Submitted:

09 August 2023

Posted:

11 August 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

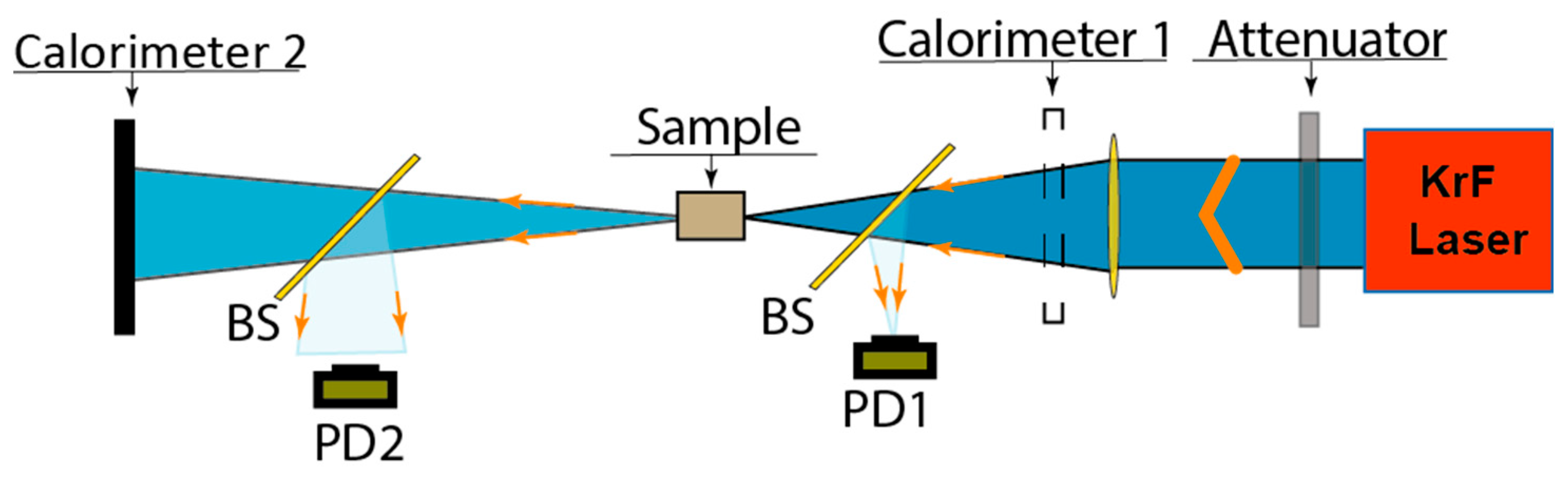

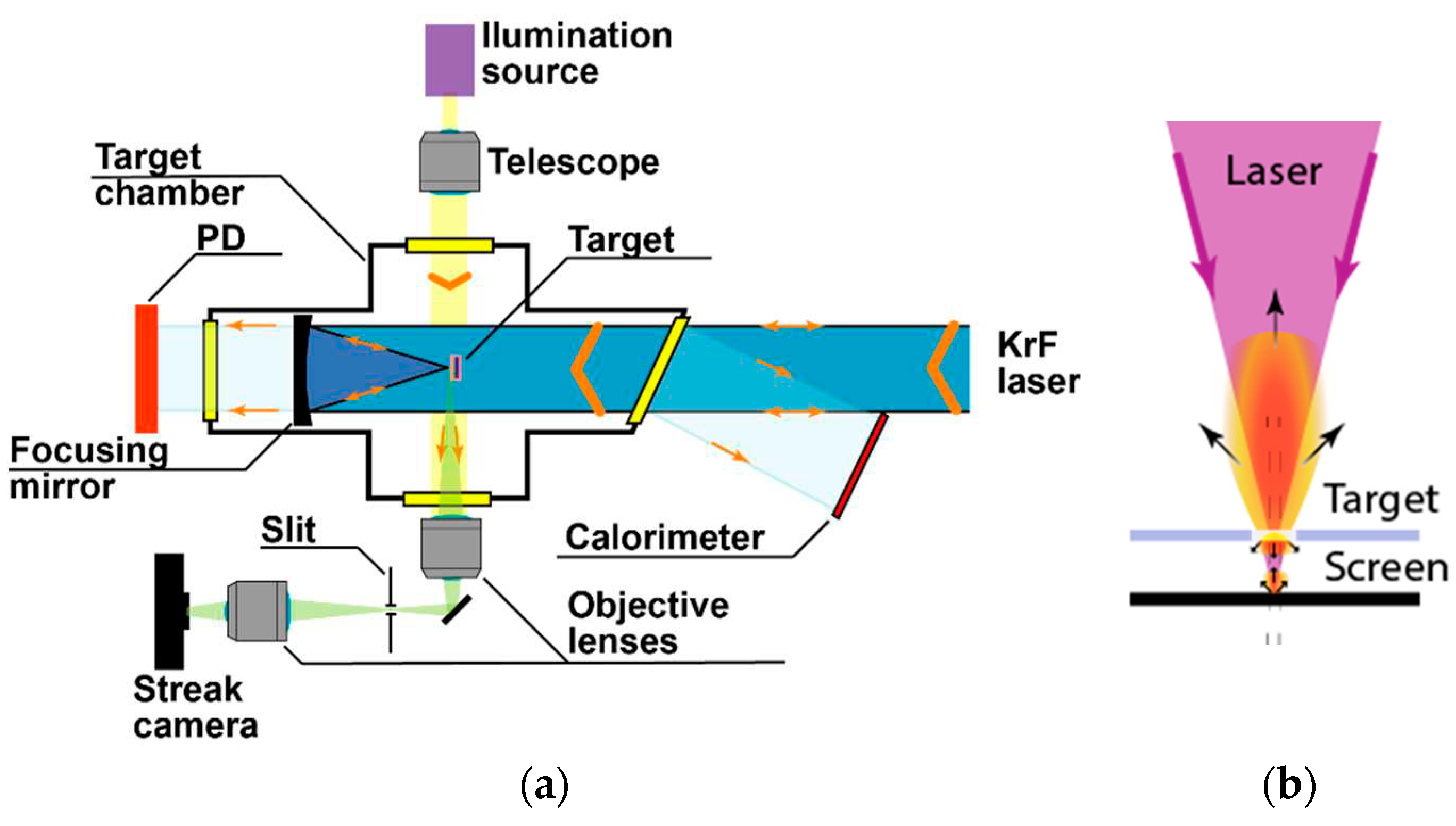

2. Experimental setup

2.1. GARPUN KrF laser description and performance of experiments

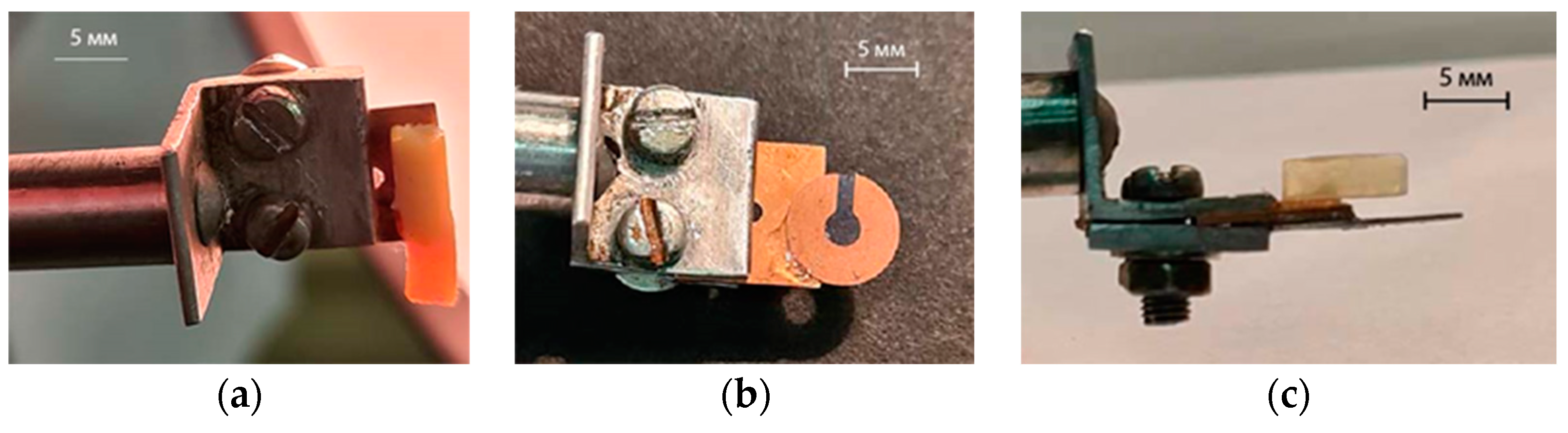

2.2. Foam target preparation

3. PLDM transmittance

3.1. Initial PLDM transmittance at 248-nm wavelength

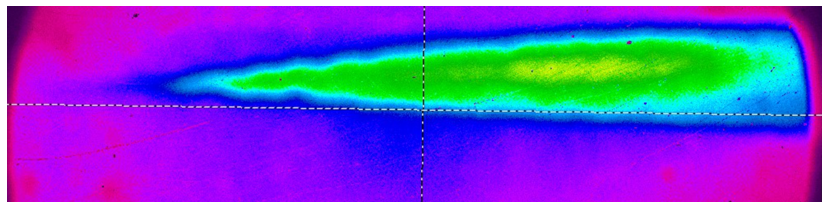

3.2. Dynamic PLDM transmittance during thermal explosion

4. PLDM hydrodynamics

5. Summary

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Basov, N.G.; Krokhin, O.N. Condition for heating up of a plasma by the radiation from an optical generator. Sov. Phys. JETP 1964, 19, 123–125. [Google Scholar]

- Nuckolls, J.; Wood, L.; Thiessen, A. and Zimmerman, G. Laser compression of matter to super-high densities: Thermonuclear (CTR) applications. Nature 1972, 239, 139–142. [Google Scholar] [CrossRef]

- Lindl, J. Development of the indirect drive approach to inertial confinement fusion and the target physics basis for ignition and gain. Phys. Plasmas 1995, 2, 3933–4024. [Google Scholar] [CrossRef]

- National Ignition Facility achieves fusion ignition. https://llnl.gov/news/national-fusion-facility-achievs ignition; https://energy.gov/articles/doe-national-laboratory-makes-history-achieving-fusion-ignition.

- Kritcher, A.; HIBRYD-E ICF team. Initial results from HYBRID-E DT experiment N210808 with >1.3 MJ yield. IFSA virtual meeting, September 2021. LLNL-PRES-826367.

- Lindl, J.; Landen, O.; Edwards, J.; Moses, E.; NIC Team. Review of the National Ignition Campaign 2009-2012. Phys. Plasmas 2014, 21, 020501. [Google Scholar] [CrossRef]

- Montgomery, D.S. Two decades of progress in understanding and control of laser plasma instabilities in indirect drive inertial fusion. Phys. Plasmas 2016, 23, 055601. [Google Scholar] [CrossRef]

- Robey, H.F.; Smalyuk, V.A.; Milovich, J.L.; Döppner, T.; Casey, D.T.; et al. Performance of indirectly driven capsule implosions on the National Ignition Facility using adiabat-shaping. Phys. Plasmas 2016, 23, 056303. [Google Scholar] [CrossRef]

- Haynam, C.A.; Wegner, P.J.; Auerbach, J.M.; Bowers, M.W.; Dixit, S.N.; et al. National Ignition Facility laser performance status. Appl. Opt. 2007, 46, 3276–3303. [Google Scholar] [CrossRef]

- Miquel, J.-L.; Lion, C.; Vivini, P. The Laser Mega-Joule: LMJ & PETAL status and program overview. J. Phys.: Conf. Ser. 2016, 688, 012067. [Google Scholar] [CrossRef]

- Craxton, R.S.; Anderson, K.S.; Boehly, T.R.; Goncharov, V.N.; Harding, D.R.; et al. Direct-drive inertial confinement fusion: A review. Phys. Plasmas 2015, 22, 110501. [Google Scholar] [CrossRef]

- Desselberger, M.; Afshar-rad, T.; Khattak, F.; Viana, S. and Willi, O. Nonuniformity imprint on the ablation surface of laser-irradiated targets. Phys. Rev. Lett. 1992, 68, 1539–1542. [Google Scholar] [CrossRef] [PubMed]

- Emery, M.H.; Gardner, J.H.; Lehmberg, R.H. and Obenschain, S.P. Hydrodynamic target response to an induced spatial incoherence-smoothed laser beam. Phys. Fluids B: Plasma Phys. 1991, 3, 2640–2651. [Google Scholar] [CrossRef]

- Malka, V.; Faure, J.; Huller, S.; Tikhonchuk, V.T.; Weber, S. and Amiranoff, F. Enhanced spatiotemporal laser-beam smoothing in gas-jet plasmas. Phys. Rev. Lett. 2003, 90, 075002. [Google Scholar] [CrossRef]

- Dunne, M.; Borghesi, M.; Iwase, A.; Jones, M.W.; Taylor, R.; et al. Evaluation of a foam buffer target design for spatially uniform ablation of laser-irradiated plasmas. Phys. Rev. Lett. 1995, 75, 3858–3861. [Google Scholar] [CrossRef] [PubMed]

- Metzler, N.; Velikovich, A.L.; Schmitt, A.J.; Gardner, J.H. Laser imprint reduction with a short shaping laser pulse incident upon a foam-plastic target. Phys. Plasmas 2002, 9, 5050–5058. [Google Scholar] [CrossRef]

- Desselberger, M.; Jones, M.W.; Edwards, J.; Dunne, M.; Willi, O. Use of X-ray preheated foam layers to reduce beam structure imprint in laser-driven targets. Phys. Rev. Lett. 1995, 74, 2961–2964. [Google Scholar] [CrossRef]

- Nishikino, M.; Shiraga, H.; Miyanaga, N.; Ohnishi, N.; Shigemori, K.; et al. Imprint reduction in a plasma layer preformed with x-ray irradiation. Phys. Plasmas 2002, 9, 1381–1391. [Google Scholar] [CrossRef]

- Hu, S.X.; Fiksel, G.; Goncharov, V.N.; Skupsky, S.; Meyerhofer, D.D.; Smalyuk, V.A. Mitigating laser imprint in direct-drive inertial confinement fusion implosions with high-Z dopants. Phys. Rev. Lett. 2012, 108, 195003. [Google Scholar] [CrossRef]

- Karasik, M.; Weaver, J.L.; Aglitskiy, Y.; Oh, J.; Obenschain, S.P. Suppression of laser nonuniformity imprinting using a thin high-Z coating. Phys. Rev. Lett. 2015, 114, 085001. [Google Scholar] [CrossRef]

- Karasik, M.; Oh, J.; Obenschain, S.P.; Schmitt, A.J.; Aglitskiy, Y.; Stoeckl, C. Order-of-magnitude laser imprint reduction using pre-expanded high-Z coatings on targets driven by a third harmonic Nd: glass laser. Phys. Plasmas 2021, 28, 032710. [Google Scholar] [CrossRef]

- Koenig, M.; Benuzzi, A.; Philippe, F.; Batani, D.; Hall, T.; et al. Equation of state data experiments for plastic foams using smoothed laser beams. Phys. Plasmas 1999, 6, 3296–3301. [Google Scholar] [CrossRef]

- Batani, D.; Nazarov, W.; Hall, T.; Lower, T.; Koenig, M. Foam-induced smoothing studied through laser-driven shock waves. Phys. Rev. E. 2000, 62, 8573–8582. [Google Scholar] [CrossRef] [PubMed]

- Gus’kov, S.Yu.; Gromov, A.I.; Merkul’ev, Yu.A.; Rozanov, V.B.; Nikishin, V.V.; et al. Nonequilibrium laser-produced plasma of volume-structured media and ICF applications. Laser Part. Beams 2000, 18, 1–10. [Google Scholar] [CrossRef]

- Nishimura, H.; Shiraga, H.; Azechi, H.; Miyanaga, N.; Nakai, M.; et al. Indirect–direct hybrid target experiments with the GEKKO XII laser. Nucl. Fusion 2000, 40, 547–556. [Google Scholar] [CrossRef]

- Willi, O.; Barringer, L.; Bell, A.; Borghesi, M.; Davies, J.; et al. Inertial confinement fusion and fast ignitor studies. Nucl. Fusion 2000, 40, 537–545. [Google Scholar] [CrossRef]

- Hall, T.; Batani, D.; Nazarov, W.; Koenig, M. and Bennuzzi, A. Recent advances in laser–plasma experiments using foams. Laser Part. Beams 2002, 20, 303–316. [Google Scholar] [CrossRef]

- Limpouch, J.; Demchenko, N.N.; Gus'kov, S.Yu.; Kalal1, M.; Kasperczuk, A.; et al. Laser interactions with plastic foam-metallic foil layered targets. Plasma Phys. Control. Fusion 2004, 46, 1831–1841. [Google Scholar] [CrossRef]

- Jiang, S.; Xu, Y.; Ding, Y.; Lai, D.; Zheng, Z.; et al. Experimental investigation of supersonic radiation propagation in low-density plastic and copper-doped foams. Science in China Ser. G Physics, Mechanics & Astronomy 2005, 48, 549–558. [Google Scholar] [CrossRef]

- Tanabe, M., Nishimura, H., Ohnishi, N., Fournier, K.B., Fujioka, S.; et al. Characterization of heat-wave propagation through laser-driven Ti-doped underdense plasma. High Energy Density Physics 2010, 6, 89–94. [CrossRef]

- Rozanov, V.B.; Barishpol’tsev, D.V.; Vergunova, G.A.; Demchenko, N.N.; Ivanov, E.M.; et al. Interaction of laser radiation with a low-density structured absorber. JETP 2016, 122, 256–276. [Google Scholar] [CrossRef]

- Cipriani, M.; Gus’kov, S.Yu.; De Angelis, R.; Consoli, F.; Rupasov, A.A.; et al. Laser-driven hydrothermal wave speed in low-Z foam of overcritical density. Phys. Plasmas 2018, 25, 092704. [Google Scholar] [CrossRef]

- Cipriani, M.; Gus’kov, S.Yu.; De Angelis, R.; Consoli, F.; Rupasov, A.A.; et al. Laser-supported hydrothermal wave in low-dense porous substance. Laser Part. Beams 2018, 36, 121–128. [Google Scholar] [CrossRef]

- Belyaev, M.A.; Berger, R.L.; Jones, O.S.; Langer, S.H. and Mariscal D.A. Laser propagation in a subcritical foam: Ion and electron heating. Phys. Plasmas 2018, 25, 123109. [Google Scholar] [CrossRef]

- Batani, K.; Aliverdiev, A.; Benocci, R.; Dezulian, R.; Amirova, A.; et al. Shock dynamics and shock collision in foam layered targets. High Power Laser Science and Engineering 2021, 9, e47. [Google Scholar] [CrossRef]

- Roycroft, R.; Bradley, P.A.; McCary, E.; Bowers, B.; Smith, H.; et al. Experiments and simulations of isochorically heated warm dense carbon foam at the Texas Petawatt Laser. Matter Radiat. Extremes 2021, 6, 014403. [Google Scholar] [CrossRef]

- Tikhonchuk, V.T.; Gong, T.; Jourdain, N.; Renner, O.; Condamine, F.P.; et al. Studies of laser-plasma interaction physics with low-density targets for direct-drive inertial confinement fusion on the Shenguang III prototype. Matter Radiat. Extremes 2021, 6, 025902. [Google Scholar] [CrossRef]

- Karasik, M.; Oh, J.; Obenschain, S.P.; Schmitt, A.J.; Aglitskiy, Y.; Stoeckl, C. Order-of-magnitude laser imprint reduction using pre-expanded high-Z coatings on targets driven by a third harmonic Nd:glass laser. Phys. Plasmas 2021, 28, 032710. [Google Scholar] [CrossRef]

- Aglitskiy, Y.; Zulick, C.; Oh, J.; Velikovich, A.L.; Schmitt, A.J.; Obenschain, S.P.; Karasik, M.; Weaver, J.L. Plasma hydrodynamic experiments on NRL Nike KrF laser. High Energy Density Phys. 2020, 37, 100866. [Google Scholar] [CrossRef]

- Bodner, S.E.; Schmitt, A.J. and Sethian, J.D. Laser requirements for a laser fusion energy power plant. High Power Laser Science and Engineering 2013, 1, 2–10. [Google Scholar] [CrossRef]

- Obenschain, S.; Lehmberg, R.; Kehne, D.; Hegeler, F.; Wolford, M.; et al. High-energy krypton fluoride lasers for inertial fusion. Appl. Opt. 2015, 34, F103–F122. [Google Scholar] [CrossRef]

- Obenschain, S.P.; Bodner, S.E.; Colombant, D.; Gerber, K.; Lehmberg, R.H.; et al. The Nike KrF laser facility: Performance and initial target experiments. Phys. Plasmas 1996, 3, 2098–2107. [Google Scholar] [CrossRef]

- Pawley, C.J.; Gerber, K.; Lehmberg, R.H.; McLean, E.A.; Mostovych, A.N.; et al. Measurements of laser-imprinted perturbations and Rayleigh–Taylor growth with the Nike KrF laser. Phys Plasmas 1997, 4, 1969–1977. [Google Scholar] [CrossRef]

- Obenschain, S.P.; Colombant, D.G.; Karasik, M.; Pawley, C.J.; Serlin, V.; et al. Effects of thin high-Z layers on the hydrodynamics of laser-accelerated plastic targets. 2002, 9, 2234–2243. [Google Scholar] [CrossRef]

- Schmitt, A.J.; Bates, J.W.; Obenschain, S.P.; Zalesak, S.T.; Fyfe, D.E.; Betti, R. Direct drive fusion energy shock ignition designs for sub-MJ lasers. Fusion Sci. Technol. 2009, 56, 377–383. [Google Scholar] [CrossRef]

- Tikhonchuk, V.T.; Gong, T.; Jourdain, N.; Renner, O.; Condamine, F.P.; et al. Studies of laser-plasma interaction physics with low-density targets for direct-drive inertial confinement fusion on the Shenguang III prototype. Matter Radiat. Extremes 2021, 6, 025902. [Google Scholar] [CrossRef]

- Rosmej, O.N.; Andreev, N.E.; Zaehter, S.; Zahn, N.; Christ, P.; Borm, B.; et al. Interaction of relativistically intense laser pulses with long-scale near critical plasmas for optimization of laser-based sources of MeV electrons and gamma-rays. New J. Phys. 2019, 21, 043044. [Google Scholar] [CrossRef]

- Rosmej, O.N.; Gyrdymov, M.; Günther, M.M.; Andreev, N.E.; Tavana, P.; et al. High-current laser-driven beams of relativistic electrons for high energy density research. Plasma Phys. Control. Fusion 2020, 62, 115024. [Google Scholar] [CrossRef]

- Zvorykin, V.D.; Lebo, I.G.; Shutov, A.V.; Ustinovskii, N.N. Self-focusing of UV radiation in 1 mm scale plasma in a deep ablative crater produced by 100 ns, 1 GW KrF laser pulse in the context of ICF. Matter Radiat. Extremes 2020, 5, 035401. [Google Scholar] [CrossRef]

- Smetanin, I.V.; Shutov, A.V.; Ustinovskii, N.N.; Veliev, P.V.; Zvorykin, V.D. A new insight into high-aspect-ratio channel drilling in translucent dielectrics with a KrF laser for waveguide applications. Materials 2022, 15, 8347. [Google Scholar] [CrossRef] [PubMed]

- Zvorykin, V.D.; Arlantsev, S.V.; Shutov, A.V.; Ustinovskii, N.N.; Veliev, P.V. Deep penetration of UV radiation into PMMA and electron acceleration in long plasma channels produced by 100 ns KrF laser pulses. Symmetry 2021, 13, 1883. [Google Scholar] [CrossRef]

- Tadjima, T. High-energy laser plasma accelerators. Laser Part. Beams 1985, 3(part 4), 351–413. [Google Scholar] [CrossRef]

- Pastukhov, A.V. Mesoporous polymer systems based on divinylbenzenecopolymers modified with linear rubbers. Eur. Polymer J. 2020, 124, 109480. [Google Scholar] [CrossRef]

- Kovalev, A.I.; Pastukhov, A.V.; Tkachenko, E.S.; Klemenkova, Z.S.; Kuvshinov, I.R.; Khotina, I.A. Polyphenylenes with Phen-1,3,5-triyl branching moieties based on p-Diacetylbenzene: synthesis and study of porosity and heat resistance. Polymer Sci., Ser C. 2020, 62, 205–213. [Google Scholar] [CrossRef]

- Sedov, L.I. Similarity and dimensional methods in mechanics; Academic Press: New York-London, 1959; pp. 363 p. [Google Scholar]

- Zvorykin, V.D.; Bakaev, V.G.; Lebo, I.G. and Sychugov, G.V. Hydrodynamics of plasma and shock waves generated by the high-power GARPUN KrF laser. Laser Part. Beams 2004, 22, 51–57. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).