834.8387097 |

| DMA_New | D1 | D2 | D3 | D4 | D5 | D6 | D7 | D8 | D9 | D10 | D11 | D12 | D13 | D14 | D15 | D16 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AL RAHMANYA – 1 | 4.07 | 3.87 | 2.56 | 4.2 | 3.96 | 3.76 | 4 | 3.43 | 2.33 | 3.12 | 3.13 | 3.23 | 2.84 | 1.99 | 3.65 | 3.81 |

| AL RAHMANYA – 3 | 3.7 | 3.41 | 2.18 | 3.7 | 3.58 | 3.23 | 3.39 | 2.73 | 2.22 | 2.31 | 2.41 | 2.33 | 3.03 | 2.61 | 2.8 | 2.98 |

| INDUSTRIAL AREA - 4 | 1.07 | 1.01 | 0.99 | 0.97 | 1.05 | 1.04 | 1.03 | 1.05 | 1.07 | 1.1 | 1.13 | 1.07 | 1.09 | 1.07 | 1.05 | 1.02 |

| BARASHI | 3.31 | 1.73 | 1.93 | 2.64 | 2.2 | 1.33 | 1.89 | 2.09 | 2.48 | 2.04 | 1.38 | 1.44 | 1.09 | 0.89 | 1.05 | 1.17 |

| MAYSALOON | 1.07 | 1.07 | 1.03 | 0.95 | 1.03 | 1.04 | 1.02 | 1.07 | 1.14 | 1.21 | 1.12 | 1.08 | 1.15 | 1.09 | 1.07 | 1.08 |

| AL FAYAH | 0.89 | 0.86 | 0.88 | 0.89 | 0.88 | 0.9 | 0.87 | 0.87 | 0.85 | 0.93 | 0.94 | 0.89 | 0.93 | 0.9 | 0.9 | 0.87 |

| AL GHUWAIR | 0.87 | 0.87 | 0.84 | 0.76 | 0.83 | 0.86 | 0.85 | 0.88 | 0.93 | 0.94 | 0.85 | 0.84 | 0.9 | 0.86 | 0.84 | 0.85 |

| BU TINA | 0.69 | 0.68 | 0.68 | 0.63 | 0.67 | 0.69 | 0.68 | 0.7 | 0.7 | 0.72 | 0.68 | 0.67 | 0.71 | 0.69 | 0.68 | 0.67 |

| AL SABKHA | 1.05 | 1.02 | 1.01 | 0.97 | 1.01 | 1.05 | 1.01 | 1.04 | 1.02 | 1.04 | 1 | 1.02 | 1.03 | 0.96 | 1.01 | 1.01 |

| AL GHAPHIA | 1.15 | 1.1 | 1.06 | 1.01 | 1.07 | 1.14 | 1.07 | 1.12 | 1.11 | 1.1 | 1.04 | 1.07 | 1.08 | 1 | 1.07 | 1.08 |

| AL NASSERYA | 0.9 | 0.8 | 0.82 | 0.8 | 1.07 | 1.08 | 0.79 | 0.84 | 0.84 | 0.89 | 0.88 | 0.83 | 0.87 | 0.83 | 0.81 | 0.81 |

| AL QADSIA | 0.9 | 0.87 | 0.88 | 0.85 | 0.89 | 0.9 | 0.87 | 0.9 | 0.87 | 0.93 | 0.91 | 0.85 | 0.93 | 0.89 | 0.87 | 0.86 |

| INDUSTRIAL AREA – 6 | 0.67 | 0.66 | 0.5 | 0.3 | 0.55 | 0.64 | 0.67 | 0.7 | 0.79 | 0.56 | 0.32 | 0.5 | 0.49 | 0.47 | 0.48 | 0.53 |

| DMA_New | D17 | D18 | D19 | D20 | D21 | D22 | D23 | D24 | D25 | D26 | D27 | D28 | D29 | D30 | D31 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AL RAHMANYA – 1 | 3.85 | 3.72 | 2.61 | 3.97 | 3.97 | 3.93 | 3.78 | 3.63 | 3.73 | 3.59 | 3.69 | 3.82 | 3.91 | 2.94 | 4.1 |

| AL RAHMANYA – 3 | 3.1 | 3.12 | 2.18 | 3.15 | 3.22 | 3.33 | 3.17 | 2.94 | 3.05 | 2.98 | 2.73 | 3.34 | 2.87 | 3.21 | 3.36 |

| INDUSTRIAL AREA - 4 | 0.98 | 0.99 | 0.92 | 0.96 | 0.98 | 0.91 | 0.86 | 0.88 | 0.84 | 0.85 | 0.89 | 0.89 | 0.98 | 0.99 | 1 |

| BARASHI | 0.93 | 1.12 | 1.25 | 1.32 | 2 | 1.6 | 1.68 | 1.26 | 1.29 | 1.57 | 1.76 | 1.95 | 1.77 | 1.64 | 1.42 |

| MAYSALOON | 1.05 | 1.01 | 1.03 | 1.04 | 1.04 | 1.01 | 1.02 | 1.01 | 0.97 | 0.98 | 0.97 | 0.95 | 0.98 | 0.96 | 0.95 |

| AL FAYAH | 0.83 | 0.84 | 0.84 | 0.87 | 0.85 | 0.82 | 0.83 | 0.86 | 0.81 | 0.83 | 0.8 | 0.82 | 0.86 | 0.88 | 0.87 |

| AL GHUWAIR | 0.82 | 0.76 | 0.79 | 0.83 | 0.84 | 0.8 | 0.8 | 0.79 | 0.72 | 0.75 | 0.75 | 0.77 | 0.8 | 0.79 | 0.77 |

| BU TINA | 0.64 | 0.6 | 0.61 | 0.67 | 0.67 | 0.63 | 0.63 | 0.64 | 0.58 | 0.59 | 0.61 | 0.62 | 0.65 | 0.66 | 0.65 |

| AL SABKHA | 0.99 | 0.95 | 0.97 | 1 | 1 | 0.96 | 1 | 1.01 | 0.96 | 0.98 | 0.99 | 0.99 | 1.01 | 1.01 | 1.01 |

| AL GHAPHIA | 1.06 | 1.02 | 1.04 | 1.08 | 1.07 | 1.02 | 1.09 | 1.09 | 1.06 | 1.07 | 1.05 | 1.07 | 1.09 | 1.08 | 1.08 |

| AL NASSERYA | 0.77 | 0.75 | 0.76 | 0.8 | 0.79 | 0.75 | 0.76 | 0.76 | 0.71 | 0.74 | 0.75 | 0.74 | 0.78 | 0.77 | 0.77 |

| AL QADSIA | 0.82 | 0.82 | 0.83 | 0.87 | 0.86 | 0.81 | 0.82 | 0.84 | 0.78 | 0.81 | 0.81 | 0.81 | 0.85 | 0.85 | 0.85 |

| INDUSTRIAL AREA – 6 | 3.85 | 3.72 | 2.61 | 3.97 | 3.97 | 3.93 | 3.78 | 3.63 | 3.73 | 3.59 | 3.69 | 3.82 | 3.91 | 2.94 | 4.1 |

| DMA_New | AVG (bars) |

|---|---|

| AL RAHMANYA - 1 | 3.522258065 |

| AL RAHMANYA - 3 | 2.979354839 |

| INDUSTRIAL AREA - 4 | 0.991290323 |

| BARASHI | 1.652258065 |

| MAYSALOON | 1.038387097 |

| AL FAYAH | 0.866451613 |

| AL GHUWAIR | 0.824193548 |

| BU TINA | 0.657741935 |

| AL SABKHA | 1.0025806 |

| AL GHAPHIA | 1.072258065 |

| AL NASSERYA | 0.81483871 |

| AL QADSIA | 0.858064516 |

| INDUSTRIAL AREA - 6 | 0.58806452 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).